High Precision Feature Fast Extraction Strategy for Aircraft Attitude Sensor Fault Based on RepVGG and SENet Attention Mechanism

Abstract

1. Introduction

- (i)

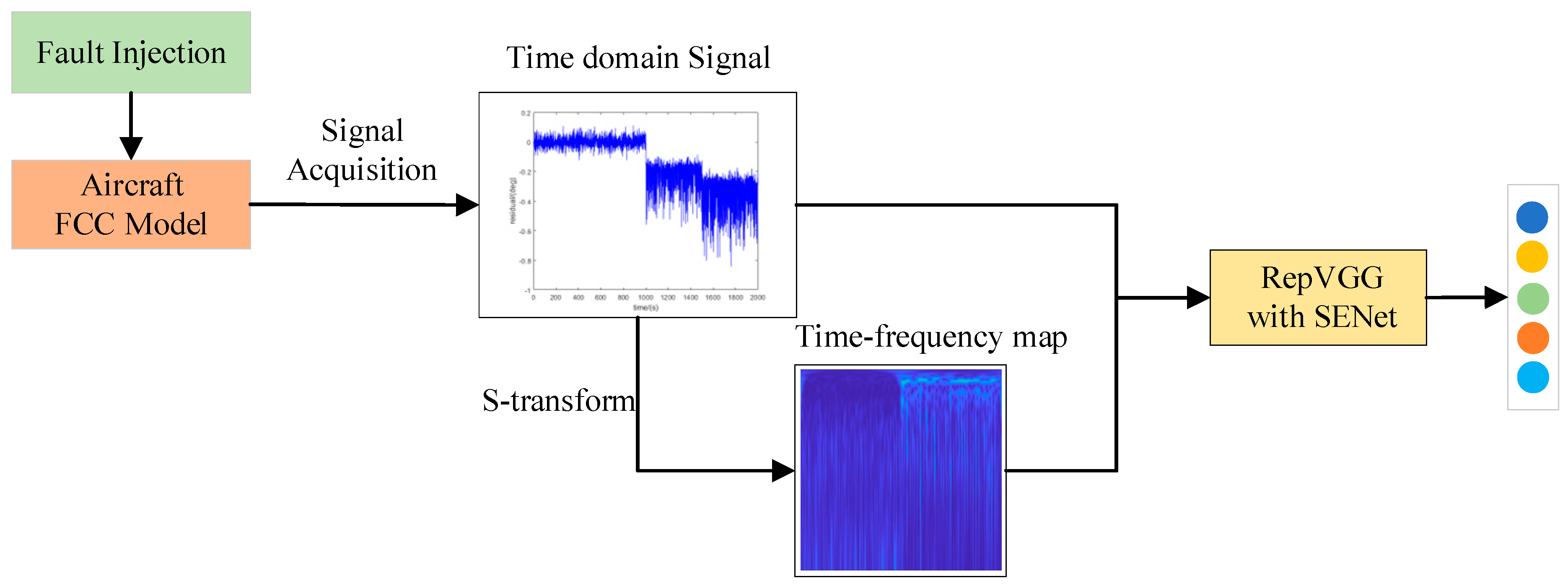

- The time sequence signal of aircraft attitude sensor is transformed into time-frequency domain, and the time-domain signal and time-frequency domain signal are taken as the feature mining object.

- (ii)

- A signal representation weight analysis and allocation strategy is designed, and the representativeness of each channel of time-domain signal and time-frequency signal is analyzed by using Squeeze-and-excitation networks (SENet) attention mechanism.

- (iii)

- A fast and high-precision diagnostic technology based on Re-parameterization visual geometry group (RepVGG) is proposed, which achieves a good diagnostic accuracy speed tradeoff.

2. Relevant Theories and Proposed Methods

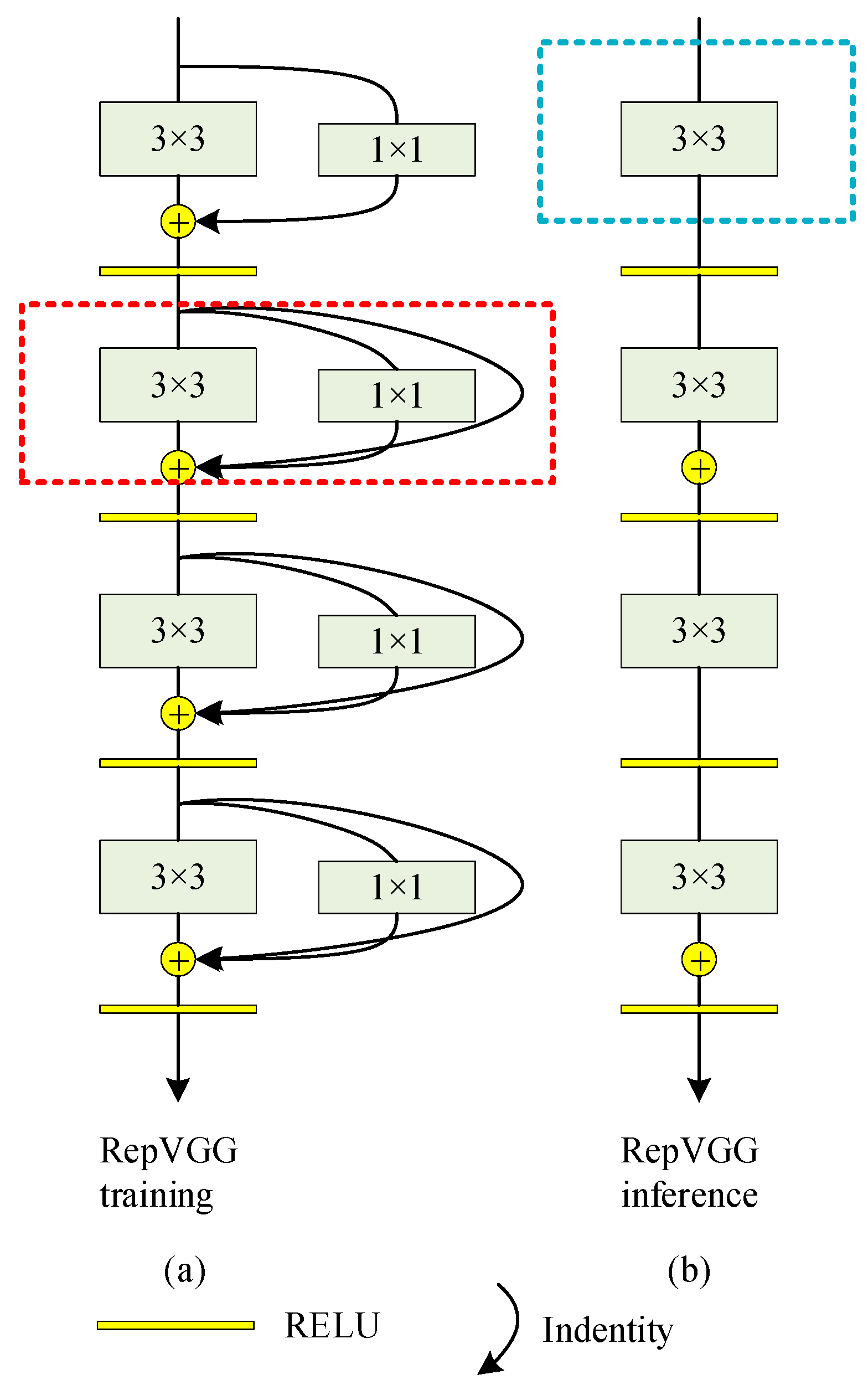

2.1. RepVGG

2.1.1. RepVGG Block

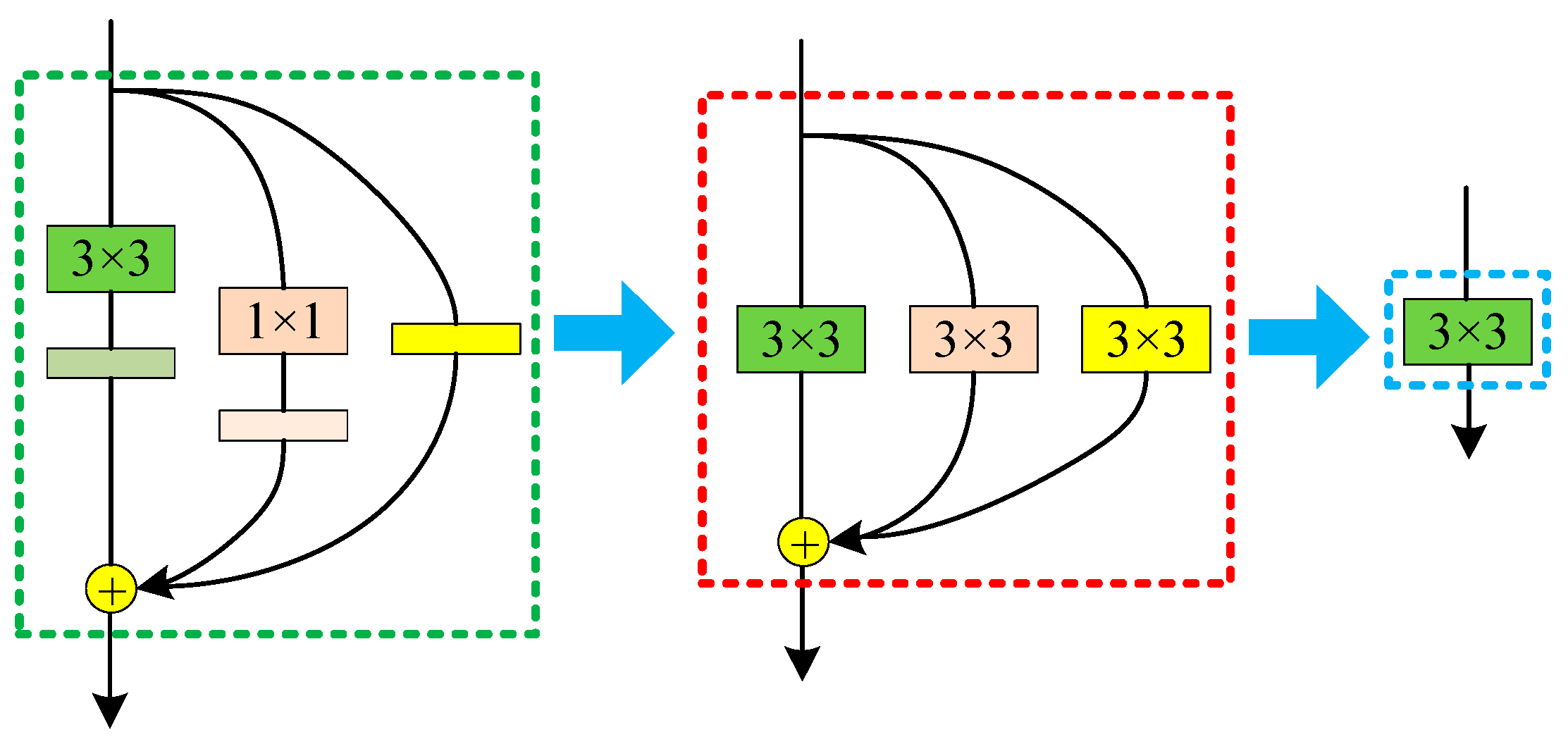

2.1.2. Structural Reparameterization

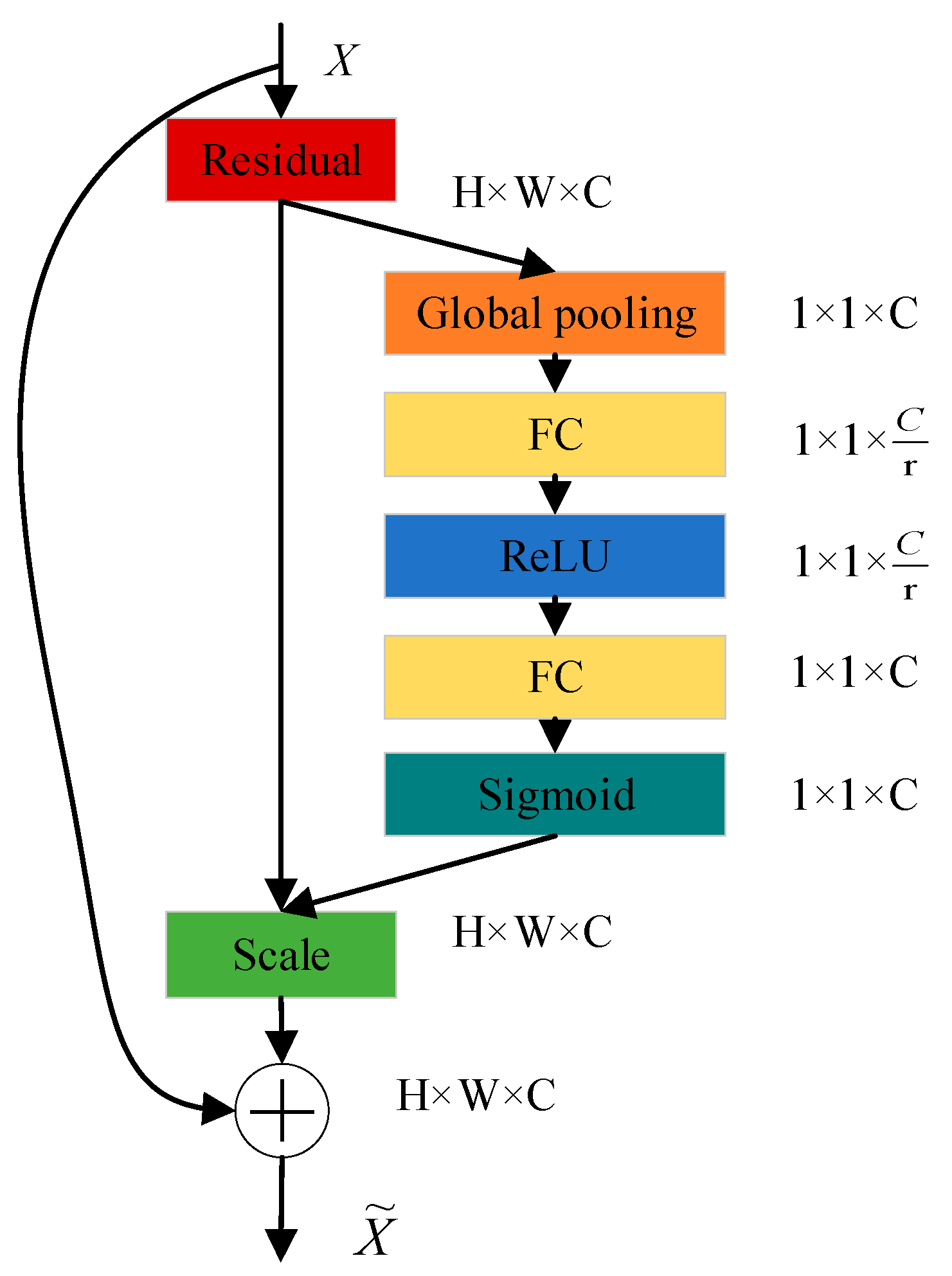

2.2. SENet Attention Mechanism

2.3. The Proposed Strategy

3. Experiment Setup and Data Set Preparation

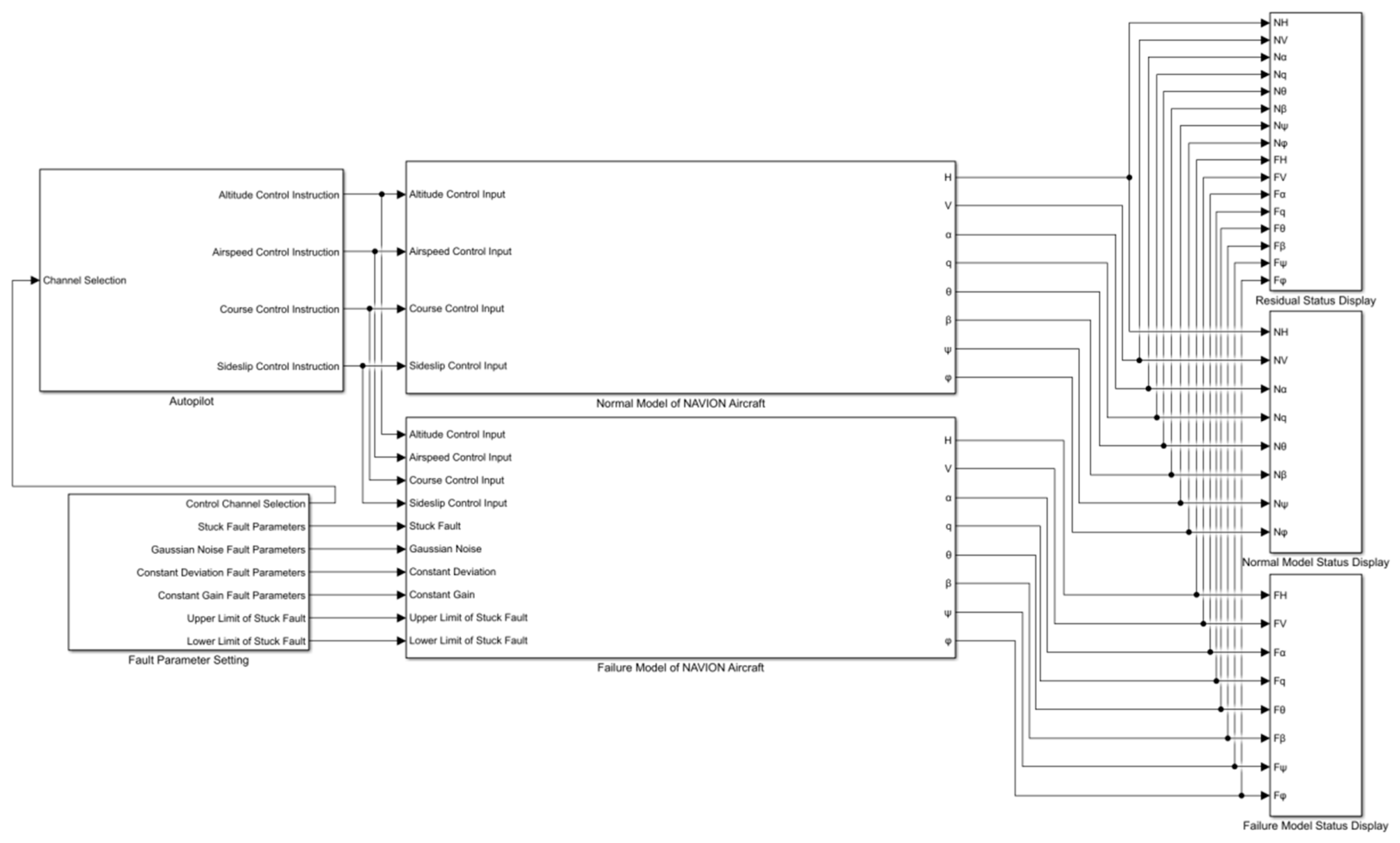

3.1. Establishment of Fault Model

3.2. Acquisition of Fault Data

3.3. Basic Parameter Settings of the Proposed Method

4. Experimental Results and Discussion

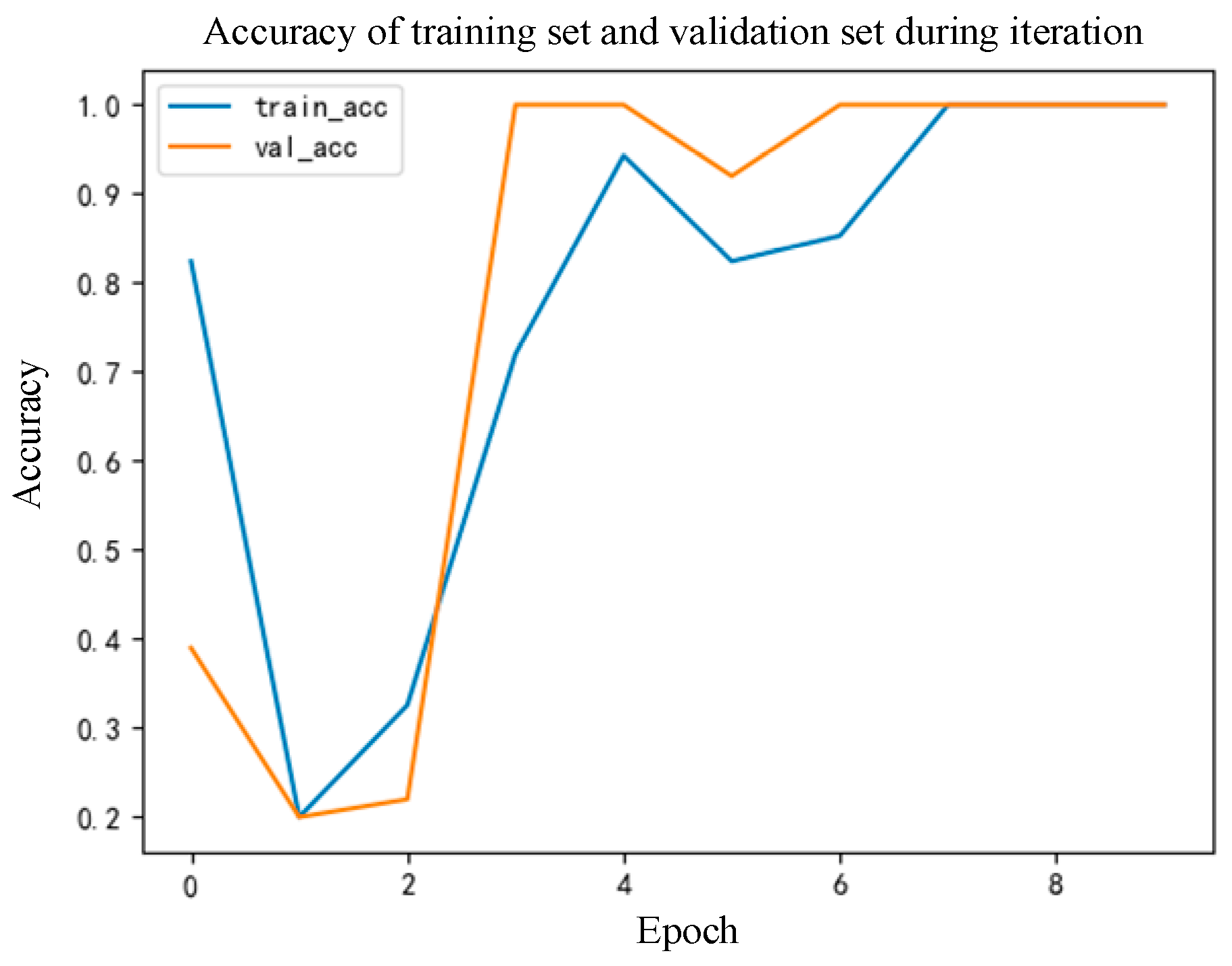

4.1. Effect of Data Set on Diagnosis Results

4.2. Ablation Experiment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qi, X.; Theilliol, D.; Qi, J.; Zhang, Y.; Han, J. A literature review on Fault Diagnosis methods for manned and unmanned helicopters. Int. Conf. Unmanned Aircr. Syst. 2013, 1114–1118. [Google Scholar] [CrossRef]

- Fuggetti, G.; Zanzi, M.; Ghetti, A. Safety improvement of fixed wing mini-UAV based on handy FDI current sensor and a FailSafe configuration of control surface actuators. Metrol. Aerosp. 2015, 356–361. [Google Scholar] [CrossRef]

- Ai, S.; Song, J.; Cai, G. A real-time fault diagnosis method for hypersonic air vehicle with sensor fault based on the auto temporal convolutional network. Aerosp. Sci. Technol. 2021, 119, 107220. [Google Scholar] [CrossRef]

- Guo, K.; Liu, L.; Shi, S.; Liu, D.; Peng, X. Uav sensor fault detection using a classifier without negative samples: A local density regulated optimization algorithm. Sensors 2019, 19, 771. [Google Scholar] [PubMed]

- Gao, Z.; Cecati, C.; Ding, S. A survey of fault diagnosis and fault-tolerant techniques-part i: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Gao, L.; Li, D.; Yao, L.; Gao, Y. Sensor drift fault diagnosis for chiller system using deep recurrent canonical correlation analysis and k-nearest neighbor classifier. ISA Trans. 2021, 122, 232–246. [Google Scholar] [CrossRef]

- He, Z.; Shao, H.; Ding, Z.; Jiang, H.; Cheng, J. Modified deep auto-encoder driven by multi-source parameters for fault transfer prognosis of aero-engine. IEEE Trans. Ind. Electron. 2022, 69, 845–855. [Google Scholar]

- Liu, Z.; Jia, Z.; Vong, C.; Bu, S.; Han, J.; Tang, X. Capturing high-discriminative fault features for electronics-rich analog system via deep learning. IEEE Trans. Ind. Inform. 2017, 13, 1213–1226. [Google Scholar] [CrossRef]

- Garramiola, F.; Poza, J.; Madina, P.; Olmo, J.; Ugalde, G. A Hybrid Sensor Fault Diagnosis for Maintenance in Railway Traction Drives. Sensors 2020, 20, 962. [Google Scholar] [CrossRef]

- Li, S.; Zhang, C.; Du, J.; Cong, X.; Zhang, L.; Jiang, Y.; Wang, L. Fault diagnosis for lithium-ion batteries in electric vehicles based on signal decomposition and two-dimensional feature clustering. Green Energy Intell. Transp. 2022, 1, 100009. [Google Scholar] [CrossRef]

- Cao, Y.; Li, P.; Zhang, Y. Parallel processing algorithm for railway signal fault diagnosis data based on cloud computing. Future Gener. Comput. Syst. 2018, 88, 279–283. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Q.; Xiao, Y.; Liu, W.; Shang, M. Research on rotor system fault diagnosis method based on vibration signal feature vector transfer learning. Eng. Fail. Anal. 2022, 139, 106424. [Google Scholar] [CrossRef]

- Zhong, M.; Xue, T.; Steven, X.D. A survey on model-based fault diagnosis for linear discrete time-varying systems. Neurocomputing 2018, 306, 51–60. [Google Scholar] [CrossRef]

- Valceschini, N.; Mazzoleni, M.; Previdi, F. Model-based fault diagnosis of sliding gates electro-mechanical actuators transmission components with motor-side measurements. IFAC-PapersOnLine 2022, 55, 784–789. [Google Scholar] [CrossRef]

- Wei, J.; Dong, G.; Chen, Z. Model-based fault diagnosis of Lithium-ion battery using strong tracking Extended Kalman Filter. Energy Procedia 2019, 158, 2500–2505. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Chen, Z.; Liu, X. Model based insulation fault diagnosis for lithium-ion battery pack in electric vehicles. Measurement 2019, 131, 443–451. [Google Scholar] [CrossRef]

- Li, X.; Shao, H.; Lu, S.; Xiang, J.; Cai, B. Highly-efficient fault diagnosis of rotating machinery under time-varying speeds using LSISMM and small infrared thermal images. IEEE Trans. Syst. 2022, 52, 7328–7340. [Google Scholar] [CrossRef]

- An, Y.; Sun, X.; Ren, B.; Li, H.; Zhang, M. A data-driven method for IGBT open-circuit fault diagnosis for the modular multilevel converter based on a modified Elman neural network. Energy Rep. 2022, 8, 80–88. [Google Scholar] [CrossRef]

- Nicholas, C.; Marcello, R.; Napolitano, G.C.; Paolo, V.; Mario, L. Fravolini, Aircraft robust data-driven multiple sensor fault diagnosis based on optimality criteria. Mech. Syst. Signal Process. 2022, 170, 108668. [Google Scholar] [CrossRef]

- Li, T.; Zhao, Y.; Zhang, C.; Luo, J.; Zhang, X. A knowledge-guided and data-driven method for building HVAC systems fault diagnosis. Build. Environ. 2021, 198, 107850. [Google Scholar] [CrossRef]

- Guo, H.; Hu, S.; Wang, F.; Zhang, L. A novel method for quantitative fault diagnosis of photovoltaic systems based on data-driven. Electr. Power Syst. Res. 2022, 210, 108121. [Google Scholar] [CrossRef]

- Andreas, L.; Daniel, J. Data-driven fault diagnosis analysis and open-set classification of time-series data. Control. Eng. Pract. 2022, 121, 105006. [Google Scholar] [CrossRef]

- Wang, Z.; Li, G.; Yao, L.; Qi, X.; Zhang, J. Data-driven fault diagnosis for wind turbines using modified multiscale fluctuation dispersion entropy and cosine pairwise-constrained supervised manifold mapping. Knowl.-Based Syst. 2021, 228, 107276. [Google Scholar] [CrossRef]

- Jia, Z.; Liu, Z.; Vong, C.M.; Wang, S.; Cai, Y. DC-DC Buck circuit fault diagnosis with insufficient state data based on deep model and transfer strategy. Expert Syst. Appl. 2023, 213, 118918. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Z.; Jia, Z.; Li, Z. Composite fault diagnosis of analog circuit system using chaotic game optimization-assisted deep ELM-AE. Measurement 2022, 202, 111826. [Google Scholar]

- Zhao, K.; Jiang, H.; Wang, K.; Pei, Z. Joint distribution adaptation network with adversarial learning for rolling bearing fault diagnosis. Knowl.-Based Syst. 2021, 222, 106974. [Google Scholar]

- Saeed, R.; Mehdi S, A.; Stefania, S.; Francesco, F. Fault diagnosis in industrial rotating equipment based on permutation entropy, signal processing and multi-output neuro-fuzzy classifier. Expert Syst. Appl. 2022, 206, 117754. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, X.; Ma, N.; Han, J.; Ding, G.; Sun, J. RepVGG: Making VGG-style ConvNets Great Again. IEEE CVPR 2021, 13733–13742. [Google Scholar]

- Hu, J.; Shen, L.; Albanie, S.; Sun, G.; Wu, E. Squeeze-and-excitation networks. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 42, 7132–7141. [Google Scholar] [CrossRef]

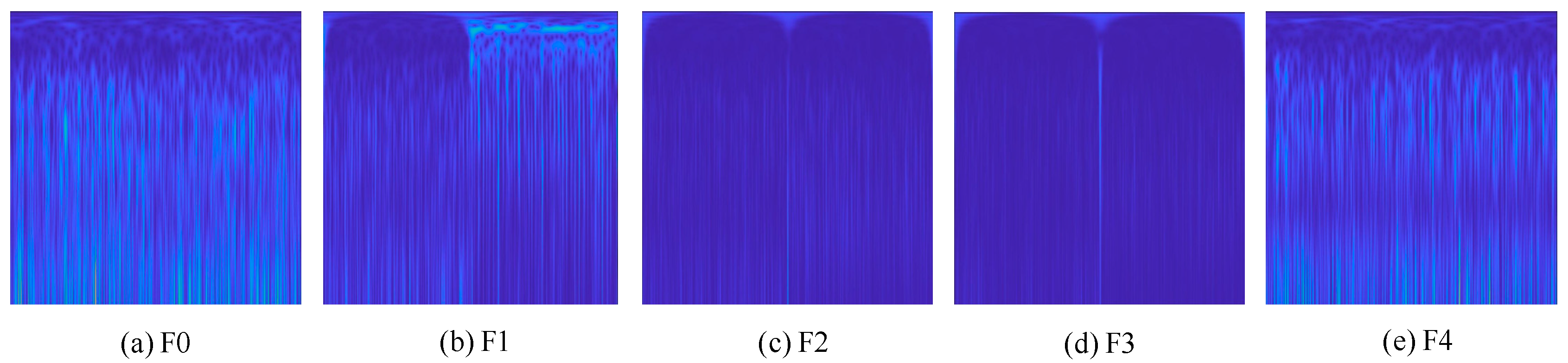

| Fault Type | Fault Manifestation | Fault Label |

|---|---|---|

| No fault | The fault free state represents the health state and is regarded as a special fault | F0 |

| Stuck | The measured value of the sensor output deviates from the normal value and reaches a stuck position | F1 |

| Constant gain | The measured value of the sensor output maintains a constant proportion to the normal output value | F2 |

| Constant deviation | The measured value of the sensor output deviates from the normal value and keeps the deviation constant | F3 |

| Excessive noise | The measured value of the sensor output contains large noise | F4 |

| Data Set | Number of Training Sets | Number of Validation Sets | Number of Test Sets |

|---|---|---|---|

| 1 | 140 | 20 | 40 |

| 2 | 280 | 40 | 80 |

| 3 | 420 | 60 | 120 |

| 4 | 700 | 100 | 200 |

| 5 | 980 | 140 | 280 |

| Parameter | Value |

|---|---|

| kernel size | 3 |

| padding | 0 |

| padding_mode | ‘zeros’ |

| num_blocks | [2, 4, 14, 1] |

| num_classes | 5 |

| width_multiplier | [0.75, 0.75, 0.75, 2.5] |

| groups | 1 |

| stride | 1 |

| dilation | 1 |

| bias | True |

| Different Datasets | Dataset 1 | Dataset 2 | Dataset 3 | Dataset 4 | Dataset 5 |

|---|---|---|---|---|---|

| Average accuracy (%) | 93.45% | 96.10% | 99.28% | 99.37% | 99.42% |

| Average training time (s) | 356.08 | 693.76 | 1019.73 | 1754.73 | 2390.49 |

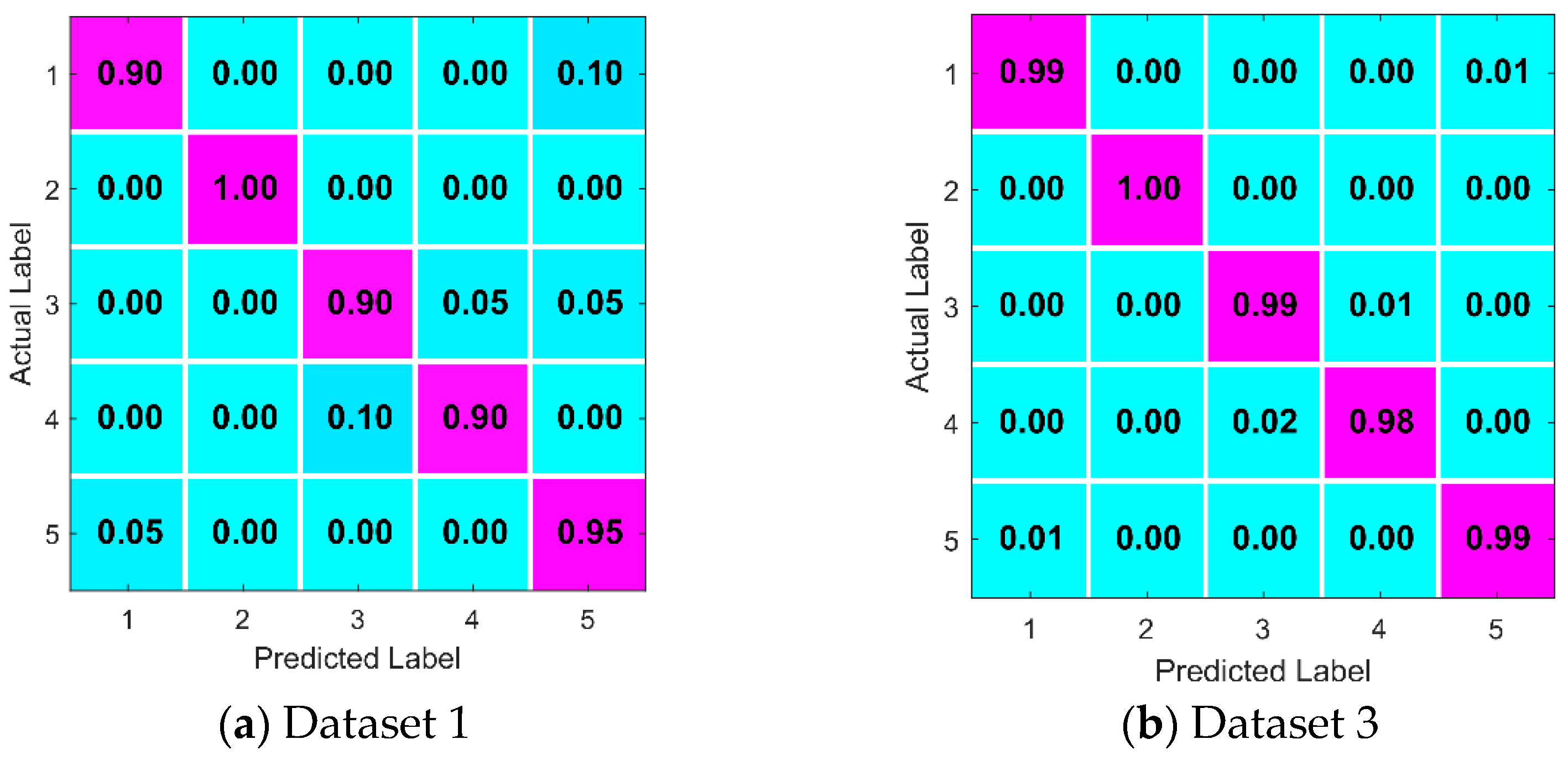

| Dataset 1 | Dataset 3 | ||

|---|---|---|---|

| Fault code | Accuracy (%) | Fault code | Accuracy (%) |

| F0 | 92.50 | F0 | 98.33 |

| F1 | 100.00 | F1 | 99.17 |

| F2 | 90.00 | F2 | 100.00 |

| F3 | 85.00 | F3 | 98.33 |

| F4 | 90.00 | F4 | 99.17 |

| Average accuracy | 91.50 | Average accuracy | 99.00 |

| No. | Time Domain Signal | S-Transform | SENet | Average Accuracy |

|---|---|---|---|---|

| 1 | √ | √ | 80.68% | |

| 2 | √ | √ | 86.35% | |

| 3 | √ | √ | 92.37% | |

| 4 | √ | 62.75% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Z.; Wang, K.; Li, Y.; Liu, Z.; Qin, J.; Yang, Q. High Precision Feature Fast Extraction Strategy for Aircraft Attitude Sensor Fault Based on RepVGG and SENet Attention Mechanism. Sensors 2022, 22, 9662. https://doi.org/10.3390/s22249662

Jia Z, Wang K, Li Y, Liu Z, Qin J, Yang Q. High Precision Feature Fast Extraction Strategy for Aircraft Attitude Sensor Fault Based on RepVGG and SENet Attention Mechanism. Sensors. 2022; 22(24):9662. https://doi.org/10.3390/s22249662

Chicago/Turabian StyleJia, Zhen, Kai Wang, Yang Li, Zhenbao Liu, Jian Qin, and Qiqi Yang. 2022. "High Precision Feature Fast Extraction Strategy for Aircraft Attitude Sensor Fault Based on RepVGG and SENet Attention Mechanism" Sensors 22, no. 24: 9662. https://doi.org/10.3390/s22249662

APA StyleJia, Z., Wang, K., Li, Y., Liu, Z., Qin, J., & Yang, Q. (2022). High Precision Feature Fast Extraction Strategy for Aircraft Attitude Sensor Fault Based on RepVGG and SENet Attention Mechanism. Sensors, 22(24), 9662. https://doi.org/10.3390/s22249662