Vehicle Teleoperation: Human in the Loop Performance Comparison of Smith Predictor with Novel Successive Reference-Pose Tracking Approach

Abstract

1. Introduction

1.1. Related Work

1.2. Contribution of Paper

1.3. Outline of Paper

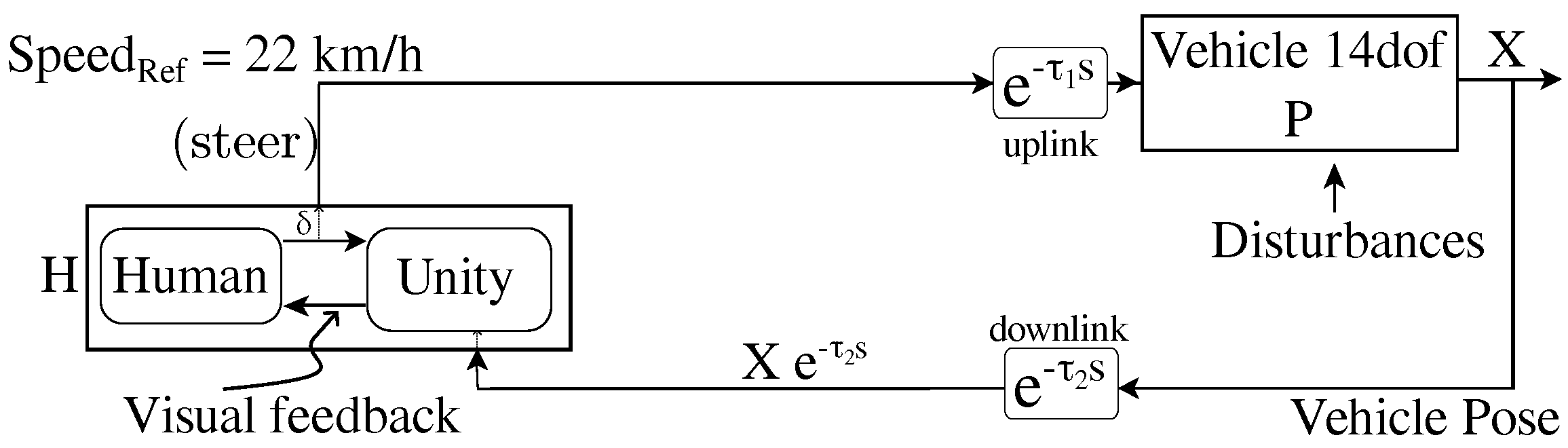

2. Method

2.1. Uplink Delay and Variable Downlink Delay Characteristics

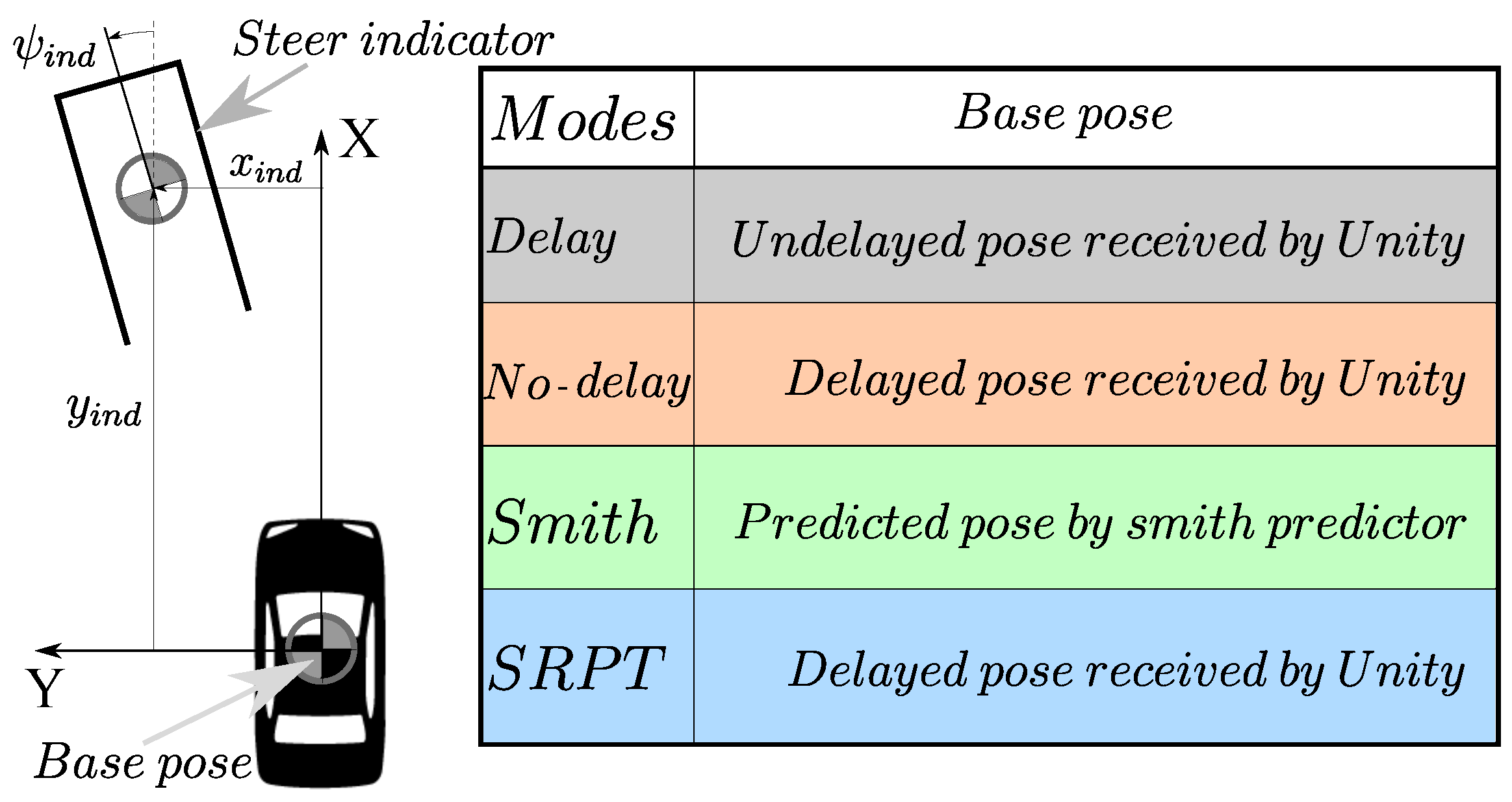

2.2. Vehicle Teleoperation Modes

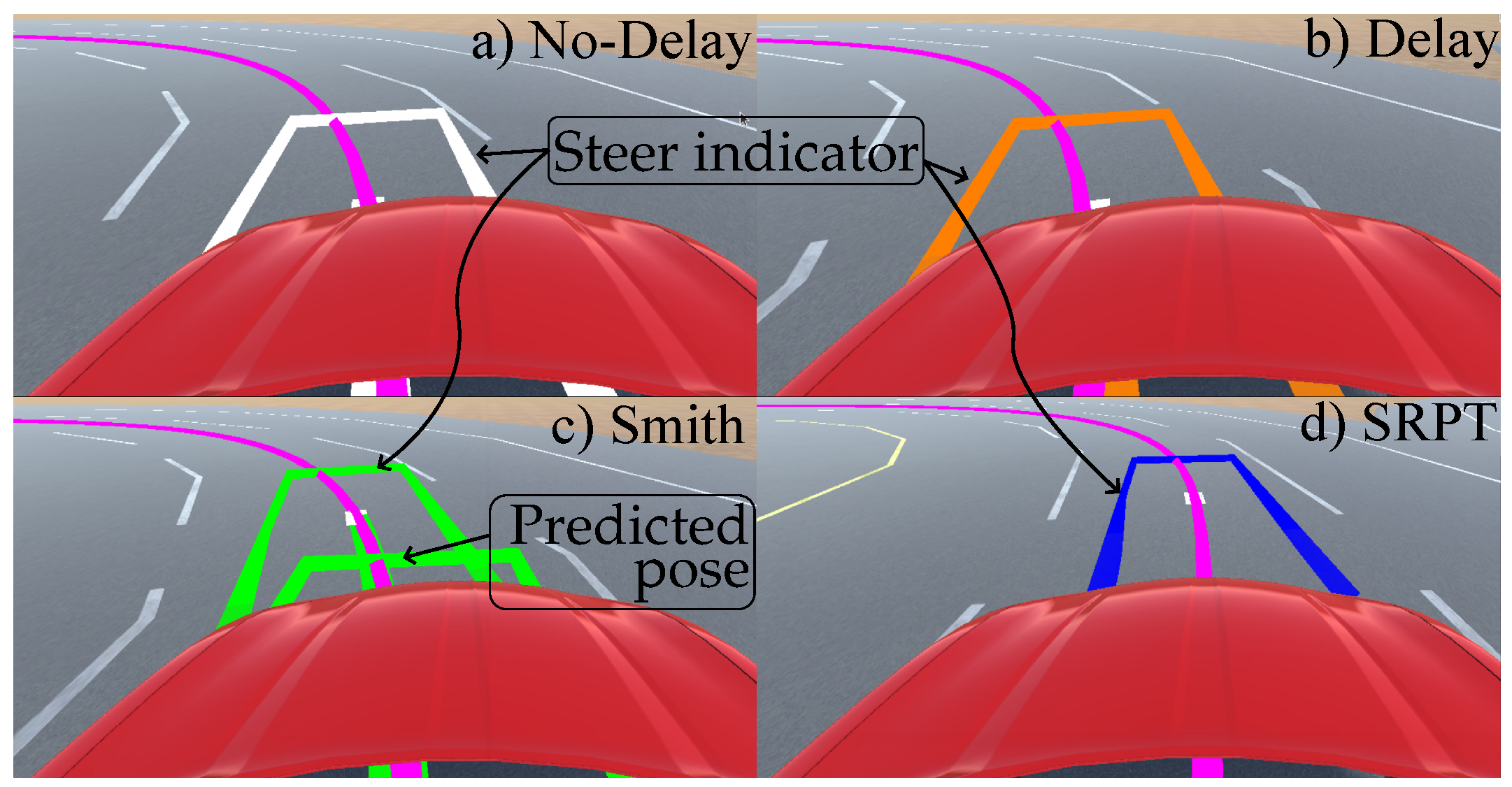

2.2.1. No-Delay Mode

2.2.2. Delay Mode

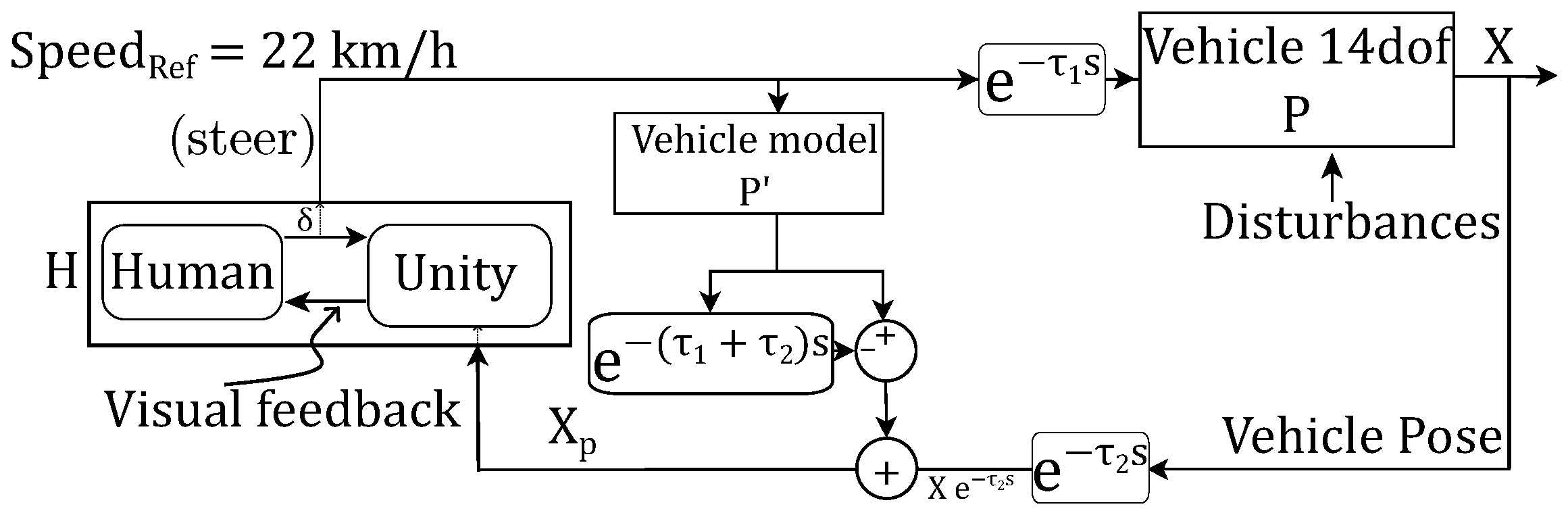

2.2.3. Smith-Predictor Mode

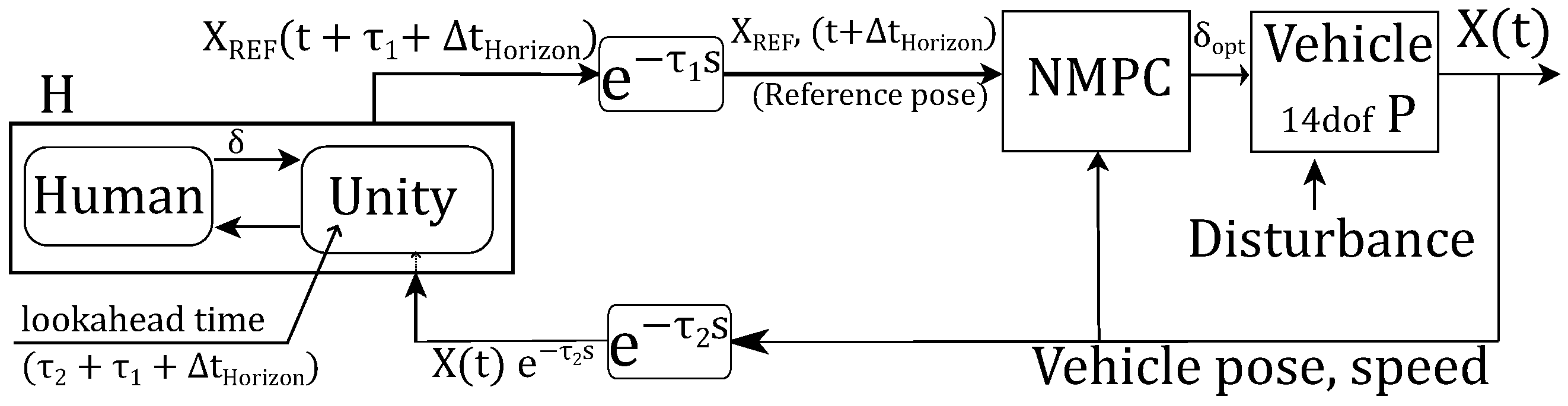

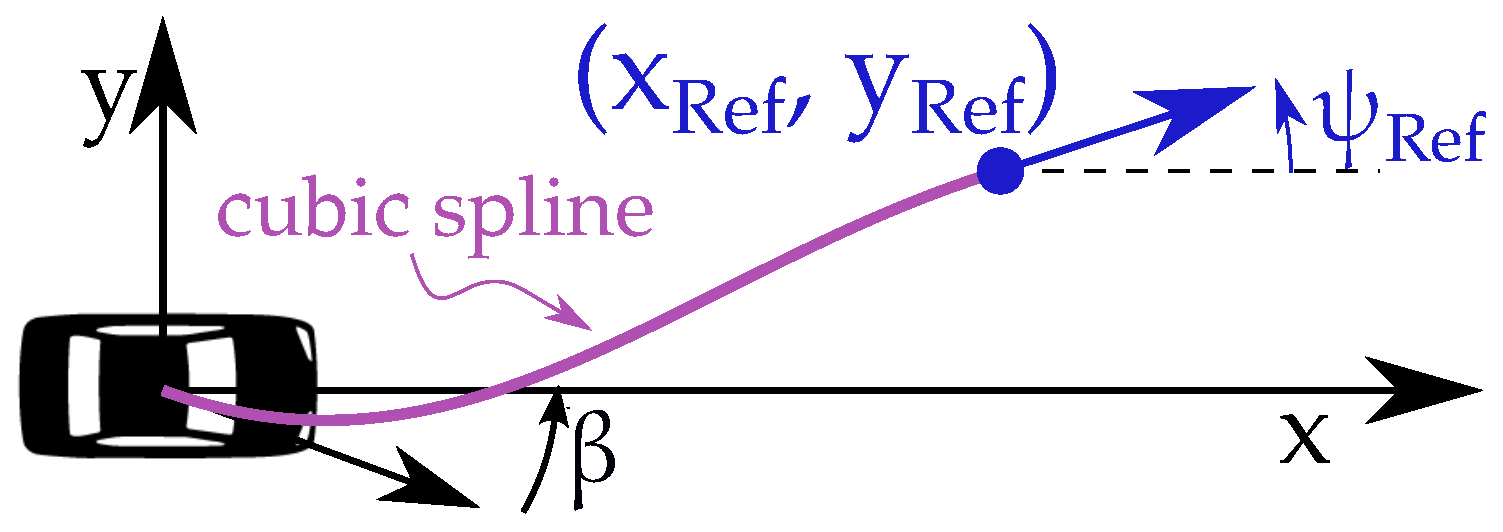

2.2.4. SRPT Mode Using NMPC

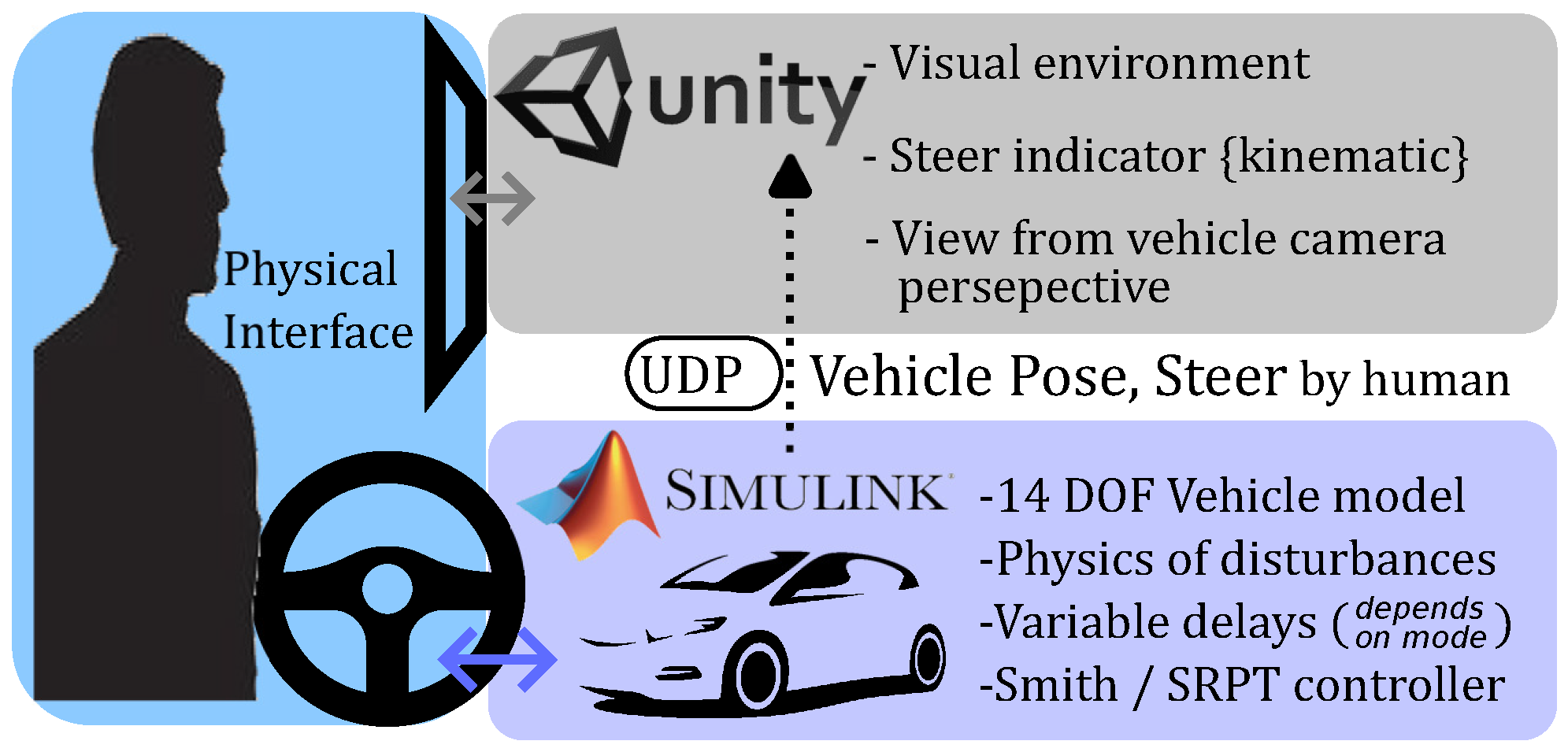

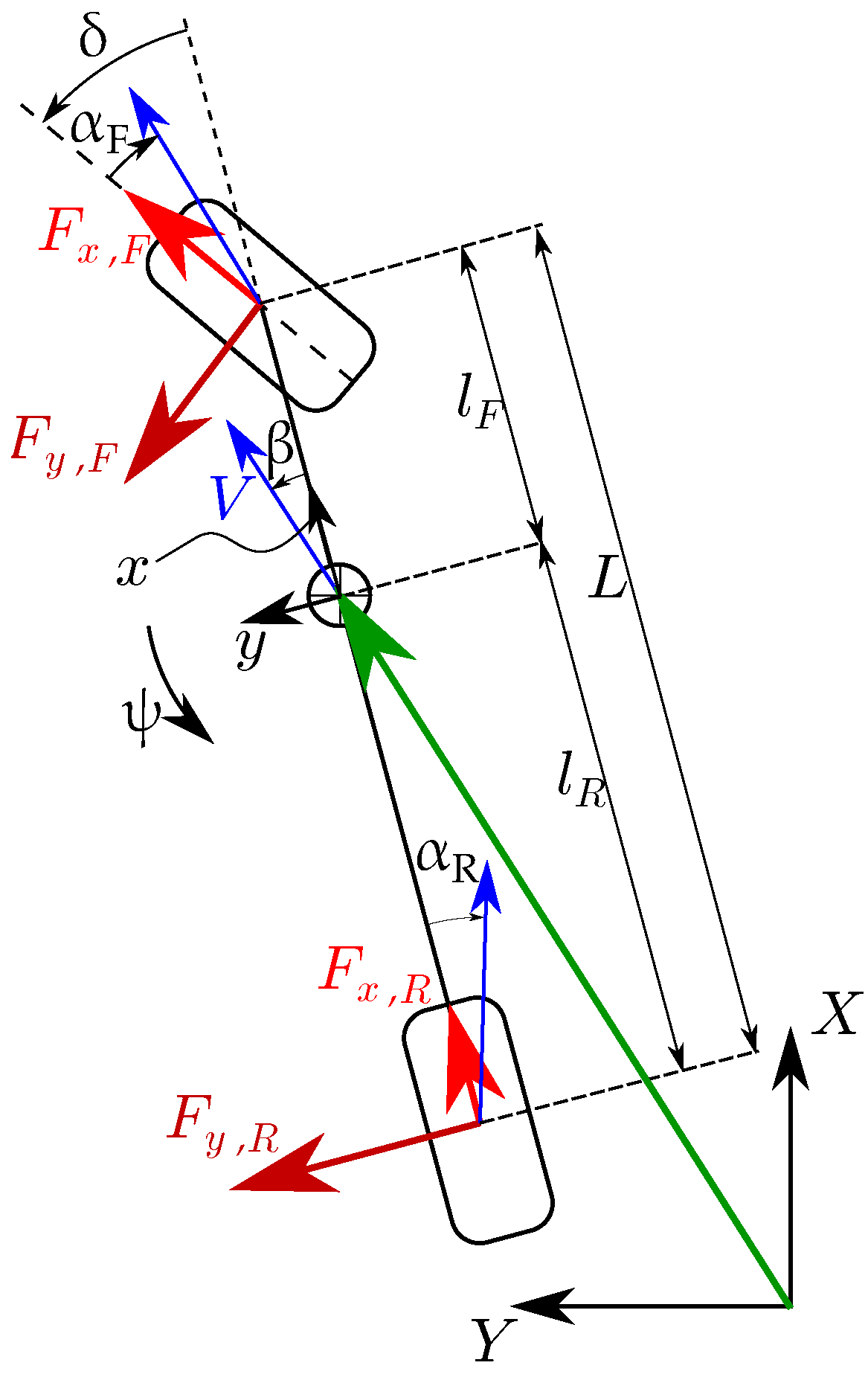

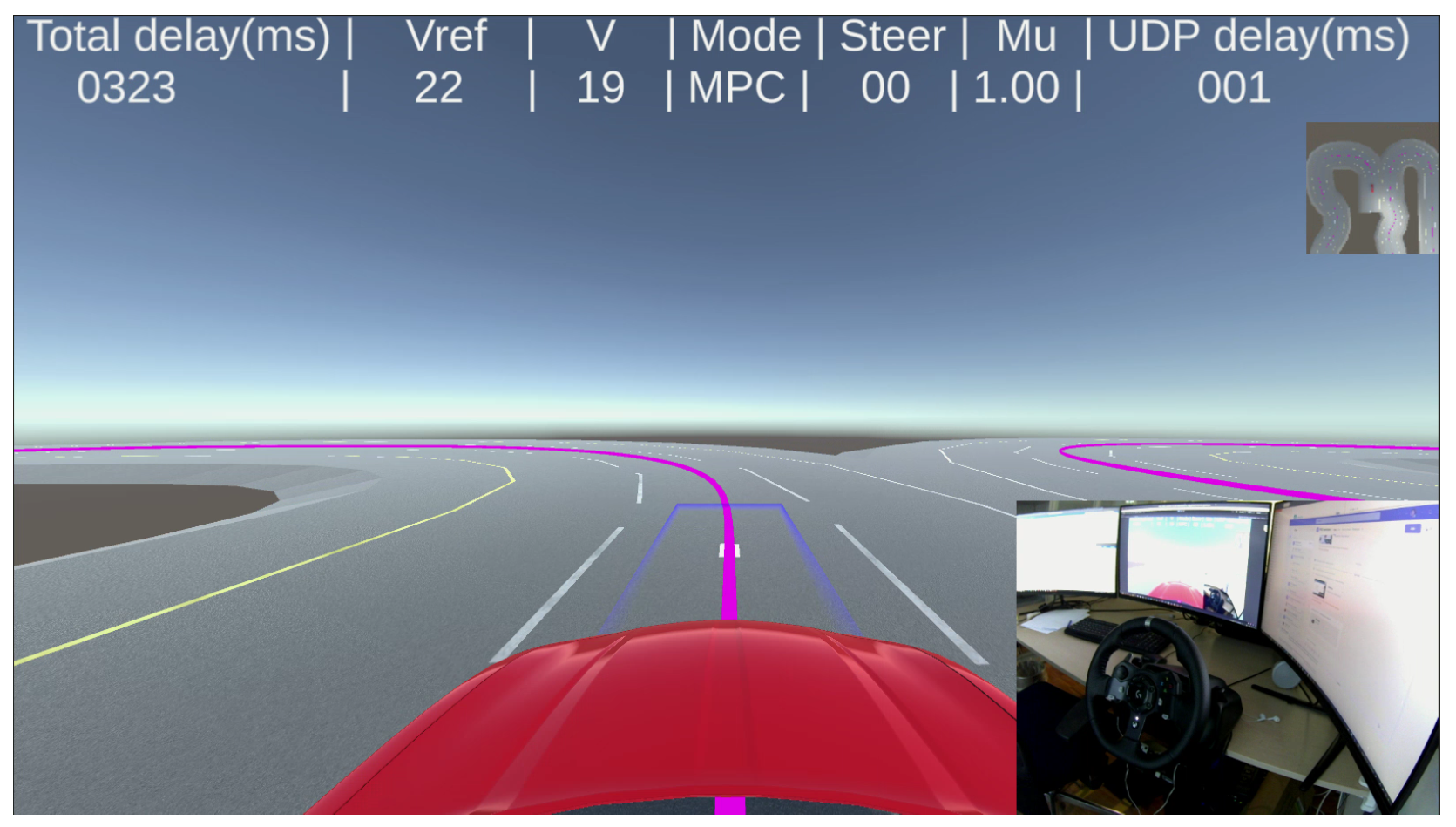

3. Simulation Platform

4. Human-in-the-Loop Experiments

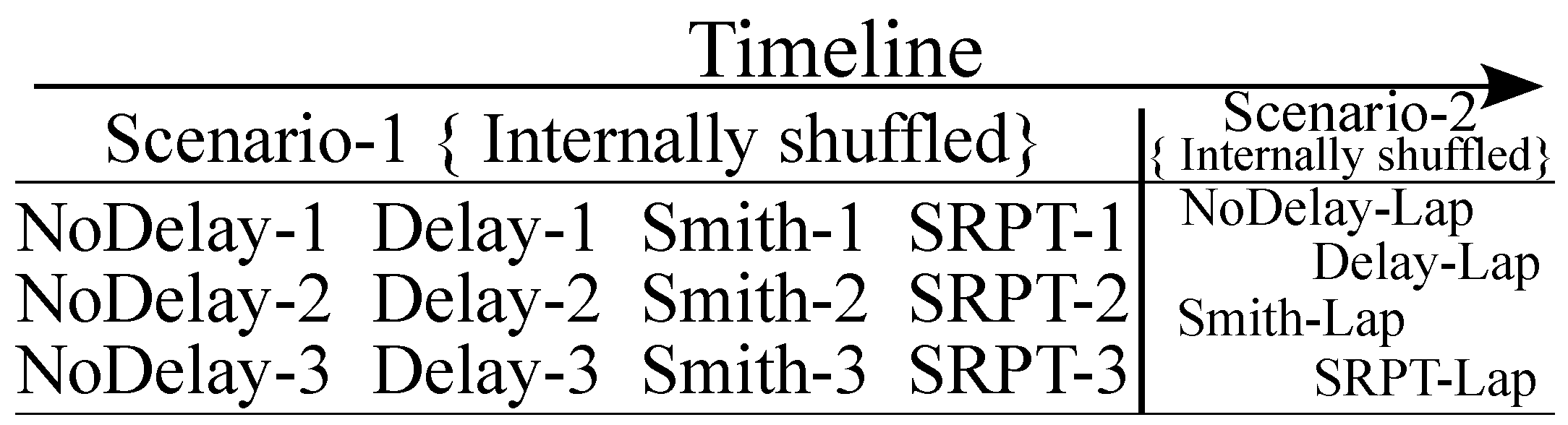

4.1. Experiment Design

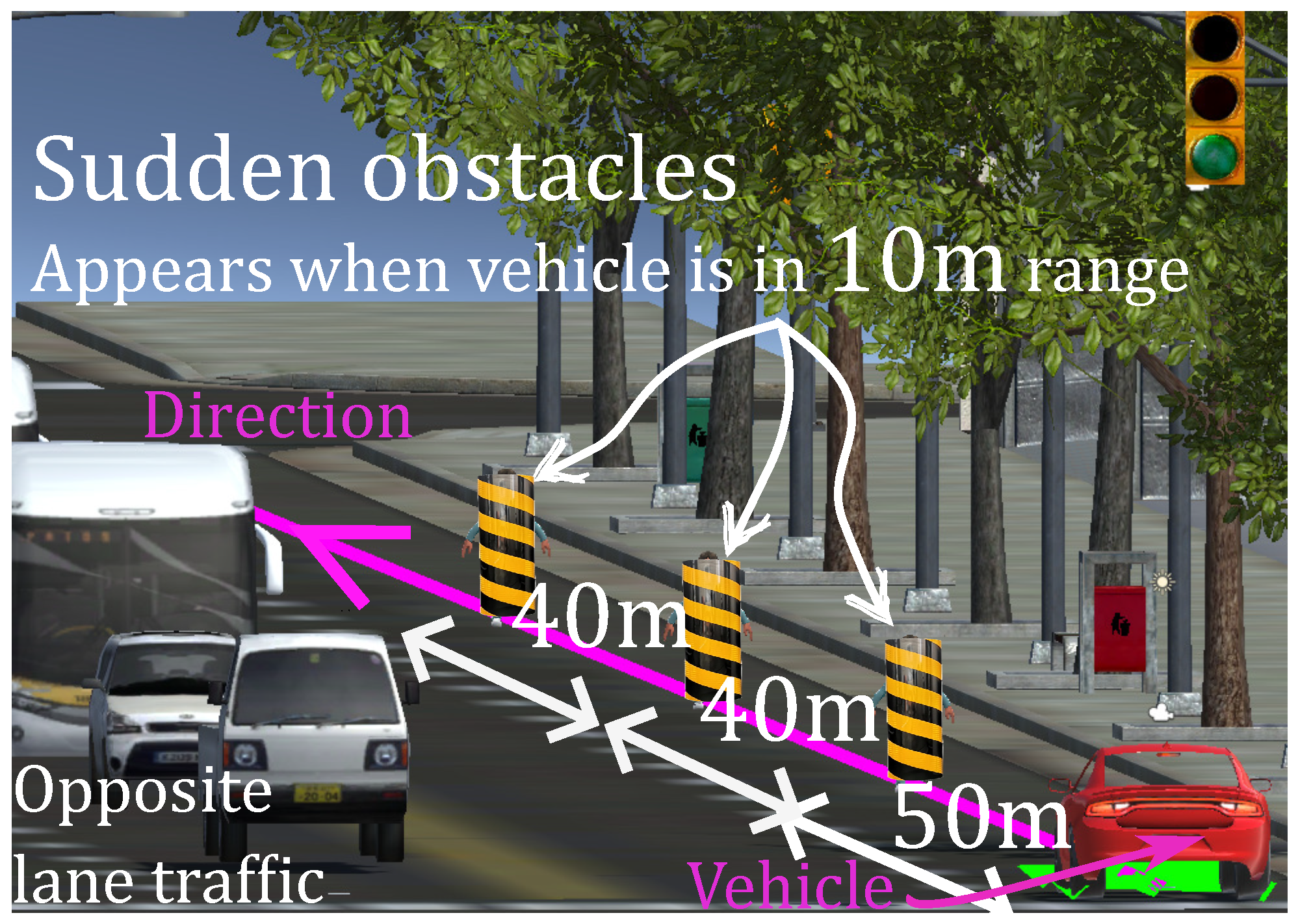

4.1.1. Scenario 1

4.1.2. Scenario 2

4.2. Test Procedure

5. Results and Discussion

- Age group 26–31 years;

- Driving experience of 7–11 years (except the 1 inexperienced driver);

- Seven of them are familiar with racing video games.

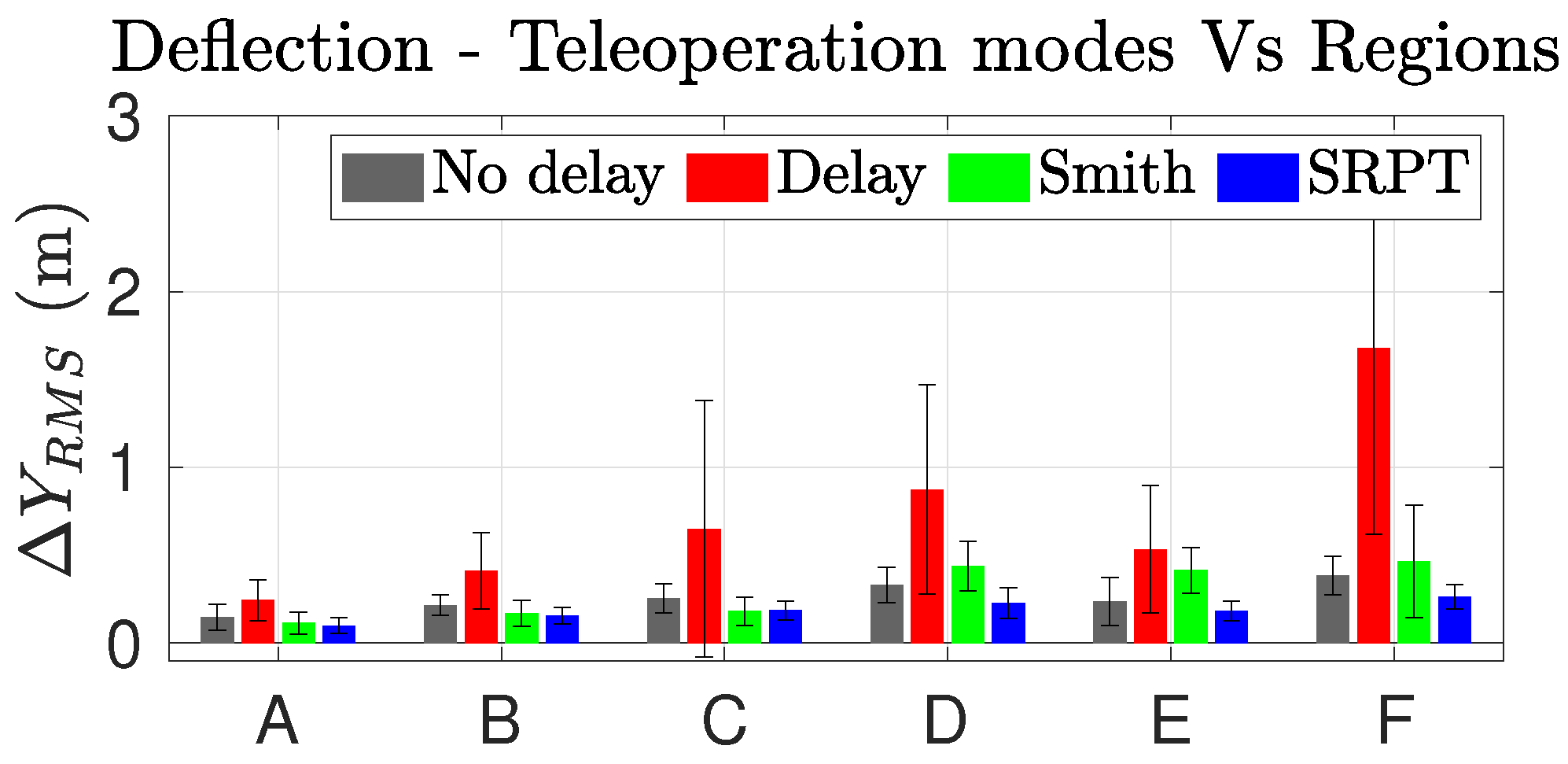

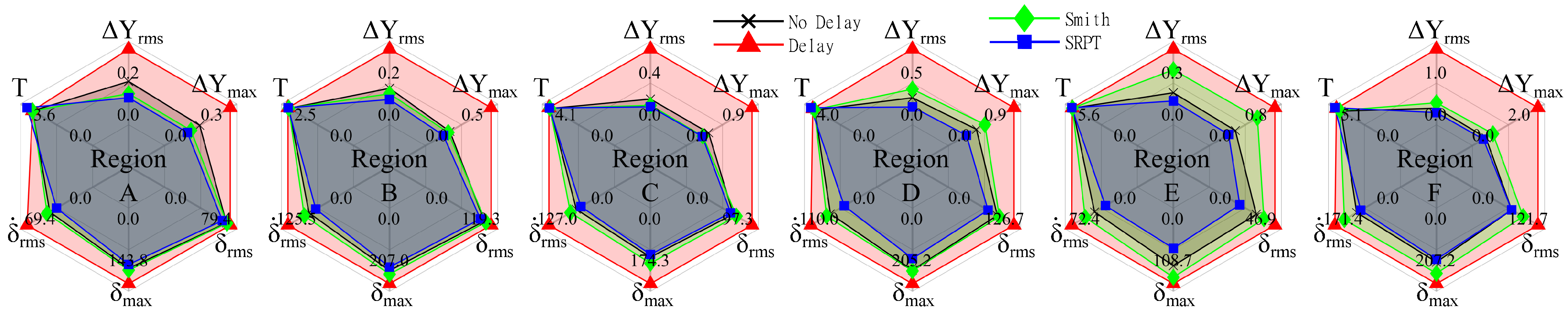

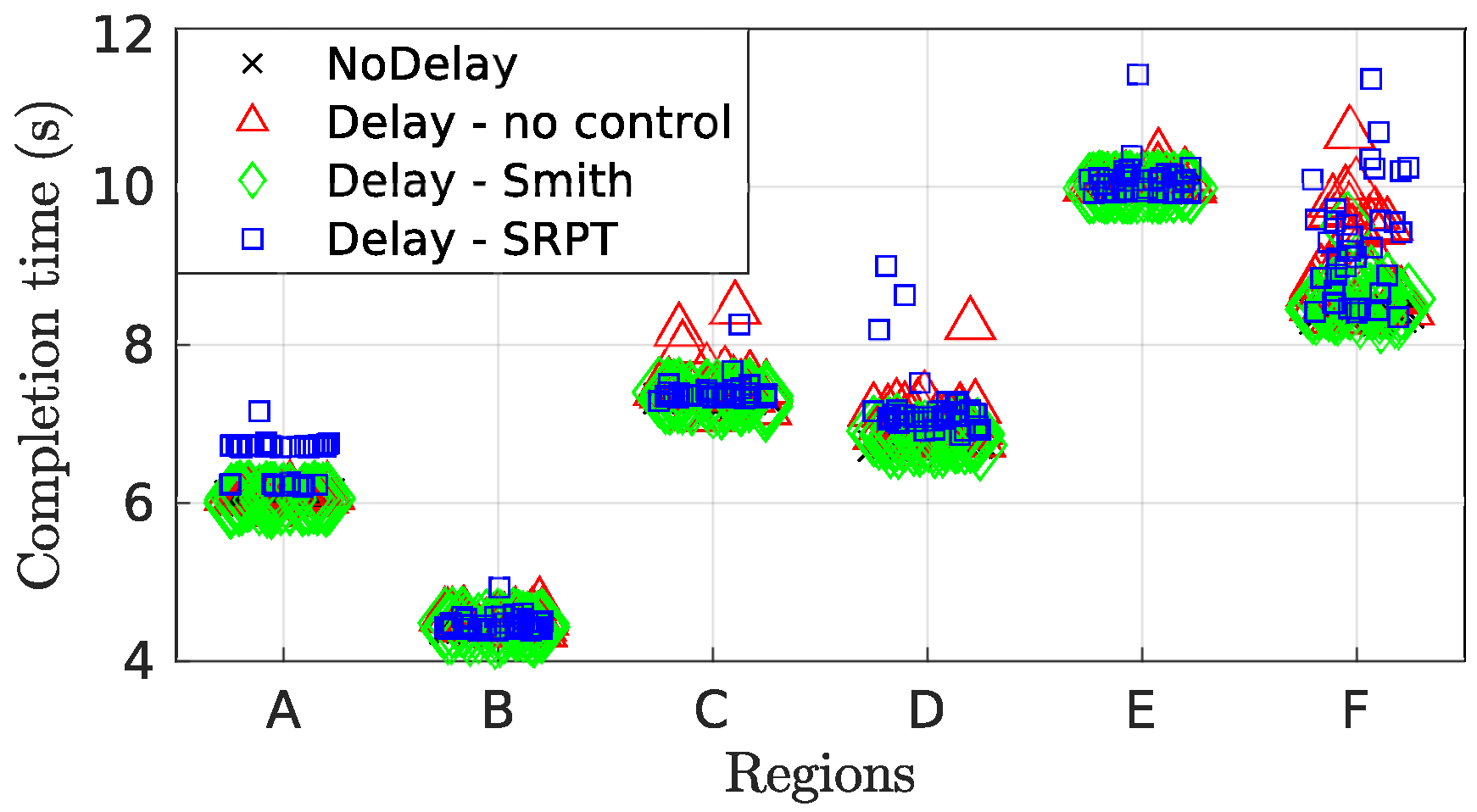

5.1. Scenario 1

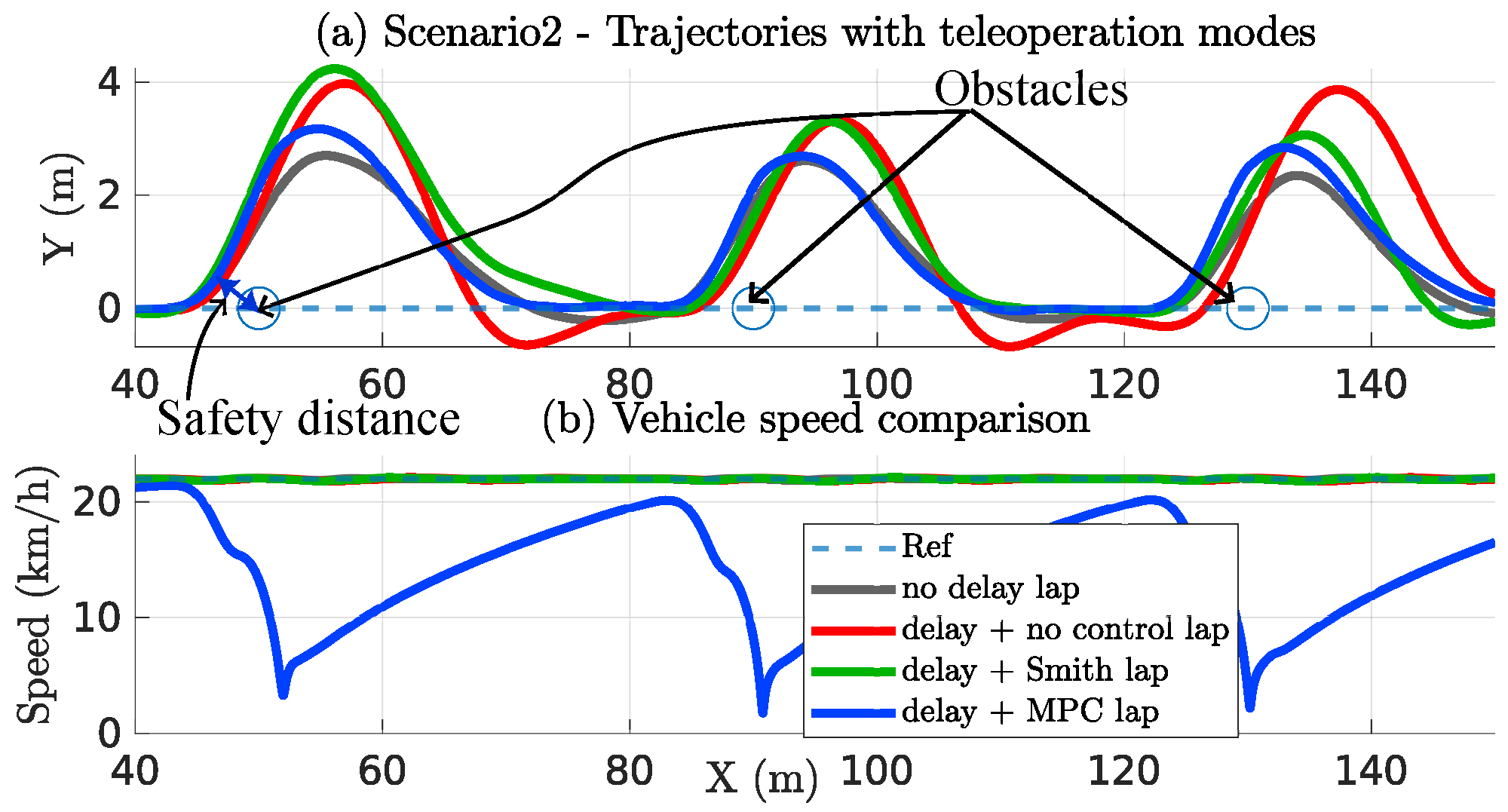

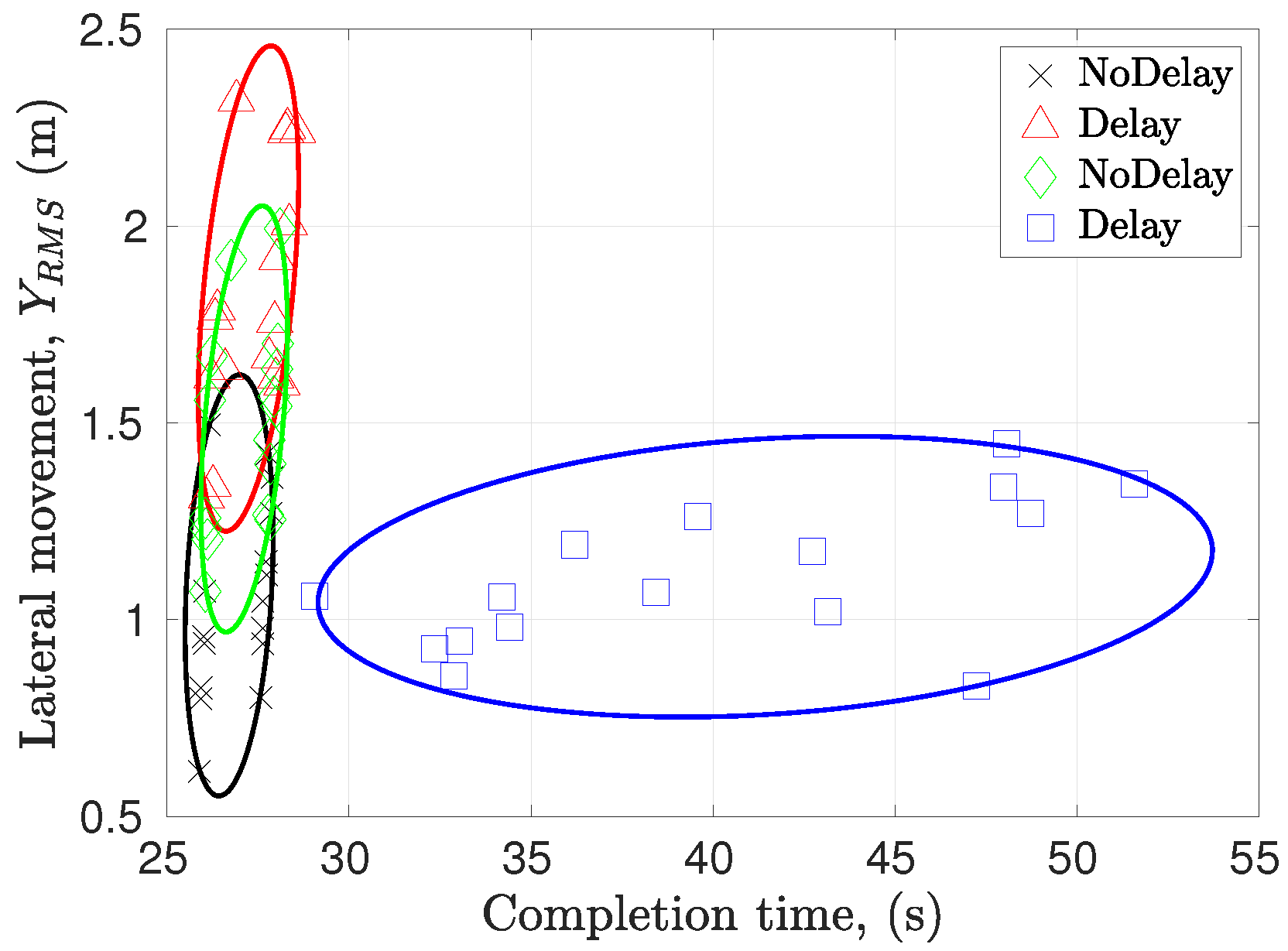

5.2. Scenario 2

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SRPT | Successive Reference-Pose Tracking |

| NMPC | Non-linear Model-Predictive Control |

| FOV | Field Of View |

| ODE | Ordinary Differential Equation |

| DOF | Degree of Freedom |

| IMU | Inertial Measurement Unit |

References

- Kettwich, C.; Schrank, A.; Oehl, M. Teleoperation of Highly Automated Vehicles in Public Transport: User-Centered Design of a Human-Machine Interface for Remote-Operation and Its Expert Usability Evaluation. Multimodal Technol. Interact. 2021, 5, 26. [Google Scholar] [CrossRef]

- Frahlich, P.; Gafert, M.; Diamond, L.; Reinthaler, M.; Neubauer, M.; Hammer, F.; Koskinen, S. Towards a Comprehensive Understanding of Stakeholder Requirements for Automated Road Transport Logistics. In Proceedings of the CEUR Workshop, Yokohama, Japan, 7 May 2021; Volume 2905. [Google Scholar]

- Gafert, M.; Fröhlich, P.; Ritzinger, U.; Baldauf, M. Challenges for Future Automated Logistics Fleet Interactions. In Proceedings of the CHI 2021 Workshop “Automation Experience at the Workplace”, CEUR, Yokohama, Japan, 7 May 2021. [Google Scholar]

- Cosenzo, K.; Barnes, M. Who needs an operator when the robot is autonomous? The challenges and advantages of robots as team members. In Designing Soldier Systems: Current Issues in Human Factors; Ashgate Publishing, Ltd.: Surrey, UK, 2012; pp. 35–51. [Google Scholar] [CrossRef]

- Chen, J.Y.C.; Haas, E.C.; Barnes, M.J. Human Performance Issues and User Interface Design for Teleoperated Robots. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2007, 37, 1231–1245. [Google Scholar] [CrossRef]

- Storms, J.; Tilbury, D. Equating user performance among communication latency distributions and simulation fidelities for a teleoperated mobile robot. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 4440–4445. [Google Scholar] [CrossRef]

- Luck, J.P.; McDermott, P.L.; Allender, L.; Russell, D.C. An Investigation of Real World Control of Robotic Assets under Communication Latency. In Proceedings of the 1st ACM SIGCHI/SIGART Conference on Human-Robot Interaction, HRI ’06, Salt Lake City, UT, USA, 2–3 March 2006; Association for Computing Machinery: New York, NY, USA, 2006; pp. 202–209. [Google Scholar] [CrossRef]

- Sheridan, T.B. Space Teleoperation Through Time Delay: Review and Prognosis. IEEE Trans. Robot. Autom. 1993, 9, 592–606. [Google Scholar] [CrossRef]

- Gorsich, D.J.; Jayakumar, P.; Cole, M.P.; Crean, C.; Jain, A.; Ersal, T. Evaluating Mobility Performance of Unmanned Ground Vehicles; US Army Tardec Warren: Warren, MI, USA, 2018. [Google Scholar] [CrossRef]

- Chucholowski, F. Evaluation of Display Methods for Teleoperation of Road Vehicles. J. Unmanned Syst. Technol. 2016, 3, 80–85. [Google Scholar] [CrossRef]

- Hosseini, A.; Richthammer, F.; Lienkamp, M. Predictive Haptic Feedback for Safe Lateral Control of Teleoperated Road Vehicles in Urban Areas. In Proceedings of the 2016 IEEE 83rd Vehicular Technology Conference (VTC Spring), Nanjing, China, 15–18 May 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Brudnak, M.J. Predictive Displays for High Latency Teleoperation. In Proceedings of the NDIA Ground Vehicle Systems Engineering and Technology Symposium, Novi, MI, USA, 2–4 August 2016. [Google Scholar]

- Prakash, J.; Vignati, M.; Vignarca, D.; Sabbioni, E.; Cheli, F. Predictive Display with Perspective Projection of surroundings in Vehicle Teleoperation to Account Time-delays. arXiv 2022, arXiv:2211.11918. [Google Scholar]

- Chen, T. Methods for Improving the Control of Teleoperated Vehicles. Ph.D. Thesis, Technical University of Munich, München, Germany, 2015. [Google Scholar]

- Zheng, Y.; Brudnak, M.J.; Jayakumar, P.; Stein, J.; Ersal, T. A Delay Compensation Framework for Predicting Heading in Teleoperated Ground Vehicles. IEEE/ASME Trans. Mechatron. 2019, 24, 2365–2376. [Google Scholar] [CrossRef]

- Zheng, Y.; Brudnak, M.J.; Jayakumar, P.; Stein, J.L.; Ersal, T. Evaluation of a Predictor-Based Framework in High-Speed Teleoperated Military UGVs. IEEE Trans. Hum.-Mach. Syst. 2020, 50, 561–572. [Google Scholar] [CrossRef]

- Kelly, A.; Chan, N.; Herman, H.; Huber, D.; Meyers, R.; Rander, P.; Warner, R.; Ziglar, J.; Capstick, E. Real-time photorealistic virtualized reality interface for remote mobile robot control. Int. J. Robot. Res. 2011, 30, 384–404. [Google Scholar] [CrossRef]

- Saparia, S.; Schimpe, A.; Ferranti, L. Active Safety System for Semi-Autonomous Teleoperated Vehicles. In Proceedings of the 2021 IEEE Intelligent Vehicles Symposium Workshops (IV Workshops), Nagoya, Japan, 11–17 July 2021; pp. 141–147. [Google Scholar] [CrossRef]

- Anderson, S.J.; Walker, J.M.; Iagnemma, K. Experimental Performance Analysis of a Homotopy-Based Shared Autonomy Framework. IEEE Trans. Hum.-Mach. Syst. 2014, 44, 190–199. [Google Scholar] [CrossRef]

- Fennel, M.; Zea, A.; Hanebeck, U.D. Haptic-Guided Path Generation for Remote Car-like Vehicles. IEEE Robot. Autom. Lett. 2021, 6, 4087–4094. [Google Scholar] [CrossRef]

- Macharet, D.G.; Florencio, D.A. A collaborative control system for telepresence robots. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 5105–5111. [Google Scholar] [CrossRef]

- Zhu, S.; Xiong, G.; Chen, H.; Gong, J. Guidance Point Generation-Based Cooperative UGV Teleoperation in Unstructured Environment. Sensors 2021, 21, 2323. [Google Scholar] [CrossRef] [PubMed]

- Prakash, J.; Vignati, M.; Sabbioni, E.; Cheli, F. Vehicle Teleoperation: Successive Reference-Pose Tracking to Improve Path Tracking and to Reduce Time-Delay Induced Instability. arXiv 2022, arXiv:2206.10340. [Google Scholar]

- Zontone, P.; Affanni, A.; Bernardini, R.; Del Linz, L.; Piras, A.; Rinaldo, R. Emotional Response Analysis Using Electrodermal Activity, Electrocardiogram and Eye Tracking Signals in Drivers with Various Car Setups. In Proceedings of the 2020 28th European Signal Processing Conference (EUSIPCO), Amsterdam, The Netherlands, 18–21 January 2021; pp. 1160–1164. [Google Scholar] [CrossRef]

- MATLAB. Vehicle Body 3DOF Single Track. Available online: www.mathworks.com/help/vdynblks/ref/vehiclebody3dof.html (accessed on 22 September 2022).

- Metzler, M. Automotive Applications of Explicit Non-Linear Model Predictive Control. Ph.D. Thesis, University of Surrey, Guildford, UK, 2019. [Google Scholar]

- Eliou, N.; Kaliabetsos, G. A new, simple and accurate transition curve type, for use in road and railway alignment design. Eur. Transp. Res. Rev. 2014, 6, 171–179. [Google Scholar] [CrossRef]

- Verschueren, R.; Frison, G.; Kouzoupis, D.; van Duijkeren, N.; Zanelli, A.; Quirynen, R.; Diehl, M. Towards a modular software package for embedded optimization. In Proceedings of the IFAC Conference on Nonlinear Model Predictive Control (NMPC), Madison, WI, USA, 19–22 August 2018. [Google Scholar]

- Verschueren, R.; Frison, G.; Kouzoupis, D.; Frey, J.; van Duijkeren, N.; Zanelli, A.; Novoselnik, B.; Albin, T.; Quirynen, R.; Diehl, M. acados—A modular open-source framework for fast embedded optimal control. Math. Program. Comput. 2021, 14, 147–183. [Google Scholar] [CrossRef]

- Baker, C. Unsteady wind loading on a wall. Wind. Struct. 2001, 4, 413–440. [Google Scholar] [CrossRef]

- Chris Baker. Modelling of Extreme Wind Gusts. Available online: https://profchrisbaker.com/2020/09/05/modelling-of-extreme-wind-gusts/ (accessed on 22 September 2022).

- Barnes, M.; Cosenzo, K.; Mitchell, D.; Chen, J. Human robot teams as soldier augmentation in future battlefields: An overview. In Proceedings of the 11th International Conference, Sorrento, Italy, 19–21 September 2005. [Google Scholar]

- Bersani, M.; Mentasti, S.; Dahal, P.; Arrigoni, S.; Vignati, M.; Cheli, F.; Matteucci, M. An integrated algorithm for ego-vehicle and obstacles state estimation for autonomous driving. Robot. Auton. Syst. 2021, 139, 103662. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| m | 1681kg |

| 2600 kg s2 | |

| [871.6; 809.4] kg | |

| [1.3; 1.4] m | |

| [9.94; 10.6] | |

| [1.46; 1.46] | |

| [9643.4; 9019.0] N | |

| [9.8; 10.4] | |

| [1.29; 1.29] | |

| [8361.2; 7827.2] N | |

| (Relaxation length) | 0.3m |

| (Braking bias) | 0.6 |

| (Aerodynamic drag) | 0.3675 N/(m2/s2) |

| (Rolling resistance coeff) | 0.01 |

| R | Q | P |

|---|---|---|

| Region | No- Delay Mode | Smith Mode | SRPT Mode | No- Delay Mode | Smith Mode | SRPT Mode |

| A | 40% | 54% | 59% | 6% | 5% | 12% |

| B | 47% | 59% | 62% | 10% | 8% | 16% |

| C | 61% | 71% | 72% | 26% | 22% | 31% |

| D | 62% | 50% | 74% | 25% | 21% | 37% |

| E | 56% | 22% | 66% | 27% | 14% | 52% |

| F | 77% | 72% | 84% | 38% | 22% | 39% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakash, J.; Vignati, M.; Sabbioni, E.; Cheli, F. Vehicle Teleoperation: Human in the Loop Performance Comparison of Smith Predictor with Novel Successive Reference-Pose Tracking Approach. Sensors 2022, 22, 9119. https://doi.org/10.3390/s22239119

Prakash J, Vignati M, Sabbioni E, Cheli F. Vehicle Teleoperation: Human in the Loop Performance Comparison of Smith Predictor with Novel Successive Reference-Pose Tracking Approach. Sensors. 2022; 22(23):9119. https://doi.org/10.3390/s22239119

Chicago/Turabian StylePrakash, Jai, Michele Vignati, Edoardo Sabbioni, and Federico Cheli. 2022. "Vehicle Teleoperation: Human in the Loop Performance Comparison of Smith Predictor with Novel Successive Reference-Pose Tracking Approach" Sensors 22, no. 23: 9119. https://doi.org/10.3390/s22239119

APA StylePrakash, J., Vignati, M., Sabbioni, E., & Cheli, F. (2022). Vehicle Teleoperation: Human in the Loop Performance Comparison of Smith Predictor with Novel Successive Reference-Pose Tracking Approach. Sensors, 22(23), 9119. https://doi.org/10.3390/s22239119