Study of a Fiber Optic Fabry-Perot Strain Sensor for Fuel Assembly Strain Detection

Abstract

1. Introduction

2. Method

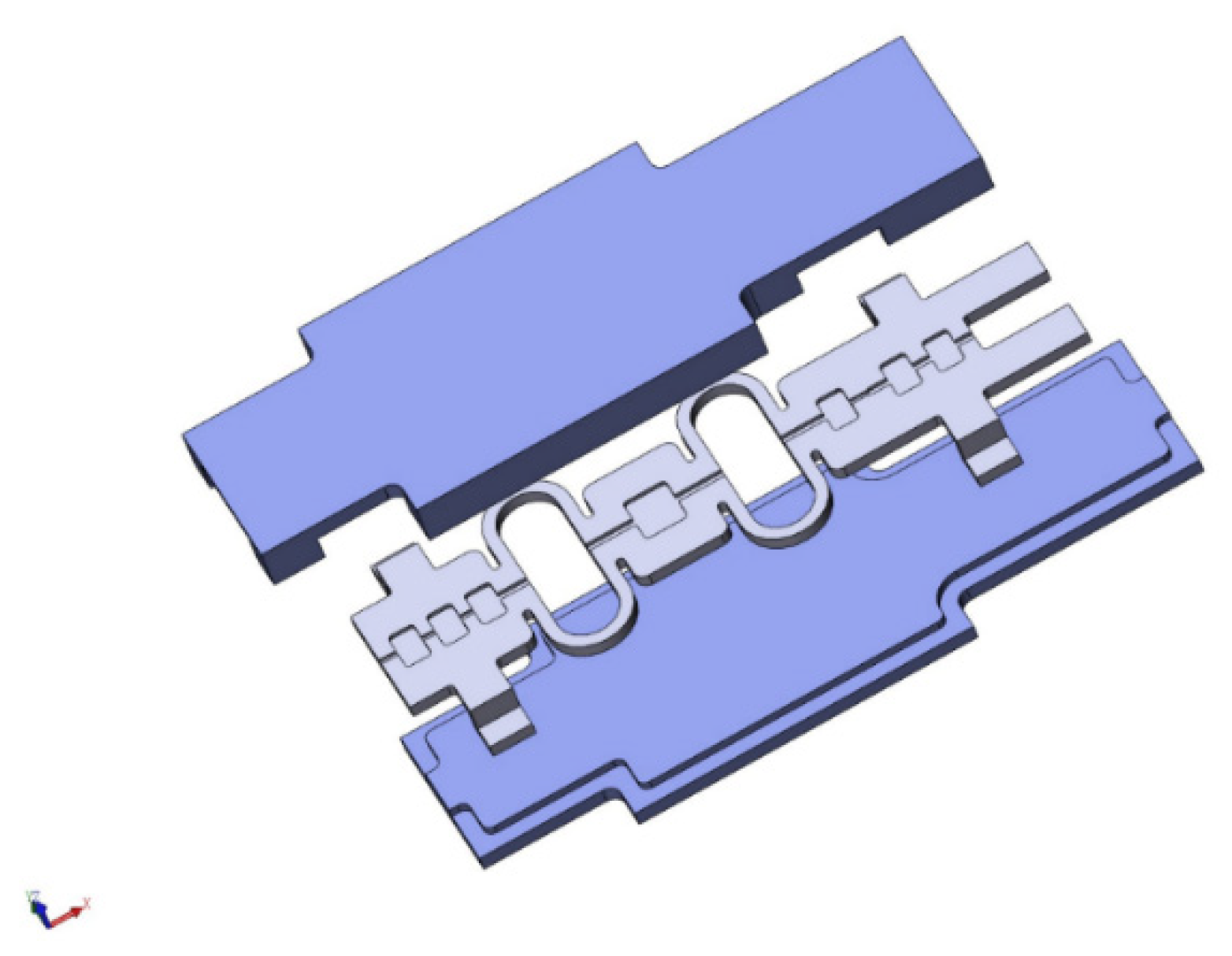

2.1. Sensing System Design

2.2. Strain Transfer Analysis

2.3. Thermal Effects

3. Experiments

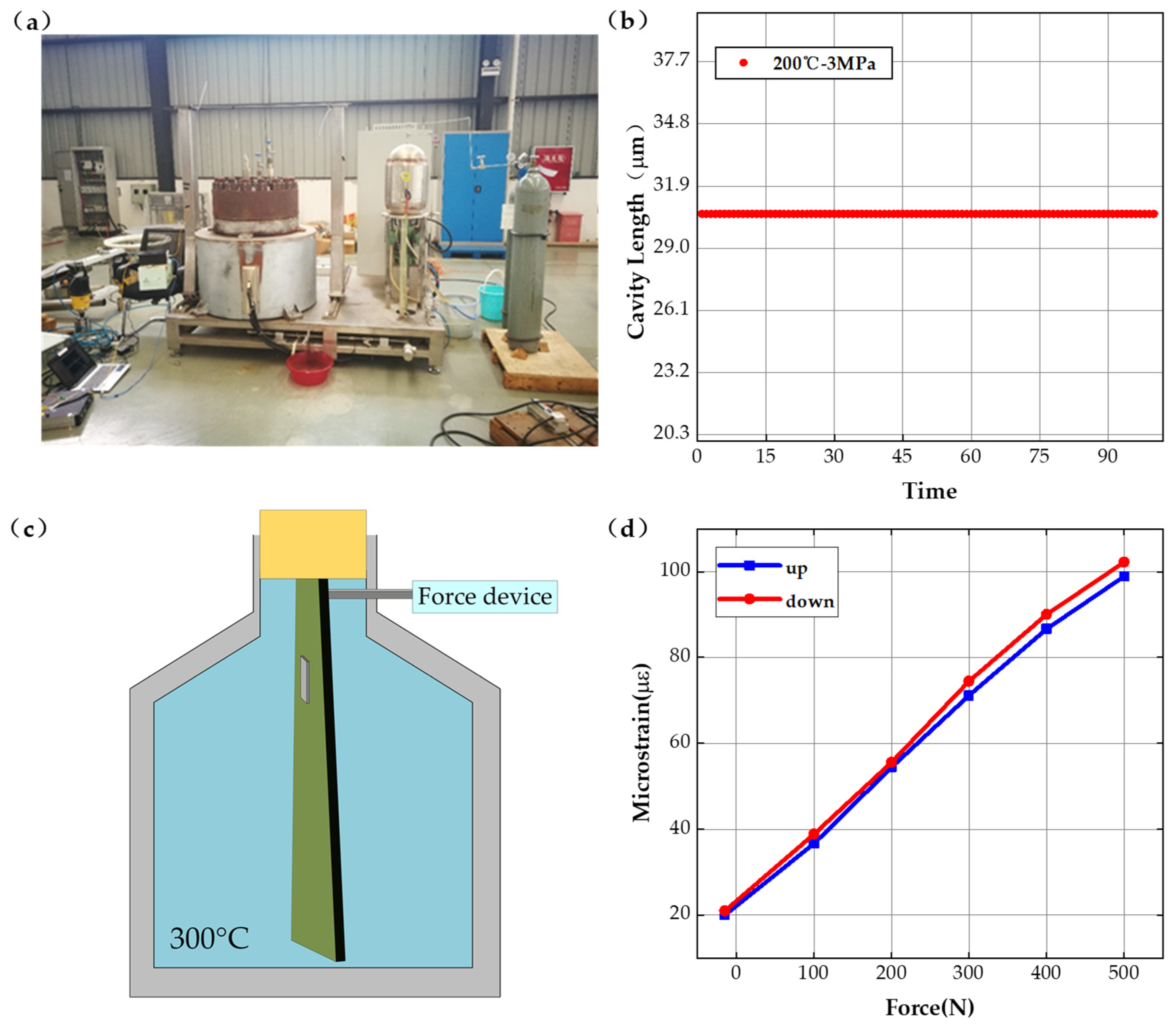

3.1. Static Testing

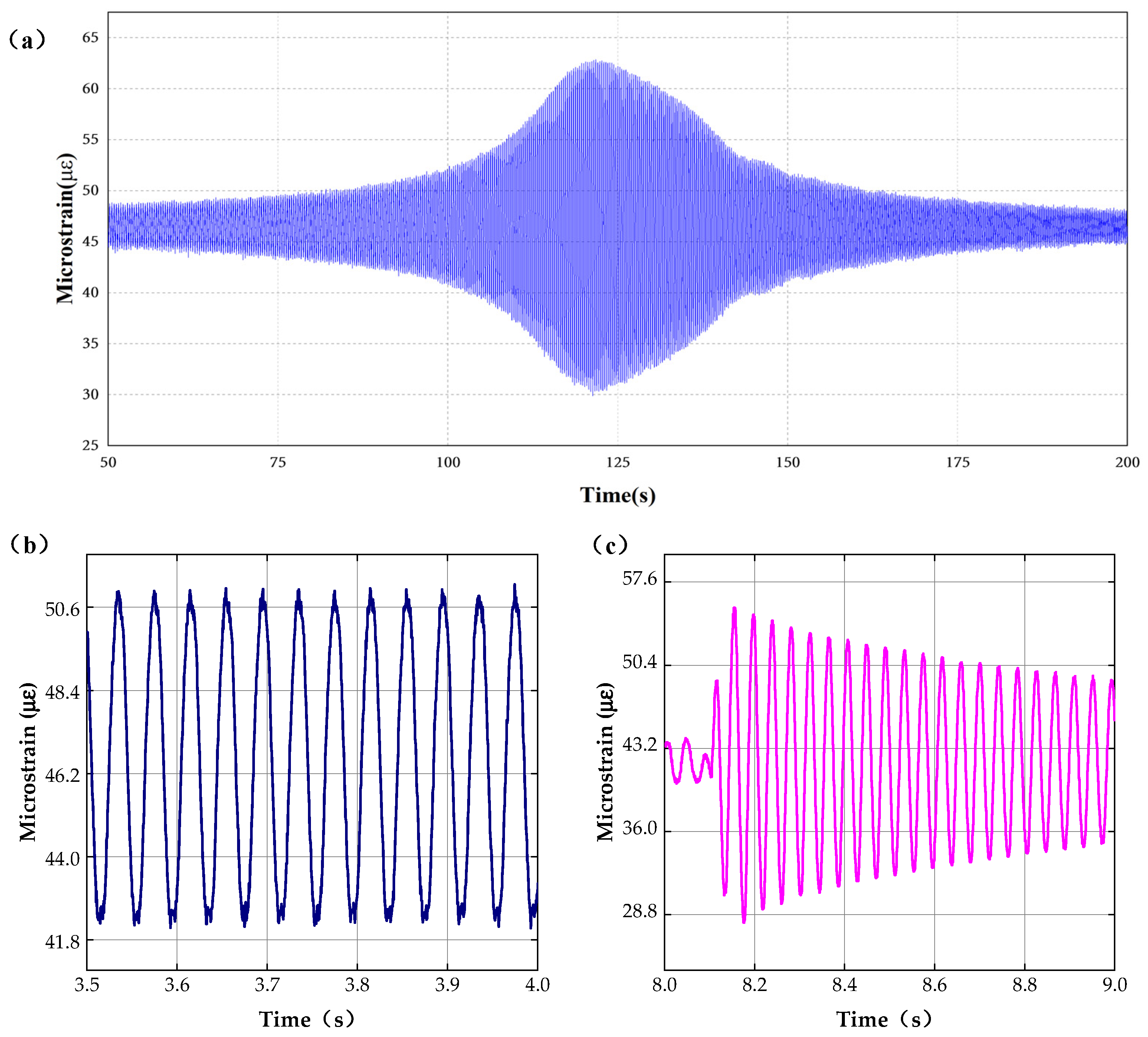

3.2. Dynamic Testing

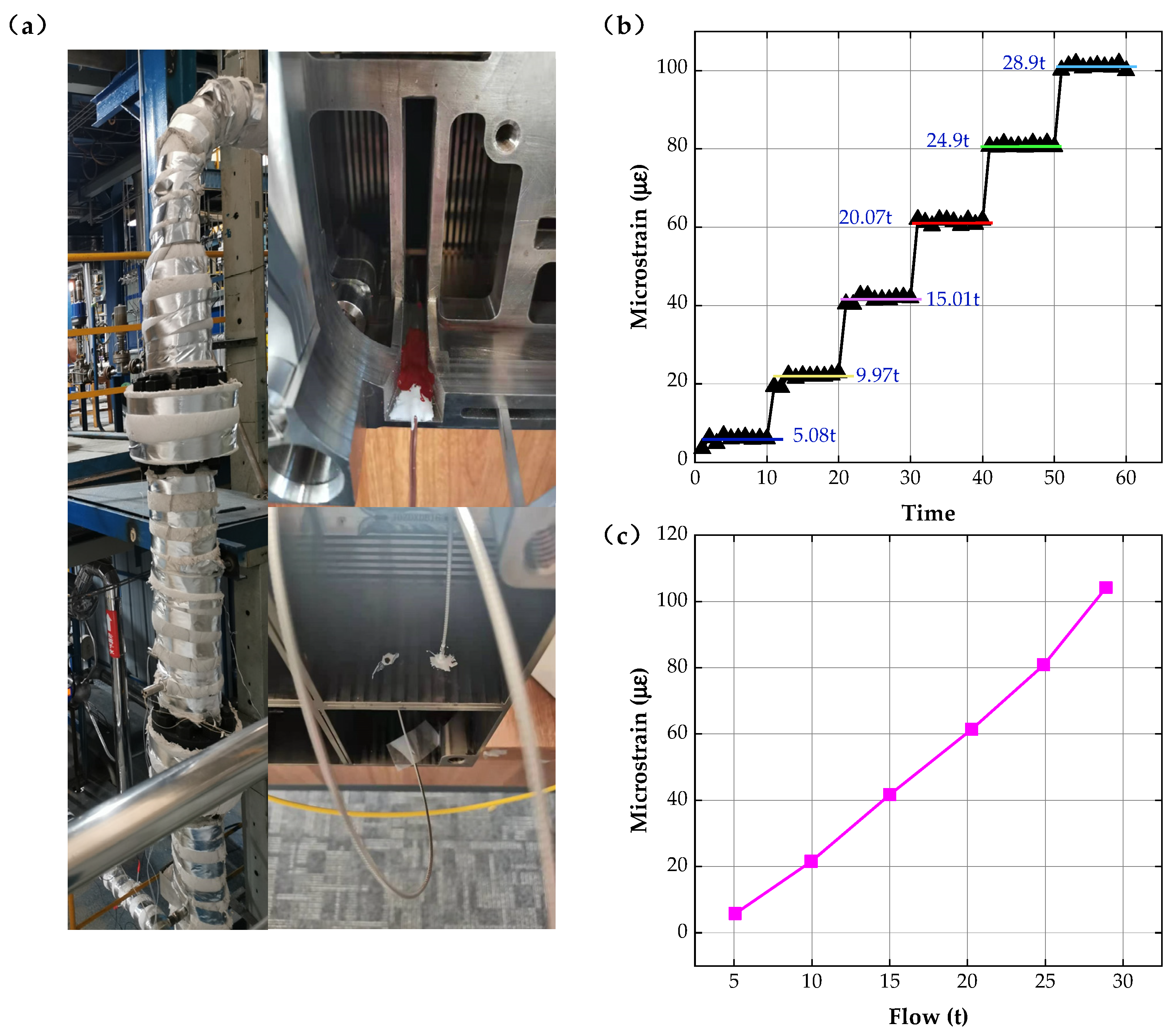

3.3. Thermal-Hydraulic Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Horvath, A.; Rachlew, E. Nuclear power in the 21st century: Challenges and possibilities. Ambio 2016, 45, 38–49. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.P. Developments of analyses on grid-to-rod fretting problems in pressurized water reactors. Prog. Nucl. Energy 2018, 106, 293–299. [Google Scholar] [CrossRef]

- Christon, M.A.; Lu, R.; Bakosi, J.; Nadiga, B.T.; Karoutas, Z.; Berndt, M. Large-eddy simulation, fuel rod vibration and grid-to-rod fretting in pressurized water reactors. J. Comput. Phys. 2016, 322, 142–161. [Google Scholar] [CrossRef]

- Da Silva, J.G.; de Carvalho, A.A.; da Silva, D.D. A Strain Gauge Tactile Sensor for Finger-Mounted Applications. IEEE Trans. Instrum. Meas. 2002, 51, 18–22. [Google Scholar] [CrossRef]

- Veerabagu, S.; Fujihara, K.; Dasari, G.R.; Ramakrishna, S. Strain distribution analysis of braided composite bone plates. Compos. Sci. Technol. 2003, 63, 427–435. [Google Scholar] [CrossRef]

- Park, J.; You, I.; Shin, S.; Jeong, U. Material Approaches to Stretchable Strain Sensors. ChemPhysChem 2015, 16, 1155–1163. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Chen, M.Q.; Peng, Y. Tapered Hollow-Core Fiber Air-Microbubble Fabry–Perot Interferometer for High Sensitivity Strain Measurement. Adv. Mater. Interfaces 2018, 5, 1800886. [Google Scholar] [CrossRef]

- Ma, Z.B.; Cheng, S.L.; Kou, W.Y.; Chen, H.B.; Wang, W.; Zhang, X.X.; Guo, T.X. Sensitivity-Enhanced Extrinsic Fabry–Perot Interferometric Fiber-Optic Microcavity Strain Sensor. Sensors 2019, 19, 4097. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Q.; Shen, C.Y.; Lou, W.M.; Shentu, C.Y. Intensity modulation type fiber-optic strain sensor based on a Mach–Zehnder interferometer constructed by an up-taper with a LPG. Opt. Commun. 2016, 364, 72–75. [Google Scholar] [CrossRef]

- Zhang, H.L.; Wu, Z.L.; Shum, P.P.; Wang, R.X.; Dinh, X.Q.; Fu, N.; Tong, W.J.; Tang, M. Fiber Bragg gratings in heterogeneous multicore fiber for directional bending sensing. J. Opt. 2016, 18, 085705. [Google Scholar] [CrossRef]

- Villatoro, J.; Van Newkirk, A.; Antonio-Lopez, E.; Zubia, J.; Schulzgen, A.; Amezcua-Correa, R. Ultrasensitive vector bending sensor based on multicore optical fiber. Opt. Lett. 2016, 41, 832–835. [Google Scholar] [CrossRef] [PubMed]

- Mihailov, S.J.; Grobnic, D.; Smelser, C.W. High-temperature multiparameter sensor based on sapphire fiber Bragg gratings. Opt. Lett. 2010, 35, 2810–2812. [Google Scholar] [CrossRef] [PubMed]

- Statkiewicz-Barabach, G.; Kowal, D.; Szczurowski, M.K.; Mergo, P.; Urbanczyk, W. Hydrostatic Pressure and Strain Sensitivity of Long Period Grating Fabricated in Polymer Microstructured Fiber. IEEE Photonics Technol. Lett. 2013, 25, 496–499. [Google Scholar] [CrossRef]

- Gao, X.K.; Ning, T.G.; Zhang, C.B.; Xu, J.; Zheng, J.J.; Lin, H.; Li, J.; Pei, L.; You, H.D. A dual-parameter fiber sensor based on few-mode fiber and fiber Bragg grating for strain and temperature sensing. Opt. Commun. 2020, 454, 124441. [Google Scholar] [CrossRef]

- Kaur, A.; Anandan, S.; Yuan, L.; Watkins, S.E.; Chandrashekhara, K.; Xiao, H.; Phan, N. Strain monitoring of bismaleimide composites using embedded microcavity sensor. Opt. Eng. 2016, 55, 037102. [Google Scholar] [CrossRef]

- Zhang, H.L.; Wu, Z.F.; Shum, P.P.; Dinh, X.Q.; Low, C.W.; Xu, Z.L.; Wang, R.X.; Dinh, X.Q.; Shao, X.G.; Fu, S.N.; et al. Highly sensitive strain sensor based on helical structure combined with Mach-Zehnder interferometer in multicore fiber. Sci. Rep. 2017, 7, 46633. [Google Scholar] [CrossRef] [PubMed]

- Xia, P.; Tan, Y.G.; Li, T.L.; Zhou, Z.D.; Lv, W.Q. A high-temperature resistant photonic crystal fiber sensor with single-side sliding Fabry-Perot cavity for super-large strain measurement. Sens. Actuator A Phys. 2021, 318, 112492. [Google Scholar] [CrossRef]

- Huang, P.J.; Wang, N.; Li, J.Y.; Zhang, J.; Xi, Z.D. Optical Fiber Demodulation System with High Performance for Assessing Fretting Damage of Steam Generator Tubes. Sensors 2018, 18, 201. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, J.; Chen, J.; Wang, N.; Zhang, J.; Zhu, Y. Study of a Fiber Optic Fabry-Perot Strain Sensor for Fuel Assembly Strain Detection. Sensors 2022, 22, 9097. https://doi.org/10.3390/s22239097

Jiao J, Chen J, Wang N, Zhang J, Zhu Y. Study of a Fiber Optic Fabry-Perot Strain Sensor for Fuel Assembly Strain Detection. Sensors. 2022; 22(23):9097. https://doi.org/10.3390/s22239097

Chicago/Turabian StyleJiao, Jianan, Jianjun Chen, Ning Wang, Jie Zhang, and Yong Zhu. 2022. "Study of a Fiber Optic Fabry-Perot Strain Sensor for Fuel Assembly Strain Detection" Sensors 22, no. 23: 9097. https://doi.org/10.3390/s22239097

APA StyleJiao, J., Chen, J., Wang, N., Zhang, J., & Zhu, Y. (2022). Study of a Fiber Optic Fabry-Perot Strain Sensor for Fuel Assembly Strain Detection. Sensors, 22(23), 9097. https://doi.org/10.3390/s22239097