Balancing of Motor Armature Based on LSTM-ZPF Signal Processing

Abstract

1. Introduction

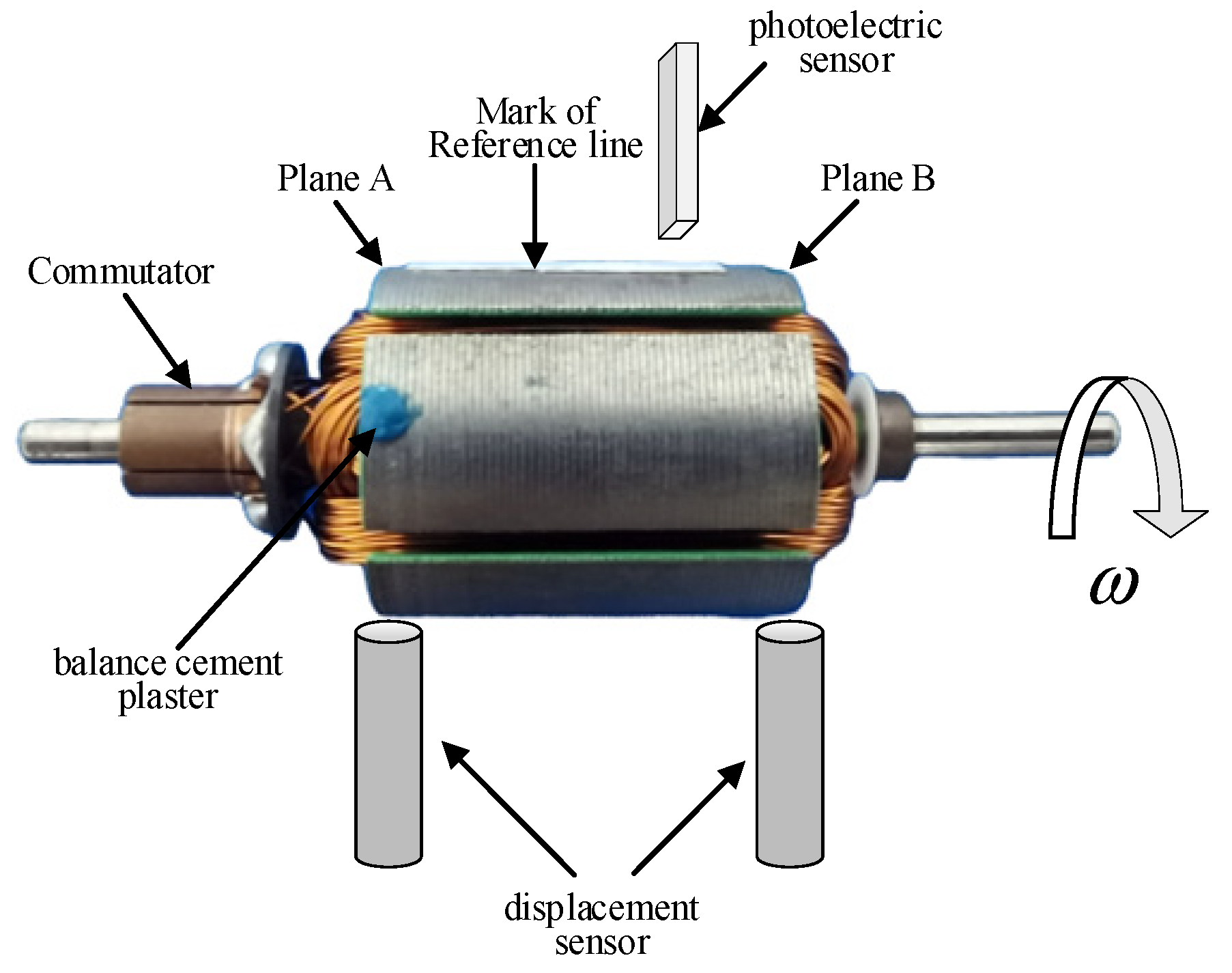

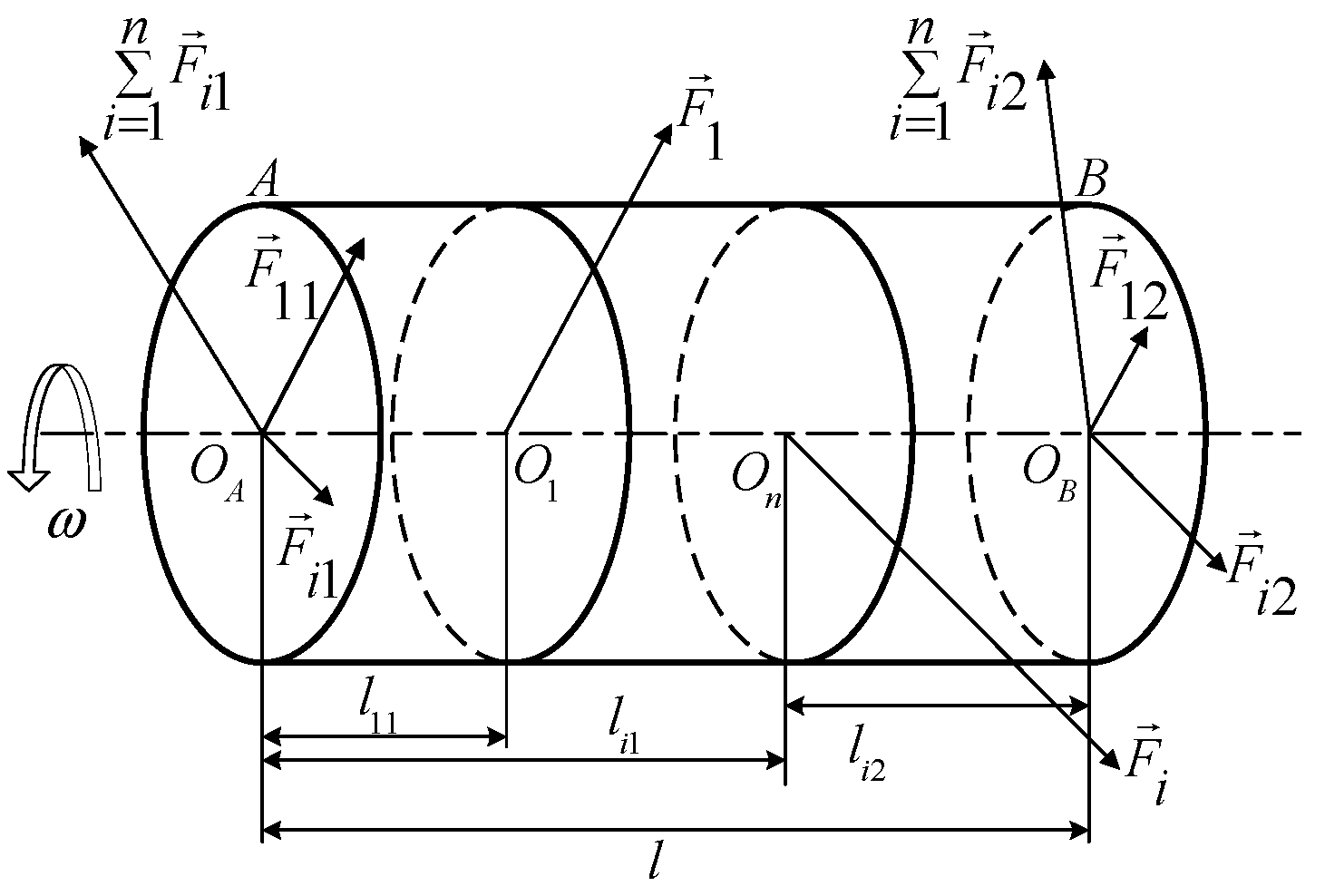

2. Problem Description

3. Basic Theory

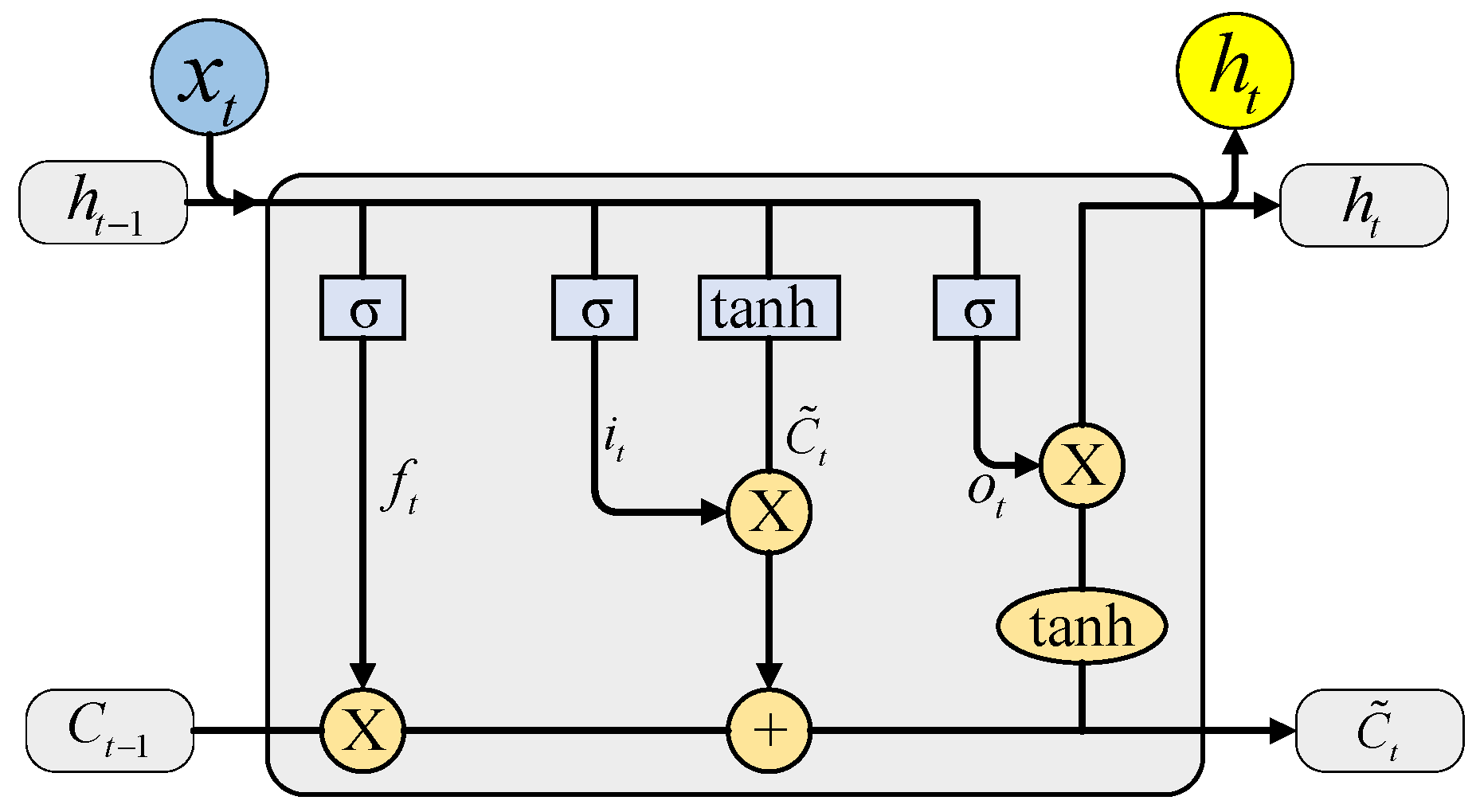

3.1. Long Short-Term Memory (LSTM)

3.2. Zero-Phase Filter (ZPF)

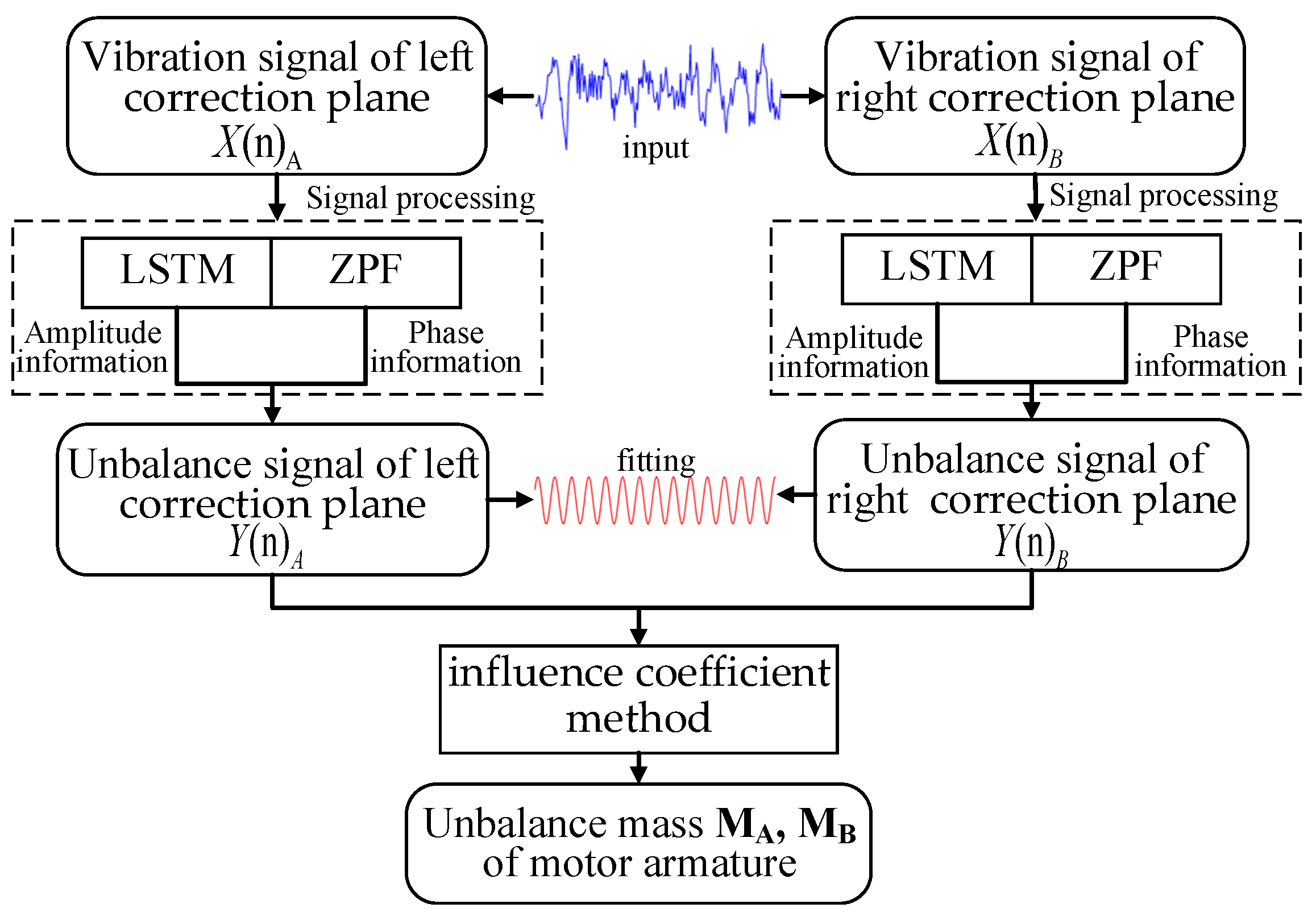

4. The Proposed Method

4.1. Principle

4.2. Evaluation Metrics

5. Case Studies

5.1. Simulated Signal

5.1.1. Data

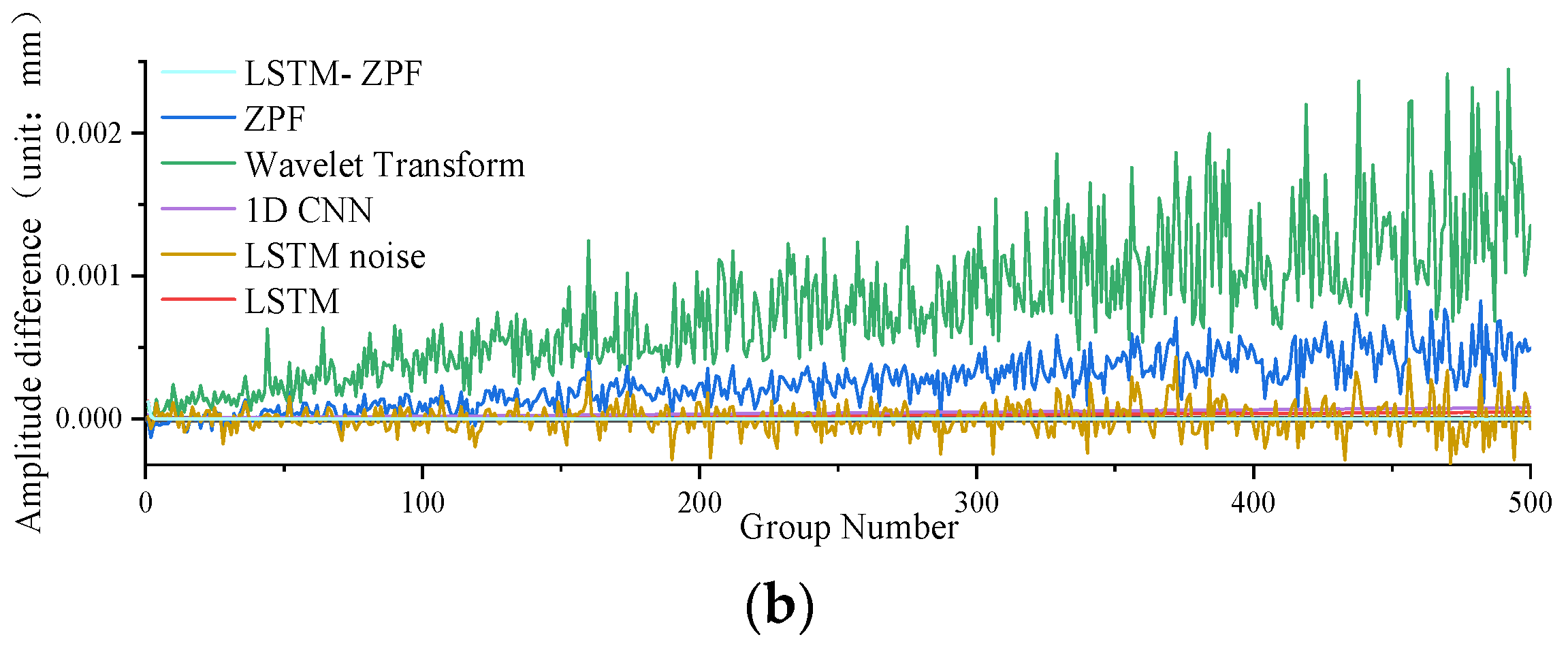

5.1.2. Simulation Verification

5.1.3. Anti-Noise Performance Analysis

- The amplitude fitting accuracy of the training set corresponding to the five SNRs is basically the same, and the accuracy is high;

- The phase fitting accuracy of the training set corresponding to the four SNRs is also basically the same. For a higher noise, there is lower phase accuracy, but the phase error is within an acceptable range, and all results exceeded those of the other filtering methods mentioned above;

- This method can effectively extract the motor armature unbalance signal at different SNRs, which makes the armature unbalanced mass calculation more accurate. It has good stability.

| SNR | Amplitude | Phase (°) | |||

|---|---|---|---|---|---|

| 40 | 0.9999 | 2.9288 × 10−5 | 1.8626 | 0.9821 | 0.2472 |

| 30 | 0.9999 | 2.7436 × 10−5 | 1.8604 | 0.9822 | 0.2466 |

| 20 | 0.9999 | 2.8445 × 10−5 | 1.8567 | 0.9817 | 0.2496 |

| 10 | 0.9999 | 2.1446 × 10−5 | 2.0650 | 0.9796 | 0.2636 |

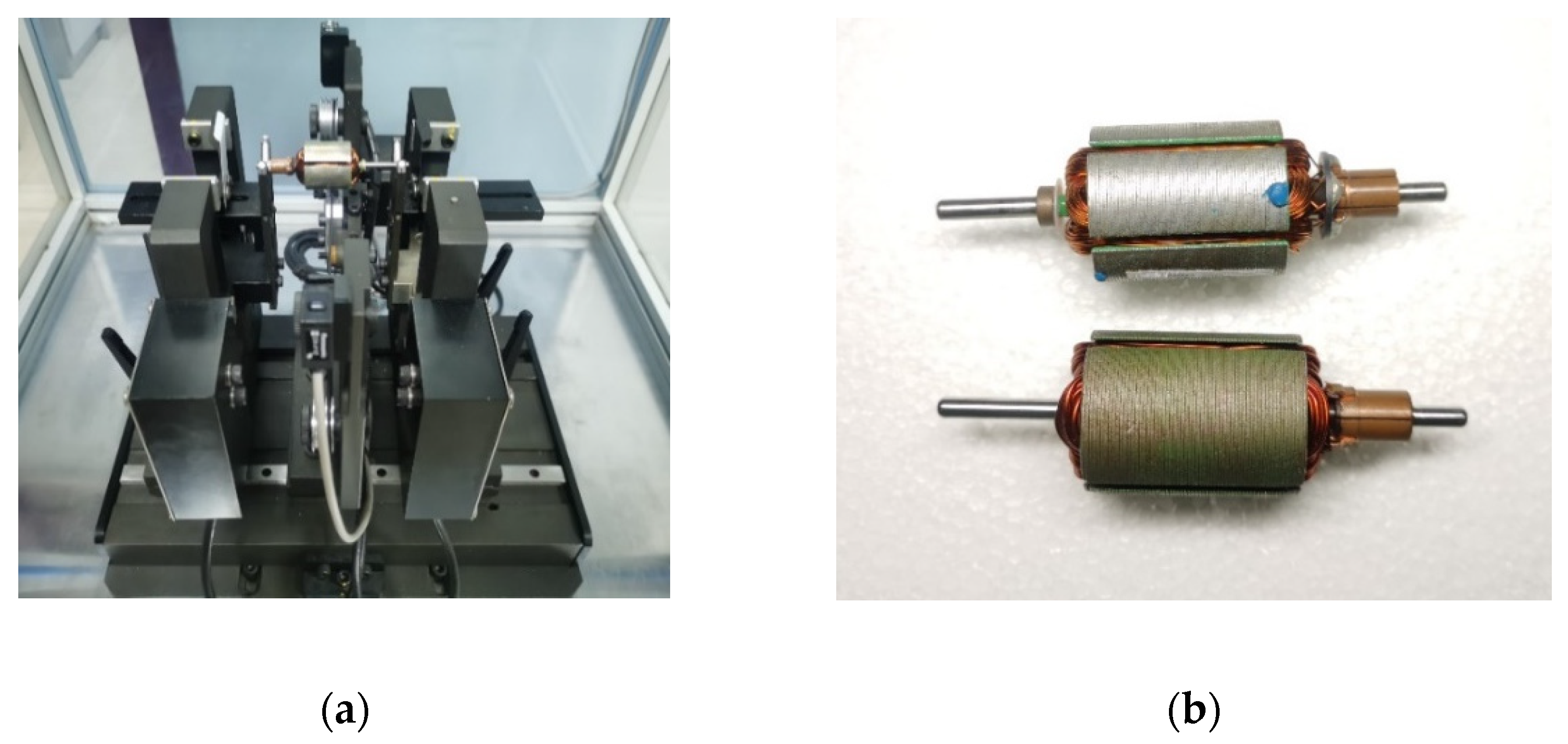

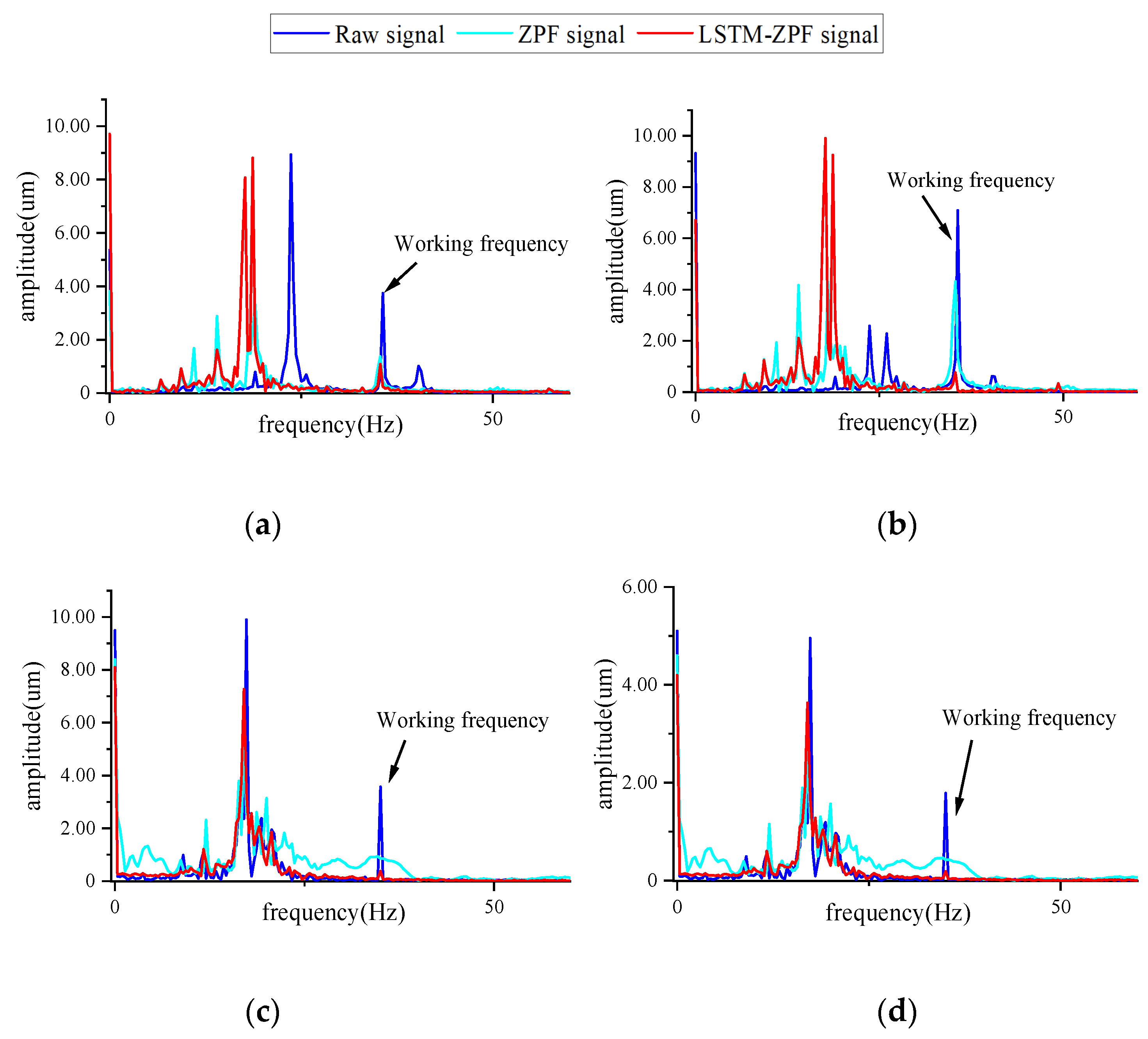

5.2. Experimental Verification

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibraheem, A.A.; Ghazaly, N.M.; Abd el-Jaber, G. Review of rotor balancing techniques. Am. J. Ind. Eng. 2019, 6, 19–25. [Google Scholar]

- Zhang, Y.; Wei, Q.; Zou, D.; Shao, M. Study on the Relationship between the Imbalance Status and Its Vibration Response in Balancing Method of Rotors. In Proceedings of the 23rd International Congress on Sound and Vibration (ICSV23), Athens, Greece, 10–14 July 2016; pp. 10–14. [Google Scholar]

- Tseng, C.-Y.; Shih, T.-W.; Lin, J.-T. Dynamic balancing scheme for motor armatures. J. Sound Vib. 2007, 304, 110–123. [Google Scholar] [CrossRef]

- Xu, X.; Fan, P.P. Rigid rotor dynamic balancing with the influence coefficient method. Sens. Transducers 2013, 157, 317. [Google Scholar]

- MacCamhaoil, M. Static and dynamic balancing of rigid rotors. Bruel & Kjaer Application Notes BO 0276-12. 2016. Available online: https://www.bksv.com/media/doc/bo0276.pdf (accessed on 15 September 2022).

- Singh, P.; Chaudhary, H. Optimum two-plane balancing of rigid rotor using discrete optimization algorithm. World J. Eng. 2019, 16, 138–146. [Google Scholar] [CrossRef]

- Mohamad, W.S.W.; Mat Isa, A.; Ismail, M. Analytical and Experimental Study on Balancing Using Influence Coefficient Method; Applied Mechanics and Materials; Trans Tech Publications: Baech, Switzerland, 2013; pp. 694–702. [Google Scholar]

- Kelm, R.; Kelm, W.; Pavelek, D. Rotor Balancing Tutorial. In Proceedings of the 45th Turbomachinery Symposium, Houston, TX, USA, 12–15 September 2016; Turbomachinery Laboratories, Texas A&M Engineering Experiment Station: College Station, TX, USA, 2016. [Google Scholar]

- Yan, X.; Jia, M. Intelligent fault diagnosis of rotating machinery using improved multiscale dispersion entropy and mRMR feature selection. Knowl. Based Syst. 2019, 163, 450–471. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, L.; Xuan, Y.; Xu, Y.; Liu, G. Shedding frequency and motion of jujube fruits in various excitation modes. Trans. ASABE 2020, 63, 881–889. [Google Scholar] [CrossRef]

- Li, L.; Cao, S.; Li, J.; Nie, R.; Hou, L. Review of rotor balancing methods. Machines 2021, 9, 89. [Google Scholar] [CrossRef]

- Tiboni, M.; Remino, C.; Bussola, R.; Amici, C. A Review on Vibration-Based Condition Monitoring of Rotating Machinery. Appl. Sci. 2022, 12, 972. [Google Scholar] [CrossRef]

- Iglesias-Martínez, M.E.; Antonino-Daviu, J.A.; Fernández de Córdoba, P.; Conejero, J.A. Rotor fault detection in induction motors based on time-frequency analysis using the bispectrum and the autocovariance of stray flux signals. Energies 2019, 12, 597. [Google Scholar] [CrossRef]

- Liu, Y.; Ming, S.; Zhao, S.; Han, J.; Ma, Y. Research on automatic balance control of active magnetic bearing-rigid rotor system. Shock Vib. 2019, 2019, 3094215. [Google Scholar] [CrossRef]

- Sadooghi, M.S.; Khadem, S.E. A new performance evaluation scheme for jet engine vibration signal denoising. Mech. Syst. Signal Process. 2016, 76, 201–212. [Google Scholar] [CrossRef]

- Cao, H.; He, D.; Xi, S.; Chen, X. Vibration signal correction of unbalanced rotor due to angular speed fluctuation. Mech. Syst. Signal Process. 2018, 107, 202–220. [Google Scholar] [CrossRef]

- Ye, R.; Wang, L.; Hou, X.; Luo, Z.; Han, Q. Balancing method without trial weights for rotor systems based on similitude scale model. Front. Mech. Eng. 2018, 13, 571–580. [Google Scholar] [CrossRef]

- Gustafsson, F. Determining the initial states in forward-backward filtering. IEEE Trans. Signal Process. 1996, 44, 988–992. [Google Scholar] [CrossRef]

- Wu, C.; Liu, J.; Peng, F.; Yu, D.; Li, R. Gearbox fault diagnosis using adaptive zero phase time-varying filter based on multi-scale chirplet sparse signal decomposition. Chin. J. Mech. Eng. 2013, 26, 831–838. [Google Scholar] [CrossRef]

- Wang, J.; Ye, Y.; Pan, X.; Gao, X. Parallel-type fractional zero-phase filtering for ECG signal denoising. Biomed. Signal Process. Control 2015, 18, 36–41. [Google Scholar] [CrossRef]

- Wang, J.; Ye, Y.; Xiang, P.; Gao, X.; Chao, Z. Fractional zero-phase filtering based on the Riemann–Liouville integral. Signal Process. 2014, 98, 150–157. [Google Scholar] [CrossRef]

- Wu, Y.; Ding, G. Research on Signal Processing of Shock Absorber Test Bench Based on Zero-Phase Filter. In Proceedings of the AOPC 2017: 3D Measurement Technology for Intelligent Manufacturing, Beijing, China, 4–6 June 2017; pp. 233–241. [Google Scholar]

- Anwar, S.; Barnes, N. Real Image Denoising with Feature Attention. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Seoul, Republic of Korea, 27–28 October 2019; pp. 3155–3164. [Google Scholar]

- Chang, M.; Li, Q.; Feng, H.; Xu, Z. Spatial-Adaptive Network for Single Image Denoising. In Proceedings of the European Conference on Computer Vision, Glasgow, UK, 23–28 August 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 171–187. [Google Scholar]

- Wang, Z.; Liu, J.; Li, G.; Han, H. Blind2Unblind: Self-Supervised Image Denoising with Visible Blind Spots. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, New Orleans, LA, USA, 19–24 June 2022; pp. 2027–2036. [Google Scholar]

- Greff, K.; Srivastava, R.K.; Koutník, J.; Steunebrink, B.R.; Schmidhuber, J. LSTM: A Search Space Odyssey. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 2222–2232. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Z.; Kong, D.; Han, H.; Zhao, Y. EA-LSTM: Evolutionary attention-based LSTM for time series prediction. Knowl. -Based Syst. 2019, 181, 104785. [Google Scholar] [CrossRef]

- Graves, A.; Schmidhuber, J. Framewise phoneme classification with bidirectional LSTM and other neural network architectures. Neural Netw. 2005, 18, 602–610. [Google Scholar] [CrossRef]

- Yao, K.; Cohn, T.; Vylomova, K.; Duh, K.; Dyer, C. Depth-gated LSTM. arXiv 2015, arXiv:1508.03790. [Google Scholar]

- Vos, K.; Peng, Z.; Jenkins, C.; Shahriar, M.R.; Borghesani, P.; Wang, W. Vibration-based anomaly detection using LSTM/SVM approaches. Mech. Syst. Signal Process. 2022, 169, 108752. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, P.; Yang, X.; Hu, A.; Su, H. Fault detection of wind turbine based on SCADA data analysis using CNN and LSTM with attention mechanism. Measurement 2021, 175, 109094. [Google Scholar] [CrossRef]

- Shen, Y.; Tan, S.; Sordoni, A.; Courville, A. Ordered neurons: Integrating tree structures into recurrent neural networks. arXiv Preprint 2018, arXiv:1810.09536. [Google Scholar]

- Andrews, H.C.; Billingsley, F.; Fiasconaro, J.; Frieden, B.; Read, R.; Shanks, J.; Treitel, S. Picture Processing and Digital Filtering; Springer Science & Business Media: Berlin, Germany, 2013; Volume 6. [Google Scholar]

- Yu, W.; Liu, Z.; Zhuang, Z.; Liu, Y.; Wang, X.; Yang, Y.; Gou, B. Super-Resolution Reconstruction of Speckle Images of Engineered Bamboo Based on an Attention-Dense Residual Network. Sensors 2022, 22, 6693. [Google Scholar] [CrossRef]

- Amari, S.I. Backpropagation and stochastic gradient descent method. Neurocomputing 1993, 5, 185–196. [Google Scholar] [CrossRef]

- Duchi, J.; Hazan, E.; Singer, Y. Adaptive Subgradient Methods for Online Learning and Stochastic Optimization. J. Mach. Learn. Res. 2011, 12, 257–269. [Google Scholar]

- Yeung, S.; Russakovsky, O.; Jin, N.; Andriluka, M.; Mori, G.; Fei-Fei, L. Every Moment Counts: Dense Detailed Labeling of Actions in Complex Videos. Int. J. Comput. Vis. 2018, 126, 375–389. [Google Scholar] [CrossRef]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Prabhu, K.M. Window Functions and Their Applications in Signal Processing; Taylor & Francis: Abingdon, UK, 2014. [Google Scholar]

- Rakshit, H.; Ullah, M.A. A Comparative Study on Window Functions for Designing Efficient FIR Filter. In Proceedings of the 2014 9th IEEE International Forum on Strategic Technology (IFOST), Cox’s Bazar, Bangladesh, 21–23 October 2014; pp. 91–96. [Google Scholar]

- Strutz, T. Data Fitting and Uncertainty: A Practical Introduction to Weighted Least Squares and Beyond; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Wu, H.; Chen, J.; Liu, X.; Xiao, Y.; Wang, M.; Zheng, Y.; Rao, Y. One-dimensional CNN-based intelligent recognition of vibrations in pipeline monitoring with DAS. J. Lightwave Technol. 2019, 37, 4359–4366. [Google Scholar] [CrossRef]

- Shao, X.; Chen, P.; Zhang, Y.; Chang, S.K. Domain Fusion CNN-LSTM for Short-Term Power Consumption Forecasting. IEEE Access 2020, 8, 188352–188362. [Google Scholar] [CrossRef]

- Du, C.; Zhang, X.; Zhong, R.; Li, F.; Yu, F.; Rong, Y.; Gong, Y. Unmanned aerial vehicle rotor fault diagnosis based on interval sampling reconstruction of vibration signals and a one-dimensional convolutional neural network deep learning method. Meas. Sci. Technol. 2022, 33, 065003. [Google Scholar] [CrossRef]

| Methods | Amplitude | Phase (°) | |||

|---|---|---|---|---|---|

| LSTM | 0.9999 | 2.9280 × 10−5 | 88.0613 | 0.0611 | 1.7884 |

| ZPF | 0.9836 | 3.1447 × 10−4 | 12.1589 | 0.7821 | 0.9868 |

| Wavelet Transform | 0.8613 | 9.1371 × 10−4 | 12.4614 | 0.7308 | 0.9577 |

| 1D CNN | 0.995 | 5.3350 × 10−5 | 88.4542 | 0.0552 | 1.7941 |

| LSTM-noise | 0.9982 | 1.0440 × 10−4 | 3.0401 | 0.9583 | 0.3767 |

| LSTM-ZPF | 0.9999 | 5.6705 × 10−6 | 2.4069 | 0.9756 | 0.2885 |

| No. | Methods | Left Unbalanced Mass (mg) | Left Phase (°) | Right Unbalanced Mass (mg) | Right Phase (°) |

|---|---|---|---|---|---|

| 1 | LSTM-ZPF | 72.4 | 3.0 | 77.5 | 146.0 |

| Hardware filtering (ZPF) | 76.2 | 6.3 | 75.3 | 139.2 | |

| 2 | LSTM-ZPF | 64.7 | 243.8 | 27.4 | 224.5 |

| Hardware filtering (ZPF) | 70.5 | 210.1 | 30.6 | 212.6 |

| Methods | Left Amplitude (μm) | Right Amplitude (μm) | ||

|---|---|---|---|---|

| No. | 1 | 2 | 1 | 2 |

| LSTM-ZPF | 1.13 | 0.75 | 0.89 | 0.66 |

| Hardware filtering (ZPF) | 1.34 | 1.09 | 4.71 | 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, R.; Li, M.; Sun, A.; Lu, Z.; Jiang, D.; Chen, W. Balancing of Motor Armature Based on LSTM-ZPF Signal Processing. Sensors 2022, 22, 9043. https://doi.org/10.3390/s22239043

Dong R, Li M, Sun A, Lu Z, Jiang D, Chen W. Balancing of Motor Armature Based on LSTM-ZPF Signal Processing. Sensors. 2022; 22(23):9043. https://doi.org/10.3390/s22239043

Chicago/Turabian StyleDong, Ruiwen, Mengxuan Li, Ao Sun, Zhenrong Lu, Dong Jiang, and Weiyu Chen. 2022. "Balancing of Motor Armature Based on LSTM-ZPF Signal Processing" Sensors 22, no. 23: 9043. https://doi.org/10.3390/s22239043

APA StyleDong, R., Li, M., Sun, A., Lu, Z., Jiang, D., & Chen, W. (2022). Balancing of Motor Armature Based on LSTM-ZPF Signal Processing. Sensors, 22(23), 9043. https://doi.org/10.3390/s22239043