Compound Fault Feature Extraction of Rolling Bearing Acoustic Signals Based on AVMD-IMVO-MCKD

Abstract

:1. Introduction

- (1)

- A new method based on AVMD-MVO-MCKD is proposed to extract the features of composite faults accurately.

- (2)

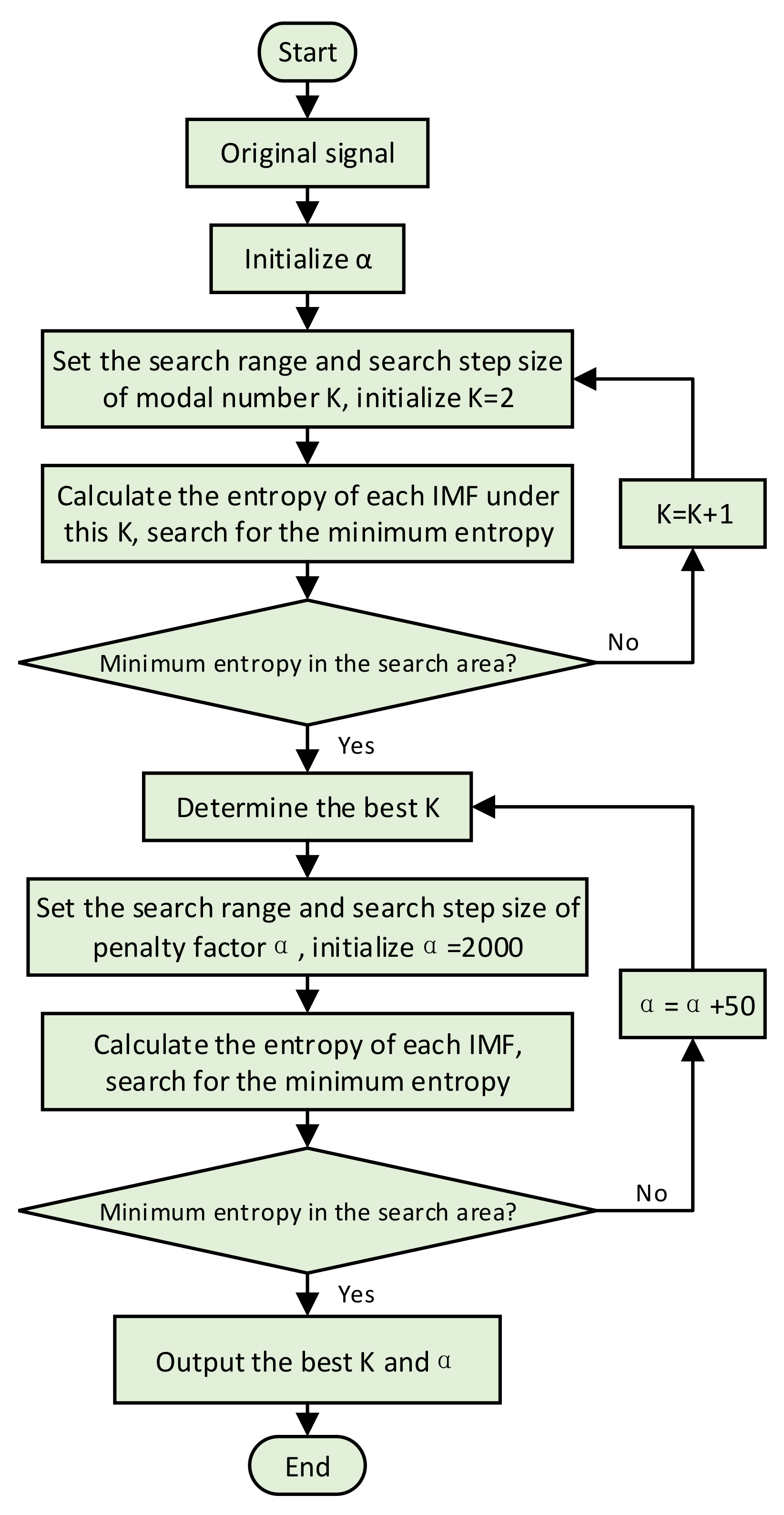

- Adaptive variational mode decomposition is proposed. Compared with the traditional signal decomposition method, the proposed method not only overcomes the shortcoming of selecting parameters based on empirical knowledge but also solves the mode aliasing problem. Compared with the existing optimization algorithms, the computational complexity is reduced.

- (3)

- The IMVO algorithm is proposed to optimize the MCKD parameters. The computational efficiency of the IMVO algorithm is improved, and the important parameters of MCKD are determined adaptively.

- (4)

- The proposed method has been successfully applied to the field of compound fault acoustic signals, which has certain reference value for further research of acoustic signal diagnosis methods.

2. Proposed Method

2.1. VMD Theory

2.2. Determination of the Penalty Factor and Modal Number of VMD

2.3. Improved Multiverse Optimization (IMVO)

2.4. MCKD Theory

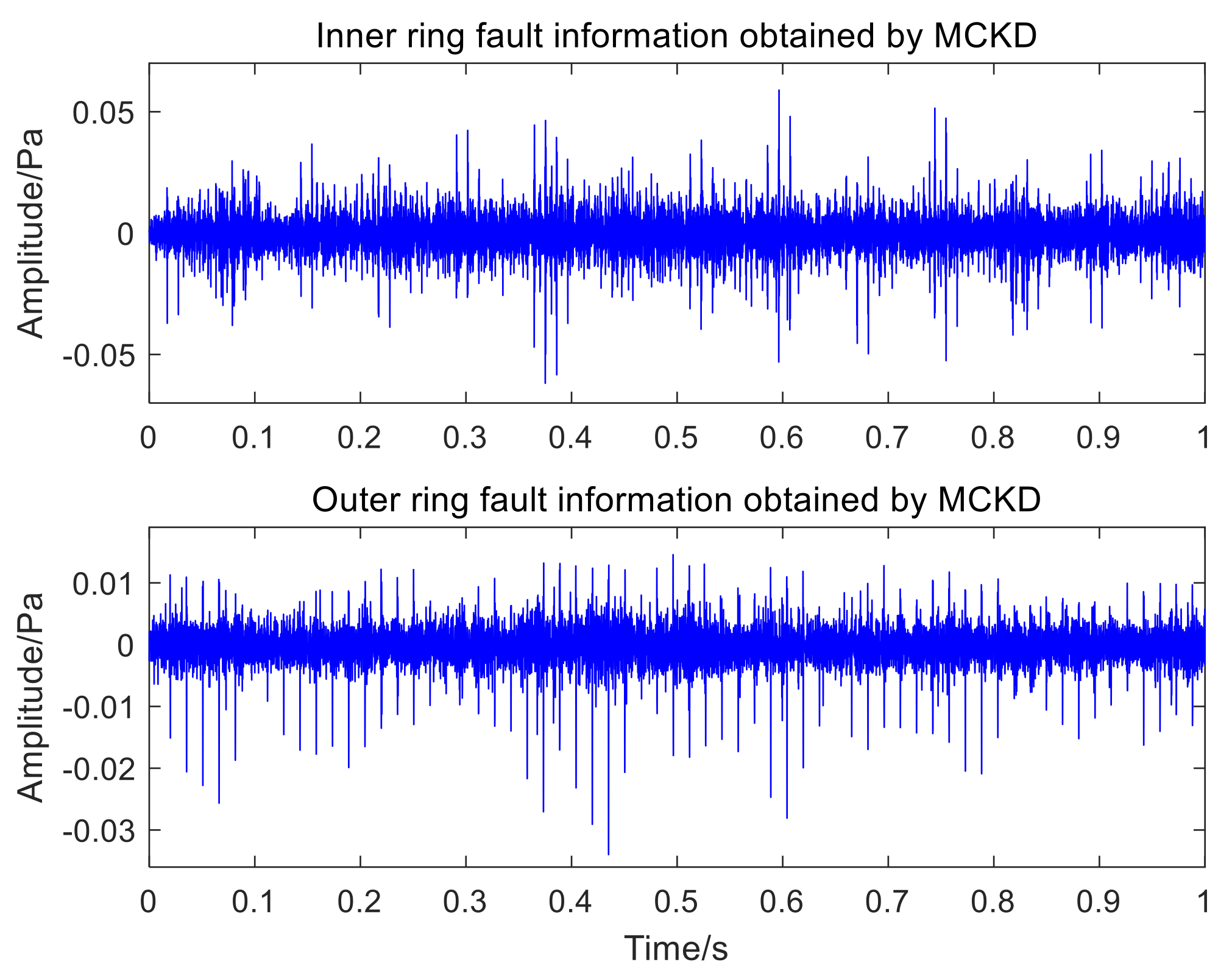

2.5. IMVO-Optimized MCKD Parameters

- (1)

- In the process of parameter setting, the maximum number of iterations of IMVO is 50, and the number of universes is 30; the optimization range of filter length L of MCKD is set to [100, 300], and the order of shift M is set to [1, 7]. According to the formula , the inner ring convolution period and the outer-ring deconvolution period are calculated. This initializes the location of the universe randomly based on the parameter setting range.

- (2)

- The inflation rates of the universe are taken and ranked, then a white hole is selected under the roulette wheel mechanism.

- (3)

- The and are updated according to Equations (5) and (6), and then boundary checking is performed.

- (4)

- We then perform a calculation operation on the current inflation rate of the universe. While the cosmic inflation rate is better than the current cosmic expansion rate, the current cosmic expansion rate is updated; otherwise, we keep the current cosmic expansion rate.

- (5)

- The universe position update is executed, and the optimal individual is found according to Formula (7).

- (6)

- When judging the termination condition, if the termination condition is satisfied, the iteration will be terminated, and the result will be output. If not, the iteration will be continued by returning to step (2).

3. Simulation Analysis

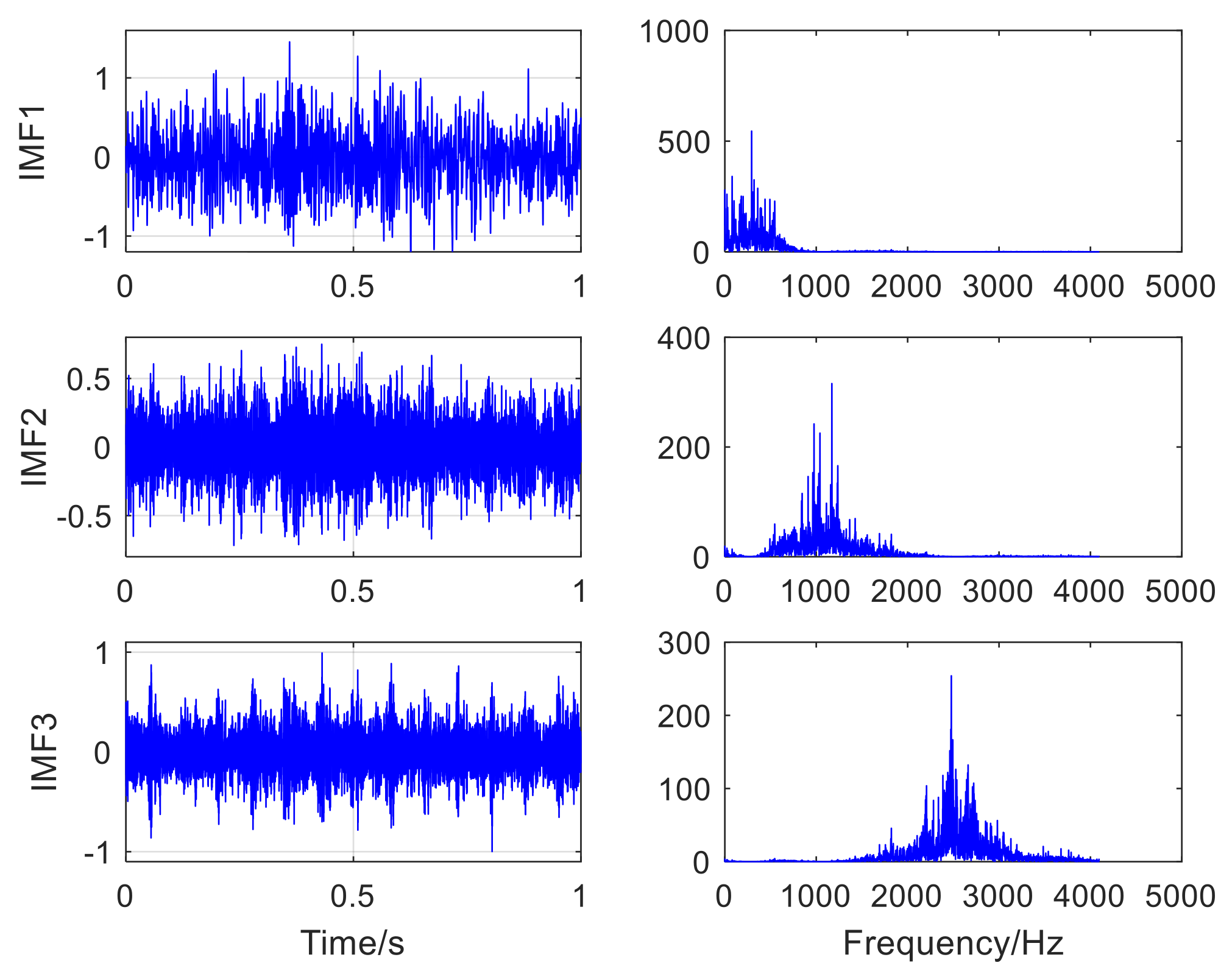

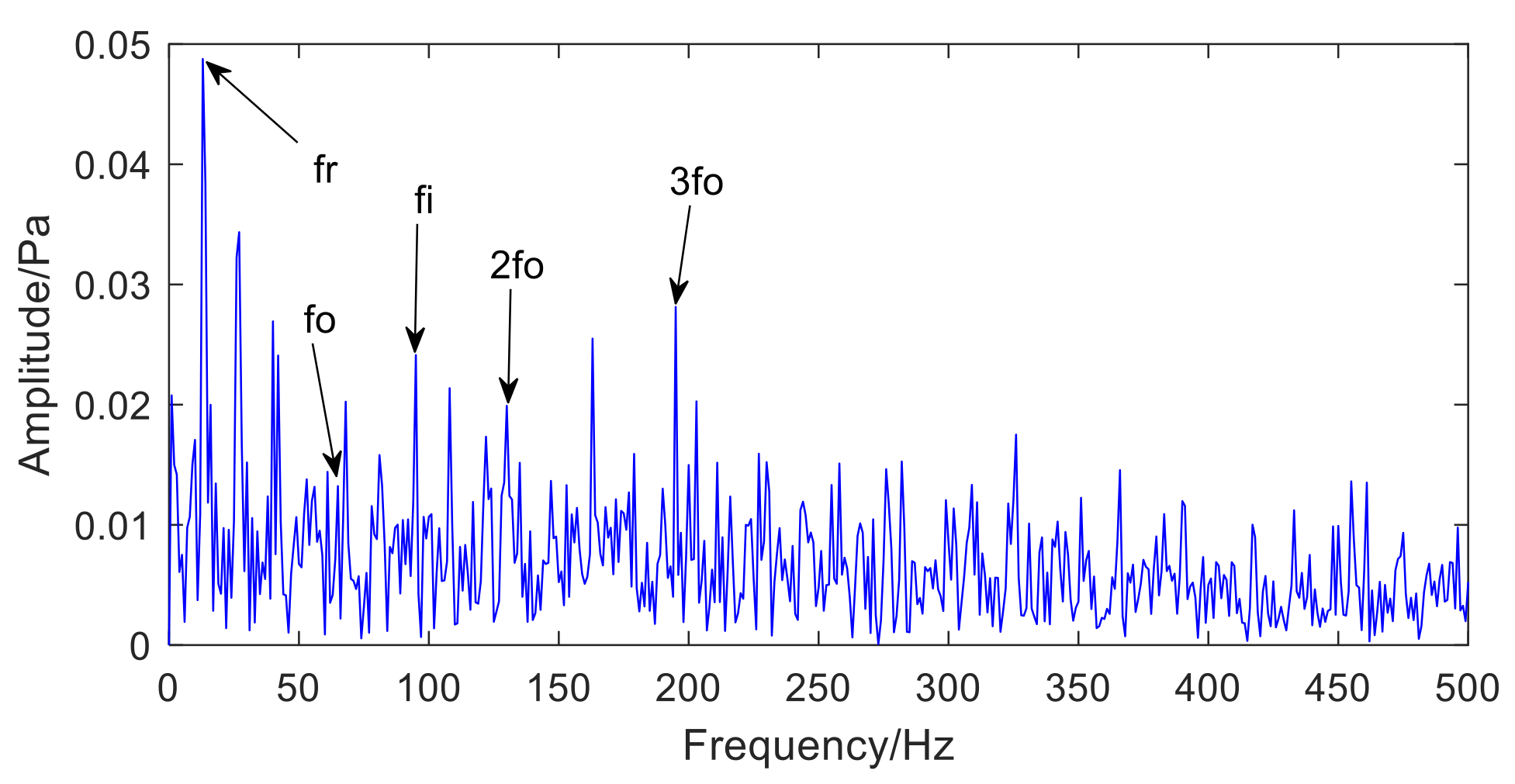

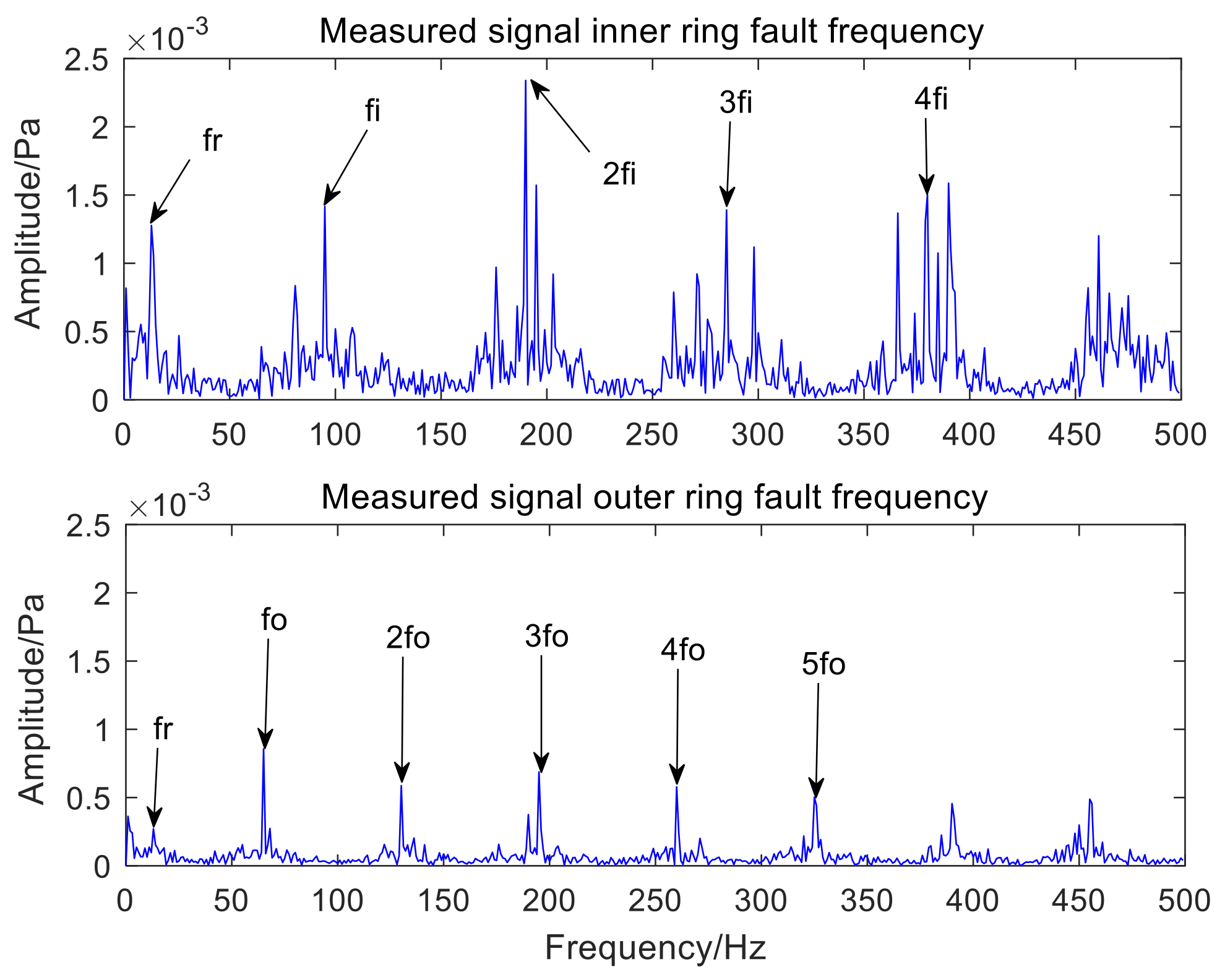

4. Experimental Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qin, Y.; Jin, L.; Zhang, A.B.; He, B. Rolling bearing fault diagnosis with adaptive harmonic kurtosis and improved bat algorithm. IEEE Trans. Instrum. Meas. 2020, 70, 1–12. [Google Scholar] [CrossRef]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Gao, S.Z.; Shi, S.; Zhang, Y.M. Rolling Bearing Compound Fault Diagnosis Based on Parameter Optimization MCKD and Convolutional Neural Network. IEEE Trans. Instrum. Meas. 2022, 71, 1–8. [Google Scholar] [CrossRef]

- Huang, H.; Xue, W.; Pang, Q.Z. Separation method of rolling bearing compound fault characteristics based on Improved harmonic wavelet packet decomposition and fast ICA. J. Mech. Sci. Technol. 2022, 36, 3263–3276. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Wang, Y.; Wei, Y.; Li, Z. A novel strategy using optimized MOMED and B-spline based envelope-derivative operator for compound fault detection of the rolling bearing. Struct. Health Monit. 2022, 14759217211062826. [Google Scholar] [CrossRef]

- Chen, Z.; Cen, J.; Xiong, J. Rolling bearing fault diagnosis using time-frequency analysis and deep transfer convolutional neural network. IEEE Access 2020, 8, 150248–150261. [Google Scholar] [CrossRef]

- Yuan, R.; Lv, Y.; Li, H.; Song, G. Robust fault diagnosis of rolling bearings using multivariate intrinsic multiscale entropy analysis and neural network under varying operating conditions. IEEE Access 2019, 7, 130804–130819. [Google Scholar] [CrossRef]

- Hu, Z.Y. Acoustic diagnosis method for engine failure. Mater. Sci. Eng. 2019, 677, 032058. [Google Scholar] [CrossRef]

- Tandon, N.; Choudhury, A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

- Gunerkar, R.S.; Jalan, A.K. Classification of Ball Bearing Faults Using Vibro-Acoustic Sensor Data Fusion. Exp. Tech. 2019, 43, 635–643. [Google Scholar] [CrossRef]

- Al-Ghamd, A.M.; Mba, D. A comparative experimental study on the use of acoustic emission and vibration analysis for bearing defect identification and estimation of defect size. Mech. Syst. Signal Processing 2006, 20, 1537–1571. [Google Scholar] [CrossRef]

- Van Hecke, B.; Yoon, J.; He, D. Low speed bearing fault diagnosis using acoustic emission sensors. Appl. Acoust. 2016, 105, 35–44. [Google Scholar] [CrossRef]

- Yao, J.; Liu, C.; Song, K.; Feng, C.; Jiang, D. Fault diagnosis of planetary gearbox based on acoustic signals. Appl. Acoust. 2021, 181, 108151. [Google Scholar] [CrossRef]

- Liu, H.M.; Li, L.; Ma, J. Rolling Bearing Fault Diagnosis Based on STFT-Deep Learning and Sound Signals. Shock Vib. 2016, 2016, 6127479. [Google Scholar] [CrossRef]

- Zhang, D.C.; Stewart, E.; Entezami, M.; Roberts, C.; Yu, D. Intelligent acoustic-based fault diagnosis of roller bearings using a deep graph convolutional network. Measurement 2020, 156, 107585. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, J.M. Bearing Fault Diagnosis Using Grad-CAM and Acoustic Emission Signals. Appl. Sci. 2020, 10, 2050. [Google Scholar] [CrossRef]

- Liu, F.; Wu, R.; Teng, F.; Liu, Y.; Lu, S.; Ju, B.; Cao, Z. A Two-Stage Learning Model for Track-Side Acoustic Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- Glowacz, A. Acoustic based fault diagnosis of three-phase induction motor. Appl. Acoust. 2018, 137, 82–89. [Google Scholar] [CrossRef]

- Ntalampiras, S. One-shot learning for acoustic diagnosis of industrial machines. Expert Syst. Appl. 2021, 178, 114984. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, X.; Zhong, X.; Zhou, H. Fault Diagnosis of Axle Box Bearing with Acoustic Signal Based on Chirplet Transform and Support Vector Machine. Shock Vib. 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, Y.; Zhang, Z.; Wu, J. Acoustic Fault Diagnosis of Rotor Bearing System. Shock Vib. 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- Verma, N.K.; Sevakula, R.K.; Dixit, S.; Salour, A. Intelligent Condition Based Monitoring Using Acoustic Signals for Air Compressors. IEEE Trans. Reliab. 2015, 65, 291–309. [Google Scholar] [CrossRef]

- Tang, G.; Luo, G.; Zhang, W.; Yang, C.; Wang, H. Underdetermined blind source separation with variational mode decomposition for compound roller bearing fault signals. Sensors 2016, 16, 897. [Google Scholar] [CrossRef]

- Ji, S.; Han, B.; Zhang, Z.; Wang, J.; Lu, B.; Yang, J.; Jiang, X. Parallel sparse filtering for intelligent fault diagnosis using acoustic signal processing. Neurocomputing 2021, 462, 466–477. [Google Scholar] [CrossRef]

- Qin, C.R.; Wang, D.; Xu, Z.; Tang, C. Improved empirical wavelet transform for compound weak bearing fault diagnosis with acoustic signals. Appl. Sci. 2020, 10, 682. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Y.; Peng, Z.; Wang, S.; Zhang, W.; Chen, X. Detection of rub-impact fault for rotor-stator systems: A novel method based on adaptive chirp mode decomposition. J. Sound Vib. 2019, 440, 83–99. [Google Scholar] [CrossRef]

- Jena, D.P.; Panigrahi, S.N. Automatic gear and bearing fault localization using vibration and acoustic signals. Appl. Acoust. 2015, 98, 20–33. [Google Scholar] [CrossRef]

- Amarnath, M.; Krishna, I.R.P. Empirical mode decomposition of acoustic signals for diagnosis of faults in gears and rolling element bearings. Meas. Technol. 2012, 6, 279–287. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, M.; Yu, Q.; Zhang, H. Comparing the applications of EMD and EEMD on time–frequency analysis of seismic signal. J. Appl. Geophys. 2012, 83, 29–34. [Google Scholar] [CrossRef]

- Yeh, J.R.; Huang, N.E.; Shieh, J.S. Complementary ensemble empirical mode decomposition: A novel noise enhanced data analysis method. Adv. Adapt. Data Anal. 2010, 2, 135–156. [Google Scholar] [CrossRef]

- Colominas, M.A.; Schlotthauer, G.; Torres, M.E. Improved complete ensemble EMD: A suitable tool for biomedical signal processing. Biomed. Signal Processing Control 2014, 14, 19–29. [Google Scholar] [CrossRef]

- Yang, Z.X.; Zhong, J.H. A hybrid EEMD-based sampEn and SVD for acoustic signal processing and fault diagnosis. Entropy 2016, 18, 112. [Google Scholar] [CrossRef]

- Lei, Y.G.; Liu, Z.; Quazri, J.; Lin, J. A fault diagnosis method of rolling element bearings based on CEEMDAN. J. Mech. Eng. Sci. 2017, 231, 1804–1815. [Google Scholar] [CrossRef]

- Zheng, J.; Cheng, J.; Yang, Y. Partly ensemble empirical mode decomposition: An improved noise-assisted method for eliminating mode mixing. Signal Processing 2014, 96, 362–374. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Processing 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Wang, X.B.; Yang, Z.X.; Yan, X.A. Novel Particle Swarm Optimization-Based Variational Mode Decomposition Method for the Fault Diagnosis of Complex Rotating Machinery. IEEE Trans. Mechatron. 2017, 23, 68–79. [Google Scholar] [CrossRef]

- Li, H.; Wu, X.; Liu, T.; Chen, Q. Bearing fault feature extraction based on VMD optimized with information entropy. J. Vib. Shock 2018, 37, 7. (In Chinese) [Google Scholar] [CrossRef]

- Yin, J.F.; Chen, X.Q.; Li, S.L. Singnal denoising based on optimized VMD and NLM. Comput. Eng. Des. 2021, 42, 1135–1142. (In Chinese) [Google Scholar] [CrossRef]

- Han, D.; Su, X.; Shi, P. Weak fault signal detection of rotating machinery based on multistable stochastic resonance and VMD-AMD. Shock Vib. 2018, 4, 1–15. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Zhong, M.; Zhong, J.; Zheng, J.; Yao, L. Detection for incipient damages of wind turbine rolling bearing based on VMD-AMCKD method. IEEE Access 2019, 7, 67944–67959. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Hatamlou, A. Multi-Verse Optimizer: A nature-inspired algorithm for global optimization. Neural Comput. Appl. 2016, 27, 495–513. [Google Scholar] [CrossRef]

- Liu, J.X. Improvement and application of Multi-Verse Optimizer. Ph.D. Thesis, Guangxi University for Nationalities, Nanning, China, 2019. (In Chinese). [Google Scholar]

- McDonald, G.L.; Zhao, Q.; Zuo, M.J. Maximum correlated Kurtosis deconvolution and application on gear tooth chip fault detection. Mech. Syst. Signal Processing 2012, 33, 237–255. [Google Scholar] [CrossRef]

- Liu, T.; Chen, J.; Dong, G.; Xiao, W.; Zhou, X. The fault detection and diagnosis in rolling element bearings using frequency band entropy. J. Mech. Eng. Sci. 2013, 227, 87–99. [Google Scholar] [CrossRef]

- Wan, S.T.; Zhang, X.; Dou, L.J. Separation of composite rolling bearings fault features with strong noise interference. J. Cent. South Univ. 2018, 49, 1905–1959. [Google Scholar]

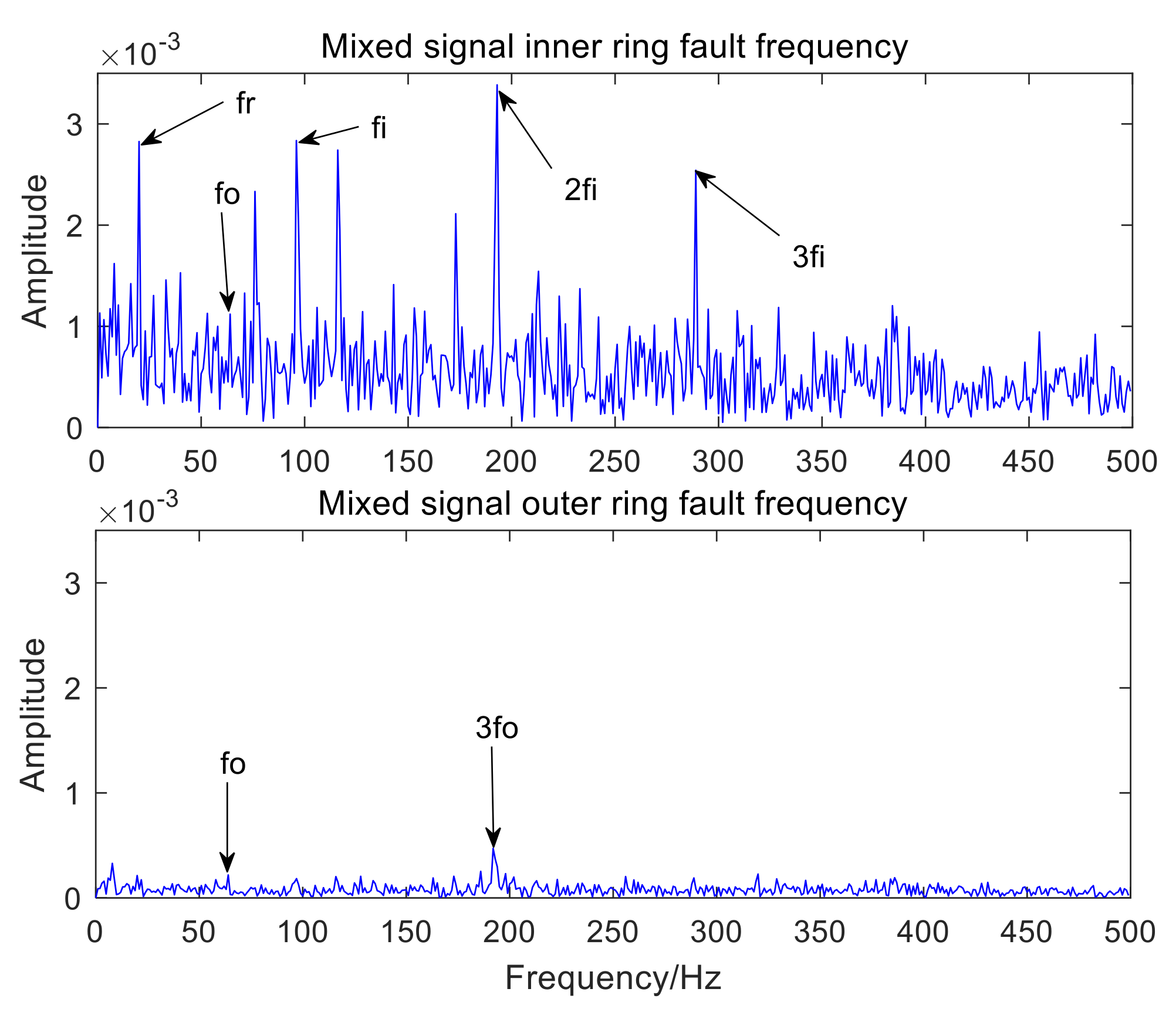

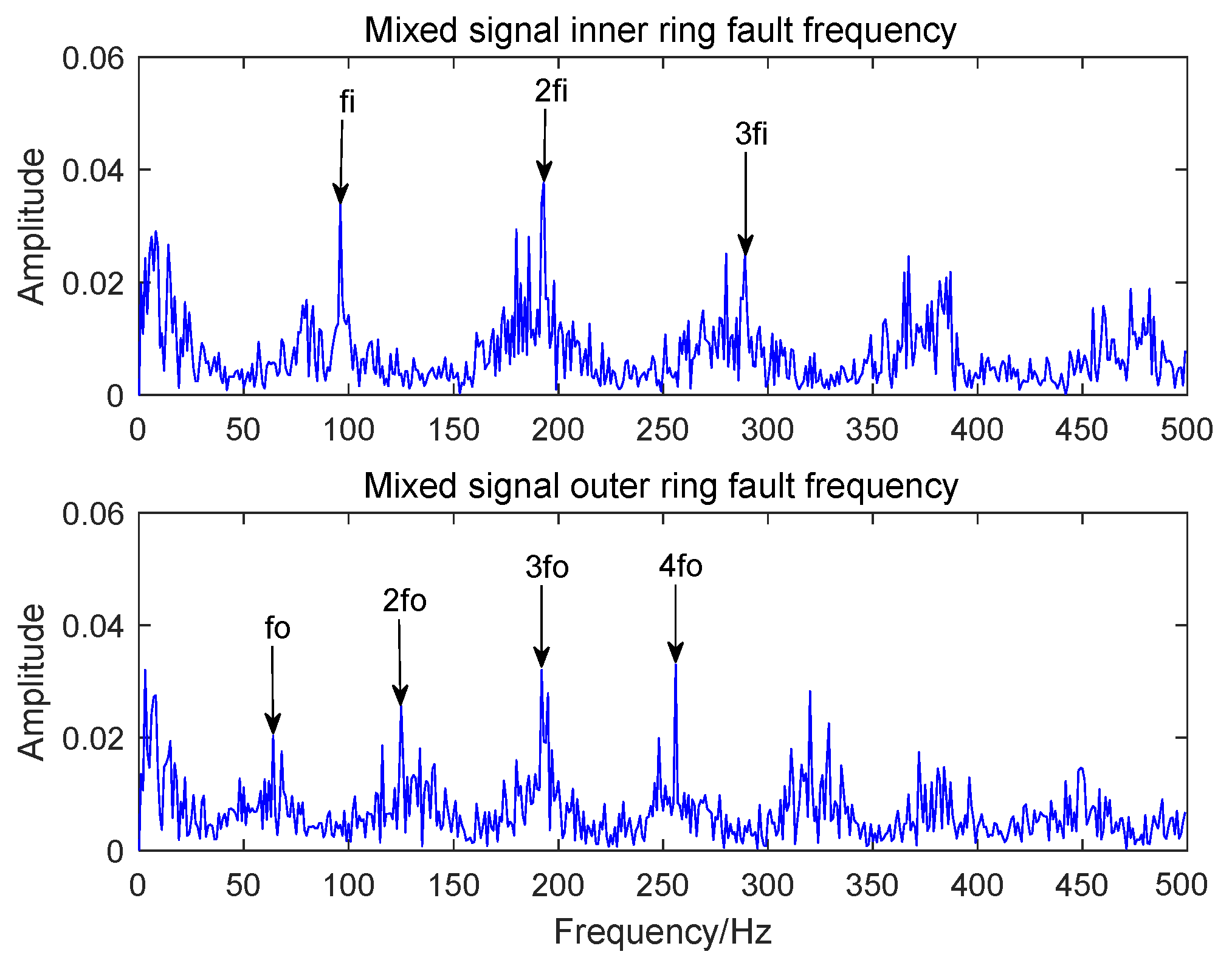

| Parameters | Values |

|---|---|

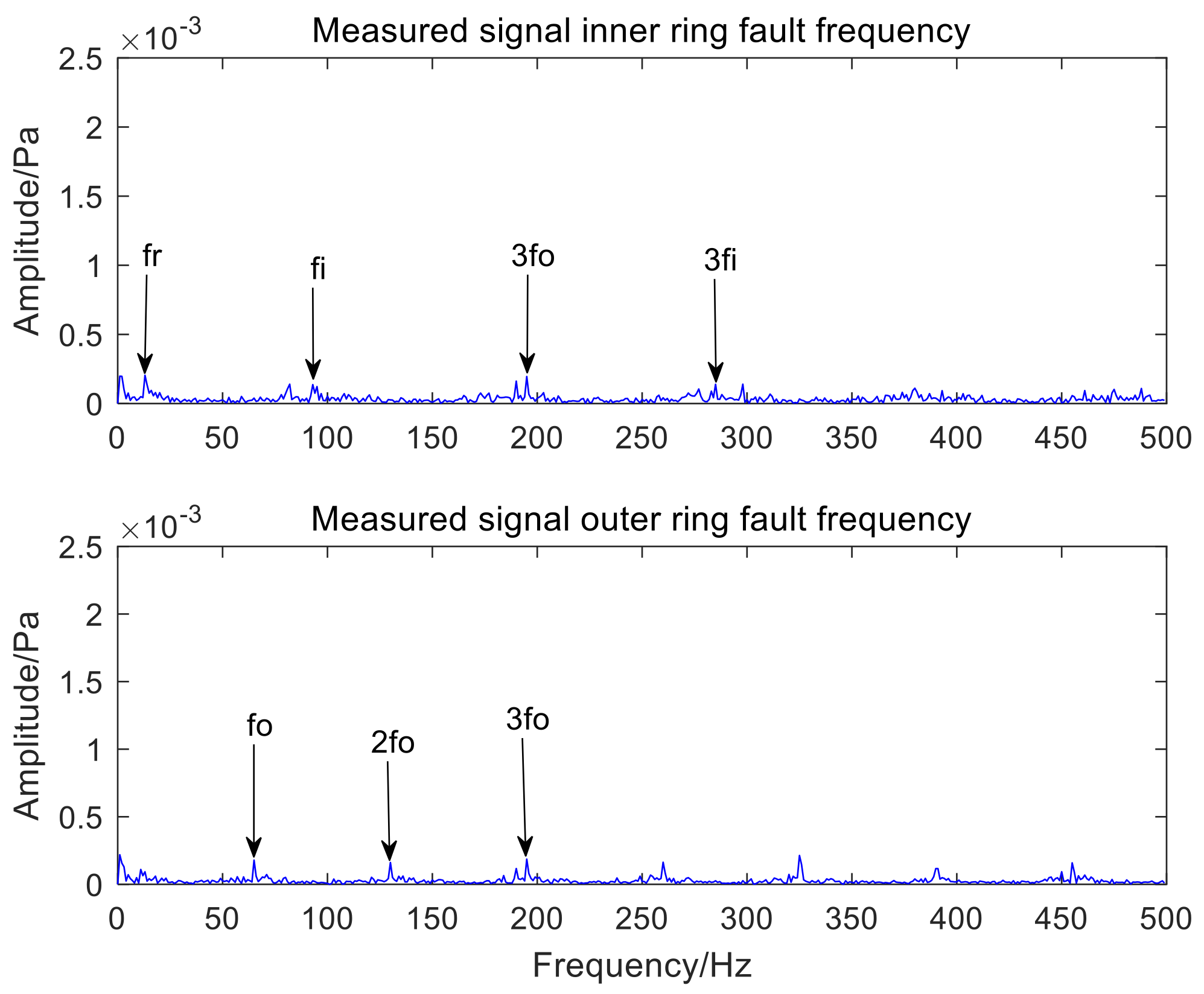

| Rotational frequency /Hz | 20 |

| Inner ring amplitude | 3 |

| Outer ring amplitude | 4 |

| Inner ring fault frequency/Hz | 95 |

| Outer ring fault frequency/Hz | 64 |

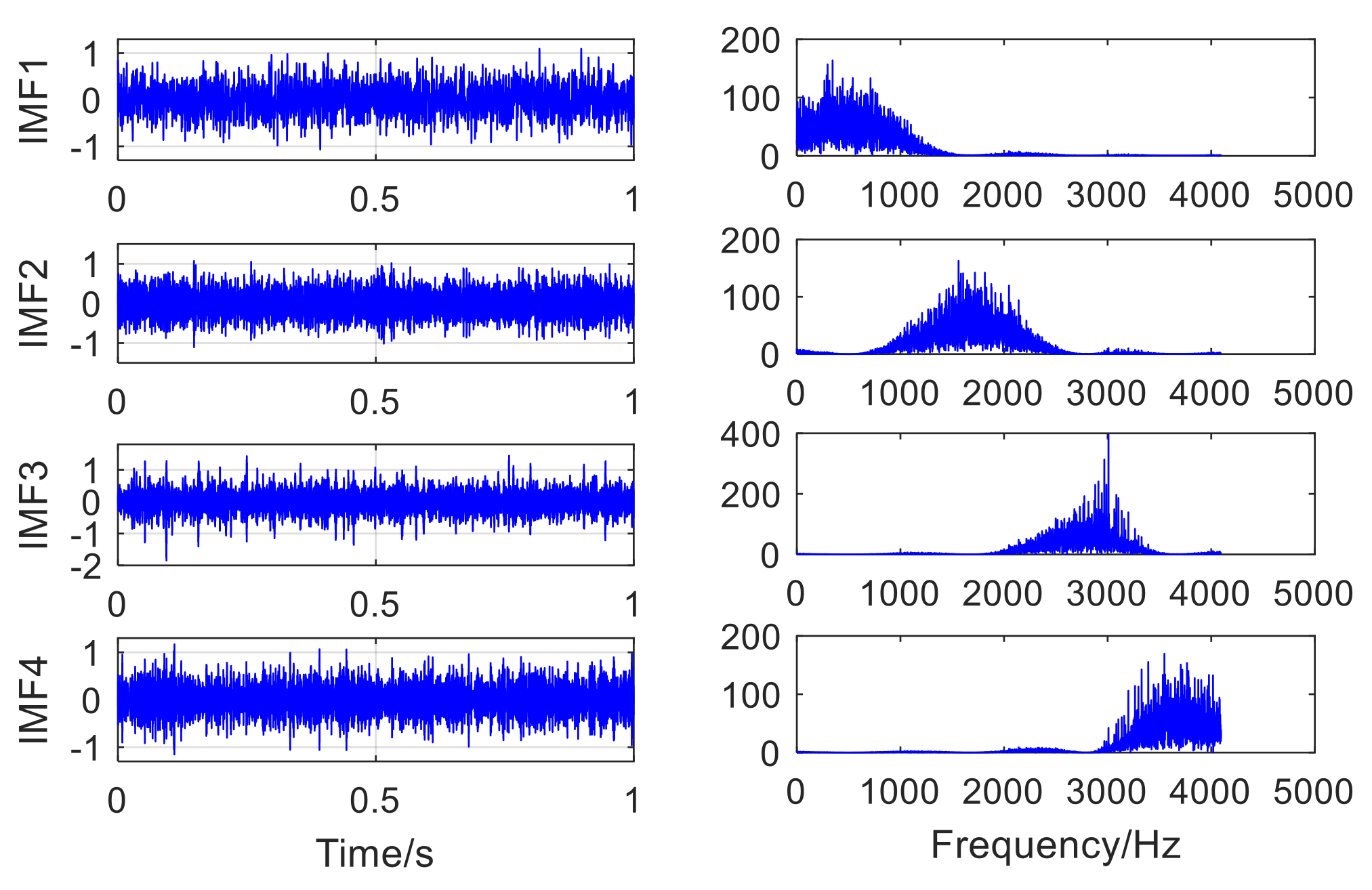

| IMF | IMF1 | IMF2 | IMF3 | IMF4 |

|---|---|---|---|---|

| Information entropy | 2.2819 | 2.2349 | 1.8184 | 2.1274 |

| Parameters | Values |

|---|---|

| Type | NU205 |

| Fault size | 15 mm × 0.5 mm × 0.5 mm |

| Pitch diameter | 39 mm |

| Diameter of cylindrical roller | 7.5 mm |

| Number of cylindrical rollers | 12 |

| The contact Angle | 0 |

| RPM | 800 r/min |

| IMF | IMF1 | IMF2 | IMF3 |

|---|---|---|---|

| Information entropy | 2.1683 | 2.2323 | 1.8919 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Zhou, J.; Liu, T. Compound Fault Feature Extraction of Rolling Bearing Acoustic Signals Based on AVMD-IMVO-MCKD. Sensors 2022, 22, 6769. https://doi.org/10.3390/s22186769

Wu S, Zhou J, Liu T. Compound Fault Feature Extraction of Rolling Bearing Acoustic Signals Based on AVMD-IMVO-MCKD. Sensors. 2022; 22(18):6769. https://doi.org/10.3390/s22186769

Chicago/Turabian StyleWu, Shishuai, Jun Zhou, and Tao Liu. 2022. "Compound Fault Feature Extraction of Rolling Bearing Acoustic Signals Based on AVMD-IMVO-MCKD" Sensors 22, no. 18: 6769. https://doi.org/10.3390/s22186769

APA StyleWu, S., Zhou, J., & Liu, T. (2022). Compound Fault Feature Extraction of Rolling Bearing Acoustic Signals Based on AVMD-IMVO-MCKD. Sensors, 22(18), 6769. https://doi.org/10.3390/s22186769