Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification

Abstract

1. Introduction

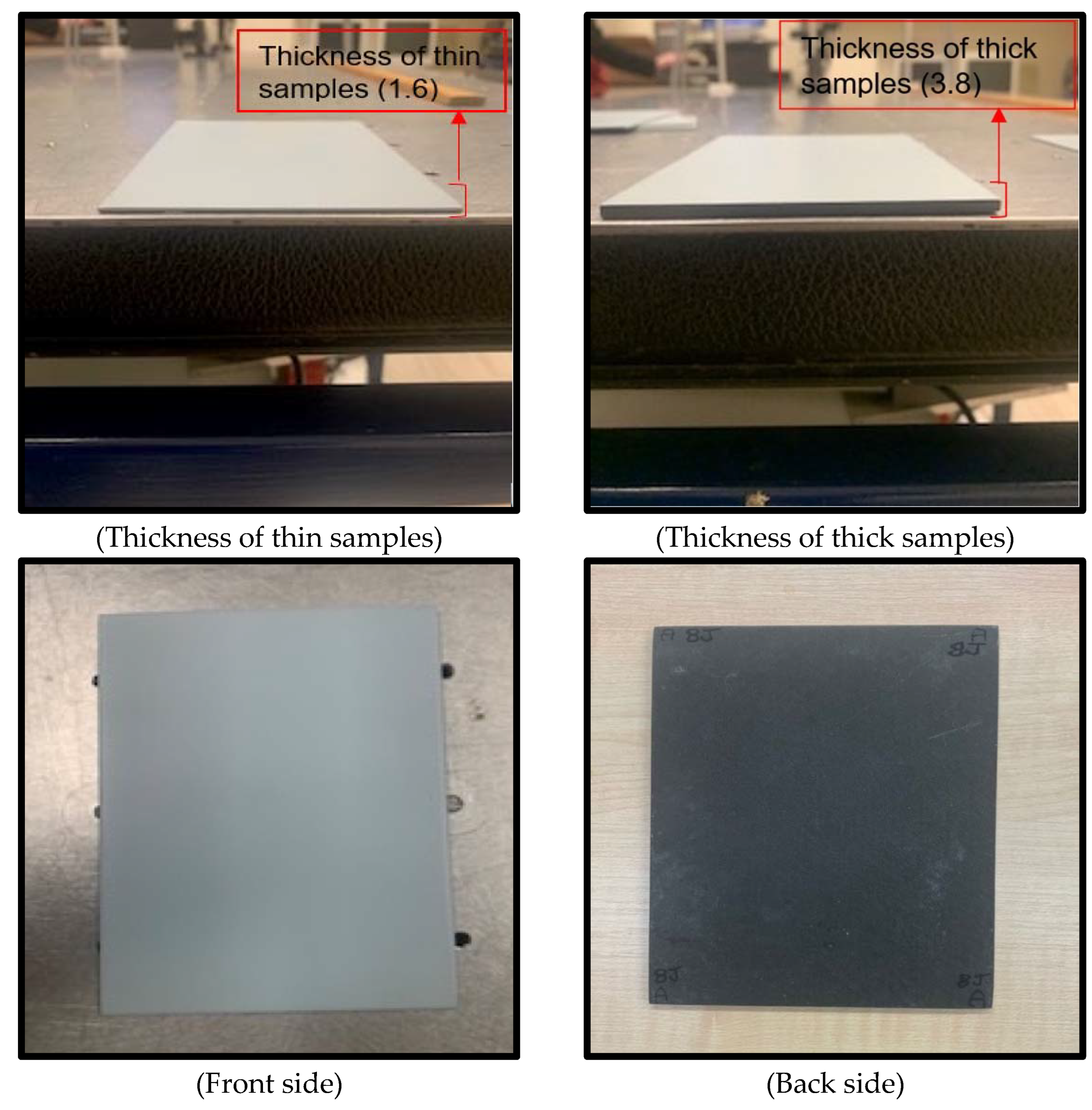

2. Tested Materials and Samples Features

- Laminate size: 100 × 150 mm

- Theoretical cured ply thickness: 0.18 mm

- Material: UD pre-preg material IMS-977-2.

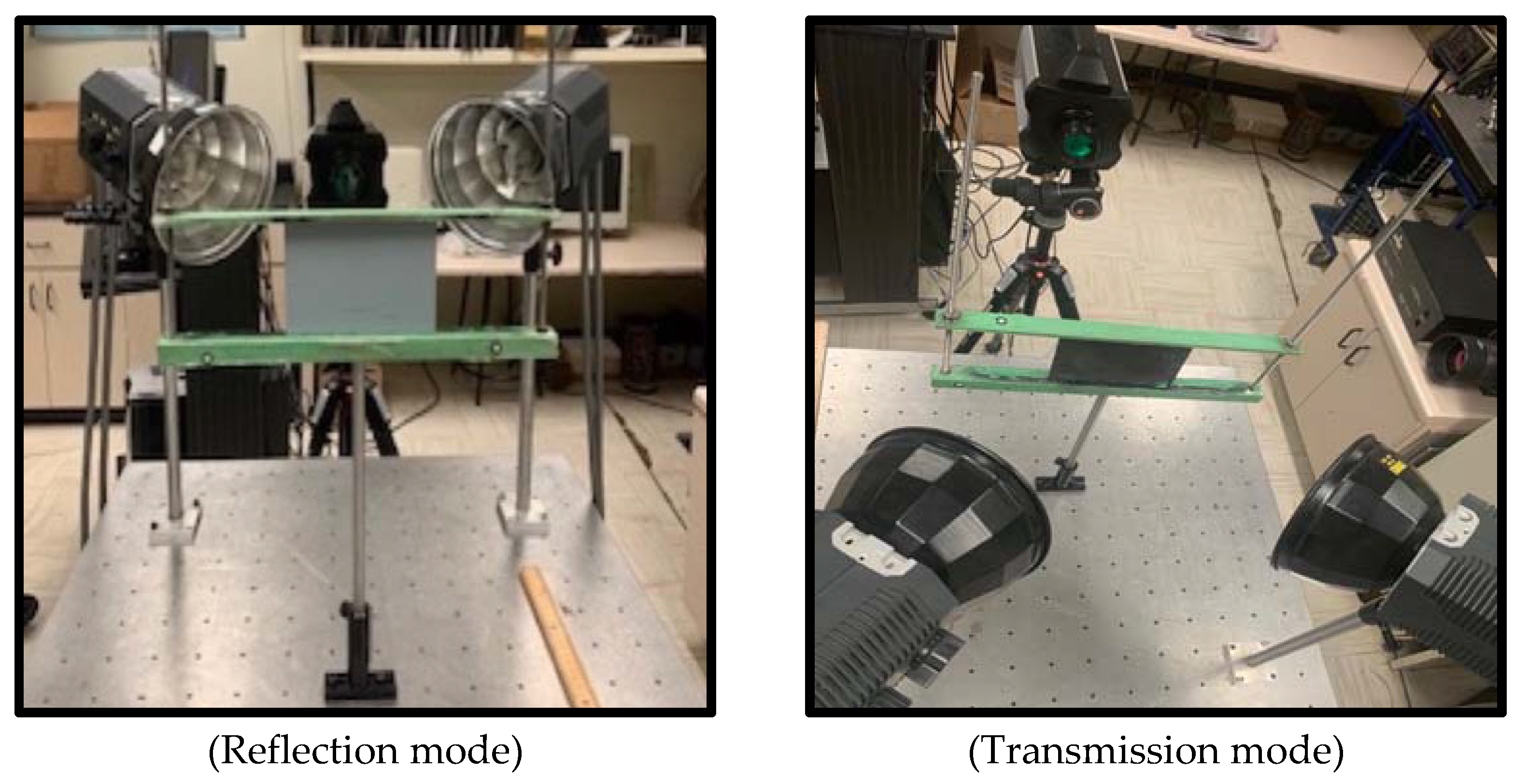

3. Lab Components

- Infrared camera (FLIR X8502sc, Teledyne FLIR LLC, Wilsonville, OR, USA), see Table 3.

- Photographic/Power flashes (BALCAR, Inc. FX60, Teledyne FLIR LLC, Wilsonville, OR, USA).

- Image acquisition software (FLIR ResearchIR Max 4, Teledyne FLIR LLC, Wilsonville, OR, USA).

- Data/pulse generation synchronization (custom-built software/hardware).

4. Pulsed Thermography (PT) Method for Image Capturing

5. Experimental Conduction

6. Image Processing Methods

6.1. Principal Component Thermography (PCT) * EOF = Empirical Orthogonal Function

6.2. Pulsed Phase Thermography (PPT)

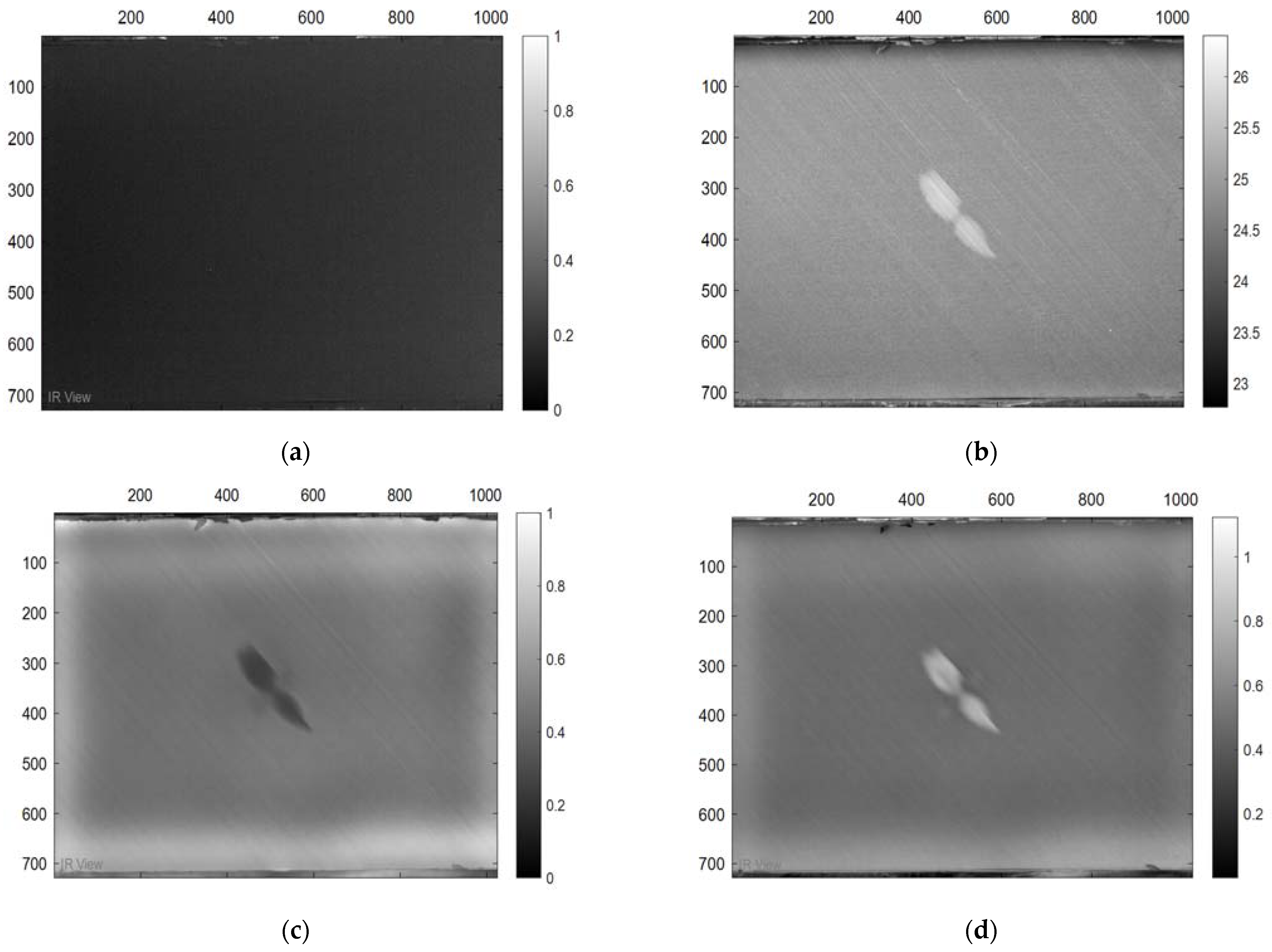

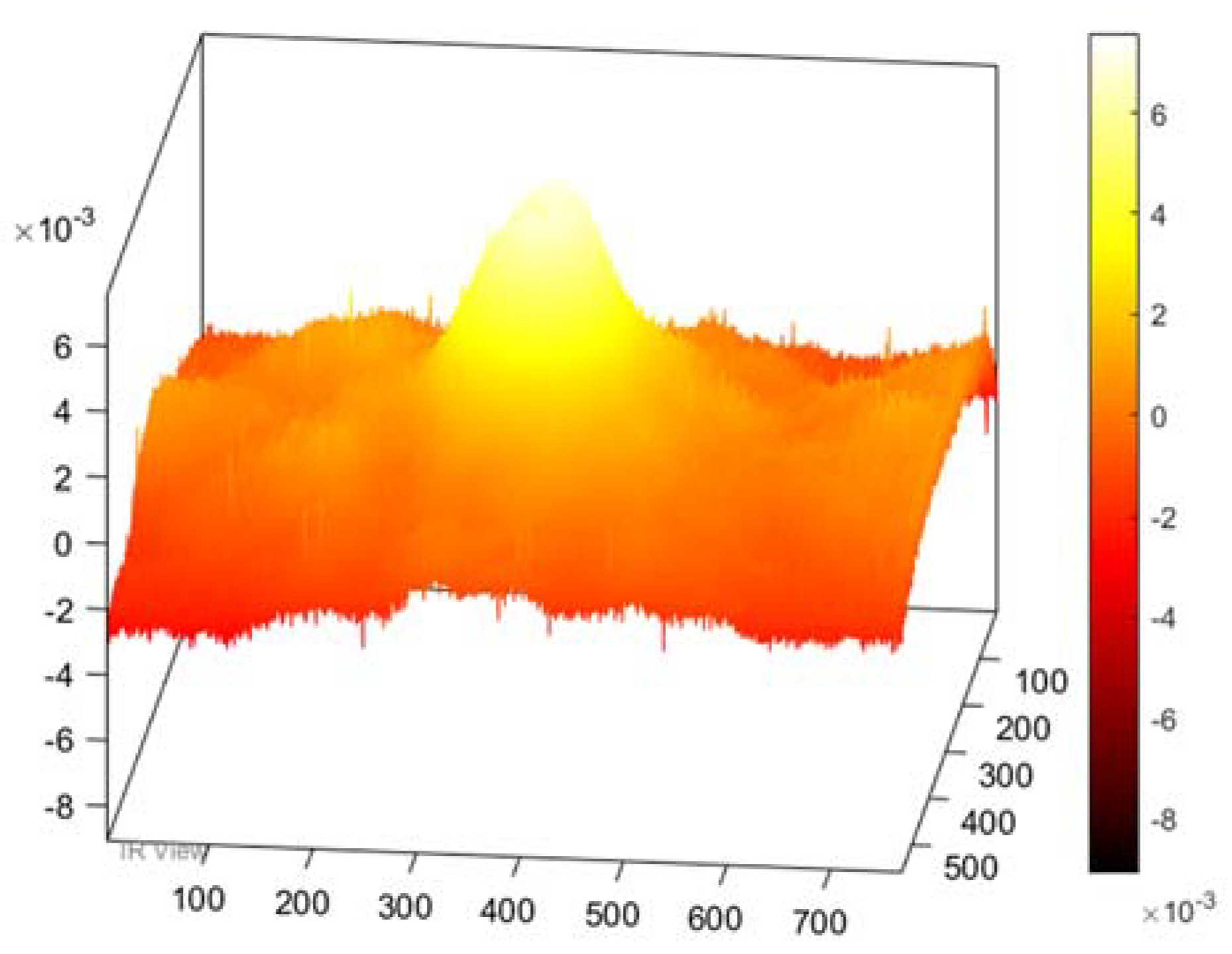

7. Image Processing Results of the Pulsed Thermographic Based on Reflection Mode

8. Image Processing Results of Pulsed Thermographics Based on Transmission Mode

9. Image Analysis and Damage Detection

- There is a discrepancy in the raw thermograms because of the different energies to which the sample were exposed.

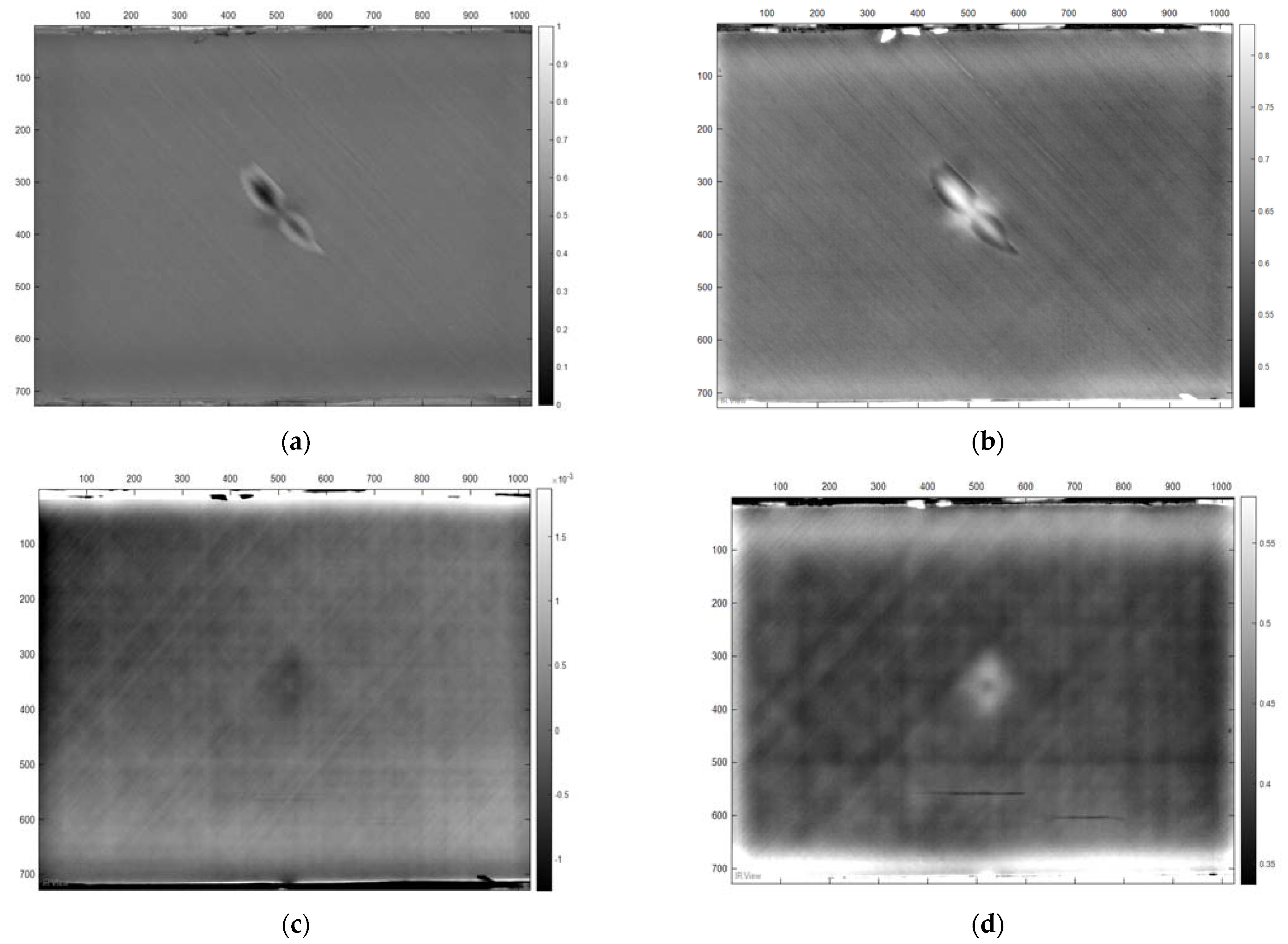

- Damage contrast varies according to the adopted configuration. i.e., reflection vs. transmission modes, as it is proven that the transmission mode offers more details of internal damage, whilst reflection shows more detail on surface and near to the surface damage.

- The clarity varies in terms of the capturing position in the event of reflection mode or transmission mode. Figure 11 presents comparative results between reflection (a and b) and transmission (c and d) mode.

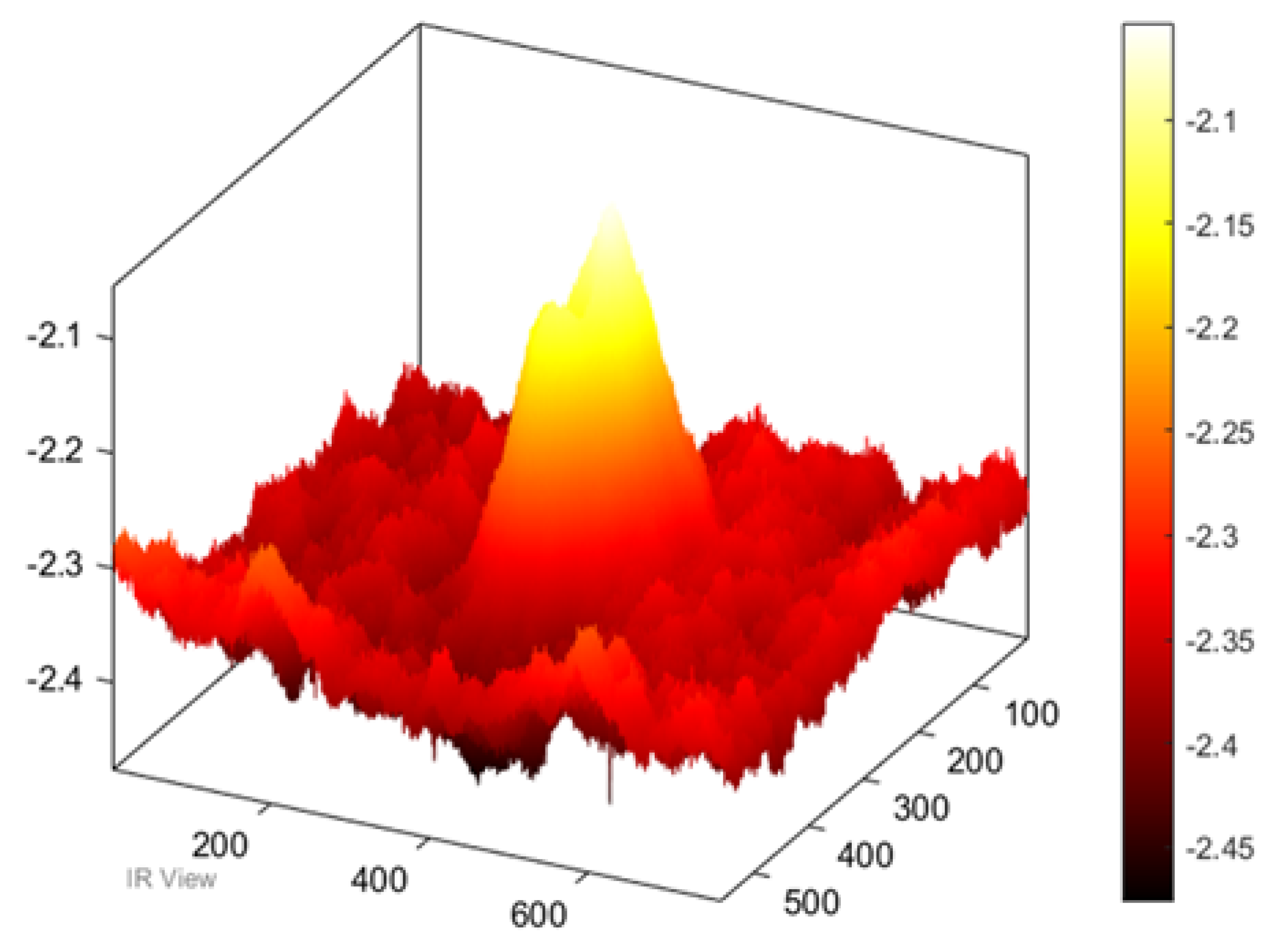

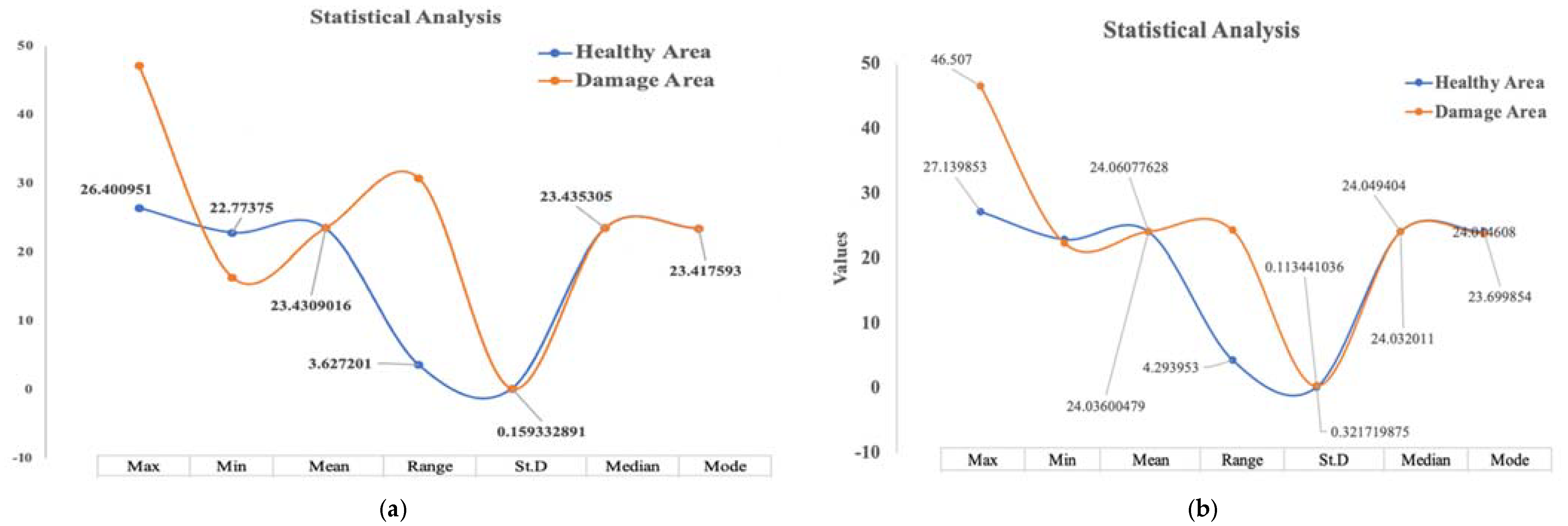

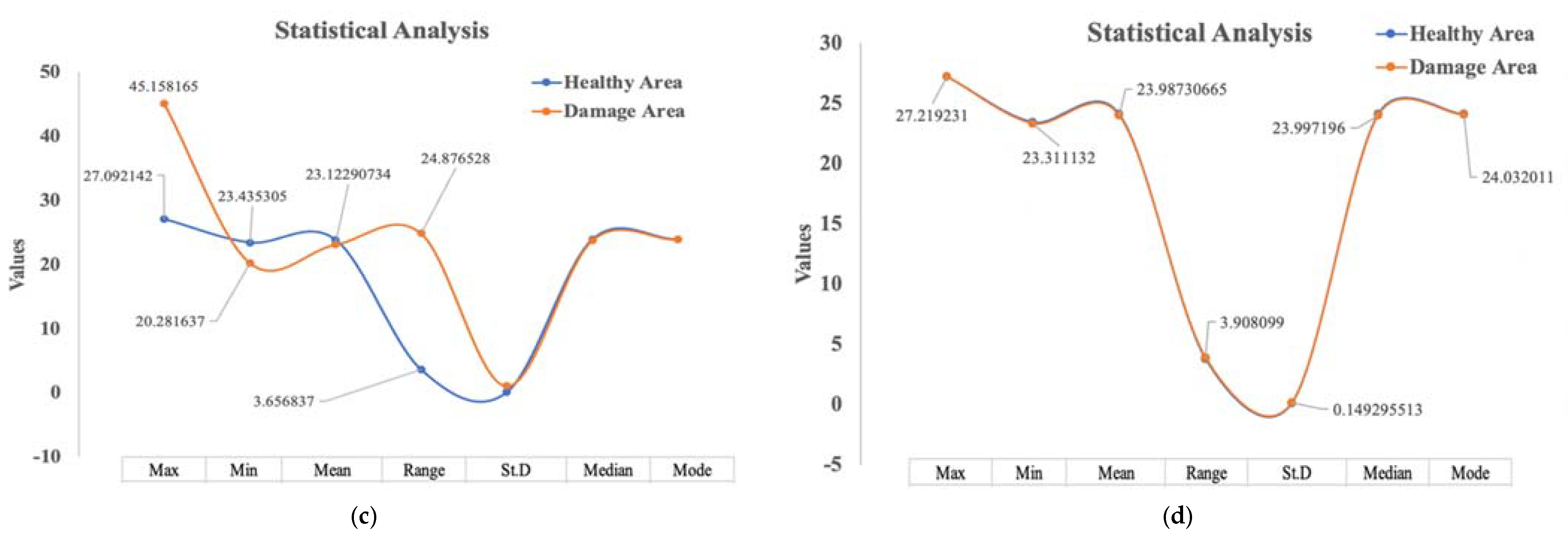

9.1. Statistical Analysis Method Results

9.1.1. Statistical Analysis Results of Damage Detection on Thin Reflection Image Sample

9.1.2. Statistical Analysis Results of Damage Detection on a Thick Reflection Image Sample

9.1.3. Statistical Analysis Results of Damage Detection on Thin Samples in Transmission

9.1.4. Statistical Analysis Results of Damage Detection on a Thick Transmission Image Sample

9.2. Machine Learning Detection Method Results

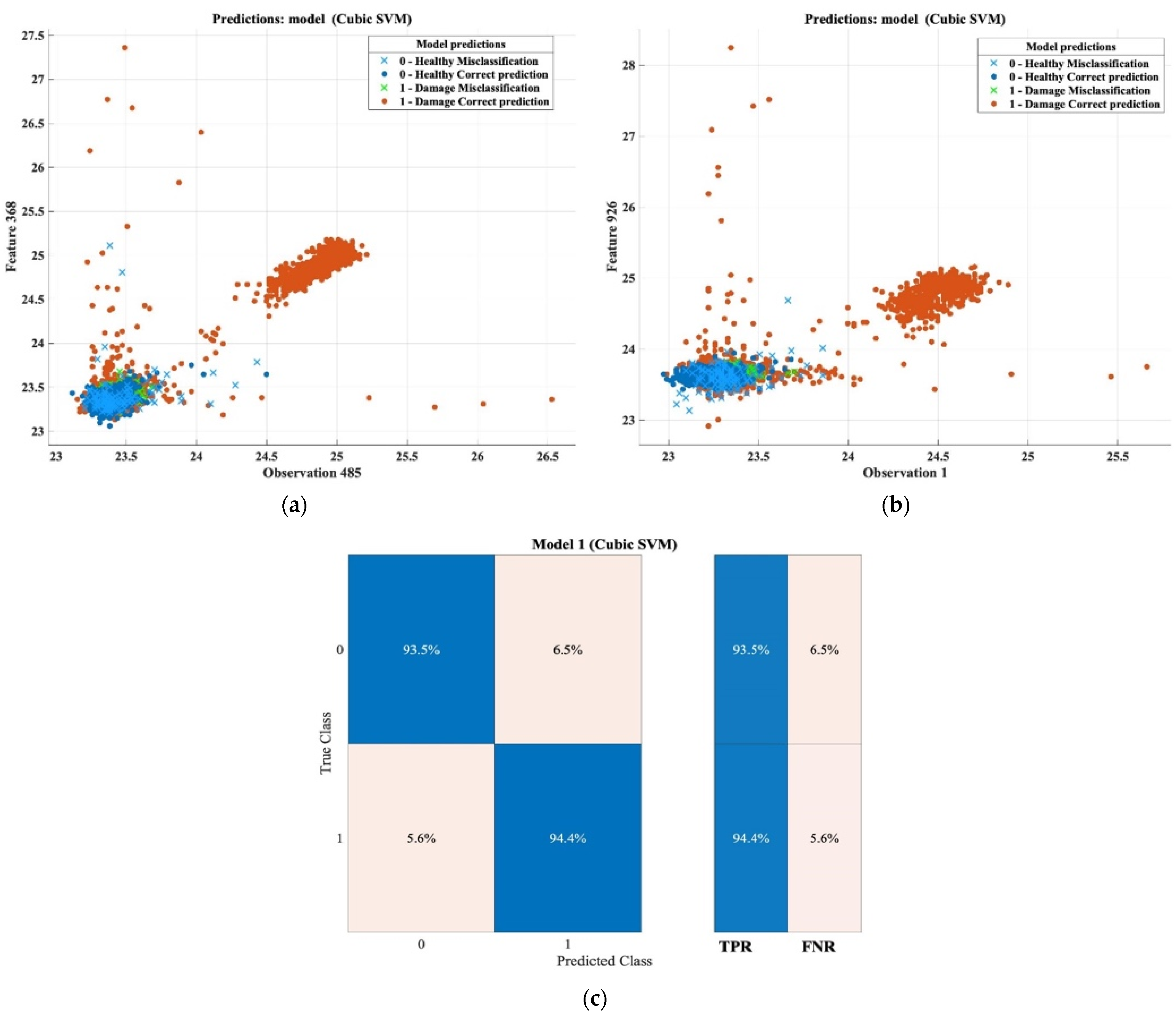

9.2.1. Damage Detection Results of Thin Reflection Image Sample

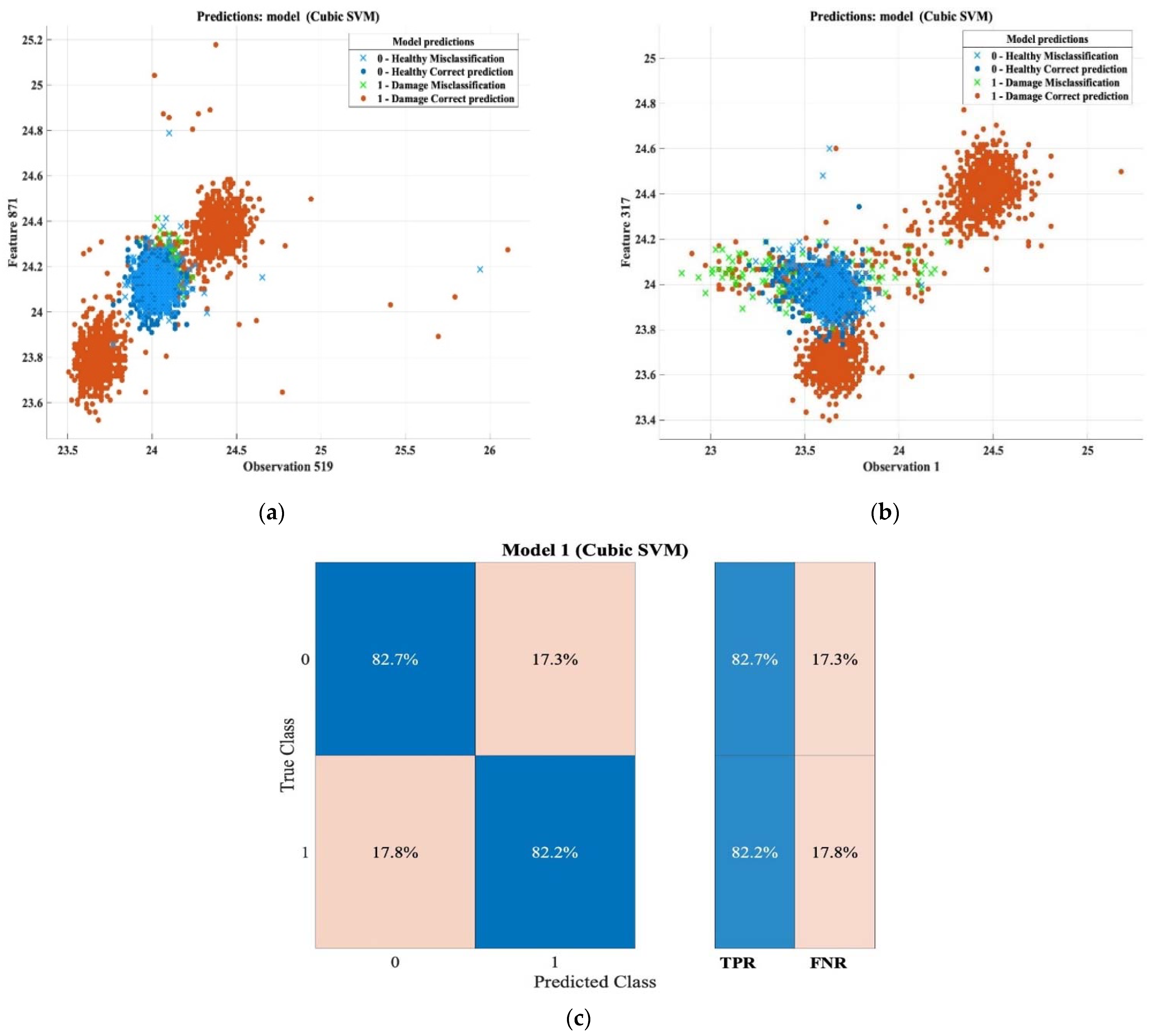

9.2.2. Damage Detection Results of Thick Samples in Reflection Mode

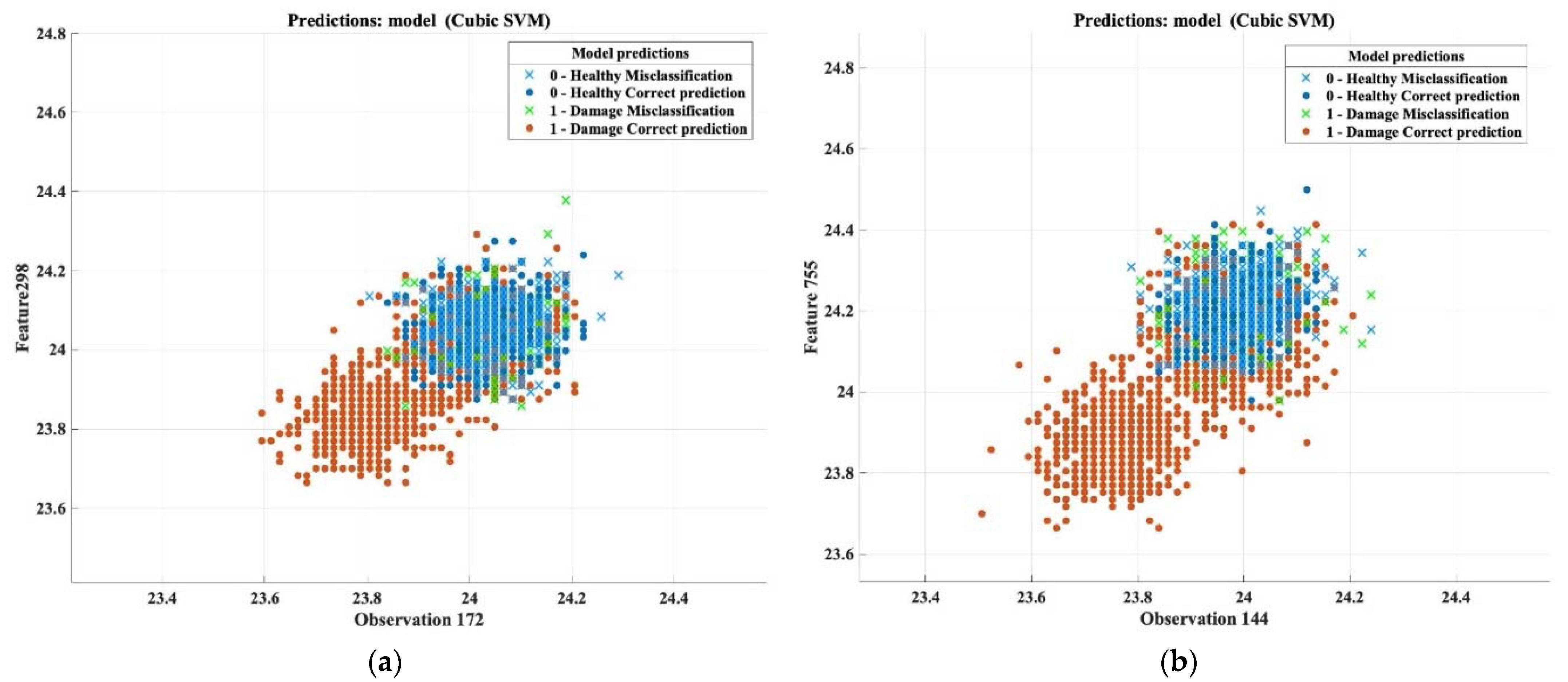

9.2.3. Damage Detection Results of Thin Samples in Transmission Mode

9.2.4. Damage Detection Results of Thick Samples in Transmission Mode

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alhammad, M.; Zanotti Fragonara, L.; Avdelidis, N.P. Diagnosis of Composite Materials in Aircraft Applications-Brief Survey of Recent Literature. Preprints 2020. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Deane, S.; Ibarra-Castanedo, C.; Pant, S.; Nooralishahi, P.; Ahmadi, M.; Genest, M.; Zolotas, A.; Zanotti-Fragonara, L.; et al. Diagnosis of composite materials in aircraft applications: Towards a UAV active thermography inspection approach. In Thermosense: Thermal Infrared Applications XLIII; SPIE: Bellingham, DC, USA, 2021; Volume 1174306, p. 4. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Hawtin, B.C.; Almond, D.P. Transient thermography in the assessment of defects of aircraft composites. NDT E Int. 2003, 36, 433–439. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Sfarra, S.; Fleuret, J.; Yousefi, B.; Garcia, D. Rail inspection using active thermography to detect rolled-in material. In Proceedings of the 14th Quantitative InfraRed Thermography Conference, Berlin, Germany, 25–29 June 2018; pp. 845–852. [Google Scholar]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Zolotas, A.; Maldague, X.P.V. Machine learning on thermographic images for the detection and classification of damage on composites. In Thermosense: Thermal Infrared Applications XLIV; SPIE: Bellingham, DC, USA, 2022; p. 18. [Google Scholar] [CrossRef]

- Garnier, C.; Pastor, M.L.; Eyma, F.; Lorrain, B. The detection of aeronautical defects in situ on composite structures using non destructive testing. Compos. Struct. 2011, 93, 1328–1336. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Maldague, X.P.V. Handbook of Technical Diagnostics; Springer: Berlin, Germany, 2013; ISBN 9783642258503. [Google Scholar]

- Wei, Z.; Fernandes, H.; Herrmann, H.G.; Tarpani, J.R.; Osman, A. A deep learning method for the impact damage segmentation of curve-shaped cfrp specimens inspected by infrared thermography. Sensors 2021, 21, 395. [Google Scholar] [CrossRef] [PubMed]

- Montesano, J.; Fawaz, Z.; Bougherara, H. Use of infrared thermography to investigate the fatigue behavior of a carbon fiber reinforced polymer composite. Compos. Struct. 2013, 97, 76–83. [Google Scholar] [CrossRef]

- Sirikham, A.; Zhao, Y.; Nezhad, H.Y.; Du, W.; Roy, R. Estimation of Damage Thickness in Fiber-Reinforced Composites using Pulsed Thermography. IEEE Trans. Ind. Inform. 2019, 15, 445–453. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, P.; Zhang, W. Development and application of infrared thermography non-destructive testing techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef] [PubMed]

- Bang, H.T.; Park, S.; Jeon, H. Defect identification in composite materials via thermography and deep learning techniques. Compos. Struct. 2020, 246, 112405. [Google Scholar] [CrossRef]

- Erazo-Aux, J.; Loaiza-Correa, H.; Restrepo-Giron, A.D.; Ibarra-Castanedo, C.; Maldague, X. Thermal imaging dataset from composite material academic samples inspected by pulsed thermography. Data Br. 2020, 32, 106313. [Google Scholar] [CrossRef] [PubMed]

- Baştanlar, Y.; Ozuysal, M. Introduction to Machine Learning Second Edition; Humana Press: Totowa, NJ, USA, 2014; Volume 1107, ISBN 9780262012430. [Google Scholar]

- Kubat, M. An Introduction to Machine Learning; Springer International Publishing: Geneva, Switzerland, 2015; pp. 1–291. [Google Scholar] [CrossRef]

- Jain, U.; Nathani, K.; Ruban, N.; Raj, A.N.J.; Zhuang, Z.; Mahesh, V.G.V. Cubic SVM classifier based feature extraction and emotion detection from speech signals. In Proceedings of the 2018 International Conference on Sensor Networks and Signal Processing (SNSP), Xi’an, China, 28–31 October 2018; pp. 386–391. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Marinetti, S.; Plotnikov, Y.A.; Winfree, W.P.; Braggiotti, A. Pulse Phase Thermography for Defect Detection and Visualization; SPIE: Newport Beach, CA, USA, 1999; pp. 230–238. [Google Scholar]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Maldague, X. Pulsed phase thermography reviewed. Quant. Infrared. Thermogr. J. 2004, 1, 47–70. [Google Scholar] [CrossRef]

| Energy (J) | Drop Height (mm) | Total Impactor Mass (g) |

|---|---|---|

| 2.5 | 200 | 1220 |

| 4 | 335 | |

| 8 | 670 | |

| 12 | 1000 | |

| 20 | 918 | 2220 |

| Coupons | Layup | Cured Thickness in mm (Averaged) | Per-Ply Thickness |

|---|---|---|---|

| Impact damage on thin coupons | [45/−45/90/0/90/0/90/−45/45] (9 layers) | 1.65 | 0.183 |

| Impact damage on thick coupons | [45/−45/90/0/90/0/90/−45/45] s (18 layers) | 3.8 | 0.211 |

| Sensor | Image Resolution | Dynamic Range | Acquisition Frequency | Spectral Range |

|---|---|---|---|---|

| InSb CCD Matrix | [pixels] 1280 × 1024 used: 512 × 512 | [bits] 14 | [Hz] 0.0015 to 180 Programmable 50 and 85 during tests | [μm] 3.0 to 5.0 |

| Type | Capturing Mode * | Images Frames | Side | No. of Data Sequences | Note | |

|---|---|---|---|---|---|---|

| Samples | Thin | Reflection | 10 × 1000 | Front | 5 | 1000 Frames per sequence |

| Back | 5 | |||||

| Transmission | 5 × 1000 | |||||

| Thick | Reflection | 10 × 1000 | front | 5 | ||

| back | 5 | |||||

| Transmission | 5 × 2000 | 2000 per sequence | ||||

| Statistical Criteria | Purpose | |

|---|---|---|

| To find the range of the numerical values of the thermal images | Minimum | To find the lowest value. |

| Maximum | To find highest value. | |

| Range | The find the difference between the lowest and highest. | |

| To find the pattern of the numerical values of the thermal images | Mean | To find the average. |

| Mode | The find the most frequent value. | |

| Median | The find middle value | |

| Standard deviation (SD) | To measure how spread out the values are. | |

| Max | Min | Mean | Range | SD | Median | Mode | |

|---|---|---|---|---|---|---|---|

| Healthy Area | 26.400951 | 22.77375 | 23.4309016 | 3.627201 | 0.159332891 | 23.435305 | 23.417593 |

| Damage Area | 47.127533 | 16.40193 | 23.43215487 | 30.725603 | 0.164197367 | 23.435305 | 23.417593 |

| Max | Min | Mean | Range | St.D | Median | Mode | |

|---|---|---|---|---|---|---|---|

| Healthy Area | 27.139853 | 22.8459 | 24.0360048 | 4.293953 | 0.11344104 | 24.032011 | 24.014608 |

| Damage Area | 46.507 | 22.245995 | 24.0607763 | 24.261005 | 0.32171987 | 24.049404 | 23.699854 |

| Max | Min | Mean | Range | St.D | Median | Mode | |

|---|---|---|---|---|---|---|---|

| Healthy Area | 27.092142 | 23.435305 | 23.8835772 | 3.656837 | 0.08099473 | 23.892551 | 23.892551 |

| Damage Area | 45.158165 | 20.281637 | 23.1229073 | 24.876528 | 1.05067575 | 23.752516 | 23.892551 |

| Max | Min | Mean | Range | St.D | Median | Mode | |

|---|---|---|---|---|---|---|---|

| Healthy Area | 27.219231 | 23.417593 | 24.0912467 | 3.801638 | 0.1076612 | 24.08416 | 24.08416 |

| Damage Area | 27.219231 | 23.311132 | 23.9873066 | 3.908099 | 0.14929551 | 23.997196 | 24.032011 |

| Cases (Samples × Frames) | Total Frames | Response/Label | |

|---|---|---|---|

| Health area (Dataset 1–2) | 3 × 1000 1 × 2000 | 5000 Frames | 0 |

| Damage area (Dataset 3–4) | 9 × 1000 3 × 2000 | 15,000 Frames | 1 |

| Total Trained Frames | 20,000 Frames | ||

| Cases | Data Group | Features | Observations |

|---|---|---|---|

| Healthy Area | Datasets 1–2 | 1024 features 768 features | 745,472 430,080 |

| Damage Area | Datasets 3–4 | 1024 features 768 features | 2,236,416 1,290,240 |

| Model | Datasets | Classes | Observations | |

|---|---|---|---|---|

| Trained Models | Model 1 | Datasets 1 and 3 | 2 | 15,120 |

| Model 2 | Datasets 2 and 4 | 2 | 18,480 | |

| Test Model | Model 3 | Generated without its trained data as a test model | Cubic SVM Algorithm | New datasets |

| Model 4 |

| Classification Results | |

|---|---|

| Accuracy | 93.5% |

| Total misclassification cost | 189 |

| Prediction speed | ~3100 obs/s |

| Training time | 8.8344 s |

| Classification Results | |

|---|---|

| Accuracy | 82.1% |

| Total misclassification cost | 521 |

| Prediction speed | ~2800 obs/s |

| Training time | 9.8159 s |

| Classification Raults | |

|---|---|

| Accuracy | 79.4% |

| Total misclassification cost | 462 |

| Prediction speed | ~3700 obs/s |

| Training time | 5.9488 s |

| Classification Results | |

|---|---|

| Accuracy | 78.7% |

| Total misclassification cost | 477 |

| Prediction speed | ~3100 obs/s |

| Training time | 7.8478 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Zolotas, A.; Maldgue, X.P.V. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. https://doi.org/10.3390/s22239031

Alhammad M, Avdelidis NP, Ibarra-Castanedo C, Torbali ME, Genest M, Zhang H, Zolotas A, Maldgue XPV. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors. 2022; 22(23):9031. https://doi.org/10.3390/s22239031

Chicago/Turabian StyleAlhammad, Muflih, Nicolas P. Avdelidis, Clemente Ibarra-Castanedo, Muhammet E. Torbali, Marc Genest, Hai Zhang, Argyrios Zolotas, and Xavier P. V. Maldgue. 2022. "Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification" Sensors 22, no. 23: 9031. https://doi.org/10.3390/s22239031

APA StyleAlhammad, M., Avdelidis, N. P., Ibarra-Castanedo, C., Torbali, M. E., Genest, M., Zhang, H., Zolotas, A., & Maldgue, X. P. V. (2022). Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors, 22(23), 9031. https://doi.org/10.3390/s22239031