An Optimized Probabilistic Roadmap Algorithm for Path Planning of Mobile Robots in Complex Environments with Narrow Channels

Abstract

:1. Introduction

- (1)

- To ensure the existence of narrow passages and optimize the number and distribution of free points in the free workspace, we extend the obstacle based on only the diagonal distance of the mobile robot, ignoring the safety distance in the movement. After that, we optimize the distribution of the sampling points using the quasi-random sampling principle in the workspace. Then, we re-classify the sampling points based on the potential energy function, in order to ensure the safety of the mobile robot during movement.

- (2)

- To improve the density of random points in the narrow channel, each obstacle point is first subjected to a random force and extended from eight directions. Then, the free points in the narrow channel are determined by combining the characteristics of narrow passages with the potential function.

- (3)

- To reduce the time required for path planning, we sample the bidirectional A*, instead of the typical local path planning planner in the learning process of the traditional PRM algorithm.

- (4)

- To shorten the distance of the path and ensure that distance from obstacles is maintained, the basic path obtained by the query process requires re-optimization by pruning techniques and potential functions, in order to improve the superiority of the final path.

2. Typical PRM Algorithm

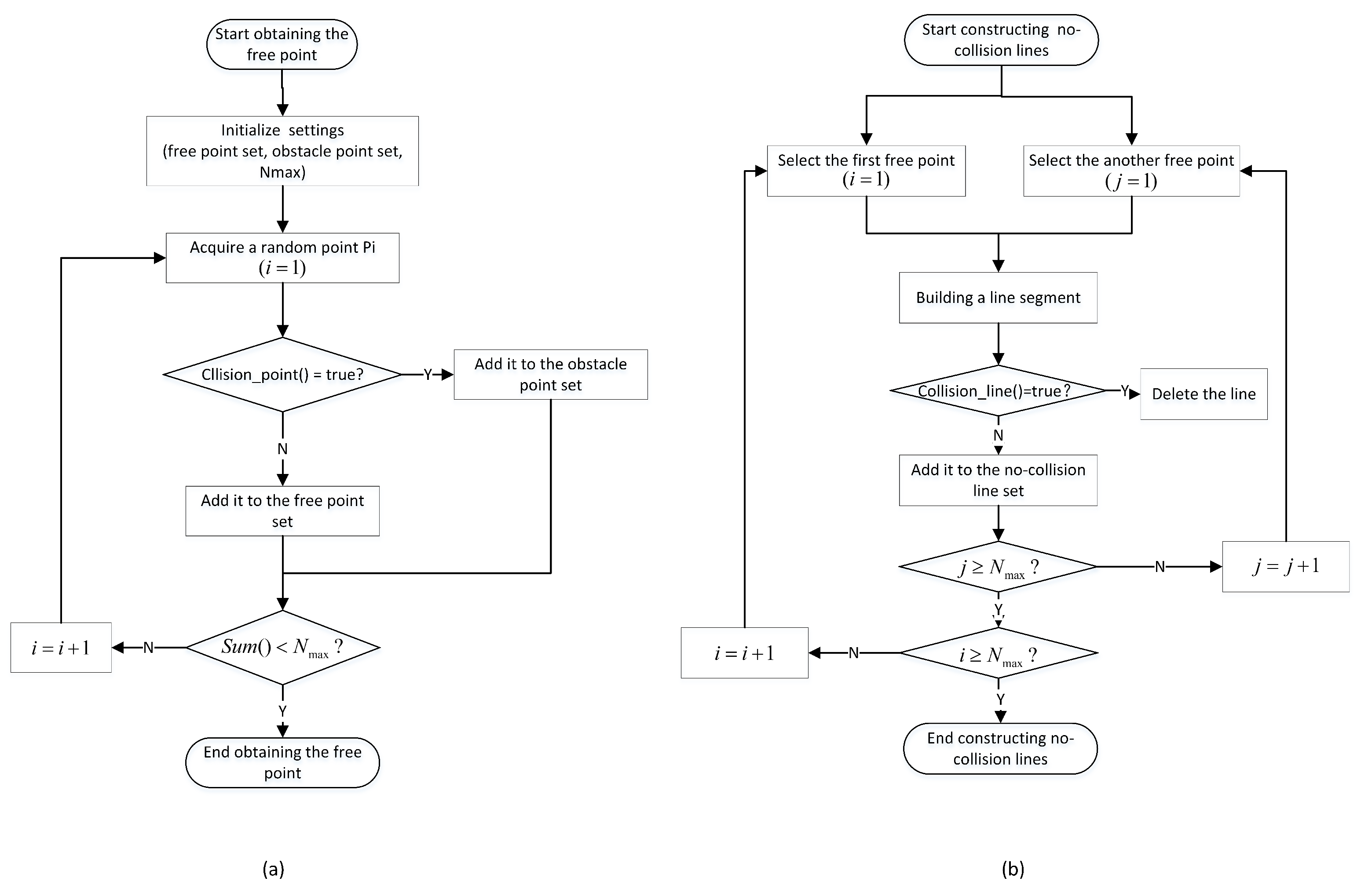

2.1. The Learning Process

2.2. The Query Process

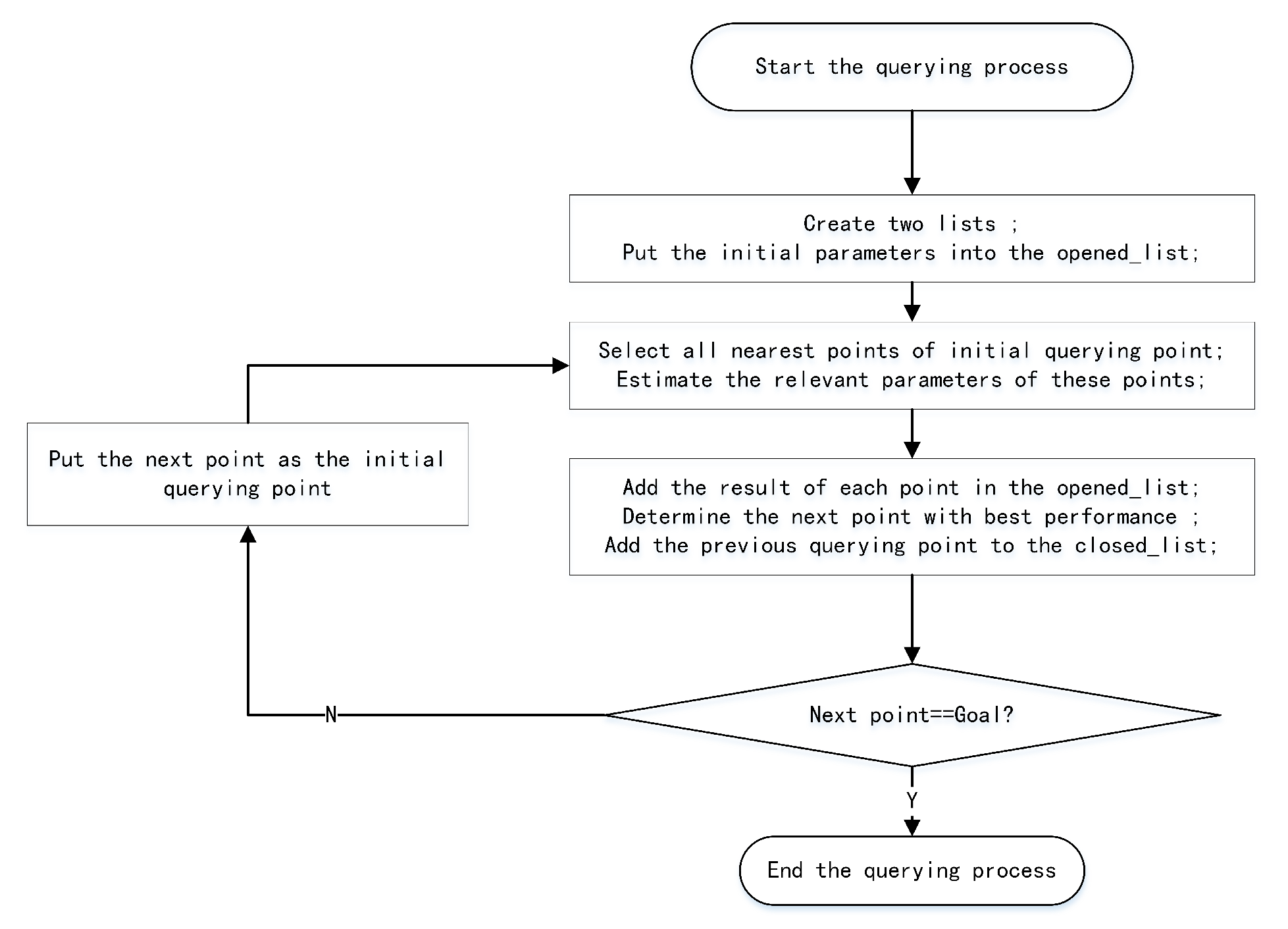

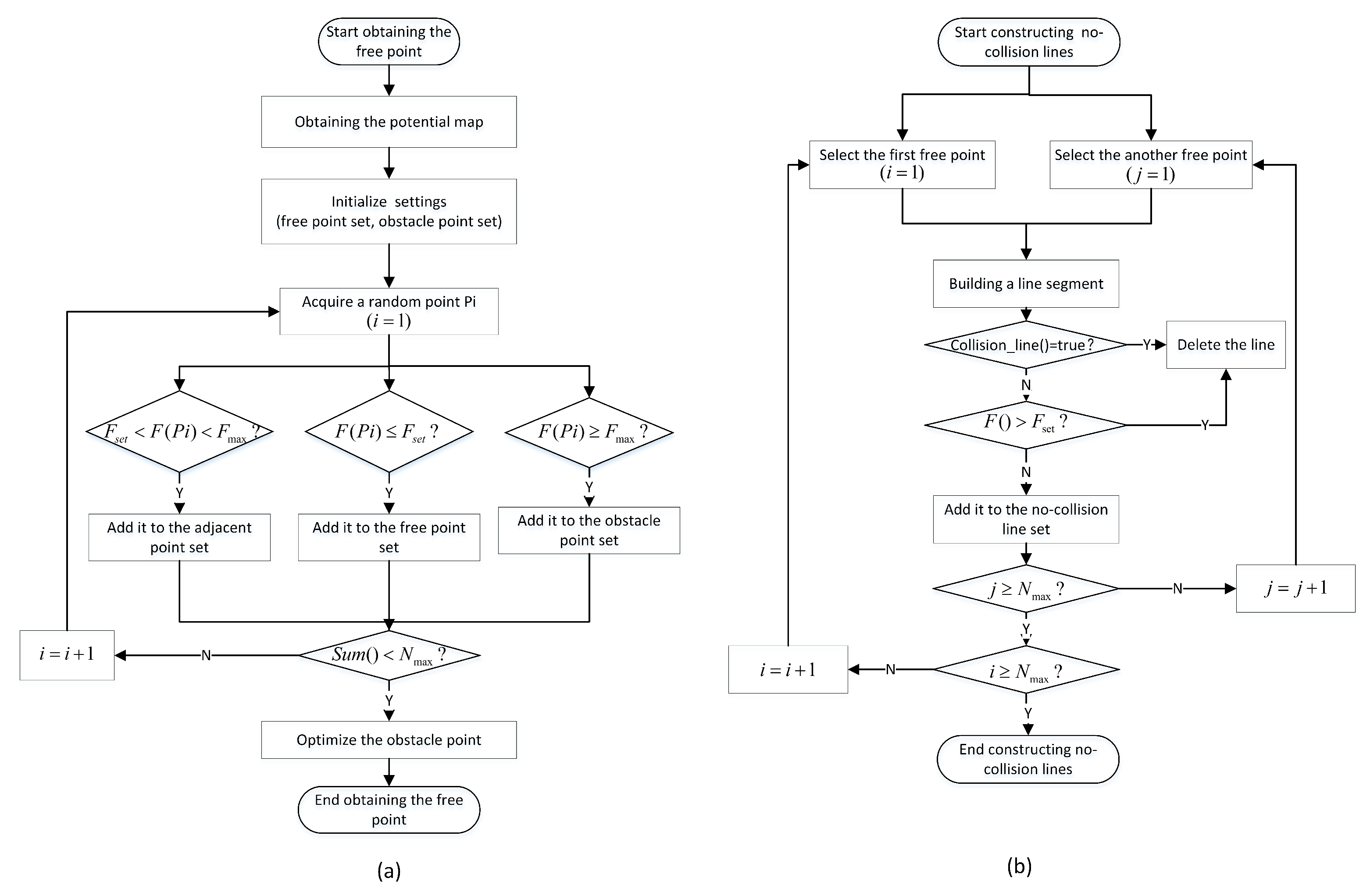

3. The Optimized Learning Process

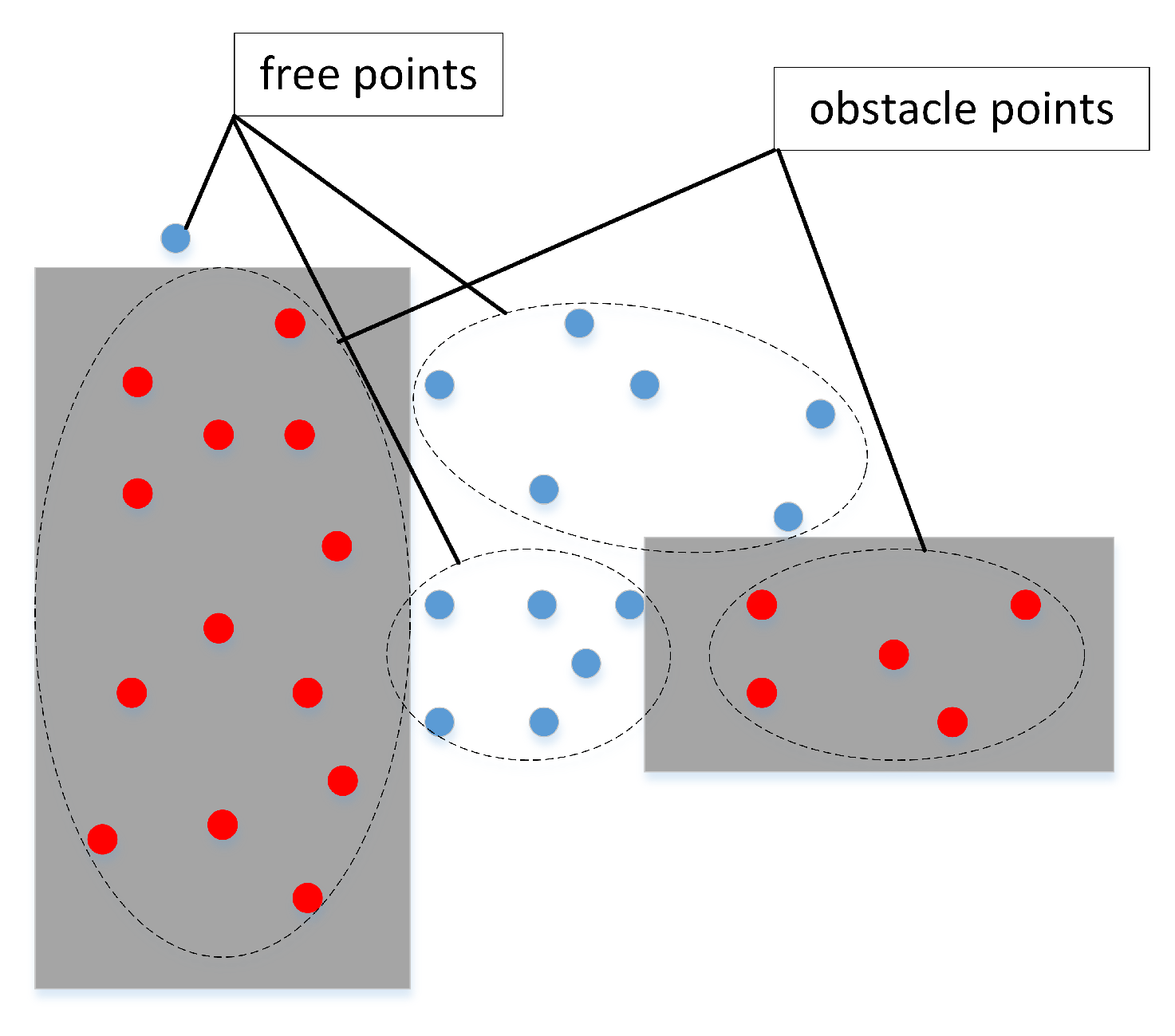

3.1. Optiming the Workspace Map and the Initial Point Classification

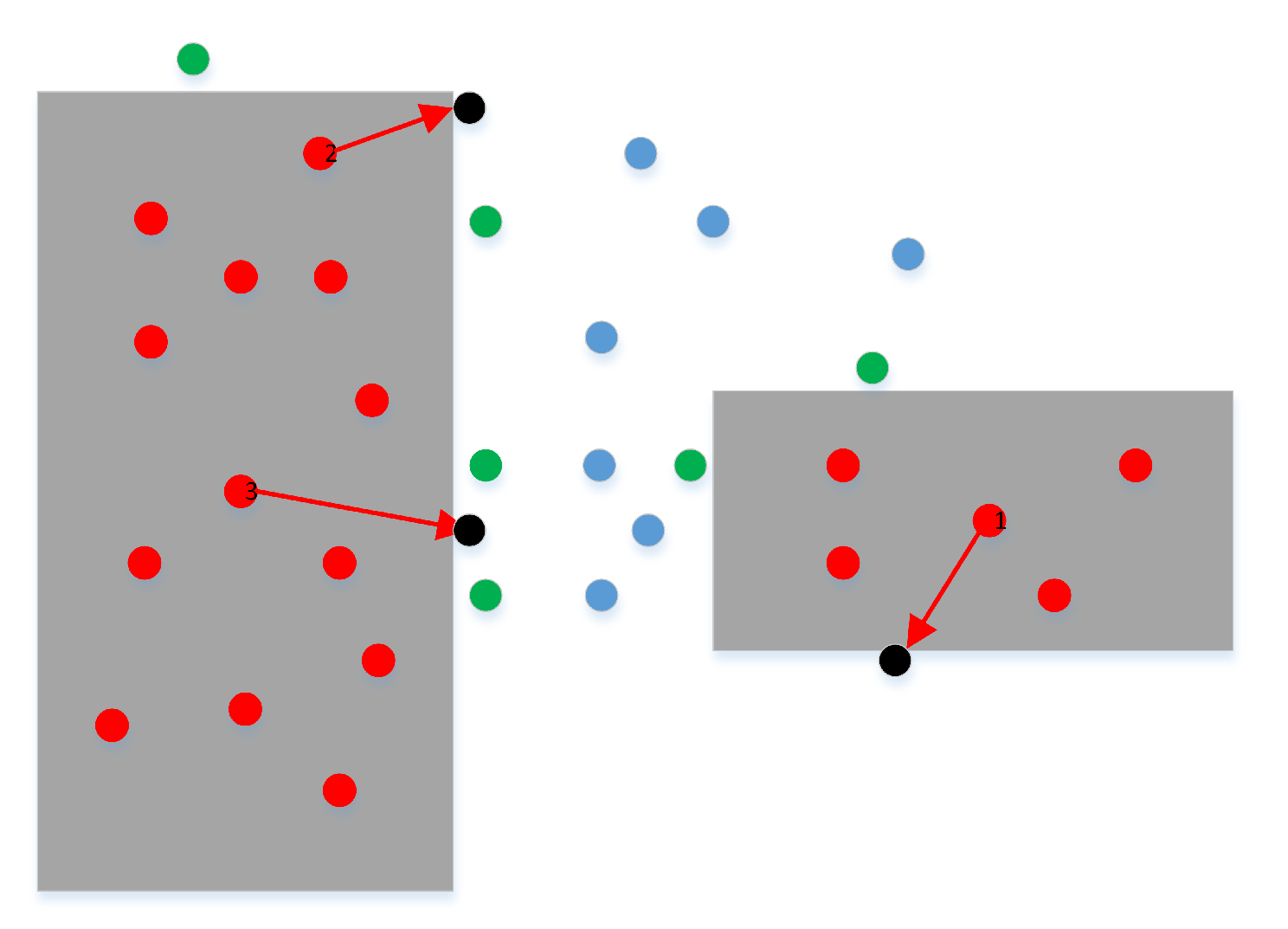

3.2. Optimizing the Obstacle Points by Artificial Potential Field

| Algorithm 1 Res_Optm = Optimize_Point_Obs(Point,Force_rand,Rep_Force,map). |

|

3.3. Improving Collision-Free Line Segments Using the Repulsive Force

- (1)

- The optimized connecting technique can effectively avoid collision with obstacles by limiting the distance between the line segment and the nearest obstacles.

- (2)

- Some free points may not be able to construct a collision-free line segment, due to the limitation of the maximum repulsive force, which can reduce the number of total line segments and optimize the required time for collision detection.

- (3)

- Even if the force used for optimizing the obstacle point is random, the maximum repulsive force can effectively ensure that the free line segment is kept outside the specified range from the obstacle, especially in the narrow passage.

4. The Optimized Query Process

4.1. Optimizing the Query Process

4.2. Optimizing Path Pruning Technology

| Algorithm 2 Path_Opt = Optimize_Init_Path(Path, Rep_Force_Line, map). |

|

5. Simulations

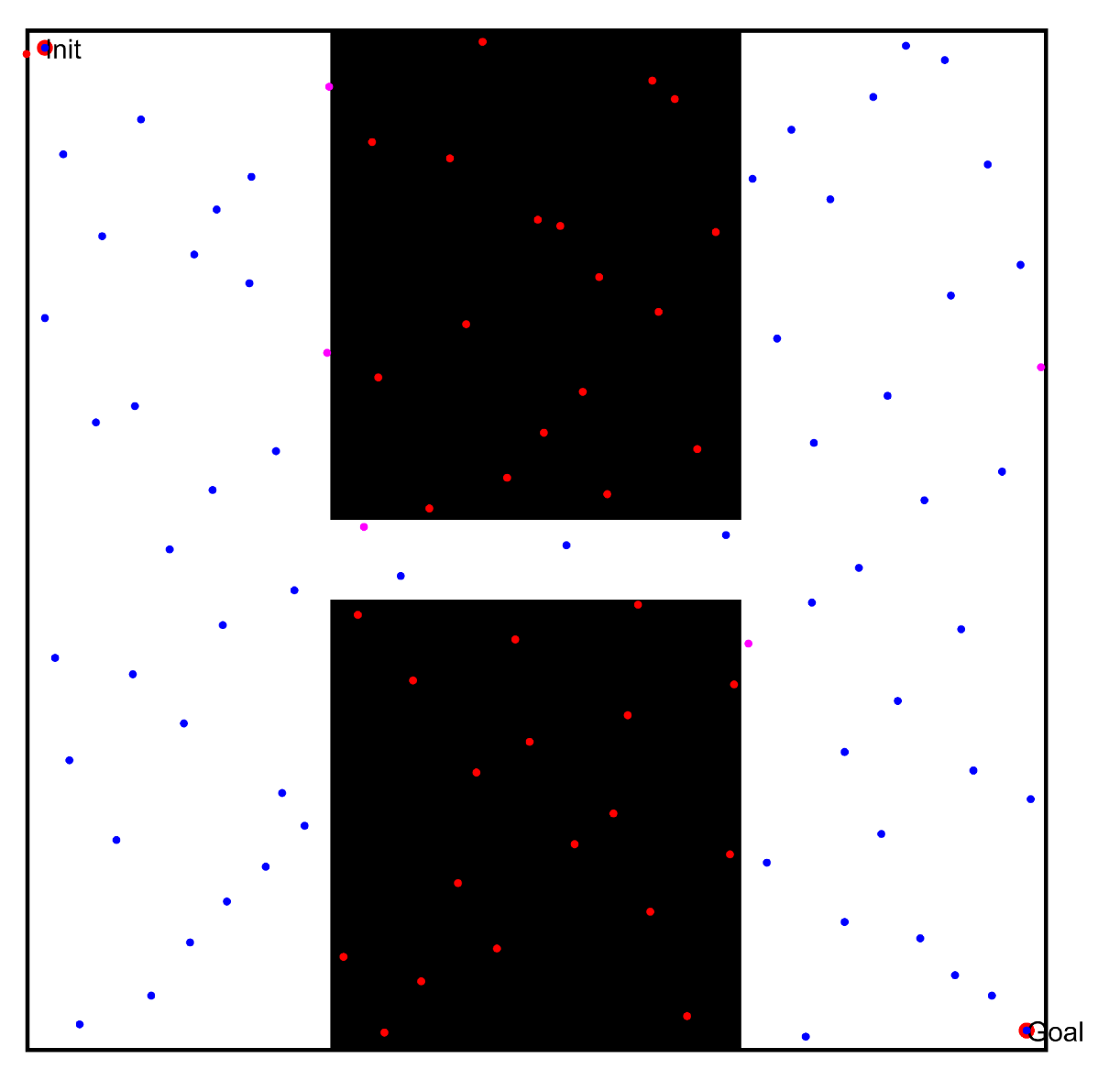

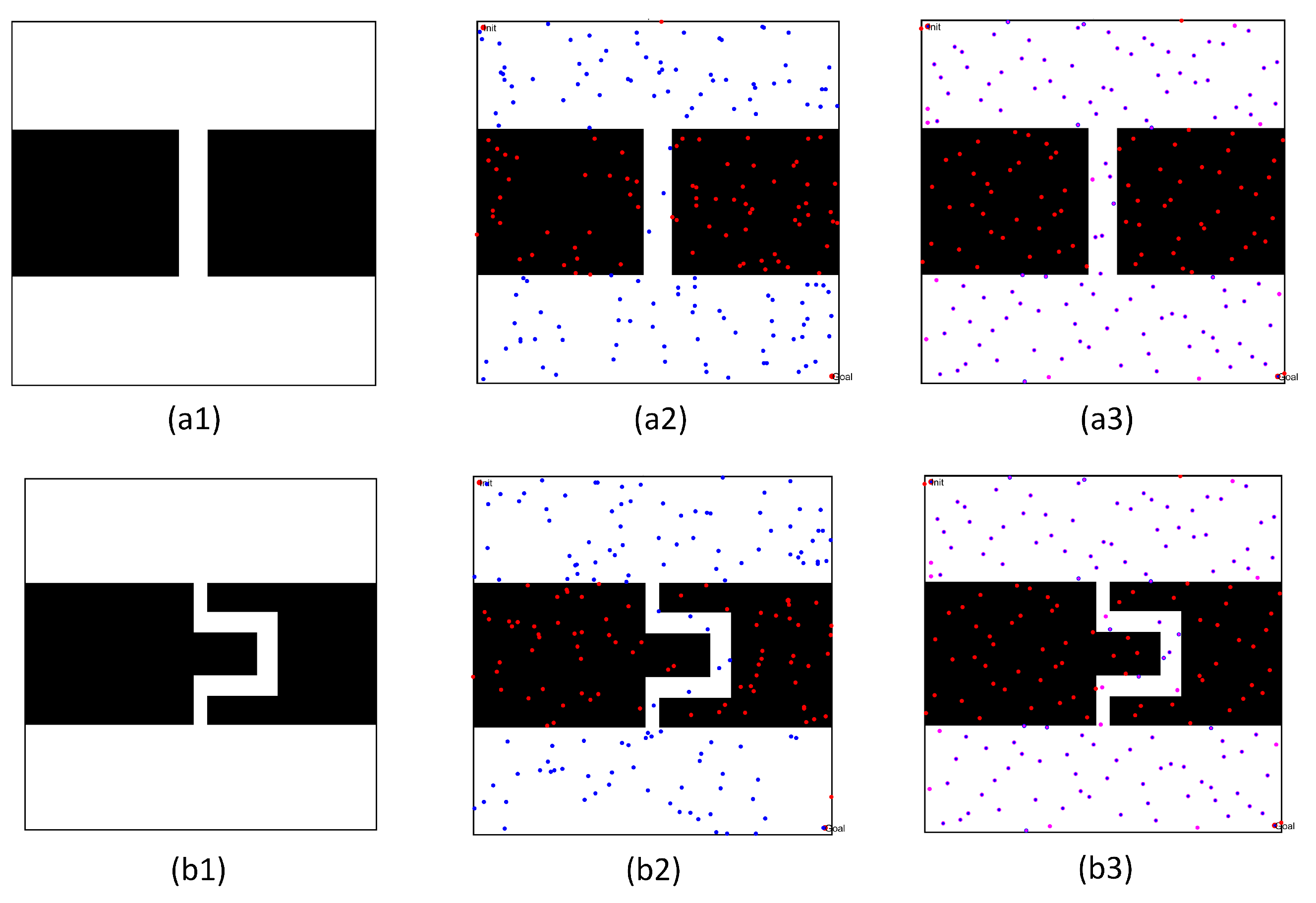

5.1. Single-Channel Path Planning Problems

- (1)

- By setting the same number of sampling points, the optimized sampling technology proposed in this paper can increase the number of free spaces to find the collision-free path. The PRM algorithm based on random sampling principle directly sets the total number of free points and the obstacle points. The other two PRM algorithms mainly directly set the number of free points.

- (2)

- By increasing the number of sampling points, the number of sampling points in the narrow channel can be rapidly increased. This is because the sampling optimization technique in this paper can turn obstacle points into free points in narrow passages.

- (3)

- By comparing the number of free points in the overall workspace to that in the narrow channel, the quasi-random sampling principle and obstacle point optimization technique proposed in this paper can significantly increase the number of sampling points in the narrow channel.

- (4)

- By comparing the success rate of finding the path, it was found that the method proposed in this paper can enhance the success rate of path planning, even when using a lower number of sampling points than the other PRM algorithms.

- (5)

- By comparing the required time for the query process shown in Table 2, it can be seen that the method proposed in this paper took less time to find an effective path, effectively increasing the efficiency of the PRM algorithm.

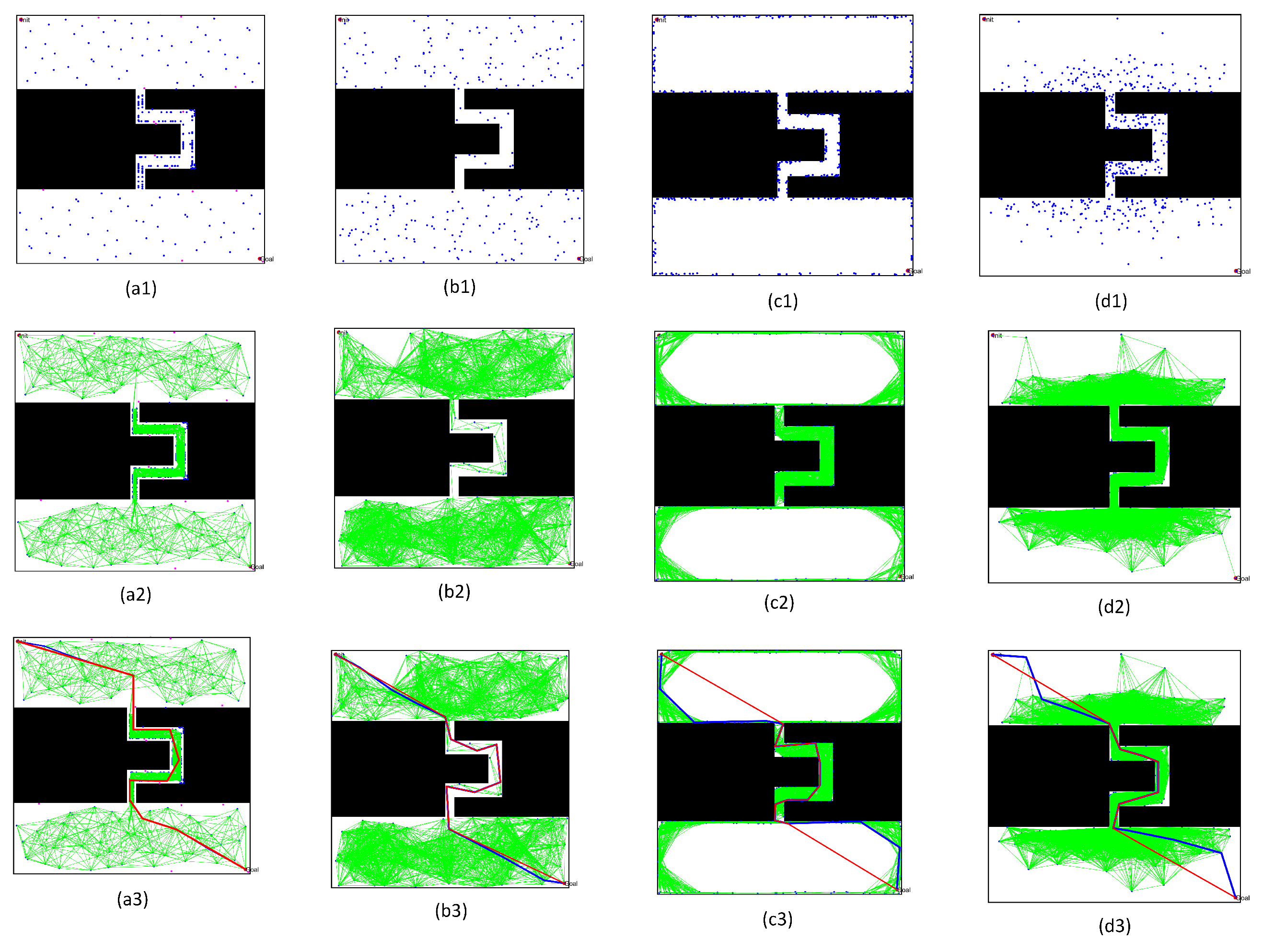

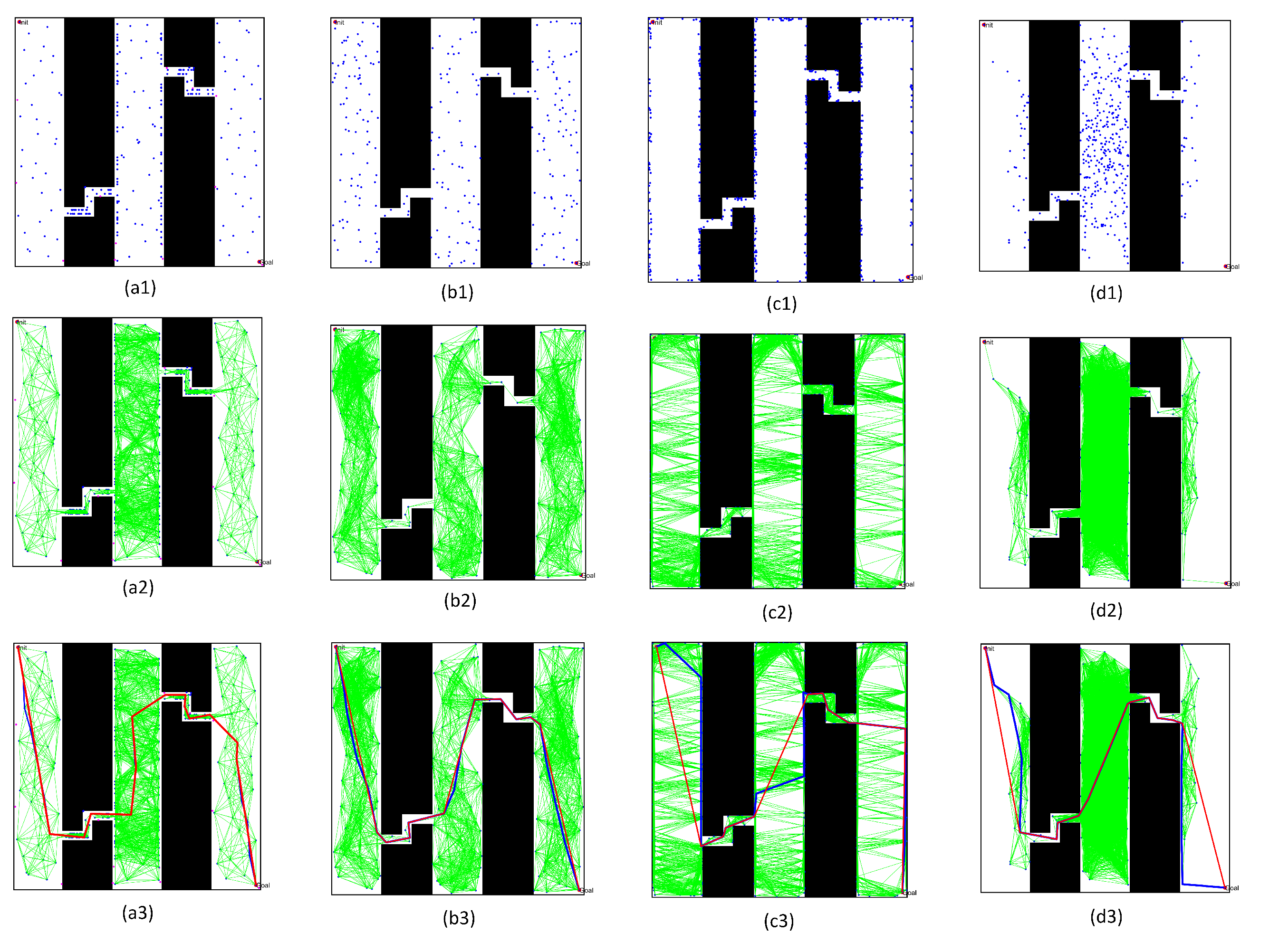

- (1)

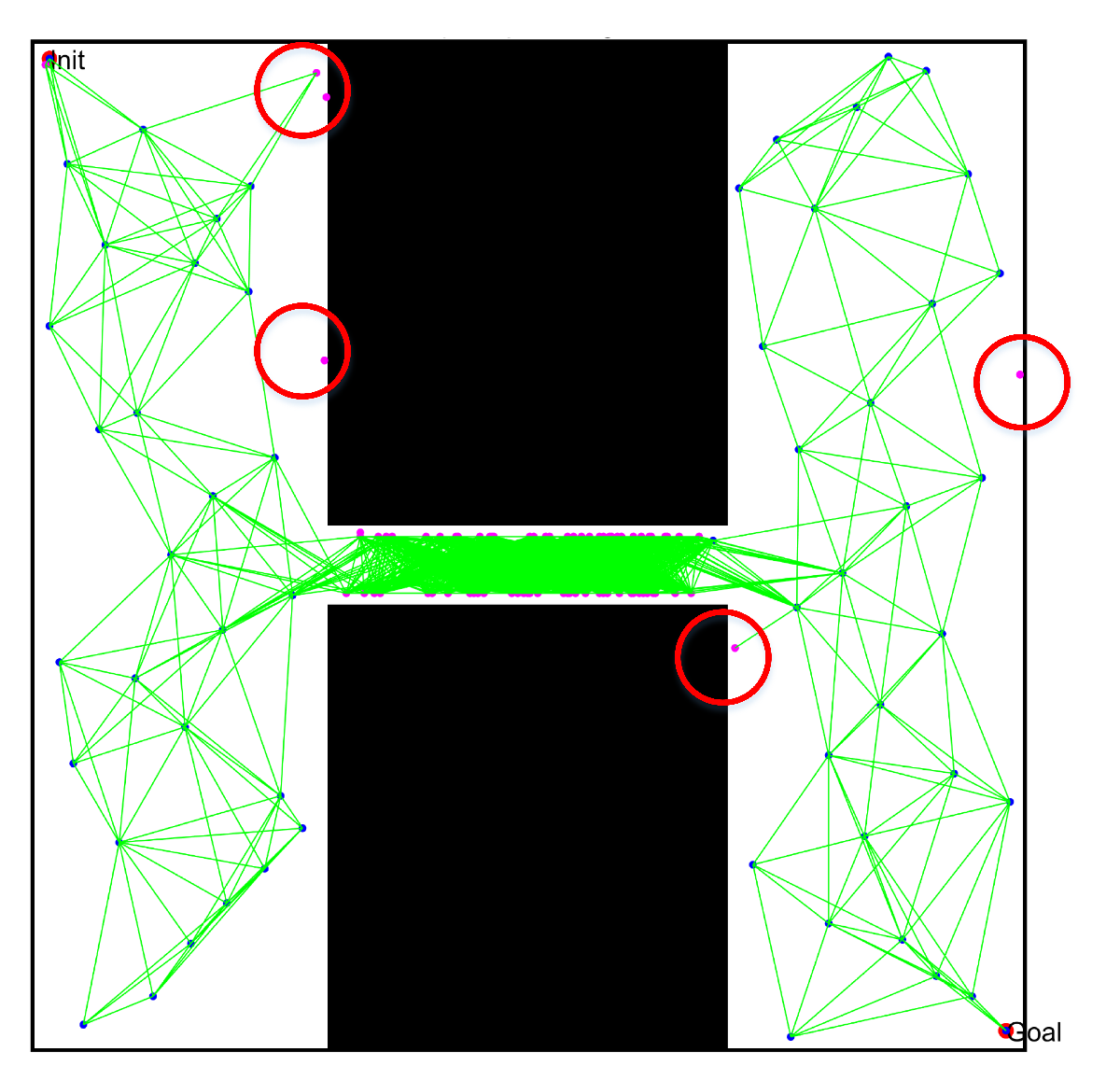

- Comparing the free space construction results in Figure 22(a1–d1) and Figure 23(a1–d1), the optimized sampling technology in this paper directly increased the sampling number in the narrow passages. Meanwhile, the collision-free local path in free space ensured that the shortest distance to obstacles was within the specified range.

- (2)

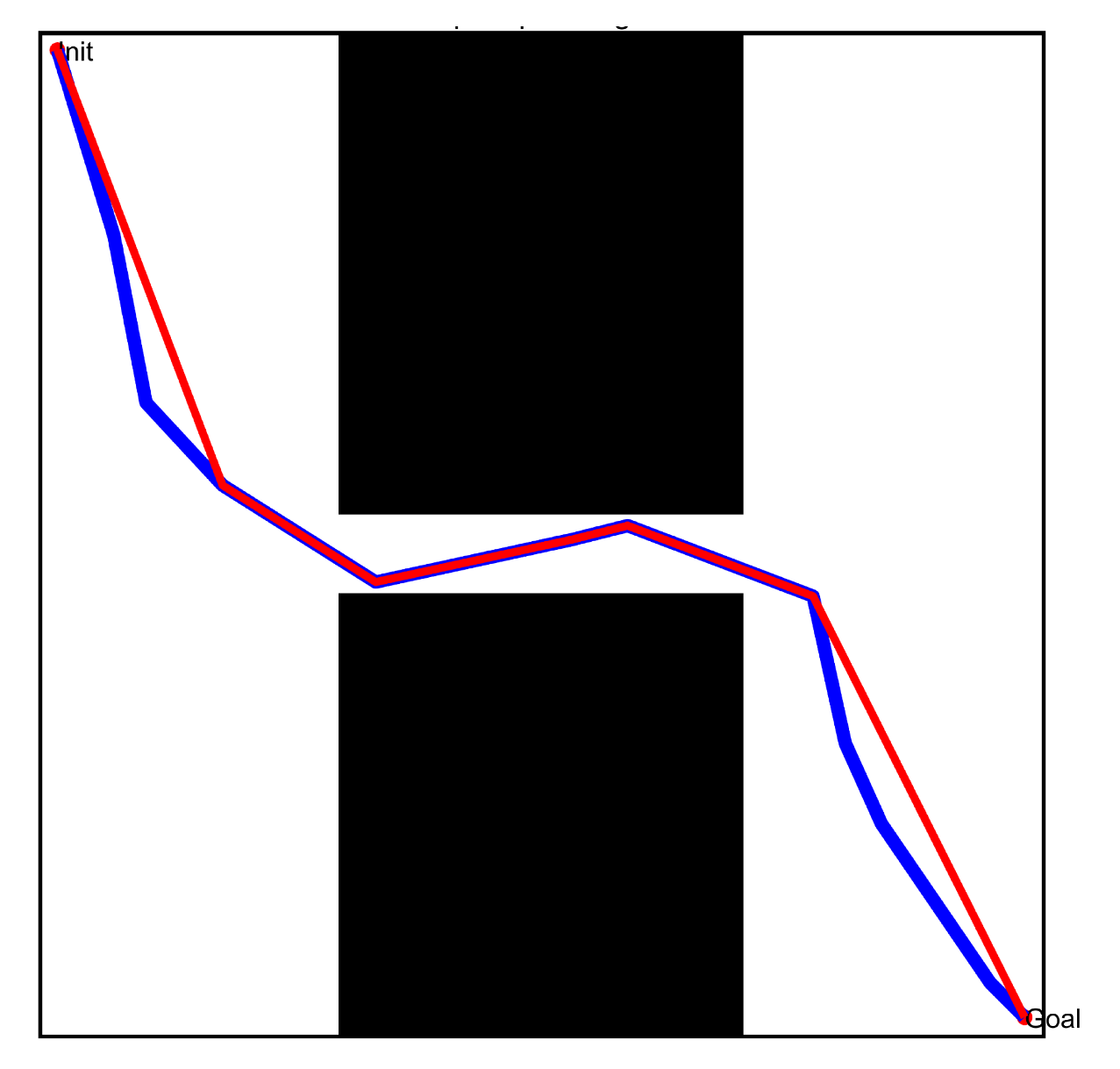

- By comparing the path query results in Figure 22(a3–d3) and Figure 23(a3–d3), the optimized query algorithm proposed in this paper could effectively obtain the initial path, showing no collision with the obstacle space. The distance from the nearest obstacle satisfied the specified distance constraint, ensuring the basic performance of the optimized path.

- (3)

- By comparing the results before and after optimizing the initial path in Figure 22(a3–d3) and Figure 23(a3–d3), the path optimization technology used in this paper could effectively delete redundant points in the initial path, meet the distance limit for the obstacles, shorten the length of the path, and optimize the actual.

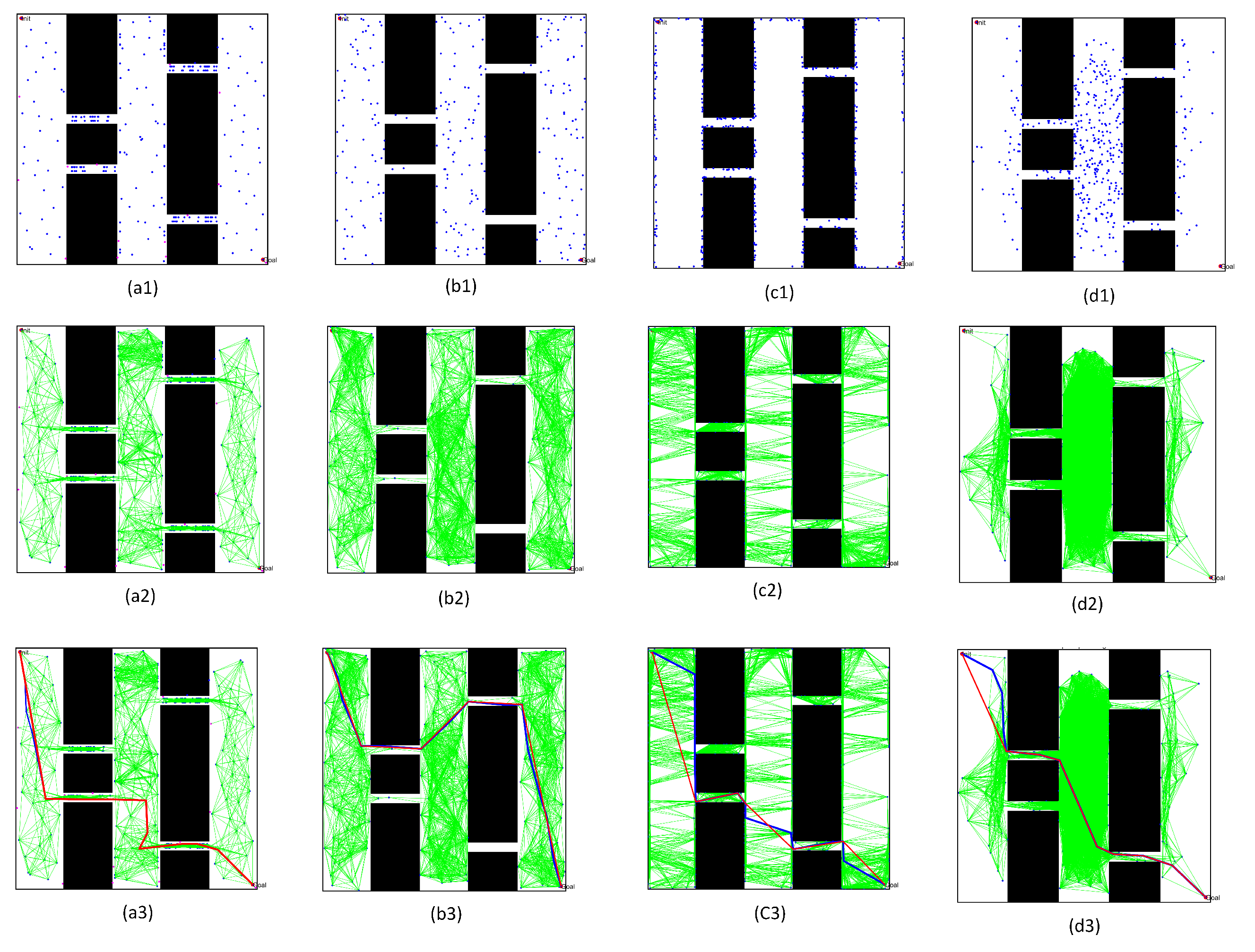

5.2. Multi-Channel Path Planning Problems

- (1)

- By increasing the number of sampling points, the number of free points in the narrow channel increased significantly in these PRM algorithms. However, the free points in the narrow channel could be increased directly by optimizing the obstacle points after obtaining the overall sampling points. Therefore, the optimized PRM algorithm proposed in this paper increased the number more than the other algorithms.

- (2)

- As the number of sampling points increased, the required time for the learning and query processes increased in these PRM algorithms. Nevertheless, the optimized PRM algorithm proposed in this paper could successfully complete path planning with a lower number of sampling points.

- (3)

- By comparing the success rate with similar time for constructing the free space, the solution success rate of the proposed algorithm was higher than that of the other algorithms within a similar time. For example, comparing Task4 with 100 points based on the new algorithm and 300 points based on the other algorithms in Table 3, the success rate of the optimized PRM algorithm reached 100%, while the success rate of the other algorithms was less than 80%.

- (4)

- By comparing the required time for the learning process, the sampling time was higher than for the other PRM algorithms. However, the other PRM algorithms could not effectively solve the path planning problem in a complex environment. For example, by setting the same initial number sampling points as 300 in the various PRM algorithms for solving Task3 and Task4, the corresponding solution success rate of the optimized PRM algorithm reached 100%, while the other PRM algorithms potentially could not solve the problem.

- (5)

- By comparing the required time for the query processes, as shown in Table 4, the required time for the optimized query process was shorter than that of other PRM methods. The optimized query process proposed in this paper can effectively improve the required time for finding the initial path in the narrow channel.

- (1)

- The density of free points obtained by Gaussian sampling was still near the obstacles, but the PRM algorithm based on bridge sampling reduced the density of free points in the narrow channels, due to the existence of wide channels in the environment. Similarly, the optimized PRM algorithm in this paper reduced the number of free points in the narrow channels due to the existence of wide channels. Compared with other methods, the number of free points obtained by the optimized PRM algorithm in the narrow channels was still the largest, as shown in Figure 25(a1) and Figure 26(a1).

- (2)

- (3)

- By comparing the paths obtained by the query process in Figure 25(a3–d3) and Figure 26(a3–d3), there was a great difference between the final path obtained by the optimized PRM algorithm and the final paths obtained by other PRM algorithms, due to the deletion of different redundant points. However, the optimized PRM algorithm effectively ensured the a certain distance from the nearest obstacle boundary was maintained. Therefore, the path optimization technology proposed in this paper can effectively improve the performance of the initial path obtained in the query process.

5.3. Path Planning of Normal Workspace

- (1)

- Comparing the distribution and the density of sampling points in Figure 27(b1,c1), the number of obstacles increased significantly, but the volume of obstacles decreased. Fewer free points could be obtained in the narrow channel by obstacle point optimization technology, leading to significantly reduced sampling probability in the workspace. However, the quasi-random sampling method can guarantee enough sampling points to construct the free space of the normal workspace effectively.

- (2)

- Comparing the actual distribution of the sampling points in Figure 27(a1), the external shape of the obstacle had changed. However, the obstacle point optimization technology could still transform the obstacle points into free points, effectively increasing the number of free points near the boundary of narrow channels. It also effectively increased the number of sampling points in free space. Therefore, the PRM algorithm proposed in this paper can still effectively deal with the path planning problem in normal environments.

- (3)

- Comparing the initial path and the optimized path in Figure 27(a3,c3), the optimized query process proposed in this paper obtained an initial path far from the obstacle space. Meanwhile, the optimized path pruning technology effectively removed the redundant points of the initial path without changing the distance to the obstacle, thus shortening the length of the path.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zafar, M.N.; Mohanta, J.C. Methodology for Path Planning and Optimization of Mobile Robots: A Review. Procedia Comput. Sci. 2018, 133, 141–152. [Google Scholar] [CrossRef]

- Patle, B.K.; Babu, L.G.; Pandey, A.; Parhi, D.R.K.; Jagadeesh, A. A review: On path planning strategies for navigation of mobile robot. Def. Technol. 2019, 15, 582–606. [Google Scholar] [CrossRef]

- Mohanta, J.C.; Keshari, A. A knowledge based fuzzy-probabilistic roadmap method for mobile robot navigation. Appl. Soft Comput. J. 2019, 79, 391–409. [Google Scholar] [CrossRef]

- Savkin, A.V.; Hoy, M. Reactive and the shortest path navigation of a wheeled mobile robot in cluttered environments. Robotica 2012, 31, 323–330. [Google Scholar] [CrossRef]

- Yang, L.; Qi, J.; Song, D.; Xiao, J.; Han, J.; Xia, Y. Survey of Robot 3D Path Planning Algorithms. J. Control Sci. Eng. 2016, 2016, 7426913. [Google Scholar] [CrossRef] [Green Version]

- Hoy, M.; Matveev, A.S.; Savkin, A.V. Algorithms for collision-free navigation of mobile robots in complex cluttered environments: A survey. Robotica 2015, 33, 463–497. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Seo, Y. Mobile robot path planning with surrounding point set and path improvement. Appl. Soft Comput. J. 2017, 57, 35–47. [Google Scholar] [CrossRef]

- Low, E.S.; Ong, P.; Cheah, K.C. Solving the optimal path planning of a mobile robot using improved Q-learning. Robot. Auton. Syst. 2019, 115, 143–161. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Liu, S.; Wang, J.; Wang, Y.; Shangguan, D. Path planning of scenic spots based on improved A* algorithm. Sci. Rep. 2022, 12, 1320. [Google Scholar] [CrossRef]

- Guruji, A.K.; Agarwal, H.; Parsediya, D.K. Time-efficient A* Algorithm for Robot Path Planning. Procedia Technol. 2016, 23, 144–149. [Google Scholar] [CrossRef]

- Raheem, F.A.; Hameed, U.I. Interactive Heuristic D* Path Planning Solution Based on PSO for Two-Link Robotic Arm in Dynamic Environment. World J. Eng. Technol. 2019, 7, 80–99. [Google Scholar] [CrossRef] [Green Version]

- Sun, S.; Yin, G.; Li, X. Path planning for mobile robot using the novel repulsive force algorithm. IOP Conf. Ser. Earth Environ. Sci. 2018, 108, 575–578. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Chang, L. A new adaptive artificial potential field and rolling window method for mobile robot path planning. In Proceedings of the 29th Chinese Control and Decision Conference, CCDC 2017, Chongqing, China, 28–30 May 2017; pp. 7144–7148. [Google Scholar] [CrossRef]

- Contreras-Cruz, M.A.; Ayala-Ramirez, V.; Hernandez-Belmonte, U.H. Mobile robot path planning using artificial bee colony and evolutionary programming. Appl. Soft Comput. 2015, 30, 319–328. [Google Scholar] [CrossRef]

- Santiago, R.M.C.; De Ocampo, A.L.; Ubando, A.T.; Bandala, A.A.; Dadios, E.P. Path planning for mobile robots using genetic algorithm and probabilistic roadmap. In Proceedings of the HNICEM 2017—9th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management, Manila, Philippines, 1–3 December 2017. [Google Scholar] [CrossRef]

- Lv, Q.; Yang, D. Multi-target path planning for mobile robot based on improved PSO algorithm. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference, ITOEC 2020, Itoec, Chongqing, China, 12–14 June 2020; pp. 1042–1047. [Google Scholar] [CrossRef]

- Miao, C.; Chen, G.; Yan, C.; Wu, Y. Path planning optimization of indoor mobile robot based on adaptive ant colony algorithm. Comput. Ind. Eng. 2021, 156, 107230. [Google Scholar] [CrossRef]

- Liu, Z.X.; Wang, Q.; Yang, B. Reinforcement Learning-Based Path Planning Algorithm for Mobile Robots. Wirel. Commun. Mob. Comput. 2022, 5, 19. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, Z.; Dong, P. Dynamic Path Planning of Unknown Environment Based on Deep Reinforcement Learning. J. Robot. 2018, 2018, 5781591. [Google Scholar] [CrossRef]

- Hsu, D.; Latombe, J.C.; Kurniawati, H. On the probabilistic foundations of probabilistic roadmap planning. Int. J. Robot. Res. 2006, 25, 627–643. [Google Scholar] [CrossRef]

- Tahir, Z.; Qureshi, A.H.; Ayaz, Y.; Nawaz, R. Potentially guided bidirectionalized RRT* for fast optimal path planning in cluttered environments. Robot. Auton. Syst. 2018, 108, 13–27. [Google Scholar] [CrossRef] [Green Version]

- Karaman, S.; Frazzoli, E. Sampling-based algorithms for optimal motion planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef] [Green Version]

- Elbanhawi, M.; Simic, M. Sampling-based robot motion planning: A review. IEEE Access 2014, 2, 56–77. [Google Scholar] [CrossRef]

- Kavraki, L.E.; Kolountzakis, M.N.; Latombe, J.C. Analysis of probabilistic roadmaps for path planning. IEEE Trans. Robot. Autom. 1998, 14, 166–171. [Google Scholar] [CrossRef] [Green Version]

- Geraerts, R.; Overmars, M.H. Sampling and node adding in probabilistic roadmap planners. Robot. Auton. Syst. 2006, 54, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Geraerts, R.; Overmars, M.H. Reachability-based analysis for Probabilistic Roadmap planners. Robot. Auton. Syst. 2007, 55, 824–836. [Google Scholar] [CrossRef] [Green Version]

- Cao, K.; Cheng, Q.; Gao, S.; Chen, Y.; Chen, C. Improved PRM for Path Planning in Narrow Passages. In Proceedings of the 2019 IEEE International Conference on Mechatronics and Automation, ICMA 2019, Tianjin, China, 4–7 August 2019; pp. 45–50. [Google Scholar] [CrossRef]

- Kannan, A.; Gupta, P.; Tiwari, R.; Prasad, S.; Khatri, A.; Kala, R. Robot motion planning using adaptive hybrid sampling in probabilistic roadmaps. Electronics 2016, 5, 16. [Google Scholar] [CrossRef]

- Branicky, M.S.; LaValle, S.M.; Olson, K.; Yang, L. Quasi-randomized path planning. In Proceedings of the IEEE International Conference on Robotics and Automation, Seoul, Republic of Korea, 21–26 May 2001; Volume 2, pp. 1481–1487. [Google Scholar] [CrossRef]

- Shukla, S.; Kumar, L.; Bera, T.; Dasgupta, R. A Levy Flight based Narrow Passage Sampling Method for Probabilistic Roadmap Planners. arXiv 2021, arXiv:2107.00817. [Google Scholar]

- Boor, V.; Overmars, M.H.; van der Stappen, A.F. Gaussian sampling strategy for probabilistic roadmap planners. In Proceedings of the IEEE International Conference on Robotics and Automation, Detroit, MI, USA, 10–15 May 1999; Volume 2, pp. 1018–1023. [Google Scholar] [CrossRef]

- Hsu, D.; Jiang, T.; Reif, J.; Sun, Z. The bridge test for sampling narrow passages with probabilistic roadmap planners. In Proceedings of the IEEE International Conference on Robotics and Automation, Taipei, Taiwan, 14–19 September 2003; Volume 3, pp. 4420–4426. [Google Scholar] [CrossRef]

- Sun, Z.; Hsu, D.; Jiang, T.; Kurniawati, H.; Reif, J.H. Narrow passage sampling for probabilistic roadmap planning. IEEE Trans. Robot. 2005, 21, 1105–1115. [Google Scholar] [CrossRef] [Green Version]

- Ye, L.; Chen, J.; Zhou, Y. Real-Time Path Planning for Robot Using OP-PRM in Complex Dynamic Environment. Front. Neurorobot. 2022, 16, 1–13. [Google Scholar] [CrossRef]

- Sanchez, A.; Arenas, J.A.; Zapata, R. Non-holonomic path planning using a quasi-random PRM approach. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–5 October 2002; IEEE: Piscataway, NJ, USA, 2002; Volume 3, pp. 2305–2310. [Google Scholar] [CrossRef]

| Map | Ns 1 | Method 2 | Nf 3 | Nc 4 | Ts 5 | Pf 6 | TL 7 | Suc 8 |

|---|---|---|---|---|---|---|---|---|

| 1 | 100 | Random | 62.9000 | 2.7500 | 0.0829 | 4.37% | 0.0490 | 25% |

| Gaussian | 102 | 18.050 | 0.0934 | 17.6% | 0.0661 | 5% | ||

| Bridge | 102 | 33.400 | 0.0854 | 32.7% | 0.3039 | 0% | ||

| Paper | 136.8 | 70.700 | 0.2825 | 51.6% | 0.6258 | 100% | ||

| 200 | Random | 123.8 | 6.3500 | 0.1324 | 5.13% | 0.1569 | 50% | |

| Gaussian | 202 | 34.7500 | 0.1655 | 17.2% | 0.2192 | 55% | ||

| Bridge | 202 | 67.2000 | 0.1341 | 33.2% | 0.3223 | 35% | ||

| Paper | 270.7 | 139.650 | 0.5442 | 51.5% | 2.4632 | 100% | ||

| 300 | Random | 186.2 | 9.1000 | 0.1955 | 4.8% | 0.3189 | 95% | |

| Gaussian | 302 | 52.6500 | 0.2078 | 17.4% | 0.4571 | 80% | ||

| Bridge | 302 | 99.1000 | 0.1975 | 32.8% | 0.3321 | 45% | ||

| Paper | 408.2 | 214.900 | 0.8185 | 52.6% | 2.7158 | 100% | ||

| 2 | 100 | Random | 65.0500 | 3.5500 | 0.0684 | 5.45% | 0.0516 | 0% |

| Gaussian | 102 | 27.2500 | 0.0799 | 26.7% | 0.0609 | 0% | ||

| Bridge | 102 | 32.0500 | 0.0694 | 31.4% | 0.3407 | 15% | ||

| Paper | 136.7 | 70.5500 | 0.2835 | 51.6% | 0.2629 | 100% | ||

| 200 | Random | 128.4 | 7.4500 | 0.1324 | 5.79% | 0.1585 | 0% | |

| Gaussian | 202 | 54.9000 | 0.1442 | 27.2% | 0.2002 | 25% | ||

| Bridge | 202 | 67.2500 | 0.1328 | 33.2% | 0.3337 | 30% | ||

| Paper | 272.3 | 140.400 | 0.5840 | 51.5% | 0.9884 | 100% | ||

| 300 | Random | 186.6 | 12.7000 | 0.2002 | 6.81% | 0.3197 | 30% | |

| Gaussian | 302 | 84.6500 | 0.2073 | 28.02% | 0.4124 | 55% | ||

| Bridge | 302 | 100.550 | 0.1961 | 33.2% | 0.3379 | 35% | ||

| Paper | 412.1 | 216.650 | 0.8806 | 52.5% | 2.3390 | 100% |

| Map | Ns 1 | TQ1 2 | TQ2 3 | Map | Ns 1 | TQ1 2 | TQ2 3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | ||||

| 1 | 100 | 0.1435 | 0.1114 | 0.1257 | 0.0365 | 0.0241 | 0.0285 | 2 | 100 | 0.0766 | 0.0495 | 0.0582 | 0.0198 | 0.0036 | 0.0103 |

| 200 | 0.3417 | 0.2621 | 0.2927 | 0.1131 | 0.0995 | 0.1056 | 200 | 0.2059 | 0.1593 | 0.1818 | 0.0426 | 0.0339 | 0.0371 | ||

| 300 | 0.6049 | 0.4956 | 0.5576 | 0.3008 | 0.2530 | 0.2735 | 300 | 0.4000 | 0.3017 | 0.3380 | 0.0928 | 0.0788 | 0.0860 | ||

| Map | Ns 1 | Method 2 | Nf 3 | Nc 4 | Ts 5 | Pf 6 | TL 7 | Suc 8 |

|---|---|---|---|---|---|---|---|---|

| 3 | 100 | Random | 61.4000 | 0.8500 | 0.0730 | 1.38% | 0.0436 | 0% |

| Gaussian | 102 | 14.350 | 0.0868 | 14.1% | 0.0589 | 0% | ||

| Bridge | 102 | 5.1000 | 0.0736 | 5.00% | 0.0392 | 0% | ||

| Paper | 139 | 39.350 | 0.2680 | 28.3% | 0.2148 | 25% | ||

| 200 | Random | 121.45 | 2.7000 | 0.1358 | 2.22% | 0.1292 | 0% | |

| Gaussian | 202 | 28.100 | 0.1460 | 13.9% | 0.1847 | 5% | ||

| Bridge | 202 | 9.5500 | 0.1355 | 4.73% | 0.0406 | 5% | ||

| Paper | 276 | 73.900 | 0.5218 | 26.7% | 0.8879 | 90% | ||

| 300 | Random | 183.8 | 5.8000 | 0.2085 | 3.15% | 0.2625 | 0% | |

| Gaussian | 302 | 48.950 | 0.2072 | 16.2% | 0.3872 | 30% | ||

| Bridge | 302 | 13 | 0.1999 | 4.30% | 0.0475 | 15% | ||

| Paper | 413 | 103.050 | 0.8010 | 25.0% | 1.9799 | 100% | ||

| 4 | 1 | Random | 61 | 2.2000 | 0.0748 | 3.61% | 0.0485 | 10% |

| Gaussian | 102 | 21.200 | 0.0881 | 20.7% | 0.0585 | 0% | ||

| Bridge | 102 | 7.1000 | 0.0746 | 6.96% | 0.0588 | 0% | ||

| Paper | 135 | 62.850 | 0.2333 | 46.5% | 0.2289 | 100% | ||

| 200 | Random | 125 | 5 | 0.1377 | 4.00% | 0.1324 | 40% | |

| Gaussian | 202 | 41.3500 | 0.1557 | 20.5% | 0.1806 | 10% | ||

| Bridge | 202 | 14.3000 | 0.1372 | 7.08% | 0.0691 | 25% | ||

| Paper | 274 | 122.200 | 0.4615 | 44.6% | 0.8141 | 100% | ||

| 300 | Random | 185 | 8.6000 | 0.2010 | 4.64% | 0.2777 | 75% | |

| Gaussian | 302 | 64.5500 | 0.2302 | 21.4% | 0.3694 | 45% | ||

| Bridge | 302 | 24 | 0.2027 | 7.95% | 0.0791 | 65% | ||

| Paper | 413 | 192 | 0.6893 | 46.5% | 1.8628 | 100% |

| Map | Ns 1 | TQ1 2 | TQ2 3 | Map | Ns 1 | TQ1 2 | TQ2 3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | Max | Min | Mean | ||||

| 3 | 100 | 0.0647 | 0.0074 | 0.0330 | 0.02284 | 0.0008 | 0.0050 | 4 | 100 | 0.0530 | 0.0410 | 0.0472 | 0.0208 | 0.0081 | 0.0098 |

| 200 | 0.2708 | 0.0261 | 0.2179 | 0.03967 | 0.0048 | 0.0286 | 200 | 0.2110 | 0.1280 | 0.1900 | 0.0413 | 0.0331 | 0.0358 | ||

| 300 | 0.5700 | 0.4416 | 0.4933 | 0.07858 | 0.0106 | 0.0714 | 300 | 0.2941 | 0.2548 | 0.2783 | 0.0735 | 0.0648 | 0.0690 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, L.; Luo, X.; Luo, Q. An Optimized Probabilistic Roadmap Algorithm for Path Planning of Mobile Robots in Complex Environments with Narrow Channels. Sensors 2022, 22, 8983. https://doi.org/10.3390/s22228983

Qiao L, Luo X, Luo Q. An Optimized Probabilistic Roadmap Algorithm for Path Planning of Mobile Robots in Complex Environments with Narrow Channels. Sensors. 2022; 22(22):8983. https://doi.org/10.3390/s22228983

Chicago/Turabian StyleQiao, Lijun, Xiao Luo, and Qingsheng Luo. 2022. "An Optimized Probabilistic Roadmap Algorithm for Path Planning of Mobile Robots in Complex Environments with Narrow Channels" Sensors 22, no. 22: 8983. https://doi.org/10.3390/s22228983

APA StyleQiao, L., Luo, X., & Luo, Q. (2022). An Optimized Probabilistic Roadmap Algorithm for Path Planning of Mobile Robots in Complex Environments with Narrow Channels. Sensors, 22(22), 8983. https://doi.org/10.3390/s22228983