Enhanced Robustness of a Bridge-Type Rf-Mems Switch for Enabling Applications in 5G and 6G Communications

Abstract

:1. Introduction

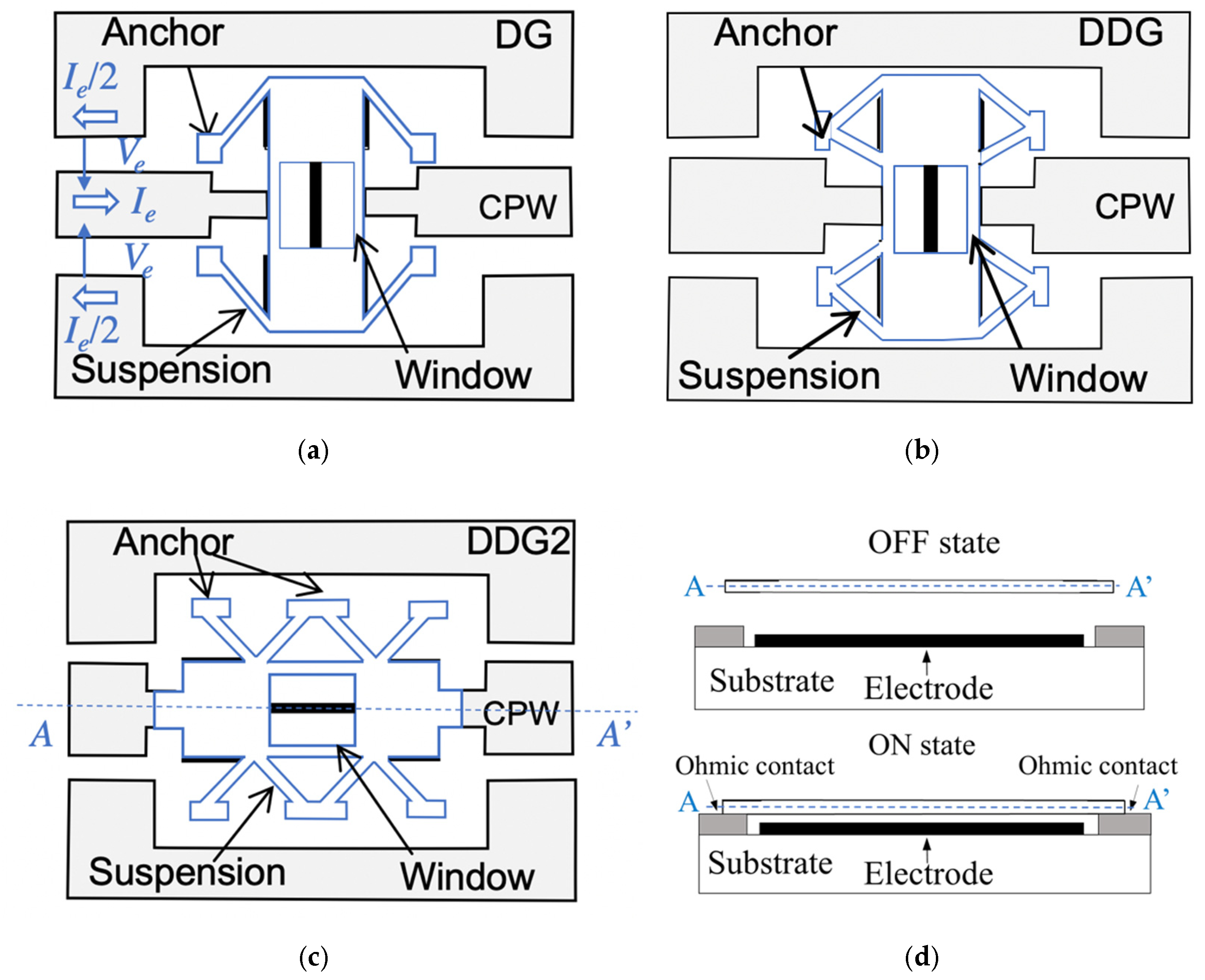

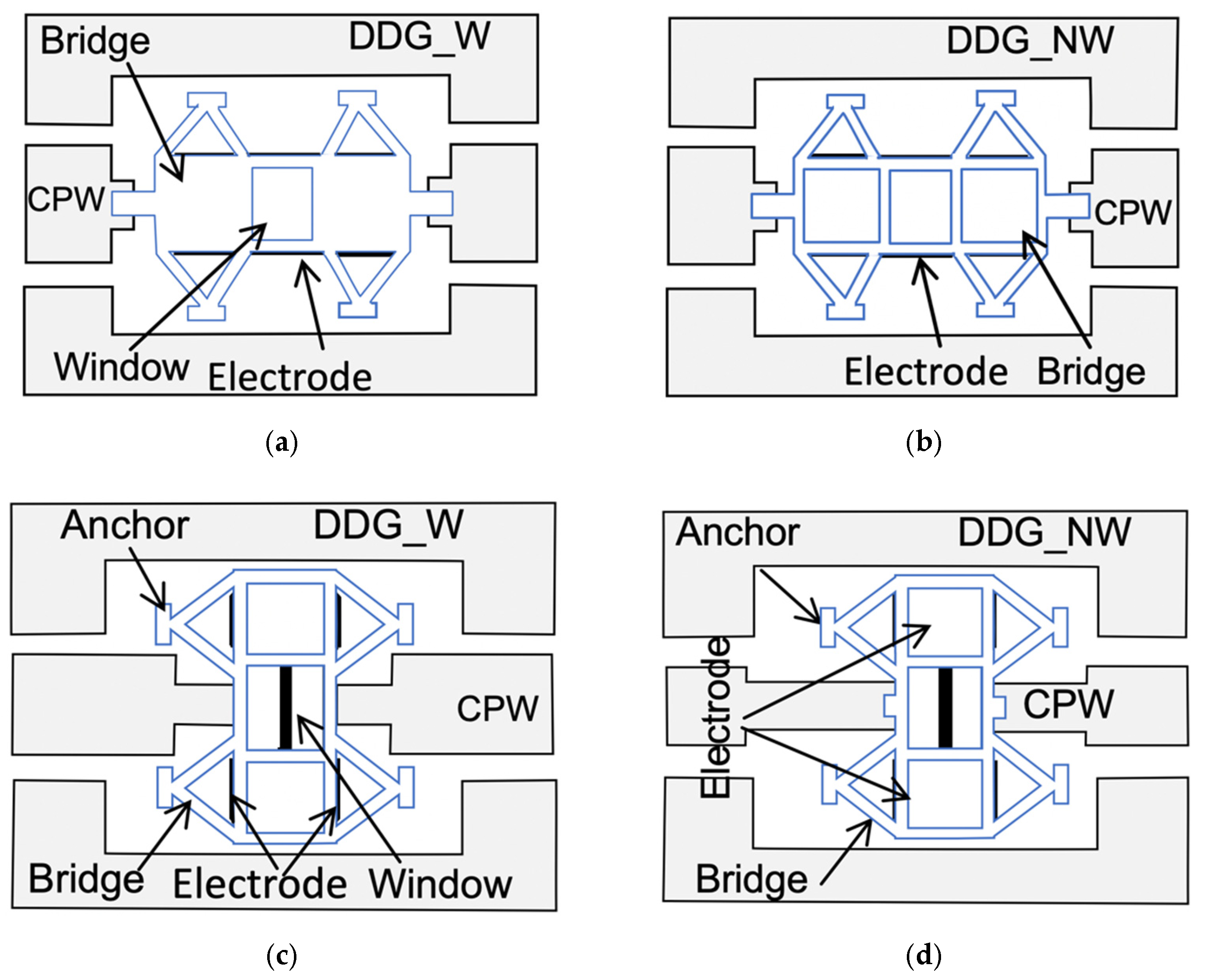

2. RF-MEMS Switches for Controlling the CPW Even Mode

3. Materials and Methods

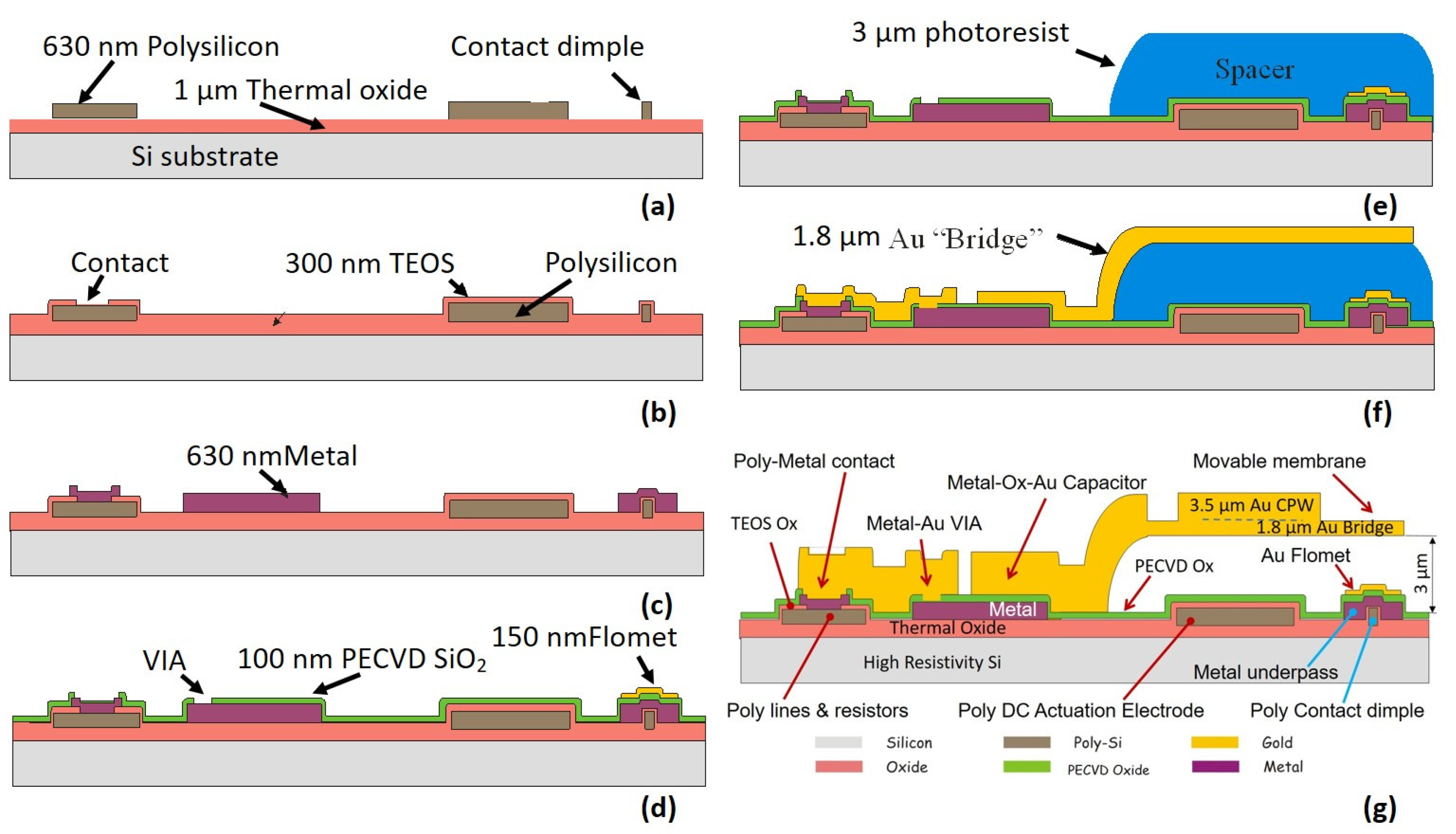

3.1. Fabrication Process

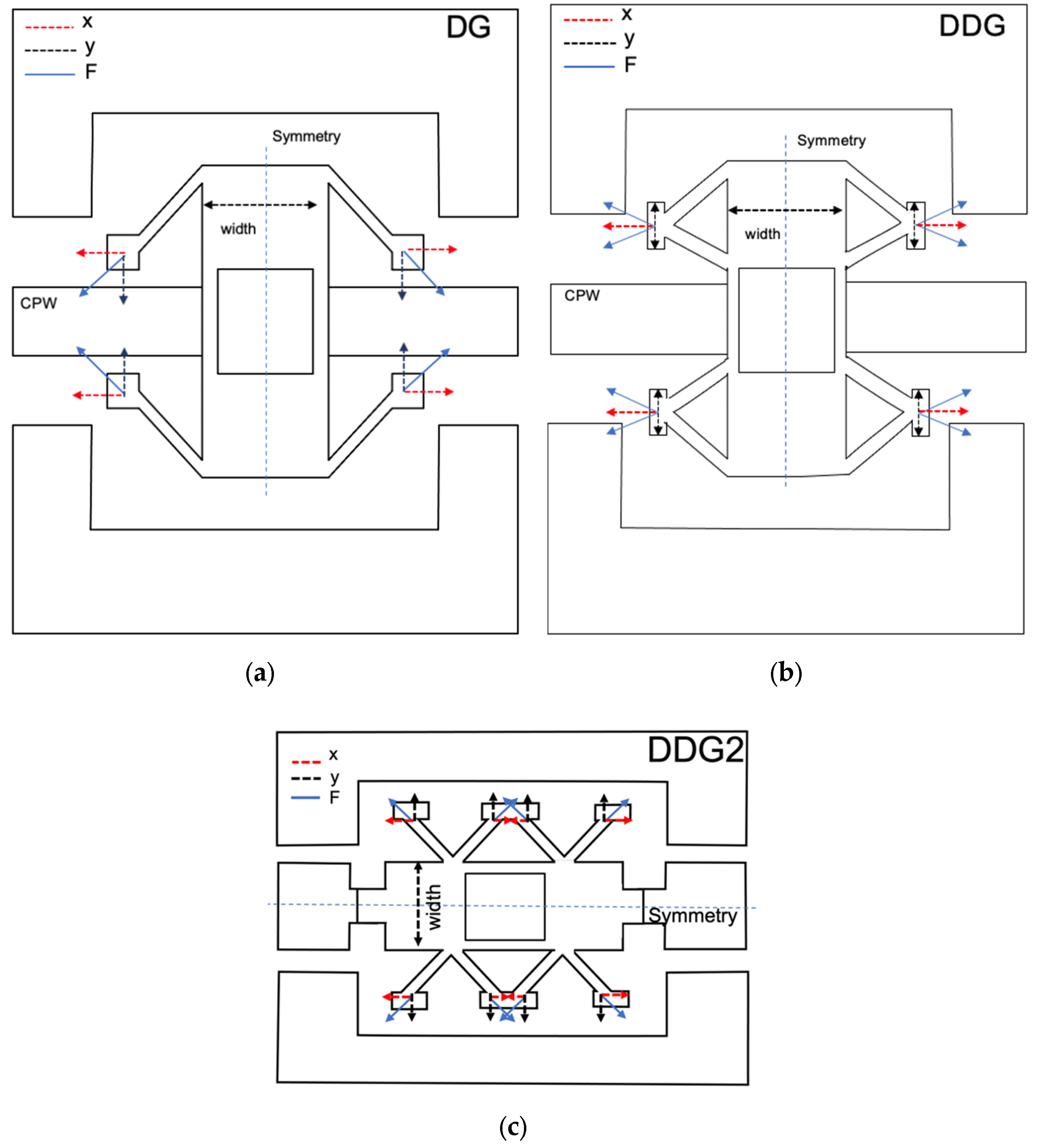

3.2. Mechanical Simulations

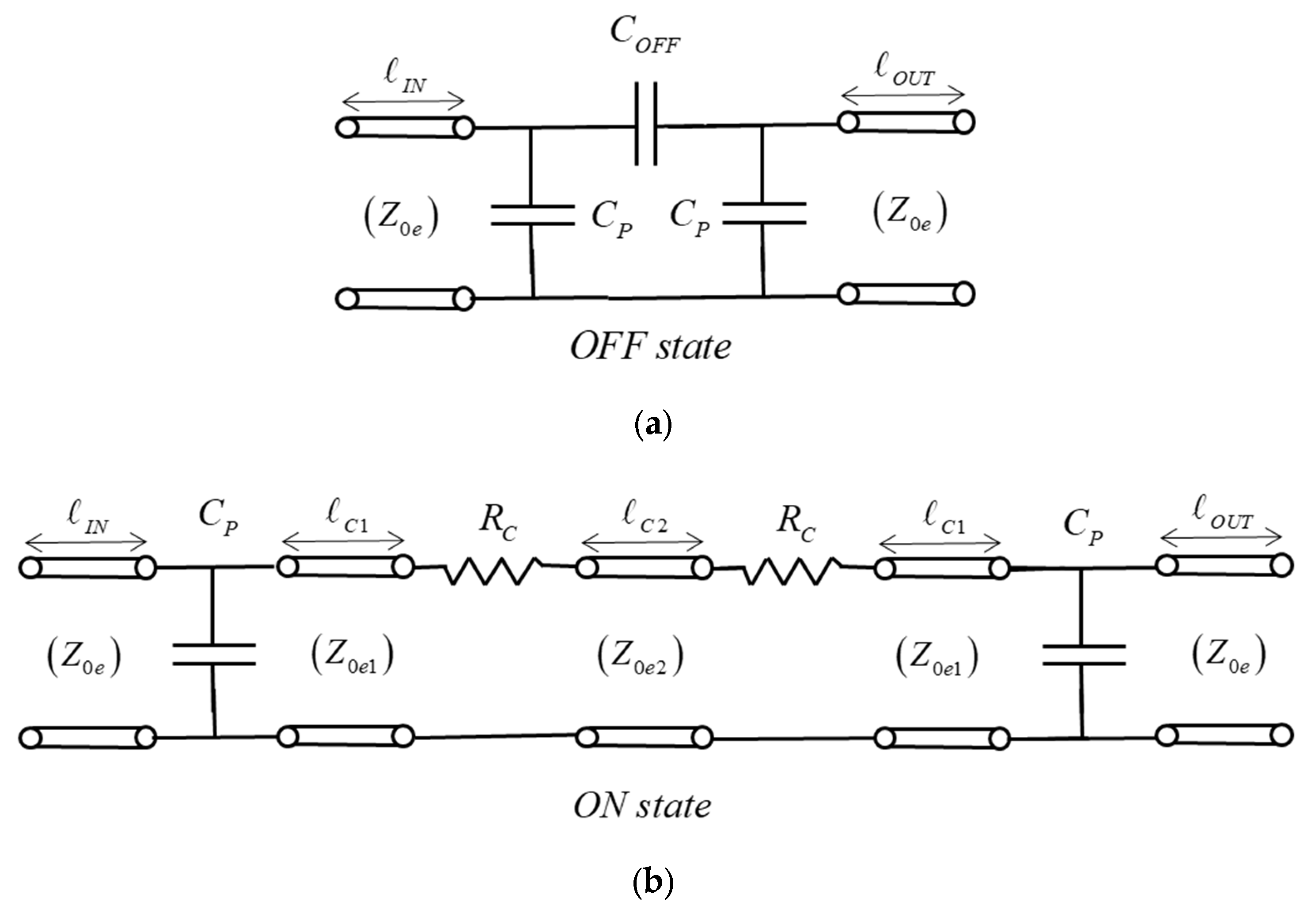

3.3. Switch RF-Design and Simulations

4. Experimental Results and Discussion

4.1. RF and Electrical Switch Characterization Methodology

4.2. Numerical Results of Mechanical Simulation and Comparison to Experimental Results

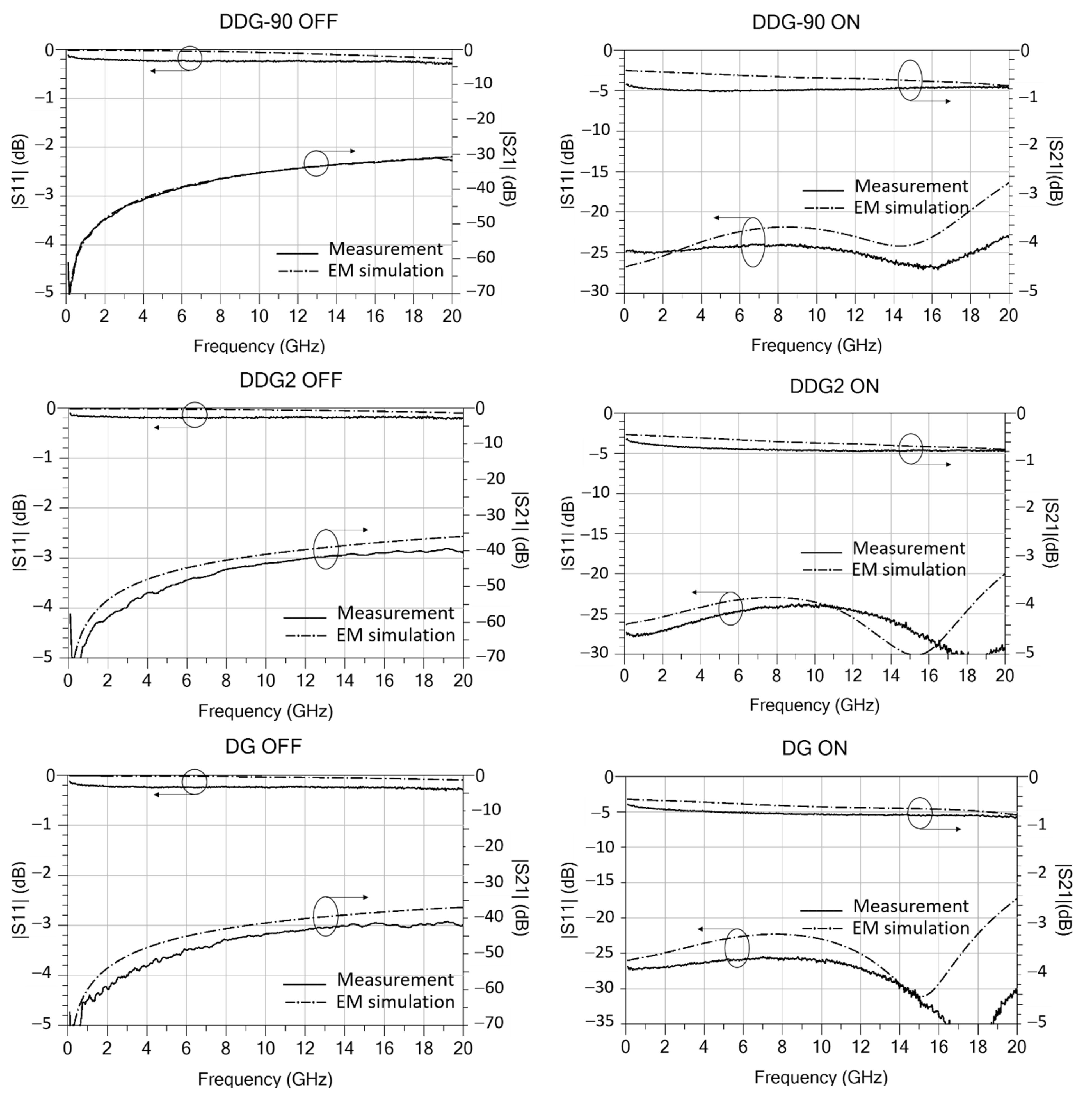

4.3. RF Experimental Results and Comparison to Results of EM Simulation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iannacci, J.; Poor, H.V. Review and Perspectives of Micro/Nano Technologies as Key-Enablers of 6G. IEEE Access 2022, 10, 55428–55458. [Google Scholar] [CrossRef]

- Guo, F.; Yu, F.R.; Zhang, H.; Li, X.; Ji, H.; Leung, V.C.M. Enabling massive IoT toward 6G: A comprehensive survey. IEEE Internet Things J. 2021, 8, 11891–11915. [Google Scholar] [CrossRef]

- Nguyen, D.C.; Ding, M.; Pathirana, P.N.; Seneviratne, A.; Li, J.; Niyato, D.; Dobre, O.; Poor, H.V. 6G Internet of Things: A comprehensive survey. IEEE Internet Things J. 2022, 9, 359–383. [Google Scholar] [CrossRef]

- Cao, T.; Hu, T.; Zhao, Y. Research Status and Development Trend of MEMS Switches: A Review. Micromachines 2020, 11, 694. [Google Scholar] [CrossRef] [PubMed]

- Bansal, D.; Bajpai, A.; Kumar, P.; Kaur, M.; Kumar, A. Effect of Stress on Pull-in Voltage of RF MEMS SPDT Switch. IEEE Trans. Electron Devices 2020, 67, 2147–2152. [Google Scholar] [CrossRef]

- Bansal, D.; Bajpai, A.; Mehta, K.; Kumar, P.; Kumar, A. Improved Design of Ohmic RF MEMS Switch for Reduced Fabrication Steps. IEEE Trans. Electron Devices 2019, 66, 4361–4366. [Google Scholar] [CrossRef]

- Le, T.-V.; Lu, C.-F.; Hsu, C.-L.; Do, T.K.; Chou, Y.-F.; Wei, W.-C. A novel three-factor authentication protocol for multiple service providers in 6G-aided intelligent healthcare systems. IEEE Access 2022, 10, 28975–28990. [Google Scholar] [CrossRef]

- Mucchi, L.; Jayousi, S.; Caputo, S.; Paoletti, E.; Zoppi, P.; Geli, S.; Dioniso, P. How 6G technology can change the future wireless healthcare. In Proceedings of the 2nd 6G Wireless Summit (6G SUMMIT), Levi, Finland, 17–20 March 2020. [Google Scholar]

- Liu, Y.-C.; Lin, M.-H.; Chang, C.-C. A V-Band Nine-State CMOS-MEMS Phase Shifter MMIC. In Proceedings of the 2022 IEEE 22nd Topical Meeting on Silicon Monolithic Integrated Circuits in RF Systems (SiRF), Las Vegas, NV, USA, 16–19 January 2022. [Google Scholar]

- Rahiminejad, S.; Alonso-delPino, M.; Reck, T.J.; Peralta, A.; Lin, R.; Jung-Kubiak, C.; Chattopadhyay, G. A Low-Loss Silicon MEMS Phase Shifter Operating in the 550-GHz Band. IEEE Trans. Terahertz Sci. Technol. 2021, 11, 477–485. [Google Scholar] [CrossRef]

- Chieh, J.-C.S.; Sharma, S.K. (Eds.) Liquid Metal, Piezoelectric, and RF MEMS-Based Reconfigurable Antennas. In Multifunctional Antennas and Arrays for Wireless Communication Systems; Wiley-IEEE Press: Hoboken, NJ, USA, 2021; pp. 172–197. ISBN 978-1-119-53505-8. [Google Scholar]

- Ge, J.; Wang, G. CmWave to MmWave Reconfigurable Antenna for 5G Applications. In Proceedings of the 2020 IEEE International Symposium on Antennas and Propagation and North American Radio Science Meeting, Toronto, ON, Canada, 5–10 July 2020; pp. 619–620. [Google Scholar]

- Gao, A.; Liu, K.; Liang, J.; Wu, T. AlN MEMS filters with extremely high bandwidth widening capability. Microsyst. Nanoeng. 2020, 6, 74. [Google Scholar] [CrossRef] [PubMed]

- Contreras, A.; Casals-Terré, J.; Pradell, L.; Giacomozzi, F.; Iannacci, J.; Ribó, M. A Ku-band RF-MEMS frequency-reconfigurable multimodal bandpass filter. Int. J. Microw. Wirel. Technol. 2014, 6, 277–285. [Google Scholar] [CrossRef]

- Contreras, A.; Ribó, M.; Pradell, L.; Casals-Terré, J.; Giacomozzi, F.; Iannacci, J. K-band RF-MEMS uniplanar reconfigurable-bandwidth bandpass filter using multimodal immittance inverters. Electron. Lett. 2013, 49, 704–706. [Google Scholar] [CrossRef]

- Heredia, J.; Ribó, M.; Pradell, L.; Wipf, S.T.; Göritz, A.; Wietstruck, M.; Wipf, C.; Kaynak, M. A 125–143-GHz Frequency-Reconfigurable BiCMOS Compact LNA Using a Single RF-MEMS Switch. IEEE Microw. Wirel. Compon. Lett. 2019, 29, 339–341. [Google Scholar] [CrossRef]

- Singh, T.; Mansour, R.R. Modeling of Frequency Shift in RF-MEMS Switches Under Residual Stress Gradient. In Proceedings of the 2018 18th International Symposium on Antenna Technology and Applied Electromagnetics (ANTEM), Waterloo, ON, Canada, 19–22 August 2018; pp. 1–2. [Google Scholar]

- Zhang, Y.; Sun, J.; Liu, H.; Liu, Z. Modeling and Measurement of Thermal–Mechanical-Stress-Creep Effect for RF MEMS Switch Up to 200 °C. Micromachines 2022, 13, 166. [Google Scholar] [CrossRef]

- Iannacci, J. RF-MEMS technology as an enabler of 5G: Low-loss ohmic switch tested up to 110 GHz. Sens. Actuators A Phys. 2018, 279, 624–629. [Google Scholar] [CrossRef]

- Iannacci, J.; Tagliapietra, G.; Bucciarelli, A. Exploitation of response surface method for the optimization of RF-MEMS reconfigurable devices in view of future beyond-5G, 6G and super-IoT applications. Sci. Rep. 2022, 12, 3543. [Google Scholar] [CrossRef]

- Ke, F.; Miao, J.; Oberhammer, J. A ruthenium-based multimetalcontact RF MEMS switch with a corrugated diaphragm. J. Microelectromech. Syst. 2008, 17, 1447–1459. [Google Scholar]

- Patel, C.D.; Rebeiz, G.M. A High-Reliability High-Linearity High-Power RF MEMS Metal-Contact Switch for DC–40-GHz Applications. IEEE Trans. Microw. Theory Tech. 2012, 60, 3096–3112. [Google Scholar] [CrossRef]

- Wipf, S.T.; Göritz, A.; Wietstruck, M.; Wipf, C.; Tillack, B.; Kaynak, M. D–band RF–MEMS SPDT switch in a 0.13 µm SiGe BiCMOS technology. IEEE Microw. Wireless Compon. Lett. 2016, 26, 1002–1004. [Google Scholar] [CrossRef]

- Contreras, A.; Casals-Terré, J.; Pradell, L.; Ribó, M.; Heredia, J.; Giacomozzi, F.; Margesin, B. RF-MEMS switches for a full control of the propagating modes in uniplanar microwave circuits and their application to reconfigurable multimodal microwave filters. Microsyst. Technol. 2017, 23, 5959–5975. [Google Scholar] [CrossRef] [Green Version]

- Iannacci, J.; Resta, G.; Bagolini, A.; Giacomozzi, F.; Bochkova, E.; Savin, E.; Kirtaev, R.; Tsarkov, A.; Donelli, M. RF-MEMS Monolithic K and Ka Band Multi-State Phase Shifters as Building Blocks for 5G and Internet of Things (IoT) Applications. Sensors 2020, 20, 2612. [Google Scholar] [CrossRef]

- Tkachenko, A.; Lysenko, I.; Kovalev, A. RF MEMS switch with double-clamp and wafer level package with through silicon vias for integration RF MEMS in applications 5G and internet of things. In Proceedings of the SPIE 12157, International Conference on Micro- and Nano-Electronics 2021, Zvenigorod, Russia, 30 January 2022; pp. 121570H-1–121570H-12. [Google Scholar]

- Giacomozzi, F.; Mulloni, V.; Colpo, S.; Iannacci, J.; Margesin, B.; Faes, A. A flexible fabrication process for RF MEMS devices. Rom. J. Inform. Sci. Technol. 2011, 14, 259–268. [Google Scholar]

- Marcelli, R.; Capoccia, G.; Sardi, G.M.; Bartolucci, G.; Margesin, B.; Iannacci, J.; Tagliapietra, G.; Giacomozzi, F.; Proietti, E. Metamaterials based RF microsystems for telecommunication applications. Ceram. Int. 2022. [Google Scholar] [CrossRef]

- Margesin, B.; Bagolini, A.; Guarnieri, V.; Giacomozzi, F.; Faes, A.; Pal, R.; Decarli, M. Stress characterization of electroplated gold layers for low temperature surface micromachining. In Proceedings of the Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS 2003, Cannes, France, 7 May 2003; pp. 402–405. [Google Scholar] [CrossRef]

- Mulloni, V.; Giacomozzi, F.; Margesin, B. Controlling stress and stress gradient during the release process in gold suspended micro-structures. Sens. Actuators A Phys. 2010, 162, 93–99. [Google Scholar] [CrossRef]

- Giacomozzi, F.; Mulloni, V.; Resta, G.; Margesin, B. MEMS packaging by using dry film resist. In Proceedings of the 2015 XVIII AISEM Annual Conference, Trento, Italy, 3–5 February 2015. [Google Scholar]

- Giacomozzi, F.; Mulloni, V.; Colpo, S.; Faes, A.; Sordo, G.; Girardi, S. RF-MEMS packaging by using quartz caps and epoxy polymers. Microsyst. Technol. 2015, 21, 1941–1948. [Google Scholar] [CrossRef]

- Mulloni, V.; Colpo, S.; Faes, A.; Margesin, B. A simple analytical method for residual stress measurement on suspended MEM structures using surface profilometry. J. Micromech. Microeng. 2013, 23, 025025. [Google Scholar] [CrossRef]

- Contreras, A.; Casals-Terré, J.; Pradell, L.; Giacomozzi, F.; Colpo, S.; Iannacci, J.; Ribó, M. A RF-MEMS switchable CPW air-bridge. In Proceedings of the 7th European Microwave Integrated Circuits Conference, Amsterdam, The Netherlands, 29–30 October 2012. [Google Scholar]

| Parameter | DG-W/NW | DDG-W/NW | DDG2-W/NW |

|---|---|---|---|

| Air gap (μm) | 2.7 | 2.7 | 2.7 |

| Supporting-beam width (μm) | 10 | 11.2 | 8.25 |

| Supporting-beam length (μm) | 92 | 75.2 | 88 |

| Angle (°) | 30° | 55° | 45° |

| Bridge width (μm) | 90 | 90 | 90 |

| Bridge length (μm) | 265 | 265 | 265 |

| Window width | 60/-- | 60/-- | 60/-- |

| Window length | 65/-- | 65/-- | 65/-- |

| Bottom-electrodes area (μm2) | 18,000/23,850 | 18,000/23,850 | 18,000/23,850 |

| Contact area (μm2) | 10 × 12.3 | 10 × 12.3 | 10 × 12.3 |

| Spring constant (N/m) | 39.9 | 182.35 | 113.96 |

| Pull-in voltage (V) | 38.2/28.5 | 81.7/70 | 65.6/56 |

| Resonant frequency (kHz) | 27.3 | 56.4 | 44.2 |

| Symbol | Description | Value |

|---|---|---|

| σ | Residual stress (MPa) [33] | 58–62 |

| E | Young modulus (GPa) [33] | 98.5 ± 6 |

| ρ | Density (kg/m3) | 19,840 |

| Parameter | In-Line Switch | 90°-Rotated Switch |

|---|---|---|

| ℓIN (μm) | 430.5 | 430.5 |

| ℓOUT (μm) | 705.5 | 705.5 |

| ℓC1 (μm) | 79.8 | 165 |

| ℓC2 (μm) | 270.4 | 100 |

| Cp (fF) | 5 | 5 |

| Z0e (Ω) | 41.6 | 41.6 |

| Z0e1 (Ω) | 89.3 | 89.3 |

| Z0e2 (Ω) | 63.8 | 34.8 |

| Rc (Ω) | 1.5 | 1.5 |

| COFF (fF) | 1.56 | 3.09 |

| Parameter | Vpull-in (V) | Vpull-out (V) | Vpull-in (V) (Simulated) |

|---|---|---|---|

| DDG-W-DL | 76.5 ± 1.5 | 57.5 ± 2.5 | 81.7 |

| DDG-NW-DL | 60 ± 0.5 | 46 ± 1.5 | 70 |

| DDG2-W-DL | 54 ± 4 | 40 ± 0.5 | 65.6 |

| DDG2-NW-DL | 49.5 ± 1.5 | 36 ± 2 | 56 |

| DG-W-DL | 40 | 30 | 38.2 |

| DG-NW-DL | 38 | 30 | 28.5 |

| Parameter | ISOL (dB) | IL (dB) | COFF (fF) | RC (Ω) | CP (fF) |

|---|---|---|---|---|---|

| DDG | 40 | 0.72 | 1.06 | 2.1 | 5 |

| DDG-90 | 31 | 0.78 | 3.09 | 2.1 | 5 |

| DDG2 | 40 | 0.79 | 1.06 | 2.2 | 5 |

| DG | 42 | 0.81 | 0.96 | 2.2 | 5 |

| Ref. | RF-MEMS Switch Structure | Stress (MPa) | Vpull-in (V) | Gap (μm) | Frequency (GHz) | Isolation (dB) | Insertion Loss (dB) |

|---|---|---|---|---|---|---|---|

| [5] | Cantilever | 50 | 16 | 2 | 12.5 | 31 | 1.5 |

| [6] | Cantilever | -- | 14.8 | 2.2 | 20 | 20 | 0.8 |

| [17] | Cantilever | -- | 60 | 3 + 9 * | -- | -- | -- |

| [19] | Membrane | 100 | 60 | 2.6 | 40 | 15 | 1 |

| [21] | Membrane | 80 | 36 | 5 | 15 | 20 | 2.8 |

| [22] | Membrane | 100 + 4 | 90 | 0.25 | 40 | 14 | 0.8 |

| [24] | Cantilever/ Membrane | 58–62 | 10.6/38.2 | 2.7 + 0.08 * | 15/15 | 10/10 | 0.9/0.9 |

| This work | Membrane | 58–62 | 65.6/56 | 2.7 + 0.03 * | 20 | 40 (in-line) | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casals-Terré, J.; Pradell, L.; Heredia, J.C.; Giacomozzi, F.; Iannacci, J.; Contreras, A.; Ribó, M. Enhanced Robustness of a Bridge-Type Rf-Mems Switch for Enabling Applications in 5G and 6G Communications. Sensors 2022, 22, 8893. https://doi.org/10.3390/s22228893

Casals-Terré J, Pradell L, Heredia JC, Giacomozzi F, Iannacci J, Contreras A, Ribó M. Enhanced Robustness of a Bridge-Type Rf-Mems Switch for Enabling Applications in 5G and 6G Communications. Sensors. 2022; 22(22):8893. https://doi.org/10.3390/s22228893

Chicago/Turabian StyleCasals-Terré, Jasmina, Lluís Pradell, Julio César Heredia, Flavio Giacomozzi, Jacopo Iannacci, Adrián Contreras, and Miquel Ribó. 2022. "Enhanced Robustness of a Bridge-Type Rf-Mems Switch for Enabling Applications in 5G and 6G Communications" Sensors 22, no. 22: 8893. https://doi.org/10.3390/s22228893

APA StyleCasals-Terré, J., Pradell, L., Heredia, J. C., Giacomozzi, F., Iannacci, J., Contreras, A., & Ribó, M. (2022). Enhanced Robustness of a Bridge-Type Rf-Mems Switch for Enabling Applications in 5G and 6G Communications. Sensors, 22(22), 8893. https://doi.org/10.3390/s22228893