Smartphone Application for Structural Health Monitoring of Bridges

Abstract

1. Introduction

2. Software Architecture and User Interfaces

2.1. Architecture Description

- Structure Identification (Step 1)—identification of the structure from a structural database. A new structure can be added via server;

- Data Acquisition (Step 2)—measurement of acceleration time series in the direction orthogonal to the screen of the smartphone (Figure 1) for a user-controlled period of time;

- Feature Extraction (Step 3)—estimation of the first three natural frequencies from the power spectral density of the accelerogram (using the Welch method). They are stored into a feature vector (observation);

- Damage Detection (Step 4)—for each new observation, a damage indicator is computed based on the Mahalanobis-squared distance (as applied in [24,25]). Subsequently, a plot of the damage indicators of the observations collected in the training database (and assumed to reflect the behavior of the undamaged structure) is presented, to which the damage indicator computed for the new observation is added in green or red if the structure is deemed undamaged or damaged, respectively.

- Multiple smartphones can be used to record acceleration time series for the same structure and centralize the information in a single database;

- For structures with existing training sets, it is possible to upload that information directly to the database and use it along data coming from the smartphone measurements to train the machine learning algorithms for damage detection;

- The web-based backoffice is accessible only to users with the right credentials, meaning that regular users cannot tamper with the information stored in the database;

- CPU-intensive calculations such as the Welch algorithm can be slow on certain mobile devices, so it is useful to offload those computations to the server;

- Facilitates the development of the application on other platforms (namely iOS) since the backoffice algorithms implemented on the server need not be changed.

2.2. User Interfaces

2.2.1. Step 1—Structure Identification

2.2.2. Step 2—Data Acquisition

2.2.3. Step 3—Feature (Natural Frequencies) Extraction

2.2.4. Step 4—Damage Detection

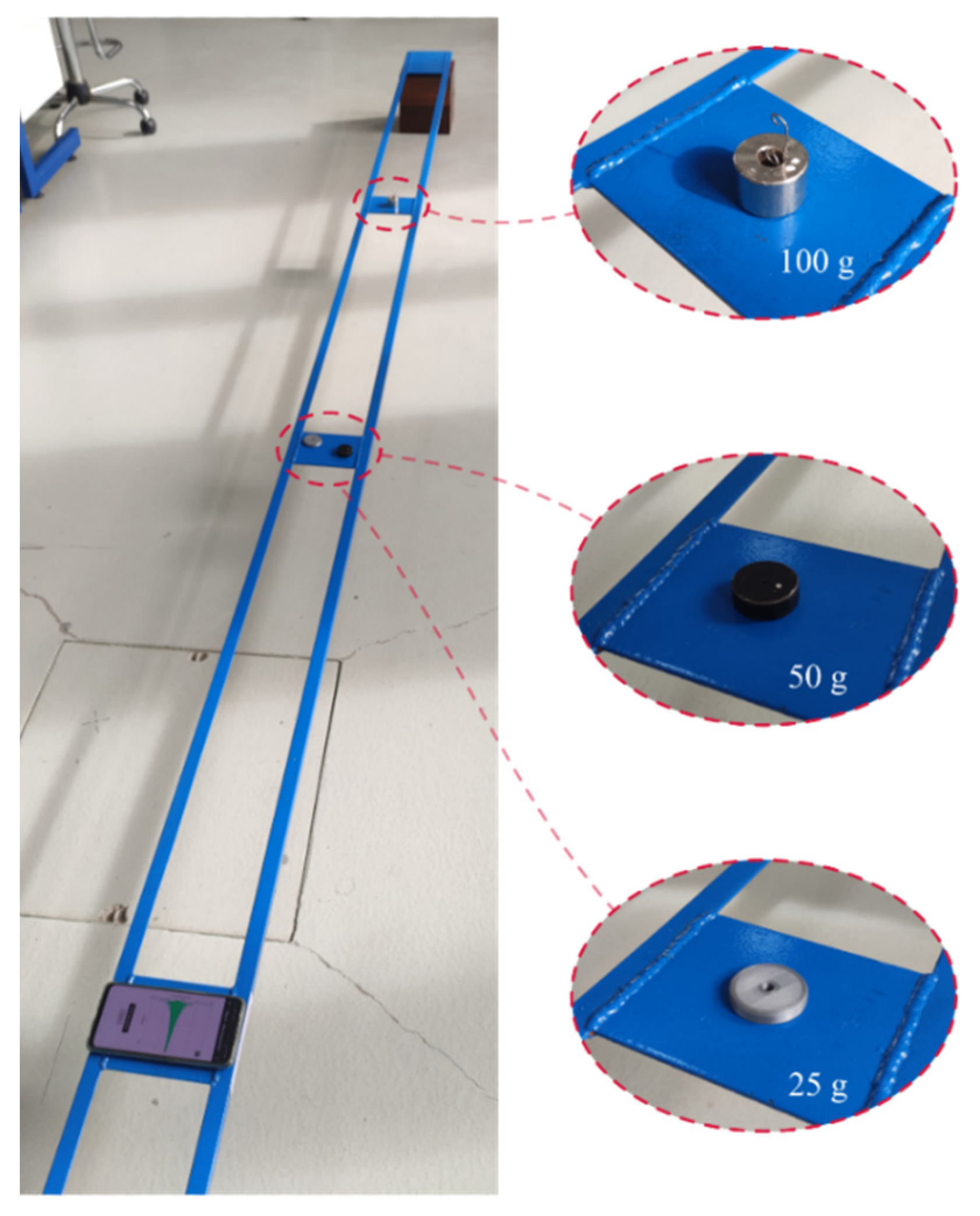

3. Case Study #1: Simply Supported Beam

3.1. Structural Description

3.2. Vibration Tests

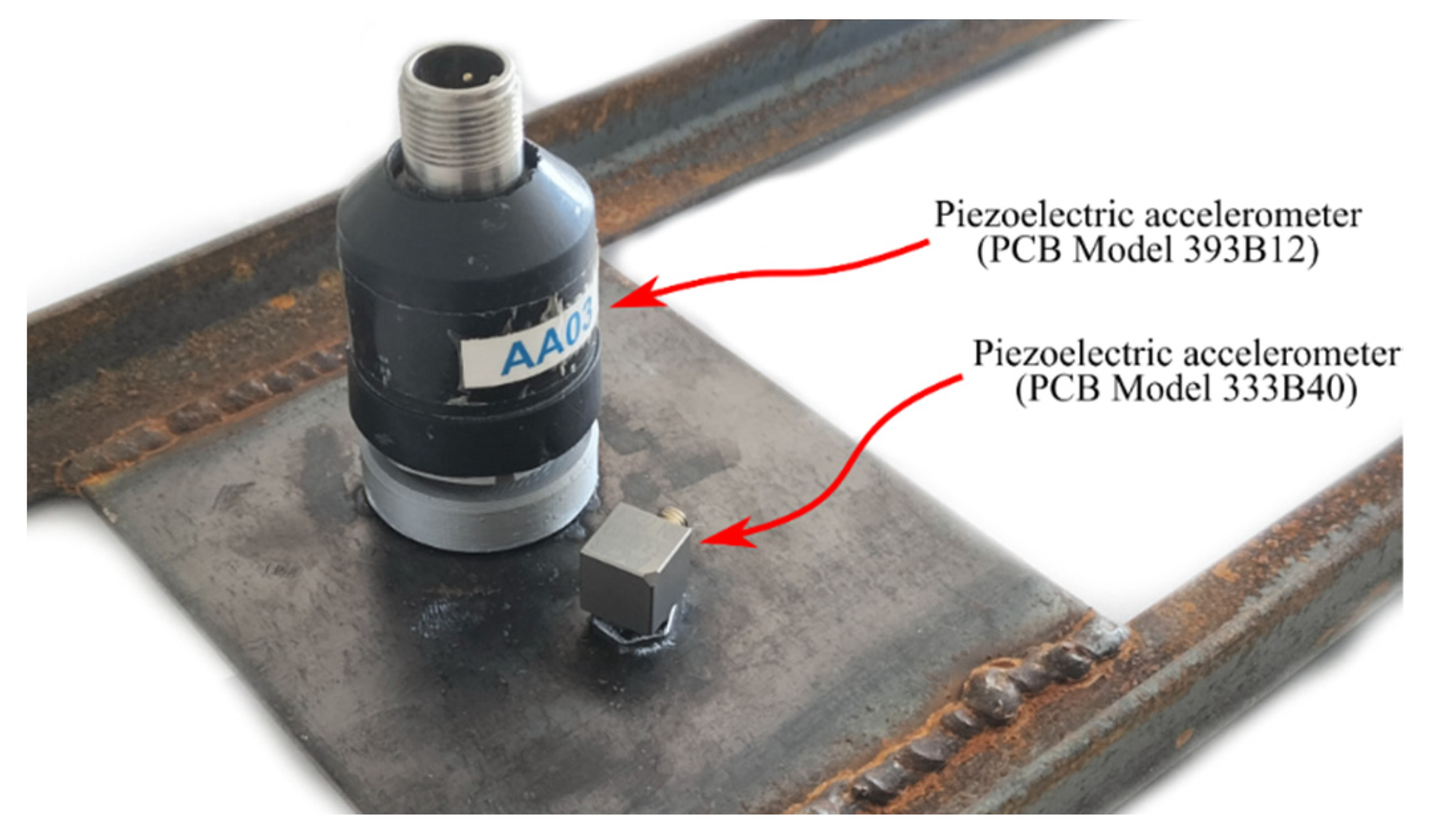

3.3. Comparative Study

3.3.1. Natural Frequencies

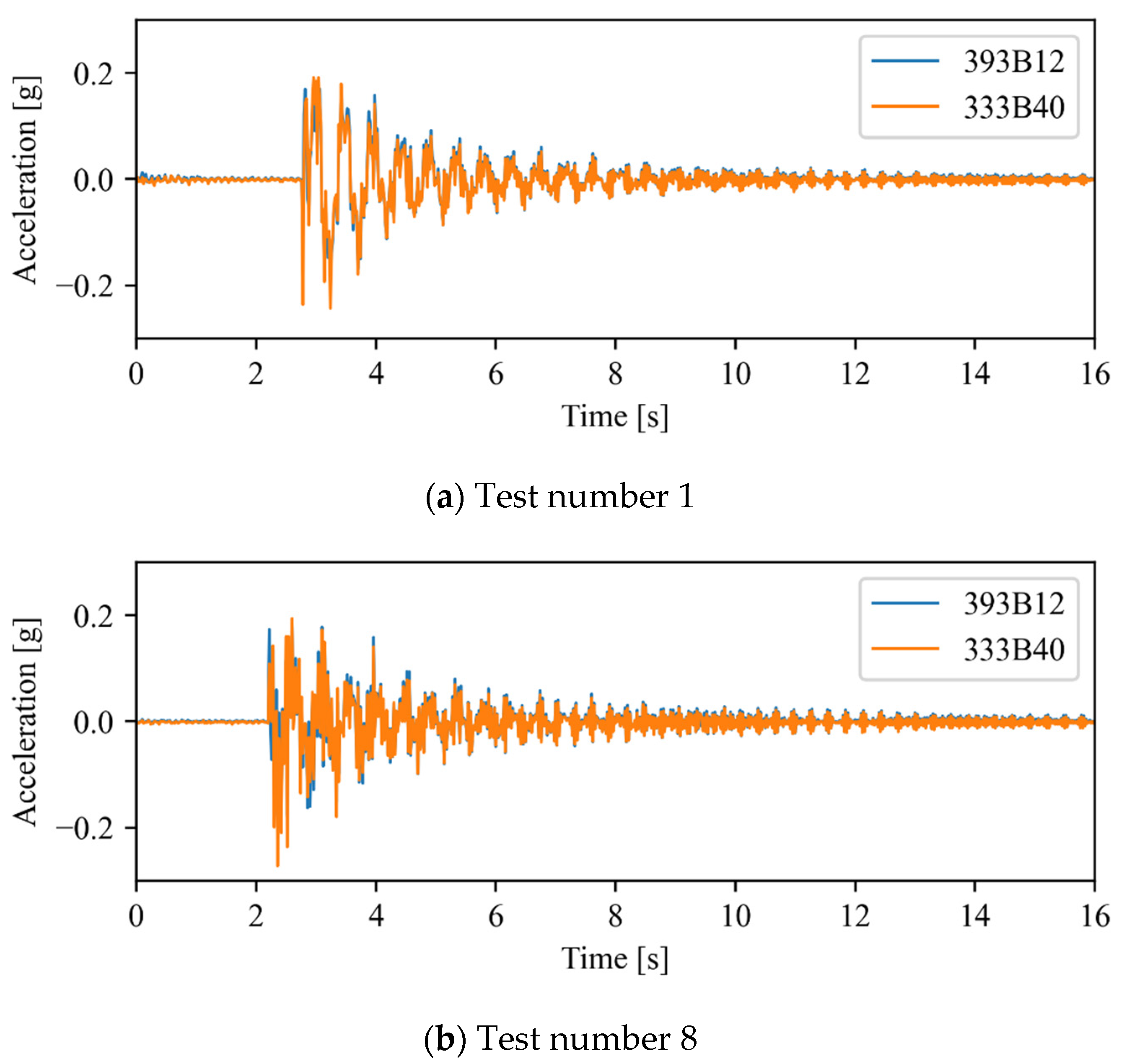

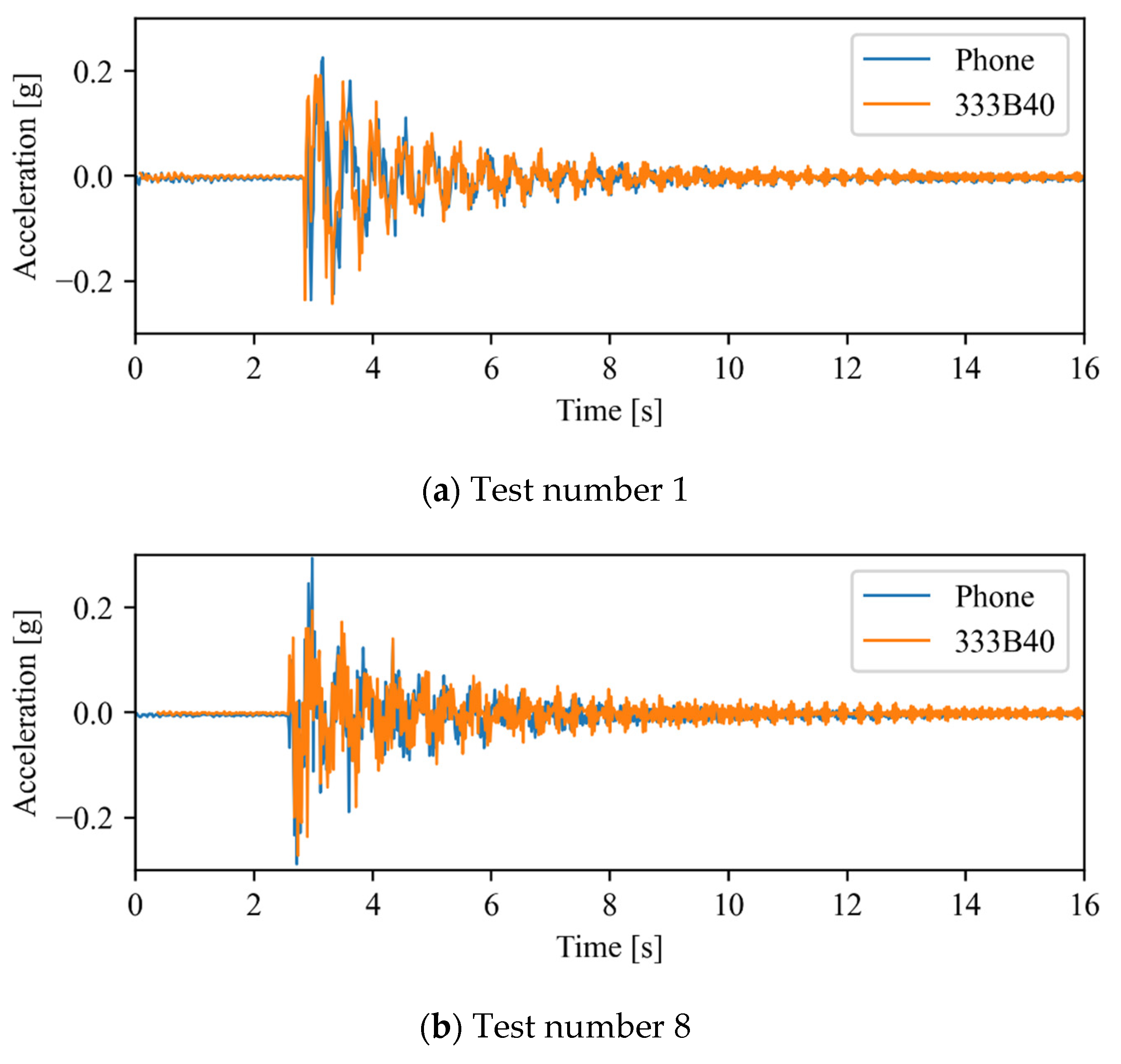

3.3.2. Time Series

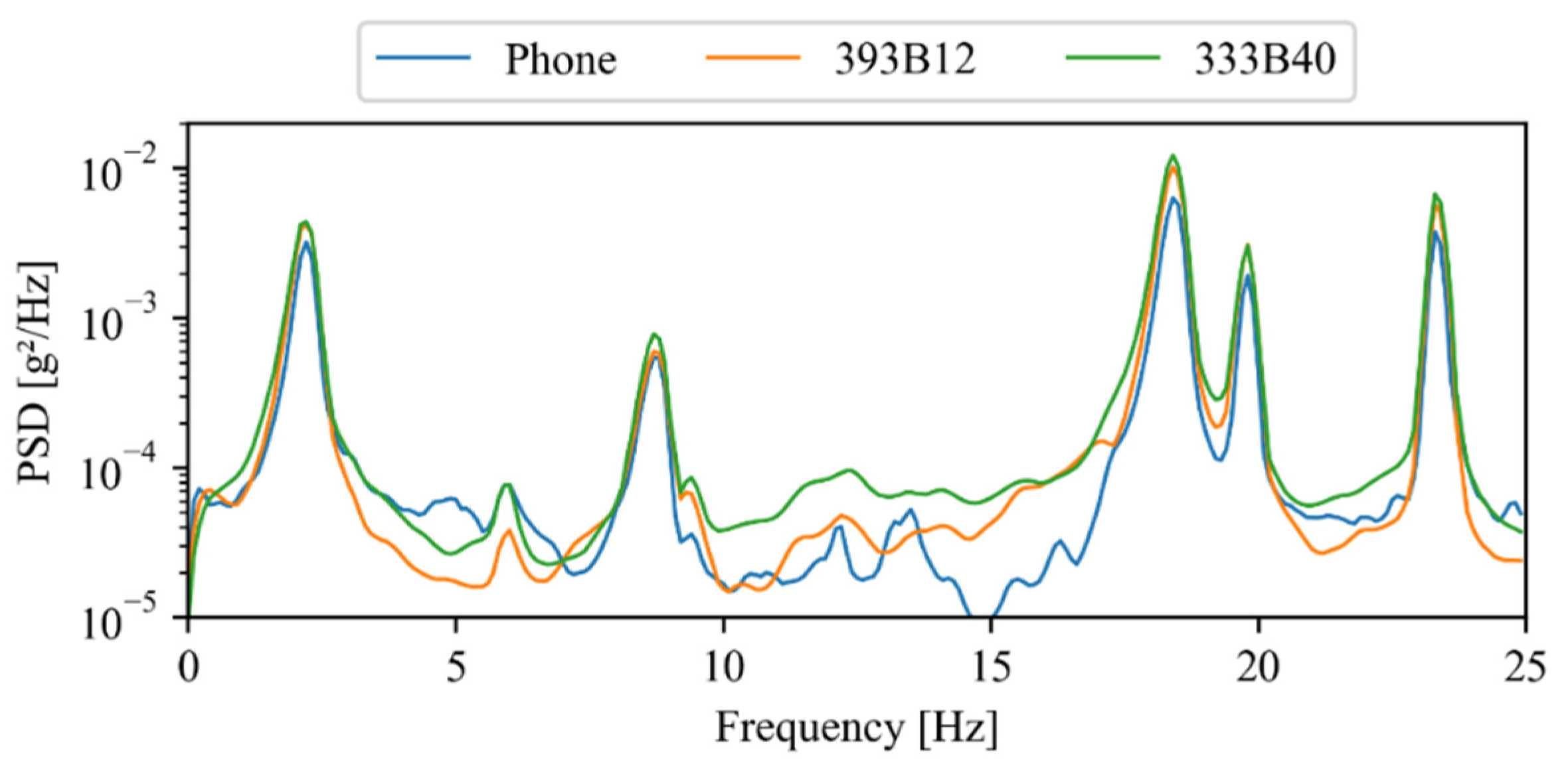

3.3.3. Power Spectral Densities

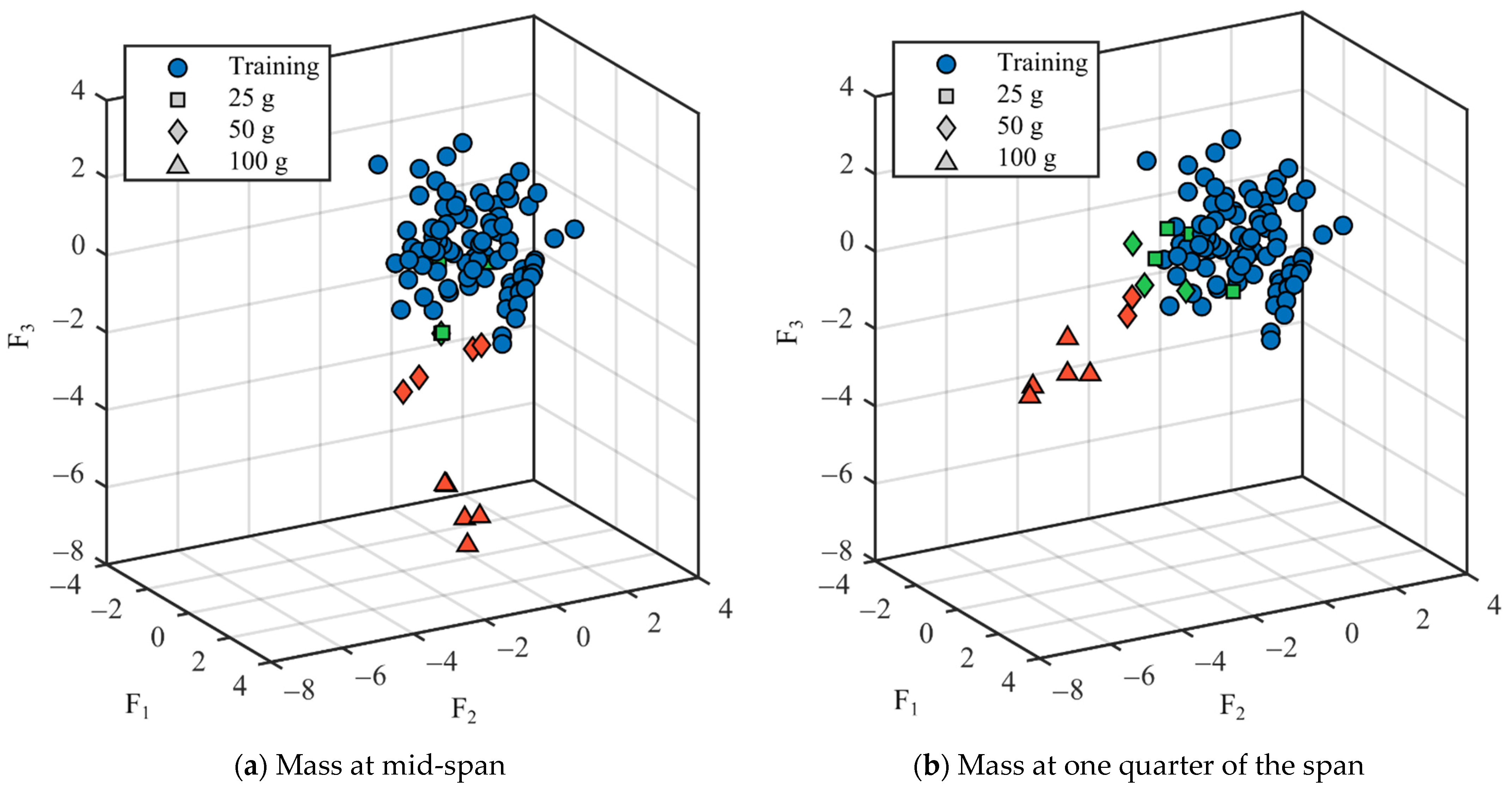

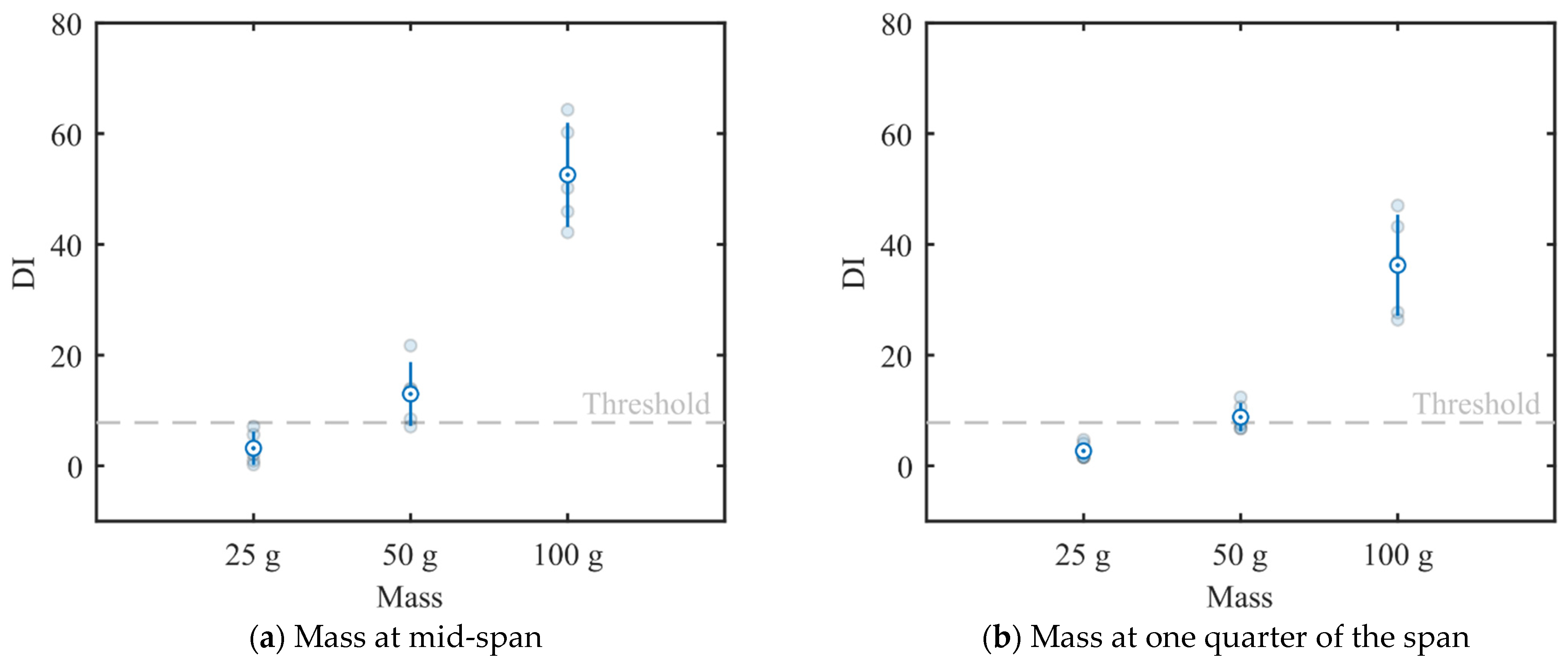

3.4. Damage Detection Capabilites

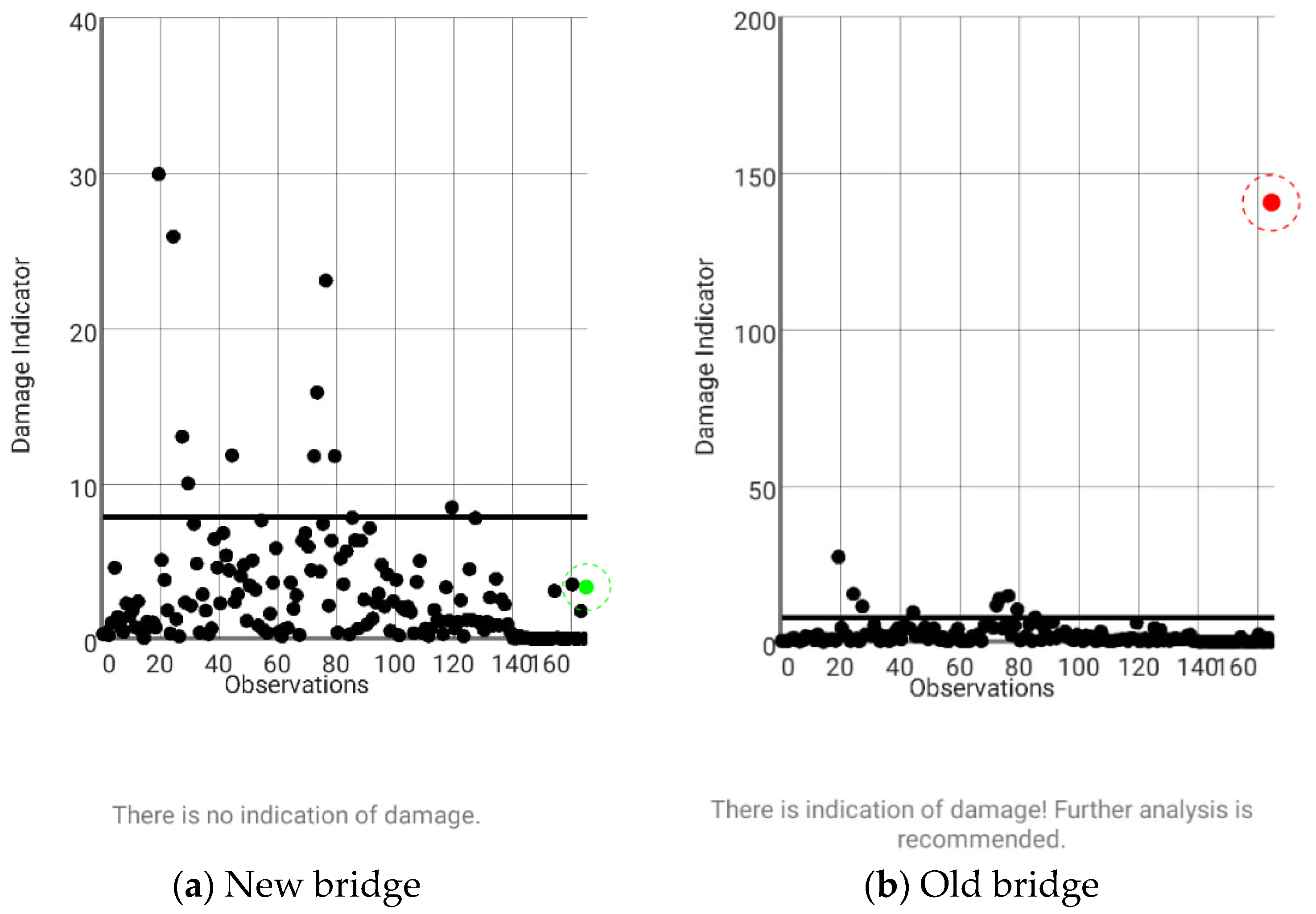

4. Case Study #2: Twin Bridges over Itacaiúnas River

4.1. Structural Description

4.2. Ambient Vibration Tests

4.3. Feature Extration and Comparative Study

4.4. Damage Detection Performance

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Figueiredo, E.; Moldovan, I.; Marques, M.B. Condition Assessment of Bridges: Past, Present and Future A Complementary Approach; Católica Editora: Lisboa, Portugal, 2013. [Google Scholar]

- Thompson, P.D.; Small, E.P.; Johnson, M.; Marshall, A.R. The Pontis Bridge Management System. Struct. Eng. Int. 1998, 8, 303–308. [Google Scholar] [CrossRef]

- Ahmed, H.; La, H.M.; Gucunski, N. Review of Non-Destructive Civil Infrastructure Evaluation for Bridges: State-of-the-Art Robotic Platforms, Sensors and Algorithms. Sensors (Basel) 2020, 20, 3954. [Google Scholar] [CrossRef] [PubMed]

- Farrar, C.R.; Worden, K. Structural Health Monitoring: A Machine Learning Perspective; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Rytter, A.; Kirkegaard, P.H.P. Vibration Based Inspection of Civil Engineering Structures. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 1994. [Google Scholar]

- Figueiredo, E.; Brownjohn, J. Three decades of statistical pattern recognition paradigm for SHM of bridges. Struct. Health Monit. 2022, 21, 14759217221075241. [Google Scholar] [CrossRef]

- Cawley, P. Structural health monitoring: Closing the gap between research and industrial deployment. Struct. Health Monit. 2018, 17, 1225–1244. [Google Scholar] [CrossRef]

- Malekloo, A.; Ozer, E.; AlHamaydeh, M.; Girolami, M. Machine learning and structural health monitoring overview with emerging technology and high-dimensional data source highlights. Struct. Health Monit. 2021, 21, 14759217211036880. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef]

- Kromanis, R.; Xu, Y.; Lydon, D.; del Rincon, J.M.; Al-Habaibeh, A. Measuring Structural Deformations in the Laboratory Environment Using Smartphones. Front. Built Environ. 2019, 5, 44. [Google Scholar] [CrossRef]

- Ozer, E.; Feng, D.; Feng, M.Q. Hybrid motion sensing and experimental modal analysis using collocated smartphone camera and accelerometers. Meas. Sci. Technol. 2017, 28, 105903. [Google Scholar] [CrossRef]

- Kromanis, R.; Kripakaran, P. A multiple camera position approach for accurate displacement measurement using computer vision. J. Civ. Struct. Health Monit. 2021, 11, 661–678. [Google Scholar] [CrossRef]

- Zhao, X.; Han, R.; Ding, Y.; Yu, Y.; Guan, Q.; Hu, W.; Li, M.; Ou, J. Portable and convenient cable force measurement using smartphone. J. Civ. Struct. Health Monit. 2015, 5, 481–491. [Google Scholar] [CrossRef]

- Zhao, X.; Ri, K.; Han, R.; Yu, Y.; Li, M.; Ou, J. Experimental Research on Quick Structural Health Monitoring Technique for Bridges Using Smartphone. Adv. Mater. Sci. Eng. 2016, 2016, 1871230. [Google Scholar] [CrossRef]

- Feng, M.; Fukuda, Y.; Mizuta, M.; Ozer, E. Citizen Sensors for SHM: Use of Accelerometer Data from Smartphones. Sensors 2015, 15, 2980. [Google Scholar] [CrossRef] [PubMed]

- Mei, Q.; Gül, M. A crowdsourcing-based methodology using smartphones for bridge health monitoring. Struct. Health Monit. 2018, 18, 1602–1619. [Google Scholar] [CrossRef]

- Sitton, J.D.; Rajan, D.; Story, B.A. Bridge frequency estimation strategies using smartphones. J. Civ. Struct. Health Monit. 2020, 10, 513–526. [Google Scholar] [CrossRef]

- Ashish, S.; Ji, D.; Xin, W.; Shogo, M. Smartphone-Based Bridge Seismic Monitoring System and Long-Term Field Application Tests. J. Struct. Eng. 2020, 146, 4019208. [Google Scholar] [CrossRef]

- Ozer, E.; Purasinghe, R.; Feng, M.Q. Multi-output modal identification of landmark suspension bridges with distributed smartphone data: Golden Gate Bridge. Struct. Control Health Monit. 2020, 27, e2576. [Google Scholar] [CrossRef]

- Ozer, E.; Feng, M.Q.; Feng, D. Citizen Sensors for SHM: Towards a Crowdsourcing Platform. Sensors 2015, 15, 14591–14614. [Google Scholar] [CrossRef]

- Figueiredo, E.; Alves, P.; Moldvan, I.; Rebelo, H.; Silva, L.; Souza, L.; Lopes, R.; Oliveira, P.; Penim, N. App4SHM—Smartphone Application for Structural Health Monitoring. In Proceedings of the 10th European Workshop on Structural Health Monitoring, Palermo, Italy, 4–7 July 2022; pp. 1034–1043. [Google Scholar]

- Pardeshi, S.S.; Patange, A.D.; Jegadeeshwaran, R.; Bhosale, M.R. Tyre Pressure Supervision of Two Wheeler Using Machine Learning. Struct. Durab. Health Monit. 2022, 16, 271–290. [Google Scholar] [CrossRef]

- Shewale, M.S.; Mulik, S.S.; Deshmukh, S.P.; Patange, A.D.; Zambare, H.B.; Sundare, A. Novel Machine Health Monitoring System. In Proceedings of the 2nd International Conference on Data Engineering and Communication Technology, Pune, India, 15–16 December 2017; Kulkarni, A., Satapathy, S., Kang, T., Kashan, A., Eds.; Springer: Singapore, 2019; Volume 828. [Google Scholar]

- Figueiredo, E.; Radu, L.; Worden, K.; Farrar, C.R. A Bayesian approach based on a Markov-chain Monte Carlo method for damage detection under unknown sources of variability. Eng. Struct. 2014, 80, 1–10. [Google Scholar] [CrossRef]

- Figueiredo, E.; Cross, E. Linear approaches to modeling nonlinearities in long-term monitoring of bridges. J. Civ. Struct. Health Monit. 2013, 3, 187–194. [Google Scholar] [CrossRef]

- Bud, A.M.; Moldovan, I.; Radu, L.; Nedelcu, M.; Figueiredo, E. Reliability of probabilistic numerical data for training machine learning algorithms to detect damage in bridges. Struct. Control Health Monit. 2022, 29, e2950. [Google Scholar] [CrossRef]

- Santos, A.; Silva, M.; Santos, R.; Figueiredo, E.; Sales, C.; Costa, J.C.W.A. A global expectation-maximization based on memetic swarm optimization for structural damage detection. Struct. Health Monit. 2016, 15, 610–625. [Google Scholar] [CrossRef]

- Hou, J.; Li, Z.; Zhang, Q.; Jankowski, Ł.; Zhang, H. Local Mass Addition and Data Fusion for Structural Damage Identification Using Approximate Models. Int. J. Struct. Stab. Dyn. 2020, 20, 2050124. [Google Scholar] [CrossRef]

| Test No. | F1 (Hz) | F2 (Hz) | F3 (Hz) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Smartphone | 393B12 | 333B40 | Smartphone | 393B12 | 333B40 | Smartphone | 393B12 | 333B40 | |

| 1 | 2.119 | 2.120 | 2.120 | 8.616 | 8.657 | 8.657 | 19.774 | 19.788 | 19.788 |

| 2 | 2.210 | 2.120 | 2.120 | 8.702 | 8.657 | 8.657 | 18.370 | 19.788 | 18.375 |

| 3 | 2.187 | 2.120 | 2.120 | 8.601 | 8.657 | 8.657 | 18.367 | 18.375 | 18.375 |

| 4 | 2.107 | 2.120 | 2.120 | 8.708 | 8.834 | 8.834 | 18.258 | 18.375 | 18.375 |

| 5 | 2.180 | 2.120 | 2.120 | 8.866 | 8.834 | 8.834 | 18.314 | 19.788 | 19.788 |

| 6 | 2.083 | 2.120 | 2.120 | 8.780 | 8.834 | 8.657 | 18.304 | 18.375 | 18.375 |

| 7 | 2.199 | 2.315 | 2.315 | 8.798 | 8.796 | 8.796 | 18.475 | 18.519 | 18.519 |

| 8 | 2.237 | 2.222 | 2.222 | 8.852 | 8.778 | 8.778 | 18.482 | 18.444 | 18.444 |

| 9 | 2.107 | 2.120 | 2.120 | 8.708 | 8.834 | 8.834 | 18.258 | 18.198 | 18.198 |

| 10 | 2.202 | 2.120 | 2.120 | 8.679 | 8.657 | 8.657 | 18.264 | 18.198 | 18.198 |

| 11 | 2.190 | 2.252 | 2.252 | 8.759 | 8.709 | 8.709 | 18.370 | 18.468 | 18.468 |

| 12 | 2.257 | 2.252 | 2.252 | 8.789 | 8.859 | 8.859 | 18.527 | 18.468 | 18.468 |

| 13 | 2.243 | 2.252 | 2.252 | 8.707 | 8.709 | 8.709 | 18.470 | 18.468 | 18.468 |

| 14 | 2.296 | 2.252 | 2.252 | 8.801 | 8.859 | 8.859 | 18.495 | 18.468 | 18.468 |

| 15 | 2.255 | 2.120 | 2.120 | 8.753 | 8.657 | 8.834 | 18.435 | 18.375 | 18.375 |

| 16 | 2.228 | 2.120 | 2.120 | 8.635 | 8.657 | 8.657 | 18.384 | 18.375 | 18.375 |

| 17 | 2.242 | 2.219 | 2.219 | 8.857 | 8.747 | 8.747 | 18.498 | 18.407 | 18.407 |

| 18 | 2.290 | 2.297 | 2.297 | 8.779 | 8.834 | 8.834 | 18.448 | 18.375 | 18.551 |

| 19 | 2.297 | 2.297 | 2.297 | 8.784 | 8.834 | 8.834 | 18.514 | 18.551 | 18.551 |

| 20 | 2.344 | 2.297 | 2.297 | 8.854 | 8.834 | 8.834 | 18.490 | 18.551 | 18.551 |

| 21 | 2.179 | 2.252 | 2.252 | 8.718 | 8.709 | 8.709 | 18.462 | 18.468 | 18.468 |

| 22 | 2.279 | 2.297 | 2.297 | 8.847 | 8.834 | 8.834 | 18.499 | 18.551 | 18.375 |

| 23 | 2.304 | 2.297 | 2.297 | 8.808 | 8.834 | 8.834 | 18.428 | 18.551 | 18.551 |

| 24 | 2.309 | 2.222 | 2.222 | 8.835 | 8.889 | 8.889 | 18.474 | 18.444 | 18.444 |

| 25 | 2.326 | 2.297 | 2.297 | 8.915 | 8.834 | 8.834 | 18.605 | 18.551 | 18.551 |

| 26 | 2.213 | 2.219 | 2.219 | 8.853 | 8.747 | 8.747 | 18.511 | 18.407 | 18.407 |

| 27 | 2.332 | 2.297 | 2.297 | 8.808 | 8.834 | 8.834 | 18.523 | 18.551 | 18.551 |

| 28 | 2.244 | 2.297 | 2.297 | 8.728 | 8.657 | 8.657 | 18.454 | 18.375 | 18.375 |

| 29 | 2.255 | 2.297 | 2.297 | 8.753 | 8.657 | 8.657 | 18.568 | 18.551 | 18.375 |

| 30 | 2.232 | 2.252 | 2.252 | 8.705 | 8.709 | 8.709 | 19.754 | 19.820 | 19.820 |

| Mean | 2.232 | 2.219 | 2.219 | 8.767 | 8.765 | 8.765 | 18.526 | 18.621 | 18.568 |

| SD | 0.067 | 0.075 | 0.075 | 0.077 | 0.080 | 0.080 | 0.343 | 0.470 | 0.420 |

| CI’s LL | 2.207 | 2.193 | 2.193 | 8.739 | 8.736 | 8.736 | 18.403 | 18.453 | 18.418 |

| CI’s UL | 2.256 | 2.246 | 2.246 | 8.794 | 8.793 | 8.793 | 18.648 | 18.789 | 18.718 |

| Condition | Mahalanobis Squared Distance | Gaussian Mixture Model | ||

|---|---|---|---|---|

| Correct | Incorrect | Correct | Incorrect | |

| Undamaged | 96 | 4 | 96 | 4 |

| 25 g at mid-span | 0 | 5 | 0 | 5 |

| 25 g at 1/4 of the span | 0 | 5 | 0 | 5 |

| 50 g at mid-span | 4 | 1 | 4 | 1 |

| 50 g at 1/4 of the span | 2 | 3 | 2 | 3 |

| 100 g at mid-span | 5 | 0 | 5 | 0 |

| 100 g at 1/4 of the span | 5 | 0 | 5 | 0 |

| Mode | Old Bridge (15 October 2021) | New Bridge (11 October 2021) |

|---|---|---|

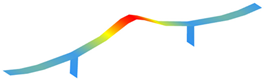

| 1 |  |  |

| 1.471 Hz | 1.025 Hz | |

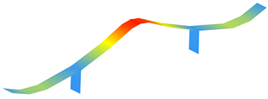

| 2 |  |  |

| 2.620 Hz | 1.731 Hz | |

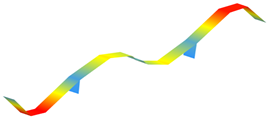

| 3 |  |  |

| 2.832 Hz | 2.100 Hz | |

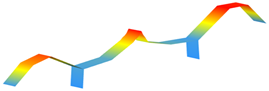

| 4 |  |  |

| 3.816 Hz | 2.905 Hz | |

| 5 |  |  |

| 5.845 Hz | 4.582 Hz |

| Mode | Old Bridge (15 October 2021) | New Bridge (11 October 2021) |

|---|---|---|

| 1 | 1.471 | 1.025 (−30.3%) |

| 2 | 2.620 | 1.731 (−33.9%) |

| 3 | 2.832 | 2.100 (−25.8%) |

| 4 | 3.816 | 2.905 (−23.9%) |

| 5 | 5.845 | 4.582 (−21.6%) |

| Starting Date and Hour | F2 (Hz) | F3 (Hz) | F4 (Hz) |

|---|---|---|---|

| 11 October 21 16:20 | 1.725 (−0.37%) | 2.094 (1.08%) | 2.909 (0.28%) |

| 11 October 21 16:40 | 1.731 (−0.02%) | 2.066 (−0.27%) | 2.891 (−0.35%) |

| 11 October 21 17:00 | 1.738 (0.39%) | 2.055 (−0.81%) | 2.903 (0.07%) |

| Mean | 1.731 | 2.072 | 2.901 |

| Starting Date and Hour | F2 (Hz) | F3 (Hz) | F4 (Hz) |

|---|---|---|---|

| 11 October 21 16:12 | 1.717 (−0.83%) | 2.039 (−1.58%) | 2.897 (−0.14%) |

| 11 October 21 16:16 | 1.757 (1.48%) | 2.027 (−2.16%) | 2.838 (−2.17%) |

| 11 October 21 16:22 | 1.772 (1.35%) | 2.025 (−2.53%) | 2.885 (−0.55%) |

| 11 October 21 16:33 | 1.738 (0.39%) | 2.070 (−0.08%) | 2.897 (−0.14%) |

| 11 October 21 16:38 | 1.757 (1.48%) | 2.030 (−2.01%) | 2.907 (0.21%) |

| 11 October 21 16:46 | 1.767 (2.06) | 2.061 (−0.52%) | 2.886 (−0.52%) |

| Mean | 1.751 (1.16%) | 2.042 (−1.43%) | 2.914 (−0.55%) |

| Sensing System | F1 (Hz) | F3 (Hz) | F5 (Hz) |

|---|---|---|---|

| GeoSIG | 1.471 | 2.832 | 5.845 |

| App4SHM | 1.507 (2.42%) | 2.848 (0.55%) | 5.842 (−0.05%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Figueiredo, E.; Moldovan, I.; Alves, P.; Rebelo, H.; Souza, L. Smartphone Application for Structural Health Monitoring of Bridges. Sensors 2022, 22, 8483. https://doi.org/10.3390/s22218483

Figueiredo E, Moldovan I, Alves P, Rebelo H, Souza L. Smartphone Application for Structural Health Monitoring of Bridges. Sensors. 2022; 22(21):8483. https://doi.org/10.3390/s22218483

Chicago/Turabian StyleFigueiredo, Eloi, Ionut Moldovan, Pedro Alves, Hugo Rebelo, and Laura Souza. 2022. "Smartphone Application for Structural Health Monitoring of Bridges" Sensors 22, no. 21: 8483. https://doi.org/10.3390/s22218483

APA StyleFigueiredo, E., Moldovan, I., Alves, P., Rebelo, H., & Souza, L. (2022). Smartphone Application for Structural Health Monitoring of Bridges. Sensors, 22(21), 8483. https://doi.org/10.3390/s22218483