Design of Synchronization Tracking Adaptive Control for Bilateral Teleoperation System with Time-Varying Delays

Abstract

1. Introduction

- A novel auxiliary variable constructed by position error integral term is proposed, and a new adaptive control scheme for teleoperation system is also developed. Compared with the existing auxiliary variables constructed by errors and error differential terms, the proposed auxiliary variables and control method have better robustness and smaller steady-state error.

- The new velocity feedback filter and velocity delay adaptive compensation are designed to avoid the use of acceleration signals and improve the stability of the system. On the other hand, only the position information is transmitted by communication to reduce the amount of communication data, and the velocity is obtained by calculating the time derivative of the position at the controller side. In this way, the time delay information will be added to the velocity signals. If the communication time delay changes greatly, it will produce a large time delay superimposed on the velocity information and weaken the stability of the system. Therefore, we design and introduce an adaptive compensation term of velocity delay to improve the stability of the system.

2. Problem Formulation

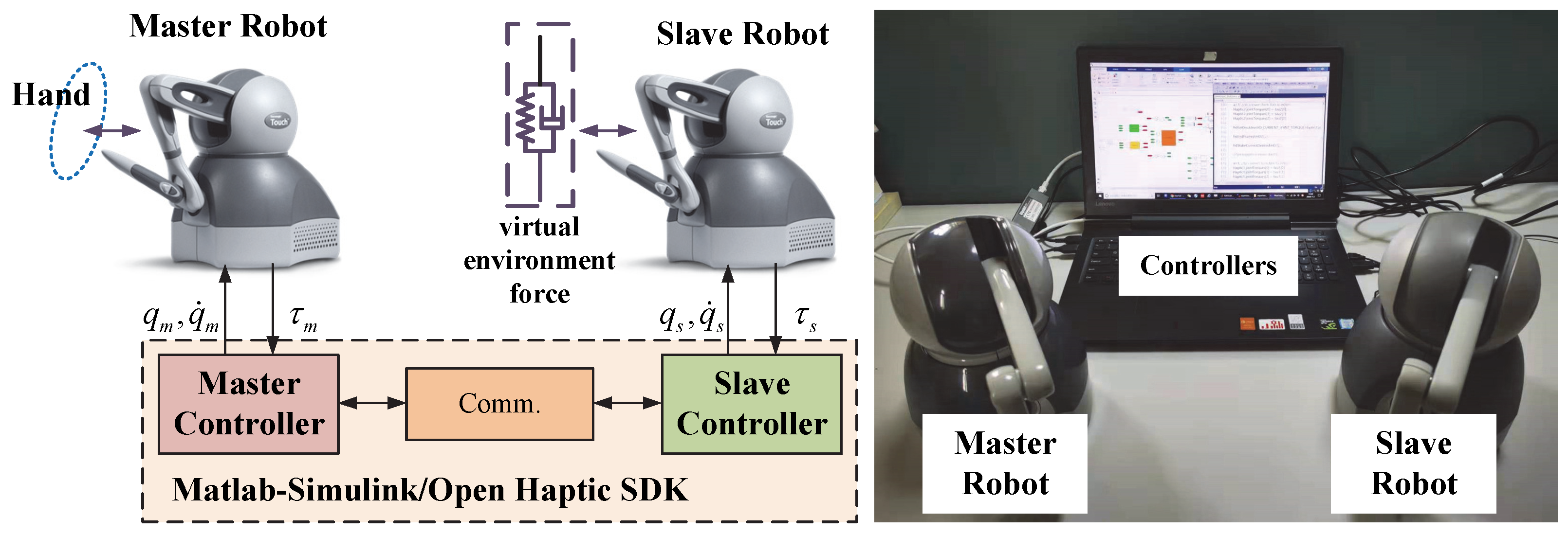

2.1. Master–Slave Telerobotic System

2.2. The Definition of RBF Neural Network

2.3. Control Objectives

- Stability. The teleoperation system is stable with proposed control laws, asymmetric time-varying delays, dynamic uncertainties, and bounded operator and environment torques.

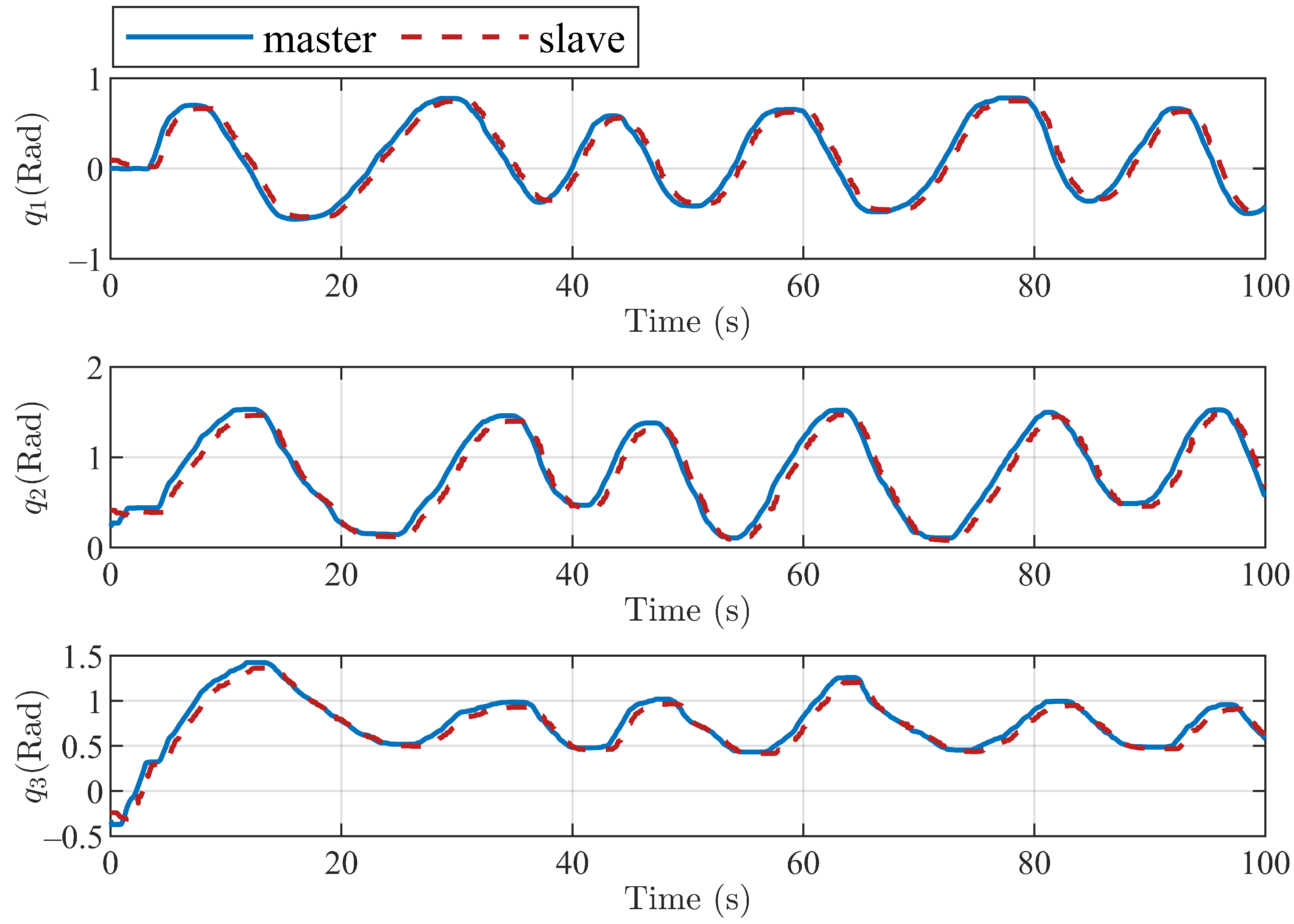

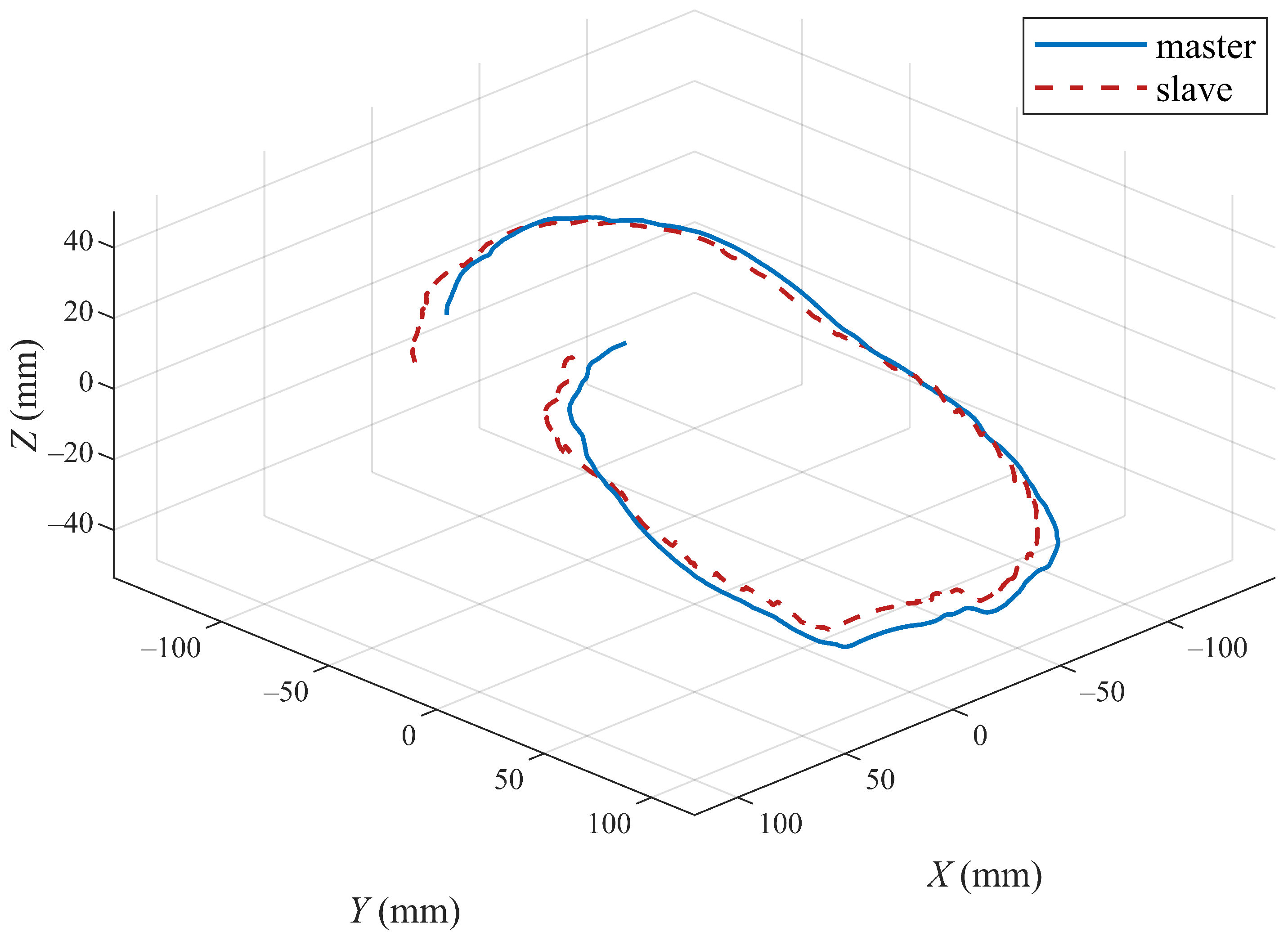

- Position tracking. The joint position of the slave robot can track the master robot when the master robot is moving. At the same time, the master robot can also track the joint position of the slave robot, which can provide certain force feedback to the operator.

3. Adaptive Control Scheme Design

4. Stability Analysis

5. Simulation and Experimental Analysis

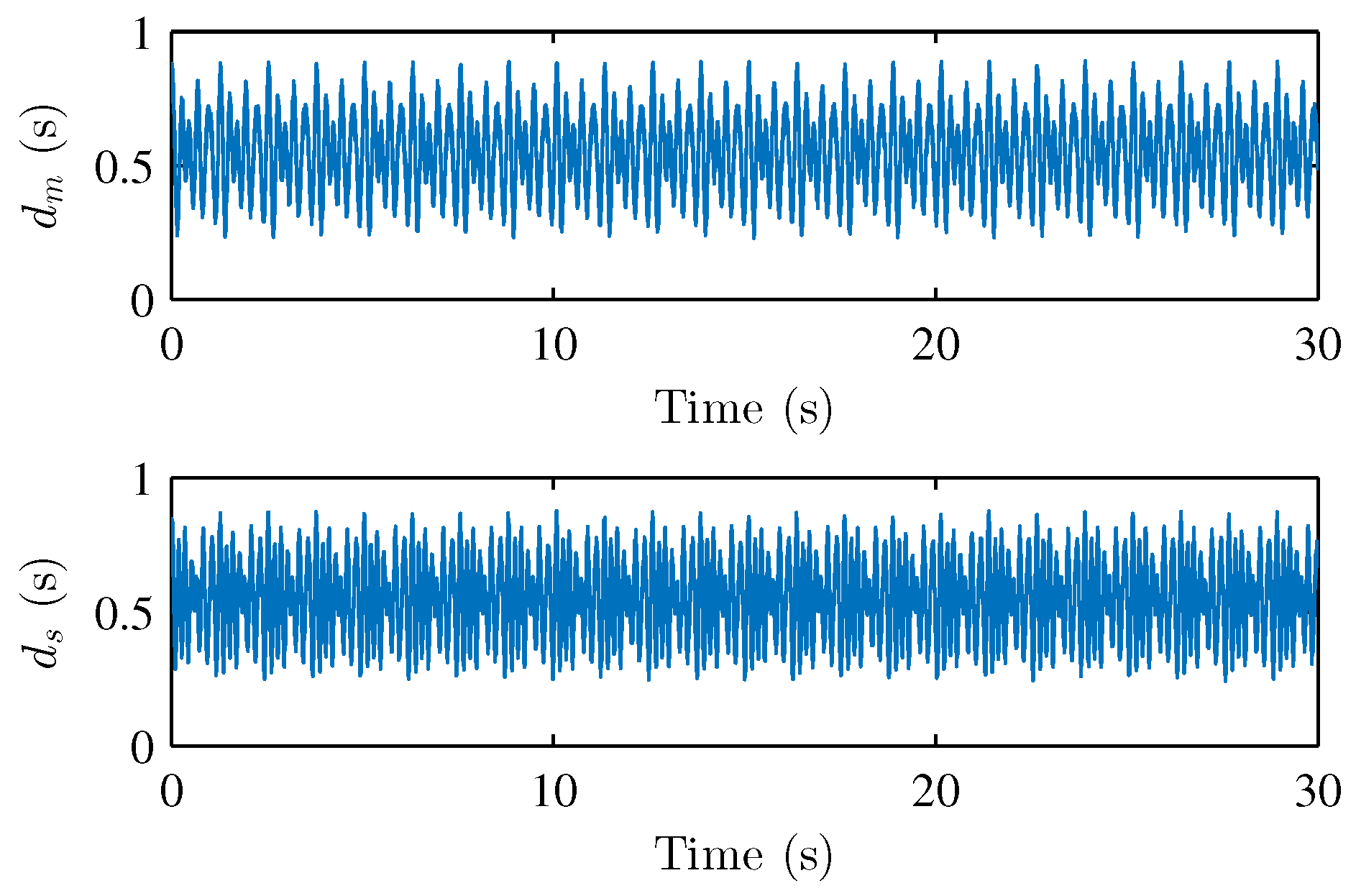

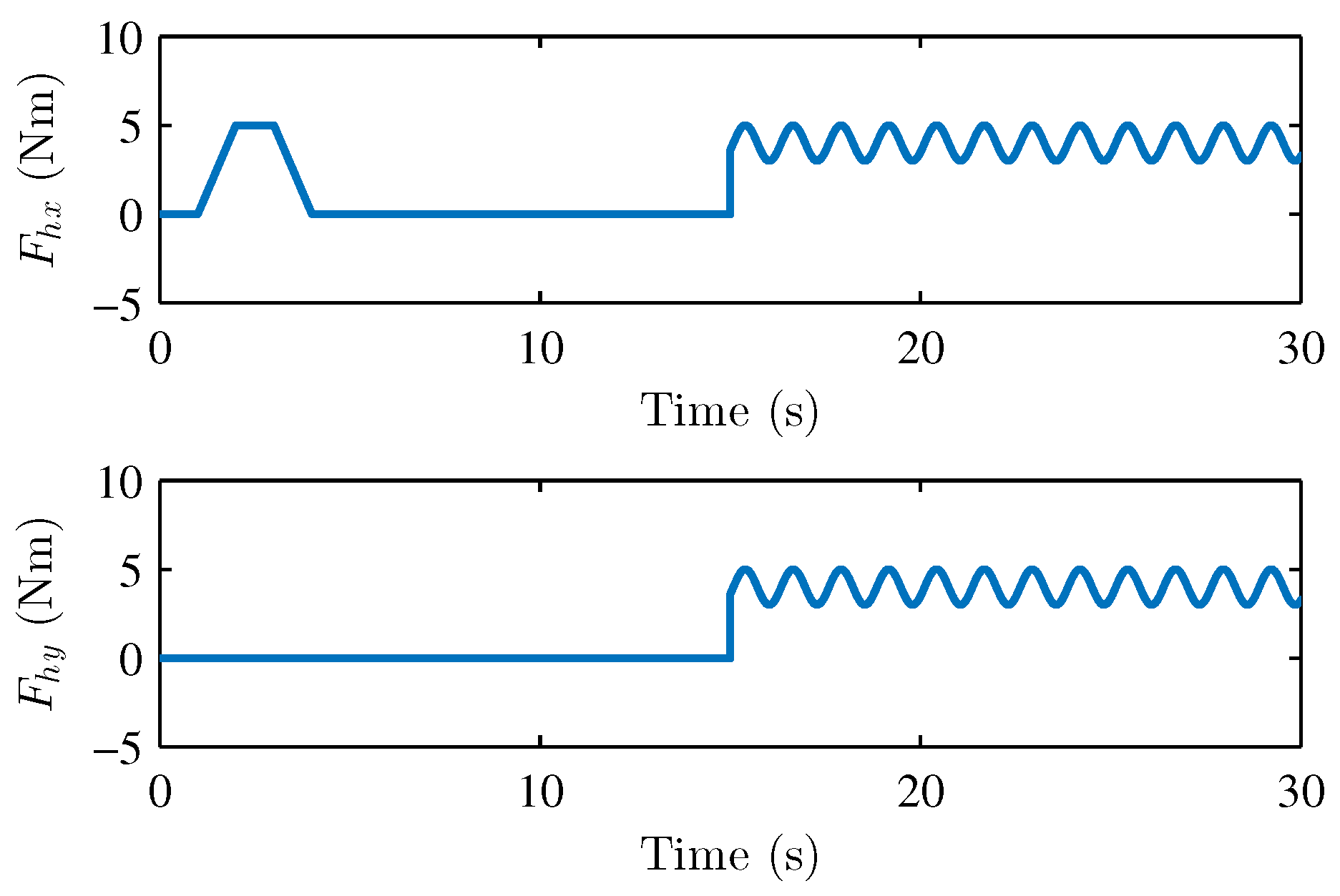

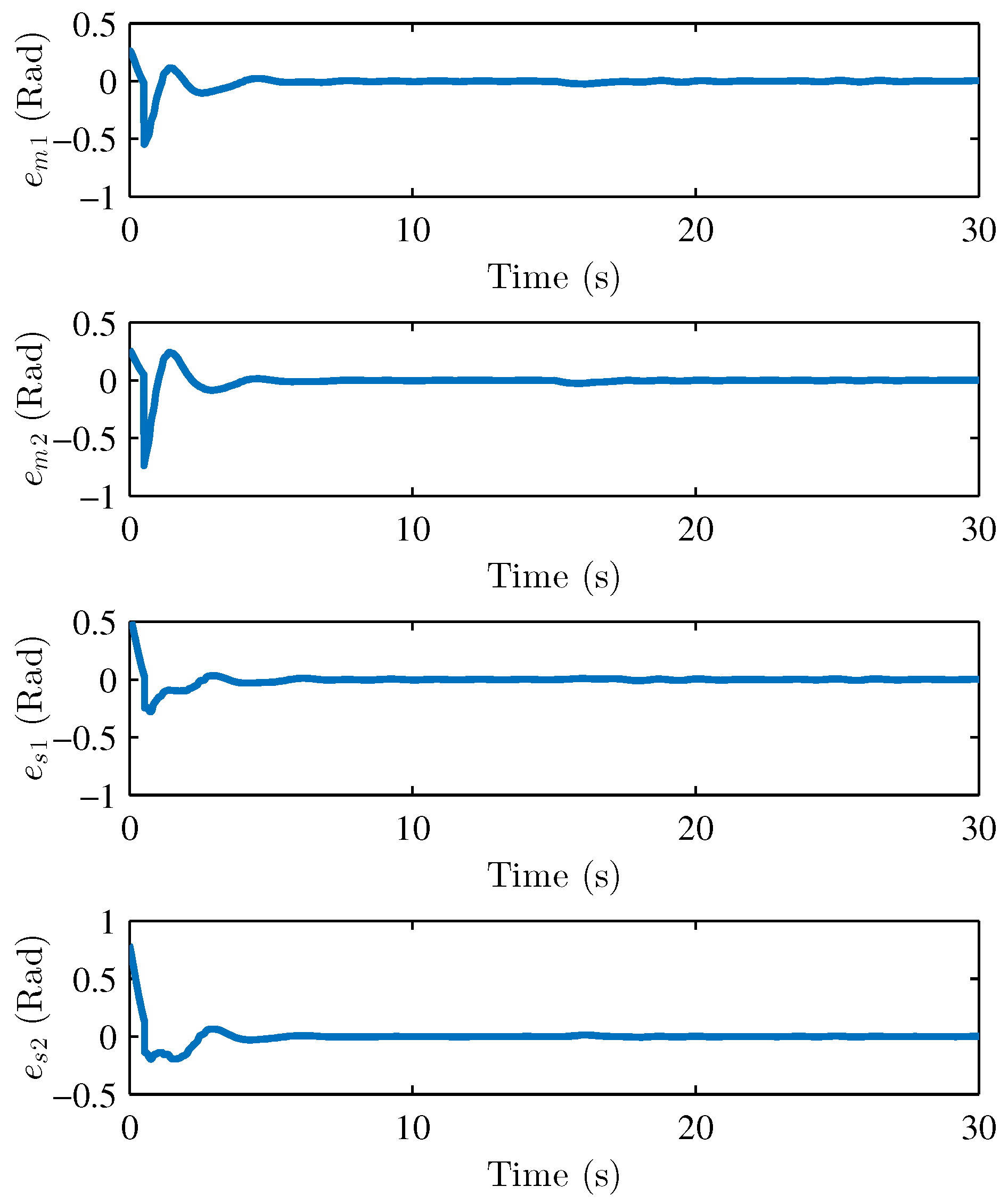

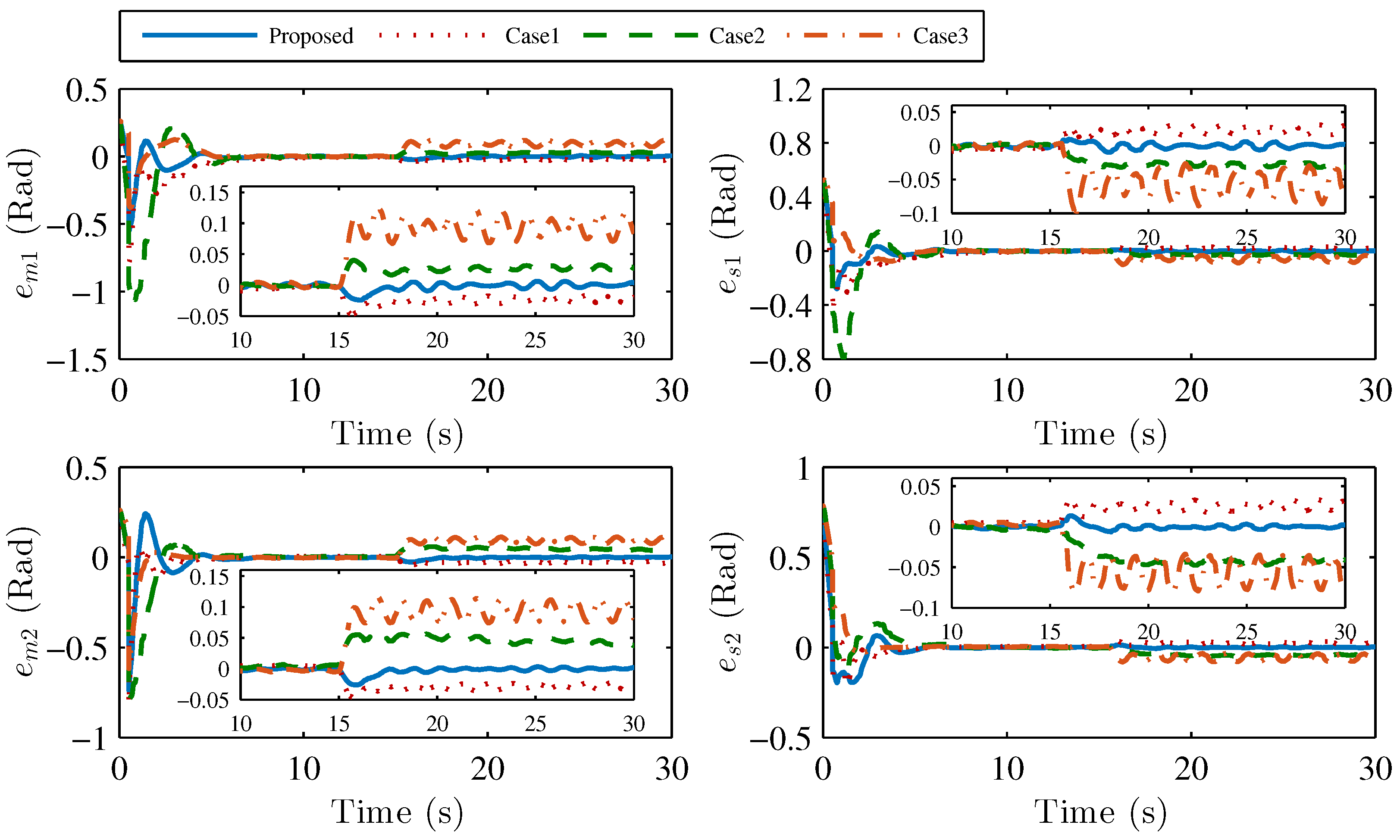

5.1. Simulation Analysis

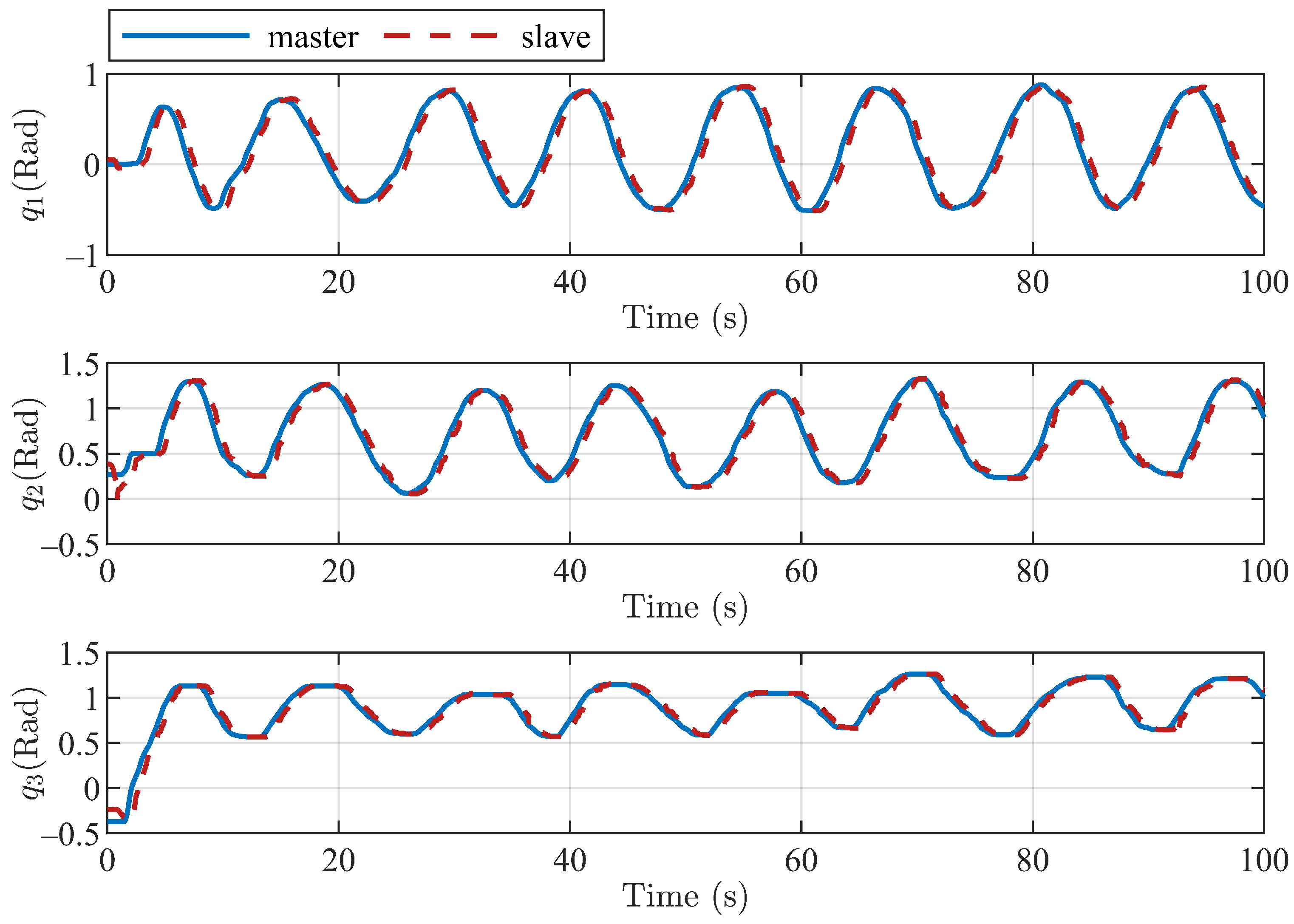

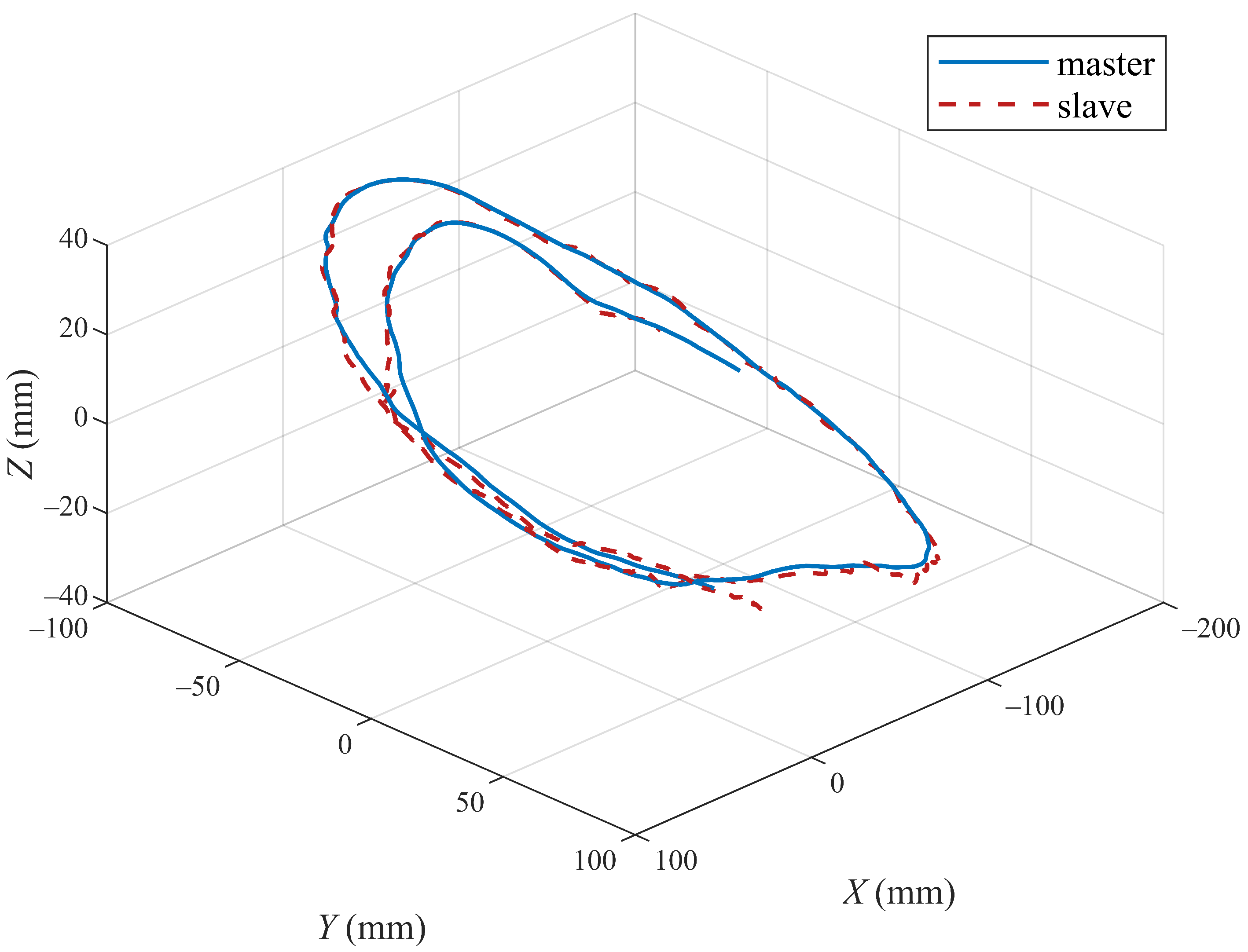

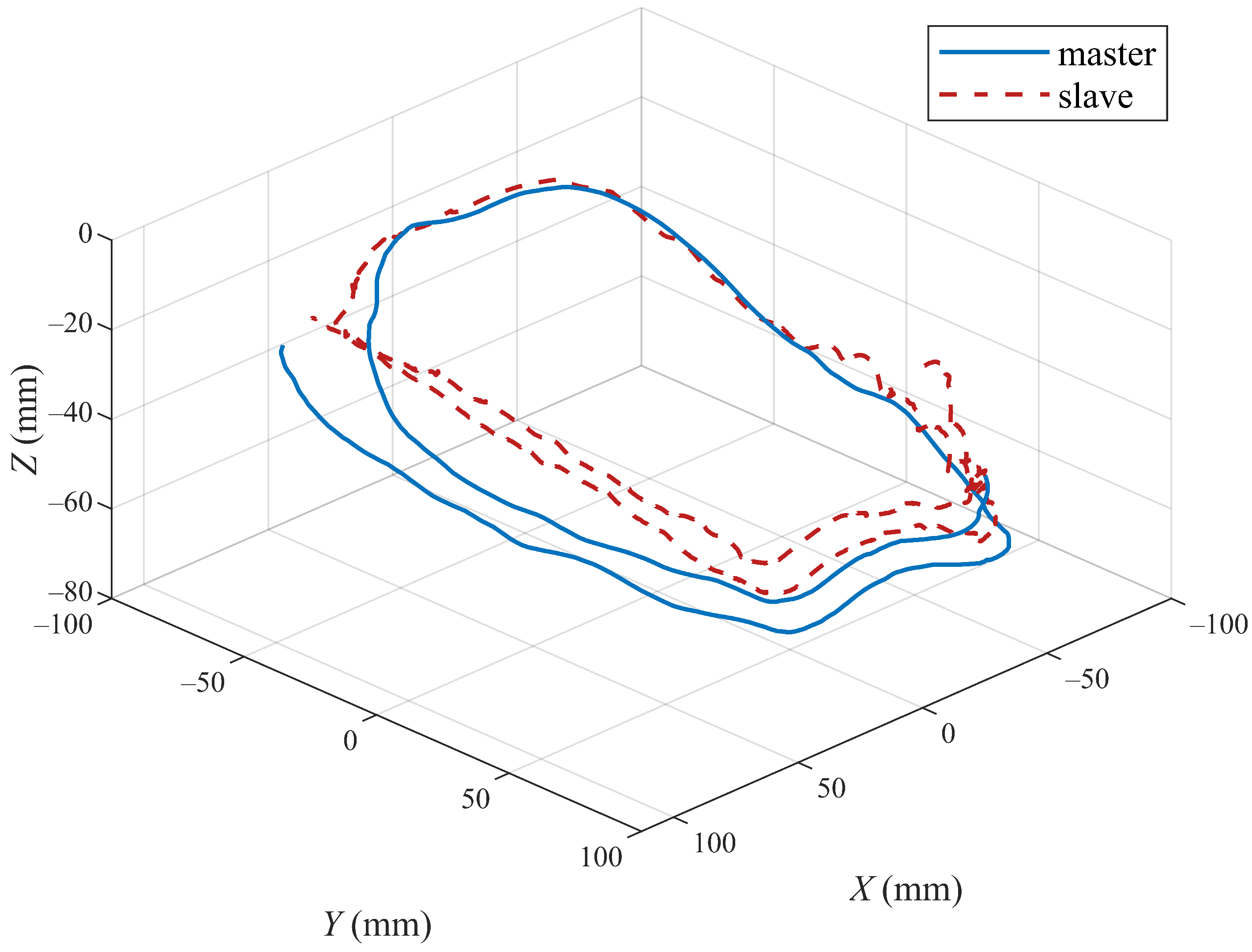

5.2. Experiment Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sheridan, T.B. Space teleoperation through time delay: Review and prognosis. IEEE Trans. Robot. Autom. 1993, 9, 592–606. [Google Scholar] [CrossRef]

- Soylu, S.; Firmani, F.; Buckham, B.J.; Podhorodeski, R.P. Comprehensive underwater vehicle-manipulator system teleoperation. In Proceedings of the Oceans 2010 MTS/IEEE Seattle, Seattle, WA, USA, 20–23 September 2010; pp. 1–8. [Google Scholar]

- Shi, B.; Wu, H.; Zhu, Y.; Shang, M. Robust control of a new asymmetric teleoperation robot based on a state observer. Sensors 2021, 21, 6197. [Google Scholar] [CrossRef] [PubMed]

- Xiong, P.W.; Zhu, X.; Song, A.; Hu, L.; Liu, X.P.; Feng, L. A target grabbing strategy for telerobot based on improved stiffness display device. IEEE/CAA J. Autom. Sin. 2016, 4, 661–667. [Google Scholar] [CrossRef]

- Kebria, P.M.; Abdi, H.; Dalvand, M.M.; Khosravi, A.; Nahavandi, S. Control methods for internet-based teleoperation systems: A review. IEEE Trans. Hum.-Mach. Syst. 2018, 49, 32–46. [Google Scholar] [CrossRef]

- Yang, Y.; Hua Chang, C.; Li, J. A novel delay-dependent finite-time control of telerobotics system with asymmetric time-varying delays. IEEE Trans. Control Syst. Technol. 2022, 30, 985–996. [Google Scholar] [CrossRef]

- Anderson, R.J.; Spong, M.W. Bilateral control of teleoperators with time delay. In Proceedings of the 1988 IEEE International Conference on Systems, Man, and Cybernetics, Beijing, China, 8–12 August 1988; pp. 131–138. [Google Scholar]

- Chen, H.C.; Liu, Y.C. Passivity-based control framework for task-space bilateral teleoperation with parametric uncertainty over unreliable networks. ISA Trans. 2017, 70, 187–199. [Google Scholar]

- Munir, S.; Book, W.J. Internet based teleoperation using wave variables with prediction. In Proceedings of the 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Proceedings (Cat. No. 01TH8556), Seoul, Korea, 21–26 May 2001; pp. 43–50. [Google Scholar]

- Chen, Z.; Huang, F.; Song, W.; Zhu, S. A novel wave-variable based time-delay compensated four-channel control design for multilateral teleoperation system. IEEE Access 2018, 6, 25506–25516. [Google Scholar] [CrossRef]

- Slawiñski, E.; Mut, V. PD-like controllers for delayed bilateral teleoperation of manipulators robots. Intern. J. Robust Nonlinear Control 2015, 25, 1801–1815. [Google Scholar] [CrossRef]

- Hua, C.C.; Yang, X.; Yan, J.; Guan, X.P. On exploring the domain of attraction for bilateral teleoperator subject to interval delay and saturated P + d control scheme. IEEE Trans. Autom. Control 2016, 62, 2923–2928. [Google Scholar] [CrossRef]

- Cho, H.C.; Park, J.H.; Kim, K.; Park, J.O. Sliding mode-based impedance controller for bilateral teleoperation under varying time-delay. In Proceedings of the IEEE International Conference on Robotics and Automation, Como, Italy, 8–12 July 2001; pp. 1025–1030. [Google Scholar]

- Yan, Y.; Ding, L.; Yang, Y.; Liu, F. Discrete sliding mode control design for bilateral teleoperation system via adaptive extended state observer. Sensors 2020, 20, 5091. [Google Scholar] [CrossRef] [PubMed]

- Al-Wais, S.; Khoo, S.; Lee, T.H.; Shanmugam, L.; Nahavandi, S. Robust H∞ cost guaranteed integral sliding mode control for the synchronization problem of nonlinear tele-operation system with variable time-delay. ISA Trans. 2018, 72, 25–36. [Google Scholar] [CrossRef] [PubMed]

- Hua, C.C.; Yang, Y.; Liu, P.X. Output-feedback adaptive control of networked teleoperation system with time-varying delay and bounded inputs. IEEE/ASME Trans. Mechatron. 2014, 20, 2009–2020. [Google Scholar] [CrossRef]

- Hua, C.C.; Liu, X.P. A new coordinated slave torque feedback control algorithm for network-based teleoperation systems. IEEE/ASME Trans. Mechatron. 2012, 18, 764–774. [Google Scholar] [CrossRef]

- Kostyukova, O.; Vista, F.P., IV; Chong, K.T. Design of feedforward and feedback position control for passive bilateral teleoperation with delays. ISA Trans. 2019, 85, 200–213. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.; Song, A.; Li, H.; Li, T. Constrained control for cloud robotic under time delay based on command governor with interval estimation. IEEE Access 2019, 7, 70999–71006. [Google Scholar] [CrossRef]

- Yang, Y.; Hua, C.; Guan, X. Adaptive fuzzy finite-time coordination control for networked nonlinear bilateral teleoperation system. IEEE Trans. Fuzzy Syst. 2013, 22, 631–641. [Google Scholar] [CrossRef]

- Sarras, I.; Nuño, E.; Basañez, L. An adaptive controller for nonlinear teleoperators with variable time-delays. J. Frankl. Inst. Eng. Appl. Math. 2014, 351, 4817–4837. [Google Scholar] [CrossRef]

- Liu, Y.C.; Khong, M.H. Adaptive control for nonlinear teleoperators with uncertain kinematics and dynamics. IEEE/ASME Trans. Mechatron. 2015, 20, 2550–2562. [Google Scholar] [CrossRef]

- Wang, H.; Liu, P.X.; Liu, S. Adaptive neural synchronization control for bilateral teleoperation systems with time delay and backlash-like hysteresis. IEEE Trans. Cybern. 2017, 47, 3018–3026. [Google Scholar] [CrossRef]

- Yang, L.; Chen, K.; Xu, Z. Adaptive tracking control of a nonlinear teleoperation system with uncertainties in kinematics and dynamics. Adv. Mech. Eng. 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Liu, Z.; Chen, K.R.; Zhang, Z.X. Adaptive fuzzy control for teleoperation system with uncertain kinematics and dynamics. Intern. J. Control Automat. Syst. 2019, 17, 1158–1166. [Google Scholar] [CrossRef]

- Li, Z.; Cao, X.; Ding, N. Adaptive fuzzy control for synchronization of nonlinear teleoperators with stochastic time-varying communication delays. IEEE Trans. Fuzzy Sys. 2011, 19, 745–757. [Google Scholar] [CrossRef]

- Yang, C.; Wang, X.; Li, Z.; Li, Y.; Su, C.Y. Teleoperation control based on combination of wave variable and neural networks. IEEE Trans. Syst. Man Cybern. Syst. 2016, 47, 2125–2136. [Google Scholar] [CrossRef]

- Kebria, P.; Khosravi, A.; Nahavandi, S.; Wu, D.; Bello, F. Adaptive type-2 fuzzy neural-network control for teleoperation systems with delay and uncertainties. IEEE Trans. Fuzzy Sys. 2020, 28, 2543–2554. [Google Scholar] [CrossRef]

- Sun, D.; Liao, Q.; Ren, H. Type-2 fuzzy modeling and control for bilateral teleoperation system with dynamic uncertainties and time-varying delays. IEEE Trans. Ind. Electron. 2017, 65, 447–459. [Google Scholar] [CrossRef]

- Sun, D.; Liao, Q.; Ren, H. Adaptive task-space synchronization control of bilateral teleoperation systems with uncertain parameters and communication delays. IEEE Access 2018, 6, 5740–5748. [Google Scholar]

- Chen, Z.; Huang, F.; Sun, W.; Gu, J.; Yao, B. RBF-neural-network-based adaptive robust control for nonlinear bilateral teleoperation manipulators with uncertainty and time delay. IEEE/ASME Trans. Mechatron. 2020, 25, 906–918. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, F.; Chen, W.; Zhang, J.; Sun, W.; Chen, J.; Gu, J.; Zhu, S. RBFNN-based adaptive sliding mode control design for delayed nonlinear multilateral telerobotic system with cooperative manipulation. IEEE Trans. Industr. Inform. 2020, 16, 1236–1247. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, Y.; Liang, B. Synchronization control for bilateral teleoperation system with position error constraints: A fixed-time approach. ISA Trans. 2019, 93, 125–136. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, S.; Yu, X.; Kong, L.; Li, Q.; Li, G. Adaptive neural network fixed-time control design for bilateral teleoperation with time delay. IEEE Trans. Cybern. 2021, 52, 9756–9769. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Zhang, H.; Yang, Y.; Yang, H. Integral sliding mode control of a bilateral teleoperation system based on extended state observers. Intern. J. Control Automat. Syst. 2017, 15, 2118–2125. [Google Scholar] [CrossRef]

- Zhang, H.; Song, A.; Li, H.; Shen, S. Novel adaptive finite time control of teleoperation system with time-varying delays and input saturation. IEEE Trans. Cybern. 2021, 57, 3724–3737. [Google Scholar] [CrossRef] [PubMed]

- Seshagiri, S.; Khalil, H.K. Output feedback control of nonlinear systems using RBF neural networks. IEEE Trans. Neural Netw. 2000, 11, 69–79. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Hou, Z.; Cheng, L.; Ji, C.; Tan, M.; Yu, H. Adaptive neural network tracking control of robot manipulators with prescribed performance. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2011, 225, 790–797. [Google Scholar] [CrossRef]

- Li, Z.; Xia, Y.; Su, C.-Y. Intelligent Networked Teleoperation Control; Springer: Berlin, Germany, 2015. [Google Scholar]

- Azimifar, F.; Abrishamkar, M.; Farzaneh, B.; Sarhan, A.; Amini, H. Improving teleoperation system performance in the presence of estimated external force. Robot. Comput.-Integr. Manuf. 2017, 46, 86–93. [Google Scholar] [CrossRef]

| RMSE | Proposed | Method 1 | Method 2 | Method 3 |

|---|---|---|---|---|

| 0.005325 | 0.018781 | 0.018986 | 0.066509 | |

| 0.005216 | 0.021510 | 0.033383 | 0.065783 | |

| 0.002939 | 0.015770 | 0.019065 | 0.041126 | |

| 0.002333 | 0.017474 | 0.028411 | 0.040475 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.; Zhang, H. Design of Synchronization Tracking Adaptive Control for Bilateral Teleoperation System with Time-Varying Delays. Sensors 2022, 22, 7798. https://doi.org/10.3390/s22207798

Chen K, Zhang H. Design of Synchronization Tracking Adaptive Control for Bilateral Teleoperation System with Time-Varying Delays. Sensors. 2022; 22(20):7798. https://doi.org/10.3390/s22207798

Chicago/Turabian StyleChen, Kesong, and Haochen Zhang. 2022. "Design of Synchronization Tracking Adaptive Control for Bilateral Teleoperation System with Time-Varying Delays" Sensors 22, no. 20: 7798. https://doi.org/10.3390/s22207798

APA StyleChen, K., & Zhang, H. (2022). Design of Synchronization Tracking Adaptive Control for Bilateral Teleoperation System with Time-Varying Delays. Sensors, 22(20), 7798. https://doi.org/10.3390/s22207798