A Novel High-Sensitivity MEMS Pressure Sensor for Rock Mass Stress Sensing

Abstract

1. Introduction

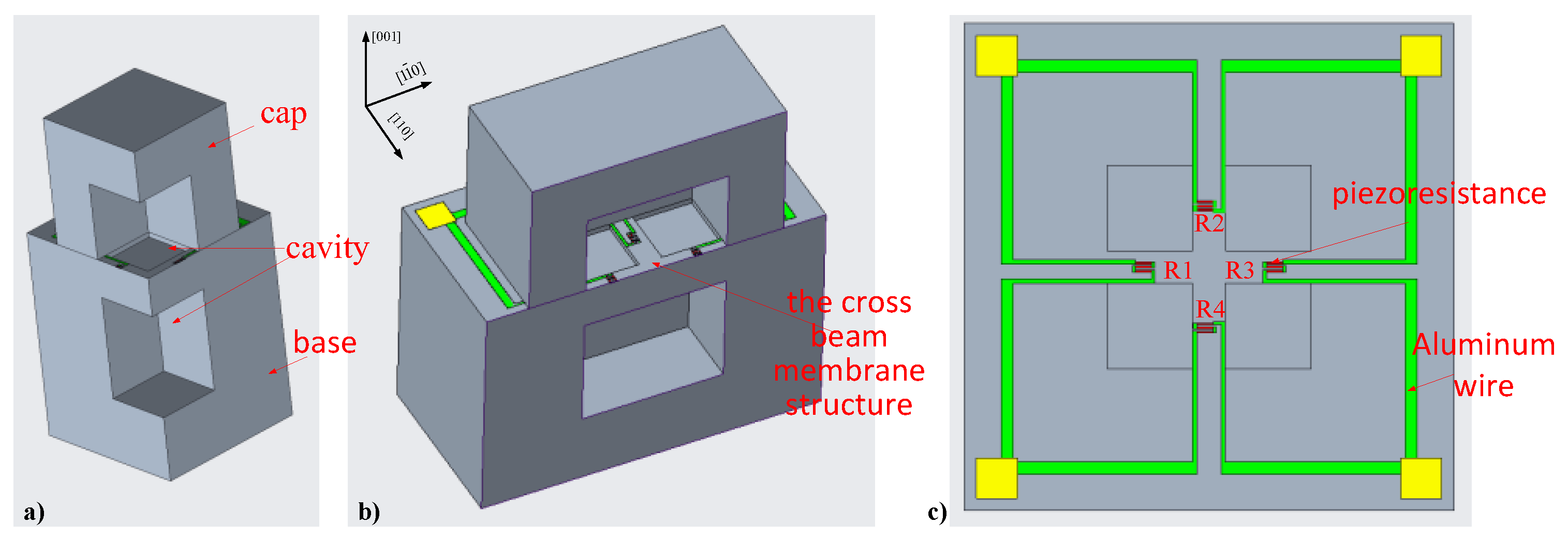

2. Principle of CCSB

2.1. The CCSB Structural Features

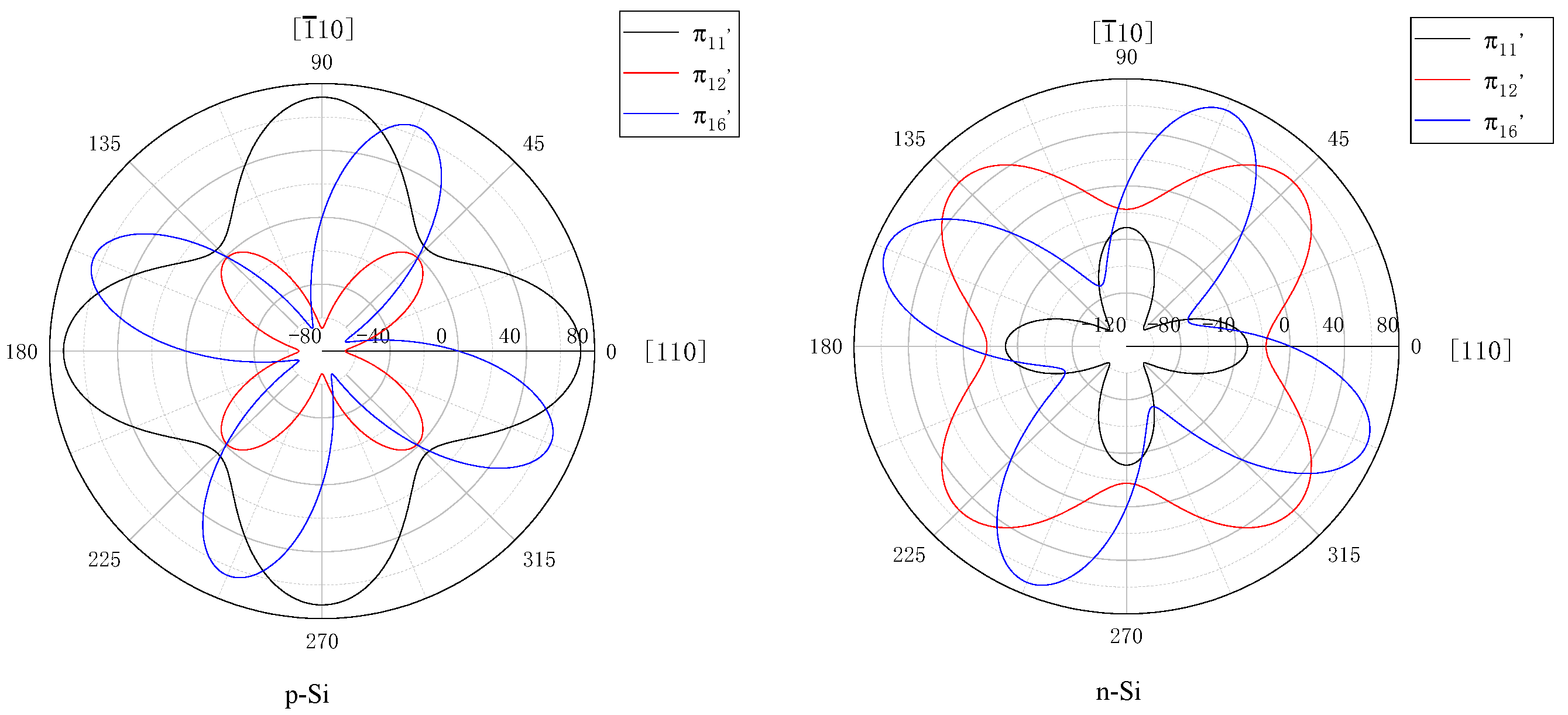

2.2. Piezoresistive Effect of CCSB

2.3. Sensor Output

3. Sensor Design

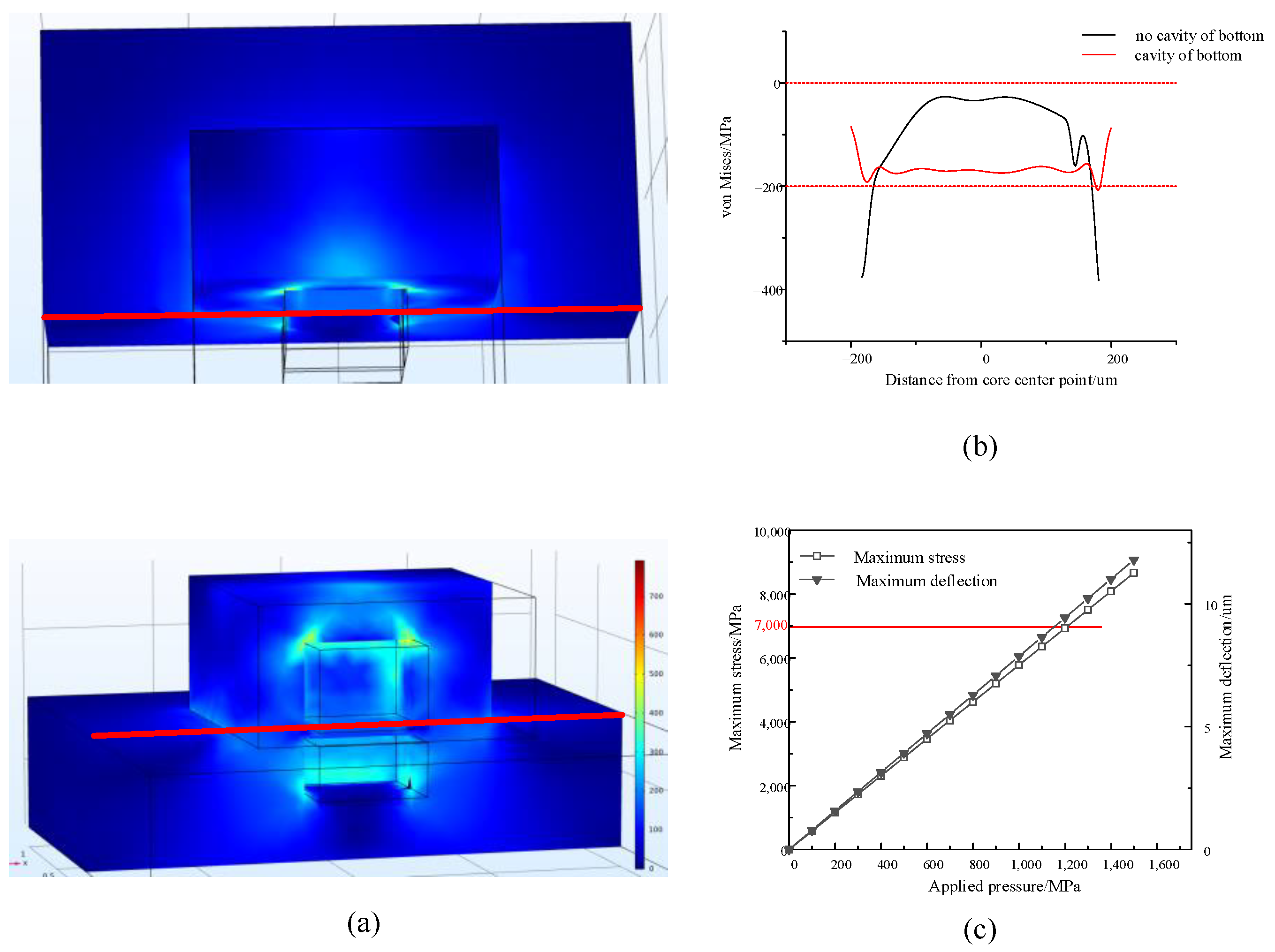

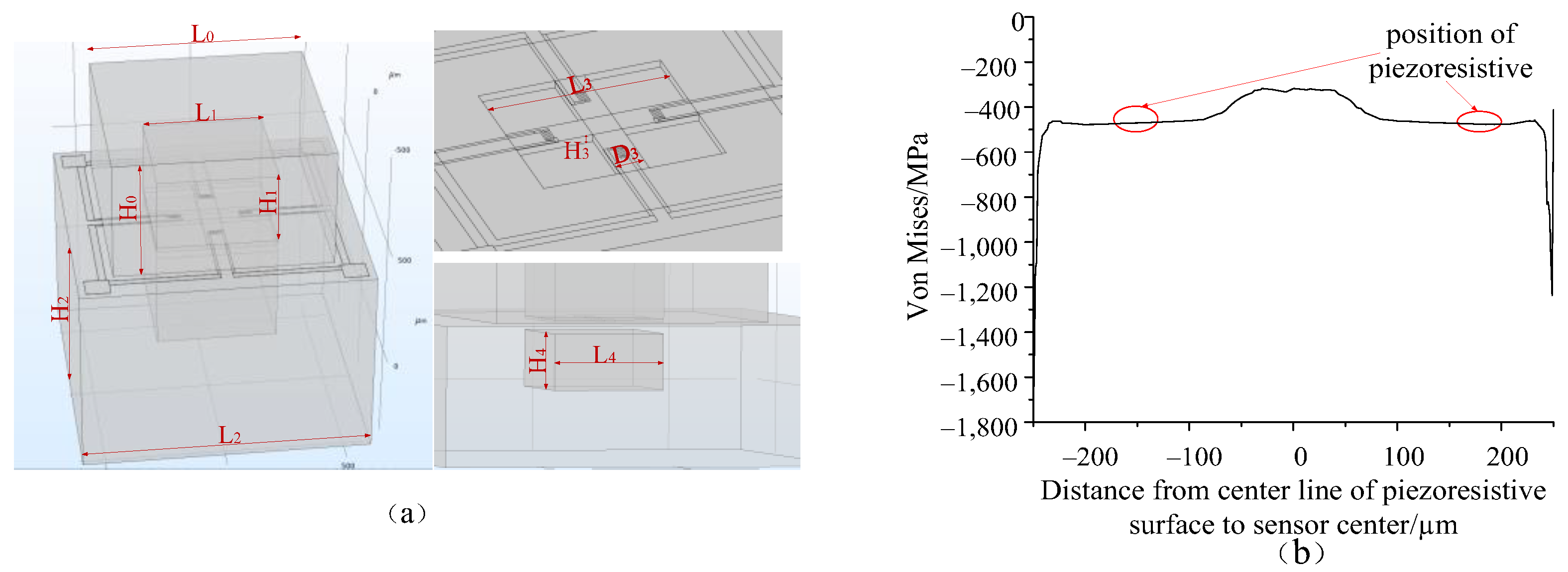

3.1. The CCSB Stress Analysis

3.2. The CCSB Structure Analysis

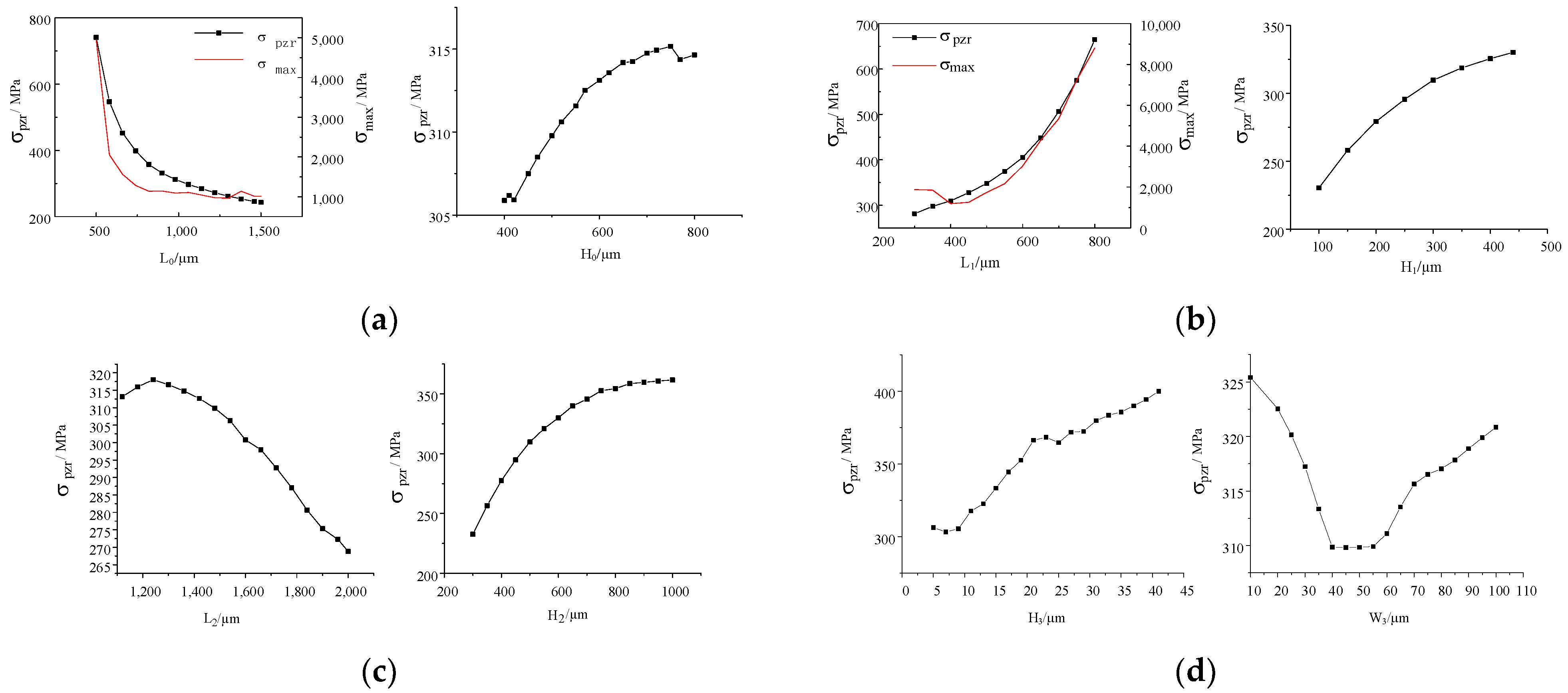

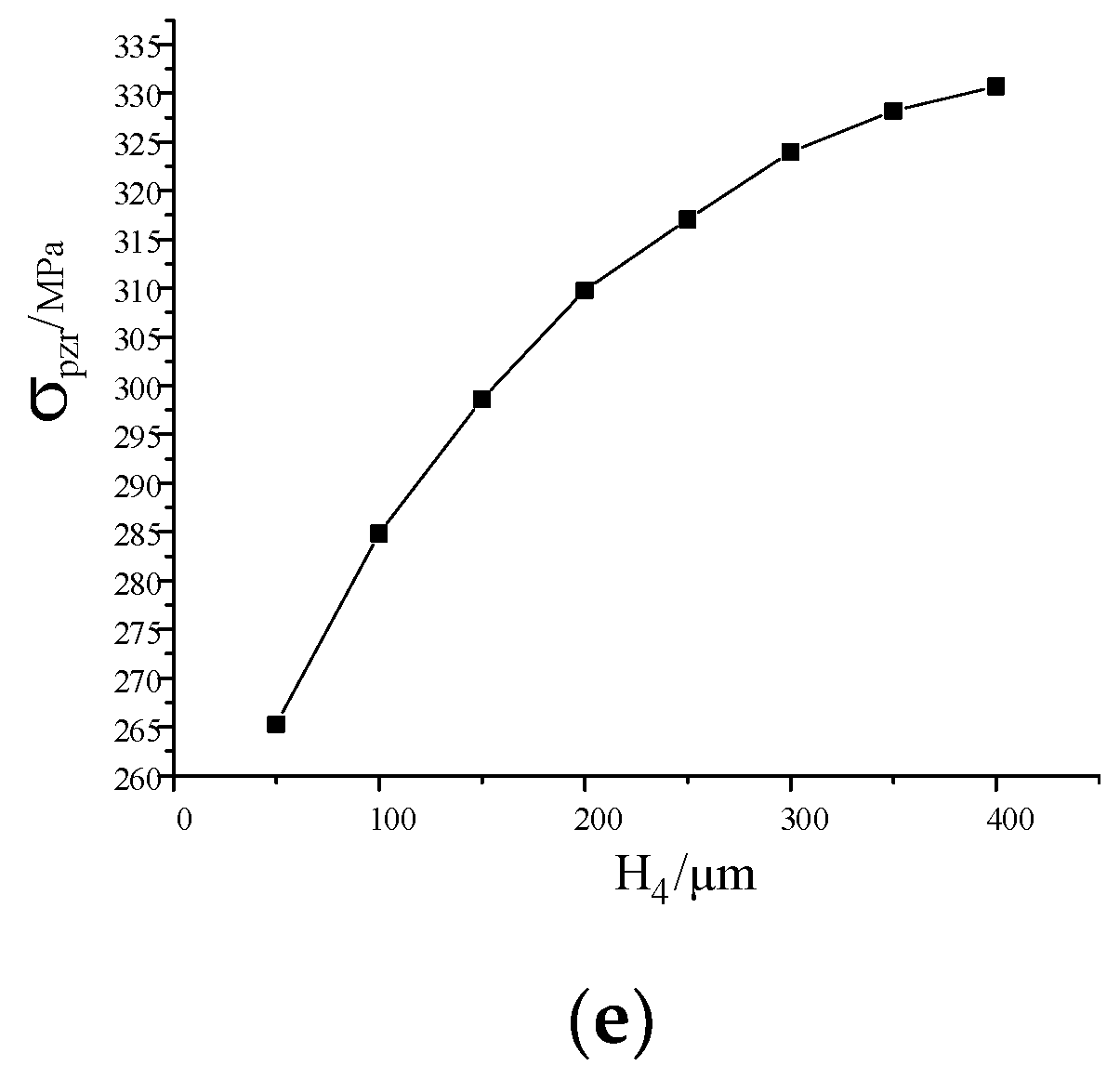

3.2.1. Structural Parameter Analysis

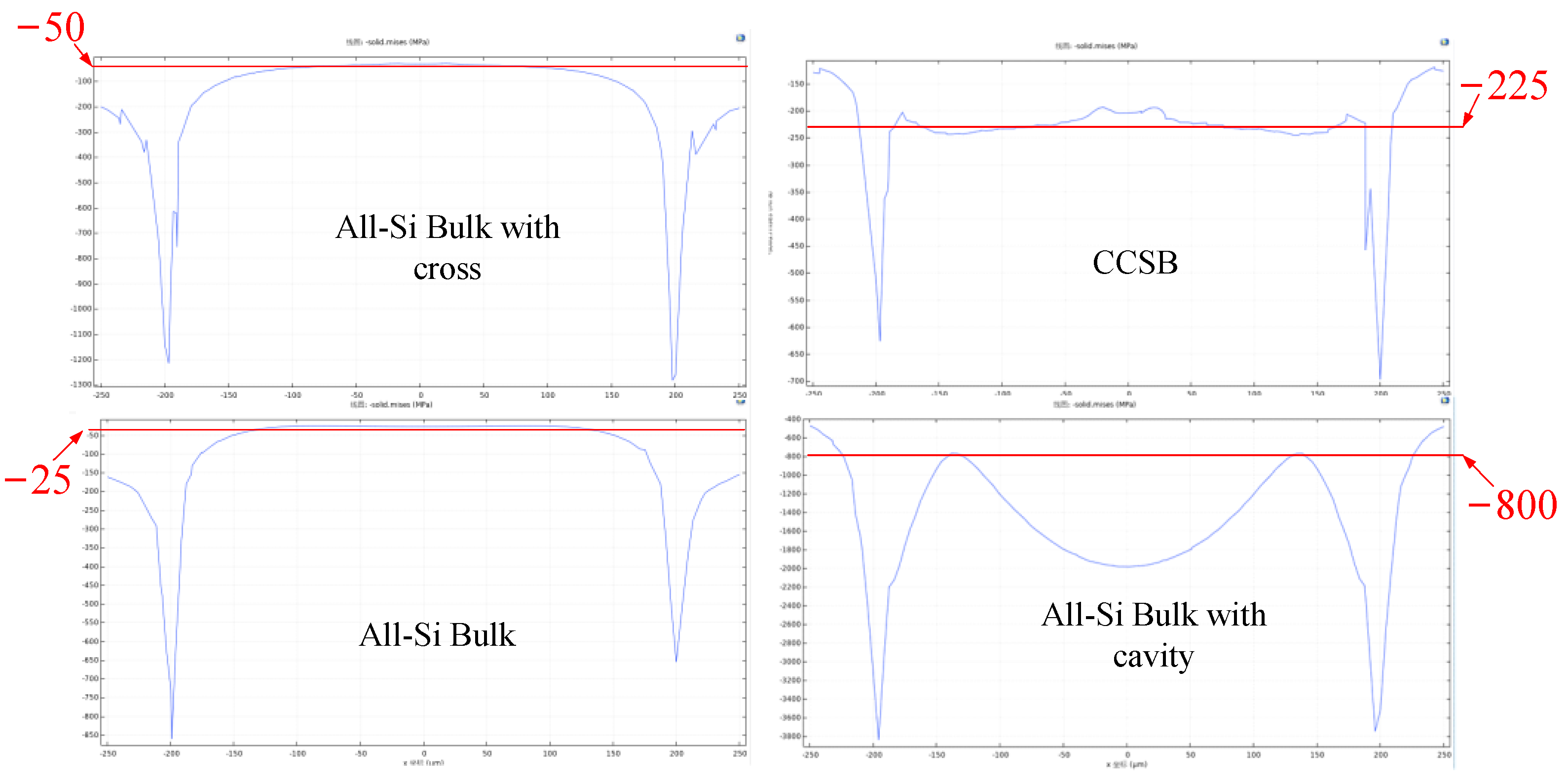

3.2.2. Numerical Simulation

3.2.3. Parameter Optimization Design

4. Results and Discussion

4.1. Simulation Results

4.2. Discussion

4.2.1. Sensitivity and Non-Linear Error

4.2.2. Structure and Pressure

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, C.; Long, J.; Liu, Y.; Li, Q.; Liu, W.; Feng, P.; Li, B.; Xian, J. Mechanism Analysis and Partition Characteristics of a Recent Highway Landslide in Southwest China Based on a 3D Multi-Point Deformation Monitoring System. Landslides 2021, 18, 2895–2906. [Google Scholar] [CrossRef]

- Xu, N.; Tang, C.; Li, H.; Dai, F.; Ma, K.; Shao, J.; Wu, J. Excavation-Induced Microseismicity: Microseismic Monitoring and Numerical Simulation. J. Zhejiang Univ. Sci. A 2012, 13, 445–460. [Google Scholar] [CrossRef]

- Su, Z.; Sui, H.; Liu, W. Development and Application of Rock-Soil Stress-StrainMate Sensor. Chin. J. Geotech. Eng. 1997, 19, 66–70. [Google Scholar]

- Zhao, W.; Zhong, K.; Chen, W. A Fiber Bragg Grating Borehole Deformation Sensor for Stress Measurement in Coal Mine Rock. Sensors 2020, 20, 3267. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Liu, Q.; Pang, S.; Xu, K.; Tang, H.; Sun, C. High-Temperature Piezoresistive Pressure Sensor Based on Implantation of Oxygen into Silicon Wafer. Sens. Actuators A Phys. 2012, 179, 277–282. [Google Scholar] [CrossRef]

- Kanoun, O.; Müller, C.; Benchirouf, A.; Sanli, A.; Dinh, T.N.; Al-Hamry, A.; Bu, L.; Gerlach, C.; Bouhamed, A. Flexible Carbon Nanotube Films for High Performance Strain Sensors. Sensors 2014, 14, 10042–10071. [Google Scholar] [CrossRef]

- Zhu, S.E.; Krishna Ghatkesar, M.; Zhang, C.; Janssen, G.C.A.M. Graphene Based Piezoresistive Pressure Sensor. Appl. Phys. Lett. 2013, 102, 111–114. [Google Scholar] [CrossRef]

- Smith, A.D.; Niklaus, F.; Paussa, A.; Vaziri, S.; Fischer, A.C.; Sterner, M.; Forsberg, F.; Delin, A.; Esseni, D.; Palestri, P.; et al. Electromechanical Piezoresistive Sensing in Suspended Graphene Membranes. Nano Lett. 2013, 13, 3237–3242. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhang, D. A High Sensitivity and High Linearity Pressure Sensor Based on a Peninsula-Structured Diaphragm for Low-Pressure Ranges. Sens. Actuators A Phys. 2014, 216, 176–189. [Google Scholar] [CrossRef]

- Tian, B.; Zhao, Y.; Jiang, Z.; Hu, B. The Design and Analysis of Beam-Membrane Structure Sensors for Micro-Pressure Measurement. Rev. Sci. Instrum. 2012, 83, 045003. [Google Scholar] [CrossRef]

- Niu, Z.; Zhao, Y.; Tian, B. Design Optimization of High Pressure and High Temperature Piezoresistive Pressure Sensor for High Sensitivity. Rev. Sci. Instrum. 2014, 85, 015001. [Google Scholar] [CrossRef]

- Nag, M.; Singh, J.; Kumar, A.; Singh, K. A High Sensitive Graphene Piezoresistive MEMS Pressure Sensor by Integration of Rod Beams in Silicon Diaphragm for Low Pressure Measurement Application. Microsyst. Technol. 2020, 26, 2971–2976. [Google Scholar] [CrossRef]

- Li, C.; Cordovilla, F.; Jagdheesh, R.; Ocaña, J.L. Design and Optimization of a Novel Structural MEMS Piezoresistive Pressure Sensor. Microsyst. Technol. 2017, 23, 4531–4541. [Google Scholar] [CrossRef]

- Tian, B.; Zhao, Y.; Jiang, Z. The Novel Structural Design for Pressure Sensors. Sens. Rev. 2010, 30, 305–313. [Google Scholar] [CrossRef]

- Yu, Z.; Zhao, Y.; Li, L.; Li, C.; Liu, Y.; Tian, B. Realization of a Micro Pressure Sensor with High Sensitivity and Overload by Introducing Beams and Islands. Microsyst. Technol. 2015, 21, 739–747. [Google Scholar] [CrossRef]

- Guan, T.; Yang, F.; Wang, W.; Huang, X.; Jiang, B.; Zhang, D. The Design and Analysis of Piezoresistive Shuriken-Structured Diaphragm Micro-Pressure Sensors. J. Microelectromech. Syst. 2017, 26, 206–214. [Google Scholar] [CrossRef]

- Tran, A.V.; Zhang, X.; Zhu, B. The Development of a New Piezoresistive Pressure Sensor for Low Pressures. IEEE Trans. Ind. Electron. 2018, 65, 6487–6496. [Google Scholar] [CrossRef]

- Liu, X. Micro-Fracture Mechanism and Stability Analysis of High Steep Rock Slope during Reservoir Impounding; Dalian University of Technology: Dalian, China, 2018. [Google Scholar]

- Heinickel, P.; Werthschützky, R. Functionality of a Novel Overload Resistant Silicon High Pressure Sensing Element. In Proceedings of the TRANSDUCERS 2009—15th International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 252–255. [Google Scholar] [CrossRef]

- Zeng, F.; Lu, L.; Zhang, Y.; Guo, S.; Wong, M.; Chau, K. MEMS Pressure Sensors for High-Temperature High-Pressure Downhole Applications. In Proceedings of the 2016 IEEE International Conference on Electron Devices and Solid-State Circuits, EDSSC 2016, Hong Kong, China, 3–5 August 2016; pp. 39–43. [Google Scholar]

- Chan, E.; Lin, D.; Lu, L.; Zhang, D.; Guo, S.; Zhang, Y.; Chau, K.; Wong, M. Realization and Characterization of a Bulk-Type All-Silicon High Pressure Sensor. J. Microelectromech. Syst. 2018, 27, 231–238. [Google Scholar] [CrossRef]

- Lin, D.; Chan, E.; Tang, Z.; Lu, L.; Wong, M.; Chau, K. A 2000-Atmosphere Bulk-Type Pressure Sensor Realized on (001) Substrate with Selective Stess-Filtering Trenches. In Proceedings of the 2019 IEEE 32nd International Conference on Micro Electro Mechanical Systems (MEMS), Seoul, Korea, 27–31 January 2019; pp. 739–742. [Google Scholar]

- Smith, C.S. Piezoresistance Effect in Germanium and Silicon. Phys. Rev. 1954, 94, 42–49. [Google Scholar] [CrossRef]

- Bao, M.; Huang, Y. Batch Derivation of Piezoresistive Coefficient Tensor by Matrix Algebra. J. Micromech. Microeng. 2004, 14, 332–334. [Google Scholar] [CrossRef]

- Wang, Z. Microsystem Design and Manufacturing; Tsinghua University Press: Beijing, China, 2008. [Google Scholar]

| π11 | π12 | π44 | |

|---|---|---|---|

| p-Si | 6.6 | −1.1 | 138.1 |

| n-Si | −102.2 | 53.4 | −13.6 |

| L0 | 1000 | L1 | 400 | L2 | 1500 | L3 | 400 | L4 | 400 |

| W0 | 1000 | W1 | 400 | W2 | 1500 | W3 | 40 | W4 | 400 |

| H0 | 500 | H1 | 300 | H2 | 500 | H3 | 10 | H4 | 200 |

| Structure Parameters | Size/μm |

|---|---|

| L0 | 900 |

| H0 | 500 |

| L1(L3,L4) | 500 |

| H1 | 300 |

| L2 | 1200 |

| H2 | 800 |

| D3 | 80 |

| H3 | 20 |

| H4 | 400 |

| Parameters | Value |

|---|---|

| P | 200 MPa |

| E | 169 GPa |

| ν | 0.27 |

| VS | 5 V |

| Structure | P (MPa) | Power Supply | Sensitivity (μV/V/MPa) | Non-Linear Error (%FSS) | Other Features | References | Application Scenarios |

|---|---|---|---|---|---|---|---|

| CCSB | 200 | 5 V | 87.74 | 0.54 | this paper | Rock mass stress monitoring | |

| All-Si Bulk | 200 | 5 V | 79 | [21] | Oil exploration | ||

| All-Si Bulk with Trench | 200 | 5 V | 49 | [22] | Oil exploration | ||

| Si-Glass Bulk | 200 | 5 V | 22.24 | 0.35 | [19] | ||

| Si Diaphragm-type | 150 | 1.5 mA | 1.1126 mV/MPa | 0.3 | [11] | Petrochemical industry | |

| Resistance strain gauge | 10 Kg | N/A | 0.5 | *1 K = 2 | [3] | Geotechnical stress measurement | |

| Fiber Bragg grating | 50 | N/A | N/A | 0.3~0.5 × 10−3 mm (Accuracy) | [4] | Rock mass stress monitoring | |

| Fiber Bragg grating | −3~13 KPa | N/A | N/A | 1.0 | 2 Pa (Resolution) | *2 Luna OS9100 | Rock mass stress monitoring |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zou, D.; Peng, P.; Yao, G.; Ren, J. A Novel High-Sensitivity MEMS Pressure Sensor for Rock Mass Stress Sensing. Sensors 2022, 22, 7593. https://doi.org/10.3390/s22197593

Wang H, Zou D, Peng P, Yao G, Ren J. A Novel High-Sensitivity MEMS Pressure Sensor for Rock Mass Stress Sensing. Sensors. 2022; 22(19):7593. https://doi.org/10.3390/s22197593

Chicago/Turabian StyleWang, Honghui, Dingkang Zou, Peng Peng, Guangle Yao, and Jizhou Ren. 2022. "A Novel High-Sensitivity MEMS Pressure Sensor for Rock Mass Stress Sensing" Sensors 22, no. 19: 7593. https://doi.org/10.3390/s22197593

APA StyleWang, H., Zou, D., Peng, P., Yao, G., & Ren, J. (2022). A Novel High-Sensitivity MEMS Pressure Sensor for Rock Mass Stress Sensing. Sensors, 22(19), 7593. https://doi.org/10.3390/s22197593