Battery-Less NFC Potentiostat for Electrochemical Point-of-Care Sensors Based on COTS Components

Abstract

1. Introduction

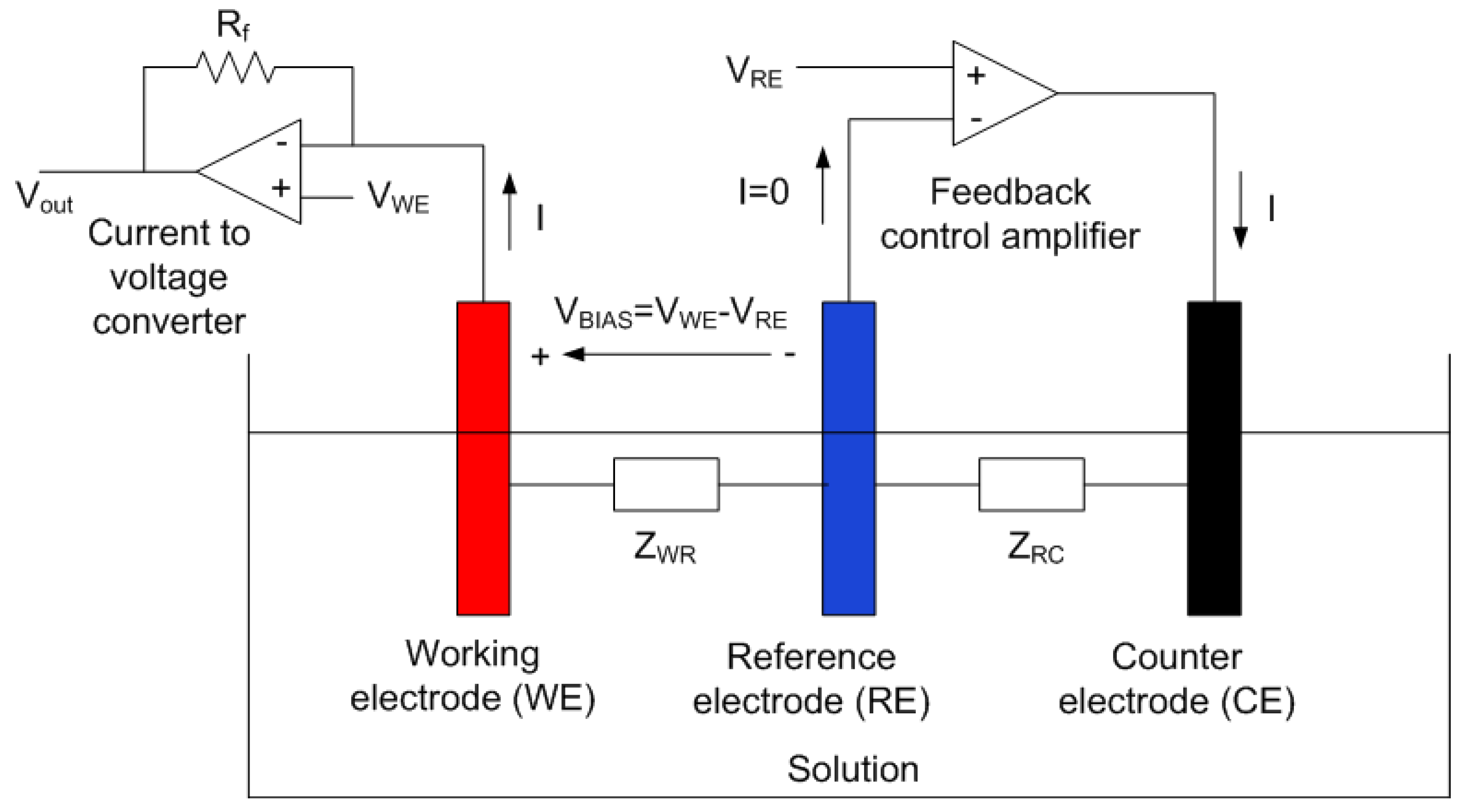

2. Electrochemical Sensors

3. System Overview and Theoretical Background

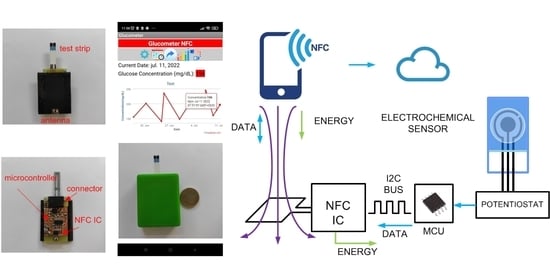

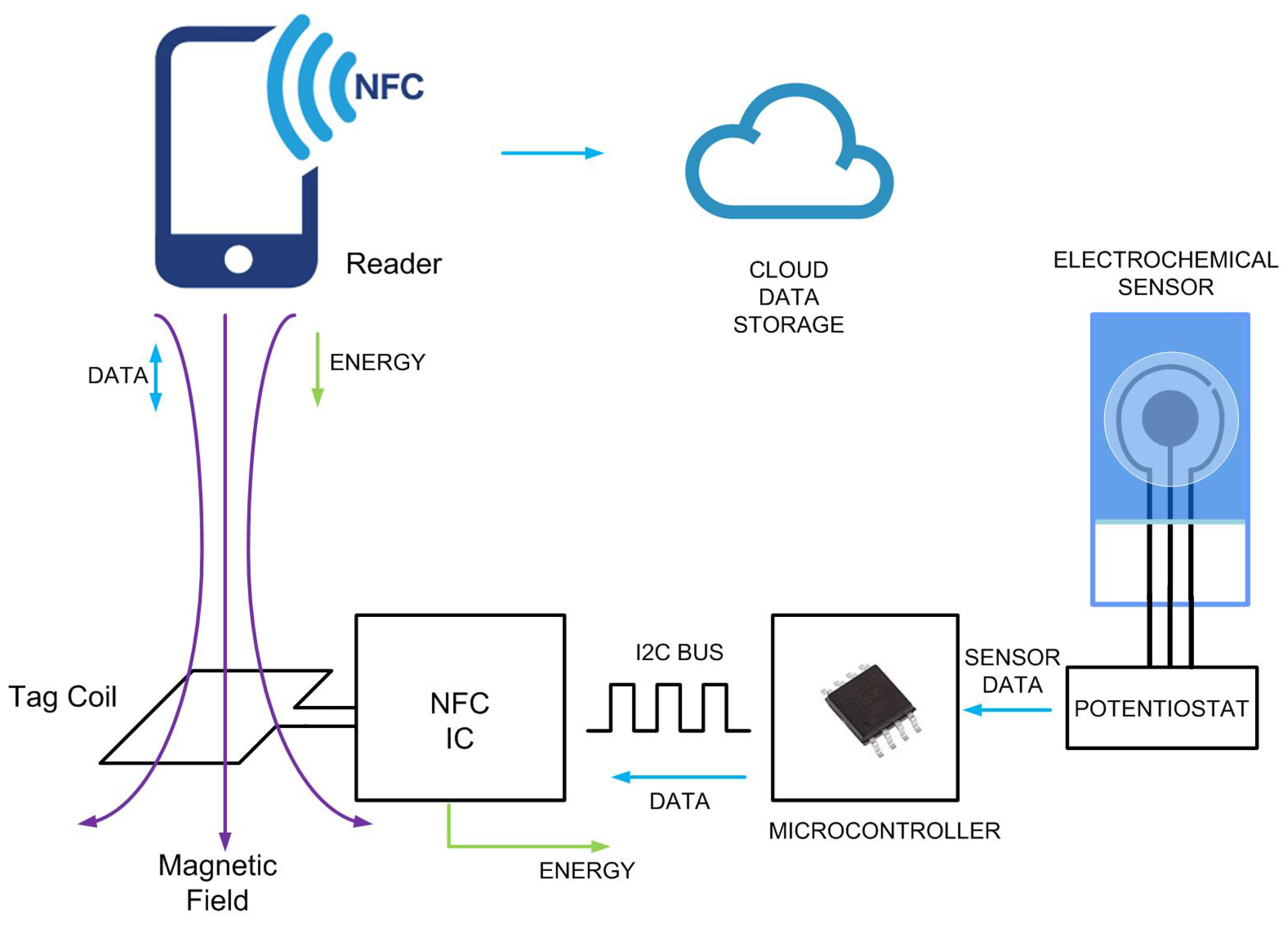

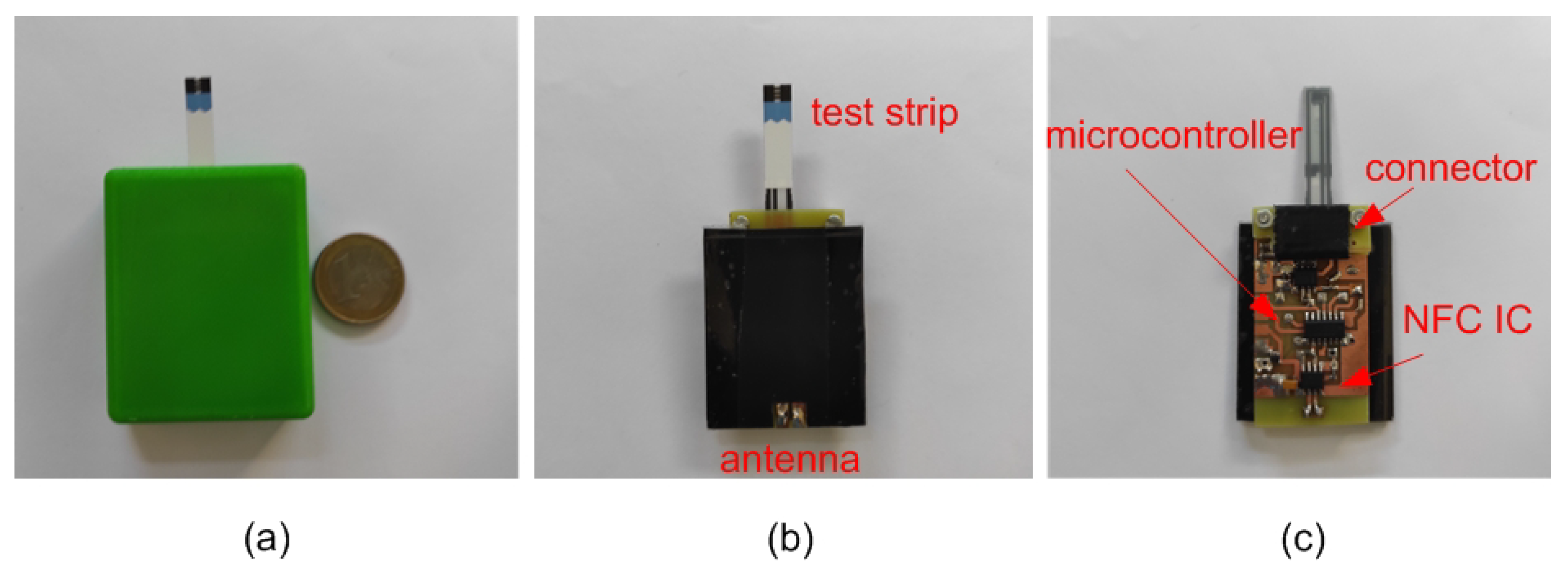

3.1. System Overview

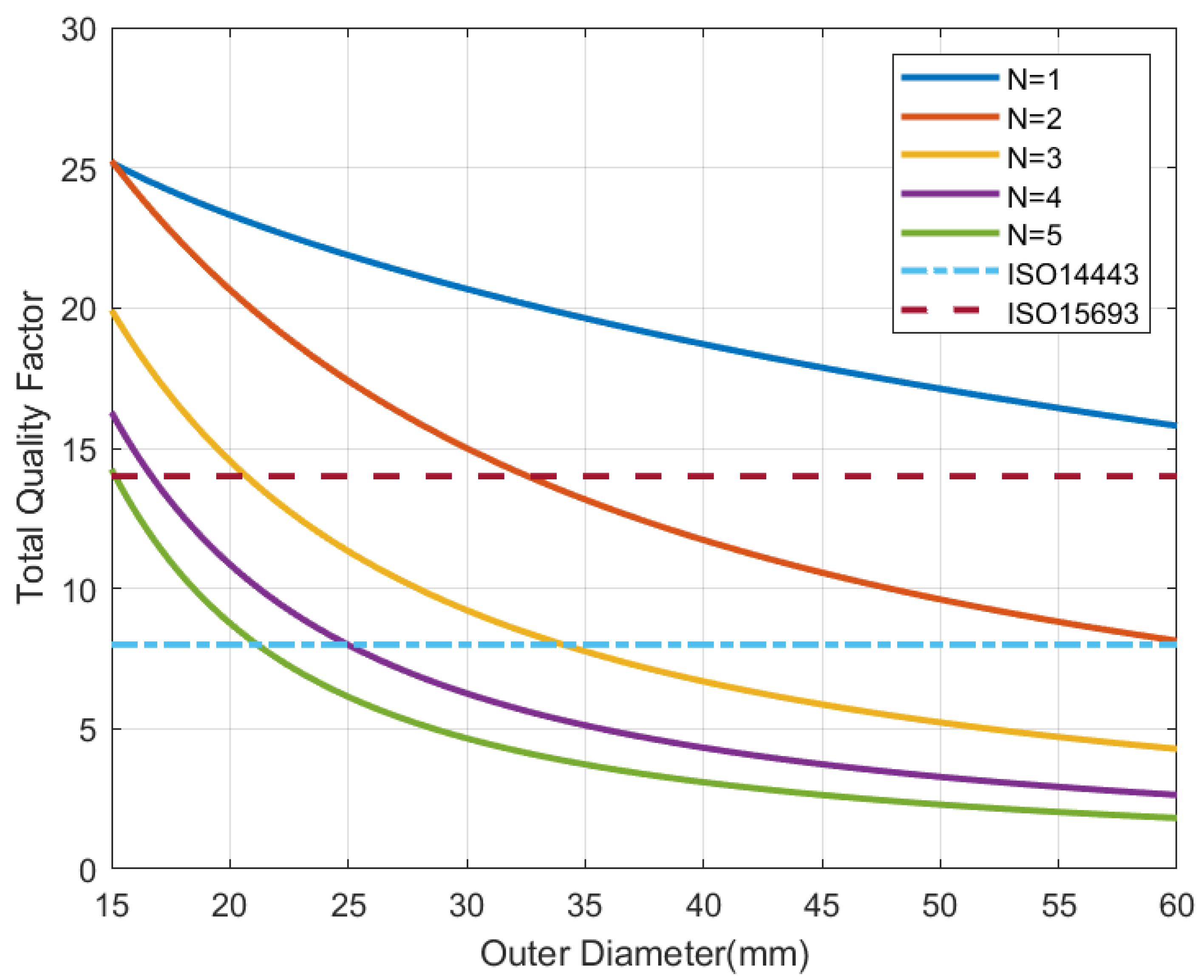

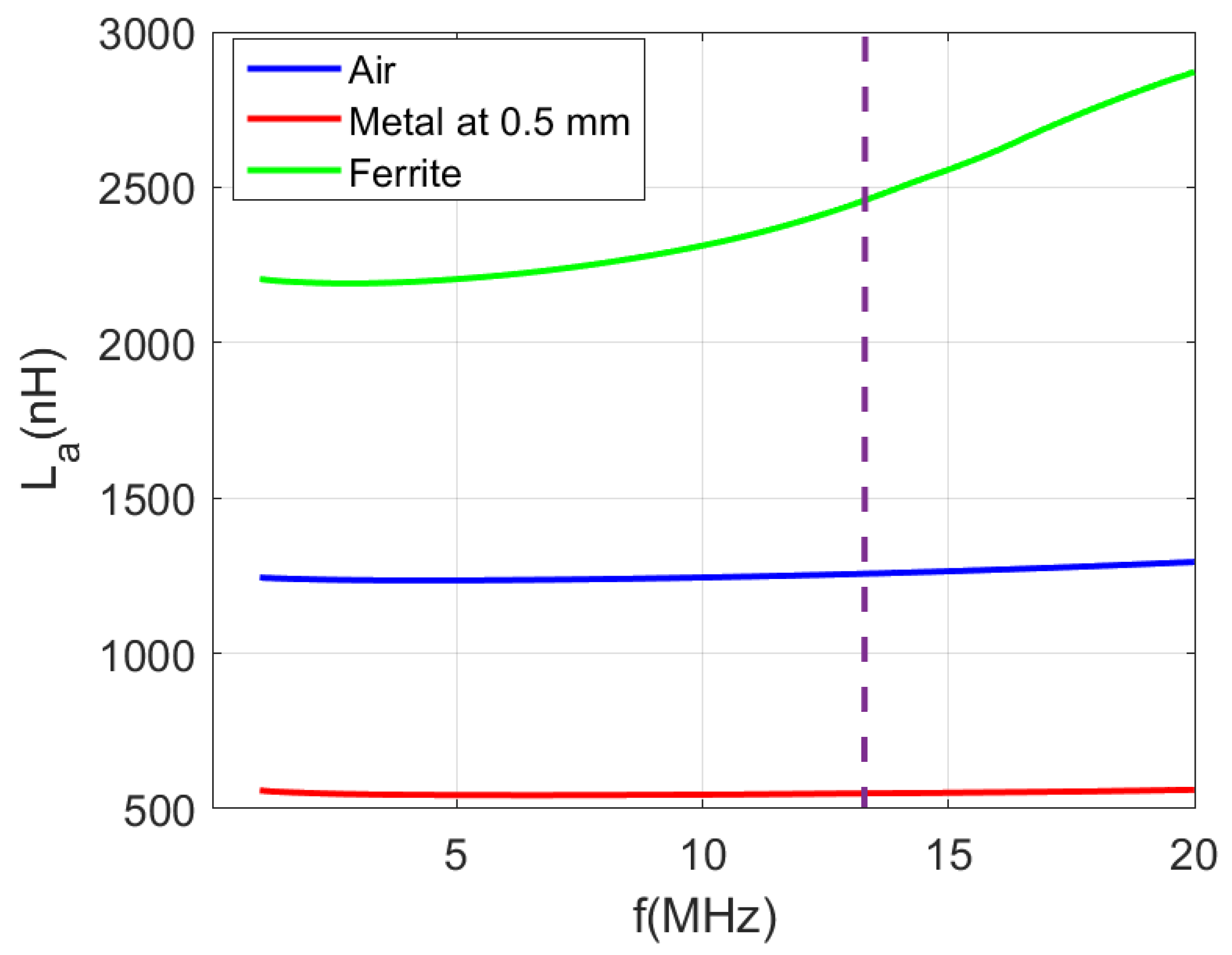

3.2. Antenna Design and Tag Tuning

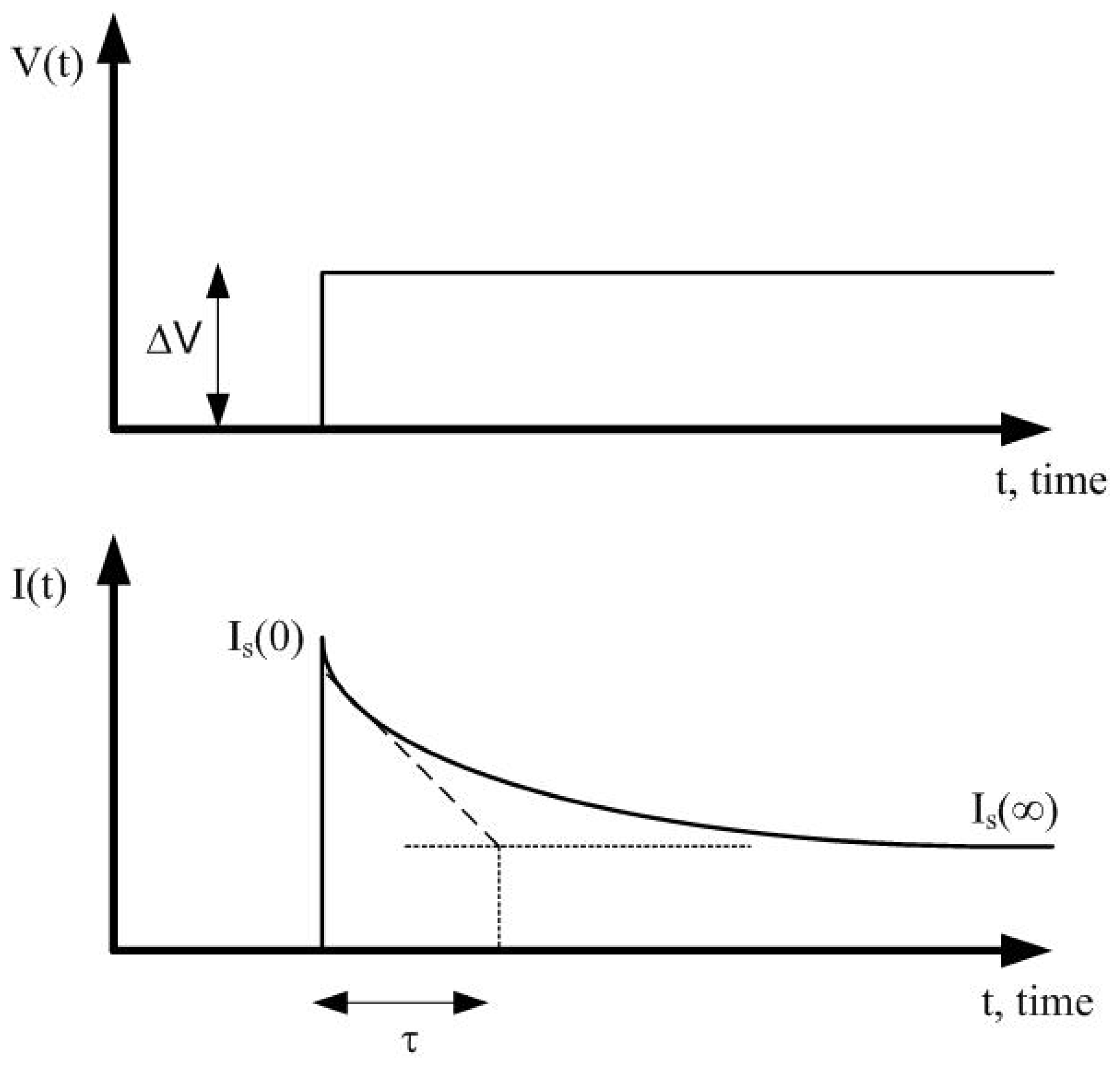

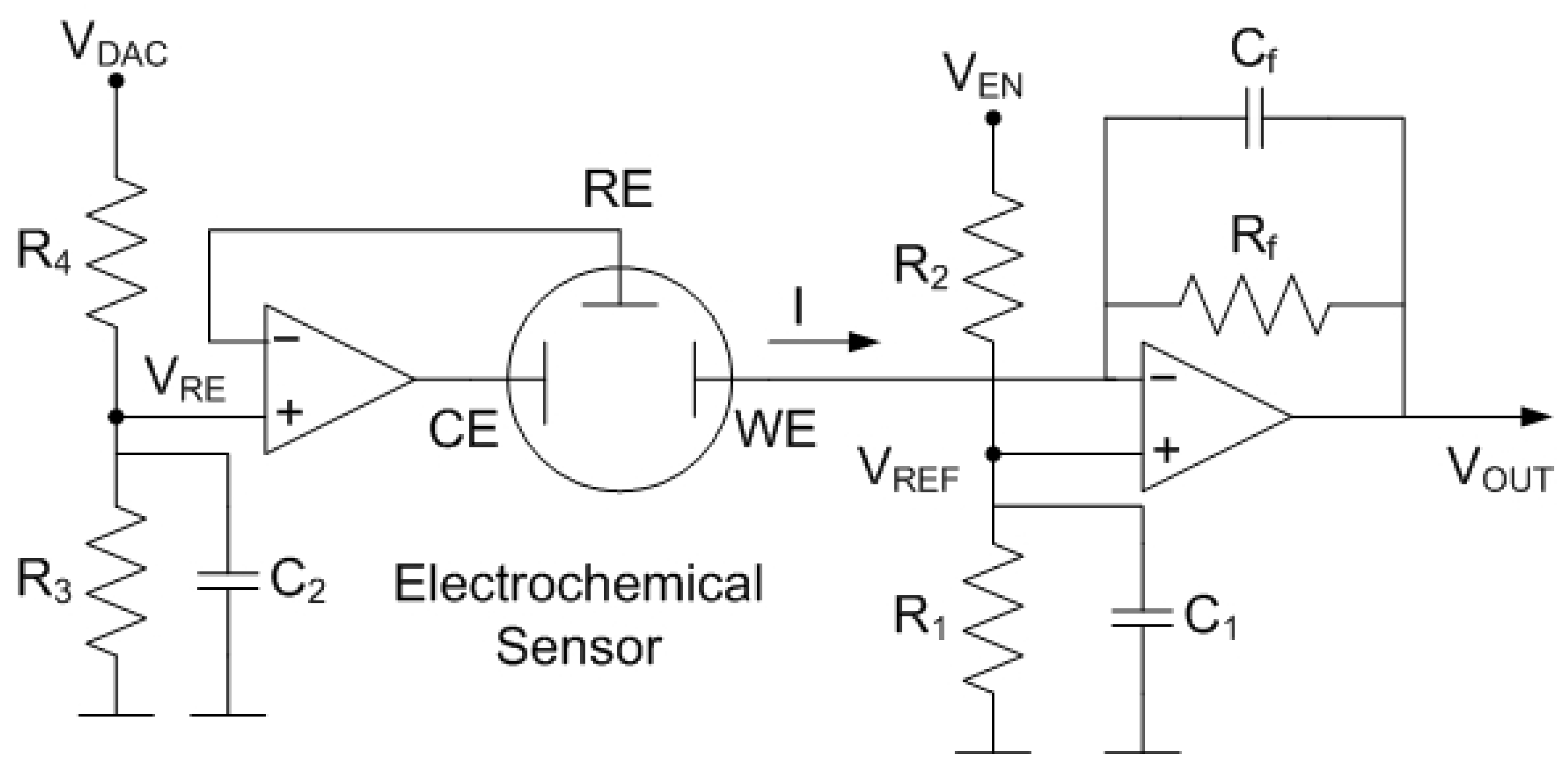

3.3. Potentiostat

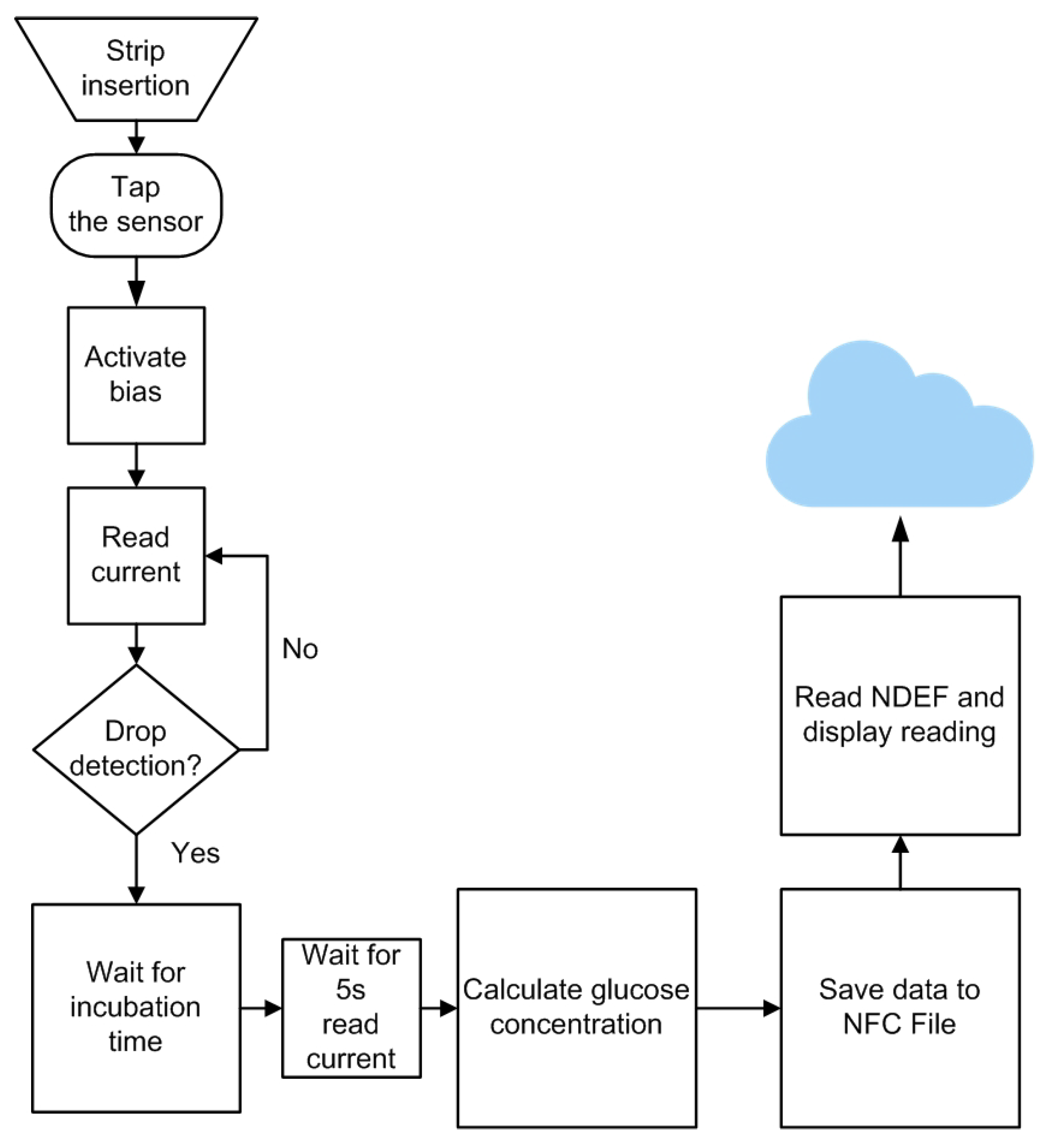

4. Glucose Sensor

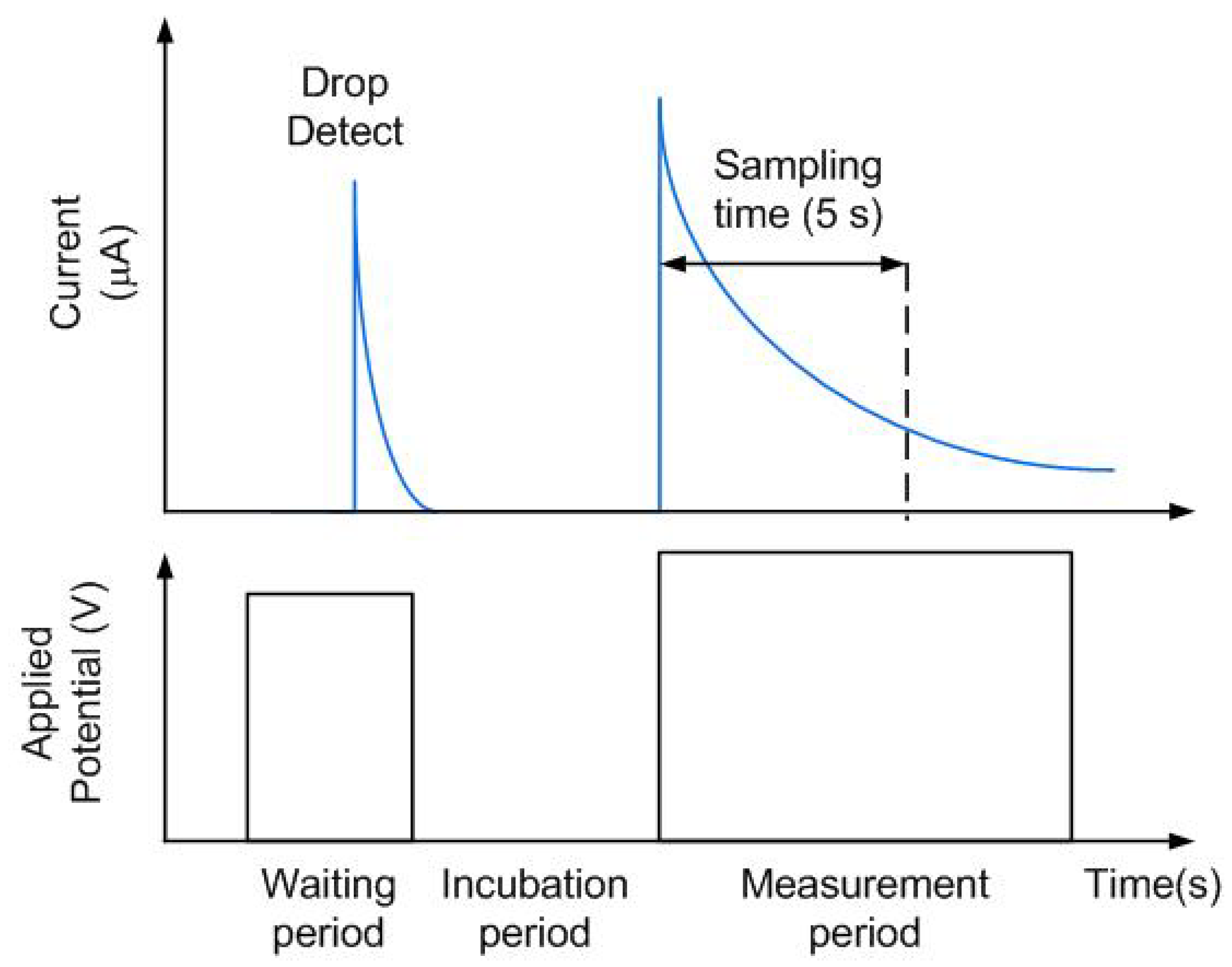

- Insert strip into the potentiostat without the sample.

- Approach the smartphone (NFC enabled) close to the NFC sensor. When the smartphone is placed over the sensor the electronics is turned on.

- The microcontroller biases the potentiostat and measures the current, waiting for a change that indicates the presence of a drop.

- The user introduces the sample by depositing a drop on the opening of the strip.

- The sample fills the chamber by capillary action.

- When the presence of the drop is detected, the microcontroller turns off the cell, and starts the incubation time (52 ms). The incubation time allows the chemicals to dissolve, the enzymatic reaction to occur and the solution to become homogeneous.

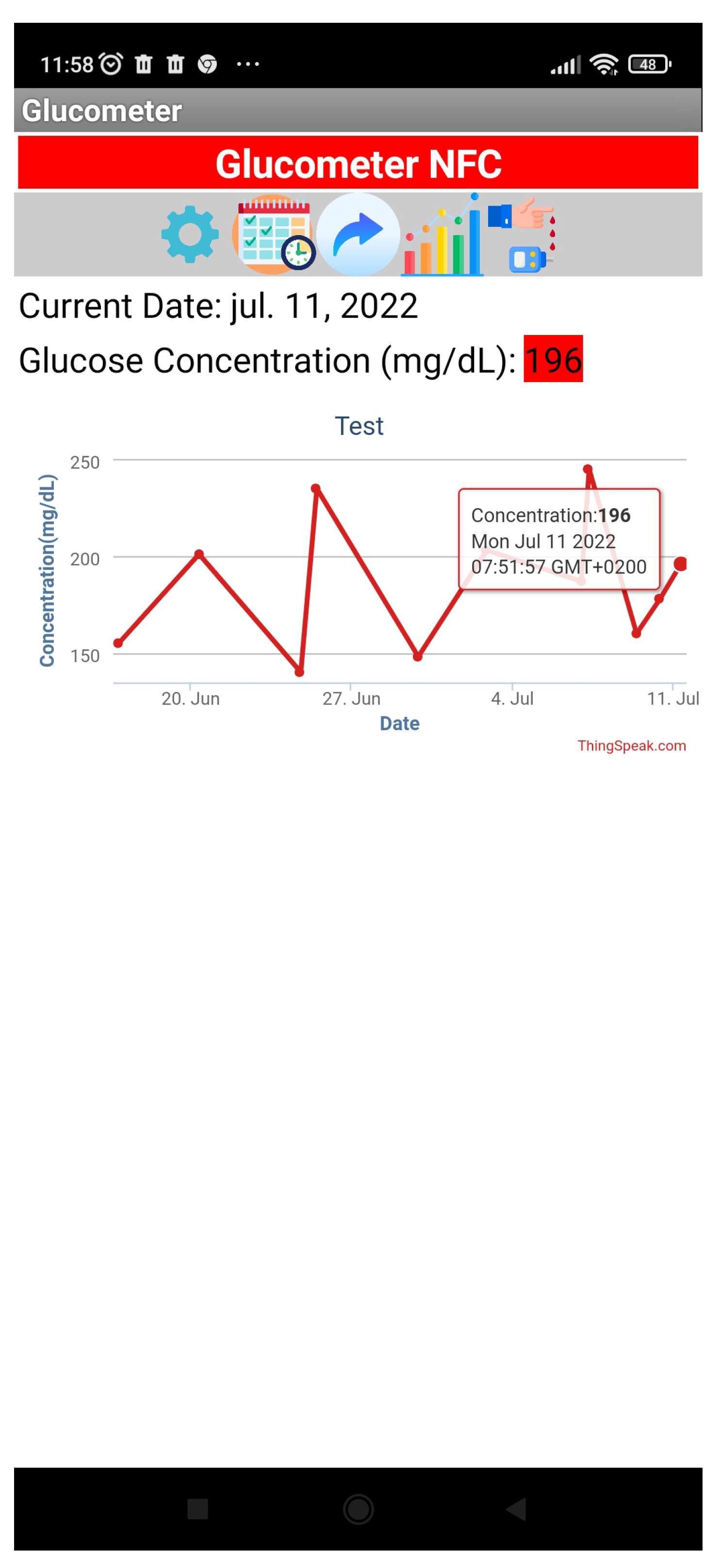

- When incubation time is completed, the potential required to electrochemically oxidize the mediator that chemically reacts with the active site of the enzyme, bringing it back to its original oxidation state, is applied The current is monitored and its final value is interpolated in a previously obtained calibration curve. Then the concentration value is reported, saving the data in the NFC IC EPPROM via I2C.

- The smartphone reads the concentration value stored in the memory and displays the result in the user’s screen, uploading the measurement into a database for later consultation.

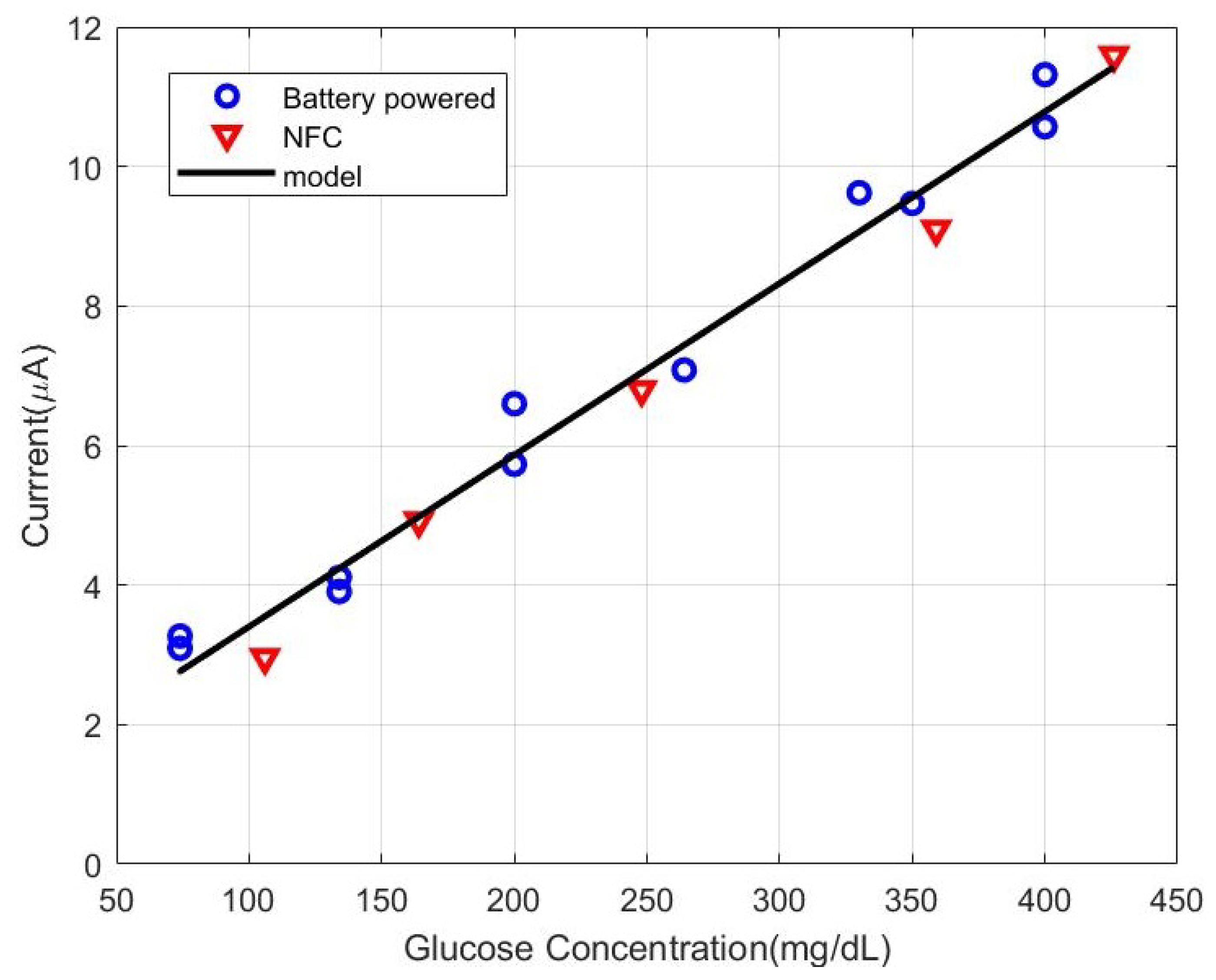

5. Results

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raghupathi, W.; Raghupathi, V. An empirical study of chronic diseases in the United States: A visual analytics approach to public health. Int. J. Environ. Res. Public Health 2018, 15, 431. [Google Scholar] [CrossRef] [PubMed]

- Lukas, H.; Xu, C.; Yu, Y.; Gao, W. Emerging telemedicine tools for remote COVID-19 diagnosis, monitoring, and management. ACS Nano 2020, 14, 16180–16193. [Google Scholar] [CrossRef] [PubMed]

- Christodouleas, D.C.; Kaur, B.; Chorti, P. From point-of-care testing to eHealth diagnostic devices (eDiagnostics). ACS Cent. Sci. 2018, 4, 1600–1616. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Geng, Z.; Fan, Z.; Liu, J.; Chen, H. Point-of-care testing based on smartphone: The current state-of-the-art (2017–2018). Biosens. Bioelectron. 2019, 132, 17–37. [Google Scholar] [CrossRef] [PubMed]

- Shrivastava, S.; Trung, T.Q.; Lee, N.E. Recent progress, challenges, and prospects of fully integrated mobile and wearable point-of-care testing systems for self-testing. Chem. Soc. Rev. 2020, 49, 1812–1866. [Google Scholar] [CrossRef] [PubMed]

- Novell, M.; Guinovart, T.; Steinberg, I.M.; Steinberg, M.; Rius, F.X.; Andrade, F.J. A novel miniaturized radiofrequency potentiometer tag using ion-selective electrodes for wireless ion sensing. Analyst 2013, 138, 5250–5257. [Google Scholar] [CrossRef]

- Rowe, A.A.; Bonham, A.J.; White, R.J.; Zimmer, M.P.; Yadgar, R.J.; Hobza, T.M.; Honea, J.W.; Ben-Yaacov, I.; Plaxco, K.W. CheapStat: An open-source,“Do-It-Yourself” potentiostat for analytical and educational applications. PLoS ONE 2011, 6, e23783. [Google Scholar] [CrossRef]

- Ainla, A.; Mousavi, M.P.; Tsaloglou, M.N.; Redston, J.; Bell, J.G.; Fernandez-Abedul, M.T.; Whitesides, G.M. Open-source potentiostat for wireless electrochemical detection with smartphones. Anal. Chem. 2018, 90, 6240–6246. [Google Scholar] [CrossRef]

- Aznar-Poveda, J.; Lopez-Pastor, J.A.; Garcia-Sanchez, A.J.; Garcia-Haro, J.; Otero, T.F. A COTS-Based Portable System to Conduct Accurate Substance Concentration Measurements. Sensors 2018, 18, 539. [Google Scholar] [CrossRef]

- Pérez, P.; Huertas, G.; Maldonado-Jacobi, A.; Martín, M.; Serrano, J.A.; Olmo, A.; Daza, P.; Yúfera, A. Sensing cell-culture assays with low-cost circuitry. Sci. Rep. 2018, 8, 8841. [Google Scholar] [CrossRef]

- Sun, A.C.; Hall, D.A. Point-of-care smartphone-based electrochemical biosensing. Electroanalysis 2019, 31, 2–16. [Google Scholar] [CrossRef]

- Beitollahi, H.; Mohammadi, S.Z.; Safaei, M.; Tajik, S. Applications of electrochemical sensors and biosensors based on modified screen-printed electrodes: A review. Anal. Methods 2020, 12, 1547–1560. [Google Scholar] [CrossRef]

- Morak, J.; Kumpusch, H.; Hayn, D.; Modre-Osprian, R.; Schreier, G. Design and evaluation of a telemonitoring concept based on NFC-enabled mobile phones and sensor devices. IEEE Trans. Inf. Technol. Biomed. 2011, 16, 17–23. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lazaro, A.; Villarino, R.; Girbau, D. A survey of NFC sensors based on energy harvesting for IoT applications. Sensors 2018, 18, 3746. [Google Scholar] [CrossRef] [PubMed]

- Amendola, S.; Milici, S.; Marrocco, G. Performance of epidermal RFID dual-loop tag and on-skin retuning. IEEE Trans. Antennas Propag. 2015, 63, 3672–3680. [Google Scholar] [CrossRef]

- Lazaro, A.; Boada, M.; Villarino, R.; Girbau, D. Study on the reading of energy-harvested implanted NFC tags using mobile phones. IEEE Access 2019, 8, 2200–2221. [Google Scholar] [CrossRef]

- Boada, M.; Lazaro, A.; Villarino, R.; Gil-Dolcet, E.; Girbau, D. Battery-Less NFC Bicycle Tire Pressure Sensor Based on a Force-Sensing Resistor. IEEE Access 2021, 9, 103975–103987. [Google Scholar] [CrossRef]

- Lazaro, A.; Boada, M.; Villarino, R.; Girbau, D. Battery-less smart diaper based on NFC technology. IEEE Sens. J. 2019, 19, 10848–10858. [Google Scholar] [CrossRef]

- Chandra Kishore, S.; Samikannu, K.; Atchudan, R.; Perumal, S.; Edison, T.N.J.I.; Alagan, M.; Sundramoorthy, A.K.; Lee, Y.R. Smartphone-Operated Wireless Chemical Sensors: A Review. Chemosensors 2022, 10, 55. [Google Scholar] [CrossRef]

- Kassal, P.; Steinberg, I.M.; Steinberg, M.D. Wireless smart tag with potentiometric input for ultra low-power chemical sensing. Sens. Actuators B Chem. 2013, 184, 254–259. [Google Scholar] [CrossRef]

- Boada, M.; Lazaro, A.; Villarino, R.; Girbau, D. Battery-less NFC sensor for pH monitoring. IEEE Access 2019, 7, 33226–33239. [Google Scholar] [CrossRef]

- Lazaro, A.; Boada, M.; Villarino, R.; Girbau, D. Color measurement and analysis of fruit with a battery-less NFC sensor. Sensors 2019, 19, 1741. [Google Scholar] [CrossRef]

- DeHennis, A.; Getzlaff, S.; Grice, D.; Mailand, M. An NFC-enabled CMOS IC for a wireless fully implantable glucose sensor. IEEE J. Biomed. Health Inform. 2015, 20, 18–28. [Google Scholar] [CrossRef] [PubMed]

- Escobedo, P.; Erenas, M.M.; Martinez-Olmos, A.; Carvajal, M.A.; Gonzalez-Chocano, S.; Capitán-Vallvey, L.F.; Palma, A.J. General-purpose passive wireless point–of–care platform based on smartphone. Biosens. Bioelectron. 2019, 141, 111360. [Google Scholar] [CrossRef]

- Xu, G.; Cheng, C.; Liu, Z.; Yuan, W.; Wu, X.; Lu, Y.; Low, S.S.; Liu, J.; Zhu, L.; Ji, D.; et al. Battery-free and wireless epidermal electrochemical system with all-printed stretchable electrode array for multiplexed In situ sweat analysis. Adv. Mater. Technol. 2019, 4, 1800658. [Google Scholar] [CrossRef]

- Krorakai, K.; Klangphukhiew, S.; Kulchat, S.; Patramanon, R. Smartphone-based NFC potentiostat for wireless electrochemical sensing. Appl. Sci. 2021, 11, 392. [Google Scholar] [CrossRef]

- Teengam, P.; Siangproh, W.; Tontisirin, S.; Jiraseree-amornkun, A.; Chuaypen, N.; Tangkijvanich, P.; Henry, C.S.; Ngamrojanavanich, N.; Chailapakul, O. NFC-enabling smartphone-based portable amperometric immunosensor for hepatitis B virus detection. Sens. Actuators B Chem. 2021, 326, 128825. [Google Scholar] [CrossRef]

- Kauffman, A. Understanding Electrochemical Cells; Technical Report 17; Solartron Instruments: Hampshire, UK, 1997; Available online: https://www.ameteksi.com/-/media/ameteksi/download_links/documentations/library/solartonanalytical/electrochemistry/technical-report-17-understanding-electrochemical-cells.pdf (accessed on 19 September 2022).

- Instruments, G. Basics of electrochemical impedance spectroscopy. G. Instrum. Complex Impedance Corros. 2007, 1–30. Available online: https://www.c3-analysentechnik.eu/downloads/applikationsberichte/gamry/5657-Application-Note-EIS.pdf (accessed on 19 September 2022).

- Randles, J.E.B. Kinetics of rapid electrode reactions. Discuss. Faraday Soc. 1947, 1, 11–19. [Google Scholar] [CrossRef]

- Taylor, S.; Gileadi, E. Physical interpretation of the Warburg impedance. Corrosion 1995, 51. Available online: https://onepetro.org/corrosion/article-pdf/2184510/nace-95090664.pdf (accessed on 19 September 2022). [CrossRef]

- Lazaro, A.; Boada, M.; Villarino, R.; Girbau, D. Feasibility Study on the Reading of Energy-Harvested Implanted NFC Tags Using Mobile Phones and Commercial NFC IC. In Proceedings of the 2020 IEEE MTT-S International Microwave Biomedical Conference (IMBioC), Virtual, 14–17 December 2020; pp. 1–3. [Google Scholar]

- Gebhart, M.; Bruckbauer, J.; Gossar, M. Chip impedance characterization for contactless proximity personal cards. In Proceedings of the 2010 7th International Symposium on Communication Systems, Networks & Digital Signal Processing (CSNDSP 2010), Newcastle Upon Tyne, UK, 21–23 July 2010; pp. 826–830. [Google Scholar]

- Gvozdenovic, N.; Mayer, L.W.; Mecklenbräuker, C.F. Measurement of harmonic distortions and impedance of HF RFID chips. In Proceedings of the 8th European Conference on Antennas and Propagation (EuCAP 2014), The Hague, The Netherlands, 6–11 April 2014; pp. 2940–2944. [Google Scholar]

- Qing, X.; Chen, Z.N. Proximity effects of metallic environments on high frequency RFID reader antenna: Study and applications. IEEE Trans. Antennas Propag. 2007, 55, 3105–3111. [Google Scholar] [CrossRef]

- Wheeler, H.A. Simple inductance formulas for radio coils. Proc. Inst. Radio Eng. 1928, 16, 1398–1400. [Google Scholar] [CrossRef]

- Wheeler, H.A. Formulas for the skin effect. Proc. IRE 1942, 30, 412–424. [Google Scholar] [CrossRef]

- Gebhart, M.; Birnstingl, S.; Bruckbauer, J.; Merlin, E. Properties of a test bench to verify Standard Compliance of Proximity Transponders. In Proceedings of the 2008 6th International Symposium on Communication Systems, Networks and Digital Signal Processing, Graz, Austria, 25–25 July 2008; pp. 306–310. [Google Scholar]

- Marechal, C.; Paret, D. The Loading Effect of Proximity Contactless Smart Card. Incidences of Impedance of the Shunt Regulator. In Proceedings of the 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–17 October 2008; pp. 1–4. [Google Scholar]

- Zhu, H.; Lai, S.; Dai, H. Solutions of metal surface effect for hf rfid systems. In Proceedings of the 2007 International Conference on Wireless Communications, Networking and Mobile Computing, Shanghai, China, 21–25 September 2007; pp. 2089–2092. [Google Scholar]

- Lee, B.; Kim, B.; Yang, S. Enhanced loop structure of NFC antenna for mobile handset applications. Int. J. Antennas Propag. 2014, 2014, 187029. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, A. NFC antenna for portable device with metal back cover. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, PR, USA, 26 June–1 July 2016; pp. 1471–1472. [Google Scholar]

- Lee, B.; Harackiewicz, F. Design of a simple structured NFC loop antenna for mobile phones applications. Prog. Electromagn. Res. C 2017, 76, 149–157. [Google Scholar] [CrossRef]

- Yanez, M.G. Glucose Meter Fundamentals and Design. Free. Semicond. 2013, AN4364. Available online: https://www.nxp.com/docs/en/application-note/AN4364.pdf (accessed on 19 September 2022).

- Dalvi, N. Glucose Meter Reference Design; AN1560; Microchip Technology Inc.: Chandler, AZ, USA, 2013. [Google Scholar]

- Danaei, G.; Finucane, M.M.; Lu, Y.; Singh, G.M.; Cowan, M.J.; Paciorek, C.J.; Lin, J.K.; Farzadfar, F.; Khang, Y.H.; Stevens, G.A.; et al. National, regional, and global trends in fasting plasma glucose and diabetes prevalence since 1980: Systematic analysis of health examination surveys and epidemiological studies with 370 country-years and 2· 7 million participants. Lancet 2011, 378, 31–40. [Google Scholar] [CrossRef]

- Dervisevic, M.; Alba, M.; Yan, L.; Senel, M.; Gengenbach, T.R.; Prieto-Simon, B.; Voelcker, N.H. Transdermal electrochemical monitoring of glucose via high-density silicon microneedle array patch. Adv. Funct. Mater. 2022, 32, 2009850. [Google Scholar] [CrossRef]

| Parameter | Free Space | at 0.5 mm Metal | with Ferrite Sheet and Metal |

|---|---|---|---|

| Number of turns N | 5 | 5 | 5 |

| Dimmensions | 30 mm × 30 mm | 30 mm × 30 mm | 30 mm × 30 mm |

| Width | 0.5 mm | 0.5 mm | 0.5 mm |

| Gap | 0.5 mm | 0.5 mm | 0.5 mm |

| Inductance | 1.26 H | 0.55 H | 2.47 H |

| Quality factor | 90.7 | 33.6 | 35.7 |

| Resonance frequency | 85 MHz | 121 MHz | 48 MHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazaro, A.; Villarino, R.; Lazaro, M.; Canellas, N.; Prieto-Simon, B.; Girbau, D. Battery-Less NFC Potentiostat for Electrochemical Point-of-Care Sensors Based on COTS Components. Sensors 2022, 22, 7213. https://doi.org/10.3390/s22197213

Lazaro A, Villarino R, Lazaro M, Canellas N, Prieto-Simon B, Girbau D. Battery-Less NFC Potentiostat for Electrochemical Point-of-Care Sensors Based on COTS Components. Sensors. 2022; 22(19):7213. https://doi.org/10.3390/s22197213

Chicago/Turabian StyleLazaro, Antonio, Ramon Villarino, Marc Lazaro, Nicolau Canellas, Beatriz Prieto-Simon, and David Girbau. 2022. "Battery-Less NFC Potentiostat for Electrochemical Point-of-Care Sensors Based on COTS Components" Sensors 22, no. 19: 7213. https://doi.org/10.3390/s22197213

APA StyleLazaro, A., Villarino, R., Lazaro, M., Canellas, N., Prieto-Simon, B., & Girbau, D. (2022). Battery-Less NFC Potentiostat for Electrochemical Point-of-Care Sensors Based on COTS Components. Sensors, 22(19), 7213. https://doi.org/10.3390/s22197213