Design of FOPID Controller for Pneumatic Control Valve Based on Improved BBO Algorithm

Abstract

:1. Introduction

2. Establishment of Mathematical Model of Pneumatic Control Valve

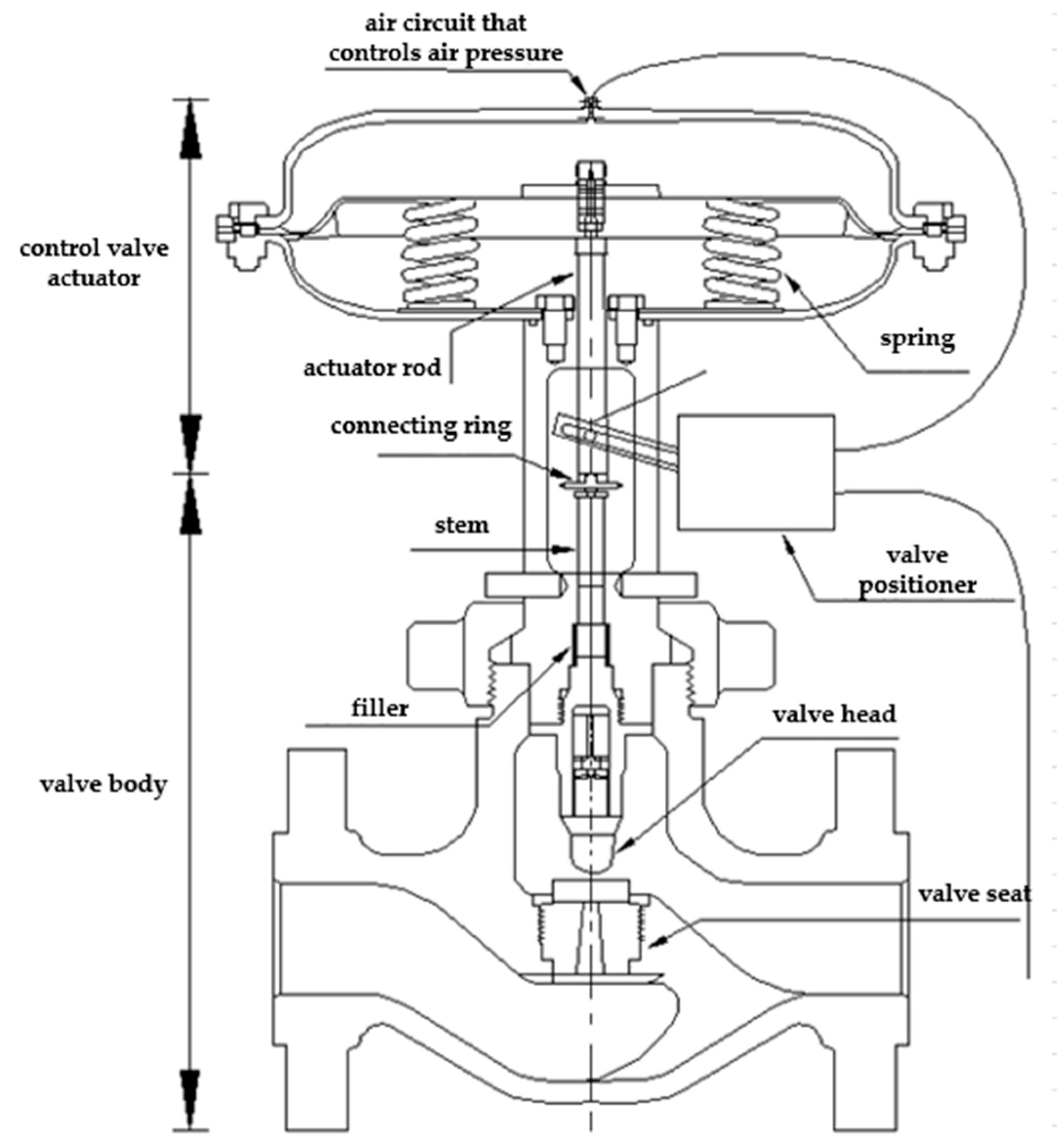

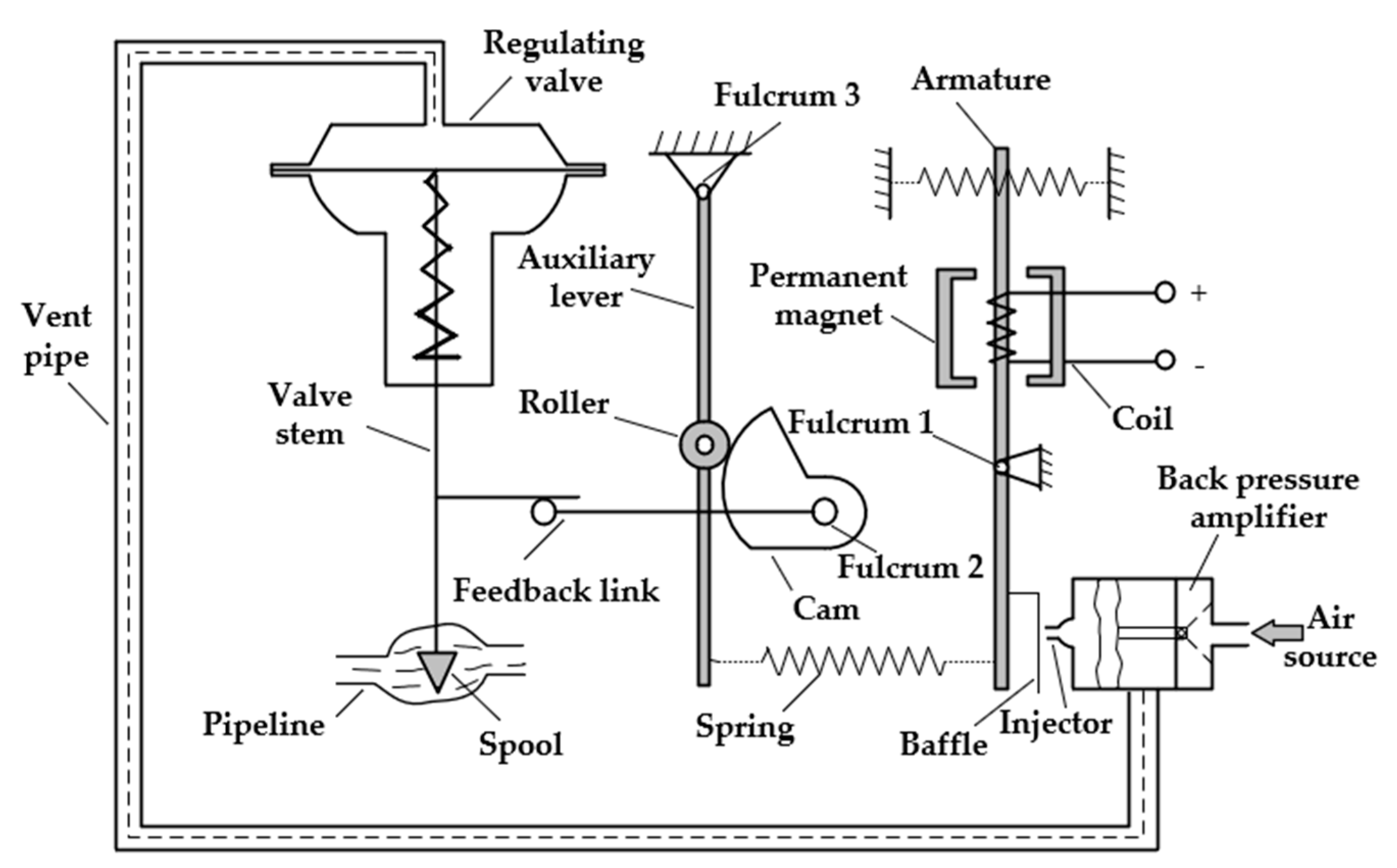

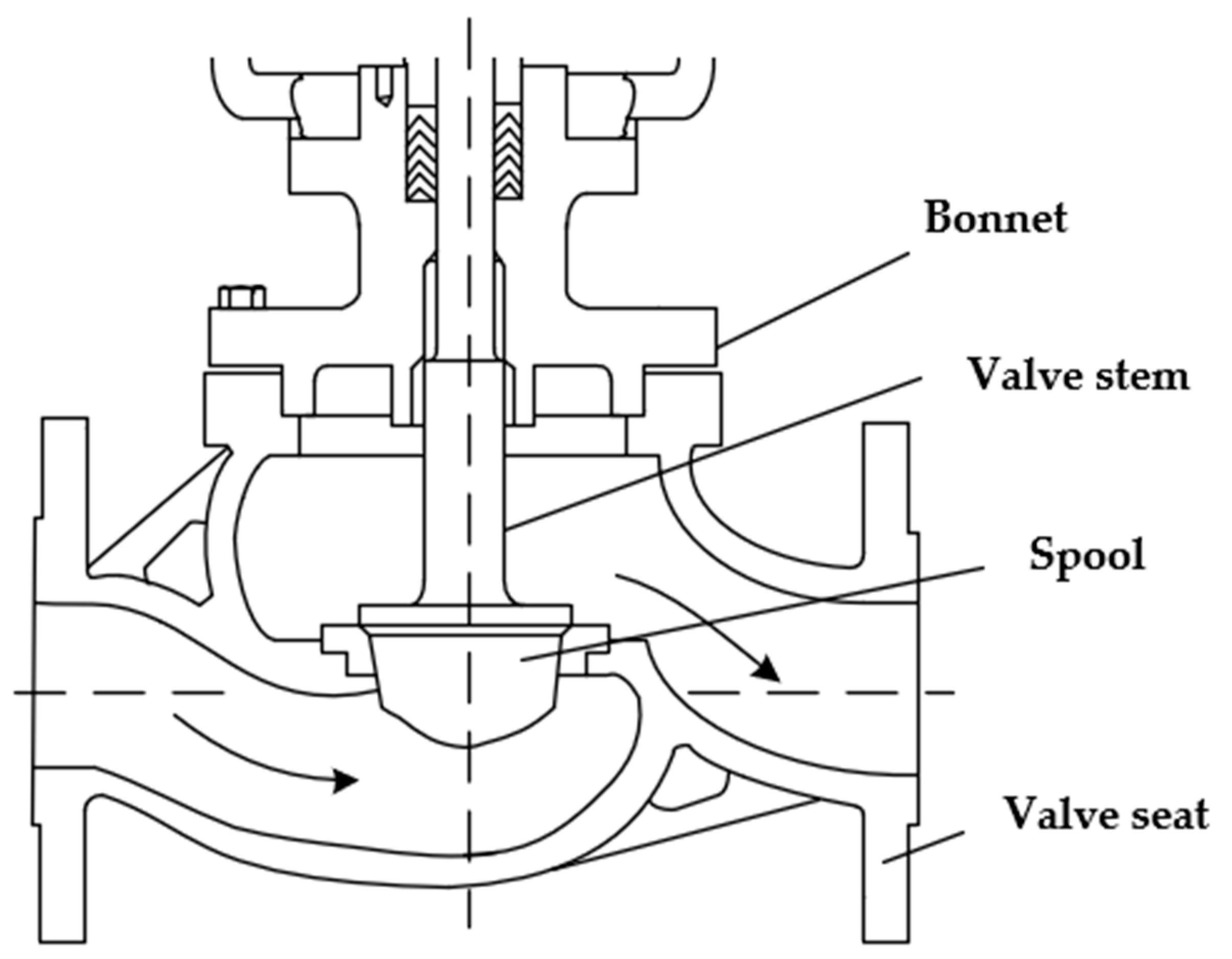

2.1. Pneumatic Control Valve Structure and Working Principle

2.2. Model Establishment of Pneumatic Control Valve

3. Biogeography-Based Optimization Algorithms and Improvements

3.1. Overview of Standard Biogeography-Based Optimization Algorithms

3.2. Description of Biogeography-Based Optimization Algorithm Operators

3.3. Improvement of Biogeography-Based Optimization Algorithm

3.3.1. Chaos Initialization

3.3.2. Improvements to the Migration Model

3.3.3. Improvement of Migration Operator

- Weight transfer operator. When the random number of a certain dimension is less than the emigration rate, 10% of the original island habitat disturbance is added, and the weight of the emigrated island habitat is reduced to 90%, i.e.,where is the -th dimension vector in the -th island habitat after the migration operation is completed, is the -component of the original island habitat , and is the -component of the -th island habitat selected to provide exchange information.

- Mixed optimal migration operator. When the random number of a certain dimension is greater than the migration rate, the variable of this dimension is still migrated, and the migration method is the convex combination of the migrated individual and the current optimal individual p1, i.e.,where , and is the -th dimension vector of the current best individual.

3.3.4. Improvement of Mutation Operator

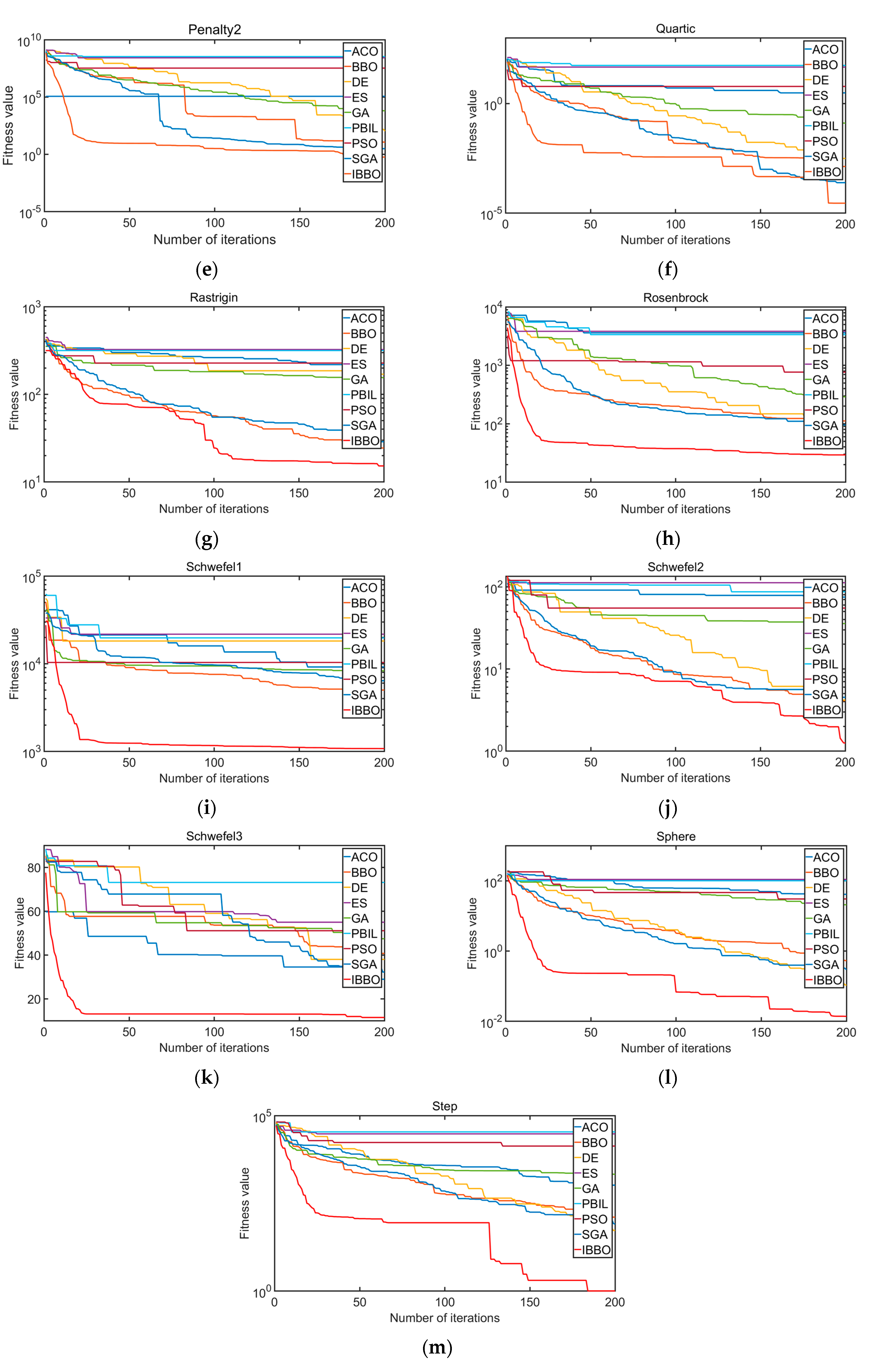

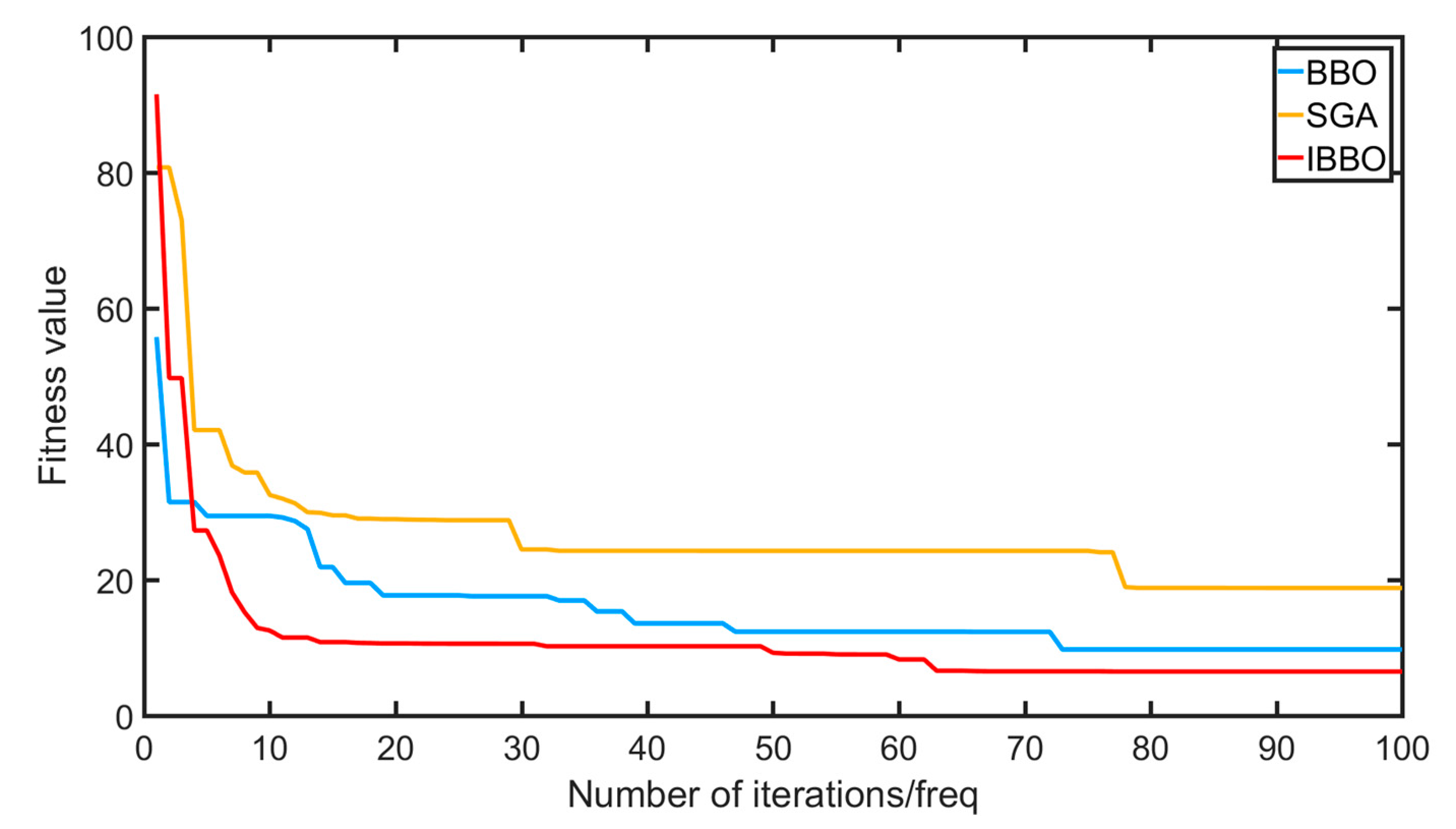

3.4. Simulation Experiment and Result Analysis

4. Parameter Identification of Pneumatic Control Valve Model

5. Fractional-Order PID Controller Design

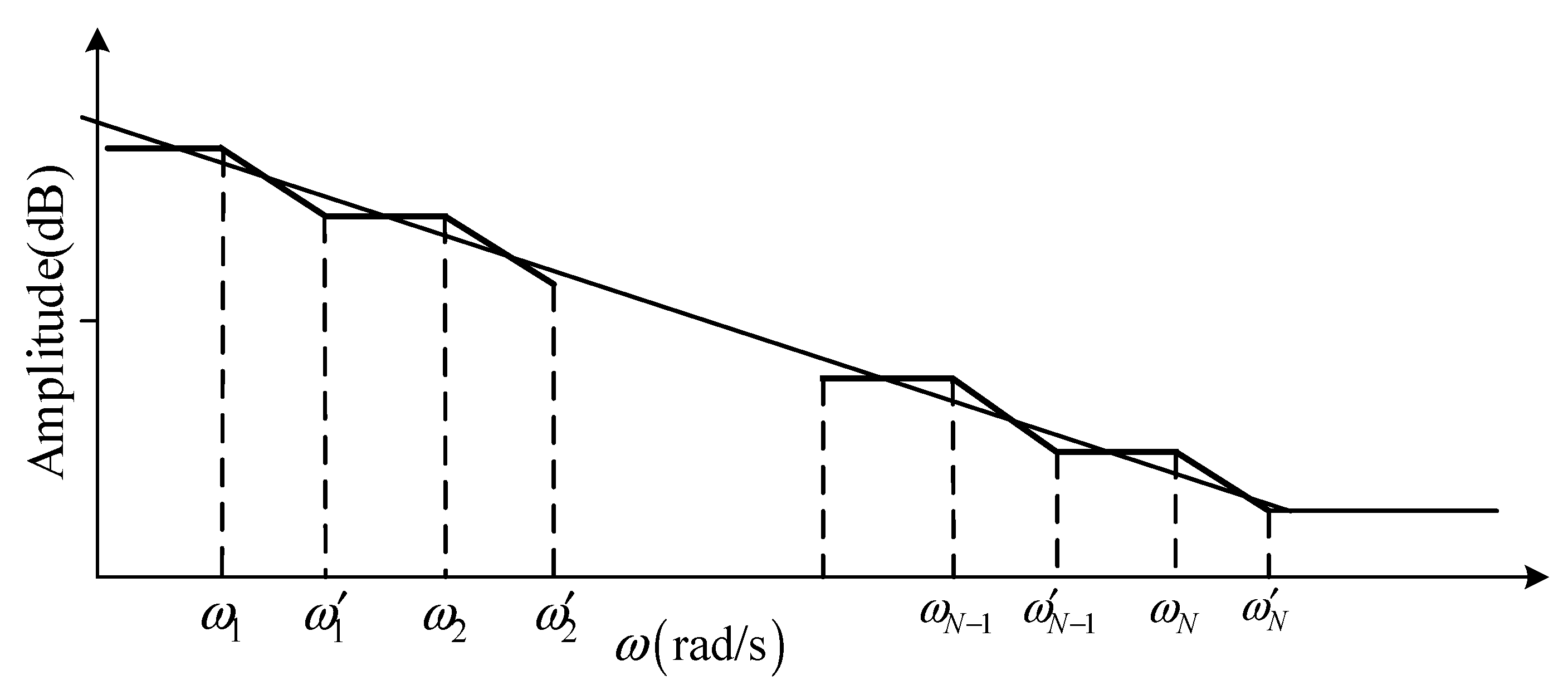

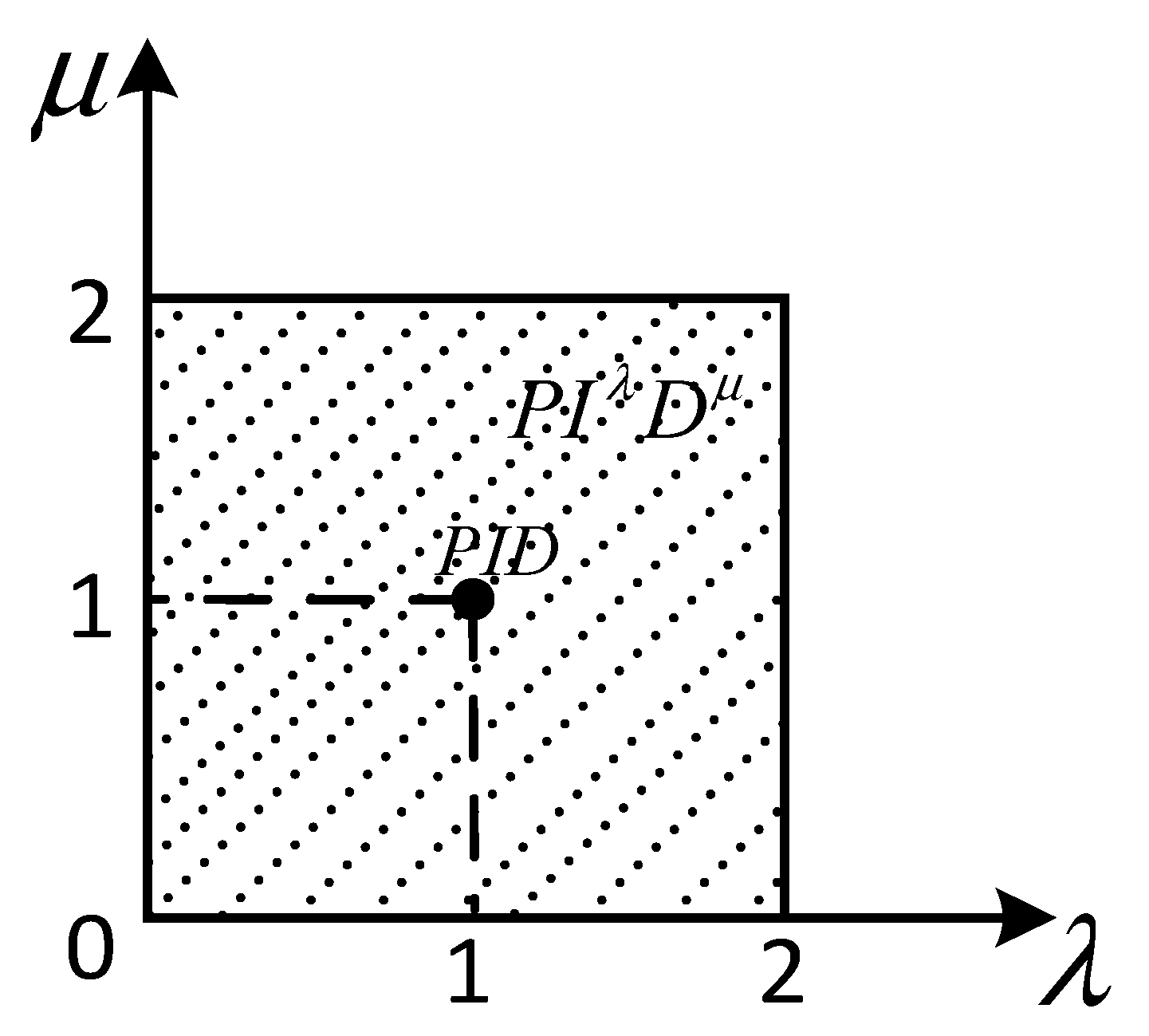

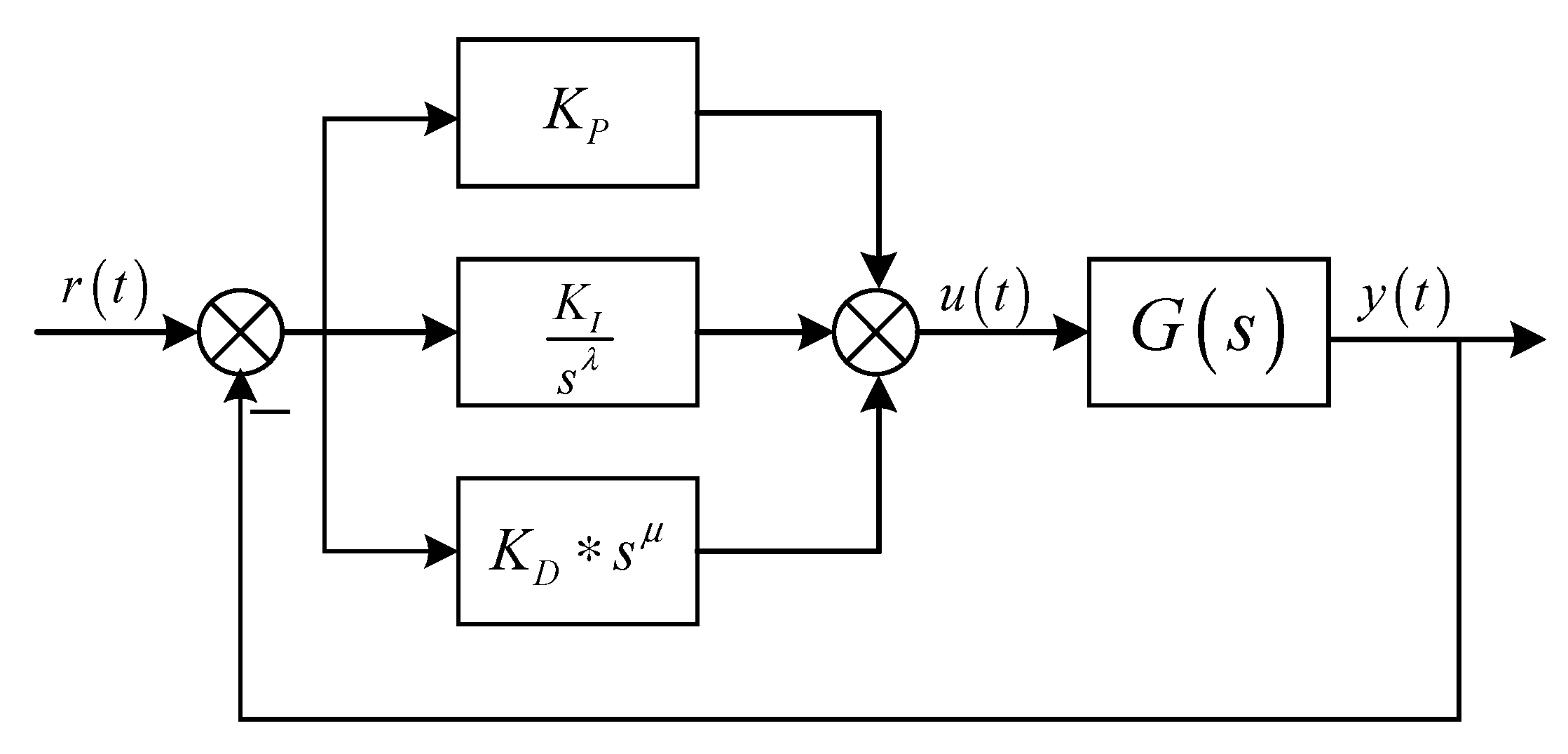

5.1. Fractional-Order PID Controller

5.2. Parameter Tuning of Fractional-Order PID Controller

5.3. Simulation

6. Experimental Verification

- The output experiment of a given step signal mainly tests the transient performance of the system. The desired signal of the valve position opening with a given output of 50% and the experimental results of air pressure are shown below.

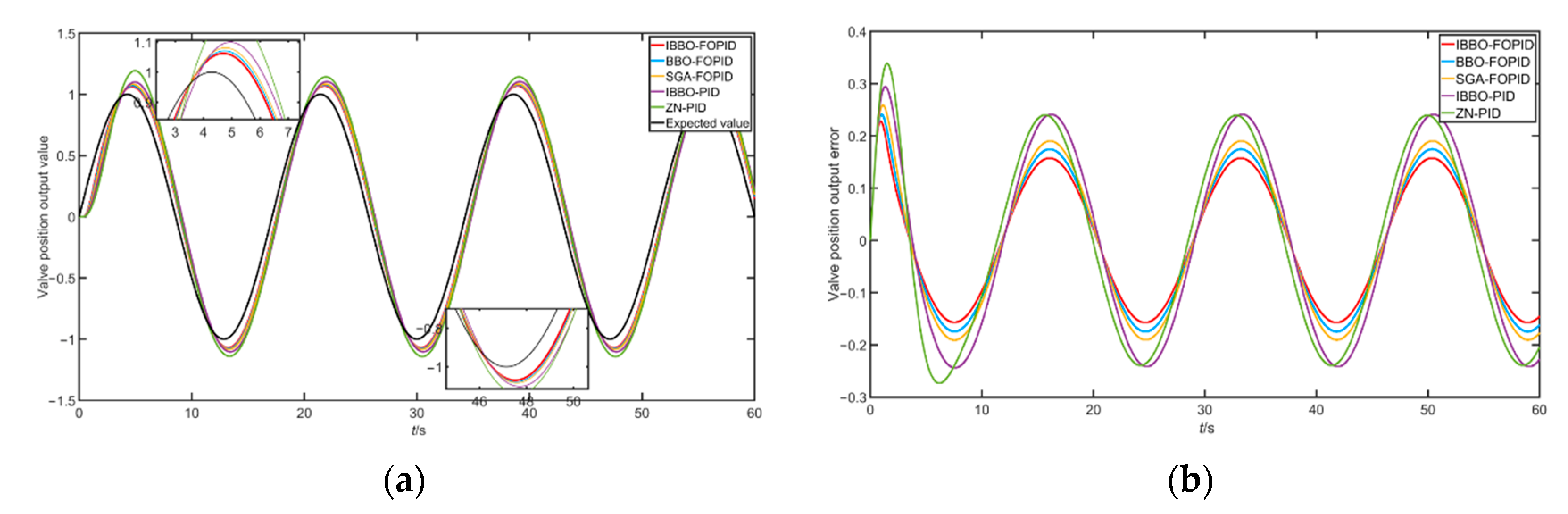

- The output experiment of a given sine wave mainly tests the dynamic performance of the controller. In the experiment, the desired valve position signal was selected as . The experimental results are shown below in Figure 19.

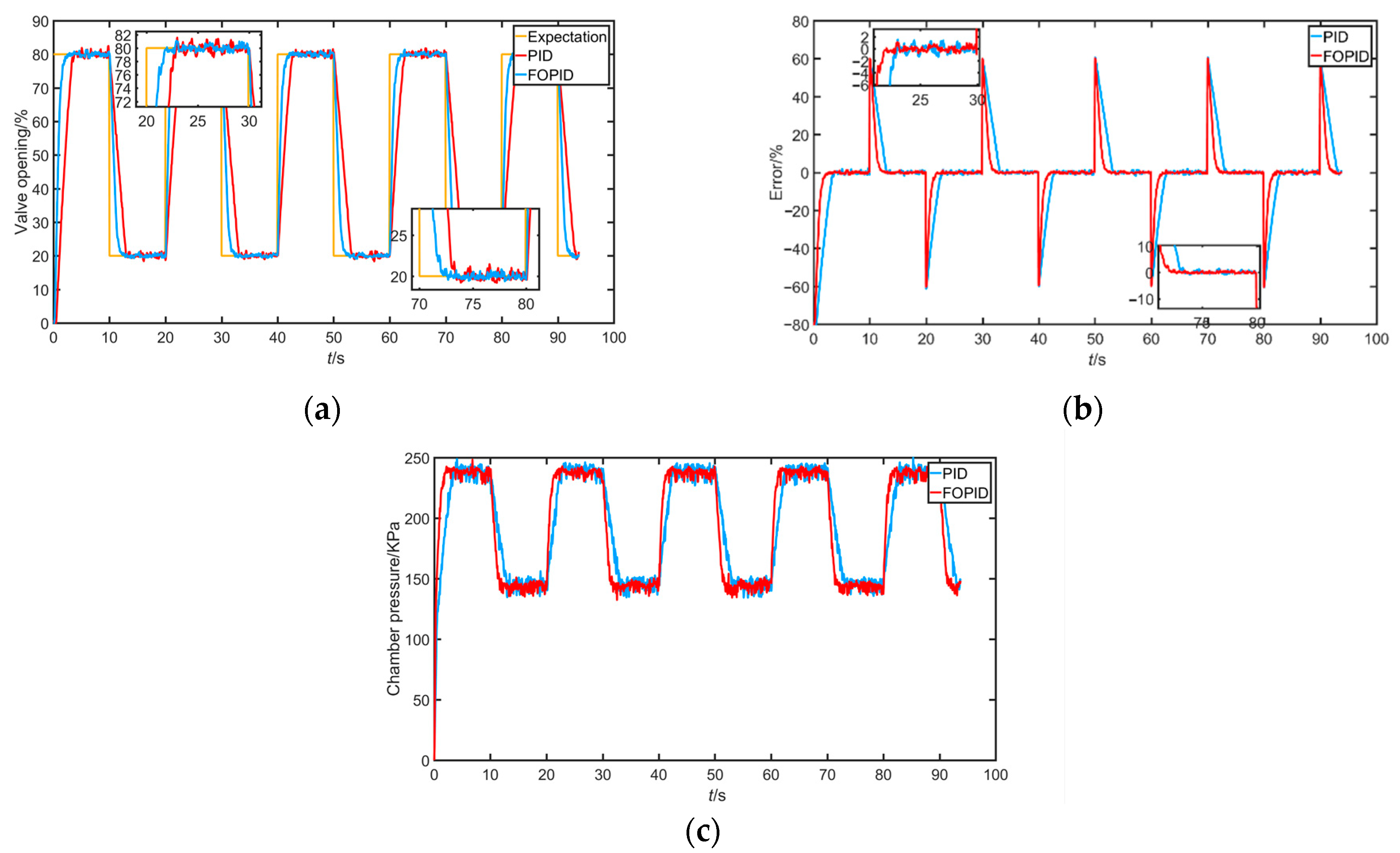

- Given the square wave output experiment, the main purpose is to test the controller’s fast performance and its ability to track mutation signals. The valve position expected value output was set to 80%–20%–80%, i.e., , and the experiment repeated four to five times. The results are shown below.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goyal, V.; Mishra, P.; Deolia, V.K. A robust fractional order parallel control structure for flow control using a pneumatic control valve with nonlinear and uncertain dynamics. Arab. J. Sci. Eng. 2019, 44, 2597–2611. [Google Scholar] [CrossRef]

- Qian, J.Y.; Wu, J.Y.; Jin, Z.J. Research progress on vibration characteristics of regulation valve. J. Vib. Shock 2020, 39, 1–13. [Google Scholar]

- Schmitt, R.; Sobrinho, M.R.S. Nonlinear dynamic modeling of a pneumatic process control valve. IEEE Lat. Am. Trans. 2018, 16, 1070–1075. [Google Scholar] [CrossRef]

- Yu, M.; Liu, W. Modeling and Analysis of a Composite Structure-Based Soft Pneumatic Actuators for Soft-Robotic Gripper. Sensors 2022, 22, 4851. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, W. A Dynamic Modeling Method for the Bi-Directional Pneumatic Actuator Using Dynamic Equilibrium Equation. Sensors 2022, 11, 7. [Google Scholar] [CrossRef]

- Youssef, S.M.; Soliman, M. Modeling of Soft Pneumatic Actuators with Different Orientation Angles Using Echo State Networks for Irregular Time Series Data. Sensors 2022, 13, 216. [Google Scholar] [CrossRef] [PubMed]

- Plestan, F.; Shtessel, Y.; Brégeault, V.; Poznyak, A. Sliding mode control with gain adaptation—Application to an electropneumatic actuator. Control Eng. Pract. 2013, 21, 679–688. [Google Scholar] [CrossRef]

- Zabiri, H.; Samyudia, Y. A hybrid formulation and design of model predictive control for systems under actuator saturation and backlash. J. Process Control 2006, 16, 693–709. [Google Scholar] [CrossRef]

- Guo, W.X.; Zhao, Y.B.; Li, R.Q. Active Disturbance Rejection Control of Valve-Controlled Cylinder Servo Systems Based on MATLAB-AMESim Cosimulation. Complexity 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Zhu, T.Y.; Dong, Q.L.; Liu, R. Application of Fuzzy Neural Network in Valve Opening Control. Instrum. Tech. Sens. 2019, 44, 2597–2611. [Google Scholar]

- Jeremiah, S.; Narayanasamy, A.; Zabiri, H. Analysis of constraint modification in model-based control valve stiction compensation. J. Teknol. 2017, 79, 7. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, X.B.; Wang, X. A Type of Control Method Based on Expert PID for Intelligent Valve Positioner. Control Eng. China 2019, 26, 87–91. [Google Scholar]

- Qi, Z.; Zhang, W.L.; Wang, M.Q. Study for the Application of Fractional Order PID Torque Control in Side-drive Coupled Tram. Acta Autom. Sin. 2020, 46, 482–494. [Google Scholar]

- Asgharnia, A.; Jamali, A.; Shahnazi, R.; Maheri, A. Load mitigation of a class of 5-MW wind turbine with RBF neural network based fractional-order PID controller. ISA Trans. 2020, 96, 272–286. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.P.; Chen, G.; Wu, R.C. Variable coefficient fractional-order PID controller and its application to a SEPIC device. IET Control Theory Appl. 2020, 14, 900–908. [Google Scholar] [CrossRef]

- Meng, F.W.; Liu, S.; Liu, K. Design of an optimal fractional order PID for constant tension control system. IEEE Access 2020, 8, 58933–58939. [Google Scholar] [CrossRef]

- Zhang, B.C.; Wang, S.F.; Hang, Z.P. Using Fractional-order PID Controller for Control of Aerodynamic Missile. J. Astronaut. 2005, 26, 653–657. [Google Scholar]

- Nie, Z.Y.; Zhu, H.Y.; Liu, J.C. Fractional order PID controller design in frequency domain based on ideal Bode transfer function and its application. Control Decis. 2019, 34, 2198–2202. [Google Scholar]

- Mohanty, D.; Panda, S. Modified salp swarm algorithm-optimized fractional-order adaptive fuzzy PID controller for frequency regulation of hybrid power system with electric vehicle. J. Control Autom. Electr. Syst. 2021, 32, 416–438. [Google Scholar] [CrossRef]

- Bučanović, L.J.; Lazarević, M.P.; Batalov, S.N. The fractional PID controllers tuned by genetic algorithms for expansion turbine in the cryogenic air separation process. Hem. Ind. 2014, 68, 519–528. [Google Scholar] [CrossRef]

- Pires, E.J.S.; Machado, J.A.T. Particle swarm optimization with fractional-order velocity. Nonlinear Dyn. 2010, 61, 295–301. [Google Scholar] [CrossRef]

- Simon, D. Biogeography-Based Optimization. IEEE Trans. Evol. Comput. 2008, 6, 702–713. [Google Scholar] [CrossRef] [Green Version]

- Li, R.H.; Meng, G.X.; Feng, Z.J.; Li, Y.J. A sliding mode variable structure control approach for a pneumatic force servo system. In 2006 6th World Congress on Intelligent Control and Automation; IEEE: Piscataway, NJ, USA, 2006; pp. 8173–8177. [Google Scholar]

| Function Name | Number of Dimensions | Scope |

|---|---|---|

| Ackley | 30 | |

| Flethcher | 30 | |

| Griewank | 30 | |

| Penalty1 | 30 | |

| Penalty2 | 30 | |

| Quartic | 30 | |

| Rastrigin | 30 | |

| Rosenbrock | 30 | |

| Schwefel1 | 30 | |

| Schwefel2 | 30 | |

| Schwefel3 | 30 | |

| Sphere | 30 | |

| Step | 30 |

| Function | ACO | BBO | DE | ES | GA | PBIL | PSO | SGA | IBBO | |

|---|---|---|---|---|---|---|---|---|---|---|

| Ackley | min | 10.6628 | 4.1256 | 3.2636 | 18.3172 | 13.7105 | 19.2149 | 15.8786 | 3.9221 | 1.9716 |

| mean | 13.5510 | 4.8965 | 3.6056 | 19.3152 | 16.7410 | 19.8378 | 16.3563 | 4.6009 | 2.4420 | |

| std | 2.3223 | 0.5765 | 0.2466 | 0.3891 | 1.4076 | 0.246 | 0.3399 | 0.5236 | 0.2927 | |

| Flenthcher | min | 1,245,598 | 111,062 | 356,329 | 1,597,417 | 214,239 | 1,109,620 | 1,403,971 | 125,131 | 105,709 |

| mean | 1.8 × 106 | 1.3 × 105 | 4.8 × 105 | 1.9 × 106 | 4.2 × 105 | 1.4 × 106 | 1.6 × 106 | 1.6 × 105 | 1.3 × 105 | |

| std | 4.0 × 105 | 2.2 × 104 | 6.6 × 104 | 2.4 × 105 | 1.5 × 105 | 2.0× 105 | 1.5 × 105 | 2.3 × 104 | 1.1 × 104 | |

| Griewank | min | 4.7090 | 2.4367 | 1.4684 | 165.044 | 20.2711 | 427.8509 | 108.994 | 1.8198 | 1.0679 |

| mean | 7.2543 | 2.9381 | 1.6811 | 221.703 | 37.9814 | 448.9497 | 140.198 | 2.2808 | 1.2268 | |

| std | 1.6275 | 0.3260 | 0.2198 | 33.3833 | 10.8546 | 24.1245 | 19.3807 | 0.5274 | 0.0677 | |

| Penalty1 | min | 1,671,844 | 3.9859 | 8.6215 | 1.2 × 108 | 9.4521 | 1.8 × 108 | 13,750,807 | 1.0272 | 0.1321 |

| mean | 3.4 × 108 | 4.5284 | 14.1119 | 1.8 × 108 | 864.382 | 2.7 × 108 | 2.0 × 107 | 1.4334 | 0.4603 | |

| std | 2.7 × 108 | 0.5636 | 3.7758 | 5.1 × 107 | 864.380 | 8.0 × 107 | 7.0 × 106 | 0.5340 | 0.1815 | |

| Penalty2 | min | 113,520 | 11.4652 | 105.1962 | 2.6 × 108 | 6259.28 | 3.3 × 108 | 3.3 × 107 | 3.0526 | 0.5626 |

| mean | 3.0 × 108 | 17.8096 | 739.8444 | 3.7 × 108 | 3.0 × 105 | 5.9 × 108 | 7.3 × 107 | 4.6854 | 2.5750 | |

| std | 3.5 × 108 | 5.9365 | 686.6578 | 6.1 × 107 | 4.0 × 105 | 1.0 × 108 | 3.2 × 107 | 1.2751 | 1.0279 | |

| Quartic | min | 3.0487 | 0.0013 | 0.0031 | 46.1170 | 0.1269 | 54.7615 | 6.2594 | 0.0002 | 2.8 × 10−5 |

| mean | 5.8396 | 0.0053 | 0.0067 | 58.5713 | 0.6576 | 65.9201 | 8.6888 | 3.9 × 10−4 | 5.7 × 10−5 | |

| std | 3.6090 | 0.0040 | 0.0033 | 7.3838 | 0.3701 | 5.9463 | 2.5195 | 1.2 × 10−4 | 2.4 × 10−5 | |

| Rastrigin | min | 217.8773 | 24.3133 | 169.2863 | 323.992 | 152.970 | 315.287 | 226.959 | 28.6717 | 15.1721 |

| mean | 251.5205 | 27.9260 | 186.6605 | 366.190 | 203.196 | 364.956 | 260.566 | 34.9787 | 19.6687 | |

| std | 20.4680 | 3.1046 | 7.7485 | 23.5157 | 36.4538 | 18.6455 | 17.4848 | 3.8464 | 1.9322 | |

| Rosenbrock | min | 3594.80 | 111.203 | 94.562 | 3816.12 | 288.426 | 3349.00 | 763.314 | 94.9775 | 29.5112 |

| mean | 4.4 × 103 | 132.272 | 108.888 | 5.1 × 103 | 405.606 | 4.4 × 103 | 1.2 × 103 | 115.377 | 33.7508 | |

| std | 451.691 | 22.5807 | 11.1501 | 926.611 | 91.3460 | 571.998 | 237.121 | 17.9313 | 2.7769 | |

| Schwefel1 | min | 9162.77 | 5002.61 | 18,129.05 | 21,679.1 | 8277.50 | 19,694.6 | 10,323.2 | 6388.35 | 1074.32 |

| mean | 1.4 × 104 | 7.0 × 103 | 2.1 × 104 | 2.9 × 104 | 1.5 × 104 | 2.4 × 104 | 1.7 × 104 | 9.4 × 103 | 1.2 × 103 | |

| std | 2.8 × 103 | 902.9220 | 2.4 × 103 | 4.1 × 103 | 3.8 × 103 | 2.7 × 103 | 3.2 × 103 | 2.2 × 103 | 108.255 | |

| Schwefel2 | min | 74.8000 | 4.1000 | 4.1630 | 111.900 | 35.6000 | 86.7000 | 54.9496 | 4.5000 | 1.2521 |

| mean | 84.3500 | 4.8800 | 4.6133 | 125.570 | 46.9900 | 100.110 | 102.771 | 6.5200 | 2.1421 | |

| std | 6.4977 | 0.6431 | 0.4821 | 10.6046 | 6.9542 | 5.9831 | 31.3971 | 1.3578 | 0.3756 | |

| Schwefel3 | min | 32.2000 | 40.7000 | 37.9842 | 54.9440 | 47.4000 | 73.1000 | 51.0582 | 28.9000 | 11.4676 |

| mean | 38.5400 | 49.4200 | 45.4736 | 61.9637 | 55.4400 | 77.3600 | 60.8716 | 39.7100 | 14.6438 | |

| std | 5.4244 | 6.8949 | 5.1956 | 5.1824 | 6.8050 | 2.2962 | 8.5732 | 6.8140 | 1.2038 | |

| Sphere | min | 40.9896 | 0.5241 | 0.1052 | 108.830 | 20.6913 | 100.080 | 30.23603 | 0.2923 | 0.0137 |

| mean | 50.8767 | 0.6823 | 0.1689 | 132.356 | 31.2184 | 128.365 | 38.4796 | 0.4767 | 0.0374 | |

| std | 6.7235 | 0.0974 | 0.0439 | 13.5977 | 6.7534 | 13.1963 | 4.2327 | 0.1093 | 0.0164 | |

| Step | min | 1036.00 | 127.000 | 53.0000 | 30,114.0 | 2126.00 | 34,324.0 | 13,524.0 | 80.0000 | 1.0000 |

| mean | 1.5 × 103 | 206.900 | 69.0000 | 34,528.0 | 3.5 × 103 | 46,144.0 | 15,917.0 | 122.600 | 10.8000 | |

| std | 360.716 | 53.2531 | 9.5812 | 4.0 × 103 | 1.3 × 103 | 6.2 × 103 | 1.5 × 103 | 52.8076 | 4.6648 | |

| Performance Indicators | IBBO-FOPID | BBO-FOPID | SGA-FOPID | IBBO-PID | ZN-PID |

|---|---|---|---|---|---|

| Overshoot (%) | 0.6760 | 2.0967 | 1.2869 | 1.2440 | 25.4546 |

| Adjustment time (s) | 3.5343 | 3.3502 | 4.1814 | 4.0370 | 8.4253 |

| Steady-state error | 0.0008 | 0.0014 | 0.0018 | 0.0025 | 0.0142 |

| Performance Indicators | Overshoot (%) | Rise Time (s) | Adjustment Time (s) |

|---|---|---|---|

| PID | 0.010207 | 6.45 | 10.35 |

| FOPID | 0.009575 | 2.55 | 4.50 |

| Performance Indicators | RMSE | MAPE (%) | ||

|---|---|---|---|---|

| Sin Signal | Square Signal | Sin Signal | Square Signal | |

| PID | 6.8681 | 20.7357 | 3.4602 | 32.2391 |

| FOPID | 3.6245 | 14.0825 | 1.7184 | 16.2357 |

| Performance Indicators | PID | FOPID | ||

|---|---|---|---|---|

| Simulation | Experiment | Simulation | Experiment | |

| Overshoot (%) | 1.2440 | 0.0102 | 0.6760 | 0.0095 |

| Adjustment time (s) | 4.0370 | 10.3500 | 3.5343 | 4.5000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, M.; Xu, Z.; Zang, Z.; Dong, X. Design of FOPID Controller for Pneumatic Control Valve Based on Improved BBO Algorithm. Sensors 2022, 22, 6706. https://doi.org/10.3390/s22176706

Zhu M, Xu Z, Zang Z, Dong X. Design of FOPID Controller for Pneumatic Control Valve Based on Improved BBO Algorithm. Sensors. 2022; 22(17):6706. https://doi.org/10.3390/s22176706

Chicago/Turabian StyleZhu, Min, Zihao Xu, Zhaoyu Zang, and Xueping Dong. 2022. "Design of FOPID Controller for Pneumatic Control Valve Based on Improved BBO Algorithm" Sensors 22, no. 17: 6706. https://doi.org/10.3390/s22176706

APA StyleZhu, M., Xu, Z., Zang, Z., & Dong, X. (2022). Design of FOPID Controller for Pneumatic Control Valve Based on Improved BBO Algorithm. Sensors, 22(17), 6706. https://doi.org/10.3390/s22176706