Carbon Microfiber-Doped Smart Concrete Sensors for Strain Monitoring in Reinforced Concrete Structures: An Experimental Study at Various Scales

Abstract

:1. Introduction

2. Materials and Samples

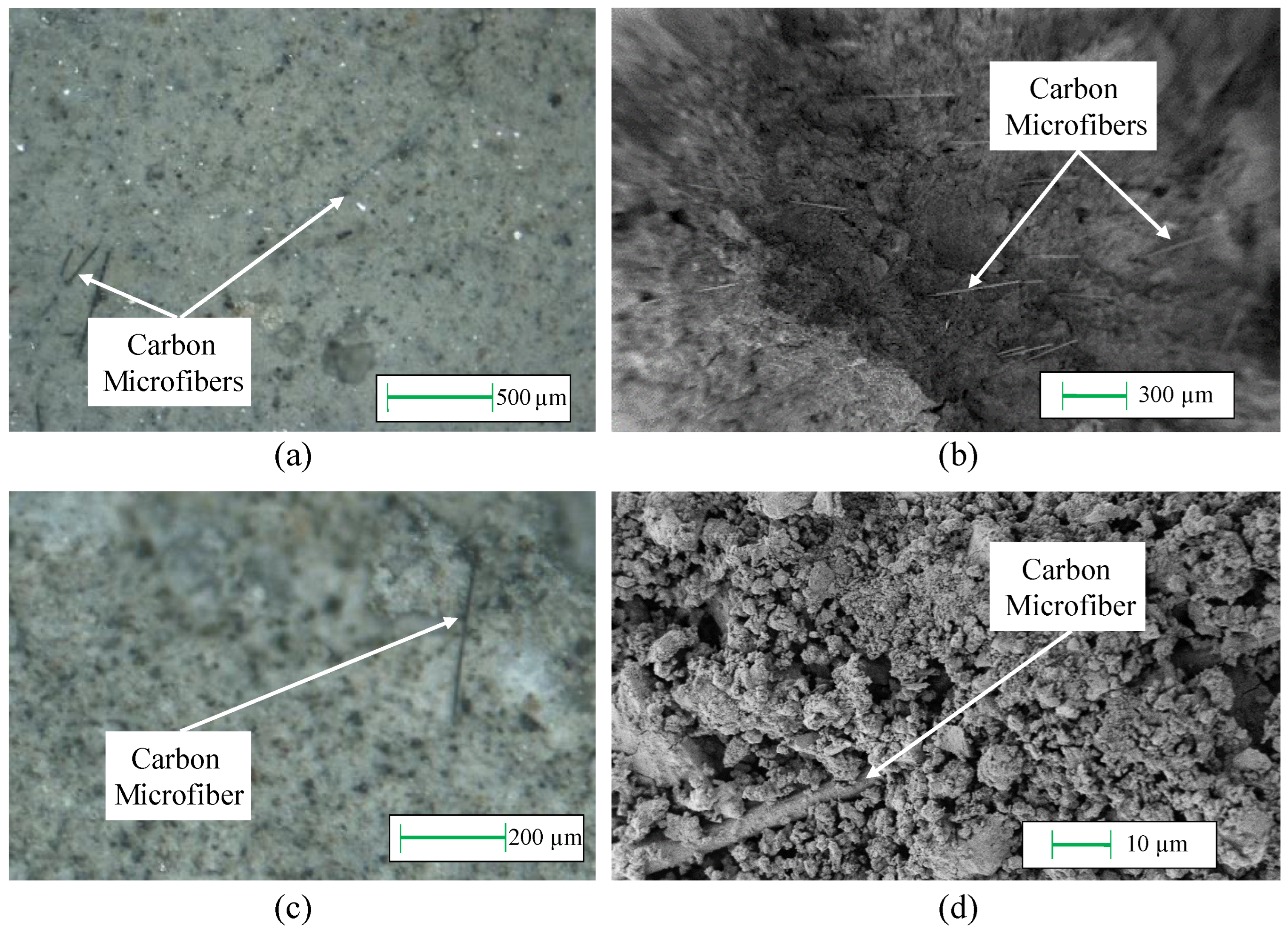

2.1. Components

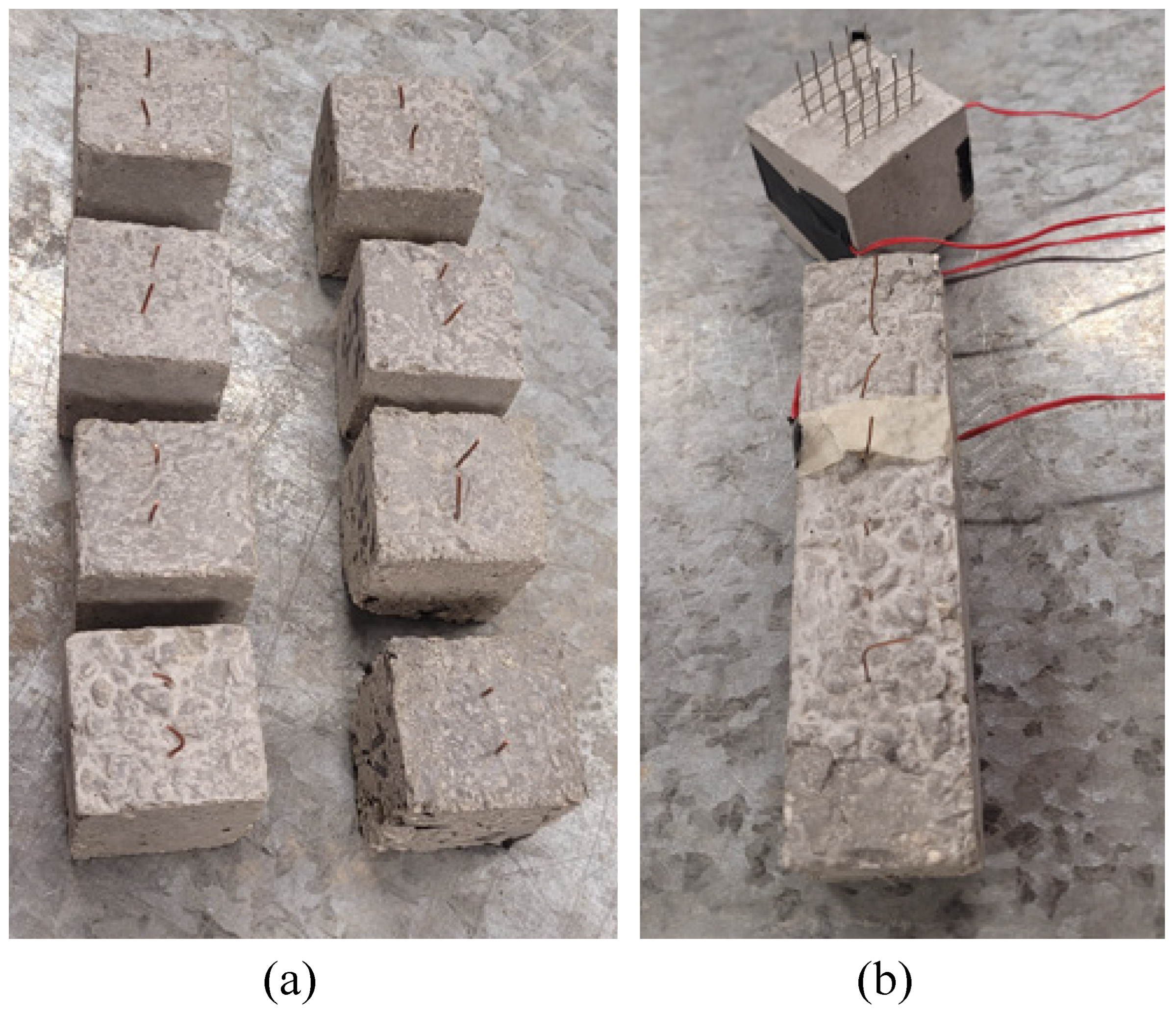

2.2. Small-Scale Samples

2.3. Middle-Scale Samples

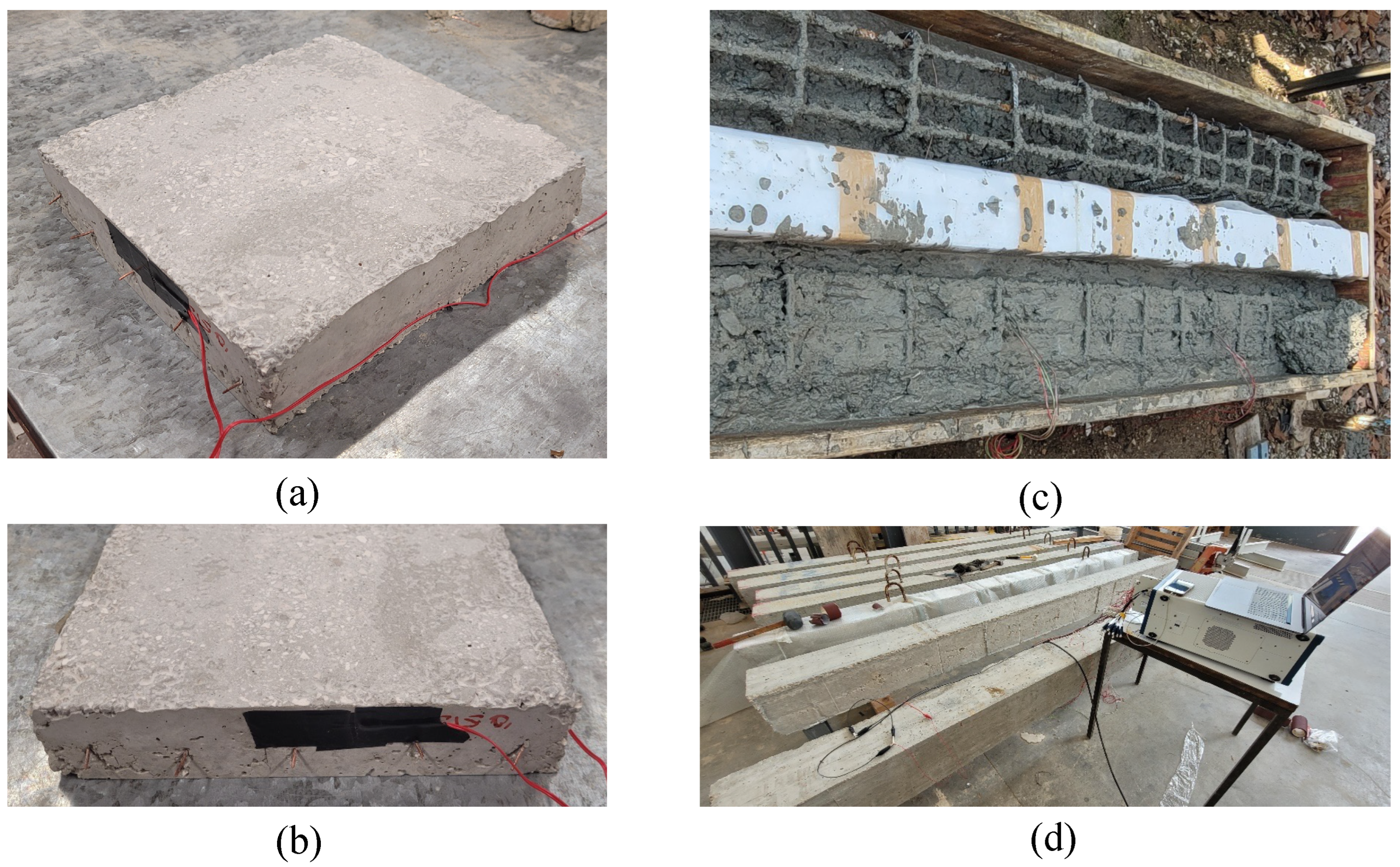

2.4. Full-Scale Samples

3. Setups and Instrumentation

4. Electrical and Dynamic Modeling

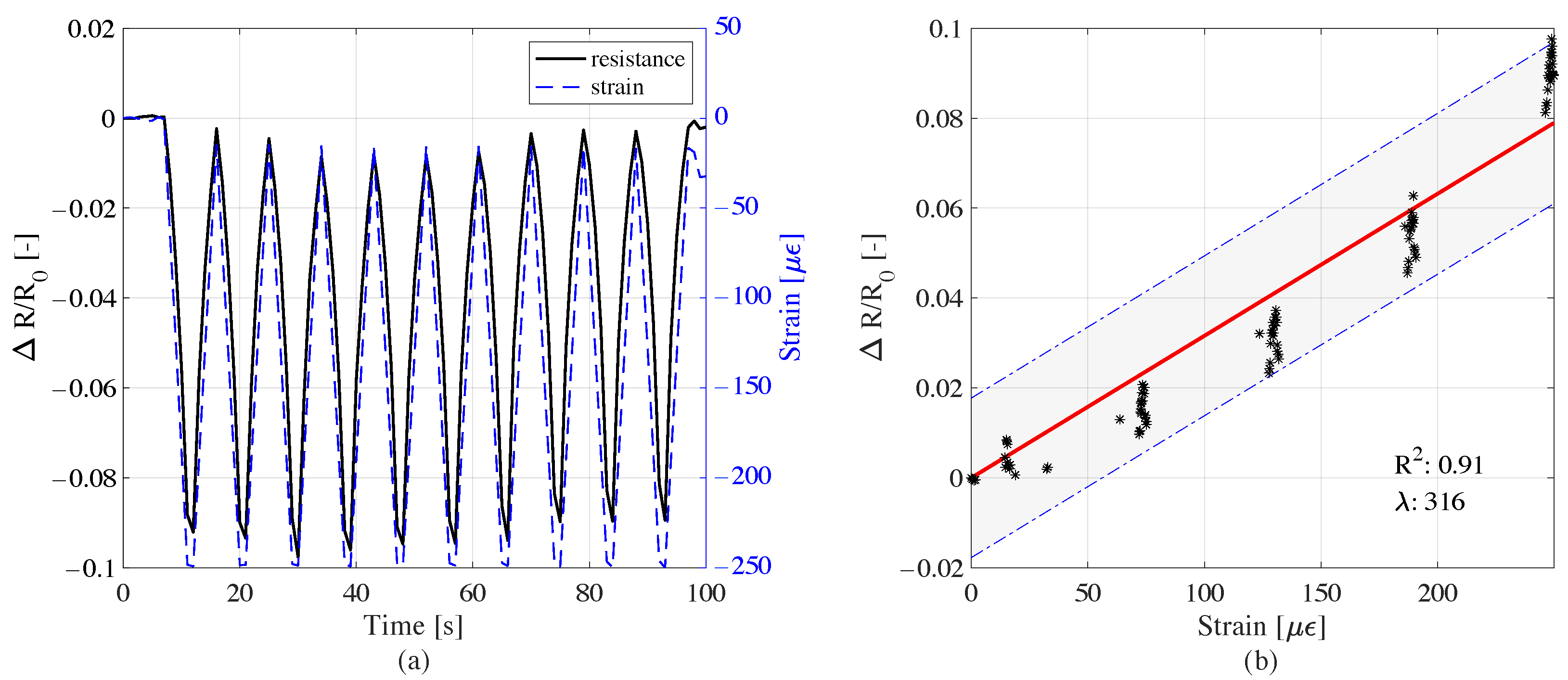

4.1. Piezoresistivity of the Samples

4.2. Natural Frequency of the Beam

5. Experimental Results

5.1. Small Cube Samples with Varying CMF Concentrations

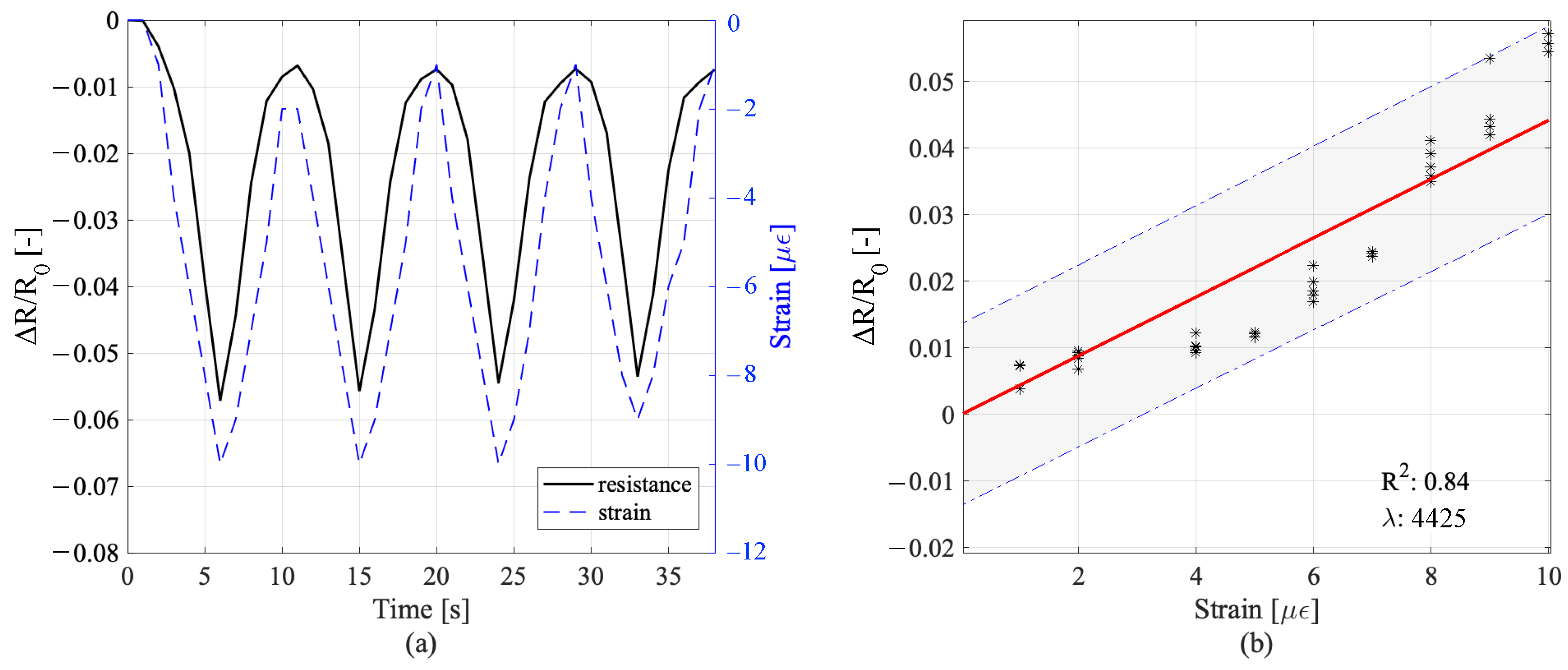

5.2. Strain Sensing Capabilities of Cube and Beam Samples under Compression Loads

5.3. Load Sensing Performance of Plate Sample under Surface Compression

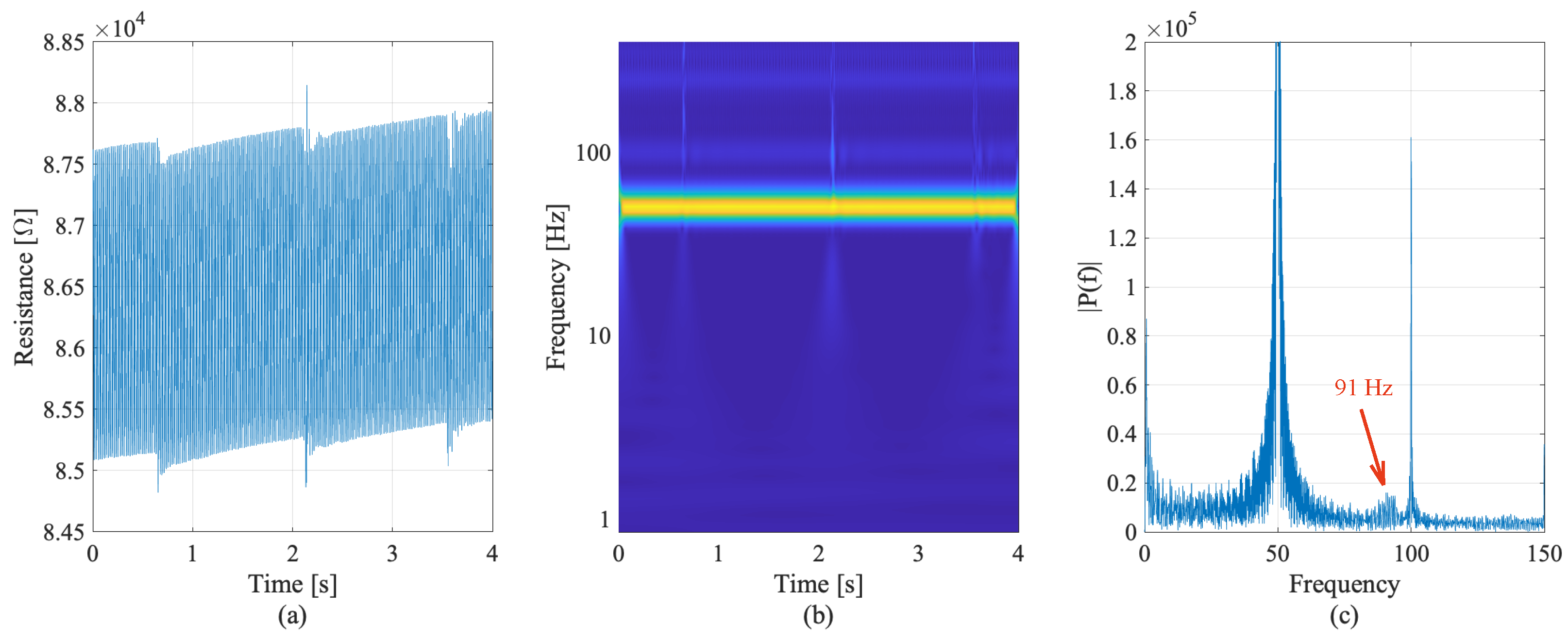

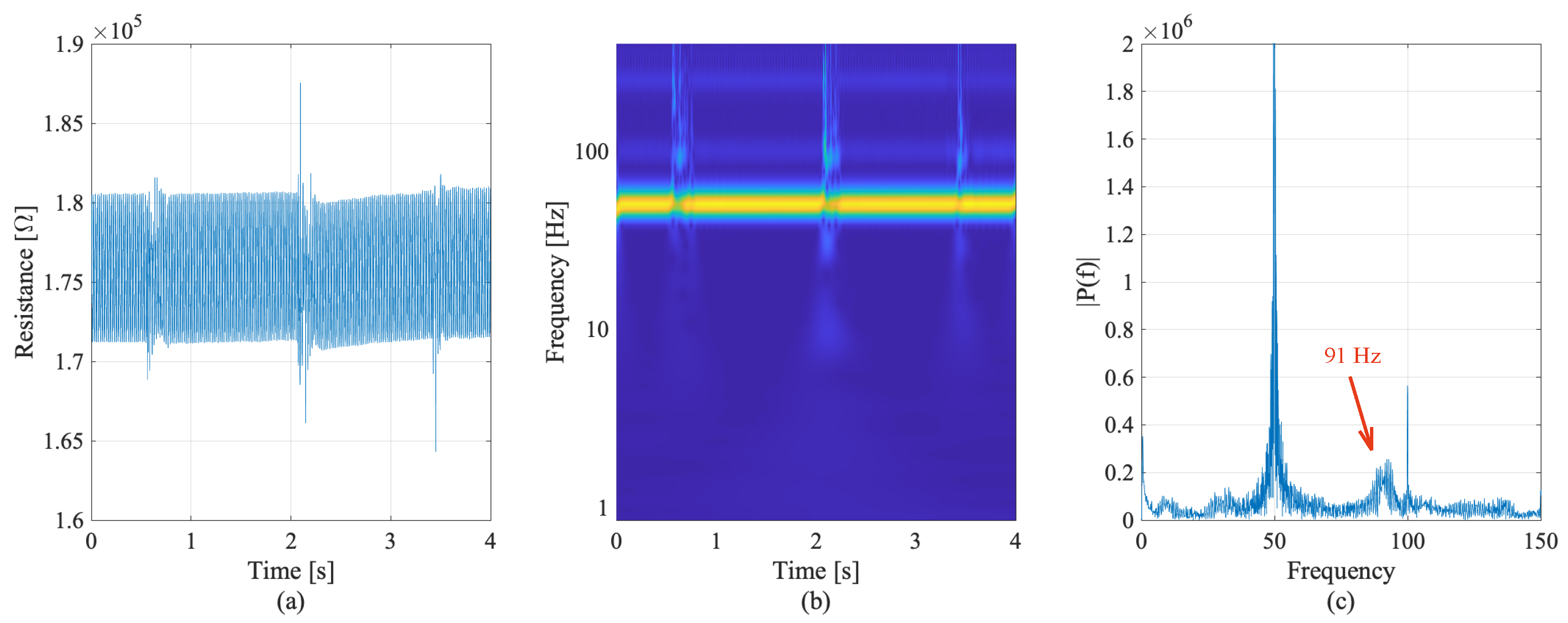

5.4. Dynamic Sensing Capabilities of Smart Concrete Sensors in Full-Scale Beam

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jahren, P.; Sui, T. History of Concrete: A Very Old and Modern Material; World Scientific: Singapore, 2017. [Google Scholar]

- de Medeiros-Junior, R.A.; de Lima, M.G.; de Medeiros, M.H. Service life of concrete structures considering the effects of temperature and relative humidity on chloride transport. Environ. Dev. Sustain. 2015, 17, 1103–1119. [Google Scholar] [CrossRef]

- Balaras, C.A.; Droutsa, K.; Dascalaki, E.; Kontoyiannidis, S. Deterioration of European apartment buildings. Energy Build. 2005, 37, 515–527. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, Z.; Wei, S.; Xu, Y.; Tang, Z.; Li, H. The state of the art of data science and engineering in structural health monitoring. Engineering 2019, 5, 234–242. [Google Scholar] [CrossRef]

- Kot, P.; Muradov, M.; Gkantou, M.; Kamaris, G.S.; Hashim, K.; Yeboah, D. Recent advancements in non-destructive testing techniques for structural health monitoring. Appl. Sci. 2021, 11, 2750. [Google Scholar] [CrossRef]

- Ragam, P.; Devidas Sahebraoji, N. Application of MEMS-based accelerometer wireless sensor systems for monitoring of blast-induced ground vibration and structural health: A review. IET Wirel. Sens. Syst. 2019, 9, 103–109. [Google Scholar] [CrossRef]

- Mei, H.; Haider, M.F.; Joseph, R.; Migot, A.; Giurgiutiu, V. Recent advances in piezoelectric wafer active sensors for structural health monitoring applications. Sensors 2019, 19, 383. [Google Scholar] [CrossRef]

- Macías, E.G.; Ubertini, F. Automated operational modal analysis and ambient noise deconvolution interferometry for the full structural identification of historic towers: A case study of the Sciri Tower in Perugia, Italy. Eng. Struct. 2020, 215, 110615. [Google Scholar] [CrossRef]

- Sharry, T.; Guan, H.; Nguyen, A.; Oh, E.; Hoang, N. Latest advances in finite element modelling and model updating of cable-stayed bridges. Infrastructures 2022, 7, 8. [Google Scholar] [CrossRef]

- Capellari, G.; Chatzi, E.; Mariani, S. Cost–benefit optimization of structural health monitoring sensor networks. Sensors 2018, 18, 2174. [Google Scholar] [CrossRef]

- Ostachowicz, W.; Soman, R.; Malinowski, P. Optimization of sensor placement for structural health monitoring: A review. Struct. Health Monit. 2019, 18, 963–988. [Google Scholar] [CrossRef]

- Cantero-Chinchilla, S.; Beck, J.L.; Chiachío, M.; Chiachío, J.; Chronopoulos, D.; Jones, A. Optimal sensor and actuator placement for structural health monitoring via an efficient convex cost-benefit optimization. Mech. Syst. Signal Process. 2020, 144, 106901. [Google Scholar] [CrossRef]

- Sajedi, S.; Liang, X. Deep generative Bayesian optimization for sensor placement in structural health monitoring. Comput.-Aided Civ. Infrastruct. Eng. 2021, 37, 1109–1127. [Google Scholar] [CrossRef]

- Testoni, N.; Zonzini, F.; Marzani, A.; Scarponi, V.; De Marchi, L. A tilt sensor node embedding a data-fusion algorithm for vibration-based SHM. Electronics 2019, 8, 45. [Google Scholar] [CrossRef]

- Glisic, B. Concise Historic Overview of Strain Sensors Used in the Monitoring of Civil Structures: The First One Hundred Years. Sensors 2022, 22, 2397. [Google Scholar] [CrossRef] [PubMed]

- Hussan, M.; Kaloop, M.R.; Sharmin, F.; Kim, D. GPS performance assessment of cable-stayed bridge using wavelet transform and monte-carlo techniques. KSCE J. Civ. Eng. 2018, 22, 4385–4398. [Google Scholar] [CrossRef]

- Sony, S.; Laventure, S.; Sadhu, A. A literature review of next-generation smart sensing technology in structural health monitoring. Struct. Control. Health Monit. 2019, 26, e2321. [Google Scholar] [CrossRef]

- Zonzini, F.; Malatesta, M.M.; Bogomolov, D.; Testoni, N.; Marzani, A.; De Marchi, L. Vibration-based SHM With upscalable and low-cost sensor networks. IEEE Trans. Instrum. Meas. 2020, 69, 7990–7998. [Google Scholar]

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Hou, T.C.; Lynch, J.P. Electrical impedance tomographic methods for sensing strain fields and crack damage in cementitious structures. J. Intell. Mater. Syst. Struct. 2009, 20, 1363–1379. [Google Scholar] [CrossRef]

- Chen, S.; Collins, F.G.; MacLeod, A.J.N.; Pan, Z.; Duan, W.; Wang, C.M. Carbon nanotube–cement composites: A retrospect. IES J. Part Civ. Struct. Eng. 2011, 4, 254–265. [Google Scholar] [CrossRef]

- Li, X.; Li, M. Multifunctional self-sensing and ductile cementitious materials. Cem. Concr. Res. 2019, 123, 105714. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D. Piezoresistivity-based strain sensing in carbon fiber-reinforced cement. ACI Mater. J. 2007, 104, 171. [Google Scholar]

- Wansom, S.; Kidner, N.; Woo, L.; Mason, T. AC-impedance response of multi-walled carbon nanotube/cement composites. Cem. Concr. Compos. 2006, 28, 509–519. [Google Scholar] [CrossRef]

- Luo, J.; Duan, Z.; Li, H. The influence of surfactants on the processing of multi-walled carbon nanotubes in reinforced cement matrix composites. Phys. Status Solidi A 2009, 206, 2783–2790. [Google Scholar] [CrossRef]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Carbon nanofiber cement sensors to detect strain and damage of concrete specimens under compression. Nanomaterials 2017, 7, 413. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Multifunctional and smart carbon nanotube reinforced cement-based materials. In Nanotechnology in Civil Infrastructure; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–47. [Google Scholar]

- Coppola, L.; Buoso, A.; Corazza, F. Electrical properties of carbon nanotubes cement composites for monitoring stress conditions in concrete structures. Appl. Mech. Mater. 2011, 82, 118–123. [Google Scholar] [CrossRef]

- Camacho-Ballesta, C.; Zornoza, E.; Garcés, P. Performance of cement-based sensors with CNT for strain sensing. Adv. Cem. Res. 2016, 28, 274–284. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.; Lee, S.H. Self-sensing capability of ultra-high-performance concrete containing steel fibers and carbon nanotubes under tension. Sens. Actuators A Phys. 2018, 276, 125–136. [Google Scholar] [CrossRef]

- Rao, R.K.; Sasmal, S. Smart nano-engineered cementitious composite sensors for vibration-based health monitoring of large structures. Sens. Actuators A Phys. 2020, 311, 112088. [Google Scholar] [CrossRef]

- Nalon, G.H.; Ribeiro, J.C.L.; de Araújo, E.N.D.; Pedroti, L.G.; de Carvalho, J.M.F.; Santos, R.F.; Aparecido-Ferreira, A. Effects of different kinds of carbon black nanoparticles on the piezoresistive and mechanical properties of cement-based composites. J. Build. Eng. 2020, 32, 101724. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, S.; Han, B.; Yu, X.; Ni, Y.Q. Effect of water content on the piezoresistive property of smart cement-based materials with carbon nanotube/nanocarbon black composite filler. Compos. Part A Appl. Sci. Manuf. 2019, 119, 8–20. [Google Scholar] [CrossRef]

- Fan, X.; Fang, D.; Sun, M.; Li, Z. Piezoresistivity of carbon fiber graphite cement-based composites with CCCW. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2011, 26, 339–343. [Google Scholar] [CrossRef]

- Li, H.; Xiao, H.g.; Ou, J.P. A study on mechanical and pressure-sensitive properties of cement mortar with nanophase materials. Cem. Concr. Res. 2004, 34, 435–438. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Birgin, H.B.; Cerni, G.; Ubertini, F. Smart Infrastructure Monitoring through Self-Sensing Composite Sensors and Systems: A Study on Smart Concrete Sensors with Varying Carbon-Based Filler. Infrastructures 2022, 7, 48. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Tiecco, M.; Meoni, A.; Ubertini, F. Improved strain sensing properties of cement-based sensors through enhanced carbon nanotube dispersion. Cem. Concr. Compos. 2021, 115, 103842. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly dispersed carbon nanotube reinforced cement based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Rainieri, C.; Pannunzio, C.; Song, Y.; Fabbrocino, G.; Schulz, M.J.; Shanov, V. The status of research on self-sensing properties of CNT-cement based composites and prospective applications to SHM. Key Eng. Mater. 2013, 569, 759–766. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Ubertini, F.; Materazzi, A.L.; Laflamme, S.; Cancelli, A.; Micheli, L. Carbon cement-based sensors for dynamic monitoring of structures. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; pp. 1–4. [Google Scholar]

- Birgin, H.B.; D’Alessandro, A.; Laflamme, S.; Ubertini, F. Hybrid carbon microfibers-graphite fillers for piezoresistive cementitious composites. Sensors 2021, 21, 518. [Google Scholar] [CrossRef]

| Components | kg/m | CMF/c Percentage (%) | kg/m |

|---|---|---|---|

| Cement | 420 | 0.000 | 0.000 |

| Aggregates | 1830 | 0.010 | 0.042 |

| Water | 212 | 0.025 | 0.105 |

| 0.050 | 0.210 | ||

| 0.100 | 0.420 | ||

| 0.250 | 1.050 | ||

| 0.500 | 2.100 | ||

| 1.000 | 4.200 | ||

| w/c ratio | 0.5 |

| Property | Units | Values |

|---|---|---|

| Density | g/cm | 1.8 |

| Fiber length chopped | mm | 6 |

| Filament diameter | m | 7 |

| Tensile strength | GPa | 4.0 |

| Tensile modulus | GPa | 240 |

| Elongation at break | % | 1.7 |

| Single filament resistivity | m | 15 |

| Bulk density | g/L | - |

| Sizing type | - | Glycerin |

| Compatible with | - | Water-based systems |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Alessandro, A.; Birgin, H.B.; Ubertini, F. Carbon Microfiber-Doped Smart Concrete Sensors for Strain Monitoring in Reinforced Concrete Structures: An Experimental Study at Various Scales. Sensors 2022, 22, 6083. https://doi.org/10.3390/s22166083

D’Alessandro A, Birgin HB, Ubertini F. Carbon Microfiber-Doped Smart Concrete Sensors for Strain Monitoring in Reinforced Concrete Structures: An Experimental Study at Various Scales. Sensors. 2022; 22(16):6083. https://doi.org/10.3390/s22166083

Chicago/Turabian StyleD’Alessandro, Antonella, Hasan Borke Birgin, and Filippo Ubertini. 2022. "Carbon Microfiber-Doped Smart Concrete Sensors for Strain Monitoring in Reinforced Concrete Structures: An Experimental Study at Various Scales" Sensors 22, no. 16: 6083. https://doi.org/10.3390/s22166083

APA StyleD’Alessandro, A., Birgin, H. B., & Ubertini, F. (2022). Carbon Microfiber-Doped Smart Concrete Sensors for Strain Monitoring in Reinforced Concrete Structures: An Experimental Study at Various Scales. Sensors, 22(16), 6083. https://doi.org/10.3390/s22166083