High-Performance Breaking and Intelligent of Miniature Circuit Breakers

Abstract

:1. Introduction

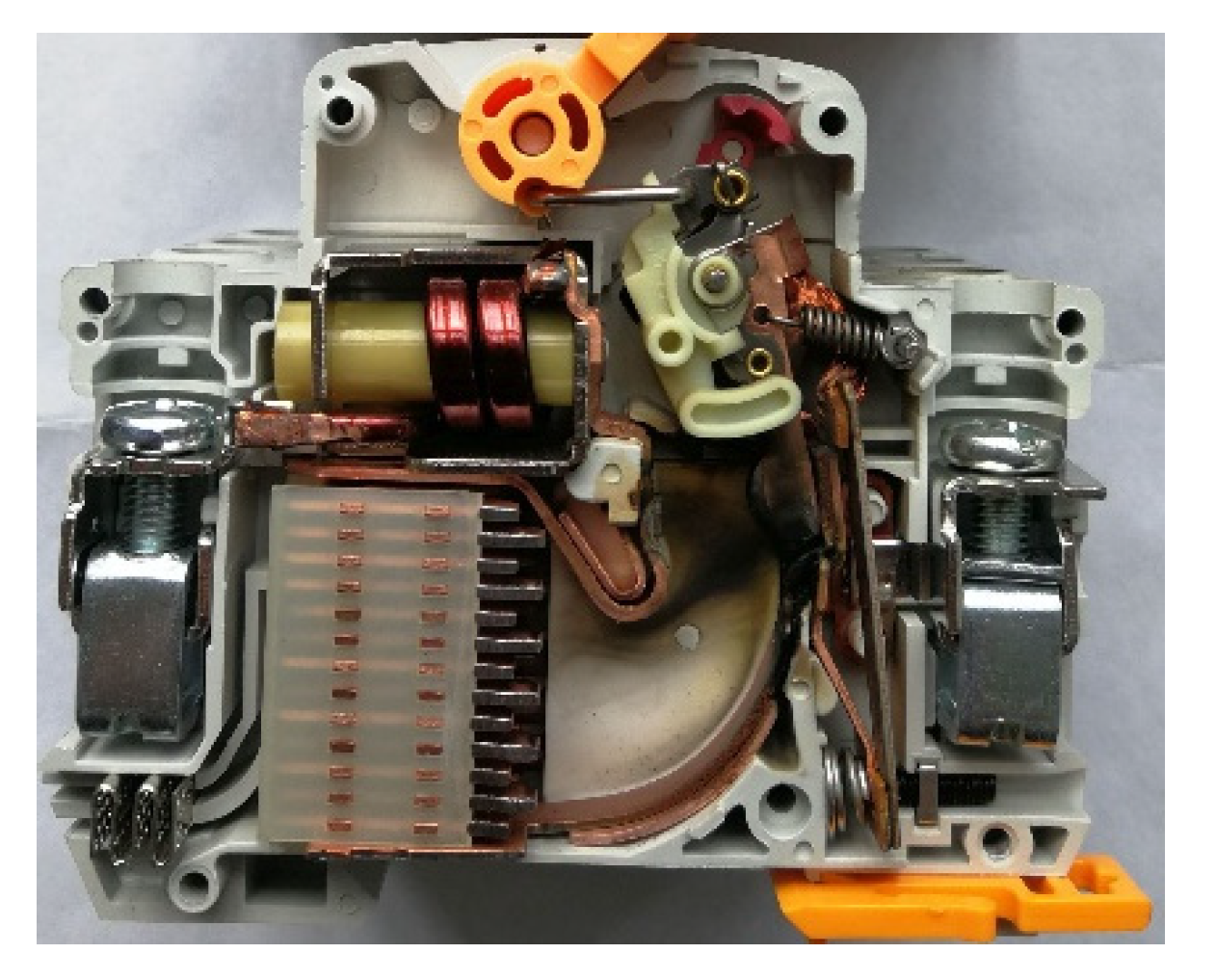

2. High-Performance DC/AC Breaking Technology

2.1. Theoretical Analysis and Practical Scheme of DC Non-Polar Arc Extinguishing

2.2. DC Breaking Test and Result Analysis

3. Intellectualization of MCB

3.1. Intelligent Platform Architecture

3.2. Intelligent and Digital Circuit Breaker System

4. Conclusions

- (1)

- The arc extinguishing strategy coordinated by air blowing and magnetic blowing was proposed. The high-voltage DC non-polar breaking capacity of circuit breaker was improved, which increased from 6 kA to 10 kA DC.

- (2)

- Through the reasonable arrangement of permanent magnet, this arc extinguishing scheme can realize DC non-polar breaking, AC and DC universal, while keeping the original circuit breaker structure size unchanged. The arc-extinguishing scheme can be extended to the research and development of high-performance DC molded case circuit breakers and frame circuit breakers.

- (3)

- Based on the cloud platform, the intelligent and digital monitoring system of circuit breaker was developed, which provides a reference for the digitalization of power equipment.

- (4)

- Through the combination of the above high-performance breaking technology and intelligent technology, the prototype was developed, confirming this technology has formed a mature product and has been promoted and transformed.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yuan, Z.; Guo, P.; Liu, G.; Zhao, Y.; Shi, Z. Review on control and protection for renewable energy integration through VSC-HVDC. High Volt. Eng. 2020, 46, 1460–1475. [Google Scholar]

- Wei, X.; Gao, S.; Zang, T.; Huang, T.; Wang, T.; Li, D. Social energy internet: Concept, architecture and outlook. Proc. CSEE 2018, 38, 4969–4986. [Google Scholar]

- Melo, G.C.G.d.; Torres, I.C.; Araújo, Í.B.Q.d.; Brito, D.B.; Barboza, E.d.A. A Low-Cost IoT System for Real-Time Monitoring of Climatic Variables and Photovoltaic Generation for Smart Grid Application. Sensors 2021, 21, 3293. [Google Scholar] [CrossRef]

- Bedi, G.; Venayagamoorthy, G.K.; Singh, R.; Brooks, R.R.; Wang, K.C. Review of Internet of Things (IoT) in electric power and energy systems. IEEE Internet Things J. 2018, 5, 847–870. [Google Scholar] [CrossRef]

- Khan, M.N.; Rahman, H.U.; Faisal, M.; Khan, F.; Ahmad, S. An IoT-Enabled Information System for Smart Navigation in Museums. Sensors 2022, 22, 312. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, H.; Shou, P. Discussion on Key Technology and Operation & Maintenance of Intelligent Power Equipment. Autom. Electr. Power Syst. 2020, 44, 1–10. [Google Scholar]

- Kim, H. Aging Characteristics of Contact Electrodes of Low Voltage DC Switches. Energies 2021, 14, 6838. [Google Scholar] [CrossRef]

- Li, X.; Jia, S.; Zhang, B. Research and application on physical farameters calculation and behavior simulation of gas switching arc. High Volt. Eng. 2020, 46, 757–771. [Google Scholar]

- Wang, G.; Wang, Y.; Zhang, L.; Xue, S.; Dong, E.; Zou, J. A Novel Model of Electromechanical Contactors for Predicting Dynamic Characteristics. Energies 2021, 14, 7466. [Google Scholar] [CrossRef]

- Ma, Z.; Peng, Z.; Zhao, C.; Xu, T. Research and Development of 5kV High-speed Medium-voltage DC air circuit breaker. High Volt. Eng. 2020, 46, 312–318. [Google Scholar]

- Li, J.; Liu, K.; Cao, Y.; Hou, C.; Liu, S. Arc root development and its influence on arc reigniting during the breaking process of the DC contactor. Proc. CSEE 2019, 39, 1241–1250. [Google Scholar]

- Yin, J.; Wang, Q.; Li, X.; Xu, H. Numerical study of influence of frequency and eddy currents on arc motion in low-voltage circuit breaker. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1373–1380. [Google Scholar] [CrossRef]

- Lindmayer, M.; Marzahn, E.; Mutzke, A.; Ruther, T.; Springstubbe, M. The process of arc splitting between metal plates in low voltage arc chutes. IEEE Trans. Compon. Packag. Technol. 2006, 29, 310–317. [Google Scholar] [CrossRef]

- Dai, R. Simulation and Experimental Research on the Arc Dynamic Characteristics in Low Voltage Arc Quenching Chamber. Ph.D. Thesis, Xi’an Jiaotong University, Xi’an, China, 2009. [Google Scholar]

- Yin, J.; Wang, Q.; Zhang, B.; Zhang, P.; Li, X. Effect of frequency on arc motion in multiple parallel contacts’ system. IEEE Trans. Plasma Sci. 2019, 47, 1957–1963. [Google Scholar] [CrossRef]

- Iturregi, A.; Barbu, B.; Torres, E.; Berger, F.; Zamora, I. Electric arc in low-voltage circuit breakers: Experiments and simulation. IEEE Trans. Plasma Sci. 2017, 45, 113–120. [Google Scholar] [CrossRef]

- Wu, Y.; Rong, M.Z.; Yang, Q.; Hu, G.X. Simulation on dynamic characteristics of arc in low voltage circuit breaker modelling. Proc. CSEE 2005, 25, 143–148. [Google Scholar]

- Wu, Y.; Rong, M.; Li, J.; Lou, J. Calculation of electric and magnetic fields in simplified chambers of low-voltage circuit breakers. IEEE Trans. Magn. 2006, 42, 1007–1010. [Google Scholar] [CrossRef]

- Qu, J.; Yuan, S.; Wang, Q.; Li, X. Application of laser arc imaging technology to observe arc behavior and contact motion. Plasma Phys. Technol. 2015, 2, 183–186. [Google Scholar]

- Li, X.; Chen, D.; Liu, H.; Chen, Y.; Li, Z. Imaging and spectrum diagnostics of air arc plasma characteristics. IEEE Trans. Plasma Sci. 2004, 32, 2243–2249. [Google Scholar] [CrossRef]

- Smugala, D.; Bonk, M. Study of Arc Parameters of AC Relays Operating under Distorted Supply Voltage Conditions. Energies 2020, 13, 4785. [Google Scholar] [CrossRef]

- Liu, Z.; Duan, X.Y.; Liao, M.F. A model-based measurement method for intelligent circuit breaker with data communication. Trans. Inst. Meas. Control. 2018, 40, 15–19. [Google Scholar] [CrossRef]

- Seničar, B.; Gabrijelčič Tomc, H. User-Centred design and development of an intelligent light switch for sensor systems. Tehnički Vjesnik 2019, 26, 125–131. [Google Scholar]

- Kim, W.; Kim, Y.-J.; Kim, H. Arc Voltage and Current Characteristics in Low-Voltage Direct Current. Energies 2018, 11, 2511. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Lang, X.; Xu, H.; Duan, J. High-Performance Breaking and Intelligent of Miniature Circuit Breakers. Sensors 2022, 22, 5990. https://doi.org/10.3390/s22165990

Yin J, Lang X, Xu H, Duan J. High-Performance Breaking and Intelligent of Miniature Circuit Breakers. Sensors. 2022; 22(16):5990. https://doi.org/10.3390/s22165990

Chicago/Turabian StyleYin, Jianning, Xiaojian Lang, Haotian Xu, and Jiandong Duan. 2022. "High-Performance Breaking and Intelligent of Miniature Circuit Breakers" Sensors 22, no. 16: 5990. https://doi.org/10.3390/s22165990

APA StyleYin, J., Lang, X., Xu, H., & Duan, J. (2022). High-Performance Breaking and Intelligent of Miniature Circuit Breakers. Sensors, 22(16), 5990. https://doi.org/10.3390/s22165990