High-Frequency Current Transformers Cascade for Power Electronics Measurements

Abstract

:1. Introduction

2. Problem Analysis

2.1. Research Goal

2.2. Benefits of the Proposed Connection

2.3. Related Work Comparison

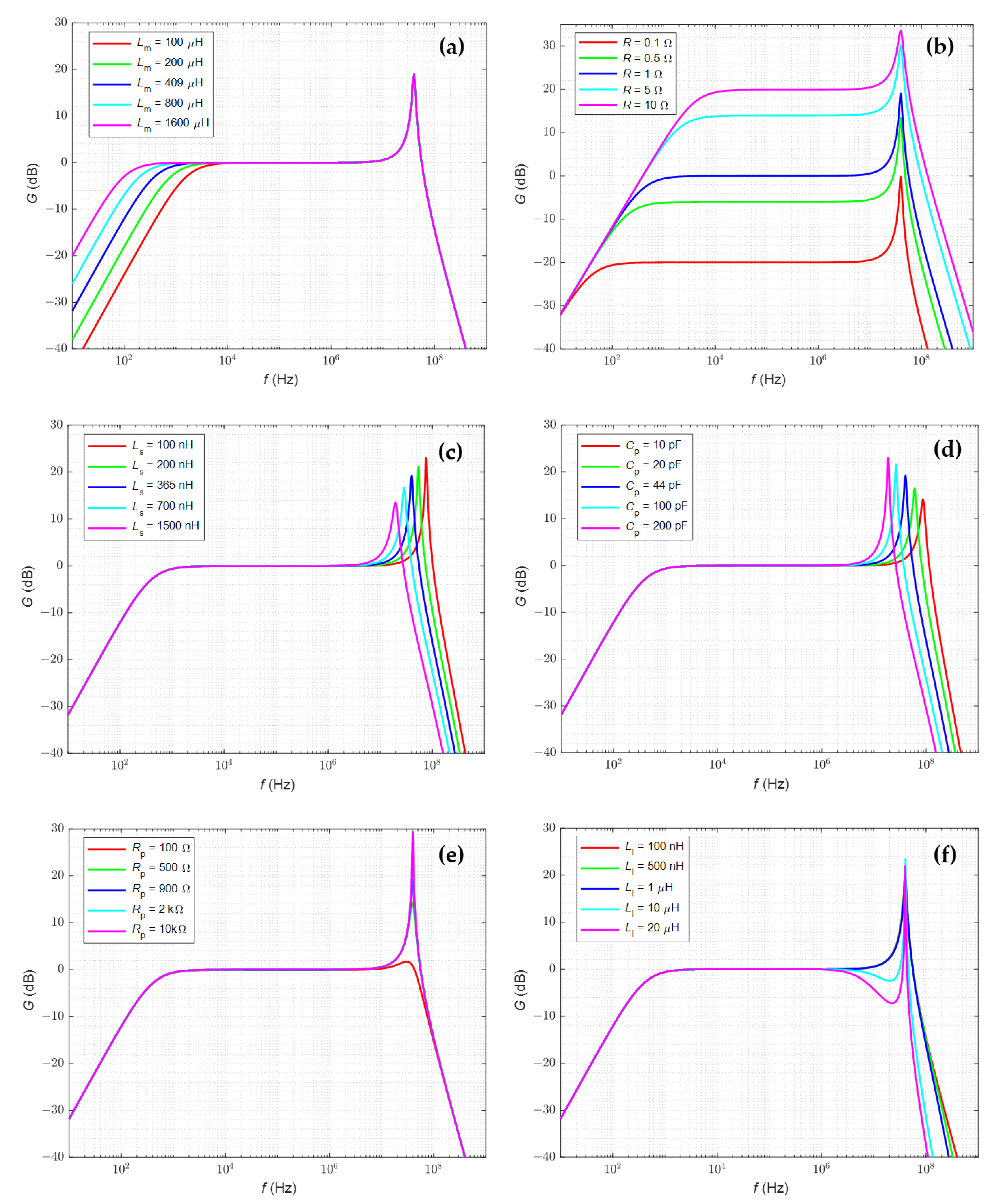

3. Bandwidth Analysis of the HFCT

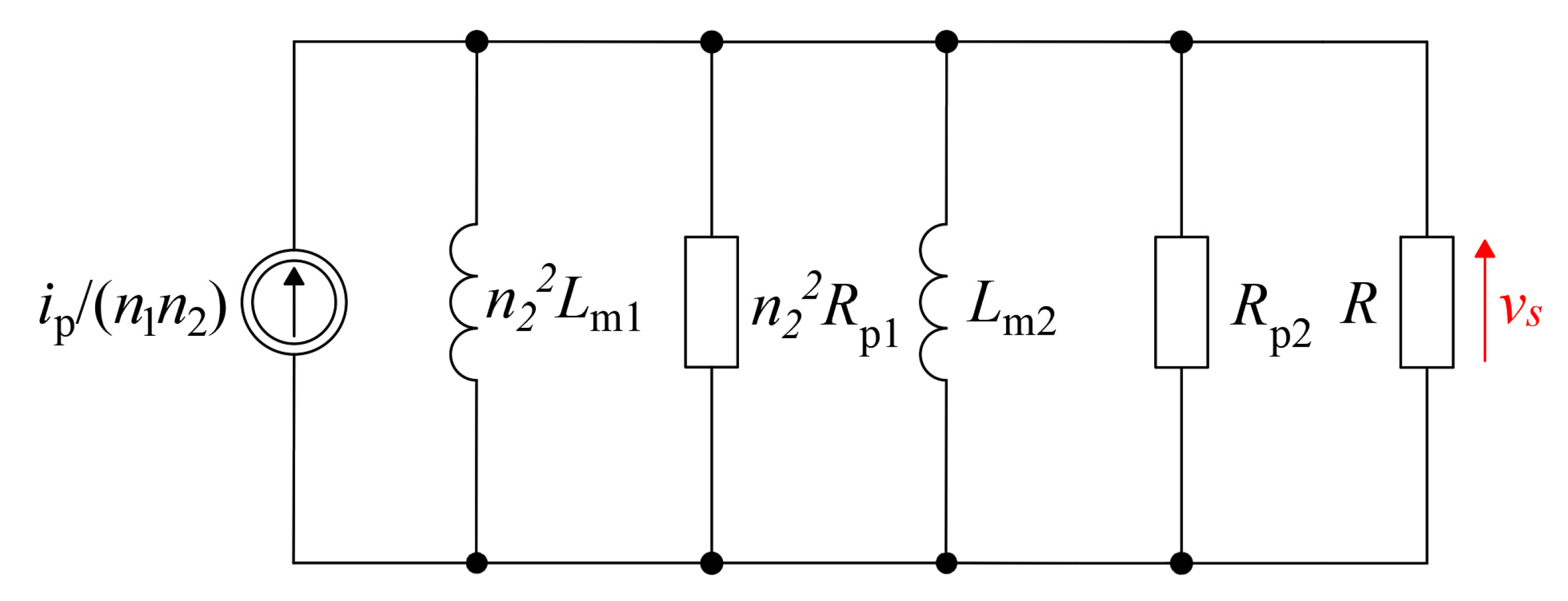

3.1. General Model of a Single HFCT

3.2. Low- and High-Frequency Response of the HFCT

3.3. Model Analysis of Cascaded Connection of Two HFCTs

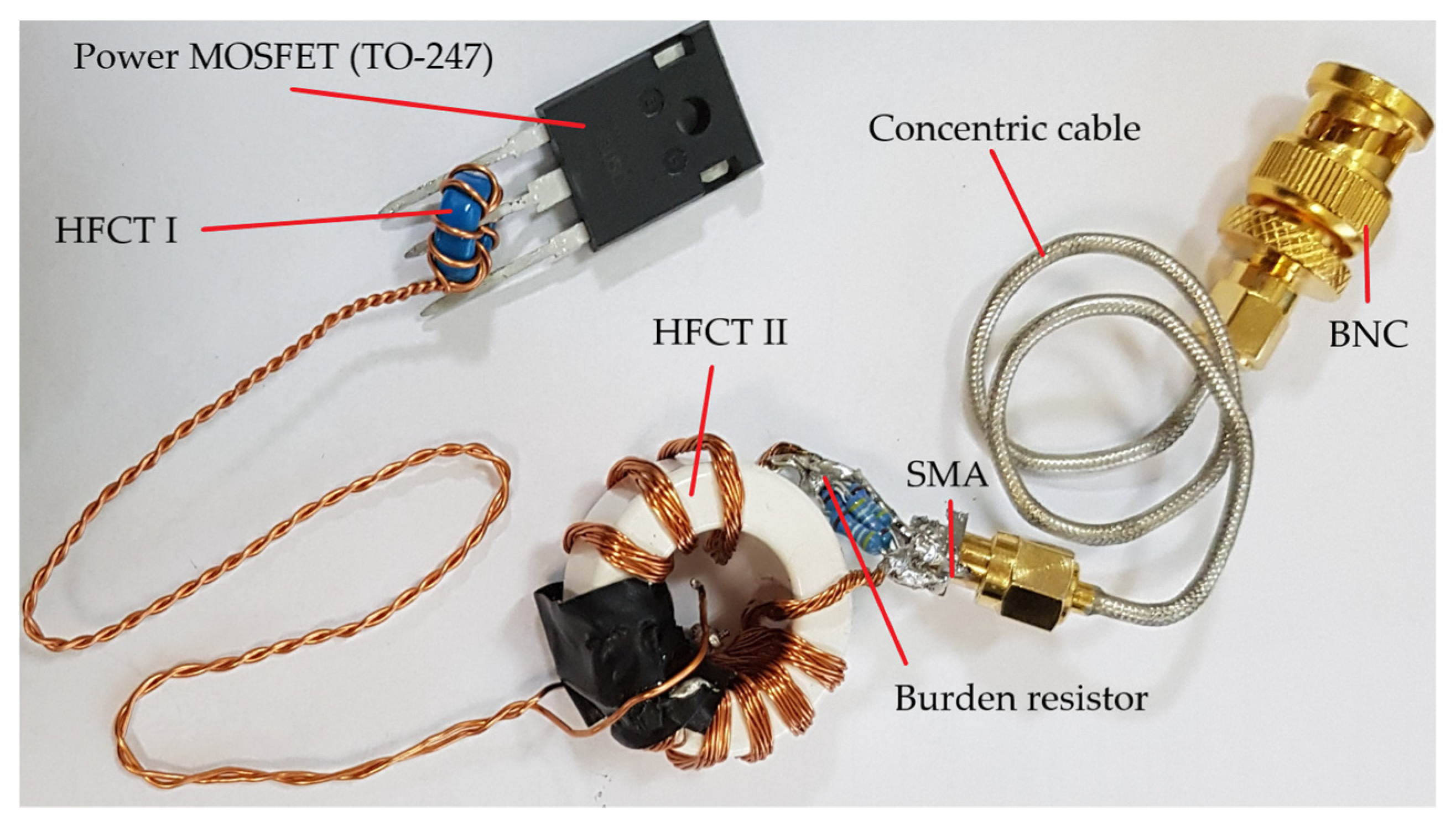

4. Experimental Result

4.1. Laboratory Setup

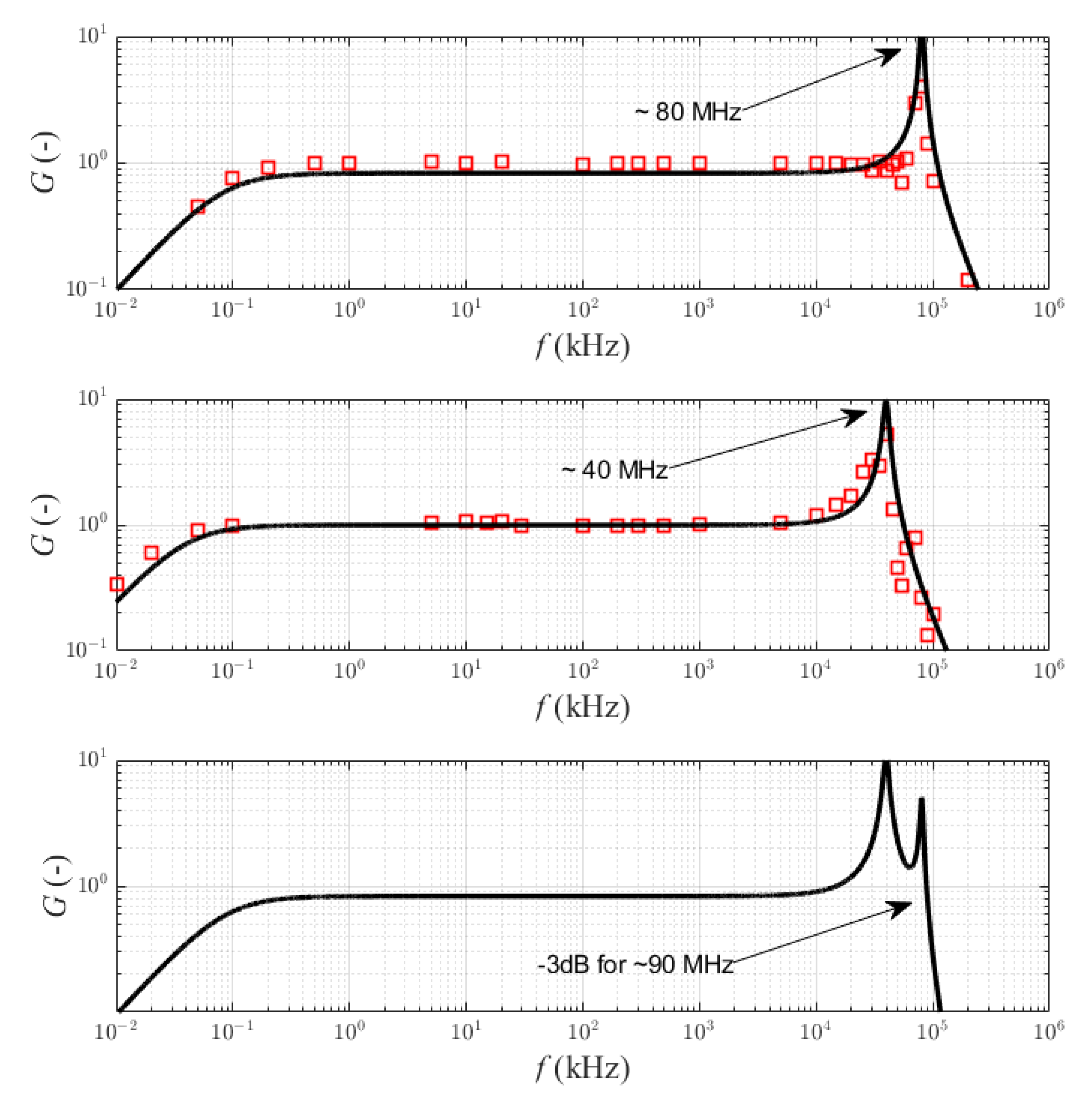

4.2. Bandwidth of the Sensor

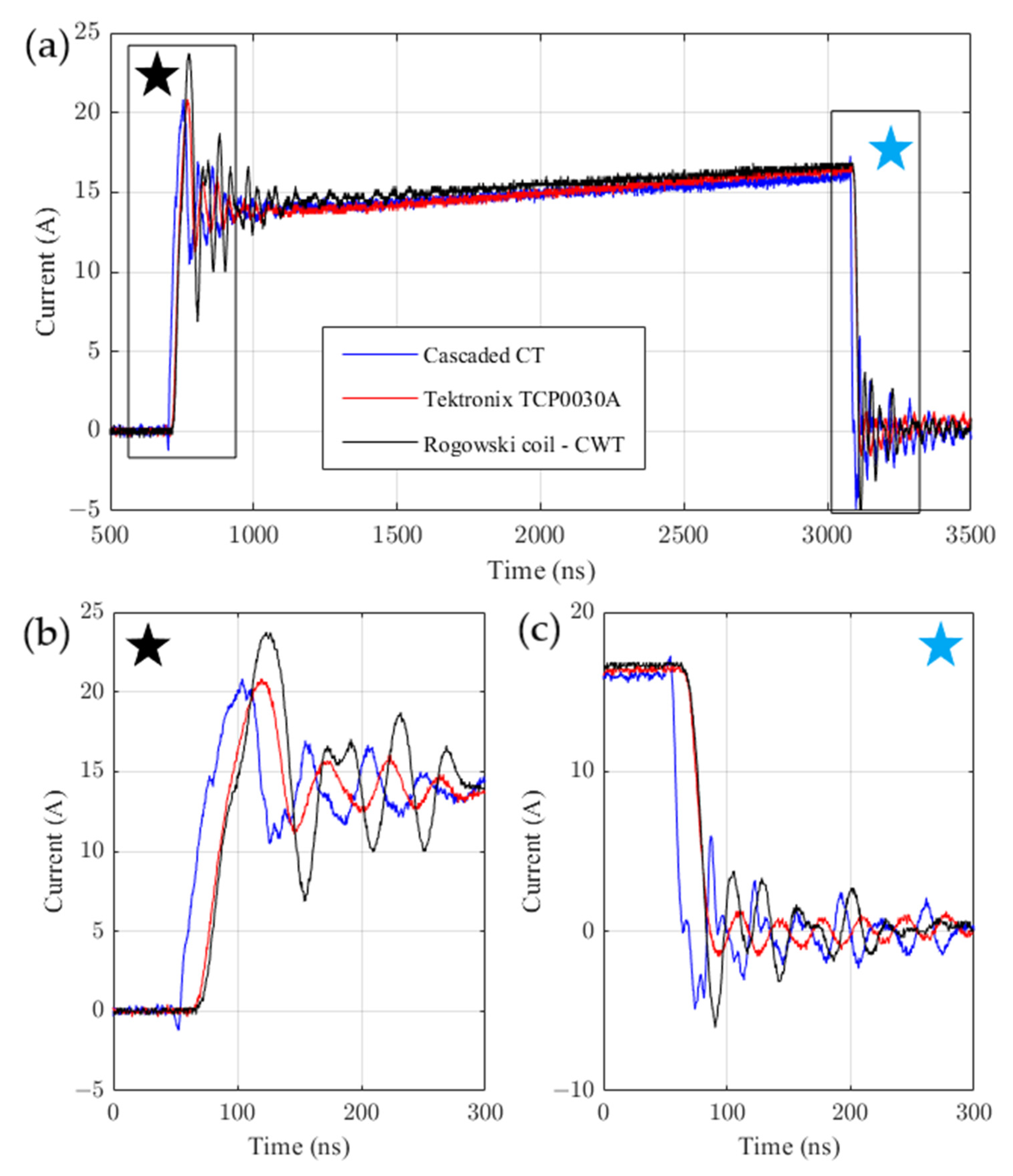

4.3. Time Domain Analysis

5. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Xin, Z.; Li, H.; Liu, Q.; Loh, P.C. A Review of Megahertz Current Sensors for Megahertz Power Converters. IEEE Trans. Power Electron. 2021, 37, 6720–6738. [Google Scholar] [CrossRef]

- Costa, F.; Poulichet, P.; Mazaleyrat, F.; Laboure, E. The current sensors in power electronics, a review. EPE J. 2001, 11, 7–18. [Google Scholar] [CrossRef]

- Li, H.; Beczkowski, S.; Munk-Nielsen, S.; Lu, K.; Wu, Q. Current measurement method for characterization of fast switching power semiconductors with Silicon Steel Current Transformer. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–19 March 2015; pp. 2527–2531. [Google Scholar] [CrossRef]

- Pogliano, U.; Bosco, G.C.; Serazio, D. Coaxial Shunts as AC–DC Transfer Standards of Current. IEEE Trans. Instrum. Meas. 2009, 58, 872–877. [Google Scholar] [CrossRef]

- Huang, A.; Wang, X.; Zhang, H.; Hwang, C.; Pommerenke, D.; Fan, J. Improved Current Shunt Characterization Method for Core Loss Measurement. IEEE Trans. Power Electron. 2022, 37, 8290–8300. [Google Scholar] [CrossRef]

- Voljc, B.; Lindic, M.; Pinter, B.; Kokalj, M.; Svetik, Z.; Lapuh, R. Evaluation of a 100 A Current Shunt for the Direct Measurement of AC Current. IEEE Trans. Instrum. Meas. 2013, 62, 1675–1680. [Google Scholar] [CrossRef]

- Dalessandro, L.; Karrer, N.; Kolar, J.W. High-Performance Planar Isolated Current Sensor for Power Electronics Applications. IEEE Trans. Power Electron. 2007, 22, 1682–1692. [Google Scholar] [CrossRef]

- Dalessandro, L.; Karrer, N.; Kolar, J.W. A novel isolated current sensor for high-performance power electronics applications. In Proceedings of the Twenty-First Annual IEEE Applied Power Electronics Conference and Exposition, 2006. APEC ‘06, Dallas, TX, USA, 19–23 March 2006; p. 8. [Google Scholar] [CrossRef]

- Chojowski, M.; Dziadecki, A.; Baszyński, M.; Dudek, R.; Stobiecki, A.; Skotniczny, J. Wide Bandwidth and Inexpensive Current Sensor for Power Electronics—An Augmented LEM Current Sensor. Energies 2021, 14, 4194. [Google Scholar] [CrossRef]

- Ahmed, A.; Coulbeck, L.; Castellazzi, A.; Johnson, C.M. Design and test of a PCB Rogowski coil for very high dI/dt detection. In Proceedings of the 2012 15th International Power Electronics and Motion Control Conference (EPE/PEMC), Novi Sad, Serbia, 4–6 September 2012; pp. 1–4. [Google Scholar] [CrossRef]

- Dubickas, V.; Edin, H. High-Frequency Model of the Rogowski Coil with a Small Number of Turns. IEEE Trans. Instrum. Meas. 2007, 56, 2284–2288. [Google Scholar] [CrossRef]

- Kondrath, N.; Kazimierczuk, M.K. Bandwidth of Current Transformers. IEEE Trans. Instrum. Meas. 2008, 58, 2008–2016. [Google Scholar] [CrossRef]

- Cataliotti, A.; Di Cara, D.; Di Franco, P.A.; Emanuel, A.E.; Nuccio, S. Frequency response of Measurement Current Transformers. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 25 July 2008; pp. 1254–1258. [Google Scholar] [CrossRef]

- Bao, G.; Gao, X.; Jiang, R.; Huang, K. A Novel Differential High-Frequency Current Transformer Sensor for Series Arc Fault Detection. Sensors 2019, 19, 3649. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodrigo-Mor, A.; Muñoz, F.A.; Castro-Heredia, L.C. Principles of Charge Estimation Methods Using High-Frequency Current Transformer Sensors in Partial Discharge Measurements. Sensors 2020, 20, 2520. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Wu, Y.; Dong, M.; Lin, J.; Li, H. Design of Current Transformer for In Situ Switching Current Measurement of Discrete SiC Power Devices. IEEE J. Emerg. Sel. Top. Ind. Electron. 2022, 1. [Google Scholar] [CrossRef]

- Ayachit, A.; Kazimierczuk, M.K. Self-Capacitance of Single-Layer Inductors with Separation Between Conductor Turns. IEEE Trans. Electromagn. Compat. 2017, 59, 1642–1645. [Google Scholar] [CrossRef]

- Pasko, S.W.; Kazimierczuk, M.K.; Grzesik, B. Self-Capacitance of Coupled Toroidal Inductors for EMI Filters. IEEE Trans. Electromagn. Compat. 2015, 57, 216–223. [Google Scholar] [CrossRef]

- Power Electronic Measurements-PEM. CWT Ultra-Mini [Online]. Available online: http://www.pemuk.com/Userfiles/CWTum/CWTUM_DS_Feb_2020.pdf (accessed on 5 May 2022).

- Tektronix, Inc. “TCP0030A Datasheet 30 A AC/DC Current Probe. Available online: https://www.tek.com/datasheet/30-ac-dc-current-probe (accessed on 1 May 2022).

- Pearson Electronics. Clamp on Current Monitors. Available online: https://www.pearsonelectronics.com/products/clamp-on-current-monitors (accessed on 28 June 2021).

- Costa, F.; Laboure, E.; Forest, F.; Gautier, C. Wide bandwidth, large AC current probe for power electronics and EMI measurements. IEEE Trans. Ind. Electron. 1997, 44, 502–511. [Google Scholar] [CrossRef]

- Tektronix, Inc. MDO3000 Mixed Domain Oscilloscope. Available online: https://www.tek.com/oscilloscope/mdo3000-mixed-domain-oscilloscope (accessed on 1 May 2022).

- Zhang, Z.; Guo, B.; Wang, F.F.; Jones, E.A.; Tolbert, L.M.; Blalock, B.J. Methodology for Wide Band-Gap Device Dynamic Characterization. IEEE Trans. Power Electron. 2017, 32, 9307–9318. [Google Scholar] [CrossRef]

- Lidow, A.; Strydom, J.; de Rooij, M.; Reusch, D. GaN Transistors for Efficient Power Conversion, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2019. [Google Scholar]

| Parameter | Lm | R | Cp | Ls | Ll | Rp |

|---|---|---|---|---|---|---|

| Unit | μH | Ω | pF | nH | μH | Ω |

| Value | 409 | 1 | 44 | 365 | 1 | 900 |

| Parameter | Lm | R | Cp | Ls | Ll | Rp | n | Outside Diameter | Internal Diameter | Length |

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | μH | Ω | pF | nH | nH | Ω | - | mm | mm | mm |

| Value | 409 | 866 | 44 | 365 | 100 | - | 1:10 | 10 | 6 | 4 |

| Parameter | Lm | R | Cp | Ls | Ll | Rp | n | Outside Diameter | Internal Diameter | Length |

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | mH | kΩ | pF | nH | nH | Ω | - | mm | mm | mm |

| Value | 1.9 | 2.47 | 87 | 45 | 7 | 1 | 1:12 | 27 | 20 | 17 |

| Parameters | HFCTs | Tektronix | Rogowski coil |

|---|---|---|---|

| Delay * [ns] | - | 13.6 | 14.5 |

| tfall [ns] | 5.7 | 12.1 | 12.0 |

| [MHz] | 70.03 | 33.06 | 33.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chojowski, M.; Baszyński, M.; Sosnowski, R.; Dziadecki, A. High-Frequency Current Transformers Cascade for Power Electronics Measurements. Sensors 2022, 22, 5846. https://doi.org/10.3390/s22155846

Chojowski M, Baszyński M, Sosnowski R, Dziadecki A. High-Frequency Current Transformers Cascade for Power Electronics Measurements. Sensors. 2022; 22(15):5846. https://doi.org/10.3390/s22155846

Chicago/Turabian StyleChojowski, Maciej, Marcin Baszyński, Robert Sosnowski, and Aleksander Dziadecki. 2022. "High-Frequency Current Transformers Cascade for Power Electronics Measurements" Sensors 22, no. 15: 5846. https://doi.org/10.3390/s22155846

APA StyleChojowski, M., Baszyński, M., Sosnowski, R., & Dziadecki, A. (2022). High-Frequency Current Transformers Cascade for Power Electronics Measurements. Sensors, 22(15), 5846. https://doi.org/10.3390/s22155846