IoT-Based Monitoring System Applied to Aeroponics Greenhouse

Abstract

:1. Introduction

2. Literature Review

2.1. Agriculture-Oriented IoT Architectures

2.2. Irrigation Systems

- The grouping of electronic sensors and vision systems with end devices.

- The administration of end devices through independent services for reading sensors, and the remote activation of actuators and acquisition systems for standard WEB, USB and thermographic cameras using a SAMBA server. Additionally, it has an alert service via SMTP in case of failure of the other services. All of the above is through the fog layer.

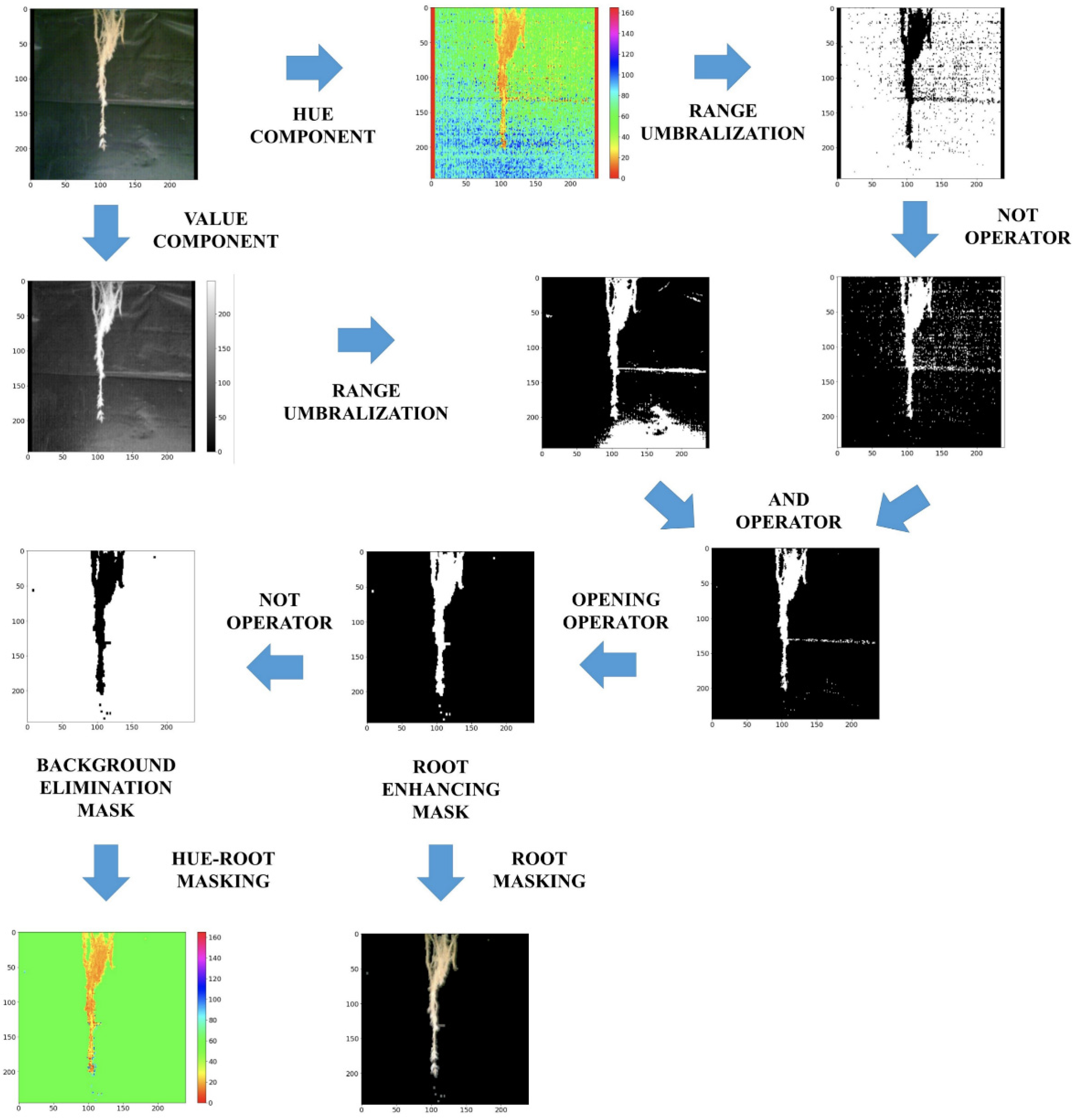

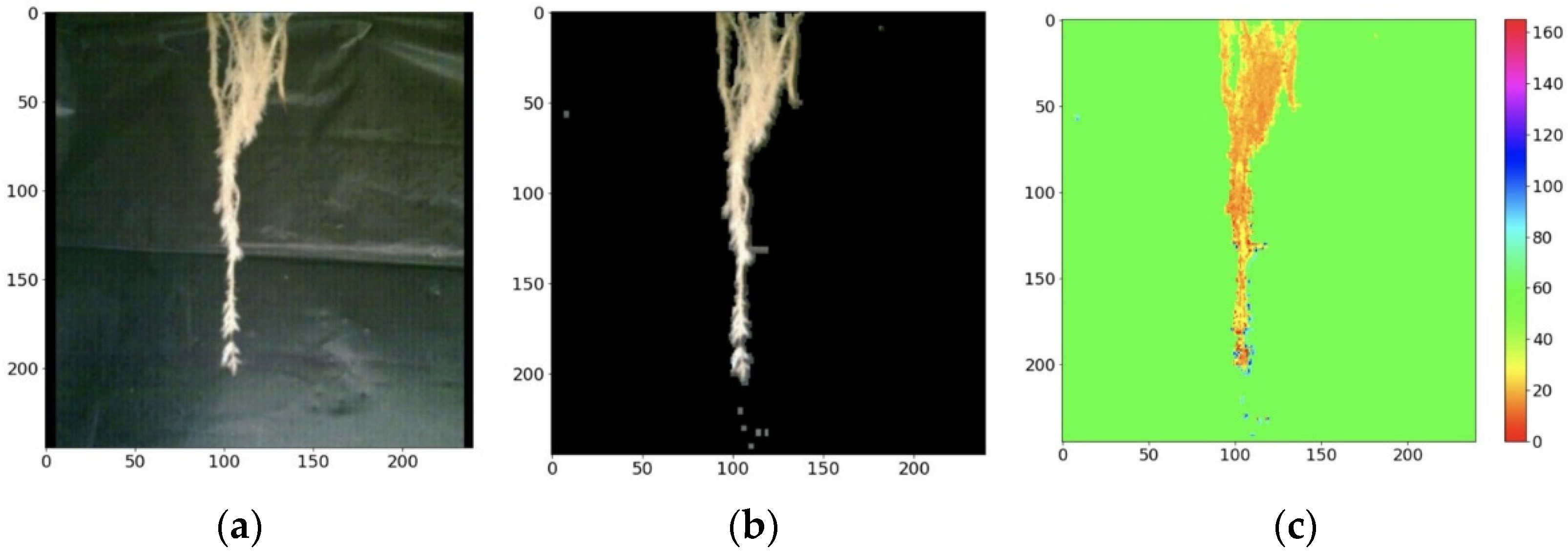

- A local and cloud database. The local database is dedicated to the storage of RGB top, side and root images, as well as thermographic images in the root. The database in the cloud is used for the storage of time-series data generated by the electronic sensors, in addition to the status of the sensors and actuators, the operating status of the services of the system, as well as the storage of the last result of the image processing.

- The implementation of an Android application for the manual registration of the variables related to the nutrient solution, environmental conditions, crop yield, historical display, data analysis reports, as well as the remote acquisition of images, activation of actuators and modification of irrigation parameters.

3. Monitoring System

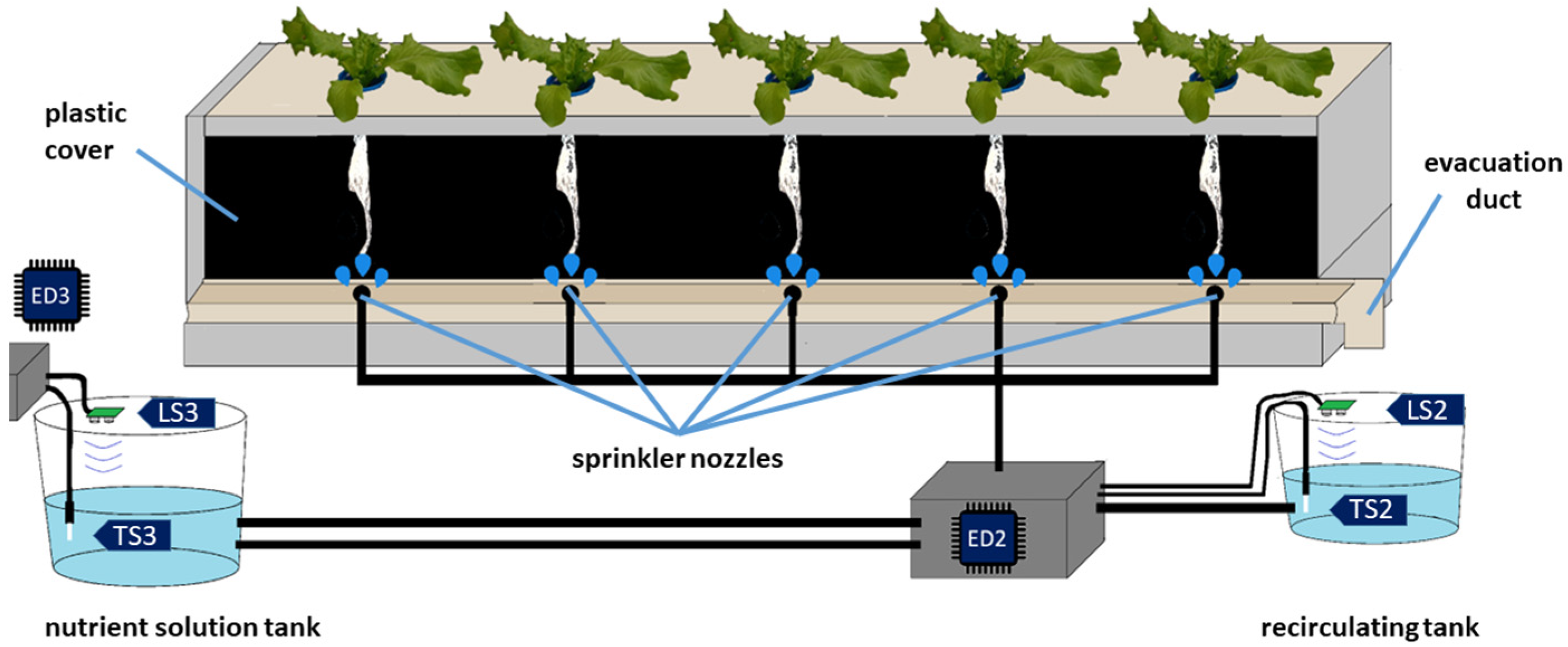

3.1. Aeroponic System Setup

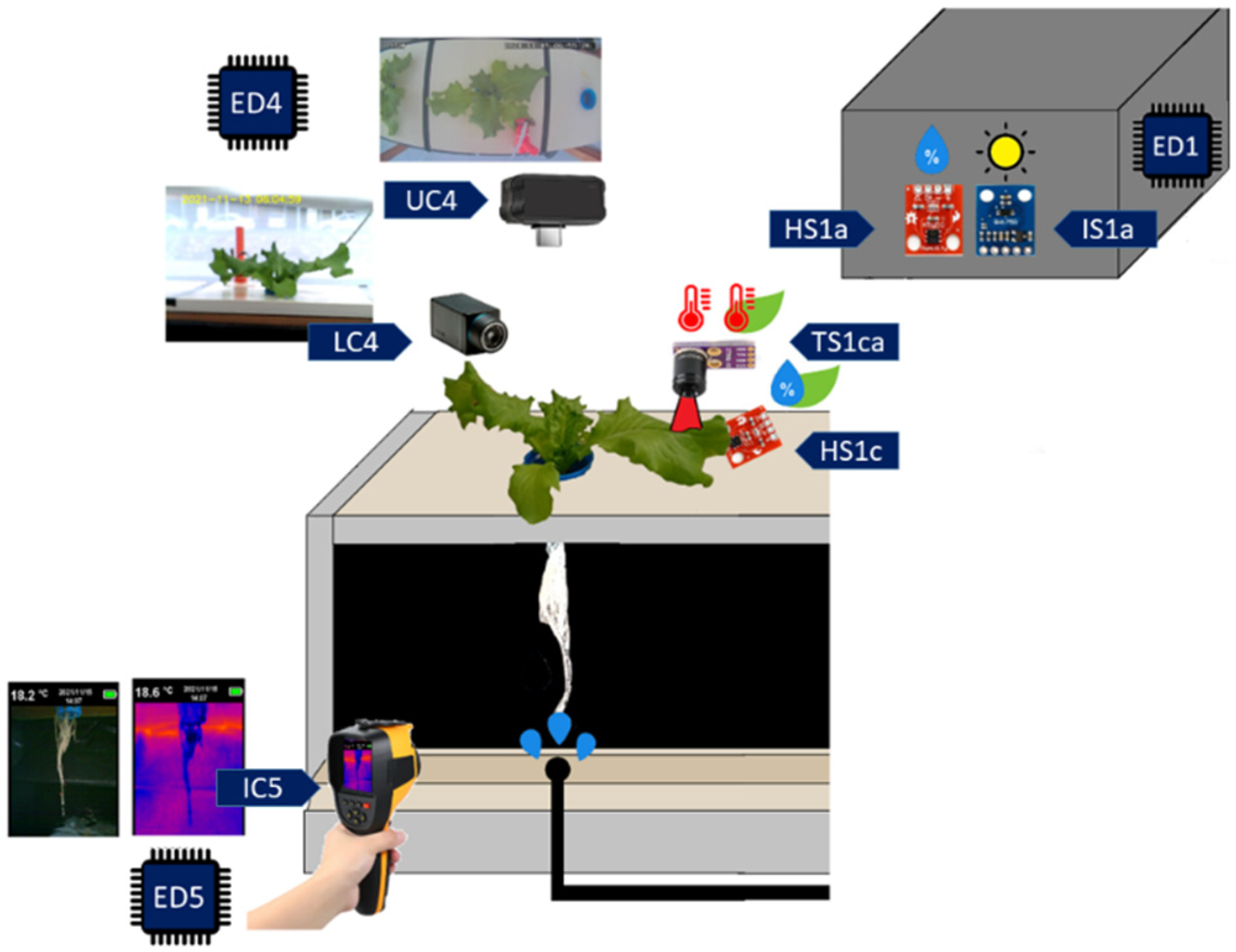

3.2. Monitoring System Proposal

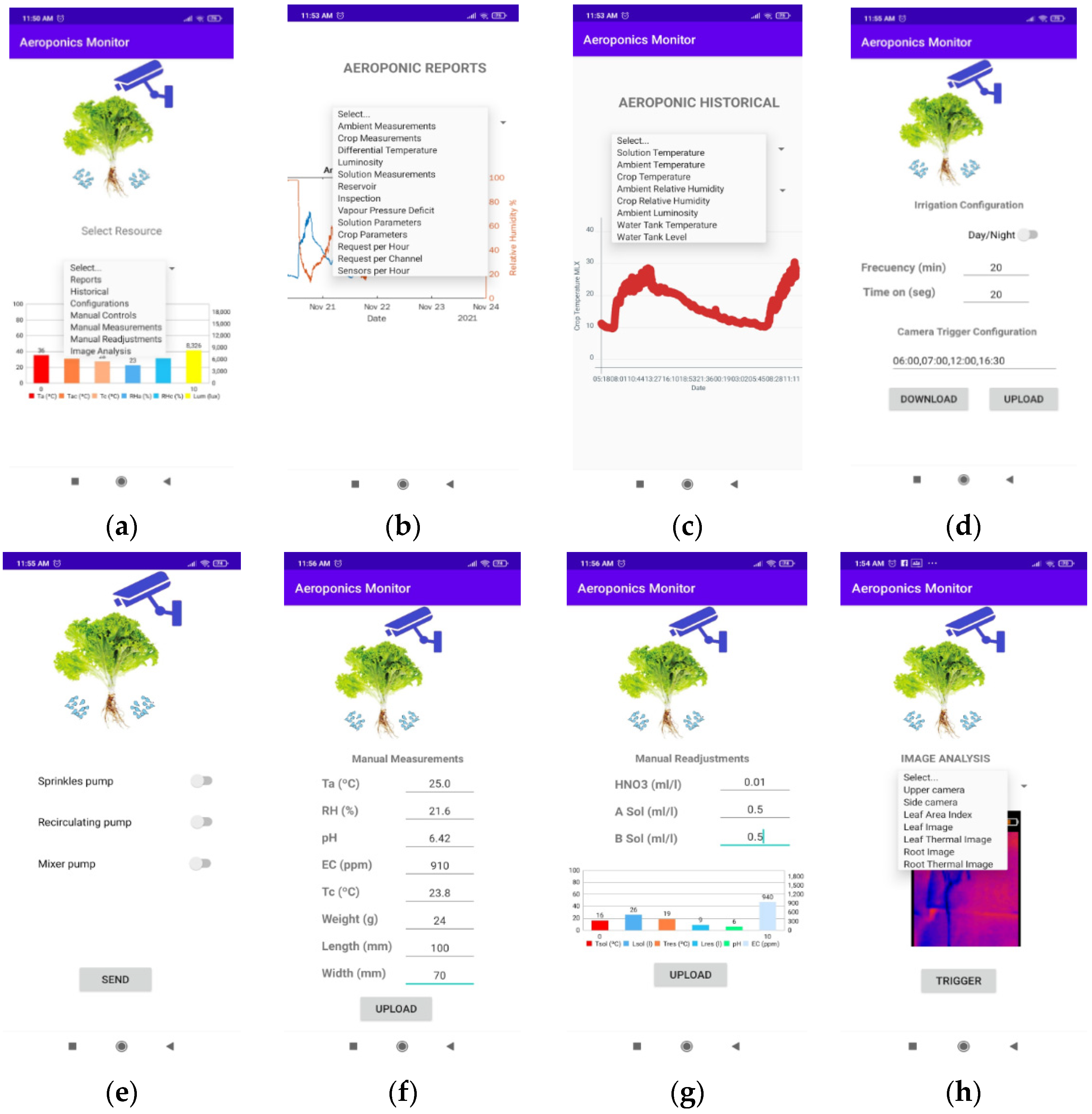

3.3. Aeroponics Monitor App

3.3.1. The Report Window

3.3.2. Record Window

3.3.3. Settings Window

3.3.4. Manual Controls Window

3.3.5. Manual Measurements Window

3.3.6. Manual Readjust Window

3.3.7. Image Analysis Window

3.4. Data Management

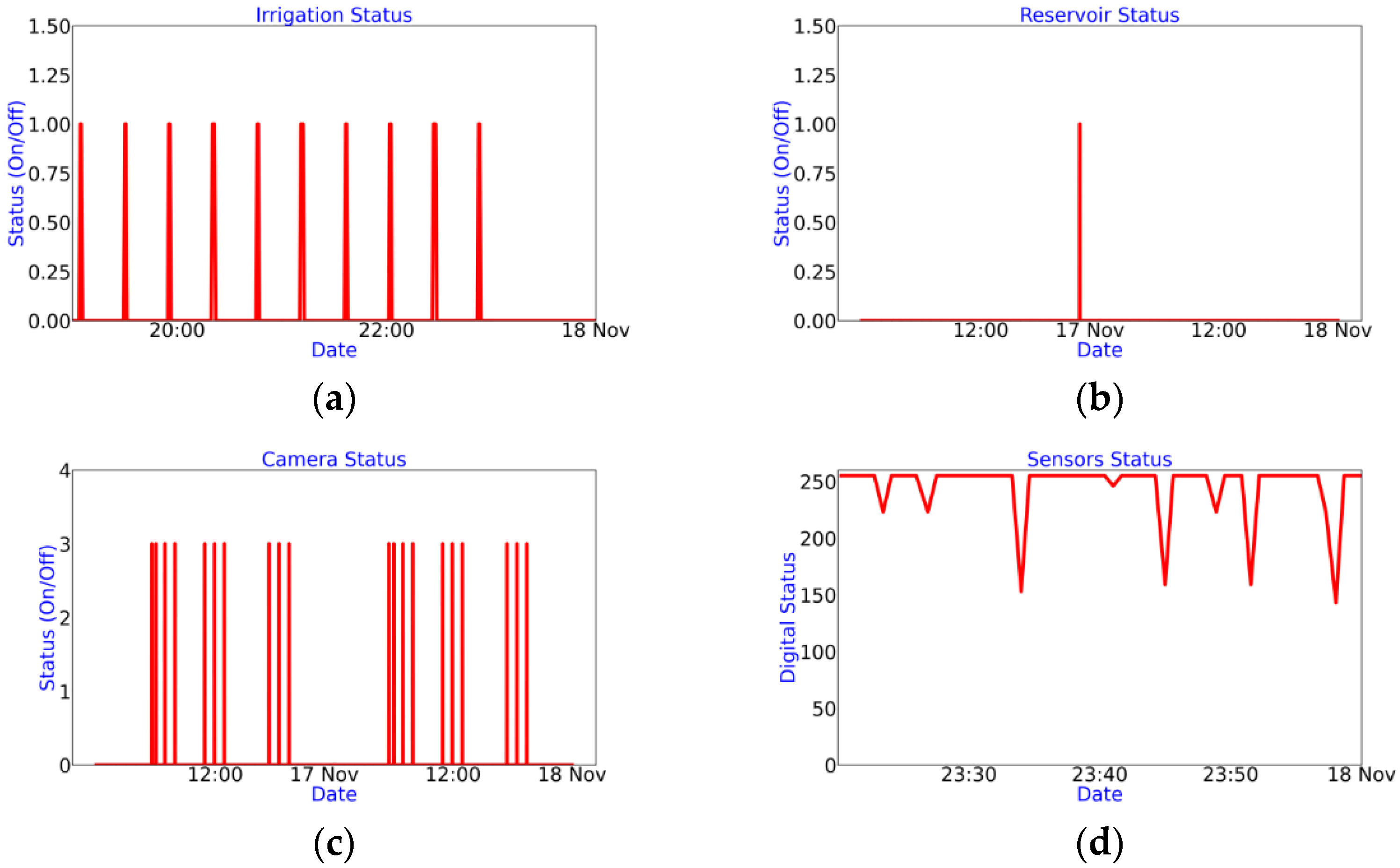

3.5. Remote Operation

3.6. Cost of Using the Platform

3.7. Improvements Using a Fog Layer

4. Results

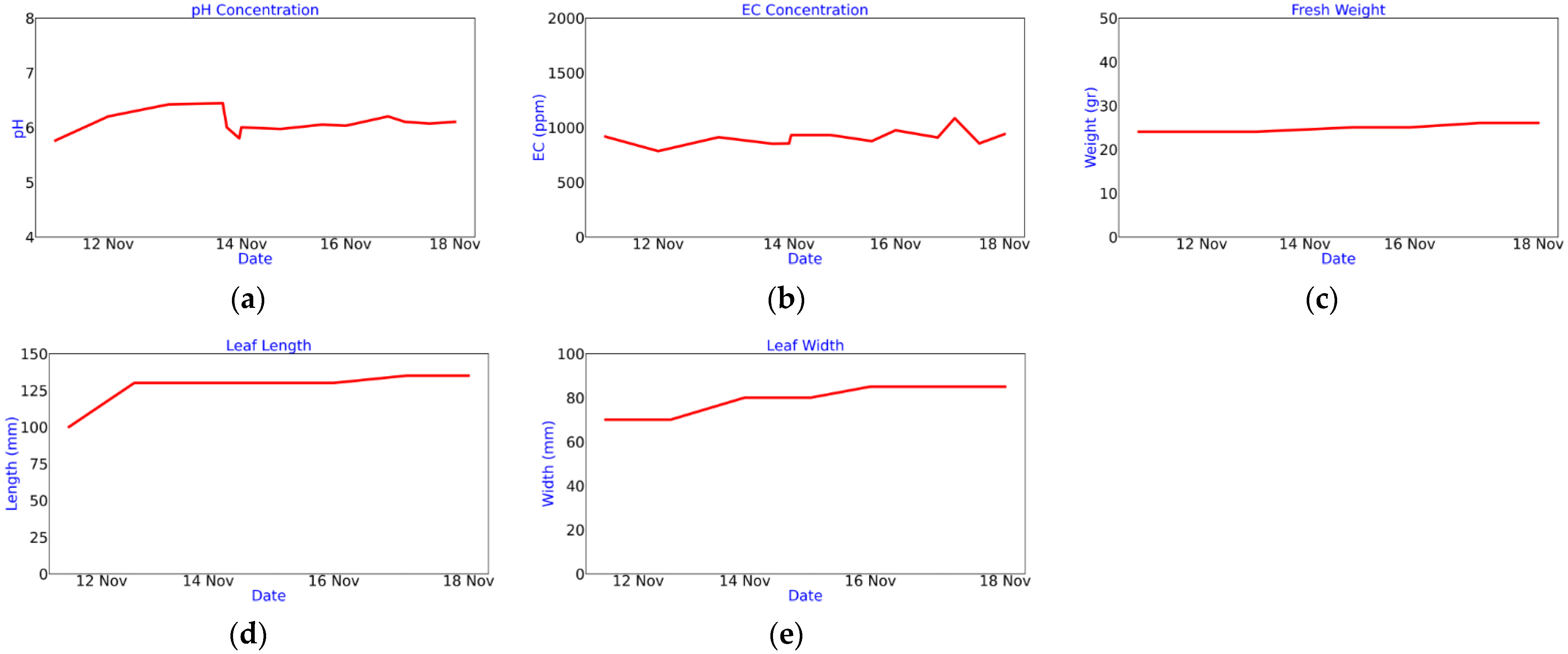

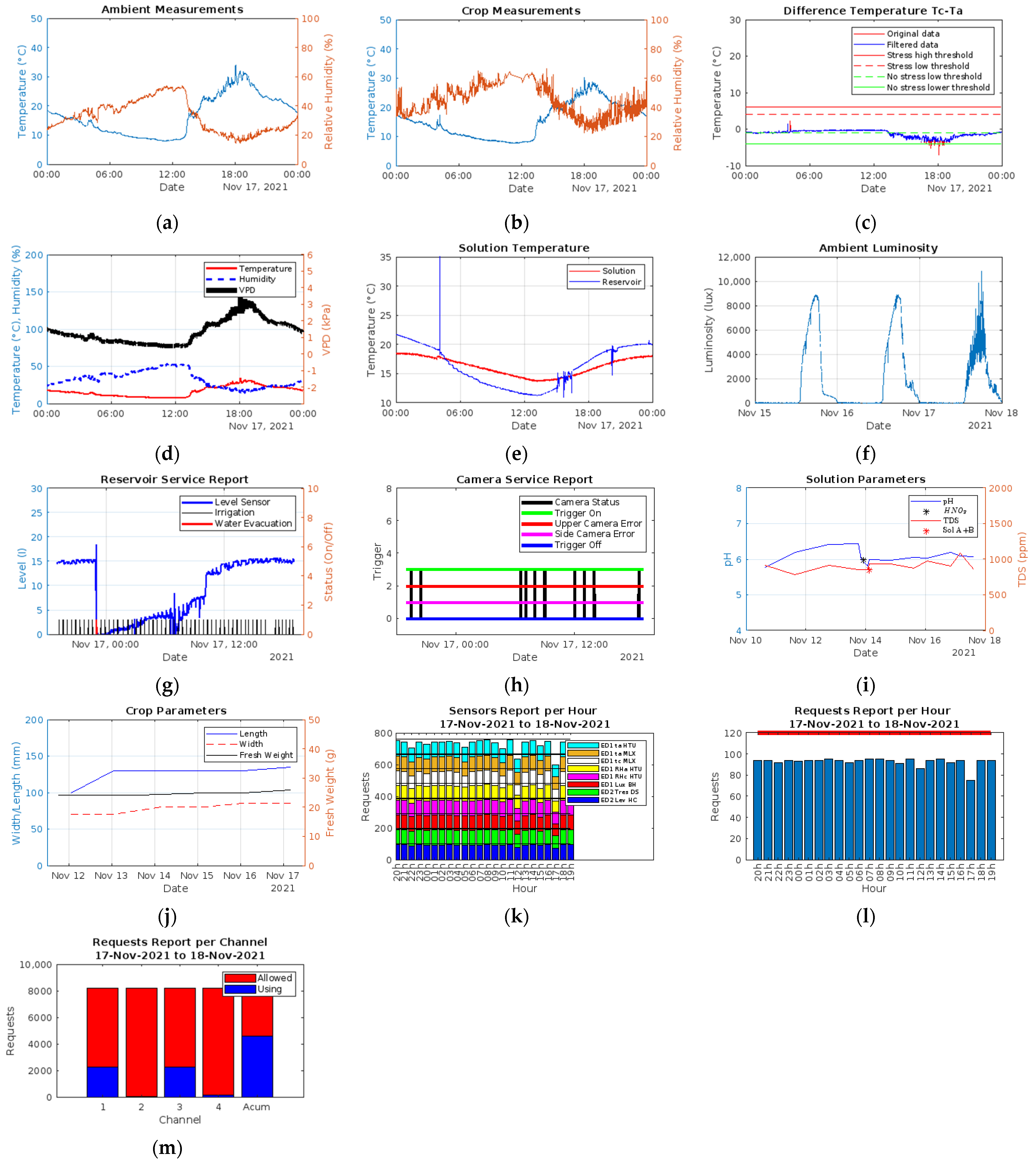

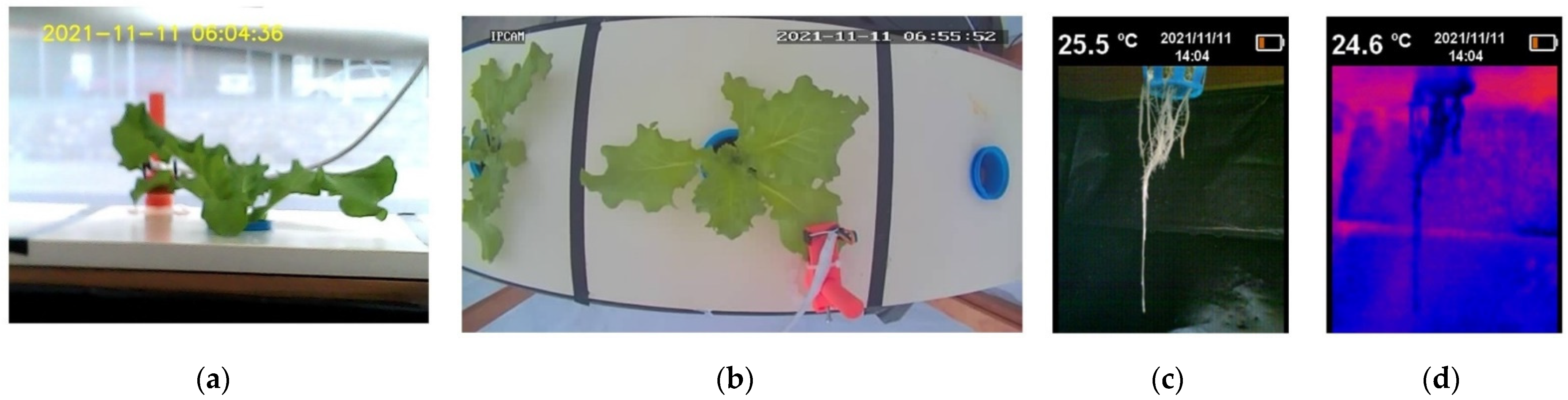

4.1. Record of Monitored Variables and Image Acquisition System

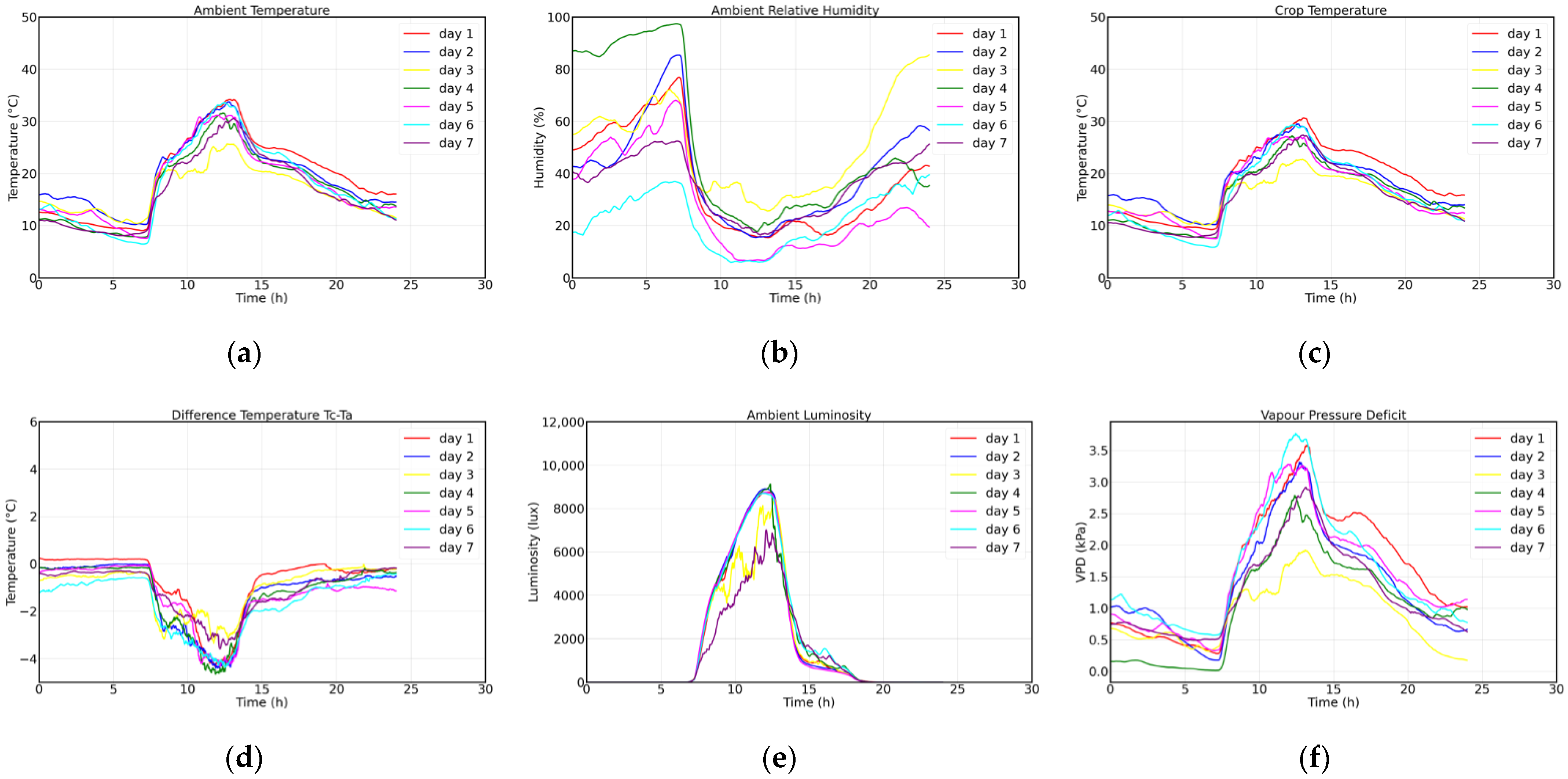

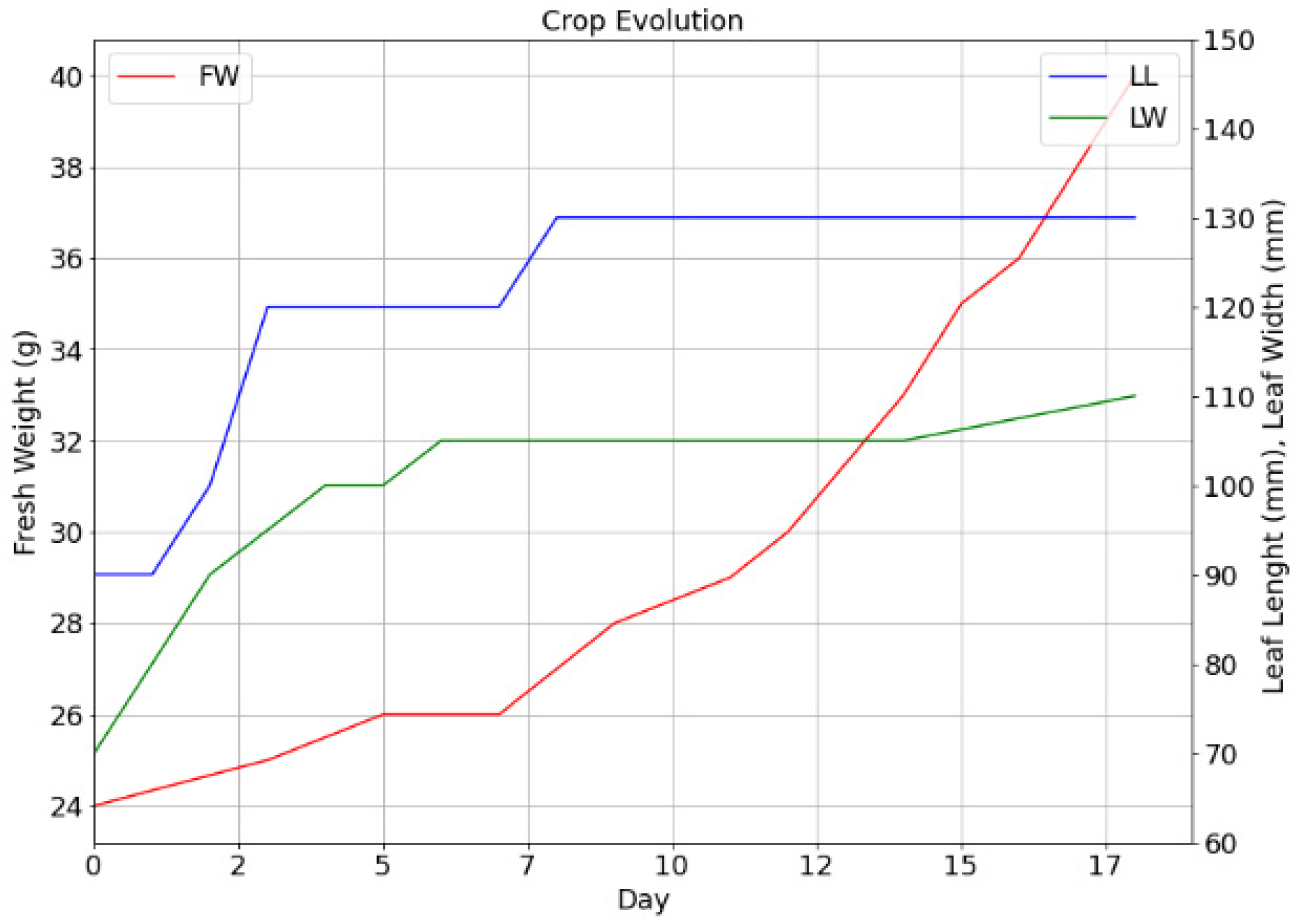

4.2. Analysis of the Environmental Variables and Image Analysis

5. Discussion

6. Conclusions and Further Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hati, A.J.; Singh, R.R. Smart Indoor Farms: Leveraging Technological Advancements to Power a Sustainable Agricultural Revolution. AgriEngineering 2021, 3, 728–767. [Google Scholar] [CrossRef]

- Hassan, S.I.; Alam, M.M.; Illahi, U.; Al Ghamdi, M.A.; Almotiri, S.H.; Su’ud, M.M. A Systematic Review on Monitoring and Advanced Control Strategies in Smart Agriculture. IEEE Access 2021, 9, 32517–32548. [Google Scholar] [CrossRef]

- Maraveas, C.; Bartzanas, T. Application of Internet of Things (IoT) for Optimized Greenhouse Environments. AgriEngineering 2021, 3, 954–970. [Google Scholar] [CrossRef]

- National Agricultural Planning 2017–2030. SAGARPA. Available online: https://www.gob.mx/cms/uploads/attachment/file/255627/Planeaci_n_Agr_cola_Nacional_2017-2030-_parte_uno.pdf (accessed on 27 June 2022).

- Agriculture, INIFAP and Proaces-Conacyt Agree on Technical Collaboration in Favor of the Agricultural Field. Available online: https://www.gob.mx/agricultura/prensa/convienen-agricultura-inifap-y-proaces-conacyt-colaboracion-tecnica-e-favor-del-campo?idiom=es (accessed on 27 June 2022).

- Khan, M.M.; Akram, M.T.; Janke, R.; Qadri, R.W.K.; Al-Sadi, A.M.; Farooque, A.A. Urban Horticulture for Food Secure Cities through and beyond COVID-19. Sustainability 2020, 12, 9592. [Google Scholar] [CrossRef]

- Wimmerova, L.; Keken, Z.; Solcova, O.; Bartos, L.; Spacilova, M.A. Comparative LCA of Aeroponic, Hydroponic, and Soil Cultivations of Bioactive Substance Producing Plants. Sustainability 2022, 14, 2421. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Chen, C.-H.; Jeng, S.-Y.; Lin, C.-J. Fuzzy Logic Controller for Automating Electrical Conductivity and pH in Hydroponic Cultivation. Appl. Sci. 2022, 12, 405. [Google Scholar] [CrossRef]

- Domingues, D.S.; Takahashi, H.W.; Camara, C.A.; Nixdorf, S.L. Automated system developed to control pH and concentration of nutrient solution evaluated in hydroponic lettuce production. Comput. Electron. Agric. 2012, 84, 53–61. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Tang, B.; Gu, M. Growth Responses and Root Characteristics of Lettuce Grown in Aeroponics, Hydroponics, and Substrate Culture. Horticulturae 2018, 4, 35. [Google Scholar] [CrossRef] [Green Version]

- Koukounaras, A. Advanced Greenhouse Horticulture: New Technologies and Cultivation Practices. Horticulturae 2021, 7, 1. [Google Scholar] [CrossRef]

- Lucero, L.; Lucero, D.; Ormeno-Mejia, E.; Collaguazo, G. Automated aeroponics vegetable growing system. Case study Lettuce. In Proceedings of the IEEE ANDESCON, Quito, Ecuador, 13–16 October 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Negrete, J. Internet of things in Mexican agriculture; a technology to increase agricultural productivity and reduce rural poverty. Res. Anal. J. 2018, 1, 40–52. [Google Scholar]

- Parkash, V.; Singh, S. A review on potential plant-based water stress indicators for vegetable crops. Sustainability 2020, 12, 3945. [Google Scholar] [CrossRef]

- Kumar, N.; Poddar, A.; Shankar, V.; Ojha, C.S.P.; Adeloye, A. Crop water stress index for scheduling irrigation of Indian mustard (Brassica juncea) based on water use efficiency considerations. J. Agron. Crop Sci. 2020, 206, 148–159. [Google Scholar] [CrossRef]

- Gong, X.; Wang, S.; Xu, C.; Zhang, H.; Ge, J. Evaluation of Several Reference Evapotranspiration Models and Determination of Crop Water Requirement for Tomato in a Solar Greenhouse. HortScience 2020, 55, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Jackson, R.D.; Idso, S.; Reginato, R.; Pinter, P. Canopy Temperature as a Crop Water Stress Indicator. Water Resour. Res. 1981, 17, 1133–1138. [Google Scholar] [CrossRef]

- Amitrano, C.; Rouphael, Y.; Pannico, A.; De Pascale, S.; De Micco, V. Reducing the Evaporative Demand Improves Photosynthesis and Water Use Efficiency of Indoor Cultivated Lettuce. Agronomy 2021, 11, 1396. [Google Scholar] [CrossRef]

- López, R.; Arteaga, R.; Vázquez, M.A.; López, I.L.; Sánchez, I.; Ruiz, A. Crop water stress index for husk Tomatoes (Physalis ixocarpa Brot.). Chapingo Ser. Hortic. 2009, 15, 259–267. [Google Scholar] [CrossRef]

- Jamroen, C.; Komkum, P.; Fongkerd, C.; Krongpha, W. An Intelligent Irrigation Scheduling System Using Low-Cost Wireless Sensor Network Toward Sustainable and Precision Agriculture. IEEE Access 2020, 8, 172756–172769. [Google Scholar] [CrossRef]

- Puengsungwan, S.; Jirasereeamornkul, K. IoT Based Root Stress Detection for Lettuce Culture Using Infrared Leaf Temperature Sensor and Light Intensity Sensor. Wirel. Pers Commun. 2020, 115, 3215–3233. [Google Scholar] [CrossRef]

- Poyen, F.B.; Kundu, P.; Ghosh, A.K. Temperature based ET Method Selection for Burdwan District in WB, INDIA. Int. J. Appl. Eng. Res. 2018, 13, 12753–12763. [Google Scholar]

- Amitrano, C.; Chirico, G.B.; De Pascale, S.; Rouphael, Y.; Micco, V. Application of a MEC model for the irrigation control in green and red-leaved lettuce in precision indoor cultivation. In Proceedings of the 2019 IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Portici, Italy, 24–26 October 2019; pp. 196–201. [Google Scholar] [CrossRef]

- Li, Q.; Wei, M.; Li, Y.; Feng, G.; Wang, Y.; Li, S.; Zhang, D. Effects of soil moisture on water transport, photosynthetic carbon gain and water use efficiency in tomato are influenced by evaporative demand. Agric. Water Manag. 2019, 226, 105818. [Google Scholar] [CrossRef]

- Inoue, T.; Sunaga, M.; Ito, M.; Yuchen, Q.; Matsushima, Y.; Sakoda, K.; Yamori, W. Minimizing VPD Fluctuations Maintains Higher Stomatal Conductance and Photosynthesis, Resulting in Improvement of Plant Growth in Lettuce. Front. Plant Sci. 2021, 12, 646144. [Google Scholar] [CrossRef] [PubMed]

- Rezvani, S.M.-e.; Abyaneh, H.Z.; Shamshiri, R.R.; Balasundram, S.K.; Dworak, V.; Goodarzi, M.; Sultan, M.; Mahns, B. IoT-Based Sensor Data Fusion for Determining Optimality Degrees of Microclimate Parameters in Commercial Greenhouse Production of Tomato. Sensors 2020, 20, 6474. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Majeed, Y.; Naranjo, G.D.; Gambacorta, E. Assessment for crop water stress with infrared thermal imagery in precision agriculture: A review and future prospects for deep learning applications. Comput. Electron. Agric. 2021, 182, 106019. [Google Scholar] [CrossRef]

- Kuncoro, C.B.D.; Sutandi, T.; Adristi, C.; Kuan, Y.-D. Aeroponics Root Chamber Temperature Conditioning Design for Smart Mini-Tuber Potato Seed Cultivation. Sustainability 2021, 13, 5140. [Google Scholar] [CrossRef]

- Martinez-Nolasco, C.; Padilla-Medina, J.A.; Nolasco, J.J.M.; Guevara-Gonzalez, R.G.; Barranco-Gutiérrez, A.I.; Diaz-Carmona, J.J. Non-Invasive Monitoring of the Thermal and Morphometric Characteristics of Lettuce Grown in an Aeroponic System through Multispectral Image System. Appl. Sci. 2022, 12, 6540. [Google Scholar] [CrossRef]

- Kamienski, C.; Soininen, J.P.; Taumberger, M.; Dantas, R.; Toscano, A.; Salmon Cinotti, T.; Filev Maia, R.; Torre Neto, A. Smart Water Management Platform: IoT-Based Precision Irrigation for Agriculture. Sensors 2019, 19, 276. [Google Scholar] [CrossRef] [Green Version]

- Kour, V.P.; Arora, S. Recent Developments of the Internet of Things in Agriculture: A Survey. IEEE Access 2020, 8, 129924–129957. [Google Scholar] [CrossRef]

- Filev, R.; Ballester, C.; Agrahari, A.; Hornbuckle, J. IRRISENS: An IoT Platform Based on Microservices Applied in Commercial-Scale Crops Working in a Multi-Cloud Environment. Sensors 2020, 20, 7163. [Google Scholar] [CrossRef] [PubMed]

- Boursianis, A.D.; Papadopoulou, M.S.; Shaouha, A.G.; Sarigiannidis, P.; Nikolaidis, S.; Goudos, S.K. Smart Irrigation System for Precision Agriculture—The AREThOU5A IoT Platform. IEEE Sens. J. 2021, 21, 17539–17547. [Google Scholar] [CrossRef]

- Roy, S.K.; Misra, S.; Raghuwanshi, N.S.; Das, S.K. AgriSens: IoT-Based Dynamic Irrigation Scheduling System for Water Management of Irrigated Crops. IEEE Internet Things J. 2021, 8, 5023–5030. [Google Scholar] [CrossRef]

- González-Amarillo, C.A.; Corrales-Muñoz, J.C.; Mendoza-Moreno, M.A.; González-Amarillo, A.M.; Hussein, A.F.; Arunkumar, N.; Ramírez-González, G. An IoT-Based Traceability System for Greenhouse Seedling Crops. IEEE Access 2018, 6, 67528–67535. [Google Scholar] [CrossRef]

- Fernández-Ahumada, L.M.; Ramírez-Faz, J.; Torres-Romero, M.; López-Luque, R. Proposal for the Design of Monitoring and Operating Irrigation Networks Based on IoT, Cloud Computing and Free Hardware Technologies. Sensors 2019, 19, 2318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohammed, M.; Riad, K.; Alqahtani, N. Efficient IoT-Based Control for a Smart Subsurface Irrigation System to Enhance Irrigation Management of Date Palm. Sensors 2021, 21, 3942. [Google Scholar] [CrossRef] [PubMed]

- Poyen, F.B.; Ghosh, A.; Kundu, P.; Hazra, S.; Sengupta, N. Prototype Model Design of Automatic Irrigation Controller. IEEE Trans. Instrum. Meas. 2021, 70, 1–17. [Google Scholar] [CrossRef]

- Lloret, J.; Sendra, S.; García-Fernández, J.; García, L.; Jimenez, J.M. A WiFi-Based Sensor Network for Flood Irrigation Control in Agriculture. Electronics 2021, 10, 2454. [Google Scholar] [CrossRef]

- Jamhari, C.A.; Wibowo, W.K.; Annisa, A.R.; Roffi, T.M. Design and Implementation of IoT System for Aeroponic Chamber Temperature Monitoring. In Proceedings of the 2020 Third International Conference on Vocational Education and Electrical Engineering (ICVEE), Surabaya, Indonesia, 3–4 October 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Gour, M.S.; Reddy, V.; Vamsi, M.; Sridhar, N.; Ram, V.T. IoT based Farming Techniques in Indoor Environment: A Brief Survey. In Proceedings of the 2020 5th International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 10–12 June 2020; pp. 790–795. [Google Scholar] [CrossRef]

- Belista, F.C.L.; Go, M.P.C.; Luceñara, L.L.; Policarpio, C.J.G.; Tan, X.J.M.; Baldovino, R.G. A Smart Aeroponic Tailored for IoT Vertical Agriculture using Network Connected Modular Environmental Chambers. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Chegini, H.; Naha, R.K.; Mahanti, A.; Thulasiraman, P. Process Automation in an IoT–Fog–Cloud Ecosystem: A Survey and Taxonomy. IoT 2021, 2, 92–118. [Google Scholar] [CrossRef]

- Thingspeak. Licence Options. Available online: https://thingspeak.com/prices/ (accessed on 26 July 2022).

- Firebase. Pricing Plans. Available online: https://firebase.google.com/pricing (accessed on 26 July 2022).

- Aleisa, M.A.; Abuhussein, A.; Alsubaei, F.S.; Sheldon, F.T. Examining the Performance of Fog-Aided, Cloud-Centered IoT in a Real-World Environment. Sensors 2021, 21, 6950. [Google Scholar] [CrossRef]

- ThingSpeak Licensing FAQ. Available online: https://thingspeak.com/pages/license_faq (accessed on 26 July 2022).

- Cloud vs. on-Device. Available online: https://firebase.google.com/docs/ml#cloud_vs_on-device (accessed on 26 July 2022).

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive Review on Climate Control and Cooling Systems in Greenhouses under Hot and Arid Conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Allen, G.R.; Pereira, S.L.; Raes, D.; Smith, M. Crop Evapotranspiration. In FAO Irrigation and Drainage 1998; Paper No. 56; FAO: Rome, Italy, 1998; 300p. [Google Scholar]

- Pipitsunthonsan, P.; Sopharat, J.; Sirisuk, P.; Chongcheawchamnan, M. Leaf Sensor for Stomata Transpiration Monitoring Using Temperature and Humidity. In Proceedings of the 2018 21st International Symposium on Wireless Personal Multimedia Communications (WPMC), Chiang Rai, Thailand, 25–28 November 2018; pp. 252–255. [Google Scholar] [CrossRef]

| Symbol | Meaning |

|---|---|

| Ta (°C) | Ambient temperature |

| RHa (%) | Ambient relative humidity |

| Tc (°C) | Crop temperature |

| RHc (%) | Crop relative humidity |

| Lum (lux) | Ambient light intensity |

| Tsol (°C) | Nutrient solution temperature |

| Lsol (l) | Nutrient solution level |

| Tres (°C) | Recirculating tank temperature |

| Lres (l) | Recirculating tank level |

| Sirr (on/off) | Irrigation pump status |

| Sres (on/off) | Recirculation pump status |

| Scam | Image acquisition system status |

| pH | Hydrogen potential |

| EC (µS/cm) | Electroconductivity |

| TDS (ppm) | Total dissolved solids in the nutrient solution |

| Fw (gr) | Fresh weight |

| Ll (mm) | Leaf length |

| Wl (mm) | Leaf width |

| HNO3 (mL/L) | Nitric acid |

| Asol (mL/L) | Solution A |

| Bsol (mL/L) | Solution B |

| DTla (°C) | Difference Temperature |

| VPD (kPa) | Vapor pressure deficit |

| Author/Architecture | Year | Objective/ Reference | Architecture/Sensors/Data Base/Protocols |

|---|---|---|---|

| Kamiienski et al./SWAMP [32] | 2018 | Soil | Five-layer architecture (application, distribution, data management, acquisition and security, communication) |

| Filev et al./ IRRISENS [34] | 2020 | Soil/Relative Humidity | Relative humidity, climatic conditions, local/cloud DB. |

| Boursianis et al./AREThOU5A [35] | 2020 | Soil | Five-layer architecture (physics, data link, network, authentication, application). Temperature and humidity, local/cloud DB, LoRaWAN, TCP/I, MQT, SL. Solar battery charging. |

| Roy et al./AgriSens [36] | 2021 | Soil/Life Cycle | Three-layer architecture (sensors and actuators, remote server, application). Humidity. Level. DB cloud. ZigBee, GSM/GPRS. |

| González-Amarillo et al. [37] | 2018 | Germination | Temperature, humidity, luminosity, water consumption. Local/cloud database. |

| Fernández-Ahumada et al. [38] | 2019 | Soil/Relative Humidity | Three-layer architecture (sensors and actuators, application, final user). Relative humidity. LoRa, SigFox, Thingspeak. |

| Mohammed et al./CSIS [39] | 2021 | Soil/ET | Volumetric water content, relative humidity, temperature, solar radiation, speed of wind, flow. |

| Poyen et al./SAIC [40] | 2021 | Soil/ET | Air/soil temperature, relative humidity, wind speed, solar radiation, atmospheric pressure. Local/Cloud DB. GSM/GPRS. |

| Lloret et al. [41] | 2021 | Flood/User | Perception, service, application, end user. Relative humidity, temperature, atmospheric pressure, rain. Temperature, salinity, level, water pests. HTTP. |

| Lucero et al. [14] | 2020 | Aeroponics/ Temperature, Relative Humidity | Temperature, relative humidity, level, pH. GSM/GPRS |

| Gour et al. [43] | 2020 | Aeroponics | Two-layer architecture (sensors and actuators, services). Relative humidity, temperature, CO2, pH, luminosity. Machine learning. |

| Belista et al. [44] | 2018 | Aeroponics | Three-layer architecture (sensors and controllers, data storage and processing, application platform). Temperature, relative humidity, level of water, EC, pH. Local DB |

| Our Proposal | 2022 | Aeroponics/VPD, Irrigation Period | Four-layer architecture (device, fog cap, cloud, application). Leaf temperature, environmental temperature and relative humidity, luminosity, pH, EC, level and nutrient solution temperature, RGB and thermographic images. Warning against service failure, status of sensors and actuators. HTTP. IoT analytics, Thingspeak, Firebase. |

| Ambient Measurement | Crop Measurement | Difference Temperature | Luminosity | Solution Measurement | Reservoir | Inspection | VPD | Solution Parameters | Crop Parameters | Request per Hour | Request per Channel | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ta | X | X | X | X | X | |||||||

| RHa | X | X | X | |||||||||

| Tc | X | X | X | X | ||||||||

| RHc | X | X | X | X | ||||||||

| Lum | X | X | X | |||||||||

| Tsol | X | X | X | |||||||||

| Lsol | X | X | ||||||||||

| Tres | X | X | X | |||||||||

| Lres | X | X | X | |||||||||

| Sirr | X | X | X | |||||||||

| Sres | X | X | X | |||||||||

| Scam | X | X | X | |||||||||

| pH | X | X | X | |||||||||

| EC | X | X | X | |||||||||

| Fw | X | X | X | |||||||||

| Ll | X | X | X | |||||||||

| Wl | X | X | X | |||||||||

| HNO3 | X | X | X | |||||||||

| Asol | X | X | X | |||||||||

| Bsol | X | X | X |

| Variable | Minimum | Maximum | Mean | Std | Time (max) | Time (min) |

|---|---|---|---|---|---|---|

| Ta | 6.47 | 34.19 | 17.91 | 6.90 | 12:52 | 07:01 |

| Tc | 5.87 | 30.66 | 16.72 | 5.93 | 13:11 | 07:02 |

| RHa | 5.87 | 97.43 | 37.78 | 21.24 | 07:02 | 10:40 |

| RHc | 12.45 | 83.62 | 42.13 | 15.68 | 07:20 | 12:27 |

| Lum | 0 | 9118 | 1702 | 2697 | 12:23 | - |

| DTla | −4.63 | 0.24 | −1.19 | 1.19 | 00:00 | 11:52 |

| VPD | 0.014 | 3.766 | 1.338 | 0.8526 | 12:25 | 07:01 |

| pH | 5.76 | 6.44 | 6.08 | 0.1859 | - | - |

| EC | 783 | 1084 | 907.6 | 69.78 | - | - |

| Fw | 24 | 26 | 24.85 | 0.8329 | - | - |

| Ll | 100 | 135 | 127.1 | 11.29 | - | - |

| Wl | 70 | 85 | 127.1 | 127.14 | - | - |

| Features | Own | Lucero [14] | Boursianis [33] | Roy [34] | Lloret [39] | Jamhari [40] | Belista [42] | ||

|---|---|---|---|---|---|---|---|---|---|

| Sensor Nodes | Ambient | X | X | X | X | X | X | X | |

| Ambient in Crop | X | ||||||||

| VPD Estimation | X | ||||||||

| RGB Image | X | ||||||||

| Thermographic Image | X | ||||||||

| Meteorological | X | X | |||||||

| Nutrient Solution | X | X | |||||||

| Alert System | X | X | X | ||||||

| Programmable | X | X | X | ||||||

| Automatic Control | Temperature | X | X | ||||||

| Humidity | X | ||||||||

| pH | |||||||||

| Friendly Interface | Remote Monitoring | App | X | X | X | X | |||

| VPN | X | ||||||||

| GSM | X | X | X | ||||||

| Web Server | X | X | X | X | |||||

| Sensors Status | X | ||||||||

| Actuators Status | X | ||||||||

| Applicable for crop diversity | X | X | X | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Méndez-Guzmán, H.A.; Padilla-Medina, J.A.; Martínez-Nolasco, C.; Martinez-Nolasco, J.J.; Barranco-Gutiérrez, A.I.; Contreras-Medina, L.M.; Leon-Rodriguez, M. IoT-Based Monitoring System Applied to Aeroponics Greenhouse. Sensors 2022, 22, 5646. https://doi.org/10.3390/s22155646

Méndez-Guzmán HA, Padilla-Medina JA, Martínez-Nolasco C, Martinez-Nolasco JJ, Barranco-Gutiérrez AI, Contreras-Medina LM, Leon-Rodriguez M. IoT-Based Monitoring System Applied to Aeroponics Greenhouse. Sensors. 2022; 22(15):5646. https://doi.org/10.3390/s22155646

Chicago/Turabian StyleMéndez-Guzmán, Hugo A., José A. Padilla-Medina, Coral Martínez-Nolasco, Juan J. Martinez-Nolasco, Alejandro I. Barranco-Gutiérrez, Luis M. Contreras-Medina, and Miguel Leon-Rodriguez. 2022. "IoT-Based Monitoring System Applied to Aeroponics Greenhouse" Sensors 22, no. 15: 5646. https://doi.org/10.3390/s22155646

APA StyleMéndez-Guzmán, H. A., Padilla-Medina, J. A., Martínez-Nolasco, C., Martinez-Nolasco, J. J., Barranco-Gutiérrez, A. I., Contreras-Medina, L. M., & Leon-Rodriguez, M. (2022). IoT-Based Monitoring System Applied to Aeroponics Greenhouse. Sensors, 22(15), 5646. https://doi.org/10.3390/s22155646