Chatter Monitoring of Machining Center Using Head Stock Structural Vibration Analyzed with a 1D Convolutional Neural Network

Abstract

:1. Introduction

2. Materials and Methods

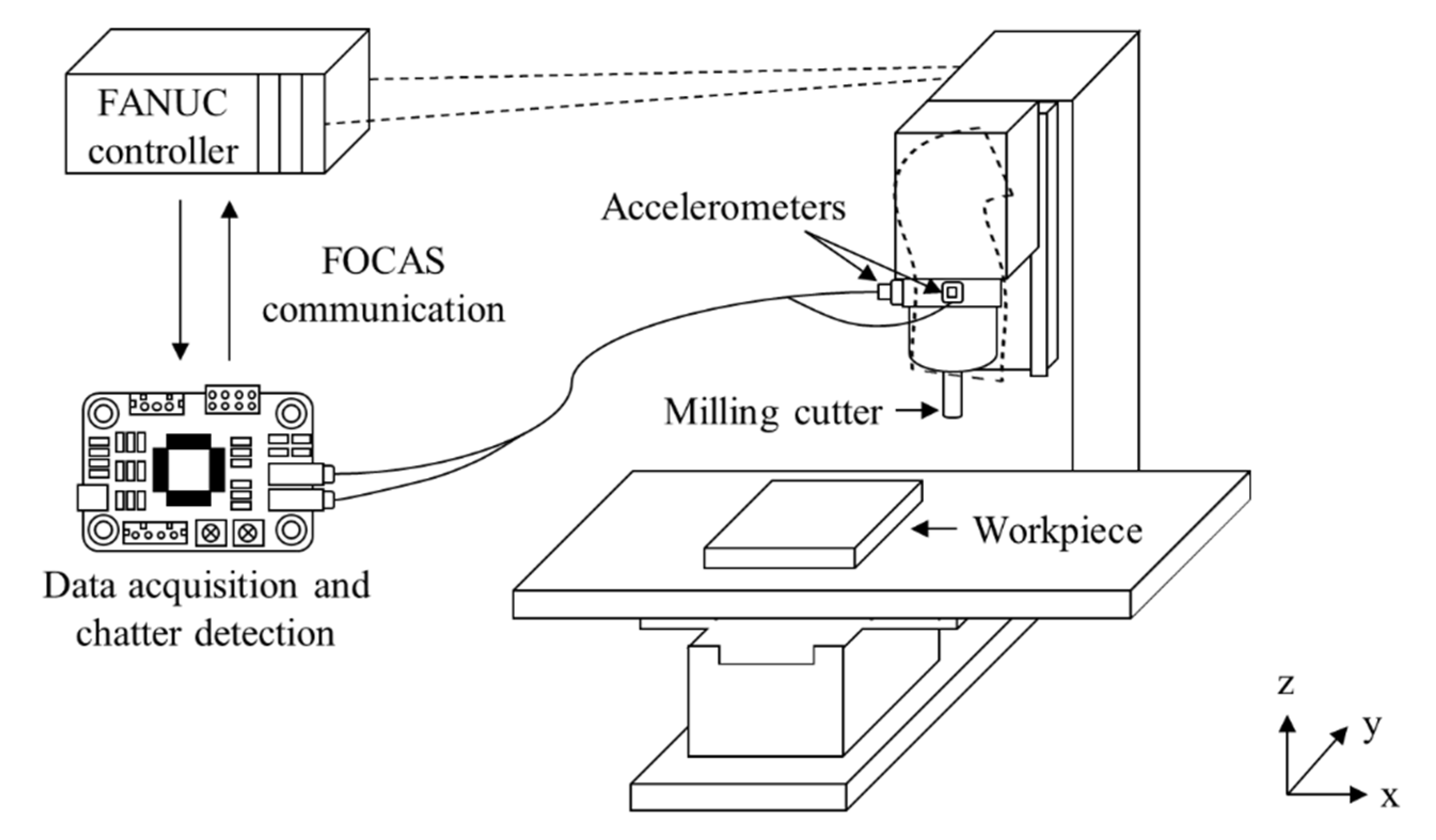

2.1. Data Acquisition for the Milling Process under Stable and Chatter States

2.2. Cepstral Analysis for Feature Extraction

2.3. Classification by 1D Convolutional Neural Network

3. Results

3.1. Modal Properties of the Machine Tool Head Stock

3.2. Feature Extraction by Cepstral Analysis

3.3. Feature Generation from the Liftered Spectrum

3.4. Chatter Detection Using the Proposed Procedure

3.5. Classification for Different Structural Vibration Characteristics—Machining by a Different Cutter

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, R.; Song, Q.; Liu, Z.; Ma, H.; Gupta, M.K.; Liu, Z. A novel unsupervised machine learning-based method for chatter detection in the milling of thin-walled parts. Sensors 2021, 21, 5779. [Google Scholar] [CrossRef] [PubMed]

- Bruneo, D.; De Vita, F. Detecting Faults at the Edge via Sensor Data Fusion Echo State Networks. Sensors 2022, 22, 2858. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, X.; Sun, J.; Ha, S.K.; Guan, Z. Theoretical and experimental investigations on active vibration control of the MRE multifunctional grille composite sandwich plates. Compos. Struct. 2022, 295, 115783. [Google Scholar] [CrossRef]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Lamraoui, M.; Barakat, M.; Thomas, M.; Badaoui, M.E. Chatter detection in milling machines by neural network classification and feature selection. J. Vib. Control 2015, 21, 1251–1266. [Google Scholar] [CrossRef]

- Cao, H.; Yue, Y.; Chen, X.; Zhang, X. Chatter detection based on synchrosqueezing transform and statistical indicators in milling process. Int. J. Adv. Manuf. Technol. 2018, 95, 961–972. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Lu, Y.; Kong, L.; Ma, Z. Online chatter detection in milling process based on fast iterative VMD and energy ratio difference. Measurement 2022, 194, 111060. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, X.; Zhao, H.; Ding, H. Development of a novel online chatter monitoring system for flexible milling process. Mech. Syst. Signal Process. 2021, 159, 107799. [Google Scholar] [CrossRef]

- Lamraoui, M.; El Badaoui, M.; Guilleti, F. Chatter stability prediction for CNC machine tool in operating condition through operational modal analysis. Mech. Ind. 2016, 17, 402. [Google Scholar] [CrossRef]

- Chen, G.; Liu, Y.-Q.; Jiang, G.-Y.; Li, C.-G.; Feng, G.-Q.; Wang, D.-Y. A novel method for identifying rotor-stator rubbing positions using the cepstrum analysis technique. J. Mech. Sci. Technol. 2014, 28, 3537–3544. [Google Scholar] [CrossRef]

- Childers, D.G.; Skinner, D.P.; Kemerait, R.C. The cepstrum: A guide to processing. Proc. IEEE 1977, 65, 1428–1443. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.; Hou, L.; Bu, X.; Ye, S.; Chen, D. Chatter detection for milling using novel p-leader multifractal features. J. Intell. Manuf. 2020, 33, 121–135. [Google Scholar] [CrossRef]

- Cherukuri, H.; Perez-Bernabeu, E.; Selles, M.; Schmitz, T.L. A neural network approach for chatter prediction in turning. Procedia Manuf. 2019, 34, 885–892. [Google Scholar] [CrossRef]

- Lee, H.; Kwon, H. Going Deeper With Contextual CNN for Hyperspectral Image Classification. IEEE Trans. Image Process. 2017, 26, 4843–4855. [Google Scholar] [CrossRef] [Green Version]

- Lawrence, S.; Giles, C.L.; Tsoi, A.C.; Back, A.D. Face recognition: A convolutional neural-network approach. IEEE Trans. Neural Netw. 1997, 8, 98–113. [Google Scholar] [CrossRef] [Green Version]

- Tran, M.-Q.; Liu, M.-K.; Tran, Q.-V. Milling chatter detection using scalogram and deep convolutional neural network. Int. J. Adv. Manuf. Technol. 2020, 107, 1505–1516. [Google Scholar] [CrossRef]

- Yang, R.-Y.; Rai, R. Machine auscultation: Enabling machine diagnostics using convolutional neural networks and large-scale machine audio data. Adv. Manuf. 2019, 7, 174–187. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Zhuang, J.; Guo, B.; Teng, W.; Wu, F. An optimized convolutional neural network for chatter detection in the milling of thin-walled parts. Int. J. Adv. Manuf. Technol. 2020, 106, 3881–3895. [Google Scholar] [CrossRef]

- Hecht-Nielsen, R. Theory of the backpropagation neural network. In Neural Networks for Perception; Elsevier: Amsterdam, The Netherlands, 1992; pp. 65–93. [Google Scholar]

- Van der Maaten, L.; Hinton, G. Visualizing data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

- CusidÓCusido, J.; Romeral, L.; Ortega, J.A.; Rosero, J.A.; Espinosa, A.G. Fault detection in induction machines using power spectral density in wavelet decomposition. IEEE Trans. Ind. Electron. 2008, 55, 633–643. [Google Scholar] [CrossRef]

- Huang, J.; Wang, X.; Ren, G.; Wang, D. A hydraulic fault diagnosis method based on sliding-window spectrum feature and deep belief network. J. Vibroeng. 2017, 19, 4272–4284. [Google Scholar] [CrossRef]

- Scholkopf, B.; Sung, K.-K.; Burges, C.J.; Girosi, F.; Niyogi, P.; Poggio, T.; Vapnik, V. Comparing support vector machines with Gaussian kernels to radial basis function classifiers. IEEE Trans. Signal. Process. 1997, 45, 2758–2765. [Google Scholar] [CrossRef] [Green Version]

| Speed (rev/min) | Radial Depth (mm) | Axial Depth (mm) | Feed Rate (mm/min) | State |

|---|---|---|---|---|

| 2000, 2300, 2600 | 0.1 | 12 | 1500 | Stable |

| 2900, 3200, 3500, 4100 | 0.2 | 12 | 1500 | Stable |

| 4700, 5000, 5300 | 0.1 | 12 | 1500 | Chatter |

| 5600, 5900, 6200 | 0.2 | 12 | 1500 | Chatter |

| Layer | Input Shape | Output Shape |

|---|---|---|

| Input layer | 650, 2 | 650, 2 |

| Convolutional layer (ReLU) | 650, 2 | 324, 10 |

| Convolutional layer (ReLU) | 324, 16 | 161, 20 |

| Convolutional layer (ReLU) | 161, 32 | 80, 30 |

| Flatten layer | 80, 30 | 2400 |

| Fully connected layer (ReLU) | 2400 | 256 |

| Dropout layer | 256 | 256 |

| Output layer (softmax) | 256 | 2 |

| Predicted State | |||

|---|---|---|---|

| Stable | Chatter | ||

| Actual state | Stable | 561 | 0 |

| Chatter | 15 | 359 | |

| Classifier | |||||||

|---|---|---|---|---|---|---|---|

| KNN | ANN | L-SVM | RBF-SVM | DNN | 1D-CNN | ||

| Input | Original spectrum | 68.78 | 63.4 | 79.8 | 76.2 | 49.7 | 73.7 |

| Liftered spectrum | 81.4 | 90.5 | 82.4 | 91.8 | 87.8 | 98.4 | |

| Speed (rev/min) | Radial Depth (mm) | Axial Depth (mm) | Feed Rate (mm/min) | State |

|---|---|---|---|---|

| 1500, 1800, 2100, 2400, 2700, 3000, 3300 | 0.1 | 15 | 1500 | Stable |

| 3600, 3900, 4200, 4500, 4800 | 0.1 | 15 | 1500 | Chatter |

| Predicted State | |||

|---|---|---|---|

| Stable | Chatter | ||

| Actual state | Stable | 559 | 2 |

| Chatter | 32 | 342 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, K.; Seong, Y.; Jeon, J.; Moon, S.; Park, J. Chatter Monitoring of Machining Center Using Head Stock Structural Vibration Analyzed with a 1D Convolutional Neural Network. Sensors 2022, 22, 5432. https://doi.org/10.3390/s22145432

Jeong K, Seong Y, Jeon J, Moon S, Park J. Chatter Monitoring of Machining Center Using Head Stock Structural Vibration Analyzed with a 1D Convolutional Neural Network. Sensors. 2022; 22(14):5432. https://doi.org/10.3390/s22145432

Chicago/Turabian StyleJeong, Kwanghun, Yeonuk Seong, Jonghoon Jeon, Seongjun Moon, and Junhong Park. 2022. "Chatter Monitoring of Machining Center Using Head Stock Structural Vibration Analyzed with a 1D Convolutional Neural Network" Sensors 22, no. 14: 5432. https://doi.org/10.3390/s22145432

APA StyleJeong, K., Seong, Y., Jeon, J., Moon, S., & Park, J. (2022). Chatter Monitoring of Machining Center Using Head Stock Structural Vibration Analyzed with a 1D Convolutional Neural Network. Sensors, 22(14), 5432. https://doi.org/10.3390/s22145432