Early Detection of Subsurface Fatigue Cracks in Rolling Element Bearings by the Knowledge-Based Analysis of Acoustic Emission

Abstract

:1. Introduction

1.1. Background and Problem Statement

1.2. Methodology

2. Experimental

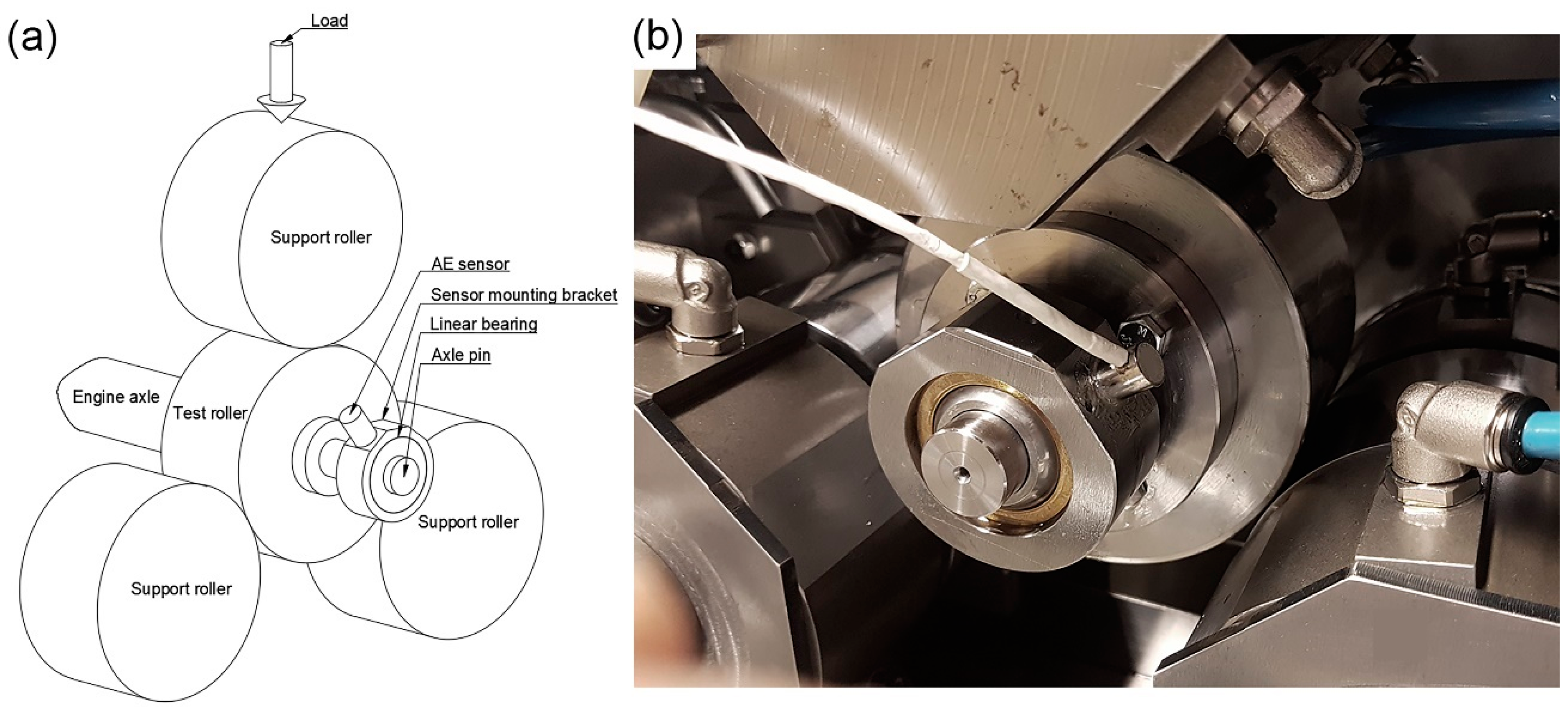

2.1. Testing Rig, Specimen and Loading Conditions

2.2. AE Acquisition System and Test Schedule

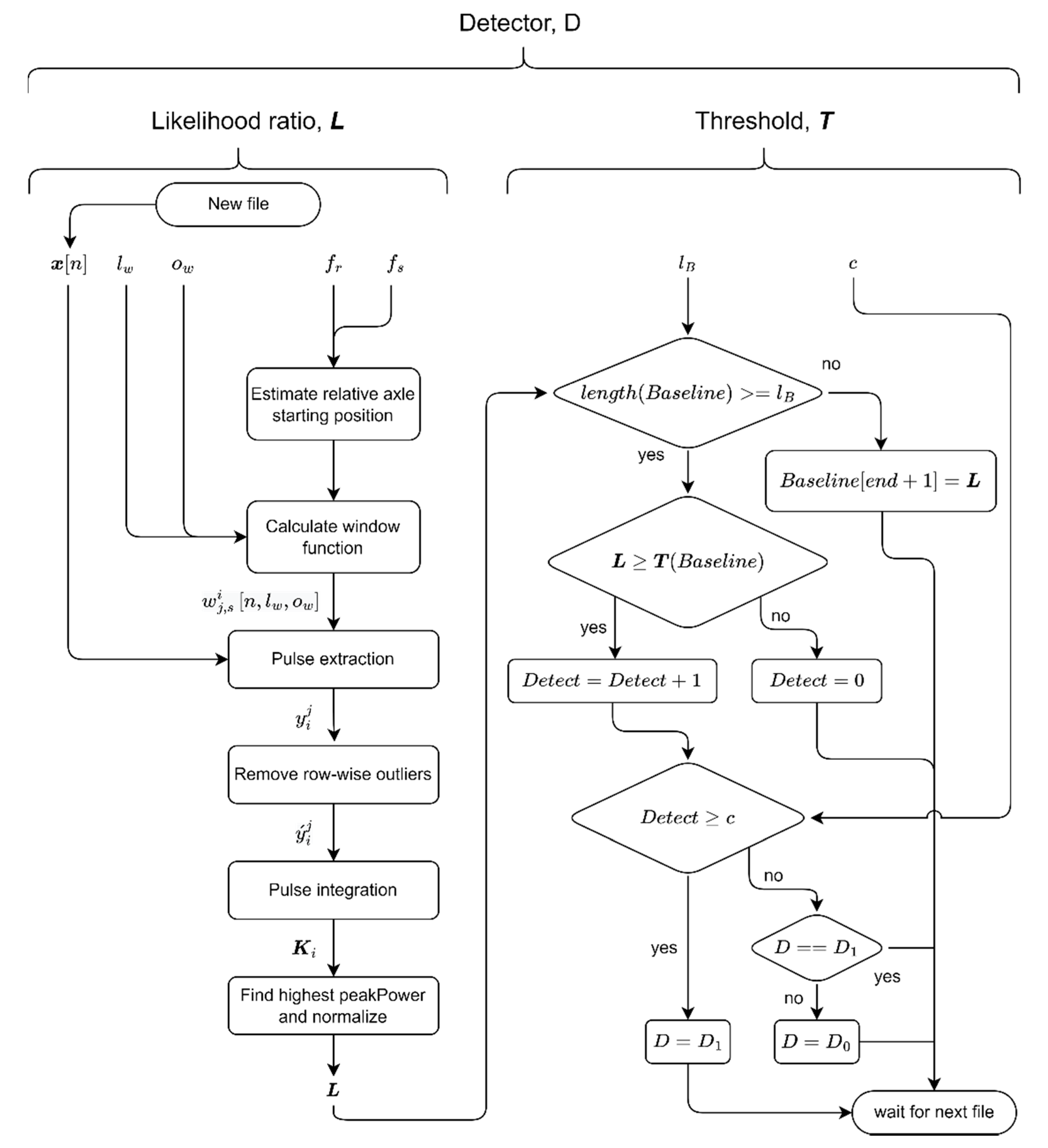

3. Proposed Detector

3.1. Hypothesis Testing

3.2. Pulse Integration Method

3.3. Detection Stage

3.3.1. Window Function

3.3.2. Pulse Extraction

3.3.3. Outlier Removal and Pulse Integration

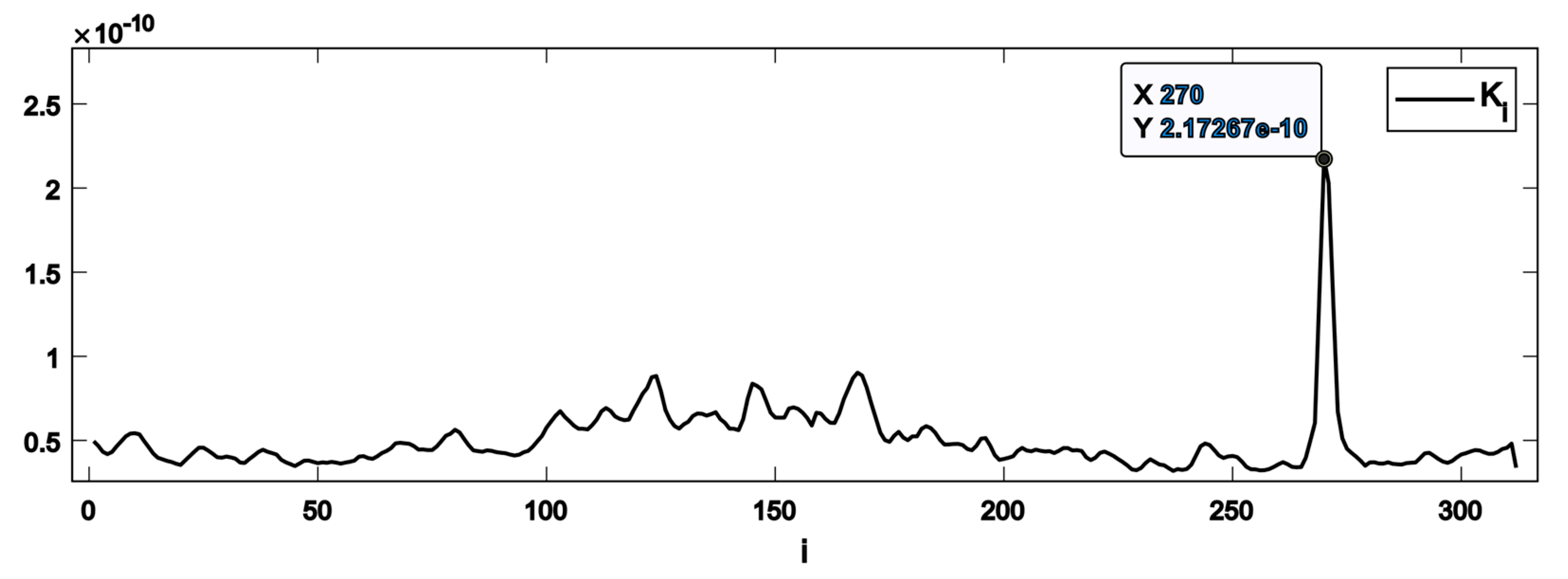

3.3.4. Health Indicator, Likelihood Ratio (L), Threshold (T), and Decision (D)

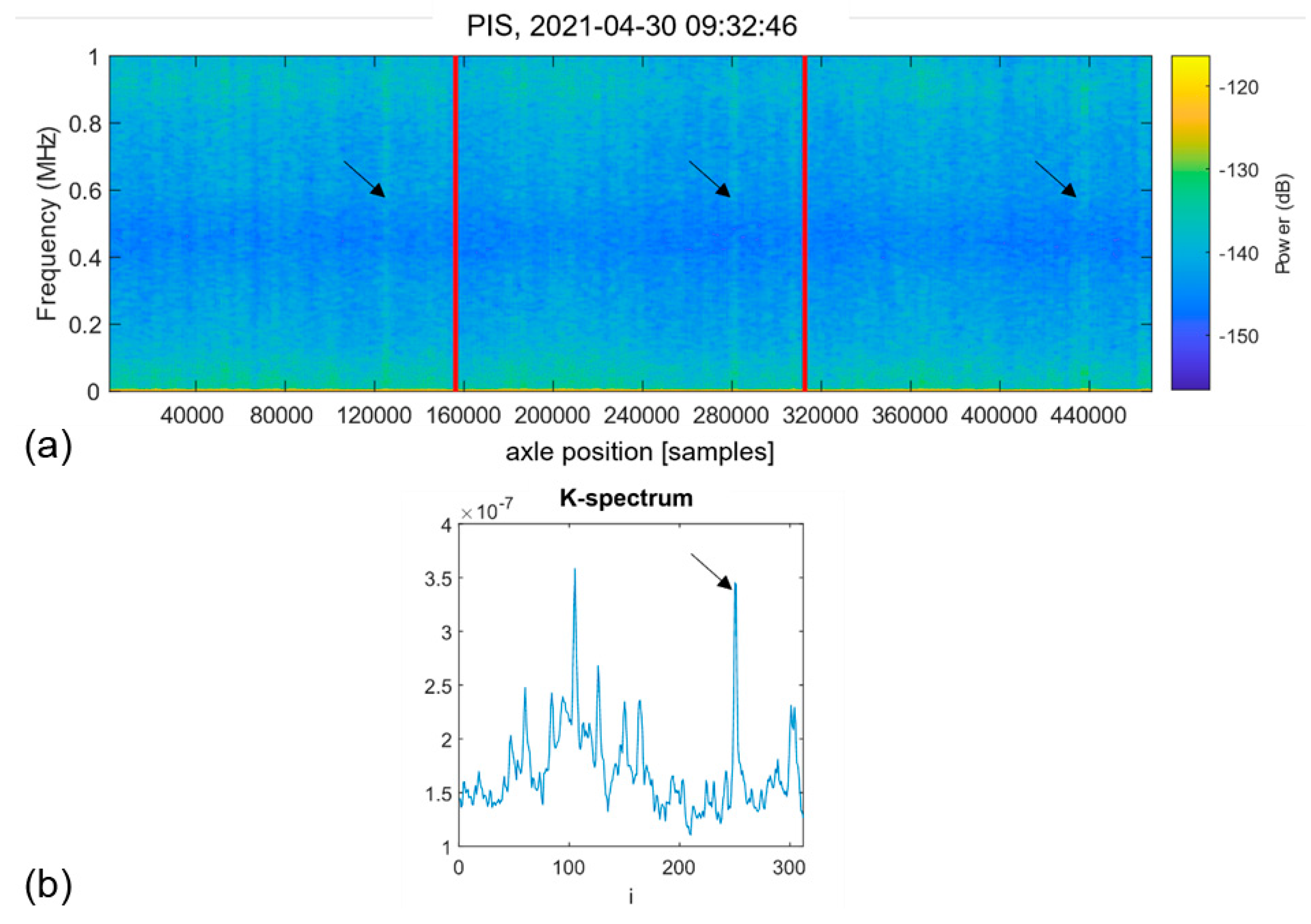

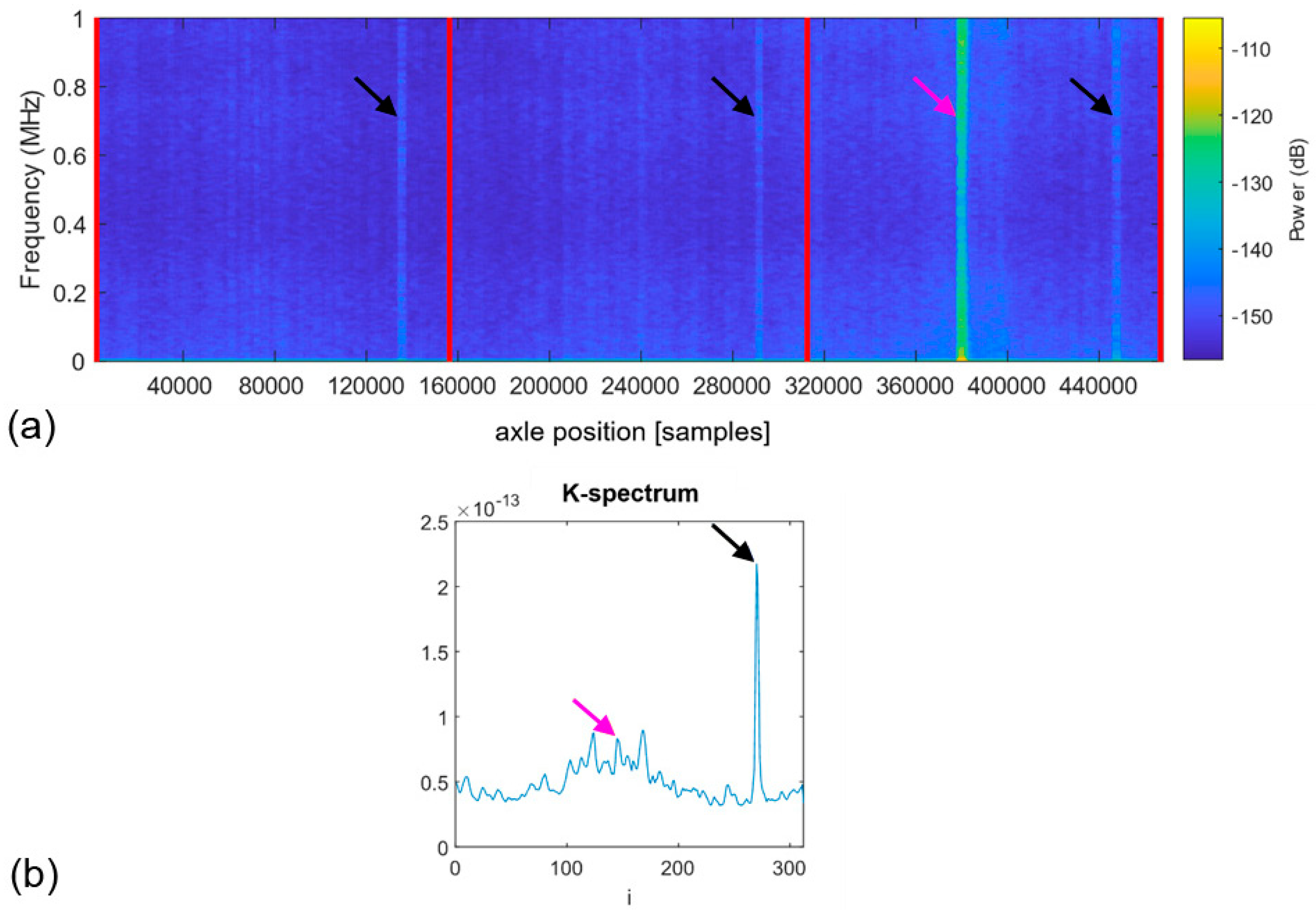

3.4. Pulse Integration Spectrum—A Novel Verification Procedure

4. Results and Discussion

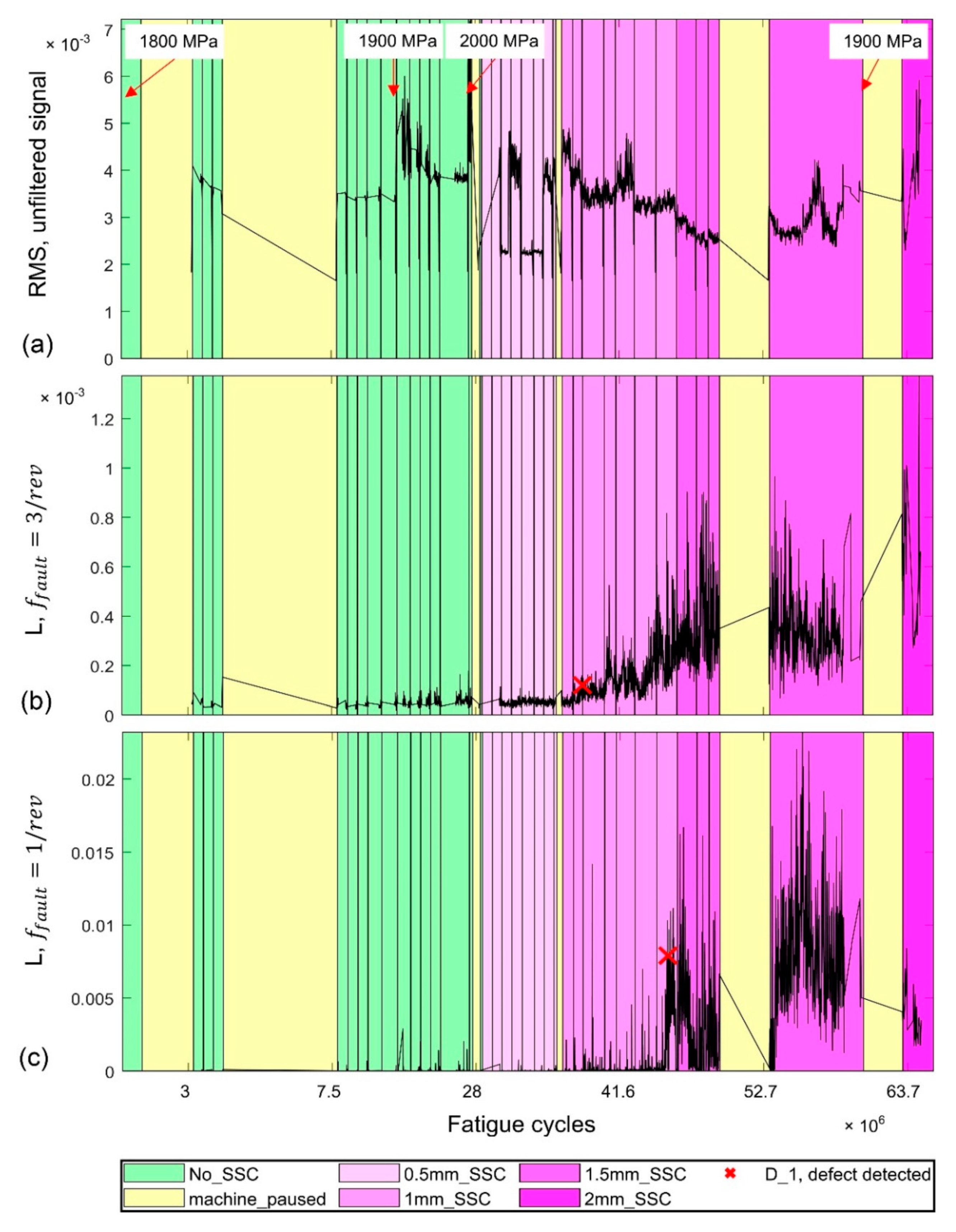

4.1. Application of the Proposed Detector to the Roller Bearing Test

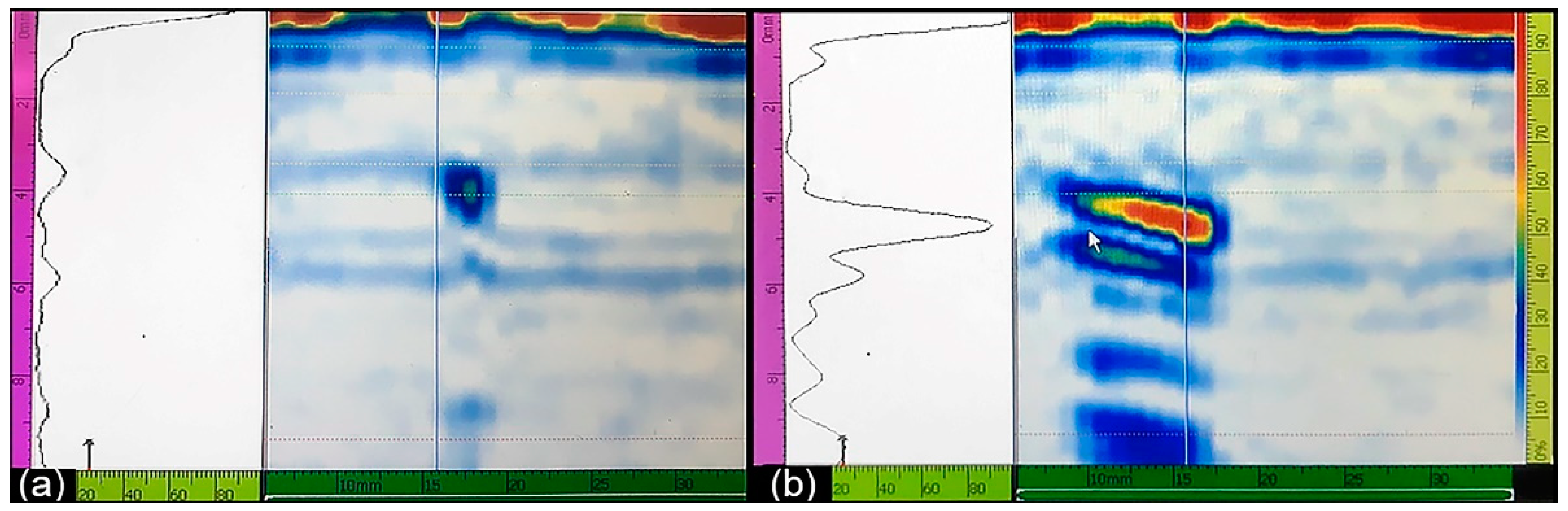

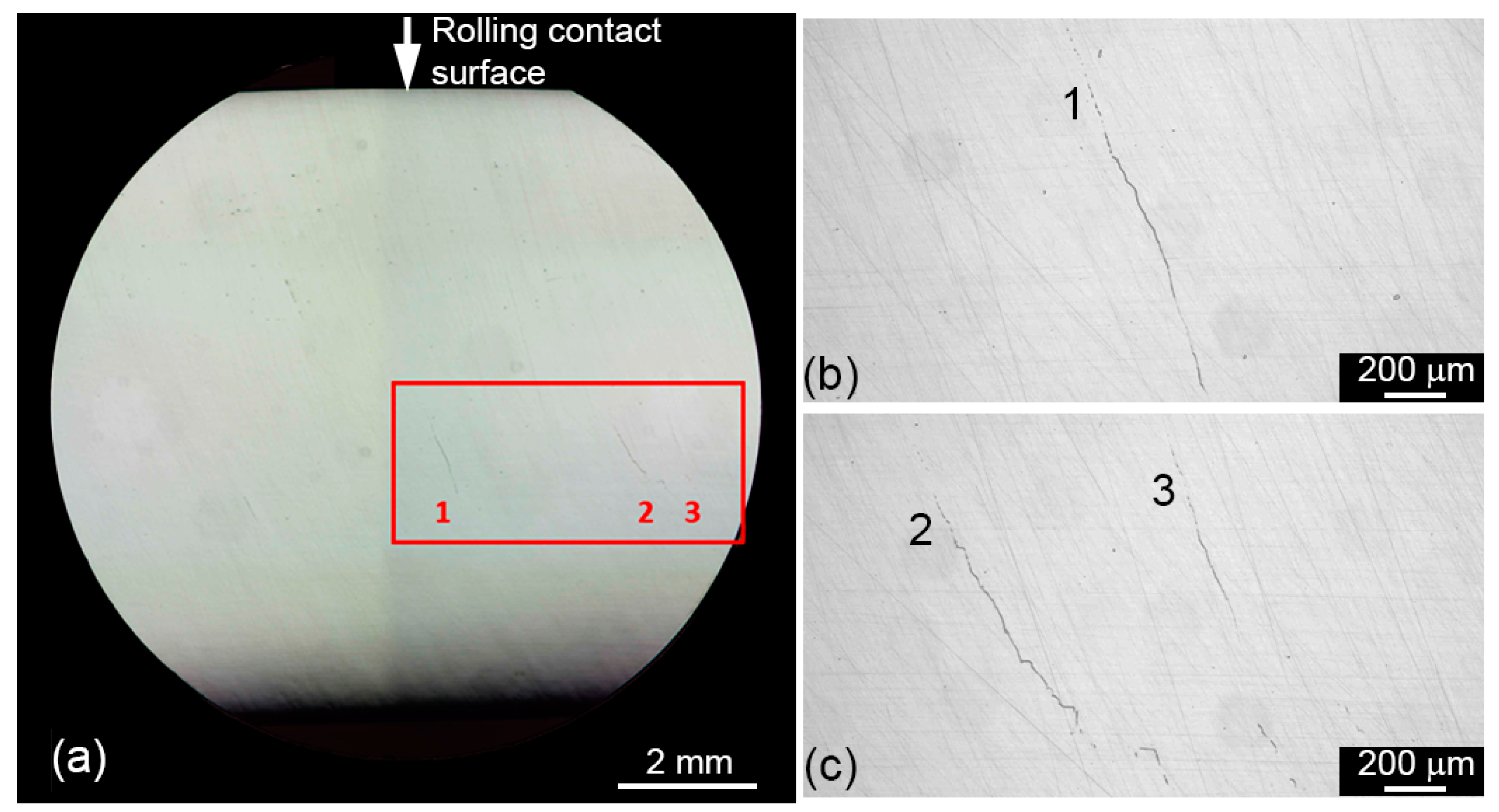

4.2. Metallographic Examination and Confirmation of Subsurface Cracking

5. Final Remarks, Conclusions, and Future Scopes

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Watanuki, D.; Tsutsumi, M.; Hidaka, H.; Wada, K.; Matsunaga, H. Fracture mechanics-based criteria for fatigue fracture of rolling bearings under the influence of defects. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 952–966. [Google Scholar] [CrossRef]

- Rao, B.K.N.; Pai, P.S.; Nagabhushana, T.N. Failure Diagnosis and Prognosis of Rolling—Element Bearings using Artificial Neural Networks: A Critical Overview. J. Phys. Conf. Ser. 2012, 364, 012023. [Google Scholar] [CrossRef]

- García Márquez, F.P.; Tobias, A.M.; Pinar Pérez, J.M.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Lei, Y. Intelligent Fault Diagnosis and Remaining Useful Life Prediction of Rotating Machinery; Butterworth-Heinemann: Oxford, UK, 2017; 366p. [Google Scholar] [CrossRef]

- Lei, Y.; Yang, B.; Jiang, X.; Jia, F.; Li, N.; Nandi, A.K. Applications of machine learning to machine fault diagnosis: A review and roadmap. Mech. Syst. Signal Proc. 2020, 138, 106587. [Google Scholar] [CrossRef]

- Sadeghi, F.; Jalalahmadi, B.; Slack, T.S.; Raje, N.; Arakere, N.K. A review of rolling contact fatigue. J. Tribol. 2009, 131, 041403. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Gabelli, A. The Progression of Surface Rolling Contact Fatigue Damage of Rolling Bearings with Artificial Dents. Tribol. Trans. 2015, 58, 418–431. [Google Scholar] [CrossRef]

- Böhme, S.A.; Merson, D.; Vinogradov, A. On subsurface initiated failures in marine bevel gears. Eng. Fail. Anal. 2020, 110, 104415. [Google Scholar] [CrossRef]

- Liang, Q.; Yan, X.; Liao, X.; Cao, S.; Lu, S.; Zheng, X.; Zhang, Y. Integrated active sensor system for real time vibration monitoring. Sci. Rep. 2015, 5, 16063. [Google Scholar] [CrossRef] [Green Version]

- Tang, L.; Liu, X.; Wu, X.; Wang, Z.; Hou, K. Defect localization on rolling element bearing stationary outer race with acoustic emission technology. Appl. Acoust. 2021, 182, 108207. [Google Scholar] [CrossRef]

- Yang, K.; Zhao, L.; Wang, C. A new intelligent bearing fault diagnosis model based on triplet network and SVM. Sci. Rep. 2022, 12, 5234. [Google Scholar] [CrossRef]

- Cempel, C.A.; Haddad, S.D. Vibroacoustic Condition Monitoring; Ellis Horwood: New York, NY, USA, 1991; 212p. [Google Scholar]

- Tandon, N.; Choudhury, A. A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribol. Int. 1999, 32, 469–480. [Google Scholar] [CrossRef]

- Tandon, N.; Yadava, G.S.; Ramakrishna, K.M. A comparison of some condition monitoring techniques for the detection of defect in induction motor ball bearings. Mech. Syst. Signal Proc. 2007, 21, 244–256. [Google Scholar] [CrossRef]

- Dekys, V. Condition Monitoring and Fault Diagnosis. Procedia Eng. 2017, 177, 502–509. [Google Scholar] [CrossRef]

- Sheriff, K.A.I.; Hariharan, V.; Kumar, B.M. Review on condition monitoring of rotating machines. Int. J. Sci. Technol. Res. 2020, 9, 2343–2346. [Google Scholar]

- Geng, Z.; Puhan, D.; Reddyhoff, T. Using acoustic emission to characterize friction and wear in dry sliding steel contacts. Tribol. Int. 2019, 134, 394–407. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Kim, J.-M. Bearing Fault Diagnosis Using Grad-CAM and Acoustic Emission Signals. Appl. Sci. 2020, 10, 2050. [Google Scholar] [CrossRef] [Green Version]

- Rastegaev, I.; Merson, D.; Rastegaeva, I.; Vinogradov, A. A Time-Frequency based Approach for Acoustic Emission Assessment of Sliding Wear. Lubricants 2020, 8, 52. [Google Scholar] [CrossRef]

- Rastegaev, I.A.; Merson, D.L.; Danyuk, A.V.; Afanasyev, M.A.; Vinogradov, A. Using acoustic emission signal categorization for reconstruction of wear development timeline in tribosystems: Case studies and application examples. Wear 2018, 410–411, 83–92. [Google Scholar] [CrossRef]

- Xue, L.; Li, N.; Lei, Y.; Li, N. Incipient Fault Detection for Rolling Element Bearings under Varying Speed Conditions. Materials 2017, 10, 675. [Google Scholar] [CrossRef] [Green Version]

- Lv, Y.; Yuan, R.; Wang, T.; Li, H.; Song, G. Health Degradation Monitoring and Early Fault Diagnosis of a Rolling Bearing Based on CEEMDAN and Improved MMSE. Materials 2018, 11, 1009. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.-H.; Tan, A.C.C.; Mathew, J.; Yang, B.-S. Condition Monitoring of Low Speed Bearings: A Comparative Study of the Ultrasound Technique Versus Vibration Measurements. In Engineering Asset Management; Springer: London, UK, 2006; pp. 182–191. [Google Scholar]

- Holweger, W.; Walther, F.; Loos, J.; Wolf, M.; Schreiber, J.; Dreher, W.; Kern, N.; Lutz, S. Non-destructive subsurface damage monitoring in bearings failure mode using fractal dimension analysis. Ind. Lubr. Tribol. 2012, 64, 132–137. [Google Scholar] [CrossRef]

- Butler, D.E. The Shock-pulse method for the detection of damaged rolling bearings. Non-Destr. Test. 1973, 6, 92–95. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Shiozawa, K.; Lu, L. Very high-cycle fatigue behaviour of shot-peened high-carbon–chromium bearing steel. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 813–822. [Google Scholar] [CrossRef]

- Shiozawa, K.; Lu, L.; Ishihara, S. S-N curve characteristics and subsurface crack initiation behaviour in ultra-long life fatigue of a high carbon-chromium bearing steel. Fatigue Fract. Eng. Mater. Struct. 2001, 24, 781–790. [Google Scholar] [CrossRef]

- Coronado, D.; Wenske, J. Monitoring the Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection Methods. Machines 2018, 6, 25. [Google Scholar] [CrossRef] [Green Version]

- Loutas, T.H.; Roulias, D.; Pauly, E.; Kostopoulos, V. The combined use of vibration, acoustic emission and oil debris on-line monitoring towards a more effective condition monitoring of rotating machinery. Mech. Syst. Signal Proc. 2011, 25, 1339–1352. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2021, 21, 108. [Google Scholar] [CrossRef]

- Lacey, S.J. An Overview of Bearing Vibration Analysis. Maint. Asset Manag. 2008, 23, 32–42. [Google Scholar]

- Nelias, D.; Yoshioka, T. Location of an acoustic emission source in a radially loaded deep groove ball-bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1998, 212, 33–45. [Google Scholar] [CrossRef]

- Meserkhani, A.; Jafari, S.M.; Rahi, A. Experimental comparison of acoustic emission sensors in the detection of outer race defect of angular contact ball bearings by artificial neural network. Measurement 2021, 168, 108198. [Google Scholar] [CrossRef]

- Vinogradov, A.; Danyuk, A.V.; Merson, D.L.; Yasnikov, I.S. Probing elementary dislocation mechanisms of local plastic deformation by the advanced acoustic emission technique. Scr. Mater. 2018, 151, 53–56. [Google Scholar] [CrossRef] [Green Version]

- Rahman, Z.; Ohba, H.; Yoshioka, T.; Yamamoto, T. Incipient damage detection and its propagation monitoring of rolling contact fatigue by acoustic emission. Tribol. Int. 2009, 42, 807–815. [Google Scholar] [CrossRef]

- Cockerill, A.; Clarke, A.; Pullin, R.; Bradshaw, T.; Cole, P.; Holford, K.M. Determination of rolling element bearing condition via acoustic emission. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1377–1388. [Google Scholar] [CrossRef] [Green Version]

- McCrory, J.P.; Vinogradov, A.; Pearson, M.R.; Pullin, R.; Holford, K.M. Acoustic Emission Monitoring of Metals. In Acoustic Emission Testing: Basics for Research—Applications in Engineering; Grosse, C.U., Ohtsu, M., Aggelis, D.G., Shiotani, T., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 529–565. [Google Scholar] [CrossRef]

- Yoshioka, T. Detection of Rolling-Contact Subsurface Fatigue Cracks Using Acoustic-Emission Technique. Lubr. Eng. 1993, 49, 303–308. [Google Scholar]

- Yoshioka, T. Clarification of Rolling-Contact Fatigue Process by Observation of Acoustic-Emission and Vibration. J. Jpn. Soc. Tribol. 1994, 39, 685–690. [Google Scholar]

- Price, E.D.; Lees, A.W.; Friswell, M.I. Detection of severe sliding and pitting fatigue wear regimes through the use of broadband acoustic emission. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2005, 219, 85–98. [Google Scholar] [CrossRef]

- Lees, A.W.; Quiney, Z.; Ganji, A.; Murray, B. The use of acoustic emission for bearing condition monitoring. J. Phys. Conf. Ser. 2011, 305, 012074. [Google Scholar] [CrossRef] [Green Version]

- Quiney, Z.; Lees, A.W.; Ganji, A.; Murray, B. Acoustic emission for the detection of subsurface cracking in bearing condition monitoring. In Proceedings of the 10th International Conference on Vibrations in Rotating Machinery, London, UK, 11–13 September 2012; Woodhead Publishing: Cambridge, UK, 2012; pp. 135–146. [Google Scholar]

- Fuentes, R.; Dwyer-Joyce, R.S.; Marshall, M.B.; Wheals, J.; Cross, E.J. Detection of sub-surface damage in wind turbine bearings using acoustic emissions and probabilistic modelling. Renew. Energy 2020, 147, 776–797. [Google Scholar] [CrossRef]

- Bathias, C. There is no infinite fatigue life in metallic materials. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 559–565. [Google Scholar] [CrossRef]

- Mughrabi, H. On the life-controlling microstructural fatigue mechanisms in ductile metals and alloys in the gigacycle regime. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 633–641. [Google Scholar] [CrossRef]

- Seleznev, M.; Weidner, A.; Biermann, H.; Vinogradov, A. Novel method for in situ damage monitoring during ultrasonic fatigue testing by the advanced acoustic emission technique. Int. J. Fatigue 2021, 142, 105918. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Proc. 2016, 72–73, 303–315. [Google Scholar] [CrossRef]

- Hemmer, M.; Van Khang, H.; Robbersmyr, K.G.; Waag, T.I.; Meyer, T.J.J. Fault Classification of Axial and Radial Roller Bearings Using Transfer Learning through a Pretrained Convolutional Neural Network. Designs 2018, 2, 56. [Google Scholar] [CrossRef] [Green Version]

- Kahr, M.; Kovács, G.; Loinig, M.; Brückl, H. Condition Monitoring of Ball Bearings Based on Machine Learning with Synthetically Generated Data. Sensors 2022, 22, 2490. [Google Scholar] [CrossRef]

- Altaf, M.; Akram, T.; Khan, M.A.; Iqbal, M.; Ch, M.M.I.; Hsu, C.-H. A New Statistical Features Based Approach for Bearing Fault Diagnosis Using Vibration Signals. Sensors 2022, 22, 2012. [Google Scholar] [CrossRef]

- Zhang, B.; Georgoulas, G.; Orchard, M.; Saxena, A.; Brown, D.; Vachtsevanos, G.; Liang, S. Rolling element bearing feature extraction and anomaly detection based on vibration monitoring. In Proceedings of the 2008 16th Mediterranean Conference on Control and Automation, Ajaccio, France, 25–27 June 2008; pp. 1792–1797. [Google Scholar]

- Liu, C.; Gryllias, K. A semi-supervised Support Vector Data Description-based fault detection method for rolling element bearings based on cyclic spectral analysis. Mech. Syst. Signal Process. 2020, 140, 106682. [Google Scholar] [CrossRef]

- Martin-del-Campo, S.; Sandin, F. Online feature learning for condition monitoring of rotating machinery. Eng. Appl. Artif. Intel. 2017, 64, 187–196. [Google Scholar] [CrossRef]

- Heng, R.B.W.; Nor, M.J.M. Statistical analysis of sound and vibration signals for monitoring rolling element bearing condition. Appl. Acoust. 1998, 53, 211–226. [Google Scholar] [CrossRef]

- Martin, H.R.; Honarvar, F. Application of statistical moments to bearing failure detection. Appl. Acoust. 1995, 44, 67–77. [Google Scholar] [CrossRef]

- Mechefske, C.K.; Mathew, J. Fault detection and diagnosis in low speed rolling element bearings Part II: The use of nearest neighbour classification. Mech. Syst. Signal Process. 1992, 6, 309–316. [Google Scholar] [CrossRef]

- Logan, D.B.; Mathew, J. Using the correlation dimension for vibration fault diagnosis of rolling element bearings—II. Selection of experimental parameters. Mech. Syst. Signal Process. 1996, 10, 251–264. [Google Scholar] [CrossRef]

- Han, M.; Pan, J. A fault diagnosis method combined with LMD, sample entropy and energy ratio for roller bearings. Measurement 2015, 76, 7–19. [Google Scholar] [CrossRef]

- Fei, C.-W.; Choy, Y.-S.; Bai, G.-C.; Tang, W.-Z. Multi-feature entropy distance approach with vibration and acoustic emission signals for process feature recognition of rolling element bearing faults. Struct. Health Monit. 2018, 17, 156–168. [Google Scholar] [CrossRef]

- Zurita-Millán, D.; Delgado-Prieto, M.; Saucedo-Dorantes, J.J.; Cariño-Corrales, J.A.; Osornio-Rios, R.A.; Ortega-Redondo, J.A.; Romero-Troncoso, R.D.J. Vibration Signal Forecasting on Rotating Machinery by means of Signal Decomposition and Neurofuzzy Modeling. Shock. Vib. 2016, 2016, 2683269. [Google Scholar] [CrossRef]

- Mba, D. Acoustic emissions and monitoring bearing health. Tribol. Trans. 2003, 46, 447–451. [Google Scholar] [CrossRef]

- Hall, L.D.; Mba, D. Acoustic emissions diagnosis of rotor-stator rubs using the KS statistic. Mech. Syst. Signal Proc. 2004, 18, 849–868. [Google Scholar] [CrossRef] [Green Version]

- Mechefske, C.K.; Sun, G.; Sheasby, J. Using acoustic emission to monitor sliding wear. Insight-Non-Destr. Test. Cond. Monit. 2002, 44, 490–497. [Google Scholar]

- Pomponi, E.; Vinogradov, A. Identification of the Health of Rotating Machinery with AE Neural Network Classifiers. In Proceedings of the 19th International Acoustic Emission Symposium (IAES-19), Kyoto, Japan, 8–12 December 2008; pp. 469–476. [Google Scholar]

- Elforjani, M.; Mba, D. Monitoring the onset and propagation of natural degradation process in a slow speed rolling element bearing with acoustic emission. J. Vib. Acoust.-Trans. ASME 2008, 130, 14. [Google Scholar] [CrossRef]

- Elforjani, M.; Mba, D. Detecting the Onset, Propagation and Location of Non-artificial Defects in a Slow Rotating Thrust Bearing With Acoustic Emission. Insight-Non-Destr. Test. Cond. Monit. 2008, 50, 264–268. [Google Scholar] [CrossRef] [Green Version]

- Elforjani, M.; Mba, D. Accelerated Natural Fault Diagnosis in Slow Speed Bearings With Acoustic Emission. Eng. Fract. Mech. 2010, 77, 112–127. [Google Scholar] [CrossRef]

- Elforjani, M.; Mba, D. Detecting AE Signals from Natural Degradation of Slow Speed Rolling Element Bearings. In Condition Monitoring of Machinery in Non-Stationary Operations; Springer: Berlin/Heidelberg, Germany, 2012; pp. 61–68. [Google Scholar]

- McDonough, R.N.; Whalen, A.D.; Whalen, A.D. Detection of Signals in Noise, 2nd ed.; Academic Press: San Diego, CA, USA, 1995; 495p. [Google Scholar]

- Agletdinov, E.; Merson, D.; Vinogradov, A. A New Method of Low Amplitude Signal Detection and Its Application in Acoustic Emission. Appl. Sci. 2019, 10, 73. [Google Scholar] [CrossRef] [Green Version]

- Pomponi, E.; Vinogradov, A.; Danyuk, A. Wavelet based approach to signal activity detection and phase picking: Application to acoustic emission. Signal Process. 2015, 115, 110–119. [Google Scholar] [CrossRef]

- Madarshahian, R.; Ziehl, P.; Caicedo, J.M. Acoustic emission Bayesian source location: Onset time challenge. Mech. Syst. Signal Proc. 2019, 123, 483–495. [Google Scholar] [CrossRef]

- Antoni, J. Cyclostationarity by examples. Mech. Syst. Signal Process. 2009, 23, 987–1036. [Google Scholar] [CrossRef]

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Gryllias, K.; Moschini, S.; Antoni, J. Application of Cyclo-Nonstationary Indicators for Bearing Monitoring Under Varying Operating Conditions. J. Eng. Gas Turbines Power 2017, 140, 012501. [Google Scholar] [CrossRef]

- Blake, L.V. Radar Range-Performance Analysis; D. C. Heath and Co.: Lexington, MA, USA, 1980. [Google Scholar]

- Skolnik, M.I. Radar Handbook, 3rd ed.; McGraw-Hill Professional: Maidenhead, UK, 2008. [Google Scholar]

- Hidle, E.L. Early Detection of Subsurface Cracks in Rolling Element Bearings Using the Acoustic Emission Time Series; Norwegian University of Science and Technology: Trondheim, Norway, 2021. [Google Scholar]

- Selin, I. Detection Theory; Princeton University Press: Princeton, NJ, USA, 1965. [Google Scholar]

- Inverse Complementary Error Function. Available online: https://se.mathworks.com/help/matlab/ref/isoutlier.html#bvolfgk (accessed on 1 July 2022).

- Scheeren, B.; Kaminski, M.L.; Pahlavan, L. Evaluation of Ultrasonic Stress Wave Transmission in Cylindrical Roller Bearings for Acoustic Emission Condition Monitoring. Sensors 2022, 22, 1500. [Google Scholar] [CrossRef]

| Recorded Axle Revolutions | |||||

| Sub Window 1 | Sub Window 2 | Sub Window 3 | ⋯ | ||

| Axle position | Window 1 | Pos1, Rev1 | Pos1, Rev2 | Pos1, Rev3 | ⋯ |

| Window 2 | Pos2, Rev1 | Pos2, Rev2 | Pos2, Rev3 | ⋯ | |

| Window 3 | Pos3, Rev1 | Pos3, Rev2 | Pos3, Rev3 | ⋯ | |

| ⋮ | ⋮ | ⋮ | ⋮ | ⋱ | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidle, E.L.; Hestmo, R.H.; Adsen, O.S.; Lange, H.; Vinogradov, A. Early Detection of Subsurface Fatigue Cracks in Rolling Element Bearings by the Knowledge-Based Analysis of Acoustic Emission. Sensors 2022, 22, 5187. https://doi.org/10.3390/s22145187

Hidle EL, Hestmo RH, Adsen OS, Lange H, Vinogradov A. Early Detection of Subsurface Fatigue Cracks in Rolling Element Bearings by the Knowledge-Based Analysis of Acoustic Emission. Sensors. 2022; 22(14):5187. https://doi.org/10.3390/s22145187

Chicago/Turabian StyleHidle, Einar Løvli, Rune Harald Hestmo, Ove Sagen Adsen, Hans Lange, and Alexei Vinogradov. 2022. "Early Detection of Subsurface Fatigue Cracks in Rolling Element Bearings by the Knowledge-Based Analysis of Acoustic Emission" Sensors 22, no. 14: 5187. https://doi.org/10.3390/s22145187

APA StyleHidle, E. L., Hestmo, R. H., Adsen, O. S., Lange, H., & Vinogradov, A. (2022). Early Detection of Subsurface Fatigue Cracks in Rolling Element Bearings by the Knowledge-Based Analysis of Acoustic Emission. Sensors, 22(14), 5187. https://doi.org/10.3390/s22145187