Adjusting the Stiffness of Supports during Milling of a Large-Size Workpiece Using the Salp Swarm Algorithm

Abstract

1. Introduction

1.1. Problems in Milling of Large-Size Details

1.2. Vibration Reduction Methods

1.3. Proposed Approach

1.4. Metaheuristic Optimization Methods

1.5. Paper Organization and Research Program

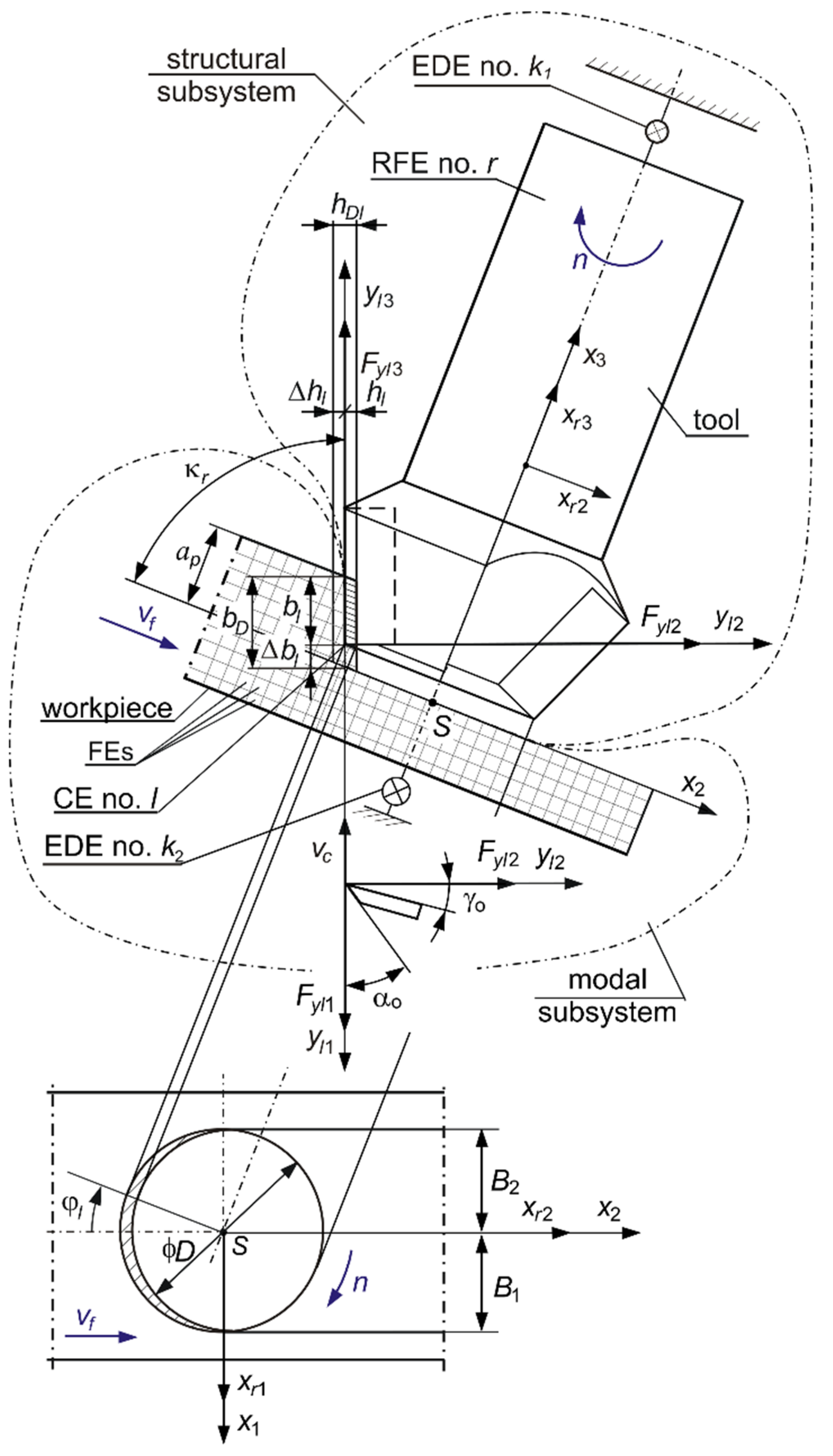

2. Dynamics of the Face-Milling Process

- The tool fixed in the holder, rotating with the desired spindle speed n, and the workpiece mounted on the table, moving with the desired feed speed υf, are the only features taken into account. The influence of the remaining parts of the milling machine on the dynamics of the machining process can be neglected [7,30].

- Only cutting forces Fyl1, Fyl2, Fyl3, acting at the instantaneous point of contact of the selected tool edge with the workpiece (i.e., CE no. l), are taken into account. They work appropriately in the direction of cutting speed vc, cutting layer thickness hl, and layer width bl. Milling medium-cut materials (e.g., cast iron) with small allowances (depth of cutting ap = 0.2 mm, feed per edge fz = 0.17 mm) causes that the cutting force components acting on one edge do not exceed 200 N

- These cutting forces depend proportionally on the instantaneous thickness of the cutting layer hl and the instantaneous width of the cutting layer bl [56,58]. Cutting speed vc values not exceeding 500 m/min allow the use of a mechanistic proportional model in the description of cutting dynamics [56].

- The passage of the current edge along the cutting layer causes a proportional feedback, and the passage of the previous edge additionally causes a delayed feedback. Because of this, it is possible to consider the effect of multiple trace regeneration in the calculation model.

- A structural subsystem, i.e., a rigid body called the Rigid Finite Element (RFE) no. r (central principal axes of inertia are xr1, xr2, xr3), that represents a milling tool connected to a tool holder by means of the Elastic Damping Element (EDE) no. k1 [56,57]. Its behavior is described in a domain of six generalized coordinates q.

- A modal subsystem, i.e., a stationary Finite Element Model (FEM) of a flexible workpiece supported by a finite number of Elastic Damping Elements (EDEs) no k2. At first, the subsystem is idealized as a set of tetrahedronal 10-node Finite Elements (FEs). The model obtained has a large number of degrees of freedom. Thus, it has been transformed to mod modal coordinates, whose number is much smaller [30].

3. Adjusting the Stiffness of Supports—General Procedure and Search Method Selection

- Identification of stiffness values for different settings for each of the adjustable stiffness supports, for example, by performing static tests at the material testing machine;

- Selecting cutting process parameters, i.e., depth of cutting, feed speed, spindle speed;

- Performing a series of simulations of milling process for given sets of support stiffness settings;

- Assessing the simulation results by comparing a chosen process quality indicator, for example, average tool–workpiece displacement or Root Mean Square (RMS) of the displacements in the time domain;

- Choosing the set of support settings that assure the best milling conditions.

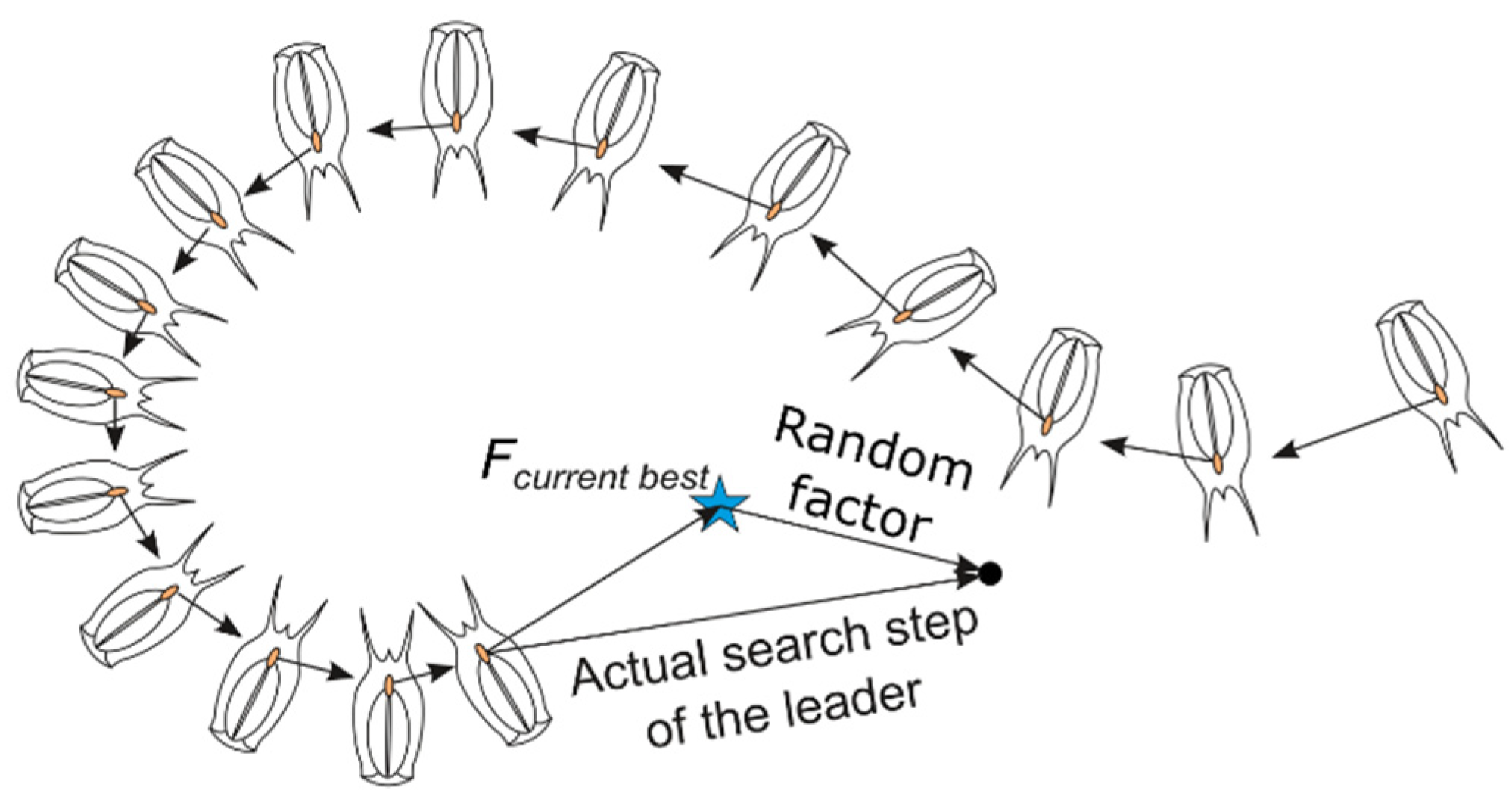

4. Salp Swarm Algorithm

5. Research and Simulation Example

5.1. Introduction

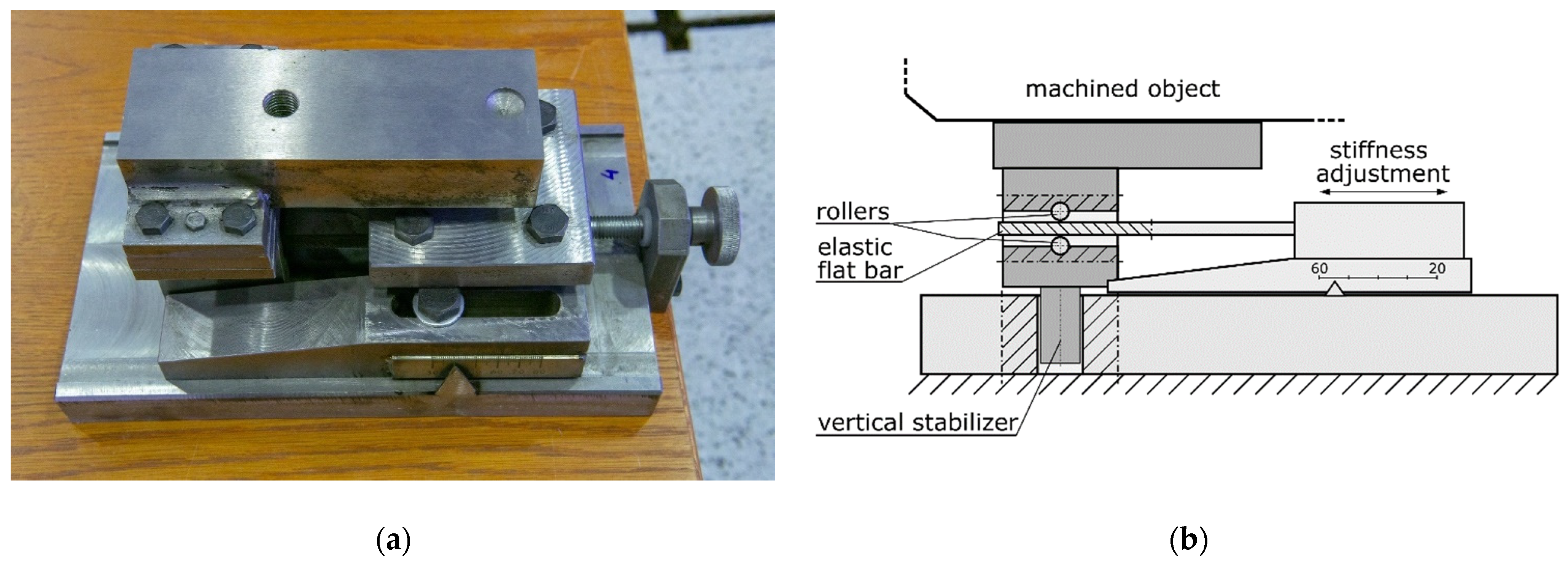

5.2. Support Characteristics

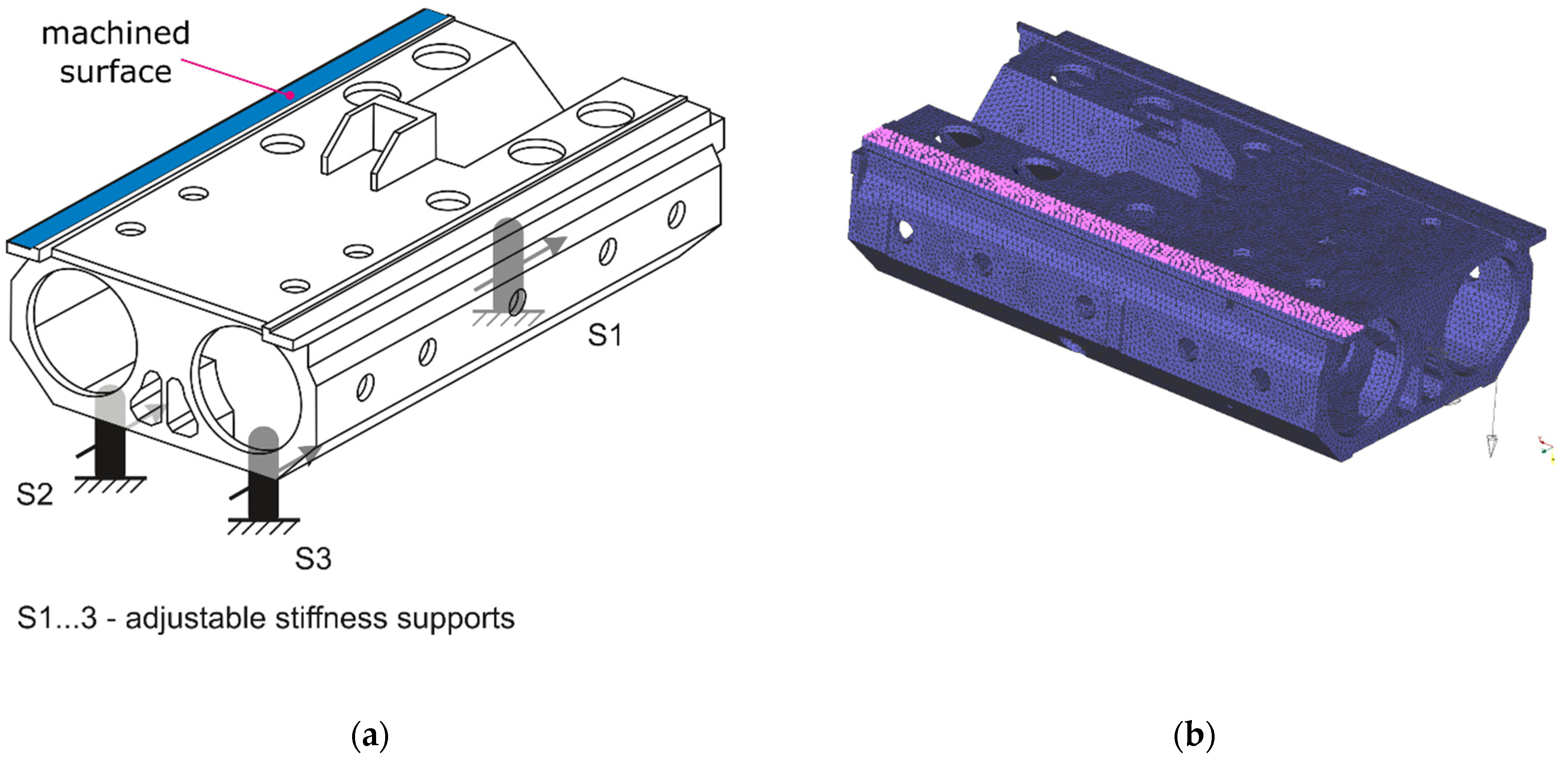

5.3. Workpiece Model

- All rigid body modes of the free–free state system;

- A set of the first few elastic modes of the free–free state system, the number of which should be not lower than the number of flexible modes of the constrained system to be computed;

- All Guyan modes [68] of a free–free state system for all combinations of Degrees of Freedom (DOF) of the supports.

5.4. Milling Process Simulations

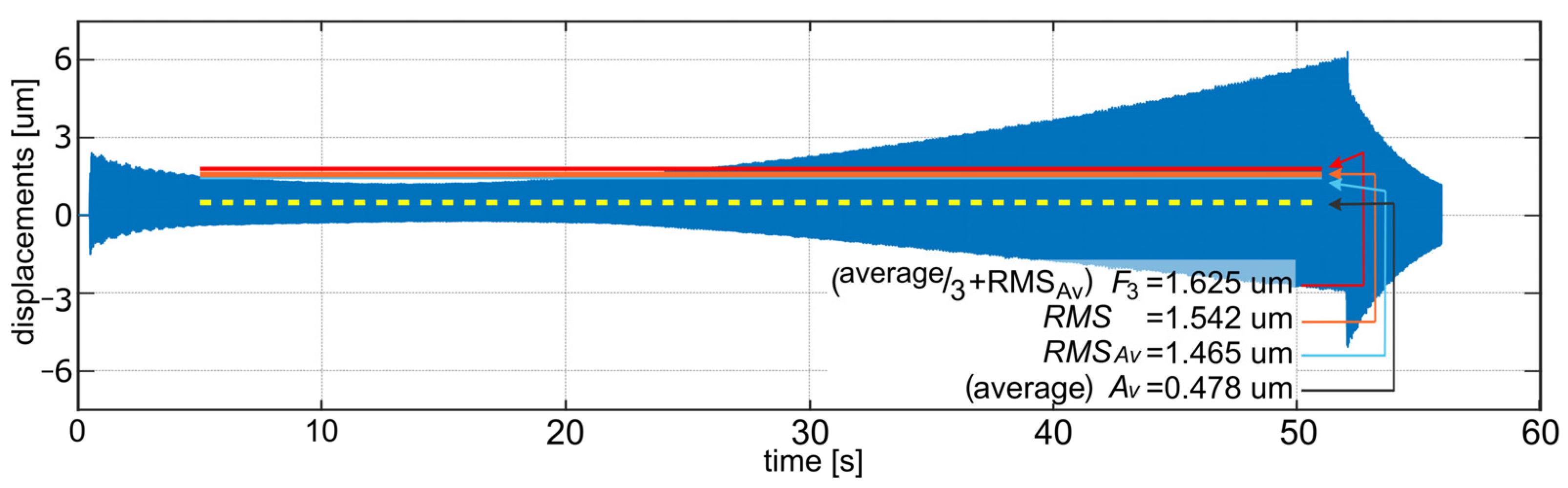

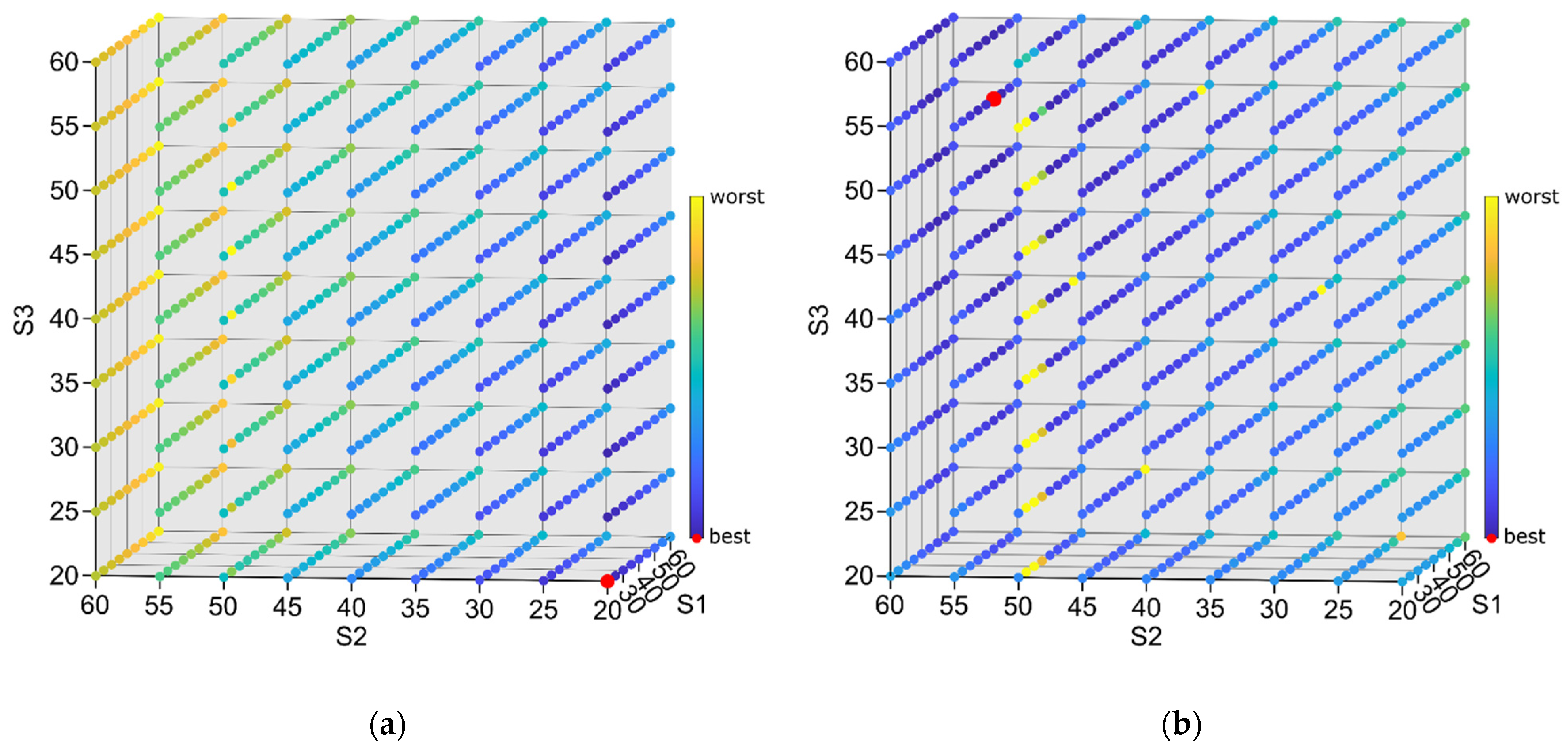

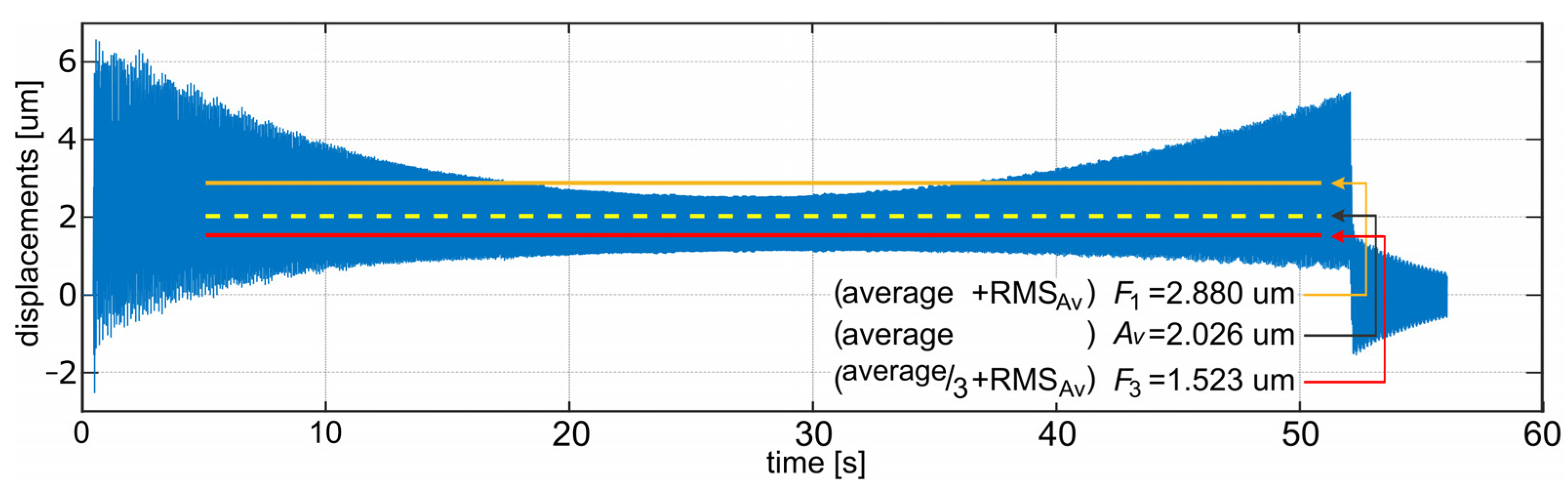

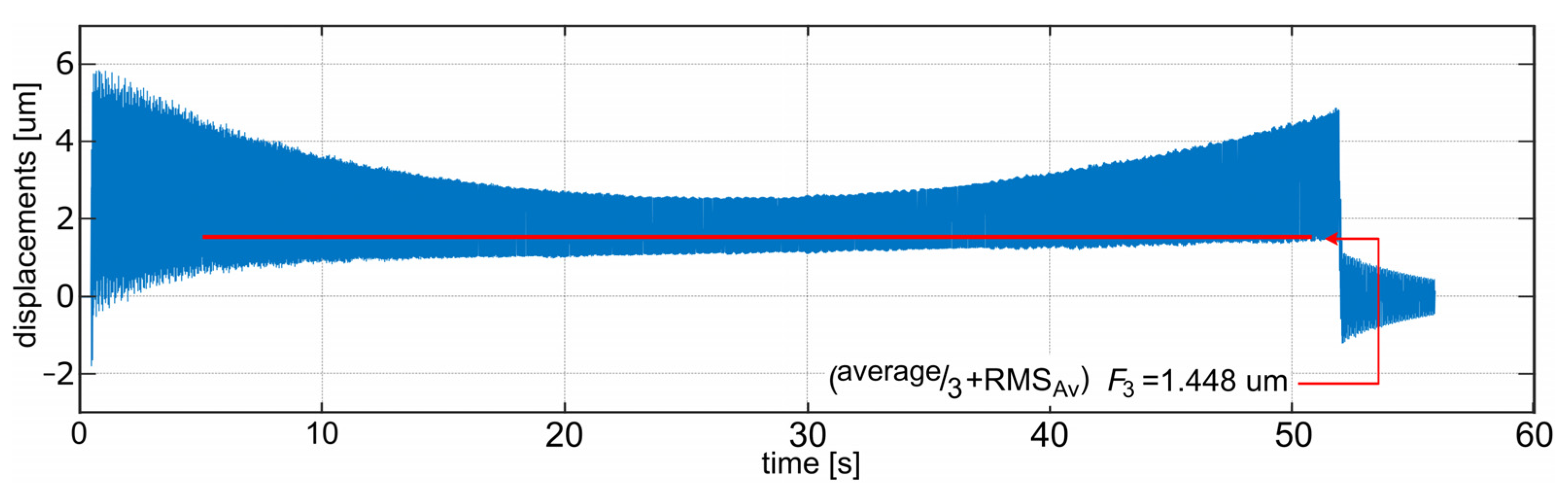

5.5. Selection of an Indicator for Comparing Simulation Results

- Av—average (mean) value of the displacements—takes into account mainly “static” displacement of the workpiece. The amplitude of vibration around the average value is not represented by this indicator; however, it may be associated with the accuracy of geometrical requirements for the workpiece.

- RMS—Root Mean Square value of the displacements—the general indicator of vibrations; however, it is strongly influenced by the mean value if it is non-zero.

- RMSAv—Root Mean Square value of the displacements but calculated for the signal after subtracting its mean value. This indicator is mathematically equivalent to the standard deviation of the observed displacements. It does not take into consideration the mean value. The advantage of this indicator is that it represents relative tool–workpiece vibrations (and not “static” displacement of the workpiece). Thus, it may be related to machined-surface quality.

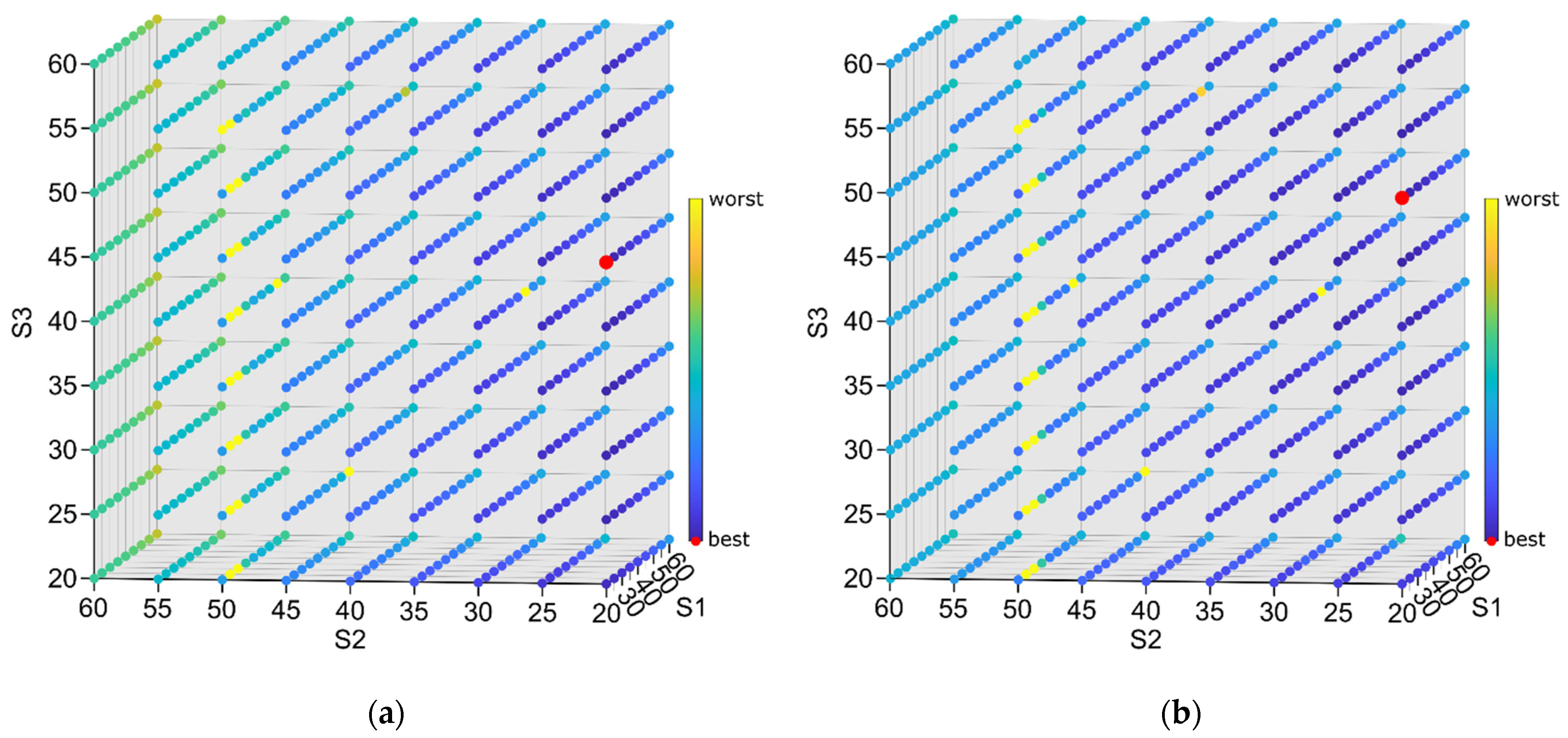

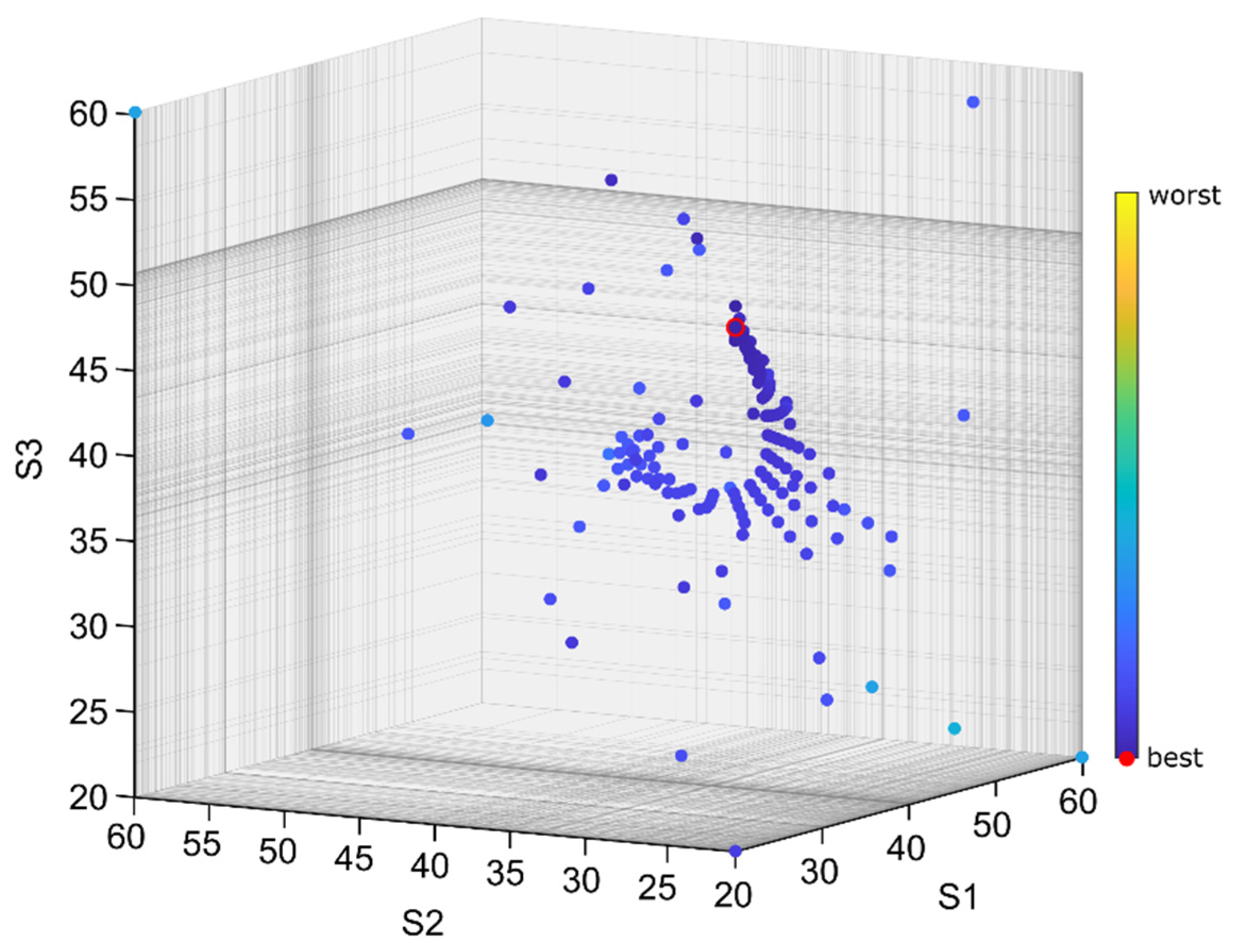

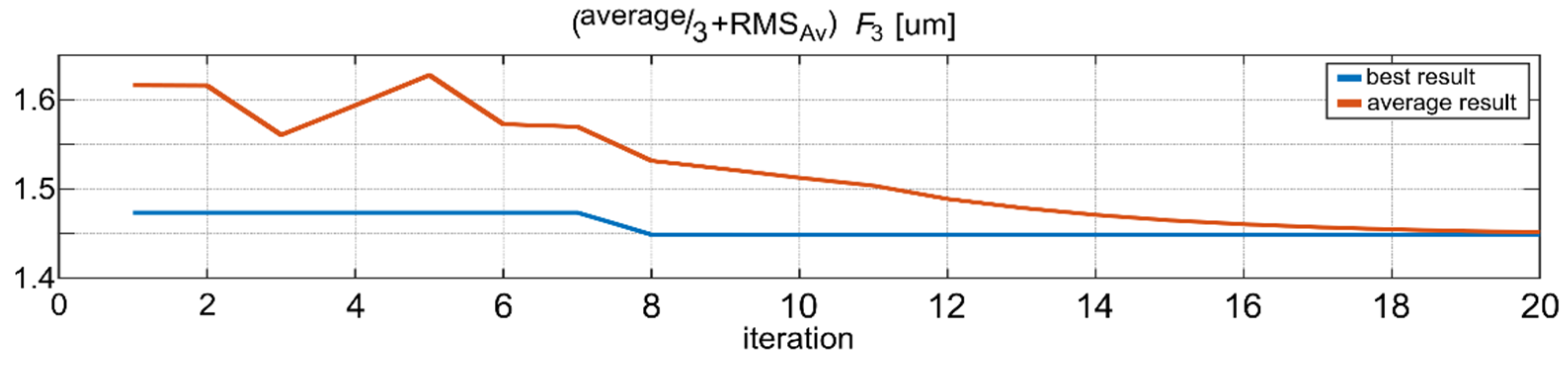

5.6. Search for the Best Set of Settings Using the Salp Swarm Algorithm

6. Results and Discussion

7. Conclusions

- Introducing adjustable stiffness supports for the workpiece may result in a reduction in vibration that occurs during the milling process. For example, the RMSAv value, which may represent relative tool–workpiece vibrations that influence machined-surface quality, was reduced by around 50%. However, efficient determination of the set of appropriate settings may be challenging, especially due to the need for performing a large number of time-consuming simulations. To overcome this issue, the salp swarm algorithm was applied.

- The salp swarm algorithm is a very efficient, fast-converging algorithm that deals very well with multidimensional problems having a complex search space. This is important for solving problems where the number of algorithm steps must be limited, for example, in cases when each step involves time-consuming calculations or simulations, which was the case presented in this paper.

- Application of the SSA algorithm leads to a significant time reduction needed for searching the space of decision variables, in terms of searching for the best combination of the stiffness coefficients for supports fastening a large-size workpiece on a milling machine. This makes the approach proposed in the paper attractive from the point of view of practical applications in manufacturing companies, where the problem of meeting the condition of minimizing the vibration level of the tool–workpiece has a significant technical importance (meeting the requirements for geometrical accuracy and quality of the processed surface) and economic importance (reduction in production time and required financial outlays).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quintana, G.; Ciurana, J. Chatter in machining processes: A review. Int. J. Mach. Tools Manuf. 2011, 51, 363–376. [Google Scholar] [CrossRef]

- Ajayan, M.; Nishad, P.N. Vibration control of 3D gantry crane with precise positioning in two dimensions. In Proceedings of the IEEE Emerging Research Areas: Magnetics, Machines and Drives (AICERA/iCMMD), Annual International Conference, Kottayam, India, 24–26 July 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F. Wear mechanisms in dry machining of aluminium alloys. Int. J. Mech. Prod. Syst. Eng. 2003, 4, 22–29. [Google Scholar]

- Huang, Y.; Hoshi, T. Optimization of fixture design with consideration of thermal deformation in face milling. J. Manuf. Syst. 2001, 19, 332–340. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Shanmugan, S.; Muthuramalingam, T.; Thakur, A.K.; Essa, F.A.; Ibrahim, A.M.M.; Mosleh, A.O. A comprehensive review on residual stresses in turning. Adv. Manuf. 2022, 10, 287–312. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Guo, J.; Huang, Y.; Ji, J.; Lee, K.-M. Temperature field sensing of a thin-wall component during machining: Numerical and experimental investigations. Int. J. Heat Mass Transf. 2018, 126, 935–945. [Google Scholar] [CrossRef]

- Uriarte, L.; Zatarain, M.; Axinte, D.; Yagüe-Fabra, J.; Ihlenfeldt, S.; Eguia, J.; Olarra, A. Machine tools for large parts. CIRP Ann.–-Manuf. Technol. 2013, 62, 731–750. [Google Scholar] [CrossRef]

- Munoa, J.; Beudaert, X.; Dombovari, Z.; Altintas, Y.; Budak, E.; Brecher, C.; Stepan, G. Chatter suppression techniques in metal cutting. CIRP Ann.–-Manuf. Technol. 2016, 65, 785–808. [Google Scholar] [CrossRef]

- Muhammad, B.B.; Wan, M.; Feng, J.; Zhang, W. Dynamic damping of machining vibration: A review. Int. J. Adv. Manuf. Technol. 2017, 89, 2935–2952. [Google Scholar] [CrossRef]

- Yue, C.; Gao, H.; Liu, X.; Liang, S.Y.; Wang, L. A review of chatter vibration research in milling. Chin. J. Aeronaut. 2019, 32, 215–242. [Google Scholar] [CrossRef]

- Ganguli, A.; Deraemaeker, A.; Preumont, A. Regenerative chatter reduction by active damping control. J. Sound Vib. 2007, 300, 847–862. [Google Scholar] [CrossRef][Green Version]

- Munoa, J.; Mancisidor, I.; Loix, N.; Uriarte, L.G.; Barcena, R.; Zatarain, M. Chatter suppression in ram type travelling column milling machines using a biaxial inertial actuator. CIRP Ann.–-Manuf. Technol. 2013, 62, 407–410. [Google Scholar] [CrossRef]

- Wan, S.; Li, X.; Su, W.; Yuan, J.; Hong, J.; Jin, X. Active damping of milling chatter vibration via a novel spindle system with an integrated electromagnetic actuator. Precis. Eng. 2019, 57, 203–210. [Google Scholar] [CrossRef]

- Wan, S.; Li, X.; Su, W.; Yuan, J.; Hong, J. Active chatter suppression for milling process with sliding mode control and electromagnetic actuator. Mech. Syst. Signal Process. 2020, 136, 106528. [Google Scholar] [CrossRef]

- Kleinwort, R.; Herb, J.; Kapfinger, P.; Sellemond, M.; Weiss, C.; Buschka, M.; Zaeh, M.F. Experimental comparison of different automatically tuned control strategies for active vibration control. CIRP J. Manuf. Sci. Technol. 2021, 35, 281–297. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, D.; Lu, Y.; Wang, F.; Liao, Z. A novel smart toolholder with embedded force sensors for milling operations. Mech. Syst. Signal Process. 2022, 175, 109130. [Google Scholar] [CrossRef]

- Kim, N.H.; Won, D.; Ziegert, J.C. Numerical analysis and parameter study of a mechanical damper for use in long slender endmills. Int. J. Mach. Tools Manuf. 2006, 46, 500–507. [Google Scholar] [CrossRef]

- Kasprowiak, M.; Parus, A.; Hoffmann, M. Vibration Suppression with Use of Input Shaping Control in Machining. Sensors 2022, 22, 2186. [Google Scholar] [CrossRef] [PubMed]

- Parus, A.; Powałka, B.; Marchelek, K.; Domek, S.; Hoffmann, M. Active vibration control in milling flexible workpieces. J. Vib. Control 2013, 19, 1103–1120. [Google Scholar] [CrossRef]

- Moradi, H.; Vossoughi, G.; Behzad, M.; Movahhedy, M.R. Vibration absorber design to suppress regenerative chatter in nonlinear milling process: Application for machining of cantilever plates. Appl. Math. Model. 2015, 39, 600–620. [Google Scholar] [CrossRef]

- Yang, Y.; Dai, W.; Liu, Q. Design and implementation of two-degree-of-freedom tuned mass damper in milling vibration mitigation. J. Sound Vib. 2015, 335, 78–88. [Google Scholar] [CrossRef]

- Pu, H.; Yuan, S.; Peng, Y.; Meng, K.; Zhao, J.; Xie, R.; Huang, Y.; Sun, Y.; Yang, Y.; Xie, S.; et al. Multi-layer electromagnetic spring with tunable negative stiffness for semi-active vibration isolation. Mech. Syst. Signal Process. 2019, 121, 942–960. [Google Scholar] [CrossRef]

- Sanz-Calle, M.; Dombovari, Z.; Munoa, J.; Iglesias, A.; López de Lacalle, L.N. Self-Tuning Algorithm for Tuneable Clamping Table for Chatter Suppression in Blade Recontouring. Appl. Sci. 2021, 11, 2569. [Google Scholar] [CrossRef]

- Sims, N.; Stanway, R.; Johnson, A. Vibration control using smart fluids: A state-of-the-art review. Shock Vib. Dig. 1999, 31, 195–203. [Google Scholar] [CrossRef]

- Altintas, Y.; Chan, P.K. In-process detection and suppression of chatter in milling. Int. J. Mach. Tools Manuf. 1992, 32, 329–347. [Google Scholar] [CrossRef]

- Soliman, E.; Ismail, F. Chatter suppression by adaptive speed modulation. Int. J. Mach. Tools Manuf. 1997, 37, 355–369. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Galewski, M. Chatter Vibration Surveillance by the Optimal-linear Spindle Speed Control. Mech. Syst. Signal Process. 2011, 25, 383–399. [Google Scholar] [CrossRef]

- Liao, Y.S.; Young, Y.C. A new on-line spindle speed regulation strategy for chatter control. Int. J. Mach. Tools Manuf. 1996, 35, 651–660. [Google Scholar] [CrossRef]

- Song, Q.; Ju, G.; Liu, Z.; Ai, X. Subdivision of chatter-free regions and optimal cutting parameters based on vibration frequencies for peripheral milling process. Int. J. Mech. Sci. 2014, 83, 172–183. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Galewski, M.A.; Mazur, M.R.; Morawska, N. A technique of experiment aided virtual prototyping to obtain the best spindle speed during face milling of large-size structures. Meccanica 2021, 56, 1–16. [Google Scholar] [CrossRef]

- Mazur, M.R.; Galewski, M.A.; Kaliński, K.J. Estimation of structural stiffness with the use of Particle Swarm Optimization. Lat. Am. J. Solids Struct. 2021, 18, 1–18. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Galewski, M.A.; Mazur, M.R.; Dziewanowski, L.F.; Morawska, N. A Method of Choosing an Optimal Clamp Torque for Fastening a Flexible Workpiece Mainly for a Face Milling Process. International Patent Application No. EP18460012, 12 November 2020. [Google Scholar]

- Kalinski, K.J.; Galewski, M.A. Optimal spindle speed determination for vibration reduction during ball-end milling of flexible details. Int. J. Mach. Tools Manuf. 2015, 92, 19–30. [Google Scholar] [CrossRef]

- Liu, H.; Wu, J.; Liu, K.; Kuang, K.; Luo, Q.; Liu, Z.; Wang, Y. Pretightening sequence planning of anchor bolts based on structure uniform deformation for large CNC machine tools. Int. J. Mach. Tools Manuf. 2019, 136, 1–18. [Google Scholar] [CrossRef]

- Li, G.; Du, S.; Huang, D.; Zhao, C.; Deng, Y. Elastic mechanics-based fixturing scheme optimization of variable stiffness structure workpieces for surface quality improvement. Precis. Eng. 2019, 56, 343–363. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Chodnicki, M.; Mazur, M.R.; Galewski, M.A. Vibration surveillance system with variable stiffness holder for flexible details milling. In Applied Non-Linear Dynamical Systems; Awrejcewicz, J., Ed.; Springer: Cham, Switzerland, 2014; Volume 93, pp. 175–184. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Galewski, M.A.; Mazur, M.; Chodnicki, M. Modelling and simulation of a new variable stiffness holder for milling of flexible details. Pol. Marit. Res. 2017, 24, 115–124. [Google Scholar] [CrossRef][Green Version]

- Kaliński, K.J.; Galewski, M.A.; Mazur, M.R.; Stawicka-Morawska, N. An Experimentally Aided Operational Virtual Prototyping to Obtain the Best Spindle Speed during Face Milling of Large-Size Structures. Materials 2021, 14, 6562. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Abualigah, L.; Elaziz, M.A.; Hussien, A.G.; Alsalibi, B.; Jalali, S.M.J.; Gandomi, A.H. Lightning search algorithm: A comprehensive survey. Appl. Intell. 2021, 51, 2353–2376. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, Australia, 27 November 1995; pp. 1942–1948. [Google Scholar]

- Goel, S. Pigeon optimization algorithm: A novel approach for solving optimization problems. In Proceedings of the 2014 International Conference on Data Mining and Intelligent Computing (ICDMIC), Delhi, India, 5 September 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Yang, X.-S.; Deb, S. Cuckoo search via levy flights. In Proceedings of the 2009 World Congress on Nature & Biologically Inspired Computing (naBIC), IEEE, Coimbatore, India, 9–11 December 2009; pp. 210–214. [Google Scholar]

- Dorigo, M.; Maniezzo, V.; Colorni, A. Ant System: Optimization by a Colony of Cooperating Agents. IEEE Trans. Syst. Man Cybern.–Part B 1996, 26, 29–41. [Google Scholar] [CrossRef]

- Saremi, S.; Mirjalili, S.; Lewis, A. Grasshopper optimization algorithm: Theory and application. Adv. Eng. Softw. 2017, 105, 30–47. [Google Scholar] [CrossRef]

- Karaboga, D. An Idea Based on Honey Bee Swarm for Numerical Optimization; Technical Report-tr06; Erciyes University, Engineering Faculty, Computer Engineering Department: Kayseri, Turkey, 2005. [Google Scholar]

- Yang, X.S. A New Metaheuristic Bat-Inspired Algorithm. In Nature Inspired Cooperative Strategies for Optimization (NISCO 2010); Studies in Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2010; Volume 284, pp. 65–74. [Google Scholar] [CrossRef]

- Mirjalili, A.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Li, L.X.; Shao, Z.J.; Qian, J.X. An Optimizing method based on autonomous animals: Fish-swarm algorithm. Syst. Eng.–-Theory Pract. 2002, 22, 32–38. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Alavi, A.H. Krill herd: A new bio-inspired optimization algorithm. Commun. Nonlinear Sci. Numer. Simul. 2012, 17, 4831–4845. [Google Scholar] [CrossRef]

- Abd Elaziz, M.; Elsheikh, A.H.; Oliva, D.; Abualigah, L.; Lu, S.; Ewees, A.A. Advanced Metaheuristic Techniques for Mechanical Design Problems: Review. Arch. Comput. Methods Eng. 2022, 29, 695–716. [Google Scholar] [CrossRef]

- Hossain, S.J.; Liao, T.W. Cutting Parameter Optimization for End Milling Operation Using Advanced Metaheuristic Algorithms. Int. J. Adv. Robot. Autom. Robot. 2017, 2, 1–12. [Google Scholar] [CrossRef]

- Nagarajan, V.; Solaiyappan, A.; Mahalingam, S.K.; Nagarajan, L.; Salunkhe, S.; Nasr, E.A.; Shanmugam, R.; Hussein, H.M.A.M. Meta-Heuristic Technique-Based Parametric Optimization for Electrochemical Machining of Monel 400 Alloys to Investigate the Material Removal Rate and the Sludge. Appl. Sci. 2022, 12, 2793. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Muthuramalingam, T.; Shanmugan, S.; Ibrahim, A.M.M.; Ramesh, B.; Khoshaim, A.B.; Moustafa, E.B.; Bedairi, B.; Panchal, H.; Sathyamurthy, R. Fine-tuned artificial intelligence model using pigeon optimizer for prediction of residual stresses during turning of Inconel 718. J. Mater. Res. Technol. 2021, 15, 3622–3634. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Elsheikh, A.H.; Moustafa, E.B.; Basha, M.; Mosleh, A.O. Prediction of residual stresses in turning of pure iron using artificial intelligence-based methods. J. Mater. Res. Technol. 2021, 11, 2181–2194. [Google Scholar] [CrossRef]

- Kaliński, K.J. A Surveillance of Dynamic Processes in Mechanical Systems; The GUT Publishing House: Gdańsk, Poland, 2012. (In Polish) [Google Scholar]

- Kalinski, K.J. The finite element method application to linear closed loop steady system vibration analysis. Int. J. Mech. Sci. 1997, 39, 315–330. [Google Scholar]

- Mazur, M.R.; Galewski, M.A.; Kaliński, K.J. FPGA Based Real Time Simulations of the Face Milling Process. IEEE Access 2020, 8, 215987–216002. [Google Scholar] [CrossRef]

- Settoul, S.; Zellagui, M.; Chenni, R. A New Optimization Algorithm for Optimal Wind Turbine Location Problem in Constantine City Electric Distribution Network Based Active Power Loss Reduction. J. Optim. Ind. Eng. 2021, 14, 13–22. [Google Scholar] [CrossRef]

- El Sehiemy, R.A.; Selim, F.; Bentouati, B.; Abido, M.A. A novel multi-objective hybrid particle swarm and salp optimization algorithm for technical-economical-environmental operation in power systems. Energy 2020, 193, 116817. [Google Scholar] [CrossRef]

- Montano, J.; Mejia, A.F.T.; Rosales Muñoz, A.A.; Andrade, F.; Garzon Rivera, O.D.; Palomeque, J.M. Salp Swarm Optimization Algorithm for Estimating the Parameters of Photovoltaic Panels Based on the Three-Diode Model. Electronics 2021, 10, 3123. [Google Scholar] [CrossRef]

- Tan, L.; Han, J.; Zhang, H. Ultra-Short-Term Wind Power Prediction by Salp Swarm Algorithm-Based Optimizing Extreme Learning Machine. IEEE Access 2020, 8, 44470–44484. [Google Scholar] [CrossRef]

- Yao, J.; Sha, Y.; Chen, Y.; Zhang, G.; Hu, X.; Bai, G.; Liu, J. IHSSAO: An Improved Hybrid Salp Swarm Algorithm and Aquila Optimizer for UAV Path Planning in Complex Terrain. Appl. Sci. 2022, 12, 5634. [Google Scholar] [CrossRef]

- Baygi, S.M.H.; Karsaz, A.; Elahi, A. A hybrid optimal PID-fuzzy control design for seismic exited structural system against earthquake: A salp swarm algorithm. In Proceedings of the 2018 6th Iranian Joint Congress on Fuzzy and Intelligent Systems (CFIS), Kerman, Iran, 28 February 2018; pp. 220–225. [Google Scholar] [CrossRef]

- Lu, H.; Iseley, T.; Matthews, J.; Liao, W.; Azimi, M. An ensemble model based on relevance vector machine and multi-objective salp swarm algorithm for predicting burst pressure of corroded pipelines. J. Pet. Sci. Eng. 2021, 203, 108585. [Google Scholar] [CrossRef]

- Faris, H.; Mirjalili, S.; Aljarah, I.; Mafarja, M.; Heidari, A.A. Salp Swarm Algorithm: Theory, Literature Review, and Application in Extreme Learning Machines. In Nature-Inspired Optimizers Theories, Literature Reviews and Applications; Mirjalili, S., Dong, J.S., Lewis, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 185–200. [Google Scholar] [CrossRef]

- Abualigah, L.; Shehab, M.; Alshinwan, M.; Alabool, H. Salp swarm algorithm: A comprehensive survey. Neural Comput. Appl. 2020, 32, 11195–11215. [Google Scholar] [CrossRef]

- Guyan, R.J. Reduction of stiffness and mass matrices. AIAA J. 1965, 3, 380. [Google Scholar] [CrossRef]

- Allemang, R.J. The Modal Assurance Criterion–Twenty Years of Use and Abuse. Sound Vib. 2003, 37, 14–23. [Google Scholar]

| Support Number | s [mm] | Linear Approximation Characteristics | ||||

|---|---|---|---|---|---|---|

| 20 | 30 | 40 | 50 | 60 | ||

| k [N/mm] | ||||||

| S1 | 15,515.24 | 13,353.17 | 10,492.44 | 7981.53 | 6218.45 | k = −239.65 s + 20298 |

| S2 | 14,678.93 | 12,685.56 | 9879.97 | 8113.67 | 6030.11 | k = −218.70 s + 19025 |

| S3 | 9669.46 | 8050.94 | 7064.00 | 5573.94 | 4683.09 | k = −124.50 s + 11988 |

| [Hz] | 185.0 | 211.3 | 242.4 | - | - | 435.7 | 585.0 | 631.2 |

| 184.6 | 211.4 | 242.2 | 295.5 | 434.3 | 434.4 | 571.5 | 630.2 |

| 0.96 | 0.05 | 0.08 | - | - | 0.01 | 0.09 | 0 | |

| 0.01 | 0.98 | 0.24 | - | - | 0 | 0.01 | 0.03 | |

| 0.08 | 0.18 | 0.95 | - | - | 0.03 | 0.05 | 0.01 | |

| 0.2 | 0 | 0 | - | - | 0 | 0.03 | 0 | |

| 0.13 | 0.08 | 0.03 | - | - | 0.01 | 0.18 | 0 | |

| 0.08 | 0 | 0 | - | - | 0.94 | 0.06 | 0.01 | |

| 0.05 | 0.03 | 0.03 | - | - | 0.05 | 0.87 | 0.01 | |

| 0 | 0.03 | 0 | - | - | 0.01 | 0.01 | 0.94 |

| 1. No. of Search Steps | 2. No. of Agents | 3. No. of Simulations | 4. No. of Passes | 5. Best Result [μm] | 6. Best Result Error [%] | 7. Worst Result Error [%] | 8. Average Error [%] | 9. Best Setting S1, S2, S3 [mm] |

|---|---|---|---|---|---|---|---|---|

| 3 non-adjustable supports | 1 | 1.62536 | ||||||

| Deterministic— 5 mm step | 729 | 1 | 1.44857 | 0.04 | 20.00, 20.00, 50.00 | |||

| Deterministic— 10 mm step | 125 | 1 | 1.44857 | 0.04 | 20.00, 20.00, 50.00 | |||

| 9 | 13 | 117 | 5 | 1.44835 | 0.02 | 4.21 | 2.03 | 20.00, 20.00, 45.83 |

| 13 | 9 | 117 | 5 | 1.44832 | 0.02 | 1.27 | 0.86 | 20.26, 20.03, 51.47 |

| 8 | 15 | 120 | 5 | 1.45544 | 0.51 | 3.64 | 1.56 | 22.81, 21.84, 48.12 |

| 15 | 8 | 120 | 5 | 1.45606 | 0.55 | 3.38 | 1.85 | 23.34, 22.85, 46.81 |

| 7 | 18 | 126 | 5 | 1.44851 | 0.03 | 5.07 | 2.16 | 20.00, 20.00, 45.67 |

| 18 | 7 | 126 | 5 | 1.45387 | 0.40 | 5.35 | 2.46 | 23.38, 20.48, 44.66 |

| 10 | 20 | 200 | 5 | 1.45900 | 0.76 | 1.46 | 1.00 | 23.34, 20.30, 38.82 |

| 20 | 10 | 200 | 5 | 1.44803 | 0.00 | 1.42 | 0.60 | 20.00, 20.00, 50.59 |

| Best | 1.44803 | 0.00 | 1.27 | 0.60 | 20.00, 20.00, 50.59 | |||

| Average | 1.45218 | 0.29 | 3.23 | 1.57 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaliński, K.J.; Galewski, M.A.; Stawicka-Morawska, N.; Mazur, M.; Parus, A. Adjusting the Stiffness of Supports during Milling of a Large-Size Workpiece Using the Salp Swarm Algorithm. Sensors 2022, 22, 5099. https://doi.org/10.3390/s22145099

Kaliński KJ, Galewski MA, Stawicka-Morawska N, Mazur M, Parus A. Adjusting the Stiffness of Supports during Milling of a Large-Size Workpiece Using the Salp Swarm Algorithm. Sensors. 2022; 22(14):5099. https://doi.org/10.3390/s22145099

Chicago/Turabian StyleKaliński, Krzysztof J., Marek A. Galewski, Natalia Stawicka-Morawska, Michał Mazur, and Arkadiusz Parus. 2022. "Adjusting the Stiffness of Supports during Milling of a Large-Size Workpiece Using the Salp Swarm Algorithm" Sensors 22, no. 14: 5099. https://doi.org/10.3390/s22145099

APA StyleKaliński, K. J., Galewski, M. A., Stawicka-Morawska, N., Mazur, M., & Parus, A. (2022). Adjusting the Stiffness of Supports during Milling of a Large-Size Workpiece Using the Salp Swarm Algorithm. Sensors, 22(14), 5099. https://doi.org/10.3390/s22145099