Vibration Suppression with Use of Input Shaping Control in Machining

Abstract

1. Introduction

2. Vibration Types Occurring during Machining

3. Preventing Vibrations—A Review

3.1. Passive Solutions

3.2. Active Vibration Control—AVC Module

3.3. Active Tool Holder for Optimal Tool Position Control

3.4. Chatter Control System

4. Control through Input Shaping Control (ISC)

- .

4.1. ZV

4.2. ZVD

4.3. ZVDD

4.4. ZVDDD

4.5. UMZV Algorithm

4.6. EI

4.7. SNA

4.8. MIS

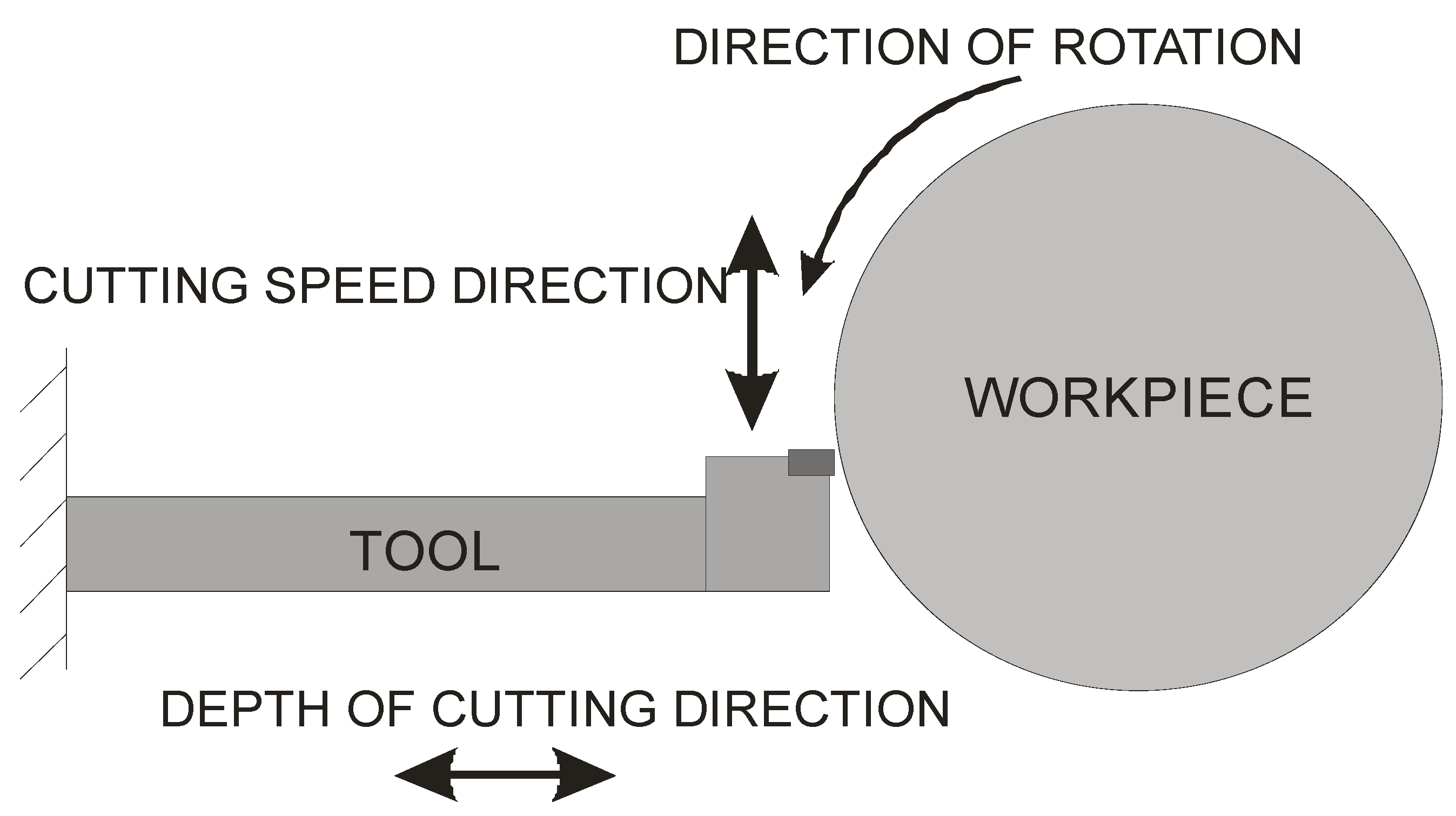

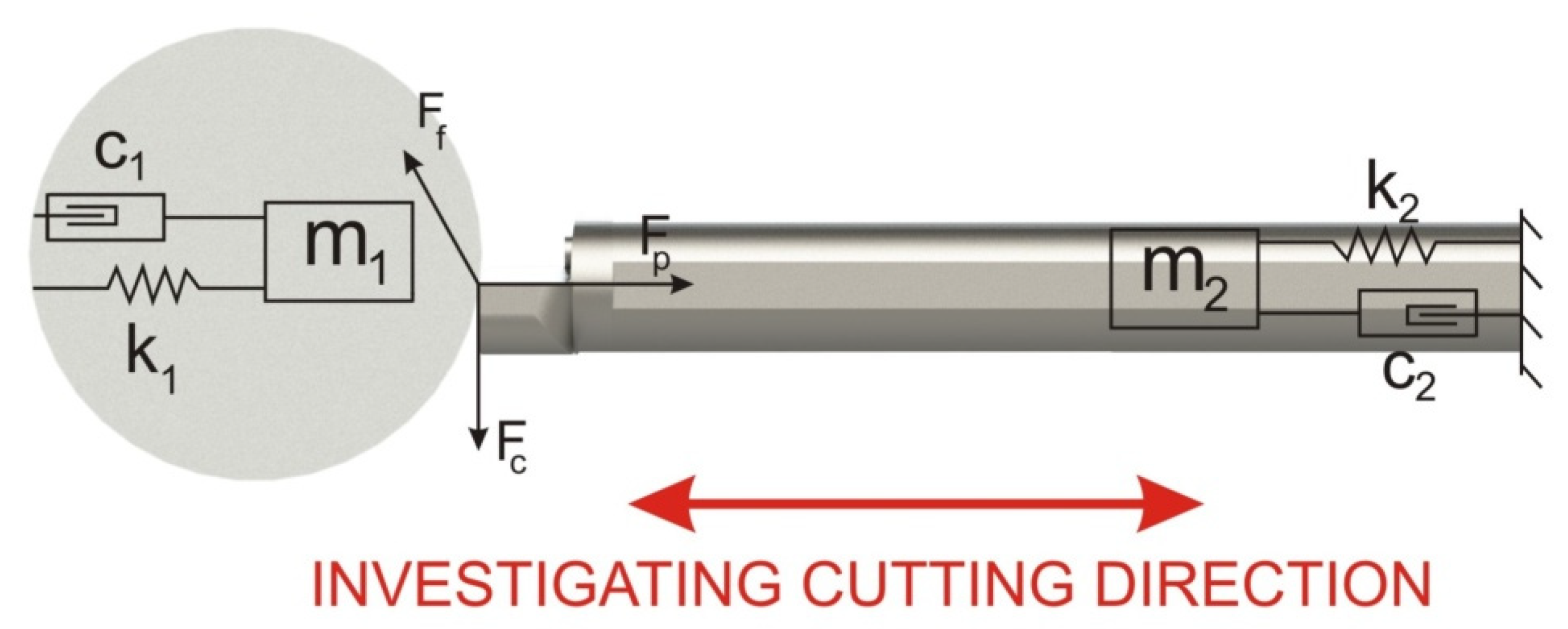

5. Modeling of the Machining Process with Implementation of ISC

5.1. Mathematical Model

5.2. Simulation Model

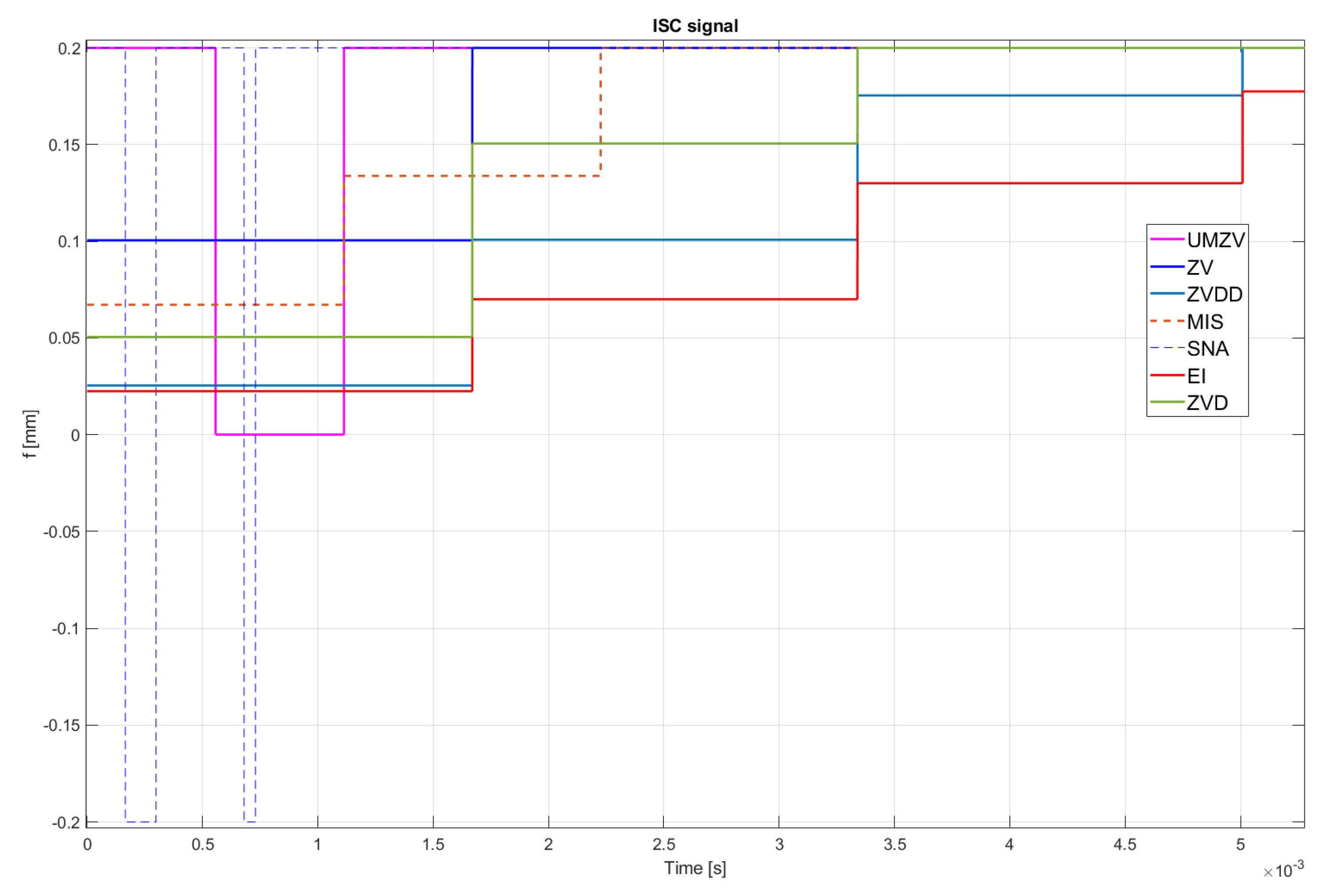

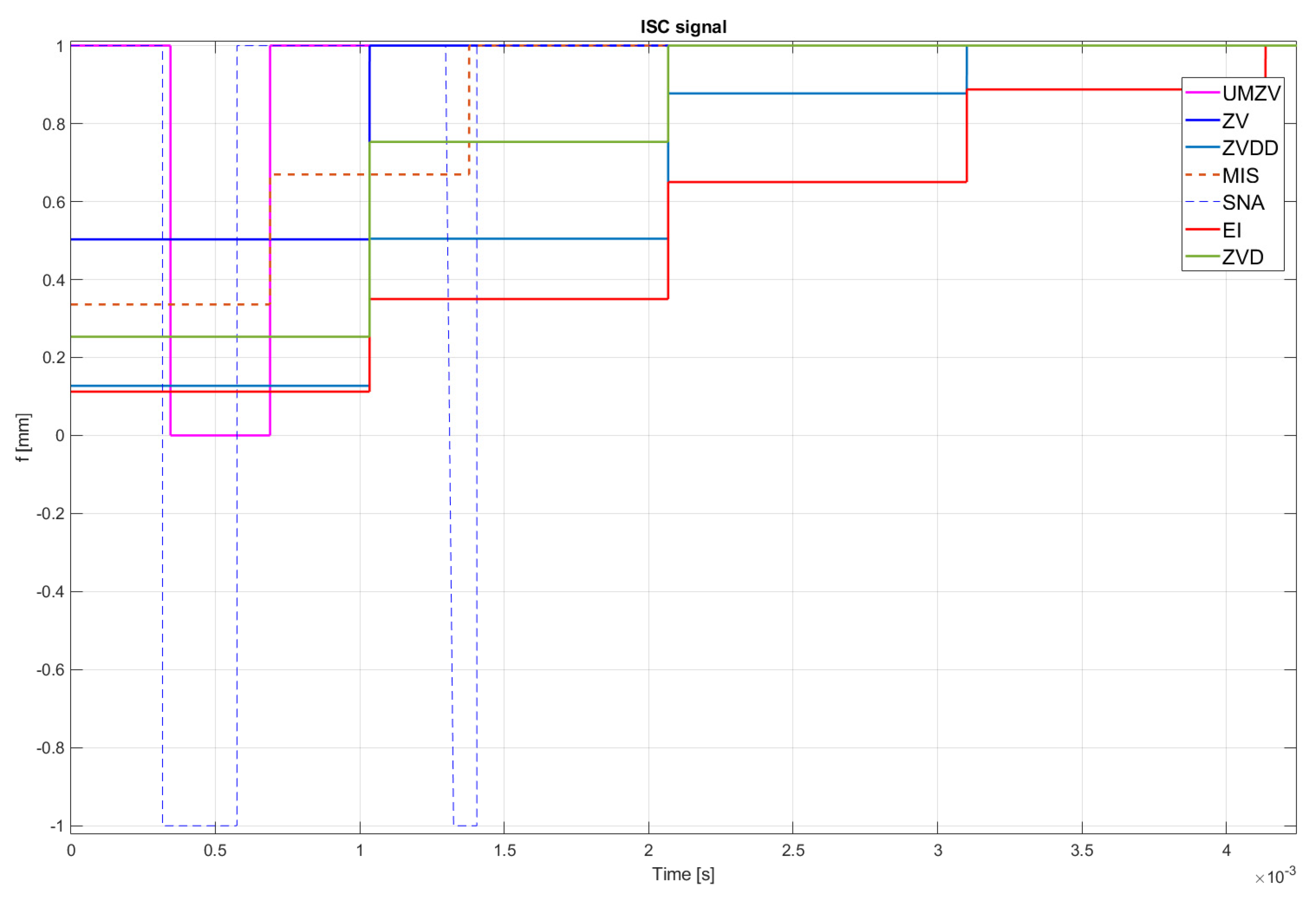

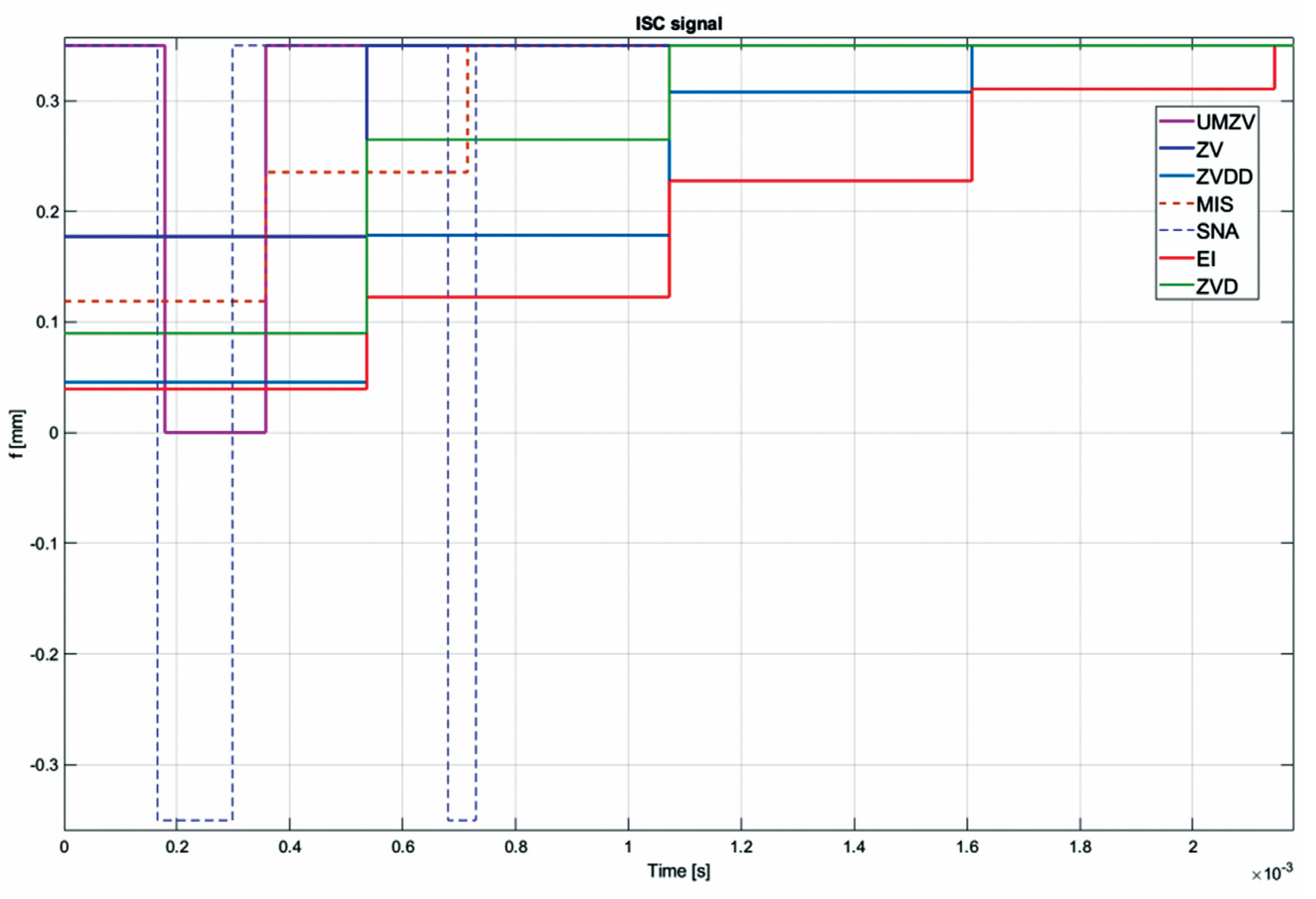

6. ISC Filter Design

- -

- -

- -

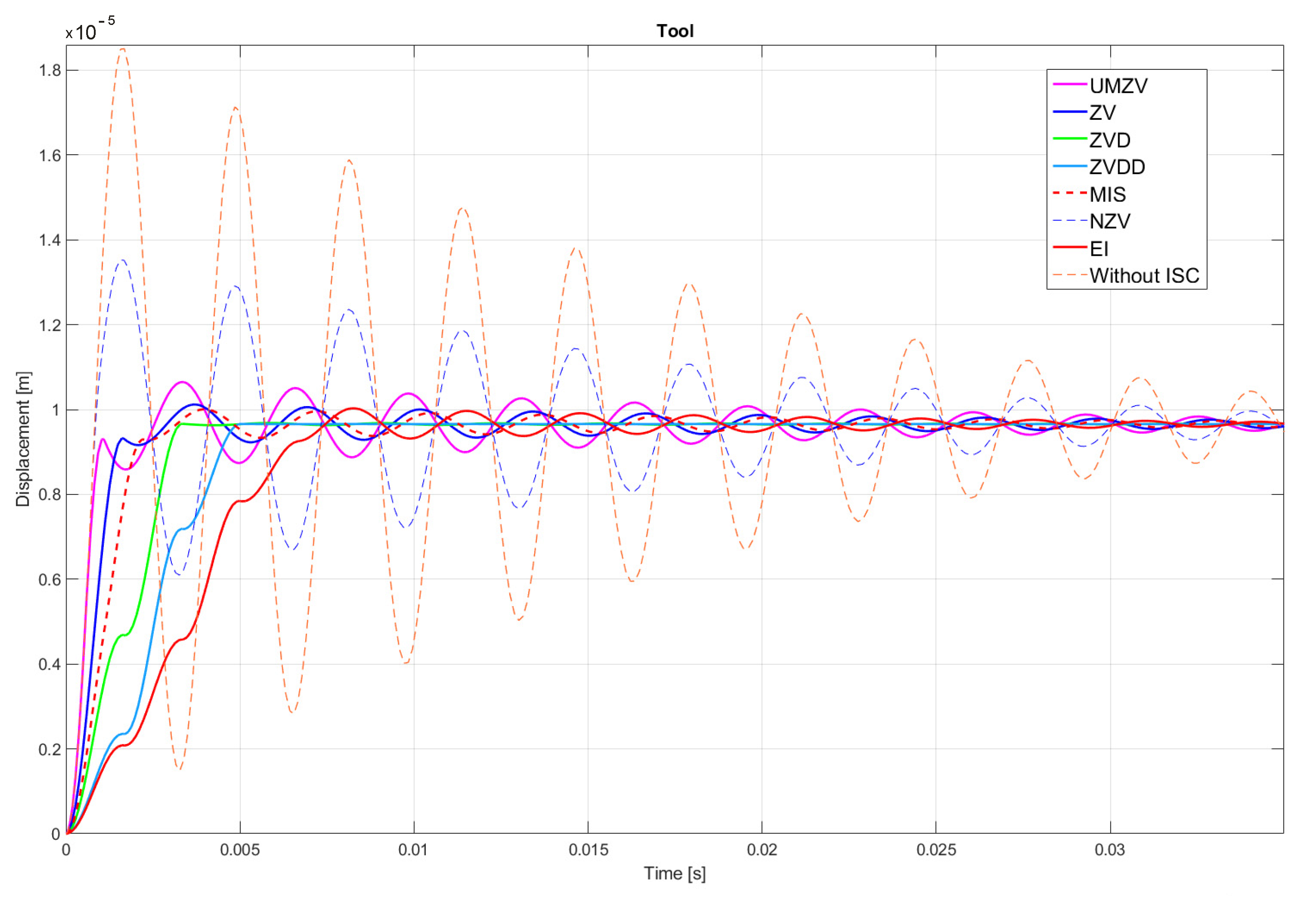

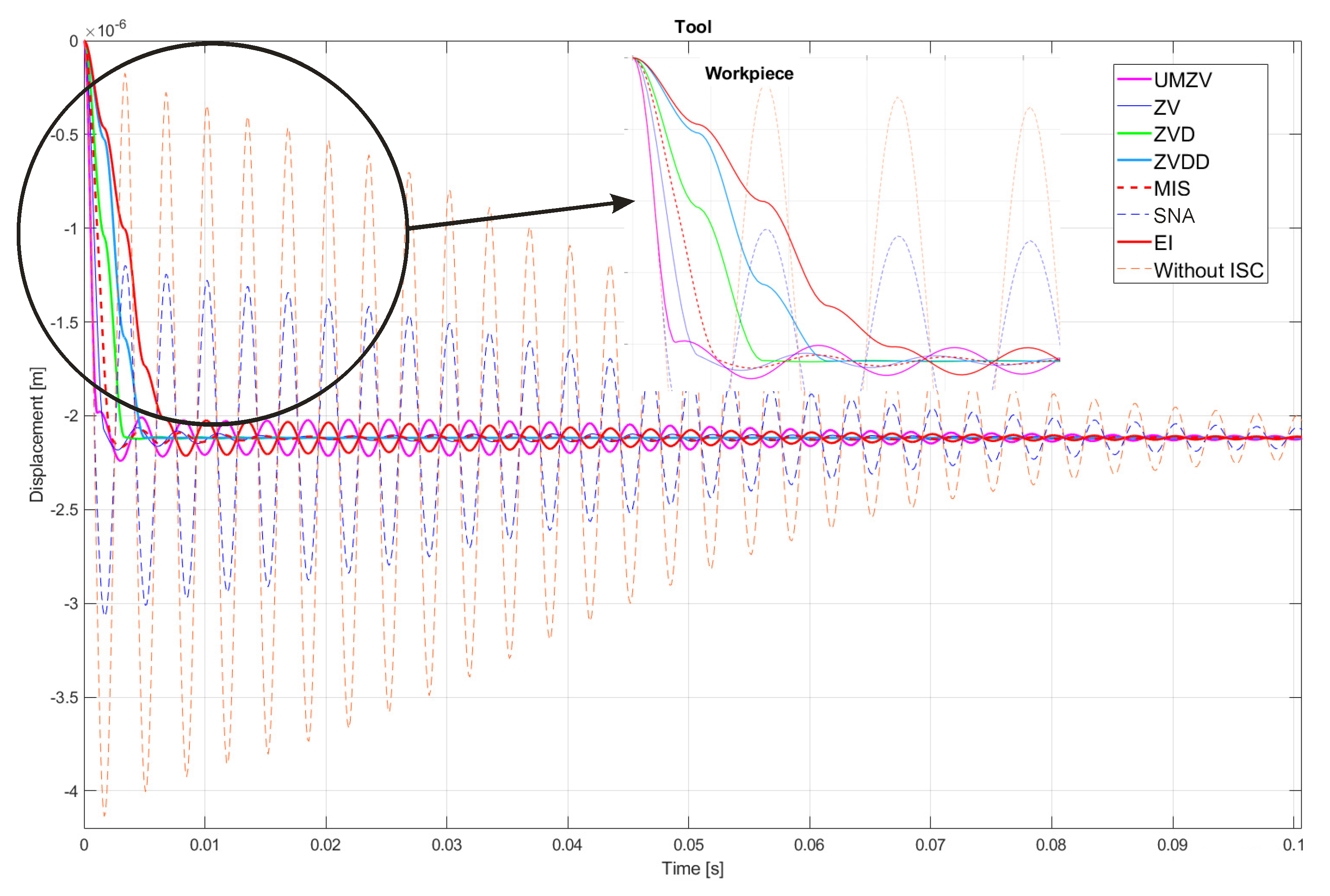

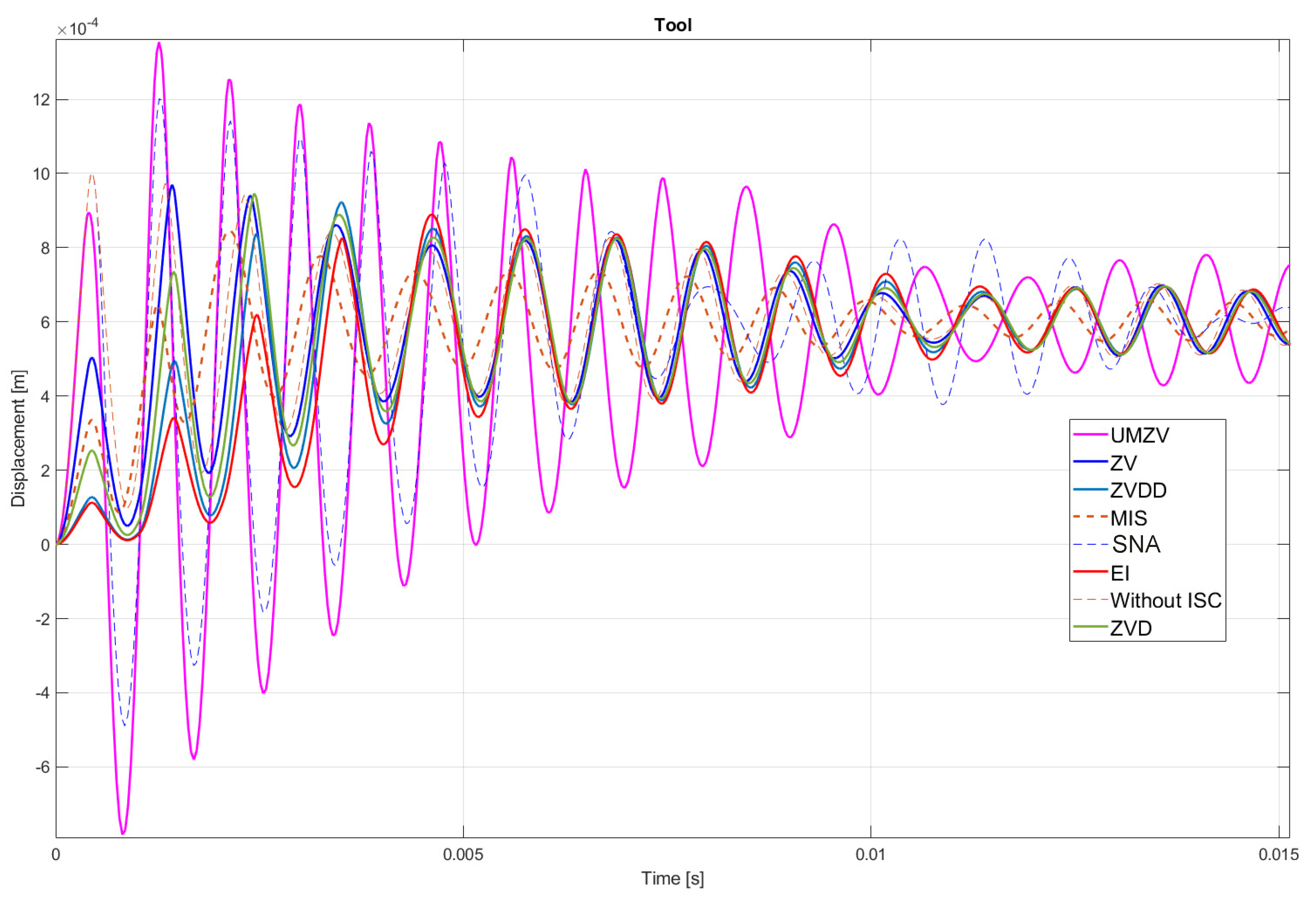

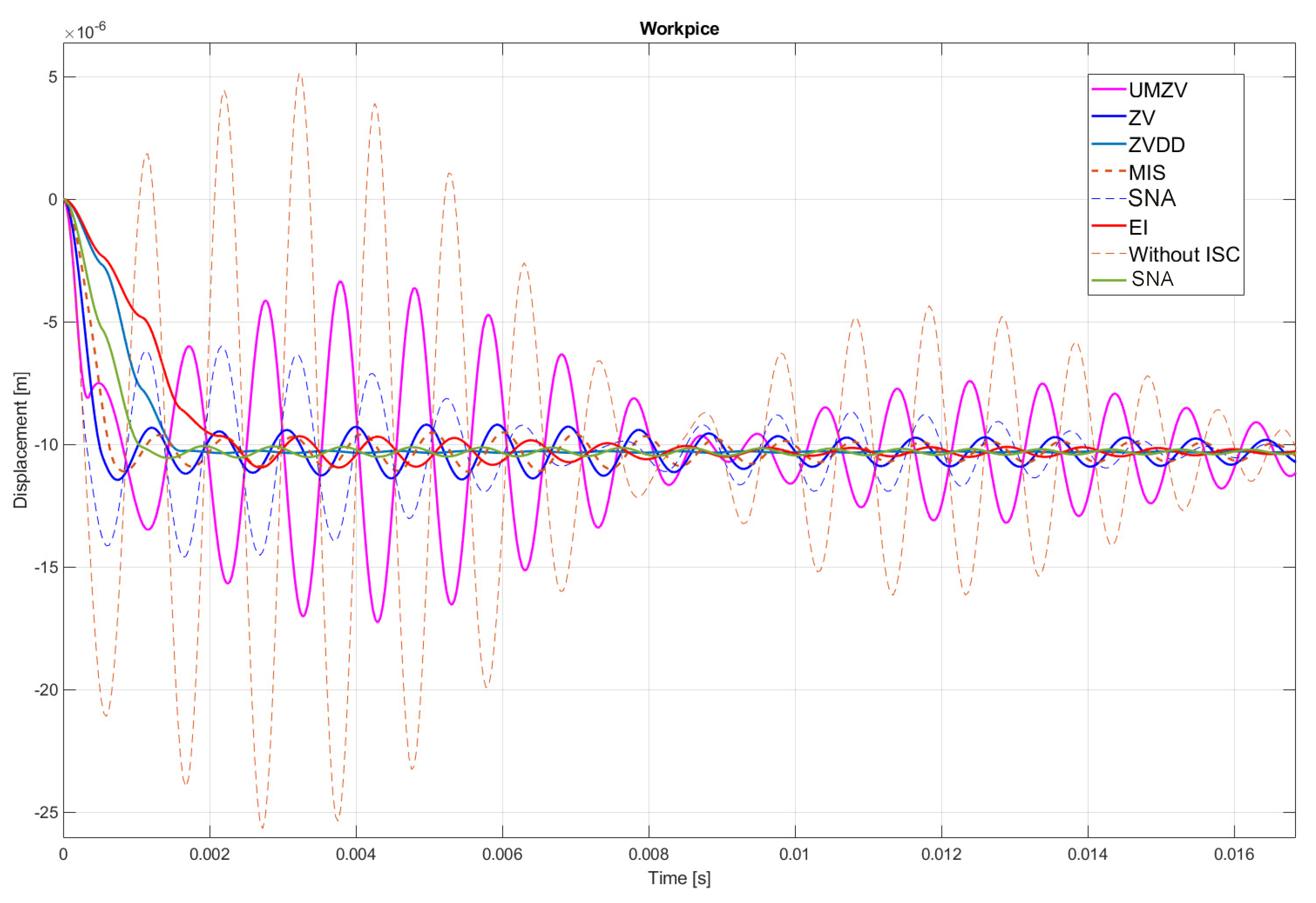

7. Results of the Simulation

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| ISC | Input Shaping Control |

| CNC | Computerized Numerical Control |

| PID | Proportional Integral Derivative |

| AVC | Active Vibration Control |

| ZV | Zero Vibration |

| CSVS | Component Synthesis Vibration Suppression |

| ZVD | Zero Vibration-Derivative |

| ZVDD | Zero Vibration-Derivative-Derivative |

| ZVDDD | Zero Vibration-Derivative-Derivative-Derivative |

| UMZV | Unity magnitude zero vibration |

| EI | Extra Intensive |

| SNA | Specified negative amplitude |

| MIS | Modified Input-Shaping |

References

- Wiesław, O. Obróbka Skrawaniem; Wydawnictwo Naukowo-Techniczne: Warsaw, Poland, 2008; ISBN 978-83-204-3389-0. [Google Scholar]

- Kaliski, S.; Solarz, L.; Dżygadło, Z. Drgania i Fale w Ciałach Stałych; Państwowe Wydawnictwo Naukowe: Warsaw, Poland, 1966. [Google Scholar]

- Parus, A.; Marchelek, K.; Domek, S.; Hoffmann, M. Podniesienie wibrostabilności w procesie skrawania z zastosowaniem eliminatora piezoelektrycznego. Modelowanie Inżynierskie 2010, 39, 159–170. [Google Scholar]

- Pettersson, L. Vibrations in Metal Cutting; Blekinge Institute of Technology, Department of Telecommunications and Signal Processing: Karlskrona, Sweden, 2002; 102p. [Google Scholar]

- Tewani, S.G.; Rouch, K.E.; Walcott, B.L. A study of cutting process stability of a boring bar with active dynamic absorber. Int. J. Mach. Tools Manuf. 1995, 35, 91–108. [Google Scholar] [CrossRef]

- Gniadek, M. Interaction of input shaping and cascade controller for DC drive control. Pozn. Univ. Technol. Acad. J. Electr. Eng. 2015, 83, 113–118. [Google Scholar]

- Singhose, W.E.; Singer, N.C.; Seering, W.P. Design and Implementation of Time-Optimal Negative Input Shapers; Convolve, Inc.: Armonk, NY, USA, 1994. [Google Scholar]

- Parus, A.; Hoffmann, M.; Okulik, T. Suppression of the Work-Piece Vibrations in Milling Using Active Clamp System. In Vibration Problems ICOVP 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 455–461. [Google Scholar] [CrossRef]

- Jasiewicz, M.; Miądlicki, K. Implementation of an Algorithm to Prevent Chatter Vibration in a CNC System. Materials 2019, 12, 3193. [Google Scholar] [CrossRef]

- Ast, A.; Braun, S.; Eberhard, P.; Heisel, U. An adaptronic approach to active vibration control of machine tools with parallel kinematics. Prod. Eng. Res. Devel. 2009, 3, 207–215. [Google Scholar] [CrossRef]

- Sandvik Coromant. Silent Tools-Application Guide, Katalog Produktów Silent Tools; Sandvik Coromant: Sandviken, Sweden, 2012. [Google Scholar]

- Conker, Ç.; Yavuz, H.; Kapucu, S.; Baltacioglu, M.; Arat, H.; Burgaç, A. Comparison of Robust Input Shapers for Elimination of Residual Vibrations. Appl. Mech. Mater. 2014, 490–491, 997. [Google Scholar] [CrossRef]

- Rahman, N.U.; Alam, M.N. Active vibration control of a piezoelectric beam using PID controller: Experimental study. Lat. Am. J. Solids Struct. 2012, 9, 657–673. [Google Scholar] [CrossRef]

- Nosouhi, R.; Behbahani, S. Chatter active control in a lathe machine using magnetostrictive actuator. AIP Conf. Proc. 2011, 1315, 1011–1016. [Google Scholar] [CrossRef]

- Hansen, C.; Snyder, S.; Qiu, X.; Brooks, L.; Moreau, D. Active Control of Noise and Vibration, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; Volume 2, ISBN 978-1-4665-6339-1. [Google Scholar]

- Preumont, A. Mechatronics: Dynamics of Electromechanical and Piezoelectric Systems. In Solid Mechanics and Its Applications; Springer: Dordrecht, The Netherlands, 2006; ISBN 978-1-4020-4695-7. [Google Scholar]

- Nestler, A.; Schubert, A. Surface Properties in Ultrasonic Vibration Assisted Turning of Particle Reinforced Aluminium Matrix Composites. Procedia CIRP 2014, 13, 125–130. [Google Scholar] [CrossRef]

- Dahbi, S.; El Moussami, H.; Ezzine, L. Optimization of turning parameters for surface roughness. In Proceedings of the Xème Conférence Internationale: Conception et Production Intégrées, Tanger, Morocco, 2–4 December 2015. [Google Scholar]

- Pettersson, L.; Håkansson, L.; Claesson, I.; Olsson, S. Active Control of Machine-Tool Vibration in a CNC Lathe Based on an Active Tool Holder Shank with Embedded Piezo Ceramic Actuators. In Proceedings of the 8th International Congress on Sound and Vibration, Hong Kong, China, 2–6 July 2001. [Google Scholar]

- Lagö, T.; Olsson, S.; Håkansson, L.; Claesson, I. Performance of a Chatter Control System for Turning and Boring Applications. In Proceedings of the 4th GRACM Congress on Computational Mechanics, GRACM2002, Patras, Greece, 27–29 June 2002. [Google Scholar]

- Feucht, F.; Ketelaer, J.; Wolff, A.; Mori, M.; Fujishima, M. Latest Machining Technologies of Hard-to-cut Materials by Ultrasonic Machine Tool. Procedia CIRP 2014, 14, 148–152. [Google Scholar] [CrossRef][Green Version]

- Park, G.; Bement, M.T.; Hartman, D.A.; Smith, R.E.; Farrar, C.R. The use of active materials for machining processes: A review. Int. J. Mach. Tools Manuf. 2007, 47, 2189–2206. [Google Scholar] [CrossRef]

- Singer, N.; Singhose, W.; Seering, W. Comparison of Filtering Methods for Reducing Residual Vibration. Eur. J. Control. 1999, 5, 208–218. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Galewski, M.A. Modified Method of Vibration Surveillance with a Use of the Optimal Control at Energy Performance Index. Mech. Syst. Signal Process. 2015, 58–59, 41–52. [Google Scholar] [CrossRef]

- Dunaj, P.; Powałka, B.; Berczyński, S.; Chodźko, M.; Okulik, T. Increasing lathe machining stability by using a composite steel–polymer concrete frame. CIRP J. Manuf. Sci. Technol. 2020, 31, 1–13. [Google Scholar] [CrossRef]

- Lim, T.-S.; Lee, C.-M.; Kim, S.-W.; Lee, D.-W. Evaluation of cutter orientations in 5-axis high speed milling of turbine blade. J. Mater. Process. Technol. 2002, 130–131, 401–406. [Google Scholar] [CrossRef]

- Arolovich, I.; Agranovich, G. Control Improvement of Under-Damped Systems and Structures by Input Shaping; Ariel University of Samaria: Ariel, Israel, 2014. [Google Scholar]

- Singer, N. Residual Vibration Reduction in Computer Controlled Machines; MIT Library: Cambridge, MA, USA, 2004. [Google Scholar]

- Huey, J.R. The Intelligent Combination of Input Shaping and PID Feedback Control. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, August 2006. [Google Scholar]

- Robertson, M.J.; Singhose, W.E. Robust analytic deflection-limiting commands. In Proceedings of the 2006 American Control Conference, Minneapolis, MN, USA, 14–16 June 2006; 6p. [Google Scholar] [CrossRef]

- Singhose, W.; Seering, W.; Singer, N. Residual Vibration Reduction Using Vector Diagrams to Generate Shaped Inputs. J. Mech. Des. 1994, 116, 654–659. [Google Scholar] [CrossRef]

- Al Hamidi, Y.; Rakotondrabe, M. Comparison study of input shaping techniques to control an underactuated flexible link system. In Sensors for Next-Generation Robotics III, Proceedings of the SPIE Commercial + Scientific Sensing and Imaging, Baltimore, MD, USA, 16–24 April 2016; Popa, D., Wijesundara, M.B.J., Eds.; SPIE: Bellingham, WA, USA, 2016; Volume 985909. [Google Scholar]

- Singhose, W.E.; Seering, W.; Singer, M. Input Shaping for Vibration Reduction with Specified Insensitivity to Modeling Errors. In Proceedings of the Japan-USA Symposium on Flexible Automation, Boston, MA, USA, 7–10 July 1996; Volume 1. [Google Scholar]

- Singhose, W.E.; Biediger, E.; Chen, Y.-H.; Mills, B.W. Reference Command Shaping Using Specified-Negative-Amplitude Input Shapers for Vibration Reduction. J. Dyn. Syst. Meas. Control. Trans. ASME 2004, 126, 210–214. [Google Scholar] [CrossRef][Green Version]

- Singhose, W.E.; Mills, B.W. Command generation using specified-negative-amplitude input shapers. In Proceedings of the American Control Conference, San Diego, CA, USA, 2–4 June 1999; Volume 1. [Google Scholar] [CrossRef]

- Shan, J.; Liu, H.-T.; Sun, D. Modified input shaping for a rotating single-link flexible manipulator. J. Sound Vib. 2005, 285, 187–207. [Google Scholar] [CrossRef]

- Vaughan, J.; Yano, A.; Singhose, W. Comparison of robust input shapers. J. Sound Vib. 2008, 315, 797–815. [Google Scholar] [CrossRef]

- Kaliński, K.J.; Galewski, M.A.; Mazur, M.; Chodnicki, M. Modelling and Simulation of a New Variable Stiffness Holder for Milling of Flexible Details. Pol. Marit. Res. 2017, 24, 115–124. [Google Scholar] [CrossRef][Green Version]

- Singh, T.; Singhose, W. Tutorial on Input Shaping/Time Delay Control of Maneuvering Flexible Structures. In Optimal Reference Shaping in Dynamical Systems, Theory and Applications; CRC Press: Boca Raton, FL, USA; 16p.

- Liu, W.D.; Ao, S.S.; Li, Y.; Zhao, C.F.; Luo, Z.; Li, Q.; Luo, T. Elimination of the over cut from a repaired turbine blade tip post-machined by electrochemical machining. J. Mater. Process. Technol. 2016, 231, 27–37. [Google Scholar] [CrossRef]

- Soori, M.; Asmael, M.; Khan, A.; Farouk, N. Minimization of surface roughness in 5-axis milling of turbine blades. Mech. Based Des. Struct. Mach. 2021, 49, 1–18. [Google Scholar] [CrossRef]

- Vavruska, P.; Sulitka, M.; Stejskal, M.; Simunek, A.; Falta, J.; Heinrich, P.; Kopal, M. Machining of thin blade using vibration prediction and continuous spindle speed control. MM Sci. J. 2019, 2019, 3330–3337. [Google Scholar] [CrossRef]

- Poyraz, Ö.; Yandı, N. Fixture design methodologies for high precision turbine blades. In Proceedings of the International Asian Congress on Contemporary Sciences V, Nakhchivan, Azerbaijan, 1–2 June 2021. [Google Scholar]

- Sanz-Calle, M.; Dombovari, Z.; Munoa, J.; Iglesias, A.; López de Lacalle, L.N. Self-Tuning Algorithm for Tuneable Clamping Table for Chatter Suppression in Blade Recontouring. Appl. Sci. 2021, 11, 2569. [Google Scholar] [CrossRef]

- Kahya, M.; Ozbayoglu, M.; Unver, H.O. Precision and energy-efficient ball-end milling of Ti6Al4V turbine blades using particle swarm optimization. Int. J. Comput. Integr. Manuf. 2021, 34, 110–133. [Google Scholar] [CrossRef]

- Bracewell, R. The Fourier Transform and lts Applications; Optics Communications; McGraw-Hill: New York, NY, USA, 1999; Volume 413, No.2, pp. 141–146. [Google Scholar]

- Bayindir, C.A. A tomographic approach for the early detection of 2D rogue waves. TWMS J. Appl. Eng. Math. 2020, 10, 638–649. [Google Scholar]

- Bayındır, C. Rogue Wave spectra of the Kundu-Eckhaus equation. Phys. Rev. E 2016, 93, 062215. [Google Scholar] [CrossRef]

- Ali, S.T.; Antoine, J.P.; Gazwau, J.P. Coherent States, Wavelets and Their Generalizations. Phys. Lett. A 2016, 380, 156–161. [Google Scholar]

- Bayindir, C. Efficient Measurement of the Vibrational Rogue Waves by Compressive Sampling Based Wavelet Analysis. In Advances in Rotor Dynamics, Control, and Structural Health Monitoring; Dutta, S., Inan, E., Dwivedy, S.K., van den Berg, J.C., Eds.; Wavelets in Physics; Springer: Singapore, 2020; pp. 327–336. ISBN 978-981-15-5692-0. [Google Scholar] [CrossRef]

- Harada, M.; Munemasa, A. Some restrictions on weight enumerators of singly even self-dual codes. IEEE Trans. Inf. Theory 2006, 52, 489–509. [Google Scholar] [CrossRef]

- Candès, E.J.; Wakin, M.B. An introduction to compressive sampling. IEEE Signal Process. Mag. 2008, 25, 21–30. [Google Scholar] [CrossRef]

| ZV | [37] |

| |

| ZVD | [37] |

| |

| ZVDD | [37] [37] [37] |

| |

| ZVDDD | [27,28] |

| |

| UMZV | [29,30] |

| |

| EI | [30,31,32,33] [30,31,32,33] where: [30,31,32,33] [30,31,32,33] |

| |

| SNA | [34,35] [34,35] [34,35] |

| |

| MIS | [29,32,36] [29,32,36] [9,32,36] |

|

| Tool weight | = 0.2 kg |

| Tool stiffness | N/m |

| Tool damping | = 70 kg/s |

| Work piece weight | = 3 kg |

| Work piece stiffness | N/m |

| Work piece damping | = 290 kg/s |

| Spindle speed | n = 800 rmp |

| The width of the cutting layer | = 0.5 mm |

| Feedspeed | f = 0.2 mm/r |

| Algorithm | A | t |

|---|---|---|

| UMZV | ||

| ZV | ||

| ZVD | ||

| ZVDD | ||

| MIS | ||

| SNA | ||

| EI |

| Spindle speed | n = 800 rmp |

| Width of the cutting layer | = 4 mm |

| Feed speed | f = 1 mm/r |

| Spindle speed | n = 800 rmp |

| Width of the cutting layer | = 3 mm |

| Feedspeed | f = 0.35 mm/r |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasprowiak, M.; Parus, A.; Hoffmann, M. Vibration Suppression with Use of Input Shaping Control in Machining. Sensors 2022, 22, 2186. https://doi.org/10.3390/s22062186

Kasprowiak M, Parus A, Hoffmann M. Vibration Suppression with Use of Input Shaping Control in Machining. Sensors. 2022; 22(6):2186. https://doi.org/10.3390/s22062186

Chicago/Turabian StyleKasprowiak, Mateusz, Arkadiusz Parus, and Marcin Hoffmann. 2022. "Vibration Suppression with Use of Input Shaping Control in Machining" Sensors 22, no. 6: 2186. https://doi.org/10.3390/s22062186

APA StyleKasprowiak, M., Parus, A., & Hoffmann, M. (2022). Vibration Suppression with Use of Input Shaping Control in Machining. Sensors, 22(6), 2186. https://doi.org/10.3390/s22062186