System Identification and Nonlinear Model Predictive Control with Collision Avoidance Applied in Hexacopters UAVs

Abstract

:1. Introduction

1.1. Motivation

1.2. Related Work

- Ground mobile robots: where Sani et al. presented nonlinear model predictive control (NMPC) to solve the competitive games between ground robots [42], another work undertaken developed by Subramanian et al. increased the ability to avoid dynamic obstacles [43], and finally, a leader–follower structure control using NMPC through visual information to mobile robots was presented by Ribeiro et al. [44].

- Robotic arms and manipulation: In the last year, this field of research has been the focus of many studies due to the complexity of the systems and the scalability of the NMPC structure. The work of Osman et al. presented a task-space controller based on (NMPC) to control a mobile manipulator 10 (DOF) [45].

- Aerial mobile robots: this field has also been the subject of a large number of studies due to the high use of aerial vehicles in real-world applications, some applications of which were studies Neunert et al., who developed an unconstrained nonlinear predictive model for generation and tracking trajectories for the AscTec Firefly hexacopter [46]; Aoki et al., who presented an NMPC for position and attitude control applied in a hexacopter without three of the six motor configurations [47]; and finally, the contribution of Tzoumanikas et al., a letter which presented the NMPC designed for micro aerial vehicles (MAVs) equipped with a robotic arm [48].

1.3. Main Contributions of This Work

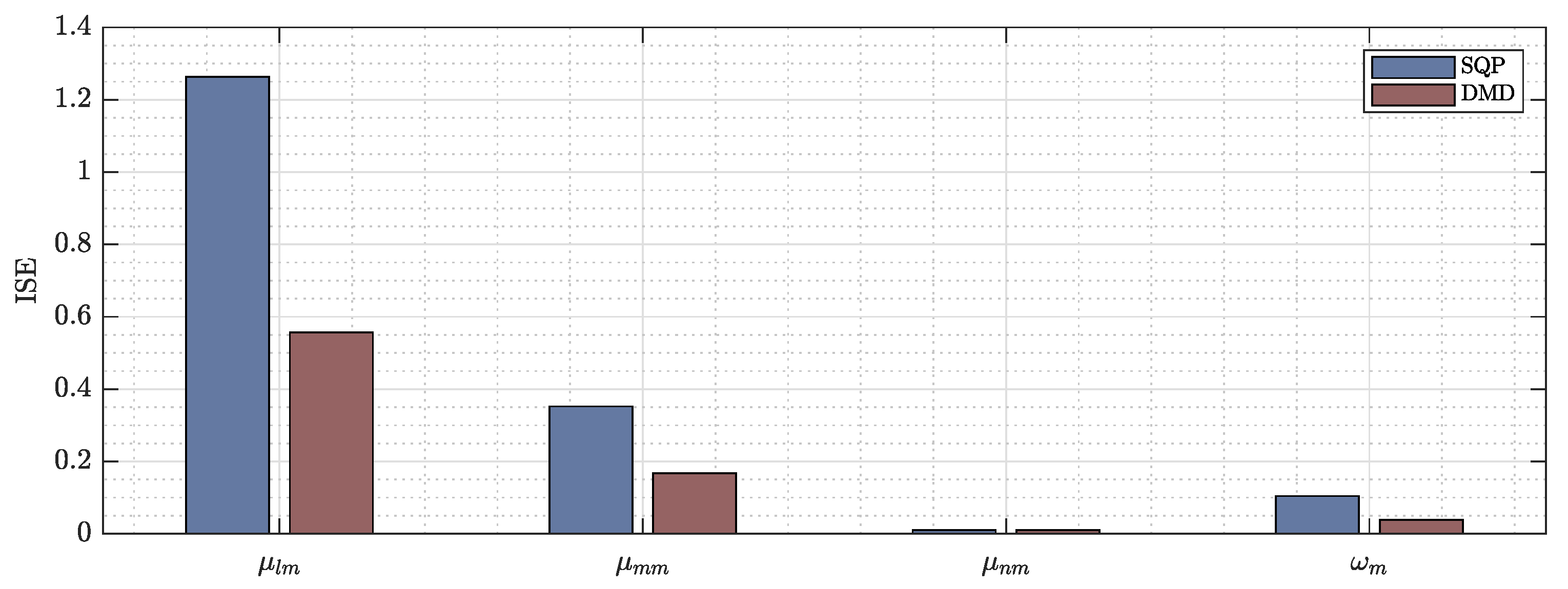

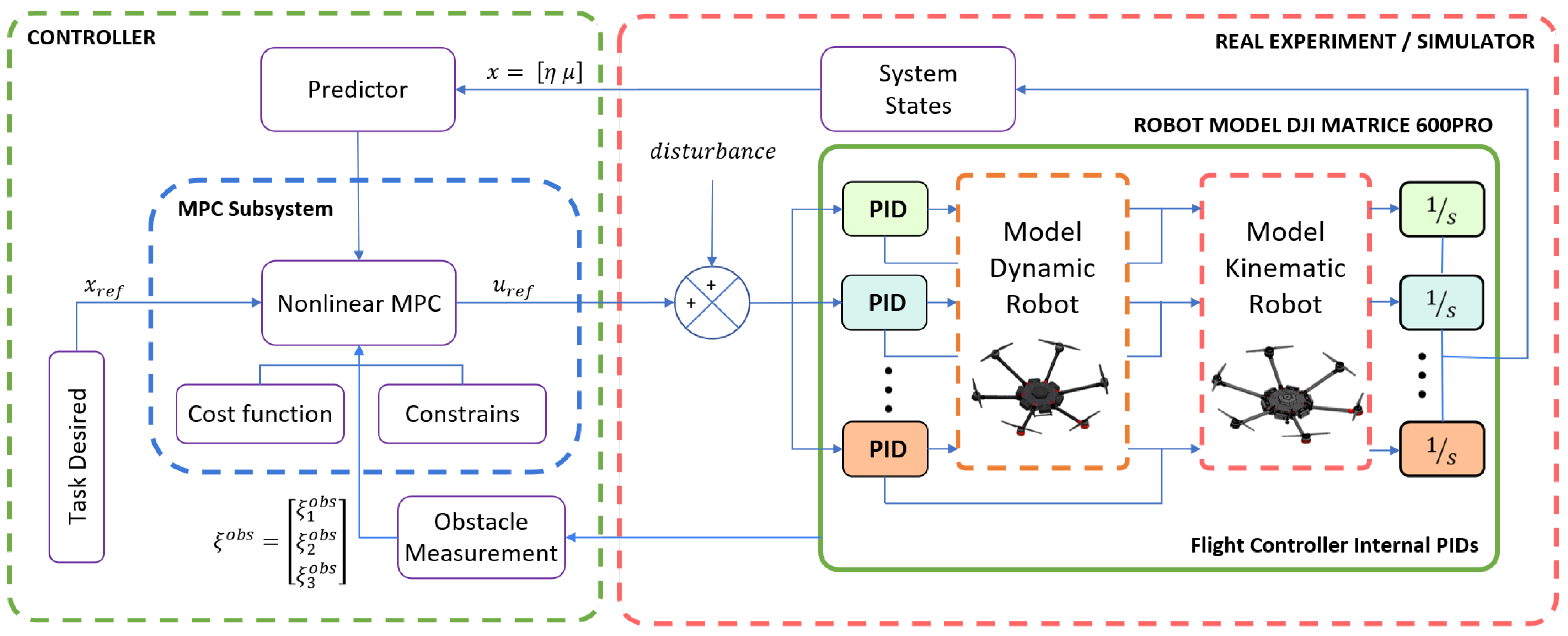

- System dynamics: a large number of research platforms cannot be controlled through torque commands; as such, this work developed a reduced dynamic model of the hexacopter using general control velocities, which is possible with the incorporation of low-level PID schemes in mathematical representation. The PIDs guarantee the required velocities generated by the high-level controllers. The mathematical representation was developed through an Euler–Lagrange formulation and the data-driven technique known as dynamic mode decomposition (DMDc). Both approaches were identified using experimental data from the (DJI MATRICE 600 PRO); furthermore, this work presents accuracy comparative results between both techniques and selects the best formulation to build the controller scheme.

- NMPC formulation: this includes the differential kinematics and the reduced dynamic representation; furthermore, due to the ability of the NMPC controller, the system constraints can be included in the optimization problem. The constraints included in this work are: control action limits, control rate of change, and the system dynamics and static and dynamic obstacles. The nonlinear optimization problem was solved using CasADI framework and the problem was transformed into a nonlinear programming problem (NLP) form using the direct multiple-shooting method. The CasADI optimization toolkit guarantees a fast convergence with the possibility of extending the solution to onboard hardware implementation.

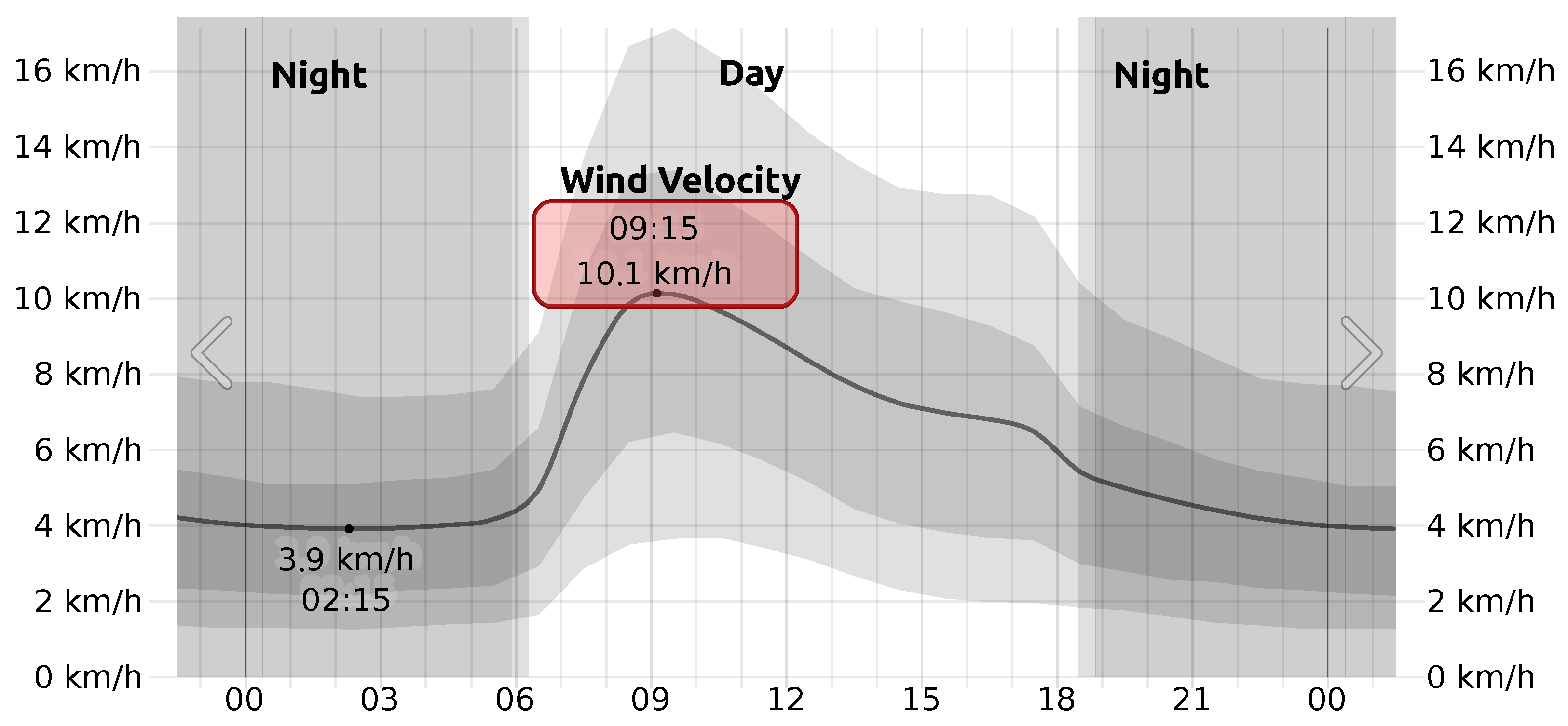

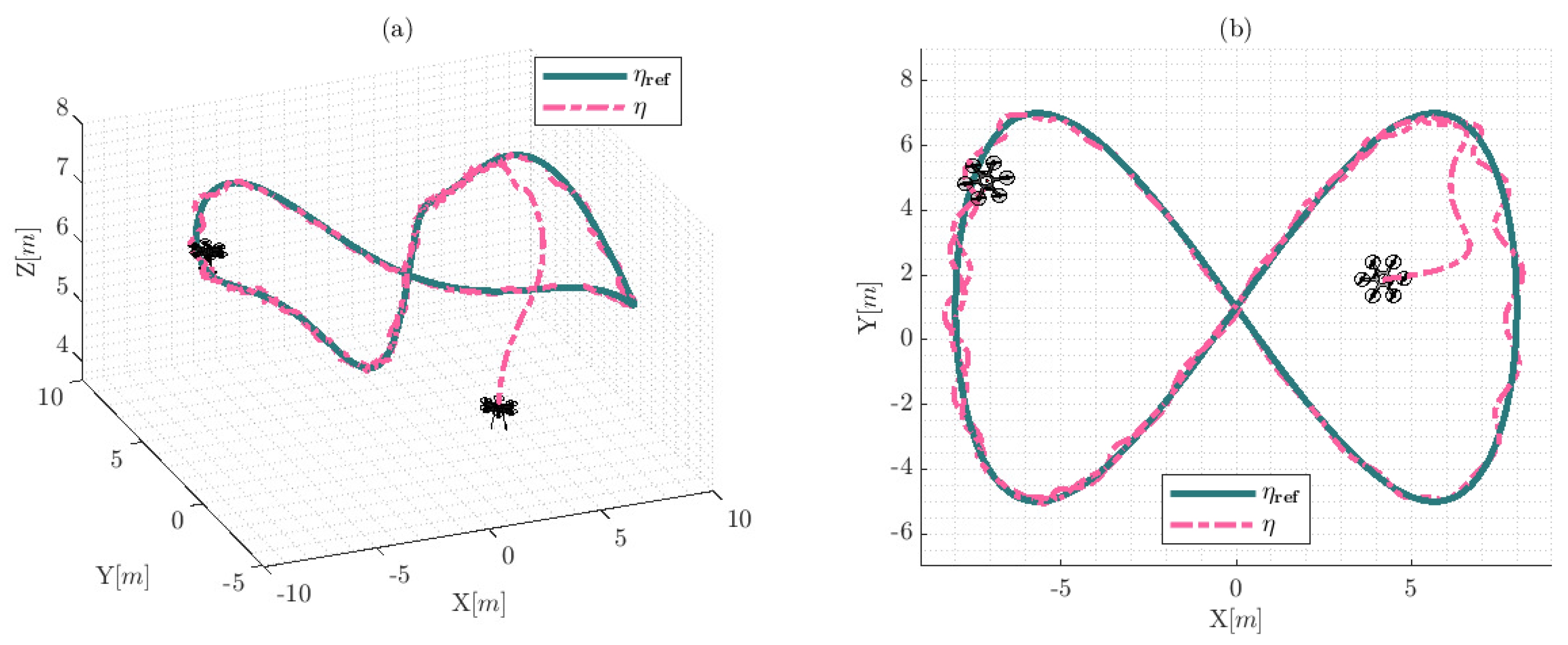

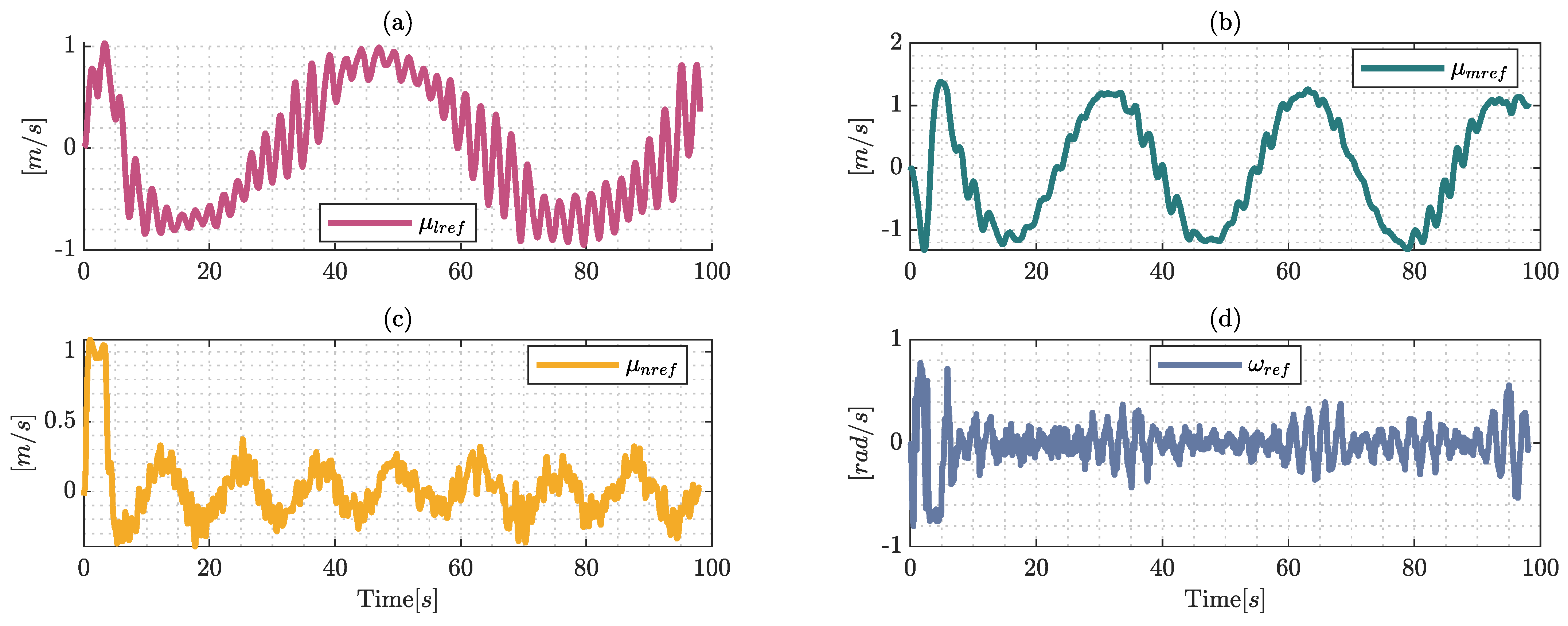

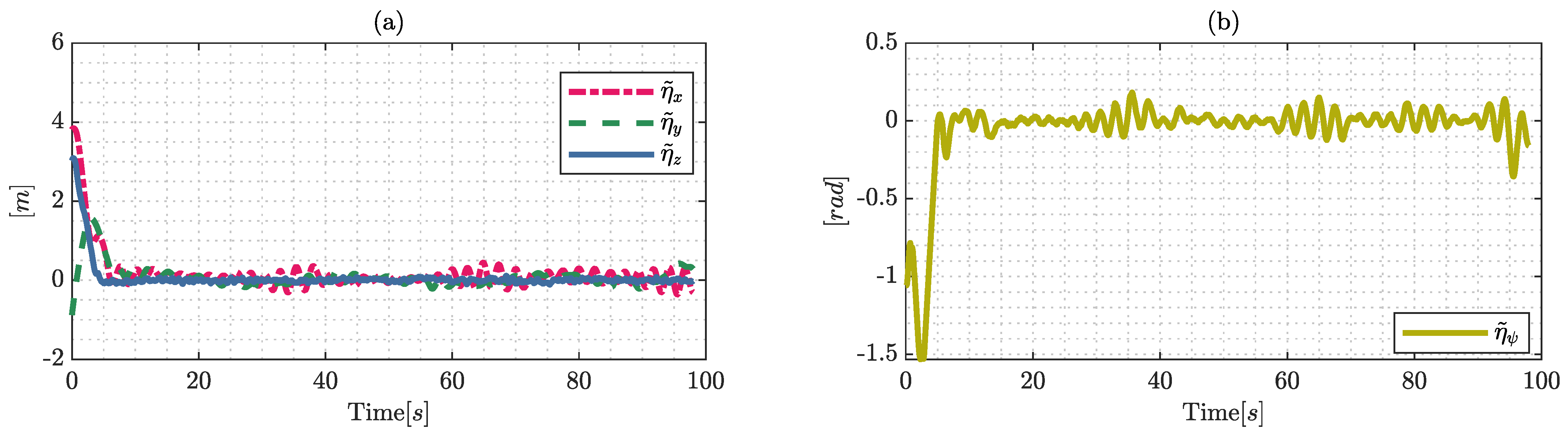

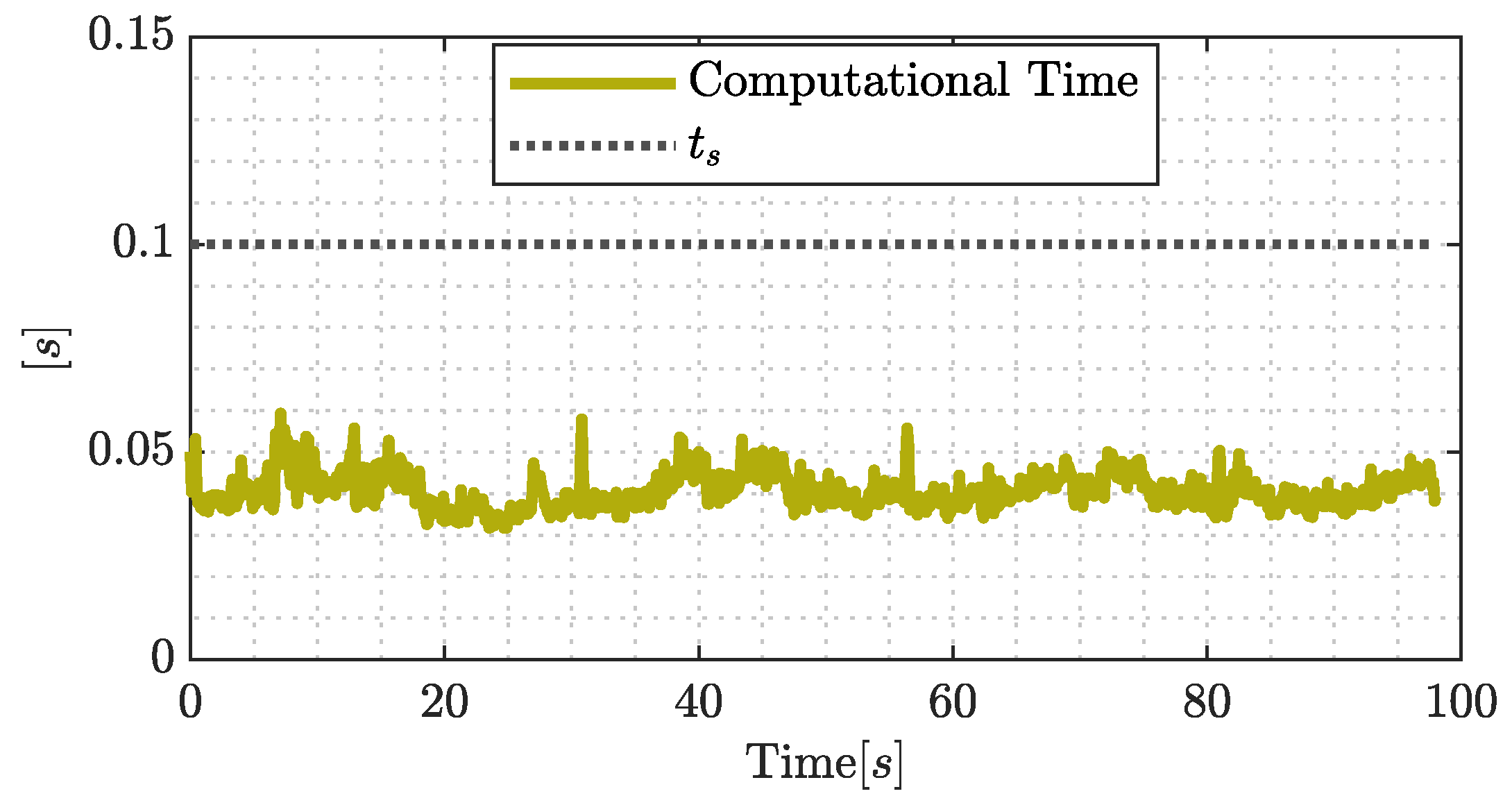

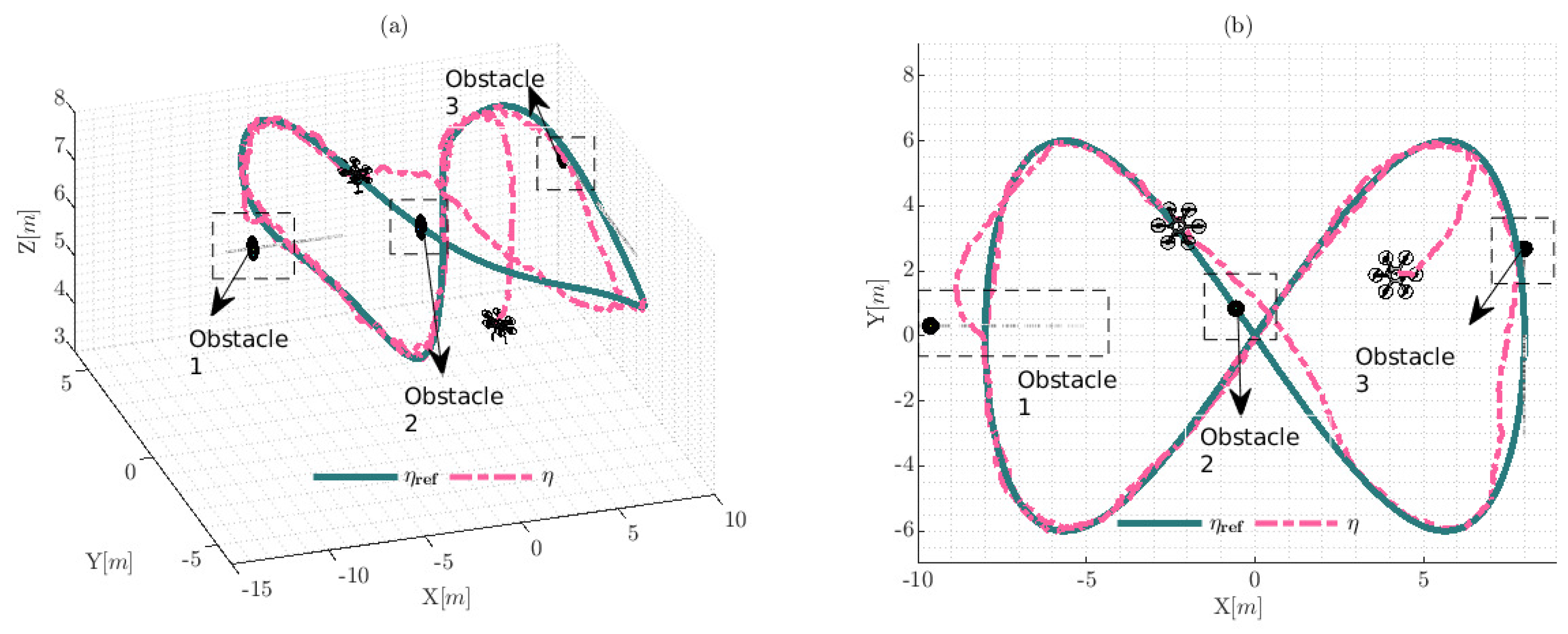

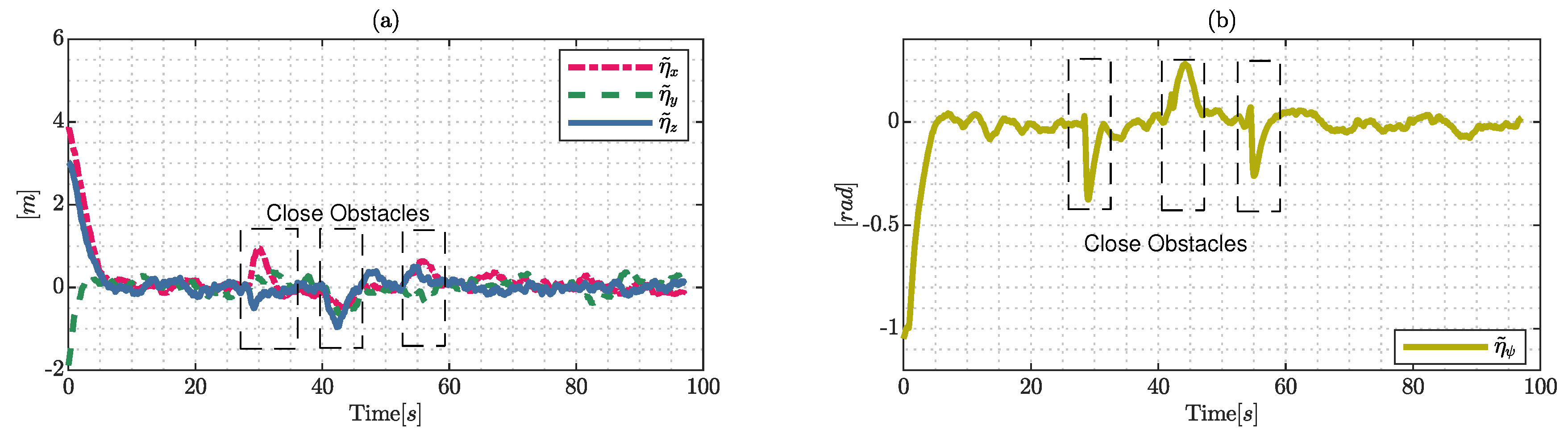

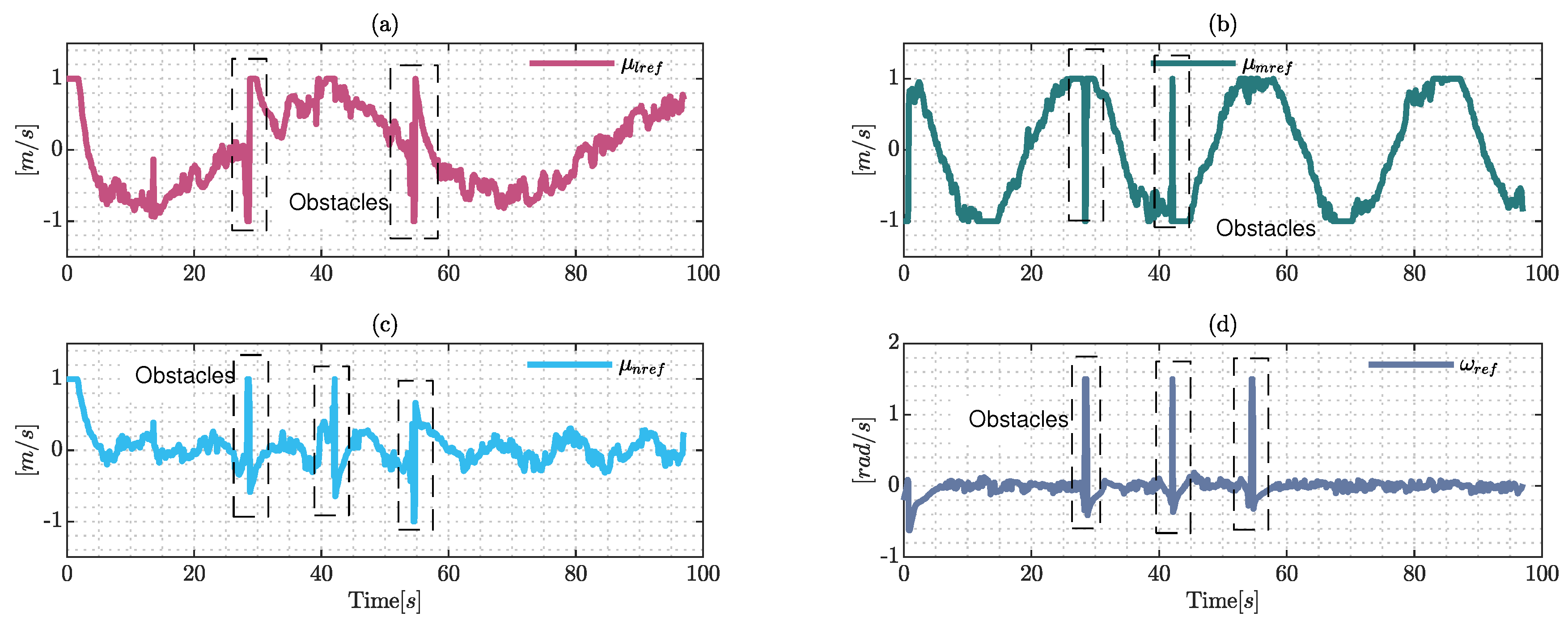

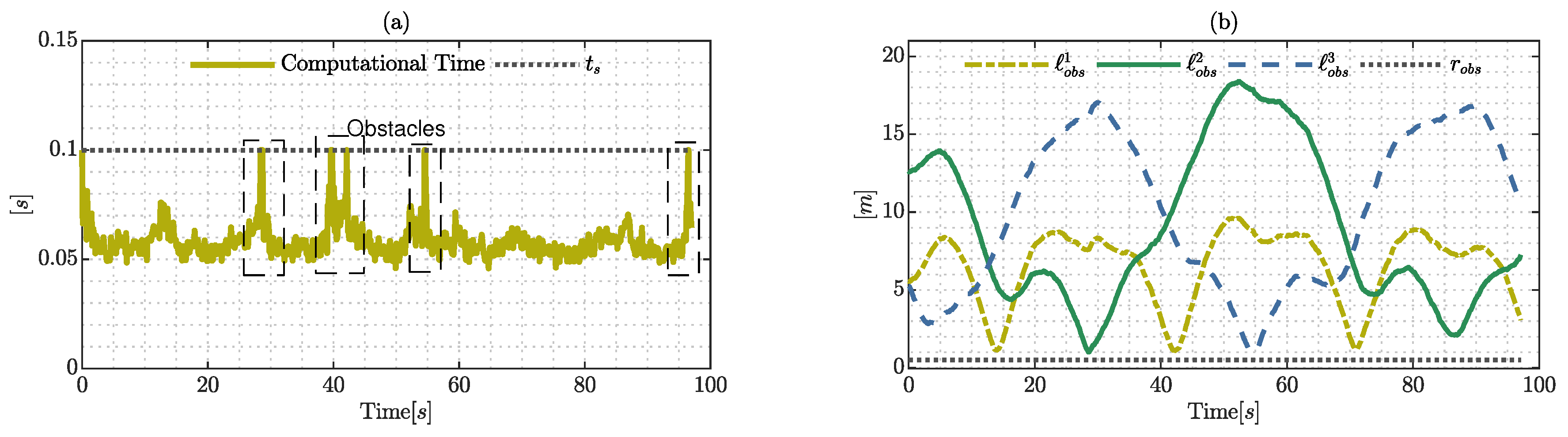

- Results: the experiments were conducted in real-world outdoor environments, where the system has a model mismatch and external disturbance product by air flows and delay in system communications. The experiments were developed through the hexacopter platform (DJI MATRICE 600 PRO) where multiple reference trajectories were selected in order to verify the performance of the controller. The metrics used in the experiments are the following: tracking accuracy, computational time and disturbance rejection. Additionally, the simulation results show the scalability in simulated high dynamic environments, considering the identified dynamics and obstacles; these results will be used as a start point in future research due to the fact that the hexacopter aerial platform does not have any sensor to measure obstacles during the experiments.

1.4. Outline

2. Materials and Methods

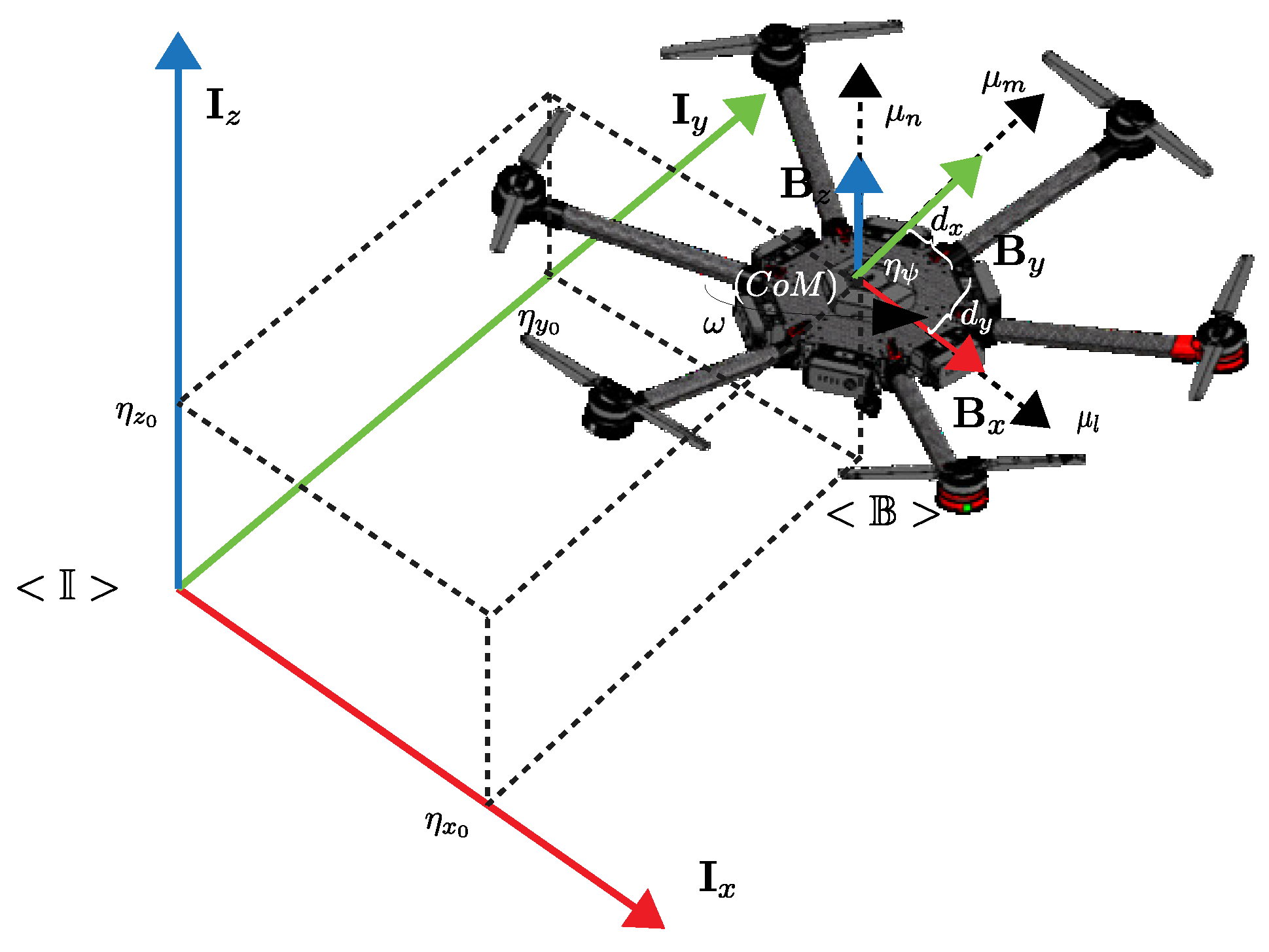

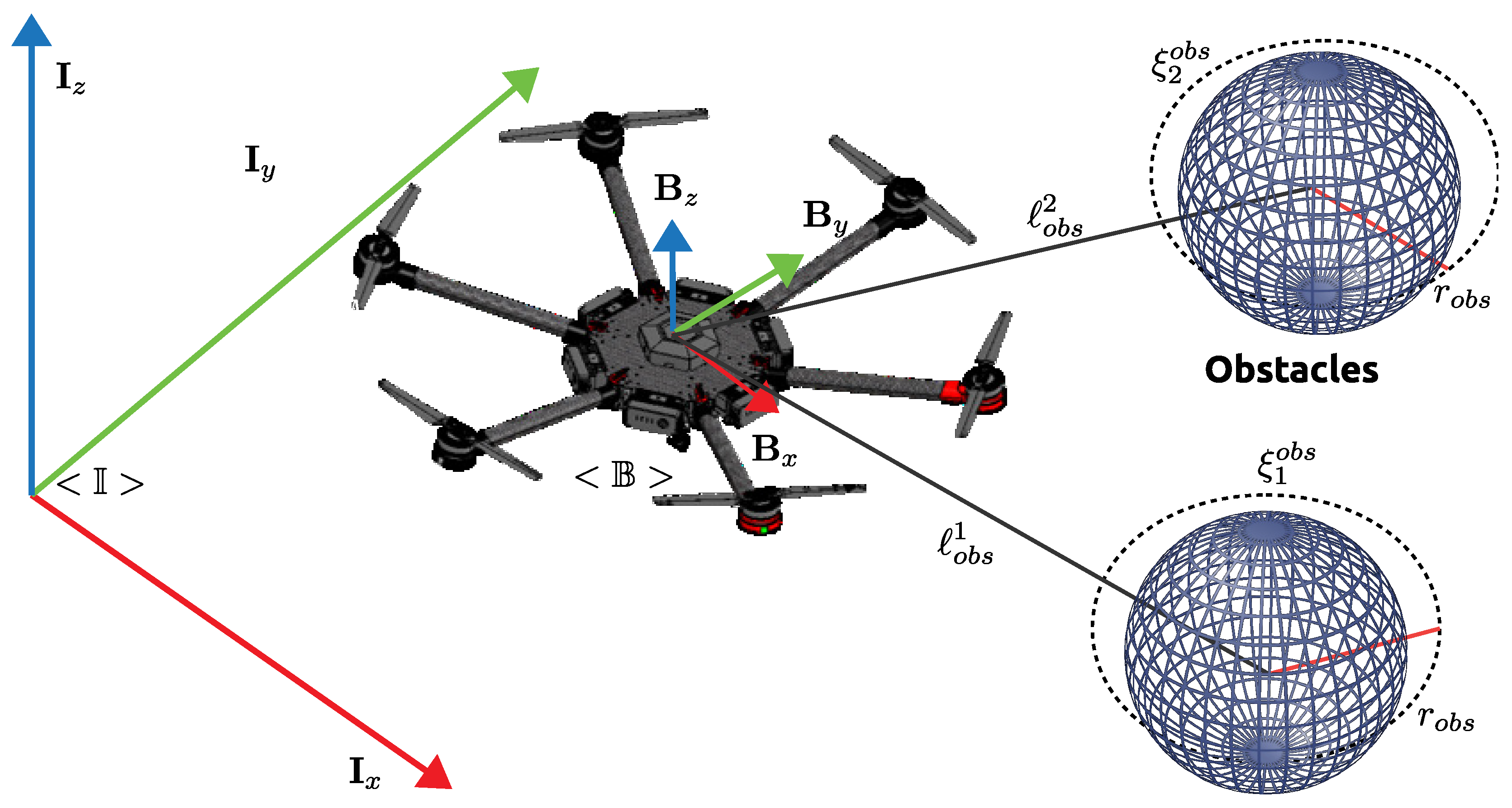

2.1. Hexacopter System Preliminaries

2.1.1. Kinematics Model

2.1.2. Dynamic Model

Euler–Lagrange Formulation

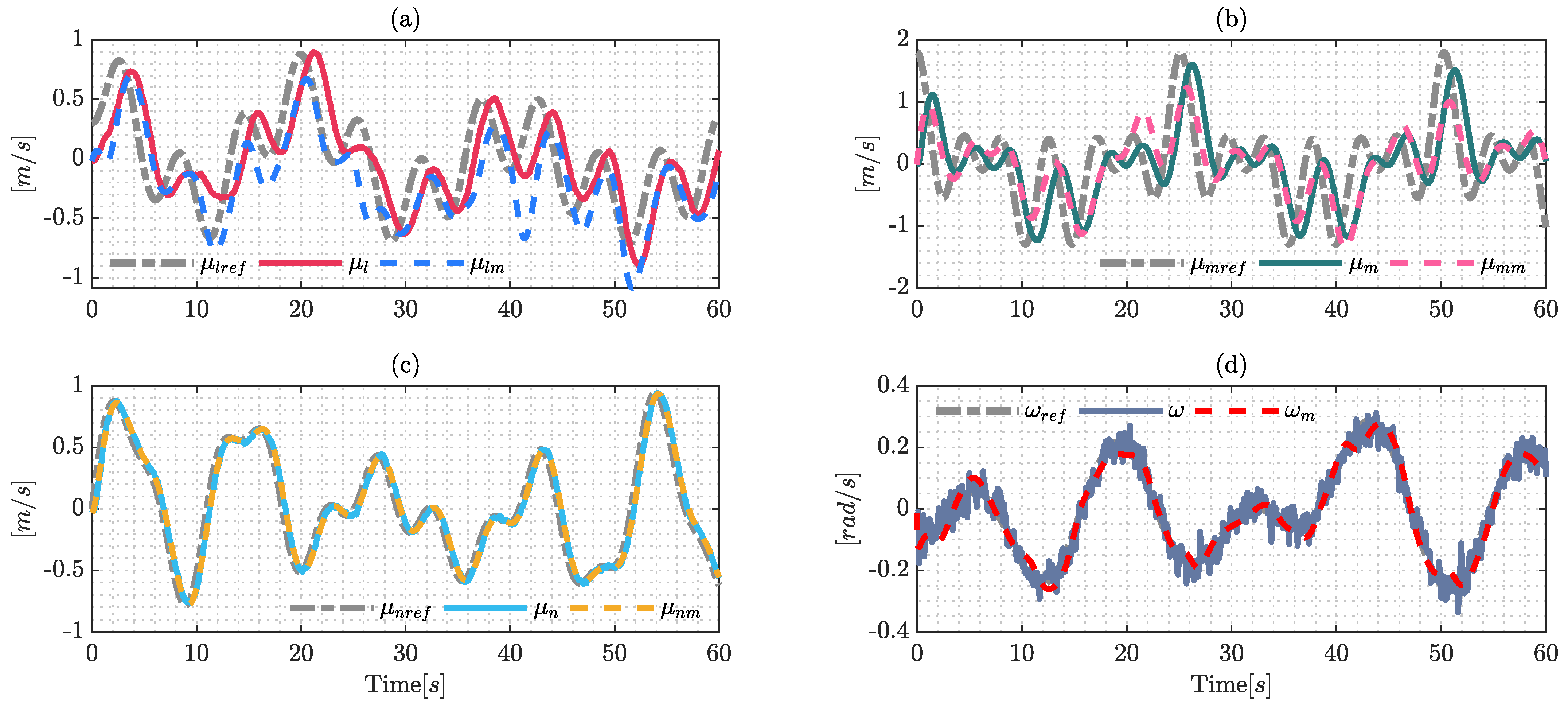

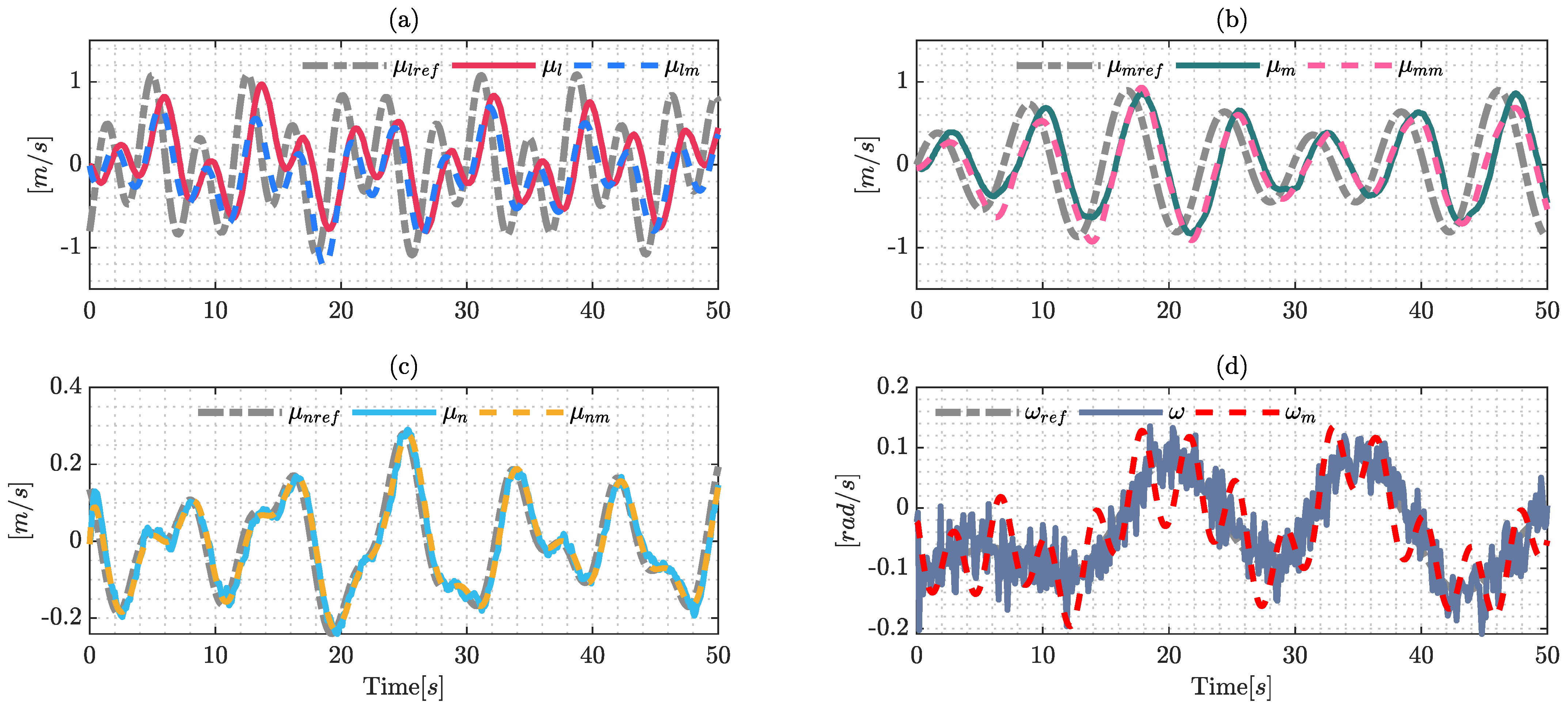

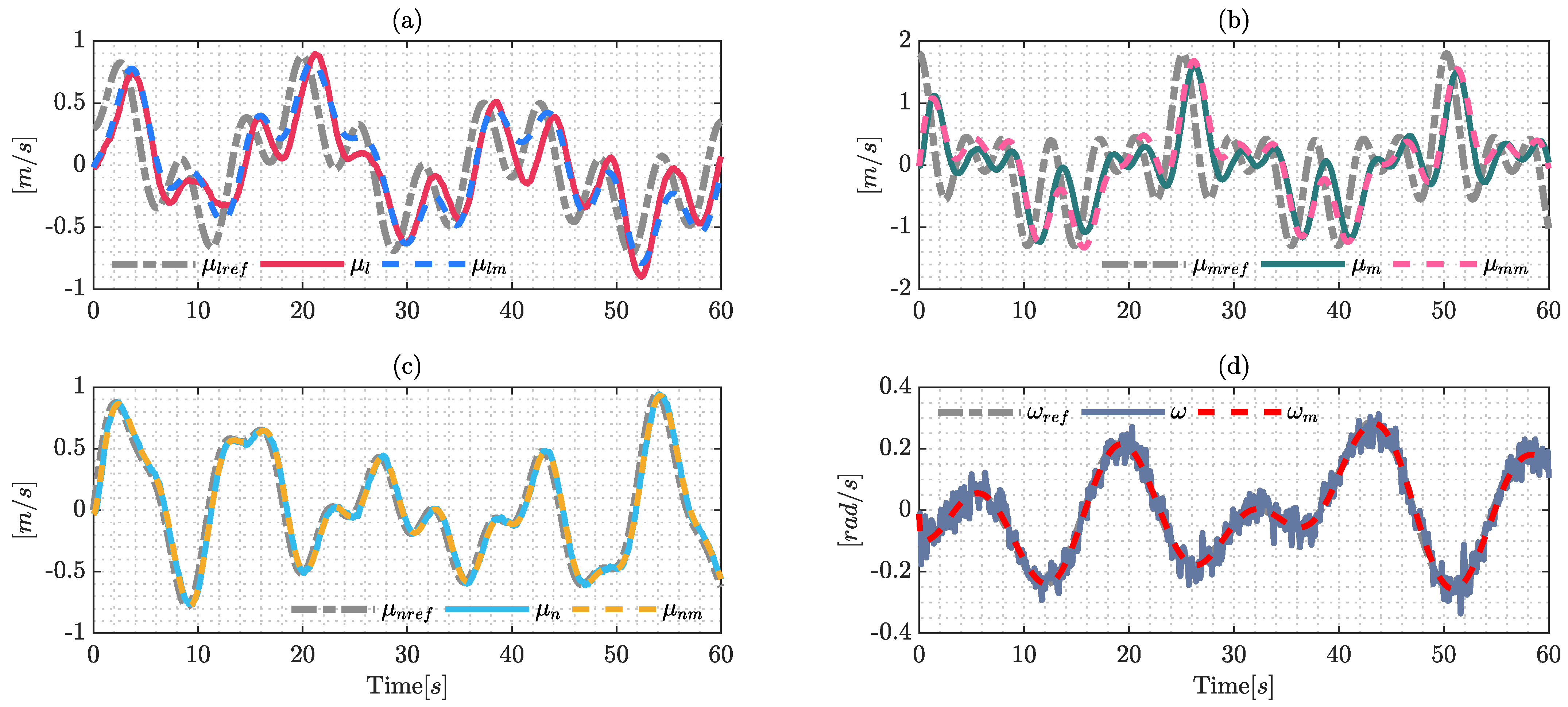

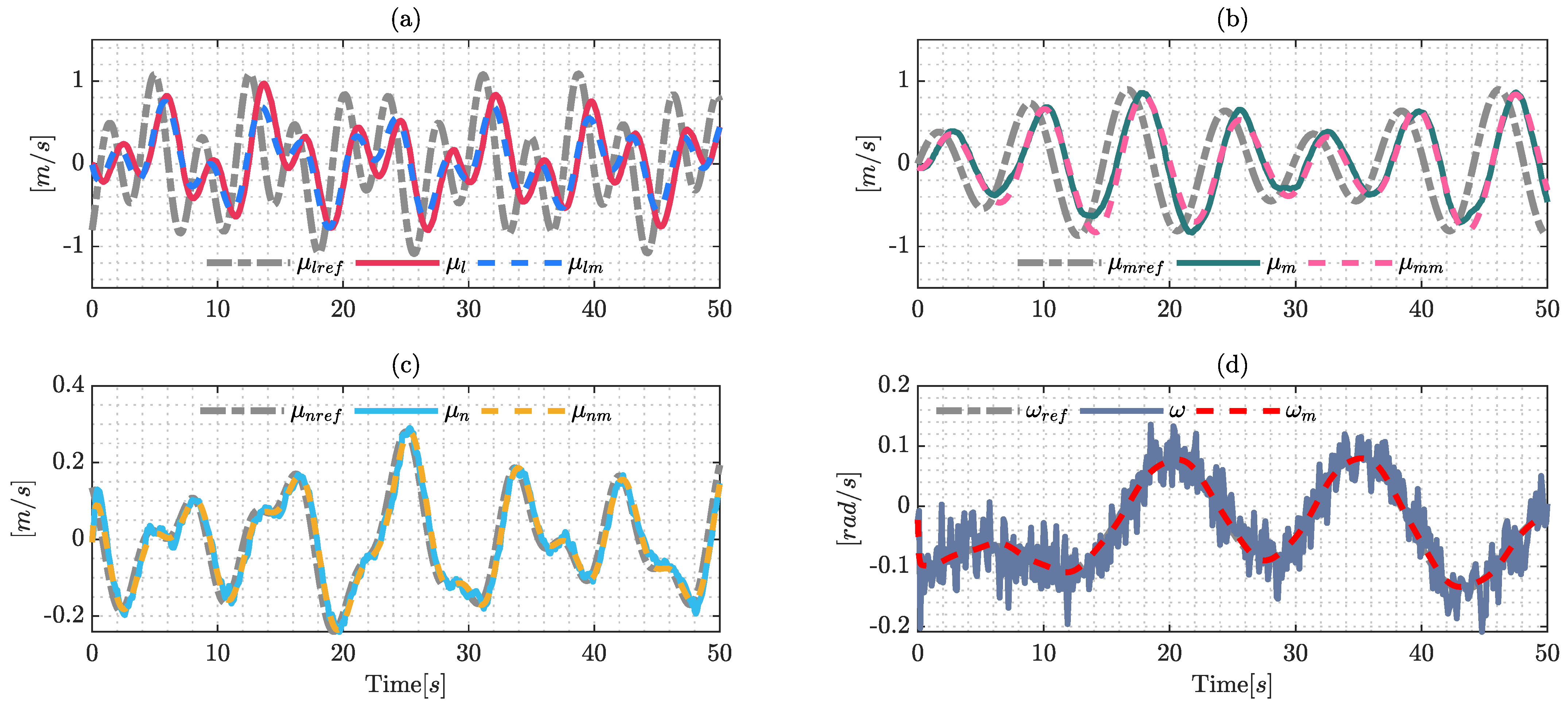

Euler–Lagrange Identification and Validation

Dynamic Mode Decomposition Formulation

Dynamic Mode Decomposition Identification and Validation

| Algorithm 1 Identification process Using DMD |

| Input: DJI MATRICE 600 PRO measurements and truncation value . Output: Matrices and . Identdo end Ident return |

2.1.3. Accuracy Comparative Results

2.2. Control Methodology

2.2.1. Nonlinear Model Predictive Control

2.2.2. Tracking Trajectory Formulation

2.2.3. Maneuverability Velocities Constraints

2.2.4. Obstacle Constraints

2.2.5. Nonlinear Model Predictive Control Formulation

3. Results and Discussions

3.1. Real-World Experiments

3.2. Simulation Experiments

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Recker, T.; Heilemann, F.; Raatz, A. Handling of large and heavy objects using a single mobile manipulator in combination with a roller board. Procedia CIRP 2021, 97, 21–26. [Google Scholar] [CrossRef]

- Ortiz, J.S.; Molina, M.F.; Andaluz, V.H.; Varela, J.; Morales, V. Coordinated Control of a Omnidirectional Double Mobile Manipulator. Lect. Notes Electr. Eng. 2018, 449, 278–286. [Google Scholar] [CrossRef]

- Ortiz, J.S.; Palacios-navarro, G.; Andaluz, V.H.; Recalde, L.F. Three-Dimensional Unified Motion Control of a Robotic Standing Wheelchair for Rehabilitation Purposes. Sensors 2021, 21, 3057. [Google Scholar] [CrossRef] [PubMed]

- Arnold, R.D.; Yamaguchi, H.; Tanaka, T. Search and rescue with autonomous flying robots through behavior-based cooperative intelligence. J. Int. Humanit. Action 2018, 3, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Moreno, R.; Pinzón-Arenas, J.O.; Pachón-Suescún, C.G. Assistant robot through deep learning. Int. J. Electr. Comput. Eng. 2020, 10, 1053–1062. [Google Scholar] [CrossRef] [Green Version]

- Yolcu, V.; Demirer, V. A Review on the Studies about the Use of Robotic Technologies in Education. SDU Int. J. Educ. Stud. 2017, 4, 127–139. [Google Scholar]

- Petersen, K.H.; Napp, N.; Stuart-Smith, R.; Rus, D.; Kovac, M. A review of collective robotic construction. Sci. Robot. 2019, 4. [Google Scholar] [CrossRef]

- Pan, M.; Linner, T.; Pan, W.; Cheng, H.; Bock, T. A framework of indicators for assessing construction automation and robotics in the sustainability context. J. Clean. Prod. 2018, 182, 82–95. [Google Scholar] [CrossRef] [Green Version]

- Chebrolu, N.; Lottes, P.; Schaefer, A.; Winterhalter, W.; Burgard, W.; Stachniss, C. Agricultural robot dataset for plant classification, localization and mapping on sugar beet fields. Int. J. Robot. Res. 2017, 36, 1045–1052. [Google Scholar] [CrossRef] [Green Version]

- Kuric, I.; Bulej, V.; Saga, M.; Pokorny, P. Development of simulation software for mobile robot path planning within multilayer map system based on metric and topological maps. Int. J. Adv. Robot. Syst. 2017, 14. [Google Scholar] [CrossRef] [Green Version]

- Shaw, I.G. Robot Wars: US Empire and geopolitics in the robotic age. Secur. Dialogue 2017, 48, 451–470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mellinger, D.; Shomin, M.; Michael, N.; Kumar, V. Cooperative Grasping and Transport Using Multiple Quadrotors. Springer Tracts Adv. Robot. 2013, 83, 545–558. [Google Scholar] [CrossRef]

- Bircher, A.; Kamel, M.; Alexis, K.; Burri, M.; Oettershagen, P.; Omari, S.; Mantel, T.; Siegwart, R. Three-dimensional coverage path planning via viewpoint resampling and tour optimization for aerial robots. Auton. Robot. 2015, 40, 1059–1078. [Google Scholar] [CrossRef]

- Bircher, A.; Kamel, M.; Alexis, K.; Oleynikova, H.; Siegwart, R. Receding horizon next-best-view planner for 3D exploration. In Proceedings of the IEEE International Conference on Robotics and Automation, Stockholm, Sweden, 16–21 May 2016; pp. 1462–1468. [Google Scholar] [CrossRef]

- Garimella, G.; Kobilarov, M. Towards model-predictive control for aerial pick-and-place. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; pp. 4692–4697. [Google Scholar] [CrossRef]

- Song, Y.; Hsu, L.T. Tightly coupled integrated navigation system via factor graph for UAV indoor localization. Aerosp. Sci. Technol. 2021, 108, 106370. [Google Scholar] [CrossRef]

- Paredes, J.A.; Álvarez, F.J.; Aguilera, T.; Villadangos, J.M. 3D Indoor Positioning of UAVs with Spread Spectrum Ultrasound and Time-of-Flight Cameras. Sensors 2017, 18, 89. [Google Scholar] [CrossRef] [Green Version]

- Sandino, J.; Vanegas, F.; Maire, F.; Caccetta, P.; Sanderson, C.; Gonzalez, F. UAV Framework for Autonomous Onboard Navigation and People/Object Detection in Cluttered Indoor Environments. Remote Sens. 2020, 12, 3386. [Google Scholar] [CrossRef]

- Radoglou–Grammatikis, P.; Sarigiannidis, P.; Lagkas, T.; Moscholios, I. A compilation of UAV applications for precision agriculture. Comput. Netw. 2020, 172, 107148. [Google Scholar] [CrossRef]

- Gupta, A.; Afrin, T.; Scully, E.; Yodo, N. Advances of UAVs toward Future Transportation: The State-of-the-Art, Challenges, and Opportunities. Future Transp. 2021, 1, 326–350. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, G.; Zhuang, Y.; Hu, H. Autonomous Flight Control for Multi-Rotor UAVs Flying at Low Altitude. IEEE Access 2019, 7, 42614–42625. [Google Scholar] [CrossRef]

- Vu, N.A.; Dang, D.K.; Le Dinh, T. Electric propulsion system sizing methodology for an agriculture multicopter. Aerosp. Sci. Technol. 2019, 90, 314–326. [Google Scholar] [CrossRef]

- Belmonte, N.; Staulo, S.; Fiorot, S.; Luetto, C.; Rizzi, P.; Baricco, M. Fuel cell powered octocopter for inspection of mobile cranes: Design, cost analysis and environmental impacts. Appl. Energy 2018, 215, 556–565. [Google Scholar] [CrossRef]

- Nguyen, N.P.; Kim, W.; Moon, J. Super-twisting observer-based sliding mode control with fuzzy variable gains and its applications to fully-actuated hexarotors. J. Frankl. Inst. 2019, 356, 4270–4303. [Google Scholar] [CrossRef]

- Ali, R.; Peng, Y.; Iqbal, M.T.; Ul Amin, R.; Zahid, O.; Khan, O.I. Adaptive backstepping sliding mode control of coaxial octorotor unmanned aerial vehicle. IEEE Access 2019, 7, 27526–27534. [Google Scholar] [CrossRef]

- Alaimo, A.; Artale, V.; Milazzo, C.L.R.; Ricciardello, A. PID Controller Applied to Hexacopter Flight. J. Intell. Robot. Syst. 2013, 73, 261–270. [Google Scholar] [CrossRef]

- Dayana Salim, N.; Derawi, D.; Abdullah, S.S.; Mazlan, S.A.; Zamzuri, H. PID plus LQR attitude control for hexarotor MAV in indoor environments. In Proceedings of the IEEE International Conference on Industrial Technology, Busan, Korea, 26 February–1 March 2014; pp. 85–90. [Google Scholar] [CrossRef]

- Chen, F.; Lei, W.; Zhang, K.; Tao, G.; Jiang, B. A novel nonlinear resilient control for a quadrotor UAV via backstepping control and nonlinear disturbance observer. Nonlinear Dyn. 2016, 2, 1281–1295. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, H.; Han, J. Research on Trajectory Planning and Tracking of Hexa-copter. MATEC Web Conf. 2018, 173, 02008. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.; Leok, M.; McClamroch, N.H. Geometric tracking control of a quadrotor UAV on SE(3). In Proceedings of the IEEE Conference on Decision and Control, Atlanta, GA, USA, 15–17 December 2010; pp. 5420–5425. [Google Scholar] [CrossRef] [Green Version]

- Mellinger, D.; Kumar, V. Minimum snap trajectory generation and control for quadrotors. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 2520–2525. [Google Scholar] [CrossRef]

- Tal, E.; Karaman, S. Accurate Tracking of Aggressive Quadrotor Trajectories Using Incremental Nonlinear Dynamic Inversion and Differential Flatness. IEEE Trans. Control Syst. Technol. 2021, 29, 1203–1218. [Google Scholar] [CrossRef]

- Faessler, M.; Franchi, A.; Scaramuzza, D. Differential Flatness of Quadrotor Dynamics Subject to Rotor Drag for Accurate Tracking of High-Speed Trajectories. IEEE Robot. Autom. Lett. 2018, 3, 620–626. [Google Scholar] [CrossRef] [Green Version]

- Santoso, F.; Garratt, M.A.; Anavatti, S.G. A self-learning TS-fuzzy system based on the C-means clustering technique for controlling the altitude of a hexacopter unmanned aerial vehicle. In Proceedings of the 2017 International Conference on Advanced Mechatronics, Intelligent Manufacture, and Industrial Automation (ICAMIMIA), Surabaya, Indonesia, 12–14 October 2017; pp. 46–51. [Google Scholar] [CrossRef]

- Dierks, T.; Jagannathan, S. Output feedback control of a quadrotor UAV using neural networks. IEEE Trans. Neural Netw. 2010, 21, 50–66. [Google Scholar] [CrossRef]

- Ferdaus, M.M.; Pratama, M.; Anavatti, S.G.; Garratt, M. A Generic Self-Evolving Neuro-Fuzzy Controller Based High-Performance Hexacopter Altitude Control System. In Proceedings of the SMC 2018: 2018 IEEE International Conference on Systems, Man, and Cybernetics, Miyazaki, Japan, 7–10 October 2018; pp. 2784–2791. [Google Scholar] [CrossRef] [Green Version]

- ul Amin, R.; Aijun, L.; Khan, M.U.; Shamshirband, S.; Kamsin, A.; ul Amin, R.; Aijun, L.; Khan, M.U.; Shamshirband, S.; Kamsin, A. An adaptive trajectory tracking control of four rotor hover vehicle using extended normalized radial basis function network. MSSP 2017, 83, 53–74. [Google Scholar] [CrossRef]

- Nieuwenhuisen, M.; Droeschel, D.; Schneider, J.; Holz, D.; Labe, T.; Behnke, S. Multimodal obstacle detection and collision avoidance for micro aerial vehicles. In Proceedings of the ECMR 2013: 2013 European Conference on Mobile Robots, Barcelona, Spain, 25–27 September 2013; pp. 7–12. [Google Scholar] [CrossRef]

- Rezaee, H.; Abdollahi, F. Adaptive artificial potential field approach for obstacle avoidance of unmanned aircrafts. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Kaohsiung, Taiwan, 11–14 July 2012. [Google Scholar] [CrossRef]

- Achtelik, M.W.; Weiss, S.; Chli, M.; Siegwart, R. Path planning for motion dependent state estimation on micro aerial vehicles. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3926–3932. [Google Scholar] [CrossRef] [Green Version]

- He, R.; Prentice, S.; Roy, N. Planning in information space for a quadrotor helicopter in a GPS-denied environment. In Proceedings of the IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 1814–1820. [Google Scholar] [CrossRef] [Green Version]

- Sani, M.; Robu, B.; Hably, A. Pursuit-evasion game for nonholonomic mobile robots with obstacle avoidance using NMPC. In Proceedings of the MED 2020: 2020 28th Mediterranean Conference on Control and Automation, Saint-Raphaël, France, 15–18 September 2020; pp. 978–983. [Google Scholar] [CrossRef]

- Subramanian, S.; Nazari, S.; Alvi, M.A.; Engell, S. Robust NMPC Schemes for the Control of Mobile Robots in the Presence of Dynamic Obstacles. In Proceedings of the MMAR 2018: 2018 23rd International Conference on Methods and Models in Automation and Robotics, Miedzyzdroje, Poland, 27–30 August 2018; pp. 768–773. [Google Scholar] [CrossRef]

- Ribeiro, T.T.; Fernandez, R.O.; Conceicao, A.G. NMPC-based Visual Leader-Follower Formation Control for Wheeled Mobile Robots. In Proceedings of the IEEE 16th International Conference on Industrial Informatics, INDIN 2018, Porto, Portugal, 18–20 July 2018; pp. 406–411. [Google Scholar] [CrossRef]

- Osman, M.; Mehrez, M.W.; Yang, S.; Jeon, S.; Melek, W. End-Effector Stabilization of a 10-DOF Mobile Manipulator using Nonlinear Model Predictive Control. IFAC-PapersOnLine 2020, 53, 9772–9777. [Google Scholar] [CrossRef]

- Neunert, M.; De Crousaz, C.; Furrer, F.; Kamel, M.; Farshidian, F.; Siegwart, R.; Buchli, J. Fast nonlinear Model Predictive Control for unified trajectory optimization and tracking. In Proceedings of the IEEE International Conference on Robotics and Automation, Stockholm, Sweden, 16–21 May 2016; pp. 1398–1404. [Google Scholar] [CrossRef]

- Aoki, Y.; Asano, Y.; Honda, A.; Motooka, N.; Ohtsuka, T. Nonlinear Model Predictive Control of Position and Attitude in a Hexacopter with Three Failed Rotors. IFAC-PapersOnLine 2018, 51, 228–233. [Google Scholar] [CrossRef]

- Tzoumanikas, D.; Graule, F.; Yan, Q.; Shah, D.; Popovic, M.; Leutenegger, S. Aerial Manipulation Using Hybrid Force and Position NMPC Applied to Aerial Writing. arXiv 2020, arXiv:2006.02116. [Google Scholar]

- Bicego, D.; Mazzetto, J.; Carli, R.; Farina, M.; Franchi, A. Nonlinear Model Predictive Control with Enhanced Actuator Model for Multi-Rotor Aerial Vehicles with Generic Designs. J. Intell. Robot. Syst. Theory Appl. 2020, 100, 1213–1247. [Google Scholar] [CrossRef]

- Foehn, P.; Romero, A.; Scaramuzza, D. Time-Optimal Planning for Quadrotor Waypoint Flight. Sci. Robot. 2021, 6. [Google Scholar] [CrossRef]

- Torrente, G.; Kaufmann, E.; Fohn, P.; Scaramuzza, D. Data-Driven MPC for Quadrotors. IEEE Robot. Autom. Lett. 2021, 6, 3769–3776. [Google Scholar] [CrossRef]

- Small, E.; Sopasakis, P.; Fresk, E.; Patrinos, P.; Nikolakopoulos, G. Aerial navigation in obstructed environments with embedded nonlinear model predictive control. In Proceedings of the 2019 18th European Control Conference, ECC 2019, Naples, Italy, 25–28 June 2019; pp. 3556–3563. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.; Kamel, M.; Alexis, K.; Siegwart, R. Model Predictive Control for Micro Aerial Vehicles: A Survey. In Proceedings of the 2021 European Control Conference (ECC), Delft, The Netherlands, 29 June–2 July 2021; pp. 1556–1563. [Google Scholar] [CrossRef]

- Quan, Q. Introduction to Multicopter Design and Control; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–384. [Google Scholar] [CrossRef]

- Zhang, H.; Rowley, C.W.; Deem, E.A.; Cattafesta, L.N. Online dynamic mode decomposition for time-varying systems. SIAM J. Appl. Dyn. Syst. 2017, 18, 1586–1609. [Google Scholar] [CrossRef]

- Schmid, P.J. Dynamic mode decomposition of numerical and experimental data. J. Fluid Mech. 2010, 656, 5–28. [Google Scholar] [CrossRef] [Green Version]

- Proctor, J.L.; Brunton, S.L.; Kutz, J.N. Dynamic Mode Decomposition with Control. SIAM J. Appl. Dyn. Syst. 2016, 15, 142–161. [Google Scholar] [CrossRef] [Green Version]

- Albersmeyer, J.; Diehl, M. The Lifted Newton Method and Its Application in Optimization. SIAM J. Optim. 2010, 20, 1655–1684. [Google Scholar] [CrossRef] [Green Version]

- Andersson, J.A.; Gillis, J.; Horn, G.; Rawlings, J.B.; Diehl, M. CasADi: A software framework for nonlinear optimization and optimal control. Math. Program. Comput. 2018, 11, 1–36. [Google Scholar] [CrossRef]

- Farshidian, F.; Kamgarpour, M.; Pardo, D.; Buchli, J. Sequential Linear Quadratic Optimal Control for Nonlinear Switched Systems. IFAC-PapersOnLine 2016, 50, 1463–1469. [Google Scholar] [CrossRef]

- Farshidian, F.; Neunert, M.; Winkler, A.W.; Rey, G.; Buchli, J. An Efficient Optimal Planning and Control Framework For Quadrupedal Locomotion. In Proceedings of the IEEE International Conference on Robotics and Automation, Singapore, 29 May–3 June 2017; pp. 93–100. [Google Scholar] [CrossRef] [Green Version]

- Giftthaler, M.; Farshidian, F.; Sandy, T.; Stadelmann, L.; Buchli, J. Efficient Kinematic Planning for Mobile Manipulators with Non-holonomic Constraints Using Optimal Control. In Proceedings of the IEEE International Conference on Robotics and Automation, Singapore, 29 May–3 June 2017; pp. 3411–3417. [Google Scholar] [CrossRef] [Green Version]

- Verschueren, R.; Frison, G.; Kouzoupis, D.; Frey, J.; Duijkeren, N.V.; Zanelli, A.; Novoselnik, B.; Albin, T.; Quirynen, R.; Diehl, M. acados: A modular open-source framework for fast embedded optimal control. Math. Program. Comput. 2019, 14, 147–183. [Google Scholar] [CrossRef]

- Gaertner, M.; Bjelonic, M.; Farshidian, F.; Hutter, M. Collision-Free MPC for Legged Robots in Static and Dynamic Scenes. In Proceedings of the IEEE International Conference on Robotics and Automation, Xi’an, China, 30 May–5 June 2021; pp. 8266–8272. [Google Scholar] [CrossRef]

| System | Dynamic Parameters | ||

|---|---|---|---|

| DJI MATRICE 600 PRO | |||

| Matrix | Approximated Values | |||

|---|---|---|---|---|

| Matrix | Approximated Values | |||

|---|---|---|---|---|

| Initial Positions | Initial Maneuverability Velocities | Reference Trajectory |

|---|---|---|

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| T | |||

| Initial Positions | Initial Maneuverability Velocities | Reference Trajectory |

|---|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Recalde, L.F.; Guevara, B.S.; Carvajal, C.P.; Andaluz, V.H.; Varela-Aldás, J.; Gandolfo, D.C. System Identification and Nonlinear Model Predictive Control with Collision Avoidance Applied in Hexacopters UAVs. Sensors 2022, 22, 4712. https://doi.org/10.3390/s22134712

Recalde LF, Guevara BS, Carvajal CP, Andaluz VH, Varela-Aldás J, Gandolfo DC. System Identification and Nonlinear Model Predictive Control with Collision Avoidance Applied in Hexacopters UAVs. Sensors. 2022; 22(13):4712. https://doi.org/10.3390/s22134712

Chicago/Turabian StyleRecalde, Luis F., Bryan S. Guevara, Christian P. Carvajal, Victor H. Andaluz, José Varela-Aldás, and Daniel C. Gandolfo. 2022. "System Identification and Nonlinear Model Predictive Control with Collision Avoidance Applied in Hexacopters UAVs" Sensors 22, no. 13: 4712. https://doi.org/10.3390/s22134712

APA StyleRecalde, L. F., Guevara, B. S., Carvajal, C. P., Andaluz, V. H., Varela-Aldás, J., & Gandolfo, D. C. (2022). System Identification and Nonlinear Model Predictive Control with Collision Avoidance Applied in Hexacopters UAVs. Sensors, 22(13), 4712. https://doi.org/10.3390/s22134712