Silicone-Textile Composite Resistive Strain Sensors for Human Motion-Related Parameters

Abstract

:1. Introduction

2. Materials and Methods

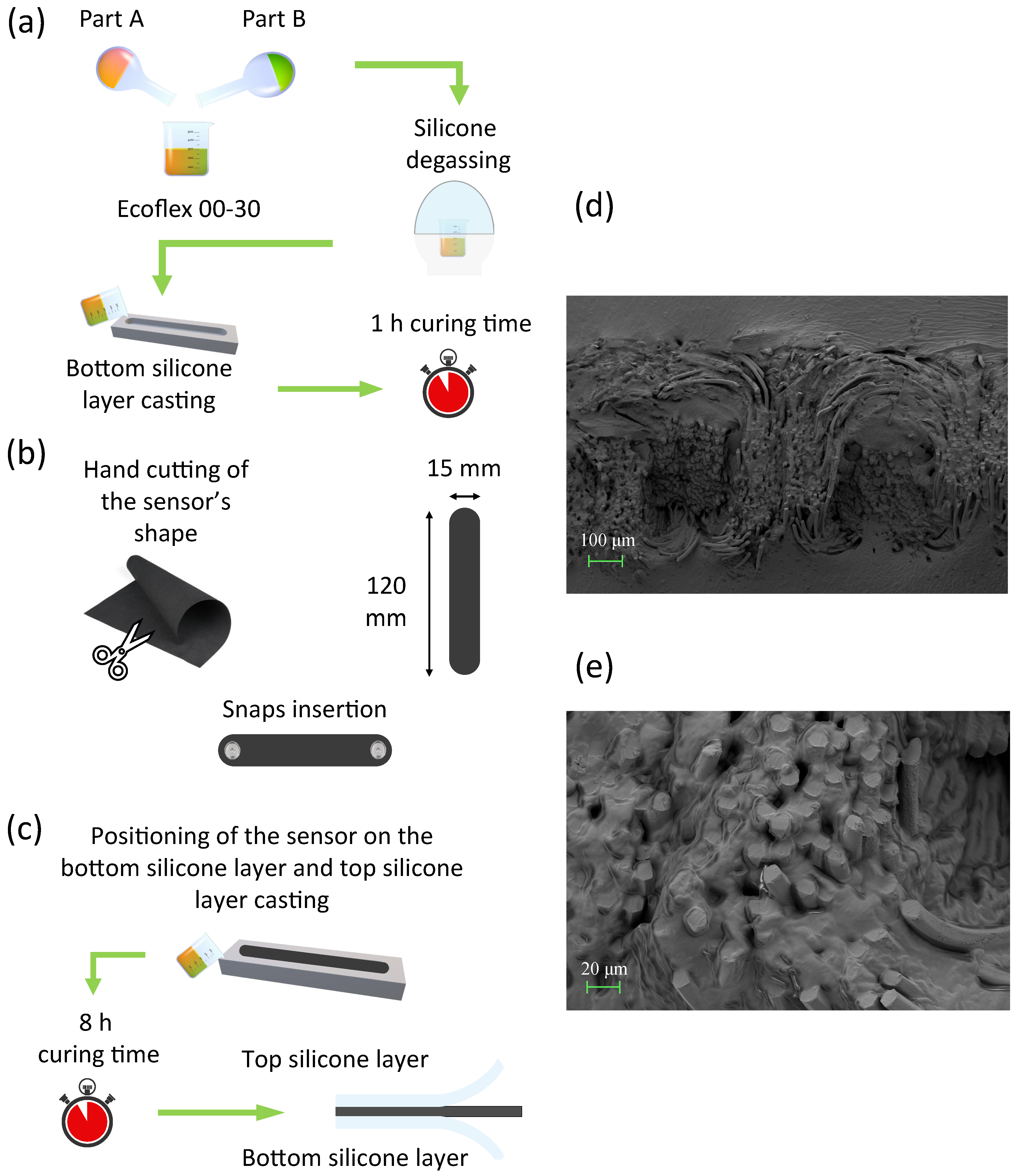

2.1. Sensors Manufacturing

2.2. Characterization of the Electro-Mechanical Properties

2.3. Moisture Influence on Electrical Resistance

2.4. Wearable Prototypes: Manufacturing and Feasibility Assessment in Real Scenarios

3. Results and Discussion

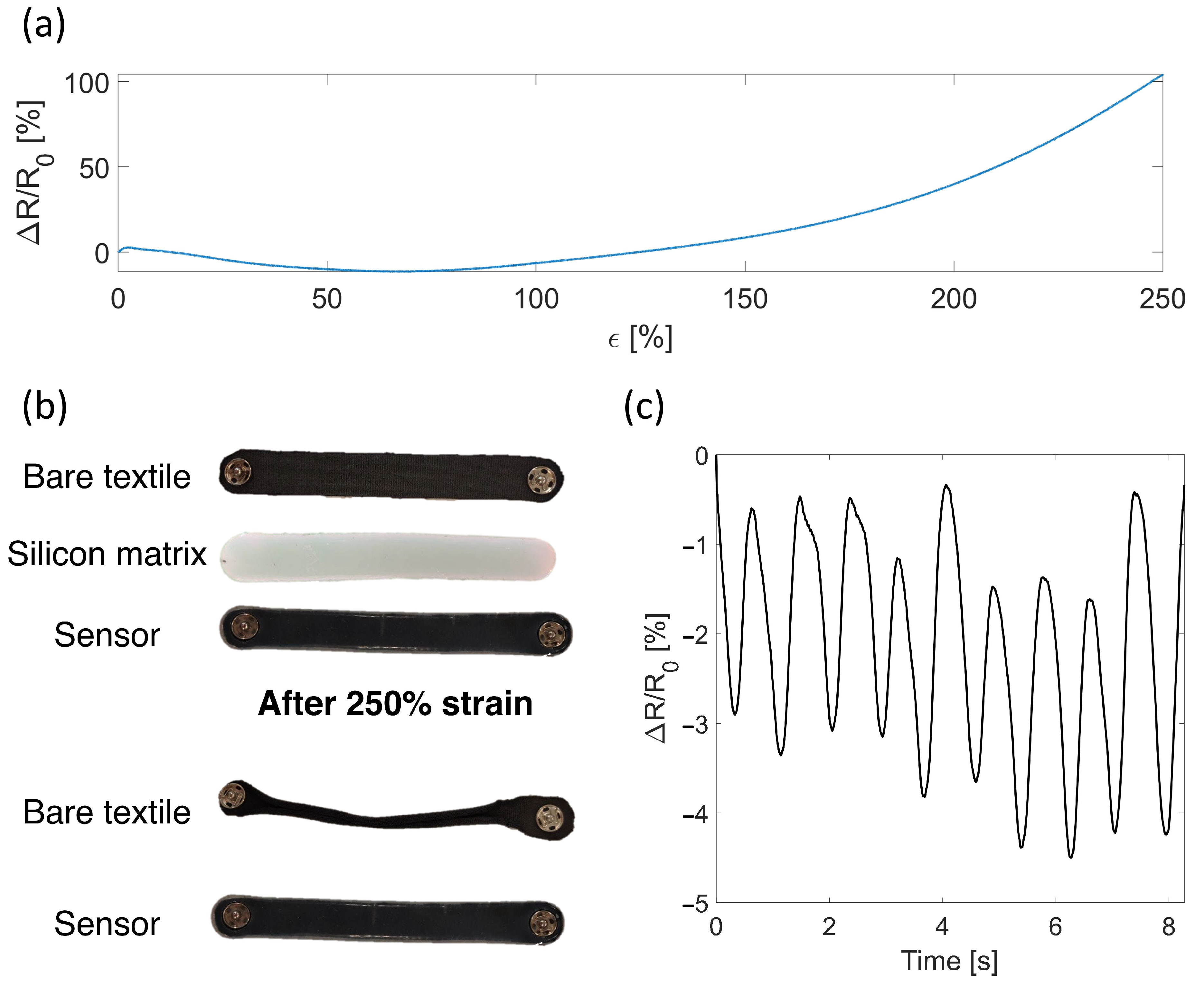

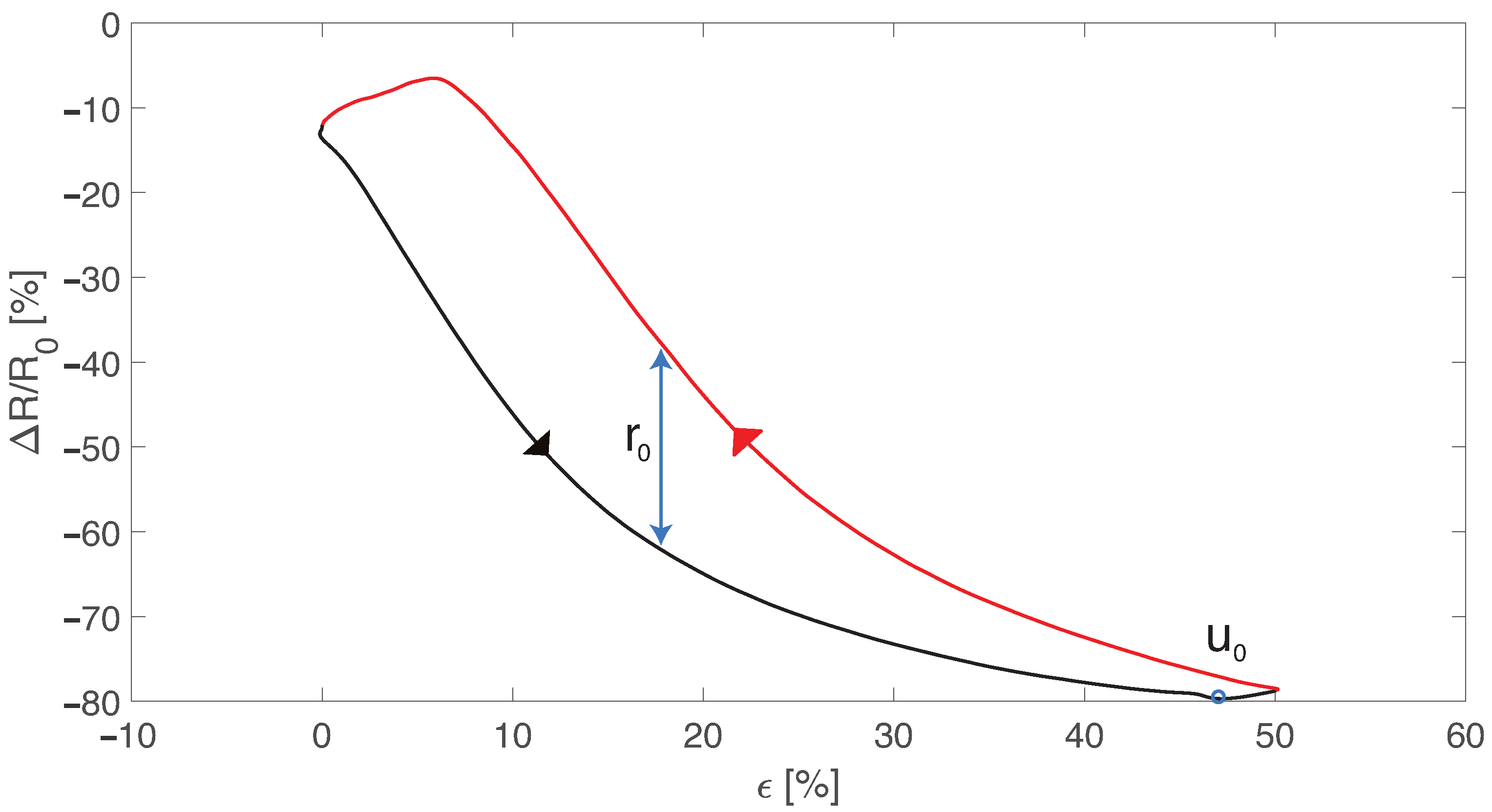

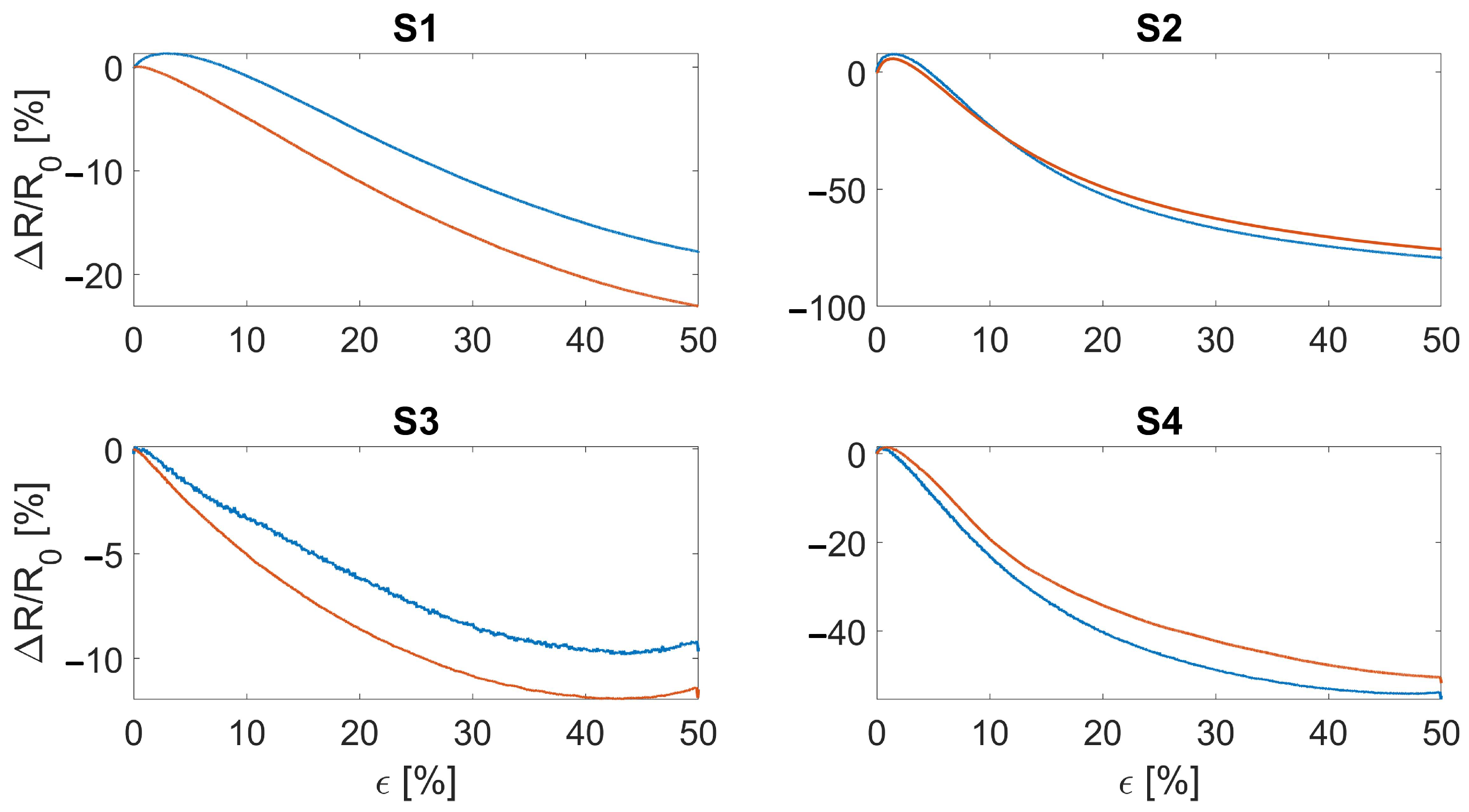

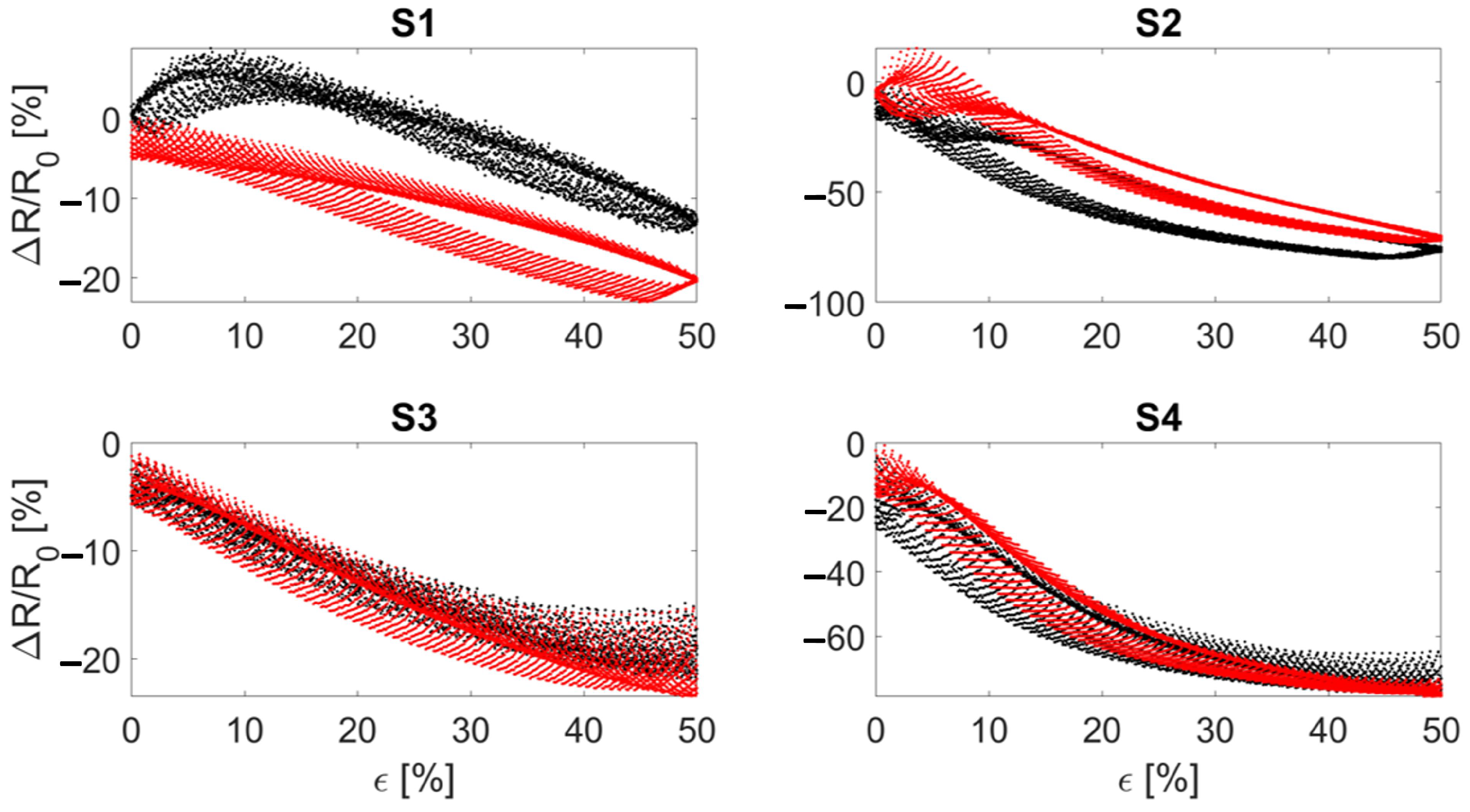

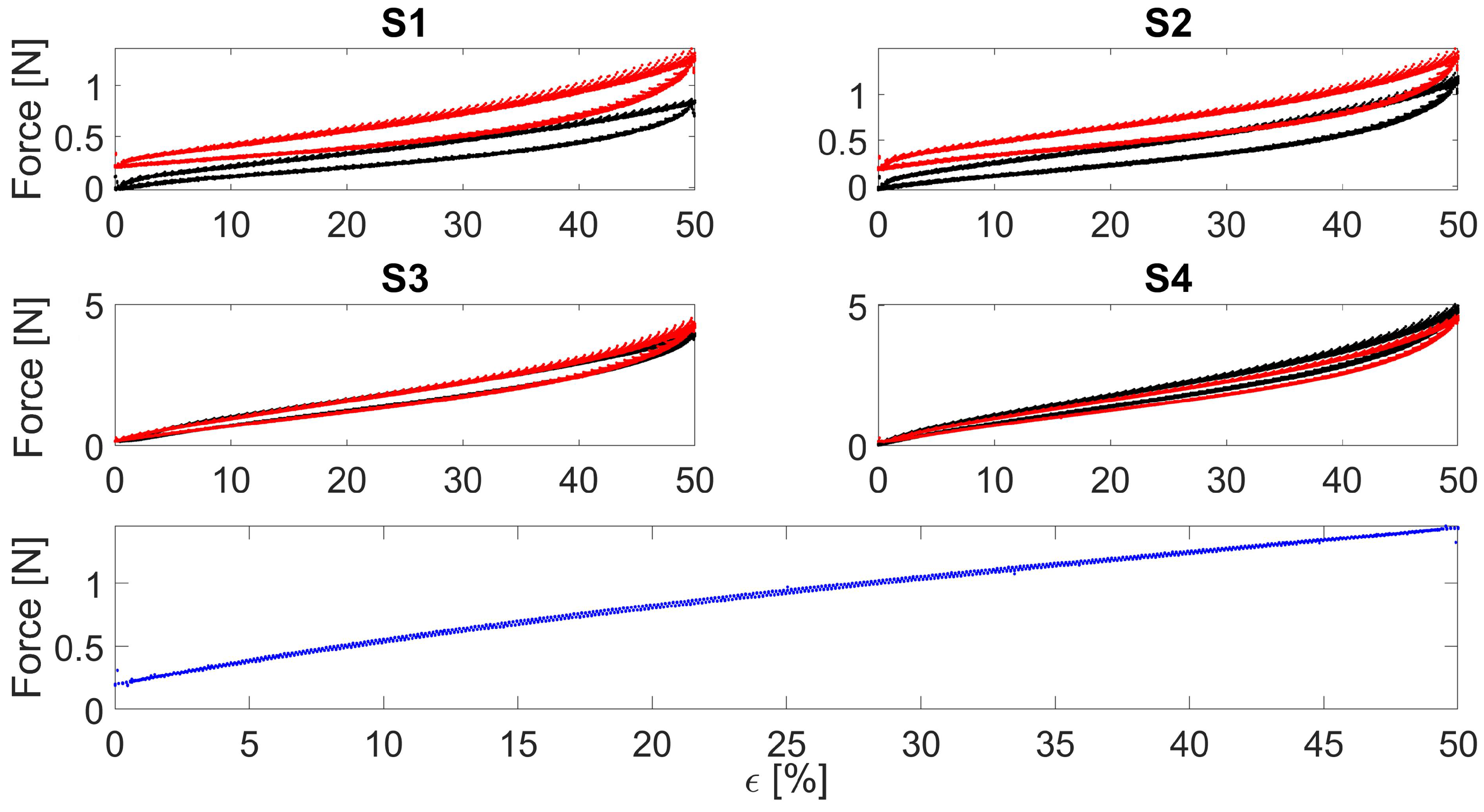

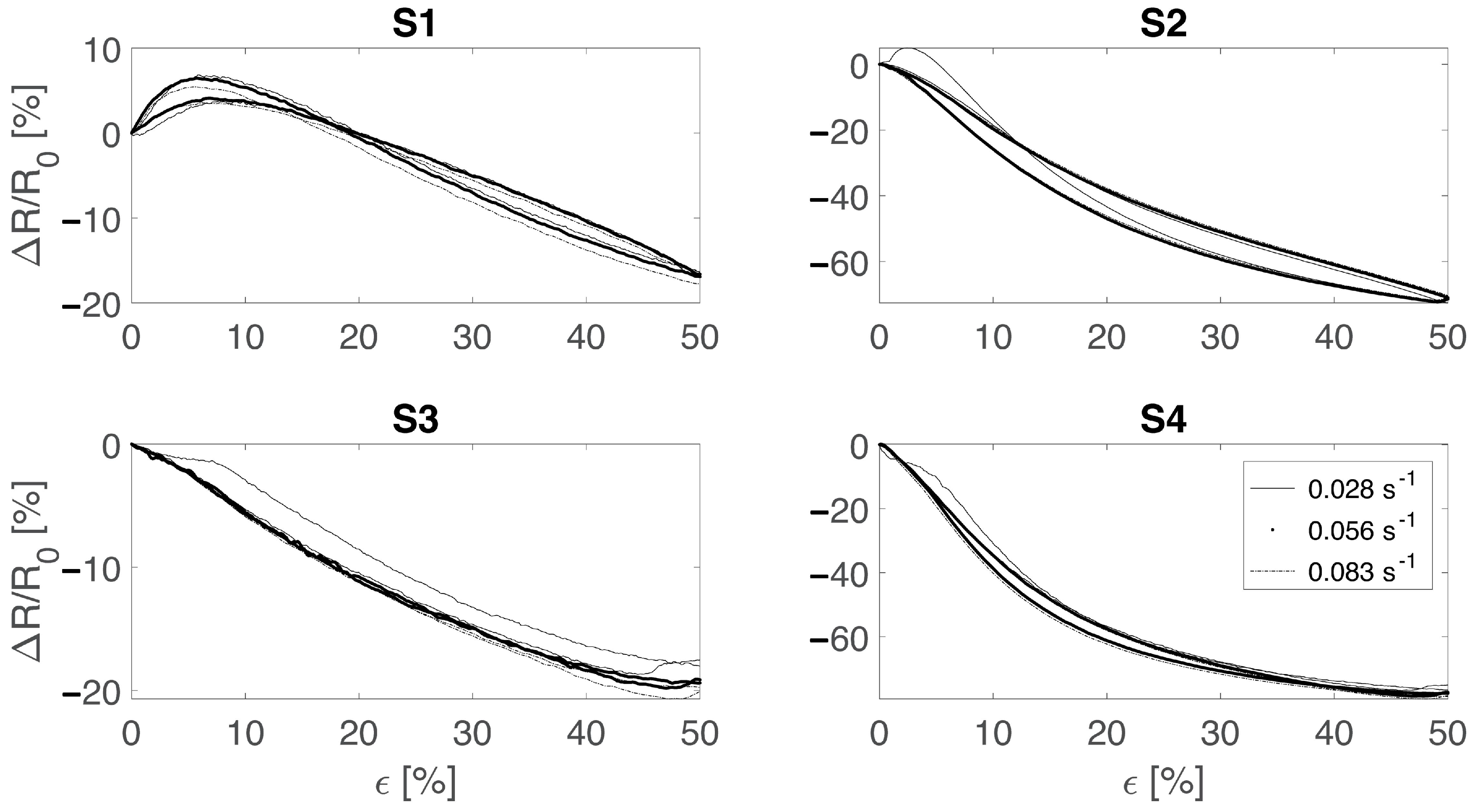

3.1. Electro-Mechanical Properties

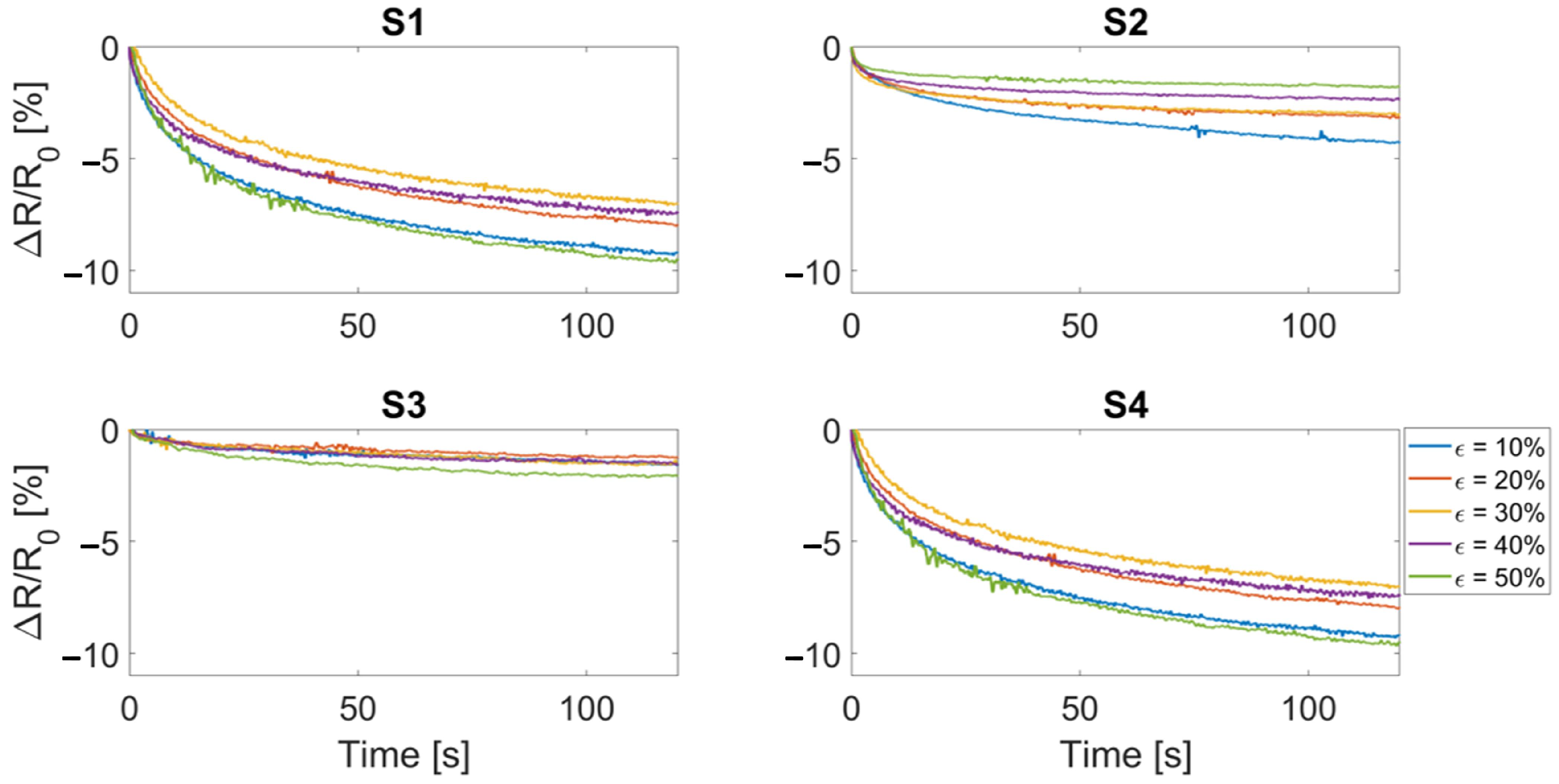

3.2. Moisture Influence on Electrical Resistance

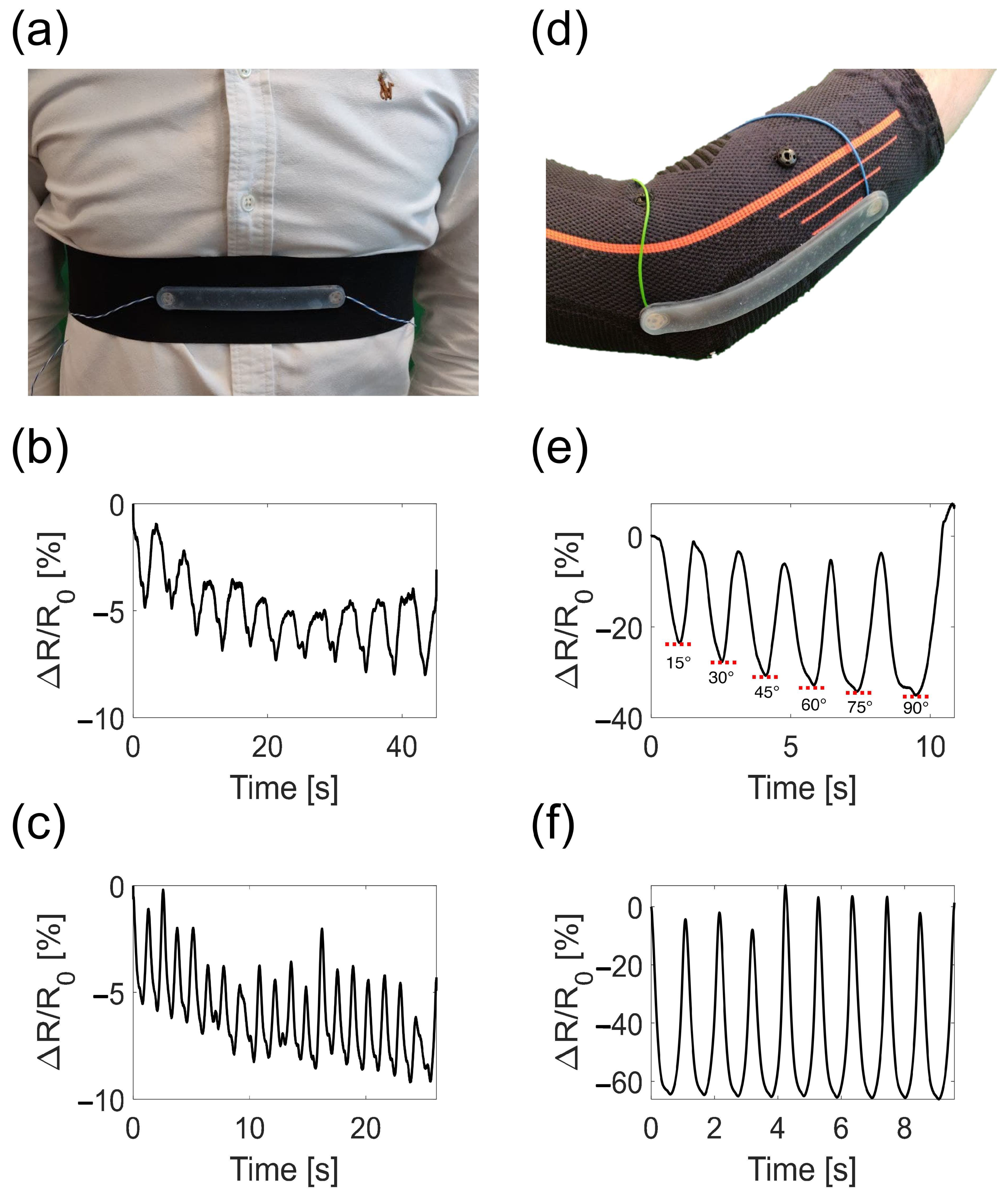

3.3. Feasibility Assessment of the Wearable System in Real Scenarios: Respiratory and Joint Motion Monitoring

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Gauge factor | |

| SEM | Scanning electron microscopy |

| BPM | Breaths per minute |

References

- Trung, T.Q.; Lee, N.E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoringand personal healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Massaroni, C.; Di Tocco, J.; Bravi, M.; Carnevale, A.; Presti, D.L.; Sabbadini, R.; Miccinilli, S.; Sterzi, S.; Formica, D.; Schena, E. Respiratory monitoring during physical activities with a multi-sensor smart garment and related algorithms. IEEE Sens. J. 2019, 20, 2173–2180. [Google Scholar] [CrossRef]

- Massaroni, C.; Di Tocco, J.; Presti, D.L.; Longo, U.G.; Miccinilli, S.; Sterzi, S.; Formica, D.; Saccomandi, P.; Schena, E. Smart textile based on piezoresistive sensing elements for respiratory monitoring. IEEE Sens. J. 2019, 19, 7718–7725. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable flexible sensors: A review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef] [Green Version]

- Lo Presti, D.; Carnevale, A.; D’Abbraccio, J.; Massari, L.; Massaroni, C.; Sabbadini, R.; Zaltieri, M.; Di Tocco, J.; Bravi, M.; Miccinilli, S.; et al. A multi-parametric wearable system to monitor neck movements and respiratory frequency of computer workers. Sensors 2020, 20, 536. [Google Scholar] [CrossRef] [Green Version]

- Di Tocco, J.; Sabbadini, R.; Raiano, L.; Fani, F.; Ripani, S.; Schena, E.; Formica, D.; Massaroni, C. Breath-jockey: Development and feasibility assessment of a wearable system for respiratory rate and kinematic parameter estimation for gallop athletes. Sensors 2020, 21, 152. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Flexible carbon nanotube nanocomposite sensor for multiple physiological parameter monitoring. Sens. Actuators A Phys. 2016, 251, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Di Tocco, J.; Massaroni, C.; Di Stefano, N.; Formica, D.; Schena, E. Wearable system based on piezoresistive sensors for monitoring bowing technique in musicians. In Proceedings of the 2019 IEEE SENSORS, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar]

- Di Tocco, J.; Carnevale, A.; Presti, D.L.; Bravi, M.; Bressi, F.; Miccinilli, S.; Sterzi, S.; Longo, U.G.; Denaro, V.; Schena, E.; et al. Wearable Device Based on a Flexible Conductive Textile for Knee Joint Movements Monitoring. IEEE Sens. J. 2021, 21, 26655–26664. [Google Scholar] [CrossRef]

- Chen, J.; Zheng, J.; Gao, Q.; Zhang, J.; Zhang, J.; Omisore, O.M.; Wang, L.; Li, H. Polydimethylsiloxane (PDMS)-based flexible resistive strain sensors for wearable applications. Appl. Sci. 2018, 8, 345. [Google Scholar] [CrossRef] [Green Version]

- Liao, X.; Zhang, Z.; Kang, Z.; Gao, F.; Liao, Q.; Zhang, Y. Ultrasensitive and stretchable resistive strain sensors designed for wearable electronics. Mater. Horiz. 2017, 4, 502–510. [Google Scholar] [CrossRef]

- Takei, K.; Honda, W.; Harada, S.; Arie, T.; Akita, S. Toward flexible and wearable human-interactive health-monitoring devices. Adv. Healthc. Mater. 2015, 4, 487–500. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.; Abu-Raya, Y.S.; Haick, H. Advanced materials for health monitoring with skin-based wearable devices. Adv. Healthc. Mater. 2017, 6, 1700024. [Google Scholar] [CrossRef] [PubMed]

- Frutiger, A.; Muth, J.T.; Vogt, D.M.; Mengüç, Y.; Campo, A.; Valentine, A.D.; Walsh, C.J.; Lewis, J.A. Capacitive soft strain sensors via multicore–shell fiber printing. Adv. Mater. 2015, 27, 2440–2446. [Google Scholar] [CrossRef]

- Min, S.D.; Yun, Y.; Shin, H. Simplified structural textile respiration sensor based on capacitive pressure sensing method. IEEE Sens. J. 2014, 14, 3245–3251. [Google Scholar]

- Kang, M.; Kim, J.; Jang, B.; Chae, Y.; Kim, J.H.; Ahn, J.H. Graphene-based three-dimensional capacitive touch sensor for wearable electronics. ACS Nano 2017, 11, 7950–7957. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, S.; Yokota, T.; Wang, H.; Jiang, Z.; Wang, J.; Koizumi, M.; Someya, T. A durable nanomesh on-skin strain gauge for natural skin motion monitoring with minimum mechanical constraints. Sci. Adv. 2020, 6, eabb7043. [Google Scholar] [CrossRef]

- Li, R.; Si, Y.; Zhu, Z.; Guo, Y.; Zhang, Y.; Pan, N.; Sun, G.; Pan, T. Supercapacitive iontronic nanofabric sensing. Adv. Mater. 2017, 29, 1700253. [Google Scholar] [CrossRef]

- Acar, G.; Ozturk, O.; Yapici, M.K. Wearable graphene nanotextile embedded smart armband for cardiac monitoring. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar]

- Atalay, A.; Sanchez, V.; Atalay, O.; Vogt, D.M.; Haufe, F.; Wood, R.J.; Walsh, C.J. Batch fabrication of customizable silicone-textile composite capacitive strain sensors for human motion tracking. Adv. Mater. Technol. 2017, 2, 1700136. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.; Jiang, Z. A novel wearable sensor device with conductive fabric and PVDF film for monitoring cardiorespiratory signals. Sens. Actuators A Phys. 2006, 128, 317–326. [Google Scholar] [CrossRef]

- Di Tocco, J.; Raiano, L.; Sabbadini, R.; Massaroni, C.; Formica, D.; Schena, E. A Wearable System with Embedded Conductive Textiles and an IMU for Unobtrusive Cardio-Respiratory Monitoring. Sensors 2021, 9, 3018. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yu, Q.; Cui, X.; Dong, M.; Zhang, J.; Wang, C.; Fan, J.; Zhu, Y.; Guo, Z. An overview of stretchable strain sensors from conductive polymer nanocomposites. J. Mater. Chem. C 2019, 7, 11710–11730. [Google Scholar] [CrossRef]

- Nambiar, S.; Yeow, J.T. Conductive polymer-based sensors for biomedical applications. Biosens. Bioelectron. 2011, 26, 1825–1832. [Google Scholar] [CrossRef]

- Zhou, K.; Dai, K.; Liu, C.; Shen, C. Flexible conductive polymer composites for smart wearable strain sensors. SmartMat 2020, 1, e1010. [Google Scholar] [CrossRef]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes–Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef] [PubMed]

- Jian, M.; Wang, C.; Wang, Q.; Wang, H.; Xia, K.; Yin, Z.; Zhang, M.; Liang, X.; Zhang, Y. Advanced carbon materials for flexible and wearable sensors. Sci. China Mater. 2017, 60, 1026–1062. [Google Scholar] [CrossRef]

- Wang, L.; Loh, K.J. Wearable carbon nanotube-based fabric sensors for monitoring human physiological performance. Smart Mater. Struct. 2017, 26, 055018. [Google Scholar] [CrossRef] [Green Version]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Grassi, A.; Cecchi, F.; Maselli, M.; Röling, M.; Laschi, C.; Cianchetti, M. Warp-knitted textile as a strain sensor: Characterization procedure and application in a comfortable wearable goniometer. IEEE Sens. J. 2017, 17, 5927–5936. [Google Scholar] [CrossRef]

| GF [·] | Sensitivity [kΩ%−1] | Hysteresis Error [%] | |

|---|---|---|---|

| S1 | −0.4 | −0.1 | 22.5 |

| S2 | −1.6 | −1.6 | 11.2 |

| S3 | −0.2 | −0.1 | 10.9 |

| S4 | −1.1 | −3.2 | 3.2 |

| Sensitivity | GF | Hysteresis | Manufacturing | Monitored Parameters | Moisture Influence | Stretchability | |

|---|---|---|---|---|---|---|---|

| [19] | - | 7.26 (60%) | R degradation 0.03 | Expensive | Vocal vowels | - | 150.2% |

| [20] | 114 nF·kPa−1 | - | - | Expensive | Pressure | - | |

| [22] | - | 1.23 | 2.50% | Moderate/ Expensive | Finger motion | - | 150% |

| [23] | - | - | - | Moderate/ Expensive | Respiration | - | |

| [27] | - | 87 ( < 40%), 6 (40% < < 100%) | - | Low-cost/ Moderate | Vocal vowels, pressure | - | 100% |

| [28] | - | 1.75 | - | Low-cost/ Moderate | Joint motion | - | 500% |

| [29] | - | 535 | - | Moderate/ Expensive | Respiration | - | 150% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Tocco, J.; Lo Presti, D.; Rainer, A.; Schena, E.; Massaroni, C. Silicone-Textile Composite Resistive Strain Sensors for Human Motion-Related Parameters. Sensors 2022, 22, 3954. https://doi.org/10.3390/s22103954

Di Tocco J, Lo Presti D, Rainer A, Schena E, Massaroni C. Silicone-Textile Composite Resistive Strain Sensors for Human Motion-Related Parameters. Sensors. 2022; 22(10):3954. https://doi.org/10.3390/s22103954

Chicago/Turabian StyleDi Tocco, Joshua, Daniela Lo Presti, Alberto Rainer, Emiliano Schena, and Carlo Massaroni. 2022. "Silicone-Textile Composite Resistive Strain Sensors for Human Motion-Related Parameters" Sensors 22, no. 10: 3954. https://doi.org/10.3390/s22103954

APA StyleDi Tocco, J., Lo Presti, D., Rainer, A., Schena, E., & Massaroni, C. (2022). Silicone-Textile Composite Resistive Strain Sensors for Human Motion-Related Parameters. Sensors, 22(10), 3954. https://doi.org/10.3390/s22103954