Integrating Pavement Sensing Data for Pavement Condition Evaluation

Abstract

:1. Introduction

2. Aim and Objectives

- To statistically treat RSP data in order to define characteristic IRI values at the FWD test locations.

- To integrate FWD and GPR data, model the pavement response and calculate pavement critical strains.

- To investigate pavement strain modelling aspects based on mechanistic principles considering both deflections and IRI values as input.

- To assess the findings of the modelling process by investigating alternative pavement models and to demonstrate the power of integrating sensing data as an effective solution towards reliable decision-making for transport infrastructure health monitoring.

3. NDT-Based Pavement Sensing

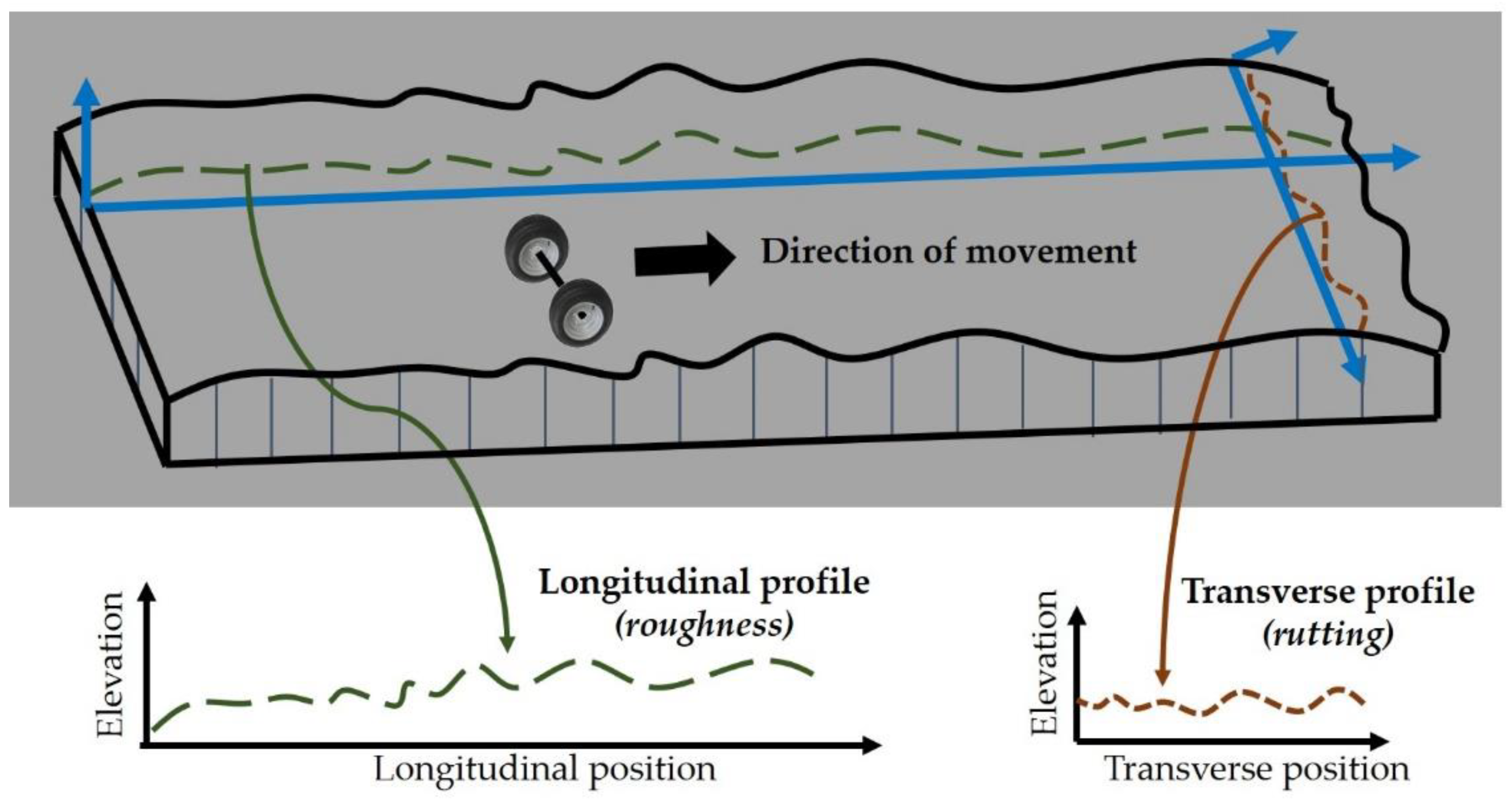

3.1. Roughness—Road Surface Profiler (RSP)

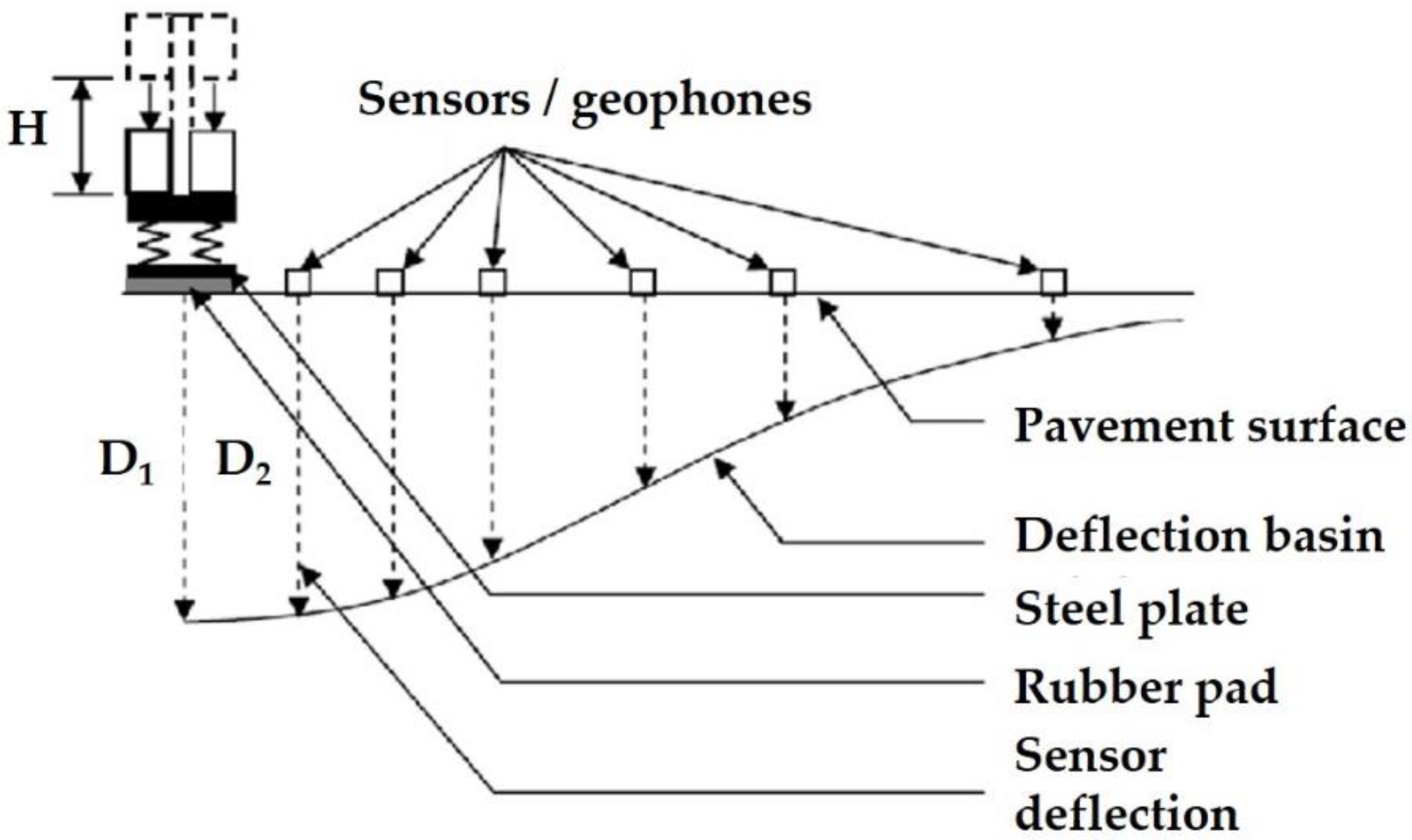

3.2. Load Response—Falling Weight Deflectometer (FWD)

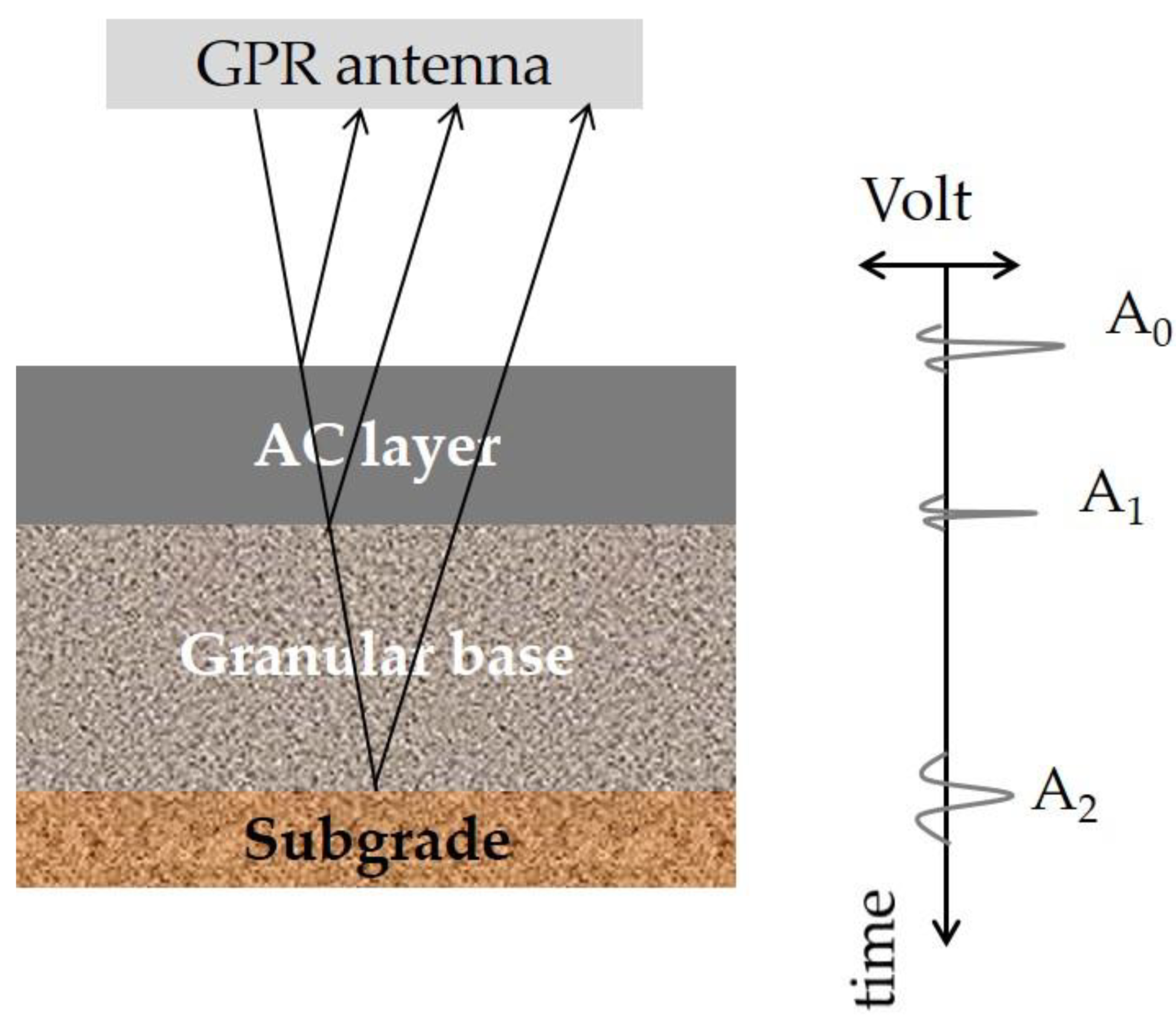

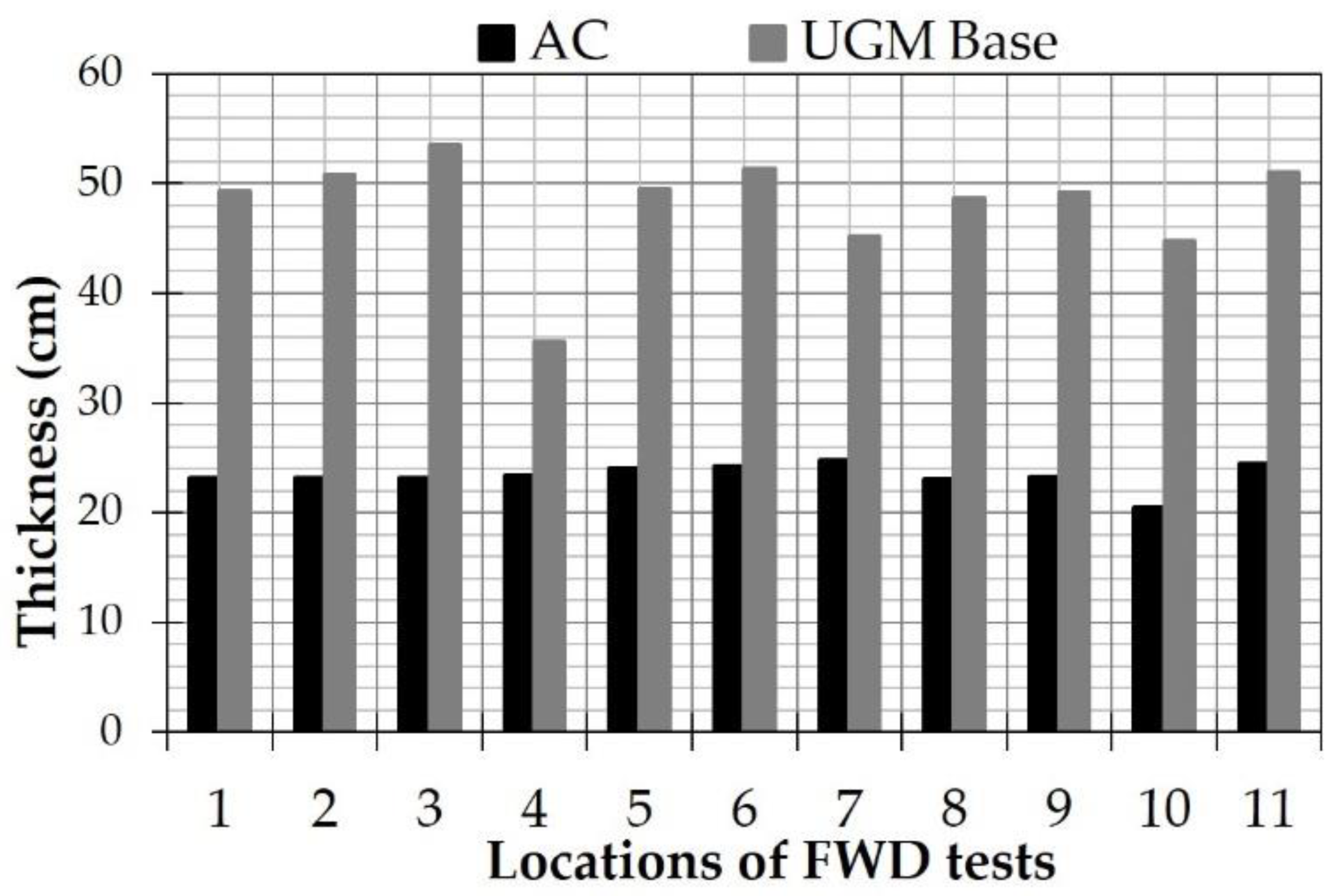

3.3. Pavement Structure—Ground Penetrating Radar (GPR)

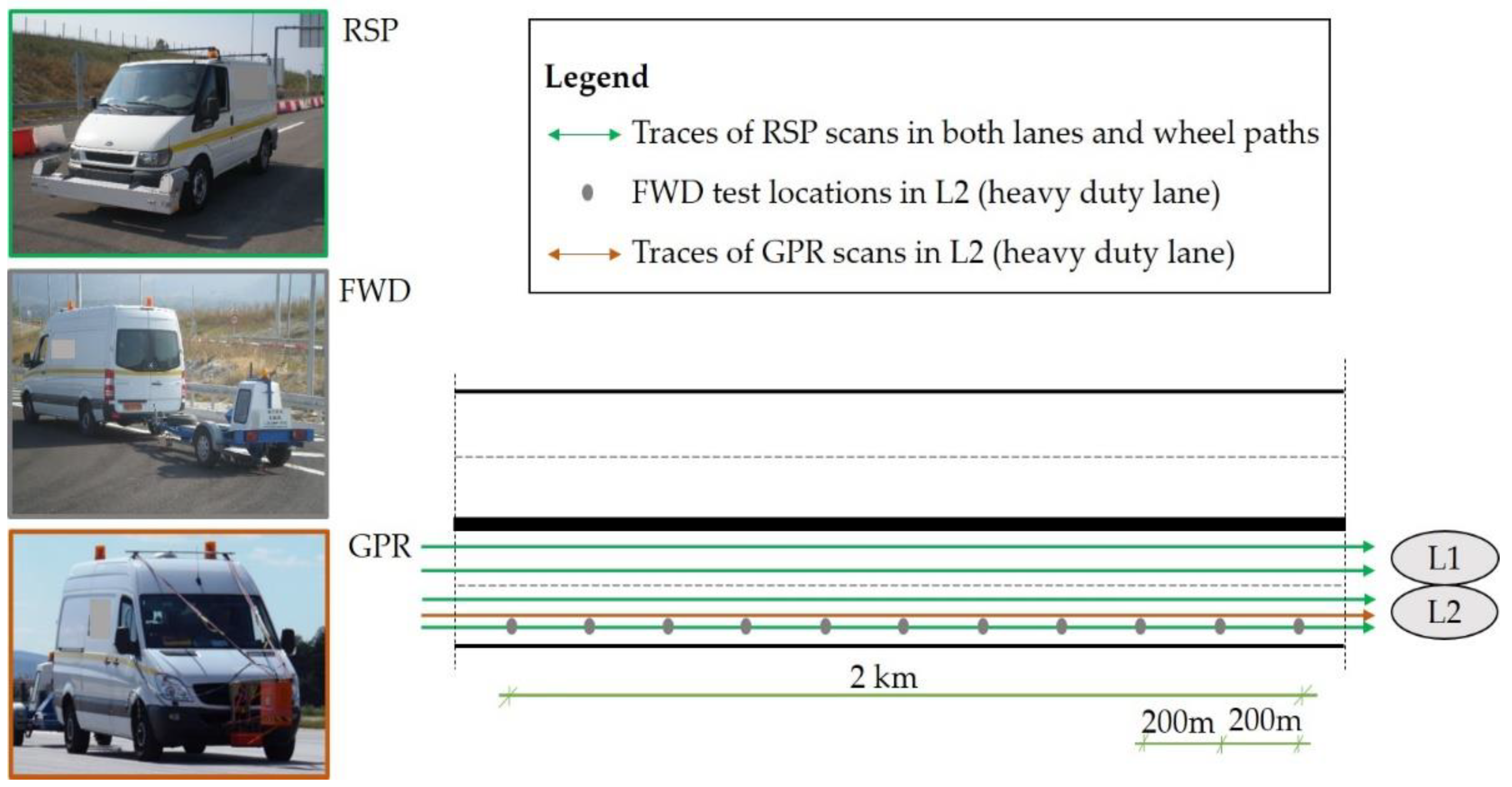

4. Test Site and LTPP Data Collection

5. Analysis

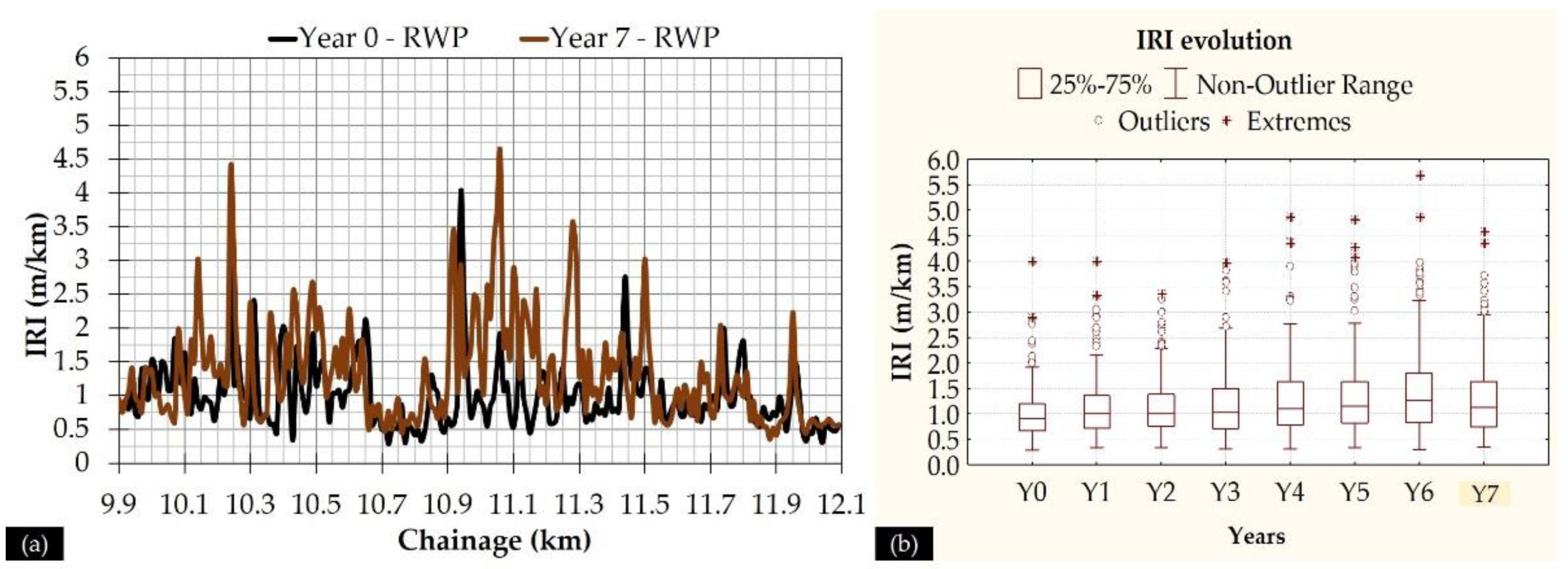

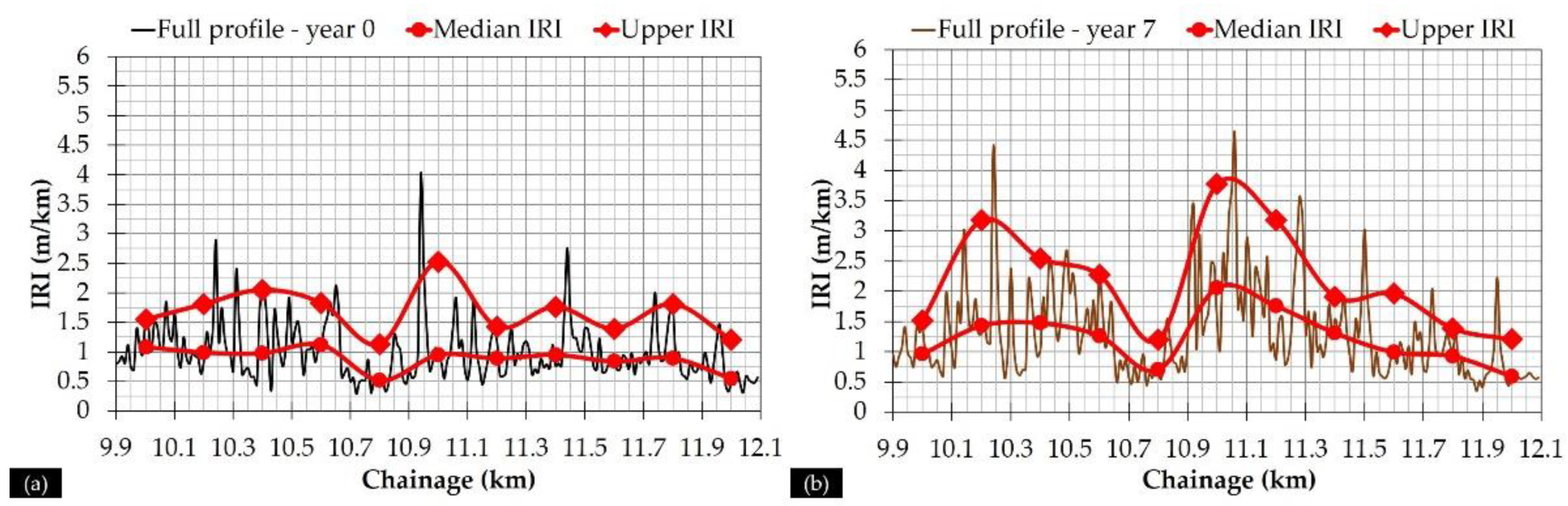

5.1. Roughness Data Processing

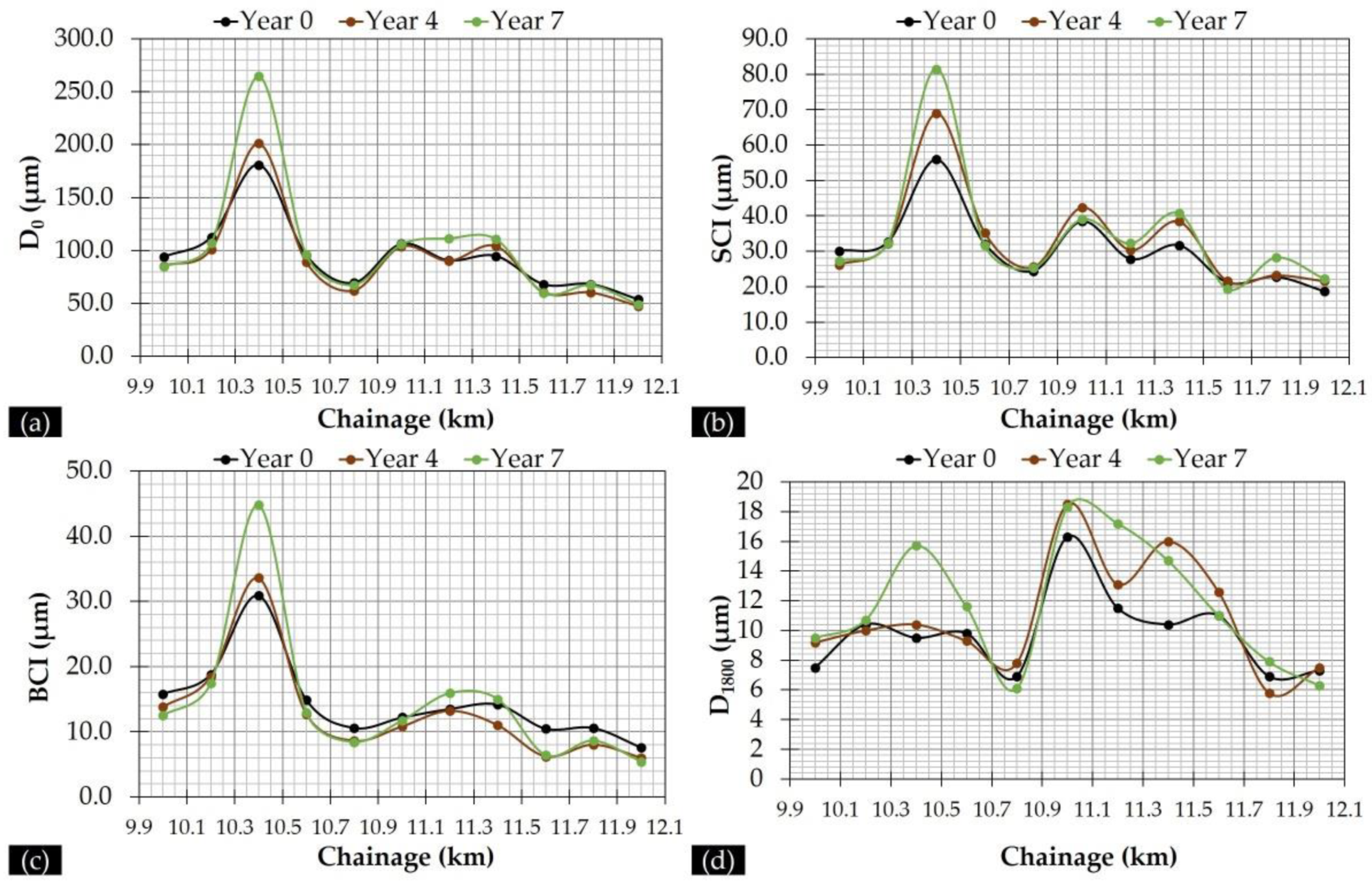

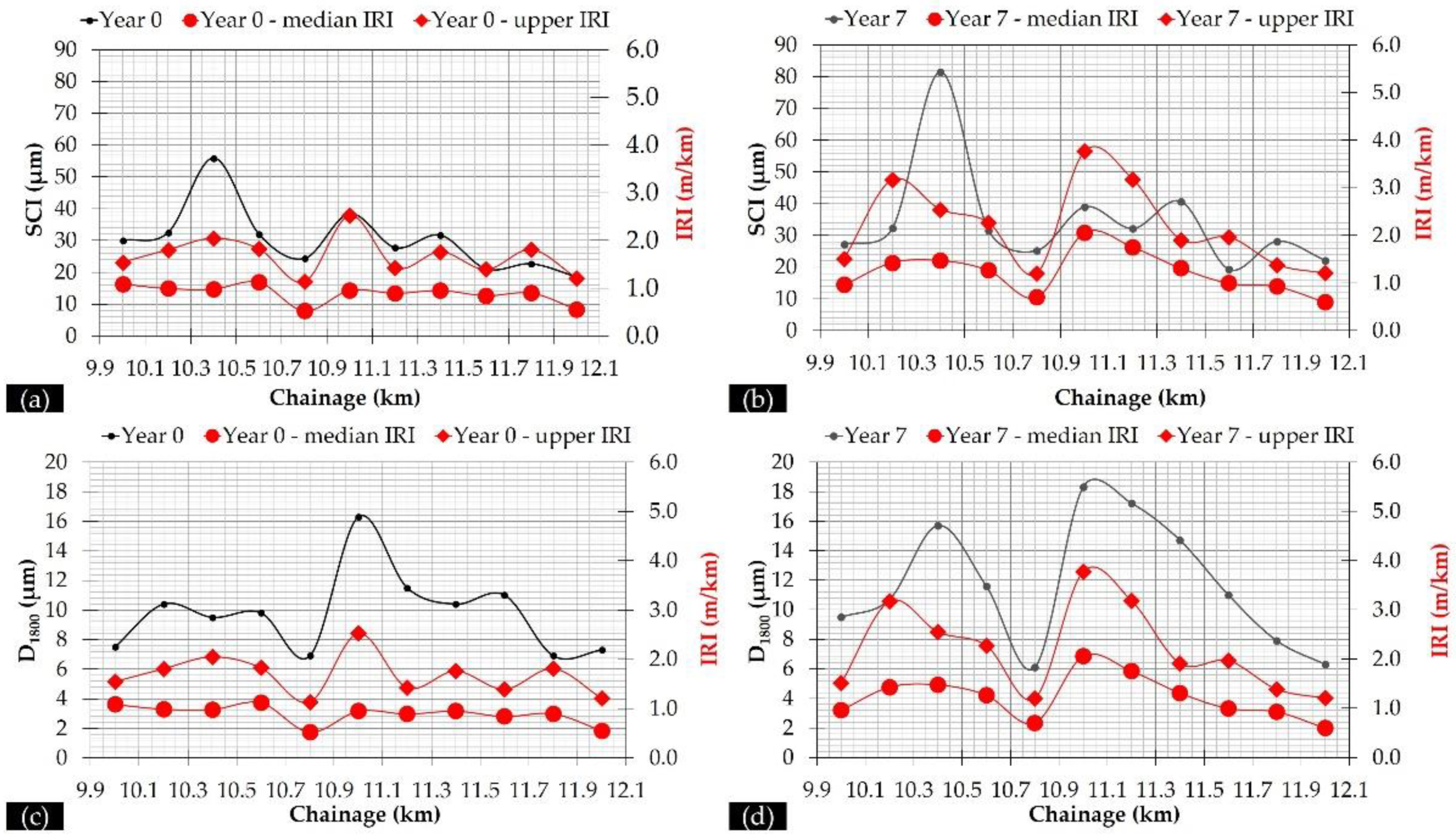

5.2. Deflections

5.3. Response Calculations

5.4. Pavement Strain Modelling

- only DBPs used as input (Case I),

- DBPs and median IRI value used as input (Case II),

- DBPs and “upper” IRI value used as input (Case III), and

- DBPs and both characteristic IRI values used as input (Case IV).

- εpred: strains predicted through models (μm/m),

- εcalc: strains calculated through MLET (μm/m), and

- n: observations (i.e., number of deflection basins under consideration).

6. Discussion Points and Assessment of Findings

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Plati, C.; Loizos, A.; Gkyrtis, K. Assessment of modern roadways using non-destructive geophysical surveying techniques. Surv. Geophys. 2020, 41, 395–430. [Google Scholar] [CrossRef]

- Liu, H.-H.; Xu, Z.-X.; Zhang, Z.-G.; Liu, B.; Hong-Hai, L.; Zhong-Xin, X.; Zhi-Geng, Z.; Bing, L. Research and verification of transfer model for roughness conditions of pavement construction. Int. J. Pavement Res. Technol. 2016, 9, 222–227. [Google Scholar] [CrossRef] [Green Version]

- Loizos, A.; Plati, C. An alternative approach to pavement roughness evaluation. Int. J. Pavement Eng. 2008, 9, 69–78. [Google Scholar] [CrossRef]

- Mubaraki, M. Highway subsurface assessment using pavement surface distress and roughness data. Int. J. Pavement Res. Technol. 2016, 9, 393–402. [Google Scholar] [CrossRef] [Green Version]

- Wix, R. Ride quality specifications—Smoothing out pavements. Road Transp. Res. 2004, 13, 33–43. [Google Scholar]

- Pomoni, M.; Plati, C.; Loizos, A. How Can Sustainable Materials in Road Construction Contribute to Vehicles’ Braking? Vehicles 2020, 2, 55–74. [Google Scholar] [CrossRef] [Green Version]

- Meyer, F.J.; Ajadi, O.A.; Hoppe, E.J. Studying the Applicability of X-Band SAR Data to the Network-Scale Mapping of Pavement Roughness on US Roads. Remote Sens. 2020, 12, 1507. [Google Scholar] [CrossRef]

- Kim, R.E.; Kang, S.; Spencer, B.F.; Al-Qadi, I.L.; Ozer, H. Impact on pavement roughness and deflection on fuel consumption using energy dissipation. J. Eng. Mech. 2019, 145, 04019080. [Google Scholar] [CrossRef]

- Abdelaziz, N.; Abd El-Hakim, R.T.; El-Badawy, S.M.; Afify, H.A. International Roughness Index prediction model for flexible pavements. Int. J. Pavement Eng. 2020, 21, 88–99. [Google Scholar] [CrossRef]

- Drainakis, A.; Pomoni, M.; Plati, C. The importance of maintaining pavement roughness to reduce carbon footprint. In Bearing Capacity of Roads, Railways and Airfields: Proceedings of the 10th International Conference on the Bearing Capacity of Roads, Railways and Airfields (BCRRA), Athens, Greece, 28–30 June 2017; Loizos, A., Al-Qadi, I., Scarpas, T., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 2135–2139. [Google Scholar]

- Ghosh, L.E.; Lu, L.; Ozer, H.; Ouyang, Y.; Al-Qadi, I.L. Effects of Pavement Surface Roughness and Congestion on Expected Freeway Traffic Energy Consumption. Transp. Res. Rec. 2015, 2503, 10–19. [Google Scholar] [CrossRef]

- Flintsch, G.W.; Valeri, S.M.; Katicha, S.W.; Izeppi, E.D.D.L.; Medina-Flintsch, A. Probe vehicles used to measure road ride quality: Pilot demonstration. Transp. Res. Rec. 2012, 2304, 158–165. [Google Scholar] [CrossRef]

- Abulizi, N.; Kawamura, A.; Tomiyama, K.; Fujita, S. Measuring and evaluating of road roughness conditions with a compact road profiler and ArcGIS. J. Traffic Transp. Eng. 2016, 3, 398–411. [Google Scholar] [CrossRef] [Green Version]

- Sayers, M.W. On the calculation of international roughness index from longitudinal road profile. Transp. Res. Rec. 1995, 1501, 1–12. [Google Scholar]

- Chandra, S.; Ravi Sekhar, C.; Kumar Bharti, A.; Kangadurai, B. Relationship between Pavement Roughness and Distress Parameters for Indian Highways. J. Transp. Eng. 2013, 139, 467–475. [Google Scholar] [CrossRef]

- Fakhri, M.; Dezfoulian, R.S. Pavement structural evaluation based on roughness and surface distress survey using neural network model. Constr. Build. Mater. 2019, 204, 768–780. [Google Scholar] [CrossRef]

- Karballaeezadeh, N.; Mohammadzadeh, D.S.; Moazemi, D.; Band, S.S.; Mosavi, A.; Reuter, U. Smart Structural Health Monitoring of Flexible Pavements Using Machine Learning Methods. Coatings 2020, 10, 1100. [Google Scholar] [CrossRef]

- Park, K.; Thomas, N.E.; Lee, K.W. Applicability of the International Roughness Index as a Predictor of Asphalt Pavement Condition. J. Transp. Eng. 2007, 133, 706–709. [Google Scholar] [CrossRef]

- Mactutis, J.A.; Alavi, S.H.; Ott, W.C. Investigation of relationship between roughness and pavement surface distress based onWesTrack project. Transp. Res. Rec. 2000, 1699, 107–113. [Google Scholar] [CrossRef]

- Bilodeau, J.P.; Gagnon, L.; Doré, G. Assessment of the relationship between the international roughness index and dynamic loading of heavy vehicles. Int. J. Pavement Eng. 2017, 18, 693–701. [Google Scholar] [CrossRef]

- Kakara, S.; Chowdary, V. Effect of Pavement Roughness and Transverse Slope on the Magnitude of Wheel Loads. Arab. J. Sci. Eng. 2020, 45, 4405–4418. [Google Scholar] [CrossRef]

- Elnashar, G.; Bhat, R.B.; Sedaghati, R. Modeling and dynamic analysis of a vehicle-flexible pavement coupled system subjected to road surface excitation. J. Mech. Sci. Technol. 2019, 33, 3115–3125. [Google Scholar] [CrossRef]

- Misaghi, S.; Tirado, C.; Nazarian, S.; Carasco, C. Impact of pavement roughness and suspension systems on vehicle dynamic loads on flexible pavements. Transp. Eng. 2021, 3, 100045. [Google Scholar] [CrossRef]

- Sollazo, G.; Fwa, T.F.; Bosurgi, G. An ANN model to correlate roughness and structural performance in asphalt pavements. Constr. Build. Mater. 2017, 134, 684–693. [Google Scholar] [CrossRef]

- Rada, G.R.; Perera, R.; Prabhakar, V. Relating Ride Quality and Structural Adequacy for Pavement Rehabilitation/Design Decisions; Report No. FHWAHRT-12-035; Federal Highway Administration: Washington, DC, USA, 2012.

- Crook, A.L.; Montgomery, S.R.; Guthrie, W.S. Use of falling weight deflectometer data for network-level flexible pavement management. Transp. Res. Rec. 2012, 2304, 75–85. [Google Scholar] [CrossRef]

- Elbagalati, O.; Elseifi, M.A.; Gaspard, K.; Zhang, Z. Implementation of the Structural Condition Index into the Louisiana Pavement Management System Based on Rolling Wheel Deflectometer Testing. Transp. Res. Rec. 2017, 2641, 39–47. [Google Scholar] [CrossRef]

- Plati, C.; Loizos, A.; Gkyrtis, K. Integration of non-destructive testing methods to assess asphalt pavement thickness. NDT E Int. 2020, 115, 102292. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Loizos, A.; Plati, C. A mechanistic framework for field response assessment of asphalt pavements. Int. J. Pavement Res. Technol. 2021, 14, 174–185. [Google Scholar] [CrossRef]

- Marecos, V.; Fontul, S.; Antunes, M.L.; Solla, M. Evaluation of a highway pavement using non-destructive tests: Falling Weight Deflectometer and Ground Penetrating Radar. Constr. Build. Mater. 2017, 154, 1164–1172. [Google Scholar] [CrossRef]

- Plati, C.; Gkyrtis, K.; Loizos, A. Integrating non-destructive testing data to produce asphalt pavement critical strains. Nondestruct. Test. Eval. 2020, 1–25. [Google Scholar] [CrossRef]

- Perera, R.; Kohn, S. Effects of Variation in Quarter-Car Simulation Speed on International Roughness Index Algorithm. Transp. Res. Rec. 2004, 1889, 144–151. [Google Scholar] [CrossRef]

- Kumar Singh, D.; Gundaliya, P.J. Flexible pavement evaluation using profilometer for unevenness. Int. Res. J. Eng. Technol. 2018, 5, 1024–1028. [Google Scholar]

- Sayers, M.W.; Karamihas, S.M. The Little Book of Profiling; UMTRI: Ann Arbor, MI, USA, 1997. [Google Scholar]

- Marecos, V.; Solla, M.; Fontul, S.; Antunes, V. Assessing the pavement subgrade by combining different non-destructive methods. Constr. Build. Mater. 2017, 135, 76–85. [Google Scholar] [CrossRef] [Green Version]

- Smith, K.D.; Bruinsma, J.E.; Wade, M.J.; Chatti, K.; Vandenbossche, J.M.; Yu, H.T. Using Falling Weight Deflectometer Data with Mechanistic-Empirical Design and Analysis, Volume I: Final Report; Report No. FHWA-HRT-16-009; Federal Highway Administration: McLean, VA, USA, 2017.

- Schmalzer, P.N. Long-Term Pavement Performance Program Manual for Falling Weight Deflectometer Measurements; Report No. FHWA-HRT-06-132; Office of Infrastructure Research and Development, Federal Highway Administration: McLean, VA, USA, 2006.

- Horak, E. Benchmarking the structural condition of flexible pavements with deflection bowl parameters. J. S. Afr. Inst. Civ. Eng. 2008, 50, 2–9. [Google Scholar]

- Kavussi, A.; Abbasghorbani, M.; Moghadas-Nejad, F.; Bamdad-Ziksari, A. A new method to determine maintenance and repair activities at network level pavement management using falling weight deflectometer. J. Civ. Eng. Manag. 2017, 23, 338–346. [Google Scholar] [CrossRef]

- Georgouli, K.; Pomoni, M.; Cliatt, B.; Loizos, A. A simplified approach for the estimation of HMA dynamic modulus for in service pavements. In Proceedings of the 6th International Conference on Bituminous Mixtures and Pavements (ICONFBMP), Thessaloniki, Greece, 10–12 June 2015; pp. 661–670. [Google Scholar]

- Leng, Z.; Al-Qadi, I.L. An innovative method for measuring pavement dielectric constant using the extended CMP method with two air-coupled GPR systems. NDT E Int. 2014, 66, 90–98. [Google Scholar] [CrossRef]

- Saarenketo, T.; Scullion, T. Road evaluation with ground penetrating radar. J. Appl. Geophys. 2000, 43, 119–138. [Google Scholar] [CrossRef]

- Zhao, S.; Al-Qadi, I.L.; Wang, S. Prediction of thin asphalt concrete overlay thickness and density using nonlinear optimization of GPR data. NDT E Int. 2018, 100, 20–30. [Google Scholar] [CrossRef]

- Shangguan, P.; Al-Qadi, I.L.; Leng, Z.; Schmitt, R.; Faheen, A. Innovative approach for asphalt pavement compaction monitoring using ground penetrating radar. Transp. Res. Rec. 2013, 2425, 79–87. [Google Scholar] [CrossRef]

- Benedetto, A.; Benedetto, F.; Tosti, F. GPR applications for geotechnical stability of transportation infrastructures. Nondestruct. Test. Eval. 2012, 27, 253–262. [Google Scholar] [CrossRef]

- Tosti, F.; Bianchini Ciampoli, L.; D’Amico, F.; Alani, A.M.; Benedetto, A. An experimental-based model for the assessment of the mechanical properties of road pavements using ground-penetrating radar. Constr. Build. Mater. 2018, 165, 966–974. [Google Scholar] [CrossRef]

- Solla, M.; Pérez-Gracia, V.; Fontul, S. A Review of GPR Application on Transport Infrastructures: Troubleshooting and Best Practices. Remote Sens. 2021, 13, 672. [Google Scholar] [CrossRef]

- Solla, M.; Gonzalez-Jorge, H.; Lorenzo, H.; Arias, P. Uncertainty evaluation of the 1 GHz GPR antenna for the estimation of concrete asphalt thickness. Measurement 2013, 46, 3032–3040. [Google Scholar] [CrossRef]

- Maser, K.R.; Scullion, T. Automated pavement subsurface profiling using radar: Case studies of four experimental field sites. Transp. Res. Rec. 1992, 1344, 148–154. [Google Scholar]

- Bianchini Ciampoli, L.; Tosti, F.; Economou, N.; Benedetto, F. Signal Processing of GPR Data for Road Surveys. Geosciences 2019, 9, 96. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Zhao, S.; Al-Qadi, I.L. Continuous real-time monitoring of flexible pavement layer density and thickness using ground penetrating radar. NDT E Int. 2018, 100, 48–54. [Google Scholar] [CrossRef]

- Maser, K.R. Condition assessment of transportation infrastructure using ground penetrating radar. J. Infrastruct. Syst. 1996, 2, 94–101. [Google Scholar] [CrossRef]

- Molenaar, A.A.A. Structural evaluation and strengthening of flexible pavements using deflection measurements and visual condition surveys. In Structural Design of Pavements—Part IV; Lecture Notes: San Jose, Costa Rica, 2006. [Google Scholar]

- Washington State Department of Transportation. Everseries User’s Guide. Pavement Analysis Computer Software and Case Studies; Washington State Department of Transportation: Olympia, WA, USA, 2005.

- BISAR. Shell Pavement Design Method, BISAR PC User Manual; Shell International Petroleum Company Limited: London, UK, 1998. [Google Scholar]

- Tarefder, R.A.; Ahmed, M.U. Consistency and accuracy of selected FWD backcalculation software for computing layer modulus of airport pavements. Int. J. Geotech. Eng. 2013, 7, 21–35. [Google Scholar] [CrossRef]

- Irwin, L.; Yang, W.; Stubstad, R. Deflection Reading Accuracy and Layer Thickness Accuracy in Backcalculation of Pavement Layer Moduli. In Nondestructive Testing of Pavements and Backcalculation of Moduli; Baladi, G., Bush, A., Eds.; ASTM International: West Conshohocken, PA, USA, 1989; pp. 229–244. [Google Scholar] [CrossRef]

- Li, M.; Wang, H. Prediction of asphalt pavement responses from FWD surface deflections using soft computing methods. J. Transp. Eng. Part B Pavements 2018, 144, 04018014. [Google Scholar] [CrossRef]

- Loizos, A.; Gkyrtis, K.; Plati, C. Modelling asphalt pavement responses based on field and laboratory data. In Accelerated Pavement Testing to Transport Infrastructure Innovation; Chabot, A., Hornych, P., Harvey, J., Loria-Salazar, L., Eds.; Springer: Cham, Switzerland, 2020; Volume 96, pp. 438–447. [Google Scholar] [CrossRef]

- Losa, M.; Bacci, R.; Leandri, P. A statistical model for prediction of critical strains in pavements from deflection measurements. Road Mater. Pavement Des. 2008, 9, 373–396. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C.; Loizos, A.; Yannis, G. Investigation of pavement skid resistance and macrotexture on a long-term basis. Int. J. Pavement Eng. 2020, 1–10. [Google Scholar] [CrossRef]

- Plati, C.; Pomoni, M.; Stergiou, T. From Mean Texture Depth to Mean Profile Depth: Exploring possibilities. In Proceedings of the 7th International Conference on Bituminous Mixtures and Pavements (ICONFBMP), Thessaloniki, Greece, 12–14 June 2019; pp. 639–644. [Google Scholar] [CrossRef]

- Irwin, L.H. Backcalculation: An overview and perspective. Presented at the 2002 FWD User Group Annual Meeting, Roanoke, VA, USA, 21–25 October 2002. [Google Scholar]

- Alani, A.M.; Tosti, F.; Bianchini Ciampoli, L.; Gagliardi, V.; Benedetto, A. An integrated investigative approach in health monitoring of masonry arch bridges using GPR and InSAR technologies. NDT E Int. 2020, 115, 102288. [Google Scholar] [CrossRef]

- Fiorentini, N.; Maboudi, M.; Leandri, P.; Losa, M.; Gerke, M. Surface Motion Prediction and Mapping for Road Infrastructures Management by PS-InSAR Measurements and Machine Learning Algorithms. Remote Sens. 2020, 12, 3976. [Google Scholar] [CrossRef]

- Karimzadeh, S.; Matsuoka, M. Remote Sensing X-Band SAR Data for Land Subsidence and Pavement Monitoring. Sensors 2020, 20, 4751. [Google Scholar] [CrossRef] [PubMed]

| Indexes | Equation | Pavement Region |

|---|---|---|

| Central (maximum) deflection: d0 [μm] | - | Overall pavement condition |

| Surface Curvature Index (SCI) [μm] | d0 − d300 | Surface layer condition |

| Base Damage Index (BDI) [μm] | d300 − d600 | Intermediate layers condition |

| Base Curvature Index (BCI) [μm] | d600 − d900 | Intermediate layers condition |

| AREA parameter (AREA) [dimensionless] | 6(d0 + 2d300 + 2d600 + d900)/d0 | Overall pavement condition |

| Area Under Pavement Profile (AUPP) [μm] | 0.5(5d0 − 2d300 − 2d600 − d900) | Upper layers pavement condition |

| Deflection at the outer geophone: d1800 [μm] | - | Subgrade condition |

| NDT System | Years after Construction | Monitoring Periods | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| RSP | X | X | X | X | X | X | X | X | 8 |

| FWD | X | X | X | X | X | X | X | X | 8 |

| GPR | X | 1 | |||||||

| Test Condition | Description |

|---|---|

| Number or GPR scans (scans/m) | 10 |

| Length of each scan (km in one file) | 10 |

| Road positioning | Right wheel path |

| Direction of scanning | Longitudinal |

| Subsection | Reference Location (FWD Test) | Year 0 | Year 7 |

|---|---|---|---|

| 1 | P1 (+10.0) | 27% | 33% |

| 2 | P2 (+10.2) | 43% | 55% |

| 3 | P3 (+10.4) | 53% | 44% |

| 4 | P4 (+10.6) | 36% | 37% |

| 5 | P5 (+10.8) | 46% | 34% |

| 6 | P6 (+11.0) | 69% | 44% |

| 7 | P7 (+11.2) | 38% | 44% |

| 8 | P8 (+11.4) | 47% | 27% |

| 9 | P9 (+11.6) | 26% | 53% |

| 10 | P10 (+11.8) | 40% | 43% |

| 11 | P11 (+12.0) | 45% | 55% |

| Pairs | Year 0 | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | Year 6 | Year 7 |

|---|---|---|---|---|---|---|---|---|

| D0-IRImedian | 0.28 | 0.21 | 0.51 | 0.24 | 0.10 | 0.23 | 0.16 | 0.24 |

| SCI-IRImedian | 0.26 | 0.19 | 0.47 | 0.18 | 0.10 | 0.16 | 0.10 | 0.21 |

| BCI-IRImedian | 0.25 | 0.13 | 0.42 | 0.13 | 0.04 | 0.20 | 0.08 | 0.17 |

| D1800-IRImedian | 0.12 | 0.77 | 0.38 | 0.30 | 0.35 | 0.30 | 0.52 | 0.88 |

| D0-IRIupper | 0.37 | 0.76 | 0.87 | 0.67 | 0.52 | 0.60 | 0.76 | 0.17 |

| SCI-IRIupper | 0.47 | 0.71 | 0.80 | 0.69 | 0.52 | 0.71 | 0.72 | 0.12 |

| BCI-IRIupper | 0.19 | 0.69 | 0.88 | 0.48 | 0.35 | 0.54 | 0.66 | 0.12 |

| D1800-IRIupper | 0.46 | 0.49 | 0.18 | 0.47 | 0.33 | 0.15 | 0.28 | 0.69 |

| Statistics | EAC at 25 °C (MPa) | EBASE (MPa) | ESUBG (MPa) | RMS (%) |

|---|---|---|---|---|

| Min | 1327 | 83 | 373 | 0.6 |

| 25% | 3095 | 400 | 625 | 2.3 |

| Median | 4621 | 639 | 778 | 3.4 |

| 75% | 5924 | 908 | 1021 | 4.9 |

| Max | 16493 | 2015 | 1457 | 12.9 |

| Mean | 5180 | 729 | 830 | 3.7 |

| Stand. Dev. | 2863 | 469 | 281 | 2.1 |

| CV % | 55% | 64% | 34% | 56% |

| Strains | Case I | Case II | Case III | Case IV |

|---|---|---|---|---|

| R2 for εH (AC) at T (°C) | 1.00 | 1.00 | Same as Case I | Same as Case II |

| RMSPE % for εH (AC) at T (°C) | 2.4 | 2.3 | Same as Case I | Same as Case II |

| R2 for εH (AC) at 20 °C | 0.97 | Same as Case I | Same as Case I | Same as Case I |

| RMSPE % for εH (AC) at 20 °C | 0.9 | Same as Case I | Same as Case I | Same as Case I |

| R2 for εV (SUBG) at T (°C) | 0.90 | 0.91 | Same as Case I | 0.92 |

| RMSPE % for εV (SUBG) at T (°C) | 9.9 | 8.2 | Same as Case I | 7.2 |

| R2 for εV (SUBG) at 20 °C | 0.75 | 0.76 | Same as Case I | Same as Case II |

| RMSPE % for εV (SUBG) at 20 °C | 18.0 | 13.8 | Same as Case I | Same as Case II |

| Model (Layers) | Strains | Case I | Case II | Case III | Case IV |

|---|---|---|---|---|---|

| A (AC/UGM/SUBG) | R2 for | 0.90 | 0.91 | Same as Case I | 0.92 |

| RMSPE % for | 9.9 | 8.2 | Same as Case I | 7.2 | |

| B (AC/UGM + SUBG/SOIL) | R2 for | 0.91 | 0.92 | Same as Case I | 0.93 |

| RMSPE % for | 9.8 | 7.8 | Same as Case I | 7.4 | |

| C (AC/UGM/SUBG or SUBG + STIFF SOIL) | R2 for | 0.90 | 0.91 | Same as Case I | 0.92 |

| RMSPE % for | 11.4 | 10.8 | Same as Case I | 9.4 |

| Variable | Model A AC/UGM/SUBG | Model B AC/UGM + SUBG/SOIL | Model C AC/UGM/SUBG or SUBG + STIFF SOIL | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t -Value | Sig. | t-Value | Sig. | t-Value | Sig. | t-Value | Sig. | t-Value | Sig. | t-Value | Sig. | |

| Constant | 15.087 | 0.000 | 7.778 | 0.000 | 10.141 | 0.000 | 5.874 | 0.000 | 14.712 | 0.000 | 1.775 | 0.080 |

| logD0 | −11.301 | 0.000 | −6.183 | 0.000 | −3.821 | 0.000 | 0.710 | 0.480 | −11.248 | 0.000 | 4.535 | 0.000 |

| logSCI | 19.039 | 0.000 | 7.203 | 0.000 | 18.277 | 0.000 | 6.859 | 0.000 | 17.632 | 0.000 | 2.053 | 0.043 |

| logBDI | 23.488 | 0.000 | 8.672 | 0.000 | 14.061 | 0.000 | 1.707 | 0.092 | 21.817 | 0.000 | 1.046 | 0.299 |

| logBCI | 12.064 | 0.000 | 2.954 | 0.004 | 5.297 | 0.000 | −3.160 | 0.002 | 10.779 | 0.000 | 0.176 | 0.861 |

| log(D900–D1200) | 5.675 | 0.000 | 1.994 | 0.050 | 2.185 | 0.032 | 0.261 | 0.795 | 5.158 | 0.000 | −0.075 | 0.941 |

| logD1800 | 5.893 | 0.000 | 12.090 | 0.000 | 1.696 | 0.094 | 18.918 | 0.000 | 6.783 | 0.000 | 8.745 | 0.000 |

| IRImedian | 2.110 | 0.038 | 6.583 | 0.000 | 1.059 | 0.293 | 7.282 | 0.000 | 2.596 | 0.011 | 5.342 | 0.000 |

| IRIupper | −1.278 | 0.205 | −2.983 | 0.004 | 0.575 | 0.567 | −3.254 | 0.002 | −1.632 | 0.107 | −3.052 | 0.003 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gkyrtis, K.; Loizos, A.; Plati, C. Integrating Pavement Sensing Data for Pavement Condition Evaluation. Sensors 2021, 21, 3104. https://doi.org/10.3390/s21093104

Gkyrtis K, Loizos A, Plati C. Integrating Pavement Sensing Data for Pavement Condition Evaluation. Sensors. 2021; 21(9):3104. https://doi.org/10.3390/s21093104

Chicago/Turabian StyleGkyrtis, Konstantinos, Andreas Loizos, and Christina Plati. 2021. "Integrating Pavement Sensing Data for Pavement Condition Evaluation" Sensors 21, no. 9: 3104. https://doi.org/10.3390/s21093104

APA StyleGkyrtis, K., Loizos, A., & Plati, C. (2021). Integrating Pavement Sensing Data for Pavement Condition Evaluation. Sensors, 21(9), 3104. https://doi.org/10.3390/s21093104