Estimation of Cavities beneath Plate Structures Using a Microphone: Laboratory Model Tests

Abstract

:1. Introduction

2. Experimental Study

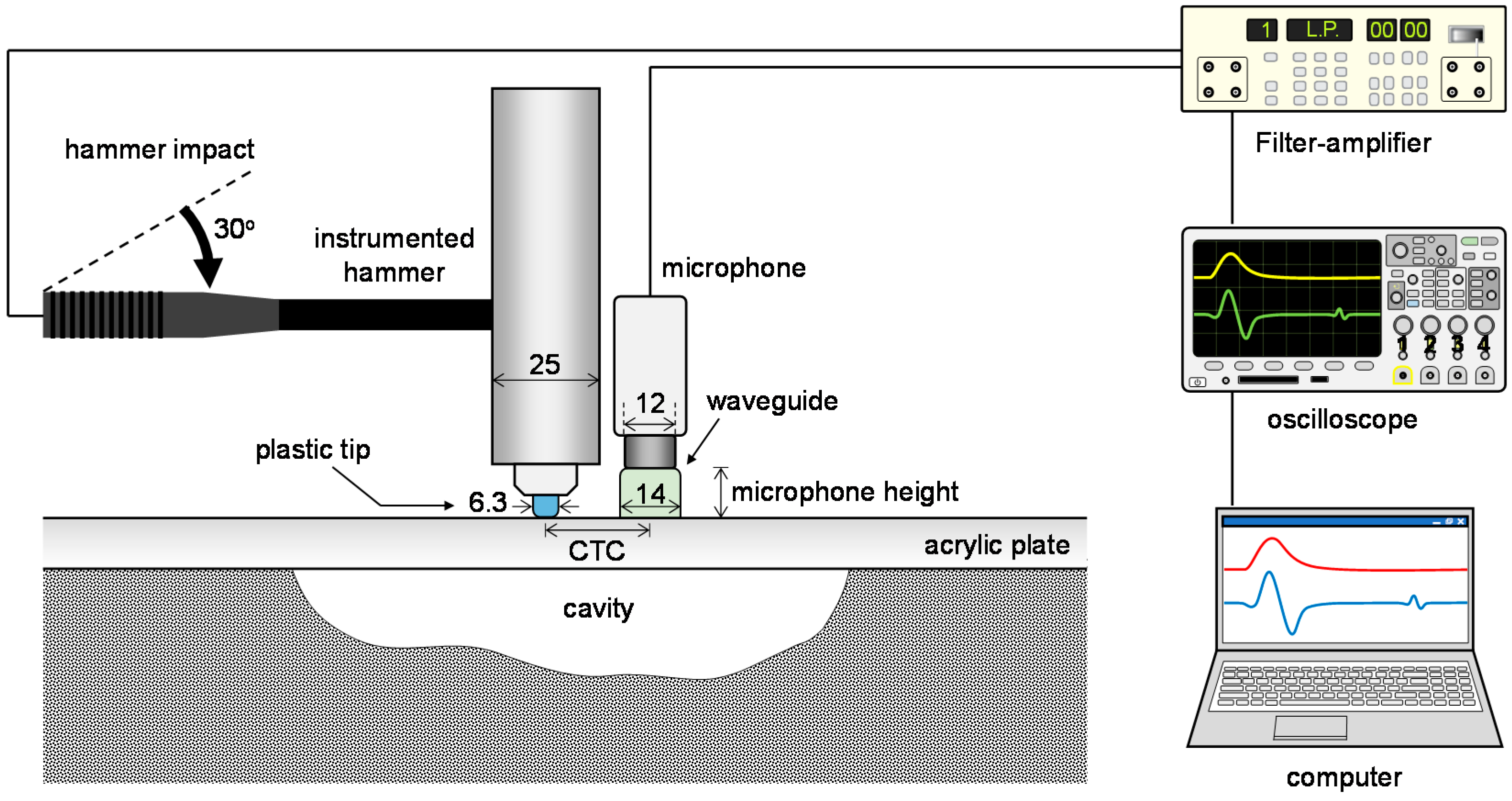

2.1. Measurement System

2.2. Experimental Setup

3. Experimental Results

3.1. Height of Microphone and Spacing between Hammer and Microphone

3.2. Measured Sound Waves

4. Analyses and Discussion

4.1. MARSE Energy

4.1.1. Value of MARSE Energy

4.1.2. Normalized MARSE Energy

4.2. Flexibility

4.2.1. Mobility Spectrum

4.2.2. Normalized Mobility

4.3. Wavelet Transforms

4.3.1. Wavelet Transform Results

4.3.2. Peak Magnitude of Wavelet Transform

4.3.3. Normalized Peak Magnitude

4.3.4. Frequency Corresponding to Peak Magnitude

4.3.5. Normalized Frequency Corresponding to Peak Magnitude

4.4. Cavity Detection

4.4.1. Cavity Identification

4.4.2. Cavity Size Estimation

5. Summary and Conclusions

- The (normalized) MARSE energy and the (normalized) flexibility at the cavity section were higher than those at the soil section due to the occurrence of flexural vibration behavior of the plate.

- Thus, the (normalized) MARSE energy at the cavity section was higher than that at the soil section for both acrylic plates. In addition, because the acrylic plate became more flexible at the cavity section due to the loss of support, the (normalized) flexibility at the cavity section was higher than that at the soil section.

- The (normalized) peak magnitude of the wavelet transform at the cavity section was greater than that at the soil section due to the higher attenuation at the soil section. Furthermore, the (normalized) frequency corresponding to the peak magnitude at the cavity section was lower than that at the soil section because the main frequency of the sound waves was lower at the cavity section.

- The accuracy of cavity detection increased for thicker plates with detection using the MARSE energy, and for thinner plates with detection using the flexibility. In addition, the accuracies of cavity detection using both the peak magnitude and the frequency are independent of the plate thickness.

- Among the four analysis methods, the cavity size can be estimated using the MARSE energy, flexibility, and frequency corresponding to the peak magnitude of the wavelet transform. When the MARSE energy was used, the cavity size was overestimated for the thinner acrylic plate, whereas it was estimated as the actual size for the thicker plate. When the flexibility was used, the cavity size was underestimated for the thinner acrylic plate, and overestimated for the thicker plate. Furthermore, the cavity size was overestimated regardless of the plate thickness based on the frequency. In other words, the cavity size may be under- or overestimated according to the plate thickness and the selected analysis method. On the other hand, the average of the cavity sizes estimated using the three methods was slightly larger than the actual cavity size regardless of the plate thickness. Therefore, the effect of the plate thickness on the estimated cavity size may be minimized by comprehensive analyses of the sound waves.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, W.-T.; Kang, S.; Lee, S.J.; Lee, J.-S. Analyses of GPR signals for characterization of ground conditions in urban areas. J. Appl. Geophys. 2018, 152, 65–76. [Google Scholar] [CrossRef]

- Benedetto, A.; Pensa, S. Indirect diagnosis of pavement structural damages using surface GPR reflection techniques. J. Appl. Geophys. 2007, 62, 107–123. [Google Scholar] [CrossRef]

- Jo, Y.-S.; Cho, S.-H.; Jang, Y.-S. Field investigation and analysis of ground sinking development in a metropolitan city, Seoul, Korea. Environ. Earth Sci. 2016, 75, 1353. [Google Scholar] [CrossRef]

- Gucunski, N.; Ganji, V.; Maher, M. Effects of obstacles on Rayleigh wave dispersion obtained from the SASW test. Soil Dyn. Earthq. Eng. 1996, 15, 223–231. [Google Scholar] [CrossRef]

- Hong, W.T.; Lee, J.S. Estimation of ground cavity configurations using ground penetrating radar and time domain reflec-tometry. Nat. Hazards 2018, 92, 1789–1807. [Google Scholar] [CrossRef]

- Lai, W.W.; Chang, R.K.; Sham, J.F. Detection and imaging of city’s underground void by GPR. In Proceedings of the 2017 9th International Workshop on Advanced Ground Penetrating Radar (IWAGPR), Edinburgh, UK, 28–30 June 2017; pp. 1–6. [Google Scholar]

- Kang, S.; Lee, J.S.; Lee, S.J.; Lee, J.W.; Hong, W.T. Detection of abnormal area of ground in urban area by rectification of ground penetrating radar signal. J. Korean Soc. Eng. Geol. 2017, 27, 217–231. [Google Scholar]

- Kang, S.; Lee, J.S.; Lee, S.J.; Park, Y.K.; Hong, W.T. The effect of directivity of antenna for the evaluation of abnormal area using ground penetrating radar. J. Korean Geotech. Soc. 2017, 33, 21–34. [Google Scholar]

- Geophysical Survey Systems, Inc. RADAN 7; GSSI: Nashua, NH, USA, 2012; Available online: https://www.geophysical.com/wp-content/uploads/2017/10/GSSI-RADAN-7-Manual.pdf (accessed on 21 April 2021).

- Yang, Y.; Lu, J.; Li, R.; Zhao, W.; Yan, D. Small-Scale Void-Size Determination in Reinforced Concrete Using GPR. Adv. Civ. Eng. 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, J.; Huang, L.; Feng, X.; Liu, F. Improving Target Detection Accuracy Based on Multipolarization MIMO GPR. IEEE Trans. Geosci. Remote Sens. 2014, 53, 15–24. [Google Scholar] [CrossRef]

- Al-Shayea, N.; Woods, R.; Gilmore, P. SASW & GPR to detect buried objects. In Proceedings of the Symposium on the Application of Geophysics to Engineering and Environmental Problems, Boston, MA, USA, 27–31 March 1994. [Google Scholar]

- Ganji, V.; Gucunski, N.; Maher, A. Detection of Underground Obstacles by SASW Method—Numerical Aspects. J. Geotech. Geoenviron. Eng. 1997, 123, 212–219. [Google Scholar] [CrossRef]

- Hu, Y.; Xia, J.; Mi, B.; Cheng, F.; Shen, C. A pitfall of muting and removing bad traces in surface-wave analysis. J. Appl. Geophys. 2018, 153, 136–142. [Google Scholar] [CrossRef]

- Zhu, J. Non-Contact NDT of Concrete Structures Using Air Coupled Sensors; Newmark Structural Engineering Laboratory, University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2008. [Google Scholar]

- Kundu, T. Nonlinear Ultrasonic and Vibroacoustical Techniques for Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Cawley, P. A high frequency coin-tap method of non-destructive testing. Mech. Syst. Signal Process. 1991, 5, 1–11. [Google Scholar] [CrossRef]

- Tong, F.; Tso, S.; Xu, X. Tile-wall bonding integrity inspection based on time-domain features of impact acoustics. Sens. Actuators A Phys. 2006, 132, 557–566. [Google Scholar] [CrossRef]

- Zhu, J.; Popovics, J.S. Imaging Concrete Structures Using Air-Coupled Impact-Echo. J. Eng. Mech. 2007, 133, 628–640. [Google Scholar] [CrossRef]

- Kang, S.; Lee, J.-S.; Yu, J.-D.; Kim, S.Y. Detection of Cavities Beneath Plate Structure using a Microphone. J. Korean Soc. Hazard Mitig. 2020, 20, 229–237. [Google Scholar] [CrossRef]

- Larson, G.D.; Martin, J.S.; Scott, W.R., Jr. Investigation of microphones as near-ground sensors for seismic detection of bur-ied landmines. J. Acoust. Soc. Am. 2007, 122, 253–258. [Google Scholar] [CrossRef]

- Nazarian, S.; Stokoe, K.H., II; Hudson, W.R. Use of Spectral Analysis of Surface Waves Method for Determination of Moduli and Thicknesses of Pavement Systems; Transportation Research Record 930; Transportation Research Board: Washington, DC, USA, 1983. [Google Scholar]

- Norinah, A.R.; Adnan, F.N.; Hamid, R. 2D finite element simulation of air-coupled impact echo testing on concrete slab. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 513, p. 012016. [Google Scholar]

- Tucker, B.J.; Bender, D.A.; Pollock, D.G.; Wolcott, M.P. Ultrasonic plate wave evaluation of natural fiber composite panels. Wood Fiber Sci. 2007, 35, 266–281. [Google Scholar]

- Ryden, N.; Lowe, M.J.; Cawley, P.; Park, C.B. Non-contact surface wave measurements using a microphone. In Proceedings of the Symposium on the Application of Geophysics to Engineering and Environmental Problems 2006, Seattle, DC, USA, 2–6 April 2016. [Google Scholar]

- Römmeler, A.; Furrer, R.; Sennhauser, U.; Lübke, B.; Wermelinger, J.; de Agostini, A.; Dual, J.; Zolliker, P.; Neuenschwander, J. Air coupled ultrasonic defect detection in polymer pipes. NDT E Int. 2019, 102, 244–253. [Google Scholar] [CrossRef]

- Yoon, S.; Rix, G.J. Near-Field Effects on Array-Based Surface Wave Methods with Active Sources. J. Geotech. Geoenviron. Eng. 2009, 135, 399–406. [Google Scholar] [CrossRef]

- Pallav, P.; Gan, T.H.; Hutchins, D.A. Elliptical-Tukey Chirp Signal for High-Resolution, Air-Coupled Ultrasonic Imaging. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2007, 54, 1530–1540. [Google Scholar] [CrossRef]

- Dassios, K.G.; Kordatos, E.Z.; Aggelis, D.G.; Matikas, T.E. Crack Growth Monitoring in Ceramic Matrix Composites by Combined Infrared Thermography and Acoustic Emission. J. Am. Ceram. Soc. 2013, 97, 251–257. [Google Scholar] [CrossRef]

- Nair, A. Acoustic Emission Monitoring and Quantitative Evaluation of Damage in Reinforced Concrete Members and Bridges. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2006. [Google Scholar]

- Gholizadeh, S.; Leman, Z.; Baharudin, B. A review of the application of acoustic emission technique in engineering. Struct. Eng. Mech. 2015, 54, 1075–1095. [Google Scholar] [CrossRef]

- Nazarian, S.; Reddy, S. Study of Parameters Affecting Impulse Response Method. J. Transp. Eng. 1996, 122, 308–315. [Google Scholar] [CrossRef]

- Whittaker, W.L.; Christiano, P. Dynamic Response of Plate on Elastic Half-Space. J. Eng. Mech. Div. 1982, 108, 133–154. [Google Scholar] [CrossRef]

- Kee, S.-H.; Gucunski, N. Interpretation of Flexural Vibration Modes from Impact-Echo Testing. J. Infrastruct. Syst. 2016, 22, 04016009. [Google Scholar] [CrossRef]

- Karabalis, D.L.; Beskos, D.E. Dynamic response of 3-D rigid surface foundations by time domain boundary element method. Earthq. Eng. Struct. D 1984, 12, 73–93. [Google Scholar] [CrossRef]

- Muho, E.V. Dynamic response of an elastic plate on a transversely isotropic viscoelastic half-space with variable with depth moduli to a rectangular moving load. Soil Dyn. Earthq. Eng. 2020, 139, 106330. [Google Scholar] [CrossRef]

- Zhu, J.; Popovics, J.S. Non-contact imaging for surface-opening cracks in concrete with air-coupled sensors. Mater. Struct. 2005, 38, 801–806. [Google Scholar] [CrossRef]

- Davis, A.G.; Dunn, C. Cebtp from theory to field experience with the non-destructive vibration testing of piles. Proc. Inst. Civ. Eng. 1974, 57, 571–593. [Google Scholar] [CrossRef]

- Nazarian, S.; Reddy, S.; Baker, M. Determination of Voids Under Rigid Pavements Using Impulse Response Method. In Nondestructive Testing of Pavements and Backcalculation of Moduli: Second Volume; ASTM International: West Conshohocken, PA, USA, 2009; p. 473. [Google Scholar]

- Ottosen, N.S.; Ristinmaa, M.; Davis, A.G. Theoretical interpretation of impulse response tests of embedded concrete structures. J. Eng. Mech. 2004, 130, 1062–1071. [Google Scholar] [CrossRef]

- Chen, D.-H.; Nazarian, S.; Bilyeu, J. Failure Analysis of a Bridge Embankment with Cracked Approach Slabs and Leaking Sand. J. Perform. Constr. Facil. 2007, 21, 375–381. [Google Scholar] [CrossRef]

- ASTM International. Standard Practice for Evaluating the Condition of Concrete Plates using the Impulse-Response Method. In Annual Book of ASTM Standard, ASTM C1740-16; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Mori, K.; Spagnoli, A.; Murakami, Y.; Kondo, G.; Torigoe, I. A new non-contacting non-destructive testing method for defect detection in concrete. NDT E Int. 2002, 35, 399–406. [Google Scholar] [CrossRef]

- ASTM International. Standard practice for measuring delaminations in concrete bridge decks by sounding. In Annual Book of ASTM Standard, ASTM D4580-12; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Shokouhi, P.; Gucunski, N.; Maher, A. Applicability and limitations of impact echo in bridge deck condition monitoring. In Proceedings of the Symposium on the Application of Geophysics to Engineering and Environmental Problems 2006, Seattle, DC, USA, 2–6 April 2016; pp. 385–401. [Google Scholar]

- Sansalone, M.; Streett, W.B. Impact-Echo: Nondestructive Testing of Concrete and Masonry; Bullbrier Press: Jersey Shore, PA, USA, 1997. [Google Scholar]

- Lee, J.-S.; Ohm, H.-S.; Yoon, S.; Lee, I.-M. Phase velocity evaluation of two-layered gypsums by using wavelet transform. KSCE J. Civ. Eng. 2013, 17, 357–363. [Google Scholar] [CrossRef]

- Yu, J.-D.; Bae, M.-H.; Lee, I.-M.; Lee, J.-S. Nongrouted Ratio Evaluation of Rock Bolts by Reflection of Guided Ultrasonic Waves. J. Geotech. Geoenviron. Eng. 2013, 139, 298–307. [Google Scholar] [CrossRef]

- Yu, J.-D.; Hong, Y.-H.; Byun, Y.-H.; Lee, J.-S. Non-destructive evaluation of the grouted ratio of a pipe roof support system in tunneling. Tunn. Undergr. Space Technol. 2016, 56, 1–11. [Google Scholar] [CrossRef]

- Tzanetakis, G.; Essl, G.; Cook, P. Audio analysis using the discrete wavelet transform. In Proceedings of the Conference in Acoustics and Music Theory Applications, Skiathos, Greece, 26–30 September 2001. [Google Scholar]

- Canal, M.R. Comparison of Wavelet and Short Time Fourier Transform Methods in the Analysis of EMG Signals. J. Med. Syst. 2010, 34, 91–94. [Google Scholar] [CrossRef] [PubMed]

- Christoforou, A.; Yigit, A. Effect of Flexibility on Low Velocity Impact Response. J. Sound Vib. 1998, 217, 563–578. [Google Scholar] [CrossRef]

| ME | FL | PM | F | NME | NFL | NPM | NF | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 8 mm | 15 mm | 8 mm | 15 mm | 8 mm | 15 mm | 8 mm | 15 mm | 8 mm | 15 mm | 8 mm | 15 mm | 8 mm | 15 mm | 8 mm | 15 mm |

| 0 | 0.63 | 0.56 | 508.0 | 345.7 | 5.5 | 4.3 | 2.1 | 2.2 | 1.8 | 5.4 | 12.3 | 3.2 | 3.1 | 2.9 | 0.62 | 0.63 |

| 10 | 0.62 | 0.55 | 499.9 | 295.8 | 5.1 | 3.7 | 2.3 | 2.3 | 1.8 | 5.3 | 12.1 | 2.8 | 2.8 | 2.5 | 0.68 | 0.66 |

| 20 | 0.61 | 0.51 | 500.9 | 293.4 | 4.4 | 3.1 | 2.5 | 2.4 | 1.7 | 4.9 | 12.1 | 2.7 | 2.4 | 2.1 | 0.72 | 0.69 |

| 30 | 0.61 | 0.45 | 420.2 | 286.7 | 4.0 | 2.9 | 2.6 | 2.6 | 1.7 | 4.3 | 10.1 | 2.6 | 2.2 | 1.9 | 0.75 | 0.74 |

| 40 | 0.59 | 0.26 | 373.1 | 252.1 | 3.8 | 2.8 | 2.7 | 2.8 | 1.7 | 2.5 | 9.0 | 2.4 | 2.1 | 1.9 | 0.79 | 0.80 |

| 50 | 0.57 | 0.18 | 353.8 | 244.4 | 3.7 | 2.6 | 2.9 | 3.0 | 1.6 | 1.8 | 8.5 | 2.3 | 2.1 | 1.7 | 0.85 | 0.86 |

| 80 | 0.45 | 0.14 | 302.5 | 167.3 | 3.5 | 2.0 | 3.3 | 3.5 | 1.3 | 1.3 | 7.3 | 1.6 | 1.9 | 1.3 | 0.97 | 1.00 |

| 100 | 0.38 | 0.12 | 268.0 | 143.6 | 2.5 | 2.0 | 3.4 | 3.5 | 1.1 | 1.1 | 6.5 | 1.3 | 1.4 | 1.3 | 1.00 | 1.00 |

| 150 | 0.35 | 0.11 | 171.1 | 129.1 | 2.1 | 1.5 | 3.4 | 3.5 | 1.0 | 1.0 | 4.1 | 1.1 | 1.2 | 1.0 | 1.00 | 1.00 |

| 200 | 0.35 | 0.10 | 41.4 | 104.7 | 1.8 | 1.5 | 3.4 | 3.5 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.00 | 1.00 |

| Normalized Value | Maximum Ratio | Estimated Cavity Size (mm) | ||

|---|---|---|---|---|

| T = 8 mm | T = 15 mm | T = 8 mm | T = 15 mm | |

| MARSE energy | 1.8 | 5.4 | 100 | 60 |

| Flexibility | 12.3 | 3.2 | 40 | 80 |

| Peak magnitude | 3.0 | 3.0 | N/A | N/A |

| Frequency | 0.63 | 0.63 | 80 | 80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, S.; Yu, J.-D.; Hong, W.-T.; Lee, J.-S. Estimation of Cavities beneath Plate Structures Using a Microphone: Laboratory Model Tests. Sensors 2021, 21, 2941. https://doi.org/10.3390/s21092941

Kang S, Yu J-D, Hong W-T, Lee J-S. Estimation of Cavities beneath Plate Structures Using a Microphone: Laboratory Model Tests. Sensors. 2021; 21(9):2941. https://doi.org/10.3390/s21092941

Chicago/Turabian StyleKang, Seonghun, Jung-Doung Yu, Won-Taek Hong, and Jong-Sub Lee. 2021. "Estimation of Cavities beneath Plate Structures Using a Microphone: Laboratory Model Tests" Sensors 21, no. 9: 2941. https://doi.org/10.3390/s21092941

APA StyleKang, S., Yu, J.-D., Hong, W.-T., & Lee, J.-S. (2021). Estimation of Cavities beneath Plate Structures Using a Microphone: Laboratory Model Tests. Sensors, 21(9), 2941. https://doi.org/10.3390/s21092941