Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Data Analysis

2.3. Test Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lopez, P.; Mabe, J.; Miró, G.; Etxeberria, L. Low Cost Photonic Sensor for In-Line Oil Quality Monitoring: Methodological Development Process towards Uncertainty Mitigation. Sensors 2018, 18, 2015. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, S.; Kondoh, J. Feasibility Study on Shear Horizontal Surface Acoustic Wave Sensors for Engine Oil Evaluation. Sensors 2020, 20, 2184. [Google Scholar] [CrossRef] [PubMed]

- Toledo, J.; Manzaneque, T.; Ruiz-Díez, V.; Jiménez-Márquez, F.; Kucera, M.; Pfusterschmied, G.; Wistrela, E.; Schmid, U.; Sánchez-Rojas, J.L. Comparison of In-Plane and out-of-Plane Piezoelectric Microresonators for Real-Time Monitoring of Engine Oil Contamination with Diesel. Microsyst. Technol. 2016, 22, 1781–1790. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, D.; He, X.; Wang, X. A Hydrodynamic Model for Measuring Fluid Density and Viscosity by Using Quartz Tuning Forks. Sensors 2020, 20, 198. [Google Scholar] [CrossRef] [PubMed]

- Wolak, A.; Zając, G. The Kinetics of Changes in Kinematic Viscosity of Engine Oils under Similar Operating Conditions. Eksploat. Niezawodn.—Maint. Reliab. 2017, 19, 260–267. [Google Scholar] [CrossRef]

- Napiórkowski, J.; Gonera, J. Analysis of Failures and Reliability Model of Farm Tractors. Agric. Eng. 2020, 24, 89–101. [Google Scholar] [CrossRef]

- Yanaseko, T.; Sato, H.; Kuboki, I.; Mossi, K.; Asanuma, H. Vibration Viscosity Sensor for Engine Oil Monitoring Using Metal Matrix Piezoelectric Composite. Materials 2019, 12, 3415. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating Oil Conditioning Sensors for Online Machine Health Monitoring—A Review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Li, J.; Li, F.; Li, J.; Lu, H. Online Oil Debris Monitoring of Rotating Machinery: A Detailed Review of More than Three Decades. Mech. Syst. Signal Process. 2021, 149, 107341. [Google Scholar] [CrossRef]

- Markova, L.V.; Myshkin, N.K.; Kong, H.; Han, H.G. On-Line Acoustic Viscometry in Oil Condition Monitoring. Tribol. Int. 2011, 44, 963–970. [Google Scholar] [CrossRef]

- Sariyerli, G.S.; Sakarya, O.; Akcadag, U.Y. Comparison Tests for the Determination of the Viscosity Values of Reference Liquids by Capillary Viscometers and Stabinger Viscometer SVM 3001. Int. J. Metrol. Qual. Eng. 2018, 9. [Google Scholar] [CrossRef]

- Lorefice, S.; Saba, F. The Italian Primary Kinematic Viscosity Standard: The Viscosity Scale. Measurement 2017, 112, 1–8. [Google Scholar] [CrossRef]

- Markova, L.V.; Makarenko, V.M.; Semenyuk, M.S.; Zozulya, A.P. On-Line Monitoring of the Viscosity of Lubricating Oils. J. Frict. Wear 2010, 31, 433–442. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Markova, L.V. Oil Viscosity Monitoring. In On-line Condition Monitoring in Industrial Lubrication and Tribology; Myshkin, N.K., Markova, L.V., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 31–59. ISBN 978-3-319-61134-1. [Google Scholar]

- Adams, M.J.; Romeo, M.J.; Rawson, P. FTIR Analysis and Monitoring of Synthetic Aviation Engine Oils. Talanta 2007, 73, 629–634. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Słowik, T.; Kuranc, A.; Kamińska, A. Designation of Chosen Heavy Metals in Used Engine Oils Using the XRF Method. Pol. J. Environ. Stud. 2015, 24, 2277–2283. [Google Scholar] [CrossRef]

- Wolak, A. TBN Performance Study on a Test Fleet in Real-World Driving Conditions Using Present-Day Engine Oils. Measurement 2018, 114, 322–331. [Google Scholar] [CrossRef]

- de Paula Pedroza, R.H.; Nicácio, J.T.N.; dos Santos, B.S.; de Lima, K.M.G. Determining the Kinematic Viscosity of Lubricant Oils for Gear Motors by Using the Near Infrared Spectroscopy (NIRS) and the Wavelength Selection. Anal. Lett. 2013, 46, 1145–1154. [Google Scholar] [CrossRef]

- Raposo, H.; Farinha, J.T.; Fonseca, I.; Galar, D. Predicting Condition Based on Oil Analysis—A Case Study. Tribol. Int. 2019, 135, 65–74. [Google Scholar] [CrossRef]

- Rauscher, M.S.; Tremmel, A.J.; Schardt, M.; Koch, A.W. Non-Dispersive Infrared Sensor for Online Condition Monitoring of Gearbox Oil. Sensors 2017, 17, 399. [Google Scholar] [CrossRef]

- Brouwer, M.D.; Gupta, L.A.; Sadeghi, F.; Peroulis, D.; Adams, D. High Temperature Dynamic Viscosity Sensor for Engine Oil Applications. Sens. Actuators Phys. 2012, 173, 102–107. [Google Scholar] [CrossRef]

- Caneca, A.R.; Pimentel, M.F.; Galvão, R.K.H.; da Matta, C.E.; de Carvalho, F.R.; Raimundo, I.M.; Pasquini, C.; Rohwedder, J.J.R. Assessment of Infrared Spectroscopy and Multivariate Techniques for Monitoring the Service Condition of Diesel-Engine Lubricating Oils. Talanta 2006, 70, 344–352. [Google Scholar] [CrossRef] [PubMed]

- van de Voort, F.R.; Sedman, J.; Cocciardi, R.A.; Pinchuk, D. FTIR Condition Monitoring of In-Service Lubricants: Ongoing Developments and Future Perspectives. Tribol. Trans. 2006, 49, 410–418. [Google Scholar] [CrossRef]

- van de Voort, F.R.; Sedman, J.; Cocciardi, R.; Juneau, S. An Automated FTIR Method for the Routine Quantitative Determination of Moisture in Lubricants: An Alternative to Karl Fischer Titration. Talanta 2007, 72, 289–295. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Zhang, Y.; Liu, F.; Tan, L.; He, Y. Fast and Noninvasive Determination of Viscosity of Lubricating Oil Based on Visible and Near Infrared Spectroscopy. In Advances in Neural Network Research and Applications; Zeng, Z., Wang, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 765–771. ISBN 978-3-642-12990-2. [Google Scholar]

- Van de Voort, F.; Sedman, J.; Pinchuk, D. An Overview of Progress and New Developments in FTIR Lubricant Condition Monitoring Methodology. J. ASTM Int. 2011, 8, 1–14. [Google Scholar] [CrossRef]

- Braga, J.W.B.; dos Santos Junior, A.A.; Martins, I.S. Determination of Viscosity Index in Lubricant Oils by Infrared Spectroscopy and PLSR. Fuel 2014, 120, 171–178. [Google Scholar] [CrossRef]

- Wu, T.; Wu, H.; Du, Y.; Peng, Z. Progress and Trend of Sensor Technology for On-Line Oil Monitoring. Sci. China Technol. Sci. 2013, 56, 2914–2926. [Google Scholar] [CrossRef]

- Katika, K.; Ahkami, M.; Fosbøl, P.L.; Halim, A.Y.; Shapiro, A.; Thomsen, K.; Xiarchos, I.; Fabricius, I.L. Comparative Analysis of Experimental Methods for Quantification of Small Amounts of Oil in Water. J. Pet. Sci. Eng. 2016, 147, 459–467. [Google Scholar] [CrossRef]

- ISO. ISO 3104:2020 Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity; ISO: Geneva, Switzerland, 2020. [Google Scholar]

- Domostroeva, N.G.; Chunovkina, A.G. COOMET.M.V-K1 Key Intercomparison of Liquid Viscosity Measurements. Metrologia 2008, 45, 07009. [Google Scholar] [CrossRef]

- JCGM 100:2008 Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement 2010. Available online: https://ncc.nesdis.noaa.gov/documents/documentation/JCGM_100_2008_E.pdf (accessed on 1 April 2021).

- Pedhazur, E. Multiple Regression in Behavioral Research: Explanation and Prediction, 3rd ed.; Harcourt Brace: Fort Worth, TX, USA, 1997. [Google Scholar]

- Azen, R.; Budescu, D.V. The Dominance Analysis Approach for Comparing Predictors in Multiple Regression. Psychol. Methods 2003, 8, 129. [Google Scholar] [CrossRef]

- Zientek, L.R.; Thompson, B. Using Commonality Analysis to Quantify Contributions That Self-Efficacy and Motivational Factors Make in Mathematics Performance. Res. Sch. 2010, 17, 1. [Google Scholar]

- Braun, M.T.; Oswald, F.L. Exploratory Regression Analysis: A Tool for Selecting Models and Determining Predictor Importance. Behav. Res. Methods 2011, 43, 331–339. [Google Scholar] [CrossRef] [PubMed]

- R Core Team. R: A Language and Environment for Statistical Computing; R Core Team: Vienna, Austria, 2013. [Google Scholar]

| Capillary Viscometer | Stabinger Viscometer | Mid-FTIR | Microchannel Viscometer | |

|---|---|---|---|---|

| Sample Volume | 18 mL | min 3 mL 1 | approx. 7 mL | 0.06 mL |

| Measurement range Standard Analytical Range @ 40 °C | 20–100 mm2/s (capillary tube size 2) | 0.2–30,000 mm2/s | 50–100 mm2/s | 1–700 mm2/s |

| Sample introduction | manually | manual filling with the use of a syringe | automatic, by integrated sample pump | manually |

| Cleaning | manually | cleaning with the use of a syringe (petrochemical gasoline) | automatic rinsing | manually |

| Reference measurement | no data | adjusted with 4 standard fluids (oil: L, M, C, H) | automatic, with heptane as reference fluid | no data |

| Measurement time | min. 240 s | 360 s 2 | 60 s | 120 s |

| Calibration | carried out using certified standards | factory calibrated with a matrix of international lubricants | ||

| Available Test Methods | ASTM D445 (EN ISO 3104) | ASTM D7042 and D4052 | e.g., ASTM D445 (MLR calculations) | ASTM D 8092 |

| Weight | approx. 28 kg | 18 kg | approx. 10 kg | 1.8 kg |

| Power supply | mains power supply | mains power supply | mains power supply | built-in rechargeable lithium ion battery |

| Capillary Viscometer | Stabinger Viscometer | Mid-FTIR | Microchannel Viscometer | |

|---|---|---|---|---|

| Viscosity repeatability | 0.26% | 0.1% 2 | ≤±3% RSD of value, typical, over range 1–350 mm2/s | Repeatability and reproducibility depend on the library used for the MLR calculations |

| Viscosity reproducibility 1 | 0.76% | 0.35% 2 | ≤±3% of measured value over range 1–350 mm2/s |

| Sample Number | Capillary Viscometer | Stabinger Viscometer | Microchannel Viscometer | Mid-FTIR | Average | The Standard Deviation | The Variation | The Coefficient of Variation |

|---|---|---|---|---|---|---|---|---|

| [%] | ||||||||

| #1 | 68.77 ± 0.08 | 68.33 ± 0.12 | 64.0 ± 1.9 | 69.8 ± 0.2 | 67.7 | 2.6 | 6.5 | 3.8 |

| #2 | 69.87 ± 0.05 | 69.55 ± 0.12 | 64.8 ± 2.2 | 75.3 ± 0.8 | 69.9 | 4.3 | 18.6 | 6.2 |

| #3 | 61.60 ± 0.08 | 61.06 ± 0.11 | 54.7 ± 1.9 | 88.4± 0.2 | 66.4 | 14.9 | 223.4 | 22.5 |

| #4 | 55.96 ± 0.10 | 55.95 ± 0.10 | 50.4 ± 2.2 | 75.3 ± 1.2 | 59.4 | 10.9 | 119.6 | 18.4 |

| #5 | 53.67 ± 0.10 | 54.18 ± 0.10 | 50.8 ± 0.6 | 82.2 ± 2.4 | 60.2 | 14.7 | 217.0 | 24.5 |

| #6 | 64.42 ± 0.13 | 64.24 ± 0.11 | 60.1 ± 0.8 | 68.7 ± 1.2 | 64.4 | 3.5 | 12.1 | 5.4 |

| #7 | 73.90 ± 0.03 | 71.40 ± 0.13 | 65.9 ± 0.8 | 68.8 ± 2.2 | 70.0 | 3.5 | 11.9 | 4.9 |

| #8 | 52.13 ± 0.05 | 52.06 ± 0.09 | 50.0 ± 2.5 | 75.7 ± 1.8 | 57.5 | 12.2 | 149.3 | 21.3 |

| #9 | 67.74 ± 0.08 | 66.31 ± 0.12 | 62.6 ± 1.9 | 68.4 ± 2.4 | 66.3 | 2.6 | 6.9 | 4.0 |

| #10 | 65.69 ± 0.08 | 66.91 ± 0.12 | 60.5 ± 1.4 | 69.4 ± 2.0 | 65.6 | 3.8 | 14.1 | 5.7 |

| #11 | 61.41 ± 0.10 | 62.2 ± 0.11 | 54.8 ± 2.5 | 63.2 ± 2.2 | 60.4 | 3.8 | 14.4 | 6.3 |

| #12 | 54.97 ± 0.03 | 54.60 ± 0.10 | 47.0 ± 1.7 | 67.2 ± 2.6 | 55.9 | 8.4 | 70.3 | 15.0 |

| #13 | 54.48 ± 0.03 | 52.87 ± 0.09 | 47.8 ± 1.9 | 74.4 ± 2.4 | 57.4 | 11.7 | 137.3 | 20.4 |

| #14 | 64.95 ± 0.13 | 65.18 ± 0.11 | 55.9 ± 2.5 | 74.4 ± 2.0 | 65.1 | 7.6 | 57.1 | 11.6 |

| #15 | 66.78 ± 0.13 | 65.87 ± 0.12 | 62.4 ± 2.5 | 62.0 ± 1.6 | 64.3 | 2.4 | 5.9 | 3.8 |

| #16 | 68.85 ± 0.08 | 70.60 ± 0.12 | 68.0 ± 5.0 | 70.8 ± 3.2 | 69.6 | 1.4 | 1.8 | 2.0 |

| #17 | 72.95 ± 0.13 | 72.38 ± 0.13 | 66.7 ± 1.1 | 70.0 ± 3.0 | 70.5 | 2.8 | 8.0 | 4.0 |

| #18 | 53.87 ± 0.13 | 53.81 ± 0.09 | 48.4 ± 1.9 | 62.9 ± 0.2 | 54.7 | 6.0 | 36.0 | 11.0 |

| #19 | 69.01 ± 0.10 | 66.73 ± 0.12 | 61.0 ± 2.2 | 69.0 ± 1.4 | 66.4 | 3.8 | 14.3 | 5.7 |

| #20 | 73.22 ± 0.13 | 73.61 ± 0.13 | 65.7 ± 2.2 | 23.8 ± 1.6 | 59.1 | 23.8 | 565.9 | 40.3 |

| #21 | 53.4 ± 0.15 | 54.39 ± 0.10 | 48.1 ± 3.3 | 62.4 ± 1.0 | 54.6 | 5.9 | 34.8 | 10.8 |

| #22 | 69.37 ± 0.13 | 69.86 ± 0.12 | 63.0 ± 2.5 | 61.8 ± 1.2 | 66.0 | 4.2 | 17.7 | 6.4 |

| #23 | 65.72 ± 0.13 | 66.91 ± 0.12 | 63.0 ± 2.2 | 62.9± 1.8 | 64.6 | 2.0 | 4.1 | 3.1 |

| #24 | 66.1 ± 0.13 | 64.94 ± 0.11 | 58.6 ± 0.6 | 84.2 ± 1.6 | 68.5 | 11.0 | 120.8 | 16.1 |

| #25 | 68.02 ± 0.05 | 64.94 ± 0.11 | 58.0 ± 1.9 | 70.9 ± 2.4 | 65.5 | 5.5 | 30.4 | 8.4 |

| #26 | 71.81 ± 0.08 | 70.92 ± 0.12 | 64.8 ± 2.5 | 59.5 ± 0.8 | 66.7 | 5.8 | 33.2 | 8.6 |

| #27 | 71.34 ± 0.10 | 70.50 ± 0.12 | 65.5 ± 2.8 | 67.8 ± 0.6 | 68.8 | 2.7 | 7.0 | 3.9 |

| #28 | 71.96 ± 0.13 | 70.17 ± 0.12 | 63.1 ± 0.6 | 75.4 ± 1.6 | 70.2 | 5.2 | 26.8 | 7.4 |

| #29 | 68.77 ± 0.10 | 69.65 ± 0.12 | 62.3 ± 1.7 | 76.1 ± 1.8 | 69.2 | 5.6 | 31.8 | 8.1 |

| #30 | 68.43 ± 0.03 | 68.79 ± 0.12 | 61.1 ± 2.2 | 62.0 ± 3.0 | 65.1 | 4.1 | 16.7 | 6.3 |

| #31 | 70.55 ± 0.08 | 70.17 ± 0.12 | 62.1 ± 1.9 | 70.9 ± 0.2 | 68.4 | 4.2 | 17.8 | 6.2 |

| #32 | 67.70 ± 0.10 | 69.29 ± 0.12 | 65.2 ± 6.1 | 63.7 ± 1.4 | 66.4 | 2.5 | 6.4 | 3.8 |

| #33 | 68.96 ± 0.13 | 68.89 ± 0.12 | 62.2 ± 2.8 | 61.5 ± 0.4 | 65.4 | 4.1 | 16.8 | 6.3 |

| #34 | 65.47 ± 0.05 | 63.42 ± 0.11 | 56.3 ± 2.5 | 82.9 ± 1.2 | 67.0 | 11.3 | 127.8 | 16.9 |

| #35 | 67.08 ± 0.05 | 67.65 ± 0.12 | 60.9 ± 2.2 | 72.0 ± 0.8 | 66.9 | 4.5 | 20.6 | 6.8 |

| #36 | 75.20 ± 0.08 | 75.25 ± 0.13 | 69.5 ± 0.8 | 92.6 ± 1.0 | 78.1 | 10.0 | 99.7 | 12.8 |

| #37 | 67.47 ± 0.08 | 67.34 ± 0.12 | 60.2 ± 2.8 | 62.5 ± 2.2 | 64.4 | 3.6 | 13.2 | 5.6 |

| #38 | 69.18 ± 0.08 | 69.52 ± 0.12 | 62.4 ± 1.9 | 67.3 ± 0.8 | 67.1 | 3.3 | 10.8 | 4.9 |

| #39 | 71.40 ± 0.08 | 71.53 ± 0.13 | 64.4 ± 3.3 | 83.9 ± 1.8 | 72.8 | 8.1 | 66.1 | 11.2 |

| #40 | 65.64 ± 0.05 | 64.80 ± 0.11 | 58.6 ± 1.9 | 80.5 ± 0.6 | 67.4 | 9.3 | 86.3 | 13.8 |

| #41 | 65.87 ± 0.03 | 62.89 ± 0.11 | 57.2 ± 2.2 | 74.1 ± 0.8 | 65.0 | 7.1 | 49.8 | 10.9 |

| #42 | 67.21 ± 0.08 | 70.20 ± 0.12 | 61.1 ± 2.5 | 67.8 ± 0.2 | 66.6 | 3.9 | 14.9 | 5.8 |

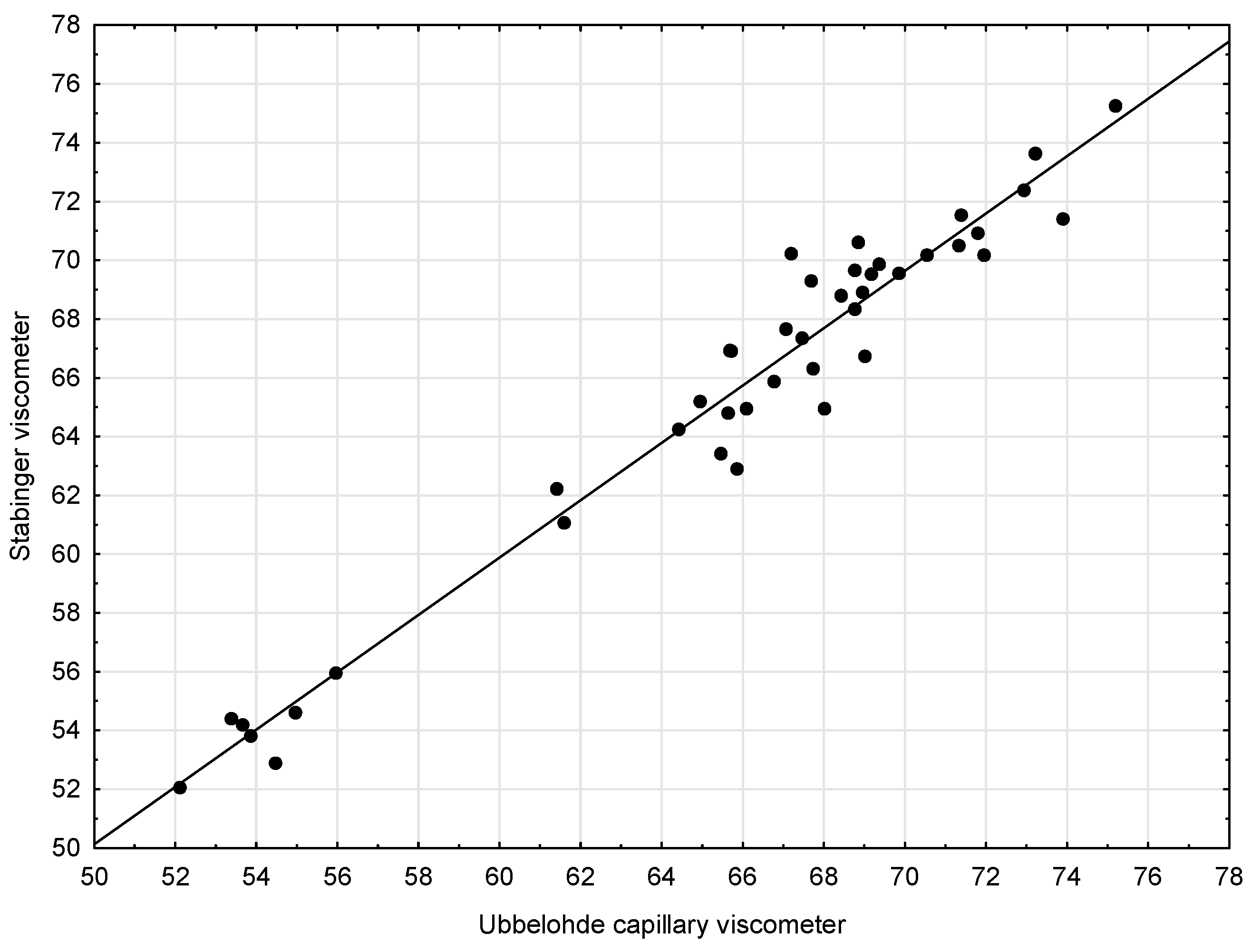

| b’ | the Standard Error (b’) | b | the Standard Error (b) | t(40) | p | |

|---|---|---|---|---|---|---|

| An intercept parameter | 1.36 | 2.15 | 0.63 | 0.53 | ||

| Capillary Viscometer | 0.98 | 0.03 | 0.98 | 0.03 | 30.11 | 0.00 |

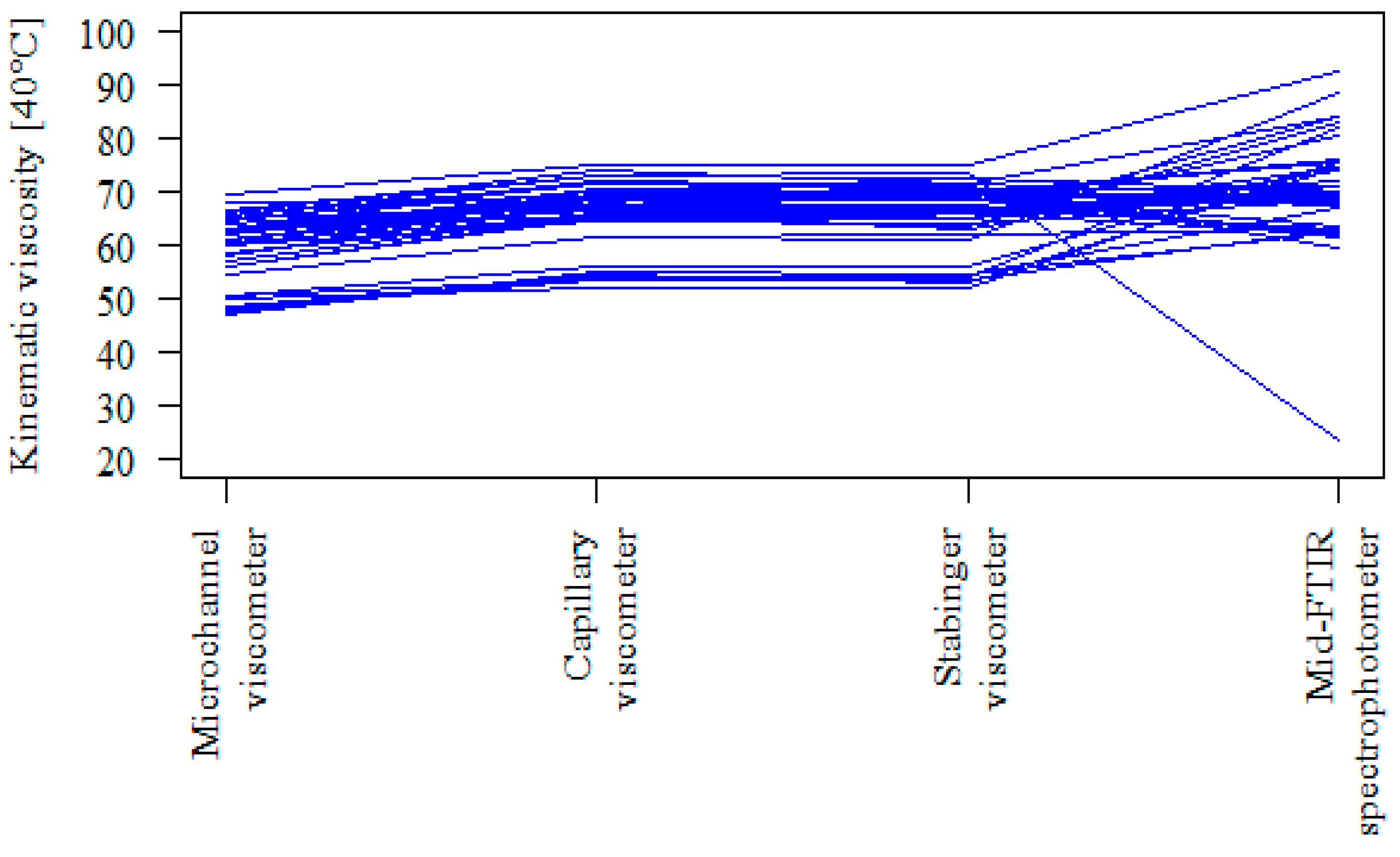

| b’ | The Standard Error (b’) | b | The Standard Error (b) | t(40) | p | |

|---|---|---|---|---|---|---|

| An intercept parameter | −0.53 | 3.30 | −0.16 | 0.87 | ||

| Capillary Viscometer | 0.95 | 0.05 | 0.91 | 0.05 | 18.36 | 0.00 |

| Microchannel Viscometer (N = 42)—A | Capillary Viscometer (N = 42)—B | Stabinger Viscometer (N = 42)—C | Mid-FTIR (N = 42)—D | p * | |

|---|---|---|---|---|---|

| 59.74 ± 5.93 | 65.97 ± 6.14 | 65.71 ± 6.12 | 70.06 ± 10.74 | p < 0.001 | |

| median | 61.13 | 67.59 | 67.12 | 69.62 | |

| quartiles | 56.54–63.8 | 65.08–69.32 | 63.62–70.09 | 63.29–75.34 | D, B, C > A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolak, A.; Zając, G.; Słowik, T. Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices. Sensors 2021, 21, 2530. https://doi.org/10.3390/s21072530

Wolak A, Zając G, Słowik T. Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices. Sensors. 2021; 21(7):2530. https://doi.org/10.3390/s21072530

Chicago/Turabian StyleWolak, Artur, Grzegorz Zając, and Tomasz Słowik. 2021. "Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices" Sensors 21, no. 7: 2530. https://doi.org/10.3390/s21072530

APA StyleWolak, A., Zając, G., & Słowik, T. (2021). Measuring Kinematic Viscosity of Engine Oils: A Comparison of Data Obtained from Four Different Devices. Sensors, 21(7), 2530. https://doi.org/10.3390/s21072530