Study of Obstacle-Crossing and Pitch Control Characteristic of a Novel Jumping Robot

Abstract

1. Introduction

2. Methods

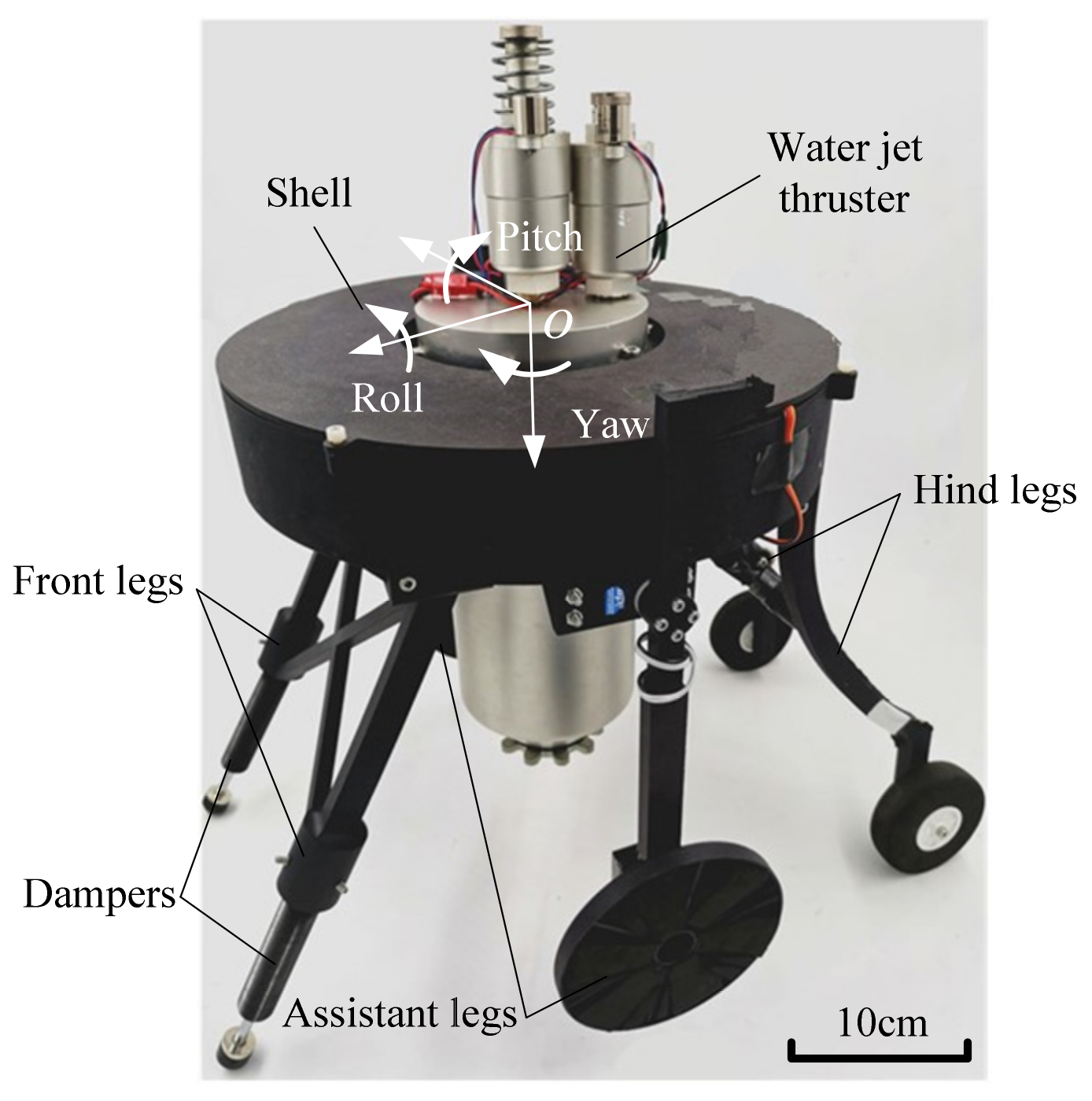

2.1. Structural Design of the Jumping Robot

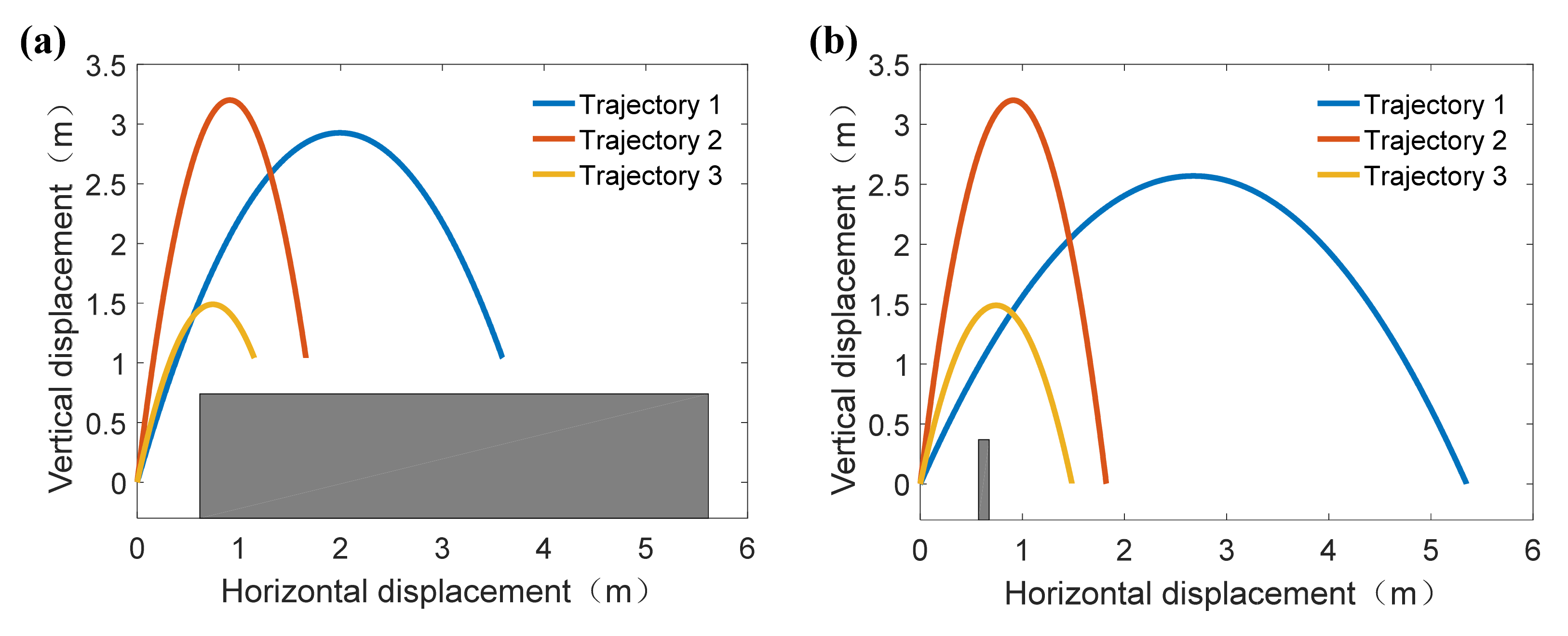

2.2. Decision Criteria of Overcoming General Obstacles

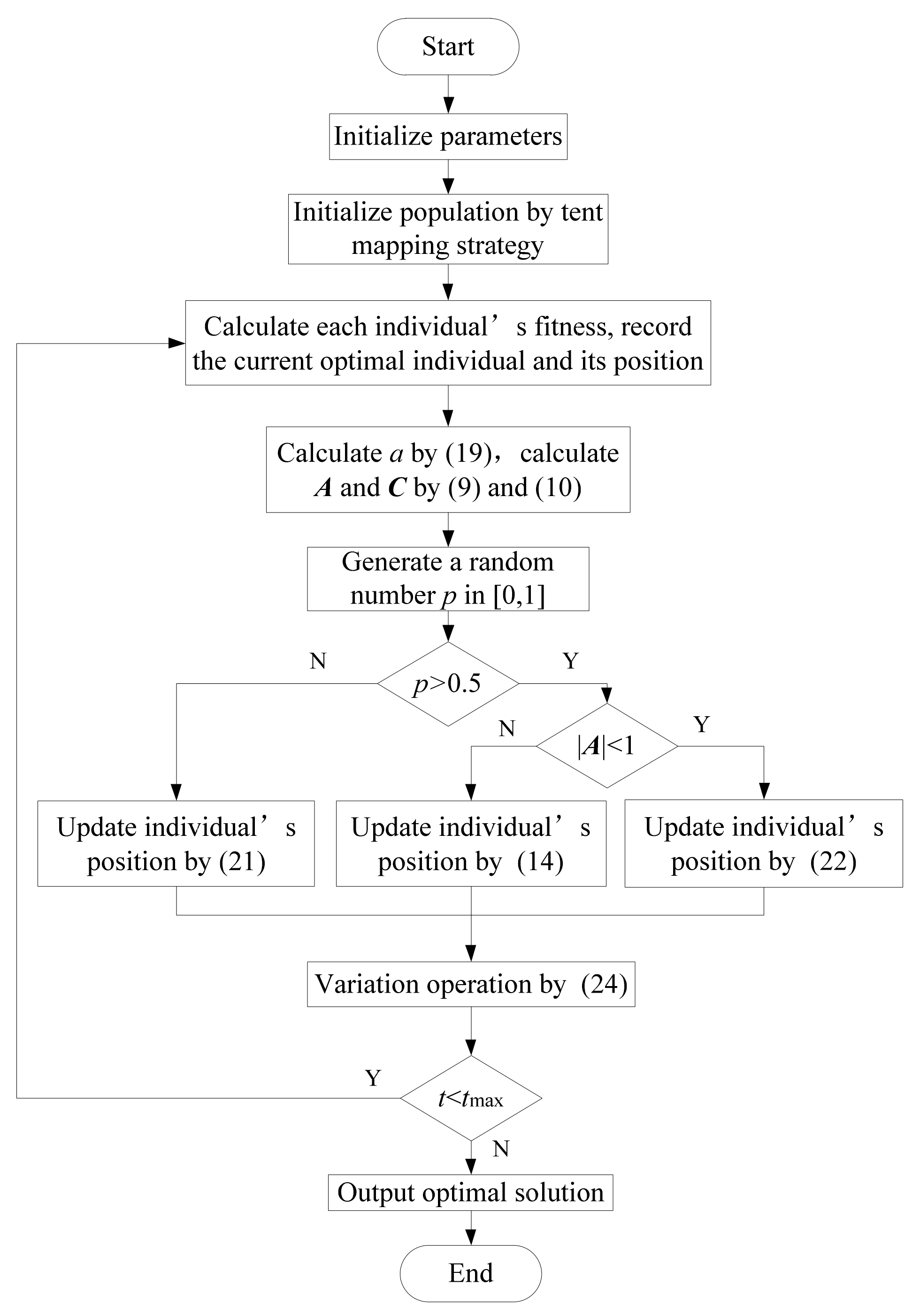

2.3. Modified Whale Optimization Algorithm

2.3.1. Standard Whale Optimization Algorithm

2.3.2. Improvement Strategy

2.3.3. Performance Test

2.3.4. Fitness Function

2.4. Dynamics Model of Aerial Pitch Control

2.5. Aerial Pitch Control Experiments of Jumping Robot

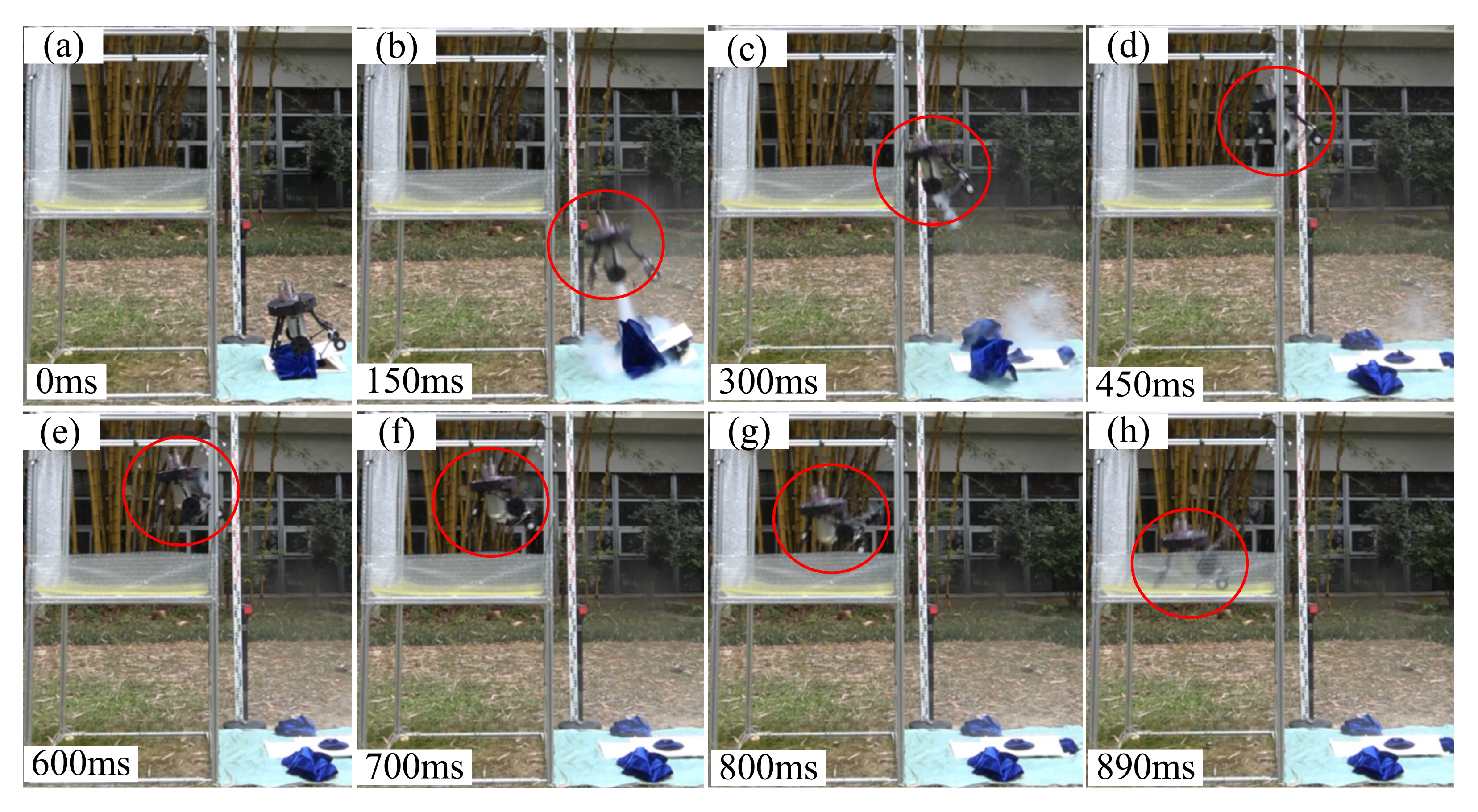

2.6. Jumping Experiments of the Robot

2.6.1. Trajectory Accuracy Verification Experiments

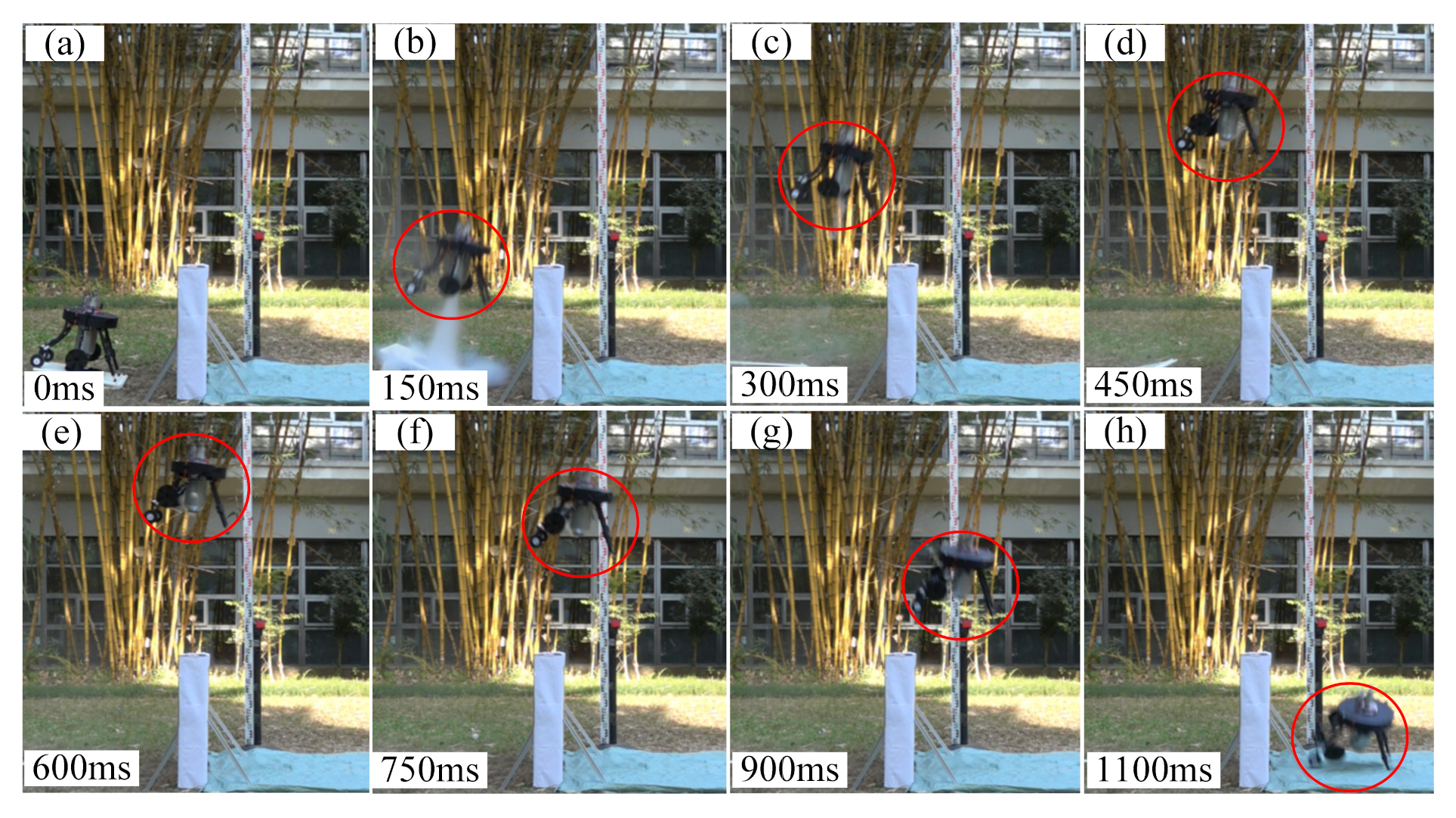

2.6.2. Obstacle-Crossing Experiments

3. Results and Discussion

3.1. Modified Whale Optimization Algorithm

3.1.1. Performance Improvement Effect of Each Improvement Strategy

3.1.2. Performance Comparison with Other Intelligent Optimization Algorithms

3.1.3. Optimization of Jumping Trajectory

3.2. Aerial Pitch Control Experiments

3.3. Jumping Experiments of the Robot

3.3.1. Trajectory Accuracy Verification Experiments

3.3.2. Obstacle-Crossing Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Name | Formula | Searching Range | Dimension | Minimum Value |

|---|---|---|---|---|

| Sphere | [−100,100] | 30 | 0 | |

| Schwefel 2.22 | [−10,10] | 30 | 0 | |

| Schwefel 1.2 | [−100,100] | 30 | 0 | |

| Rosenbrock | [−30,30] | 30 | 0 | |

| Schwefel 2.26 | [−500,500] | 30 | −12,569.5 | |

| Rastrigin | [−5.12,5.12] | 30 | 0 | |

| Ackley | [−32,32] | 30 | 0 | |

| Griewank | [−600,600] | 30 | 0 | |

| Shekel | [−65,65] | 2 | 1 | |

| Kowalik | [−5,5] | 4 | 0.00030 |

References

- Alexander, R.M.N. Principles of Animal Locomotion; Princeton University Press: Princeton, NJ, USA, 2013; ISBN 9781400849512. [Google Scholar]

- Stoeter, S.; Papanikolopoulos, N. Autonomous Stair-Climbing with Miniature Jumping Robots. IEEE Trans. Syst. Man. Cybern. B Cybern. 2005, 35, 313–325. [Google Scholar] [CrossRef] [PubMed]

- Fischer, G.J.; Spletzer, B.L. Long-range hopping mobility platform. Unmanned Gr. Veh. Technol. V 2003, 5083, 83. [Google Scholar] [CrossRef]

- Fischer, G.J. Wheeled hopping mobility. In Proceedings of the European Symposium on Optics & Photonics for Defence & Security, Bruges, Belgium, 26 October 2005; p. 59860H. [Google Scholar]

- Ackerman, E. Boston Dynamics Sand Flea Robot Demonstrates Astonishing Jumping Skills. Available online: https://spectrum.ieee.org/automaton/robotics/military-robots/boston-dynamics-sand-flea-demonstrates-astonishing-jumping-skills (accessed on 28 January 2021).

- Liu, G.H.; Lin, H.Y.; Lin, H.Y.; Chen, S.T.; Lin, P.C. A bio-inspired hopping kangaroo robot with an active tail. J. Bionic Eng. 2014, 11, 541–555. [Google Scholar] [CrossRef]

- Wang, H.; Luan, Y.; Oetomo, D.; Wang, Z. Design, Analysis and Experimental Evaluation of a Gas-Fuel-Powered Actuator for Robotic Hoppers. IEEE/ASME Trans. Mechatron. 2015, 20, 264–2275. [Google Scholar] [CrossRef]

- Zaitsev, V.; Gvirsman, O.; Ben Hanan, U.; Weiss, A.; Ayali, A.; Kósa, G. A locust-inspired miniature jumping robot. Bioinspir. Biomim. 2015, 10, 66012. [Google Scholar] [CrossRef] [PubMed]

- Weiss, A.; Zaitsev, V.; Nabi, N.; Hanan, U. Ben. Landing recovery and orientation control of a locust-inspired miniature jumping robot. Eng. Res. Express 2020, 2. [Google Scholar] [CrossRef]

- Yu, J.; Su, Z.; Wu, Z.; Tan, M. Development of a Fast-Swimming Dolphin Robot Capable of Leaping. IEEE/ASME Trans. Mechatron. 2016, 21, 2307–2316. [Google Scholar] [CrossRef]

- Yan, J.; Wang, T.; Zhang, X.; Zhao, J. Structural design and dynamic analysis of biologically inspired water-jumping robot. In Proceedings of the 2014 IEEE International Conference on Information and Automation, Hailar, China, 28–30 July 2014; pp. 1295–1299. [Google Scholar]

- Siddall, R.; Kovač, M. A water jet thruster for an aquatic micro air vehicle. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; pp. 3979–3985. [Google Scholar]

- Zufferey, R.; Ancel, A.O.; Farinha, A.; Siddall, R.; Armanini, S.F.; Nasr, M.; Brahmal, R.V.; Kennedy, G.; Kovac, M. Consecutive aquatic jump-gliding with water-reactive fuel. Sci. Robot. 2019, 4. [Google Scholar] [CrossRef] [PubMed]

- Siddall, R.; Kovač, M. Launching the AquaMAV: Bioinspired design for aerial-aquatic robotic platforms. Bioinspir. Biomim. 2014, 9, 31001. [Google Scholar] [CrossRef] [PubMed]

- Jusufi, A.; Goldman, D.I.; Revzen, S.; Full, R.J. Active tails enhance arboreal acrobatics in geckos. Proc. Natl. Acad. Sci. USA 2008, 105, 4215–4219. [Google Scholar] [CrossRef] [PubMed]

- Libby, T.; Moore, T.Y.; Chang-Siu, E.; Li, D.; Cohen, D.J.; Jusufi, A.; Full, R.J. Tail-assisted pitch control in lizards, robots and dinosaurs. Nature 2012, 481, 181–186. [Google Scholar] [CrossRef] [PubMed]

- Jusufi, A.; Kawano, D.T.; Libby, T.; Full, R.J. Righting and turning in mid-air using appendage inertia: Reptile tails, analytical models and bio-inspired robots. Bioinspir. Biomim. 2010, 5, 45001. [Google Scholar] [CrossRef] [PubMed]

- Johnson, A.M.; Libby, T.; Chang-Siu, E.; Tomizuka, M.; Full, R.J.; Koditschek, D.E. Tail assisted dynamic self righting. In Proceedings of the 15th International Conference on Climbing and Walking Robots and the Support Technologies, Baltimore, MD, USA, 23–26 July 2012; pp. 611–620. [Google Scholar]

- Chang-Siu, E.; Libby, T.; Tomizuka, M.; Full, R. A lizard-inspired active tail enables rapid maneuvers and dynamic stabilization in a terrestrial robot. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 1887–1894. [Google Scholar]

- Kohut, N.J.; Pullin, A.O.; Haldane, D.W.; Zarrouk, D.; Fearing, R.S. Precise dynamic turning of a 10 cm legged robot on a low friction surface using a tail. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3299–3306. [Google Scholar]

- Mo, J.; Miao, Z.; Li, B.; Zhang, Y.; Song, Z. Design, analysis, and performance verification of a water jet thruster for amphibious jumping robot. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 5431–5447. [Google Scholar] [CrossRef]

- Mo, J.; Xiao, J.; Lin, F.; Li, Y.; Song, Z. Study of a new water jet thruster for robotic returnable jumping. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Shan, L.; Qiang, H.; Li, J.; Wang, Z.Q. Chaotic optimization algorithm based on Tent map. Kongzhi yu Juece/Control Decis. 2005, 20, 179–182. [Google Scholar]

- Mirjalili, S. Dragonfly algorithm: A new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems. Neural Comput. Appl. 2016, 27, 1053–1073. [Google Scholar] [CrossRef]

- Heidari, A.A.; Mirjalili, S.; Faris, H.; Aljarah, I.; Mafarja, M.; Chen, H. Harris hawks optimization: Algorithm and applications. Futur. Gener. Comput. Syst. 2019, 97, 849–872. [Google Scholar] [CrossRef]

- Yang, Y.L.; Chao, P.C.P.; Sung, C.K. Landing posture control for a generalized twin-body system using methods of input-output linearization and computed torque. IEEE/ASME Trans. Mechatron. 2009, 14, 326–336. [Google Scholar] [CrossRef]

- Agrawal, S.K.; Zhang, C. An approach to posture control of free-falling twin bodies using differential flatness. In Proceedings of the IEEE/RSJ 2010 International Conference on Intelligent Robots and Systems, Taipei, Taiwan, China, 18–22 October 2010; pp. 685–690. [Google Scholar]

- Chang-Siu, E.; Libby, T.; Brown, M.; Full, R.J.; Tomizuka, M. A nonlinear feedback controller for aerial self-righting by a tailed robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 32–39. [Google Scholar]

- Li, Z.; Montgomery, R. Dynamics and optimal control of a legged robot in flight phase. In Proceedings of the IEEE International Conference on Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 1816–1821. [Google Scholar]

- Zhao, J.; Xu, J.; Gao, B.; Xi, N.; Cintron, F.J.; Mutka, M.W.; Xiao, L. MSU jumper: A single-motor-actuated miniature steerable jumping robot. IEEE Trans. Robot. 2013, 29, 602–614. [Google Scholar] [CrossRef]

- Gu, E.Y.L. Robotic Dynamics: Modeling and Formulations; Springer: Berlin, Germany, 2013; pp. 231–291. ISBN 978-3-642-39046-3. [Google Scholar]

- Chapra, S.C. Applied Numerical Methods with MATLAB for Engineers and Scientists; McGraw-Hill Science/Engineering/Math: New York, NY, USA, 2006; ISBN 9780874216561. [Google Scholar]

- Heumann, C.; Schomaker, M.; Shalabh. Introduction to Statistics and Data Analysis; Springer International Publishing: Berlin, Germany, 2016; ISBN 9783319461625. [Google Scholar]

| Component | Mass (g) | Amount |

|---|---|---|

| Water jet thruster | 1348 | 1 |

| Shell | 1231 | 1 |

| Front legs and dampers | 485 | 2 |

| Hind legs, driven wheels and payload | 456 | 2 |

| Servos of Assistant legs | 121 | 2 |

| Assistant legs | 182 | 2 |

| Driving wheels and their servos | 256 | 2 |

| Battery | 138 | 1 |

| Control electronics | 147 | 1 |

| Total | 4364 | - |

| Experiment No. | Pitch Angle (°) | Initial Falling Height (m) | Assistant Leg’s Theoretical Rotation Angle (°) | |

|---|---|---|---|---|

| Group 1 | 1 | −12 | 1.35 | −34.2 |

| 2 | −12 | 1.4 | −34.2 | |

| 3 | −17 | 1.35 | −48.5 | |

| 4 | −17 | 1.4 | −48.5 | |

| 5 | −17 | 1.4 | / | |

| Group 2 | 6 | −15 | 1.05 | −49.3 |

| 7 | −15 | 1.3 | −49.3 | |

| 8 | 15 | 1.05 | 49.3 | |

| 9 | 15 | 1.3 | 49.3 | |

| 10 | 15 | 1.3 | / |

| Benchmark Function | Evaluation Indicator | MWOA-I | MWOA-II | MWOA-III | MWOA |

|---|---|---|---|---|---|

| f1 | Mean value | 1.05 × 10−73 | 0 | 1.54 × 10−174 | 0 |

| Standard deviation | 4.82 × 10−73 | 0 | 0 | 0 | |

| f2 | Mean value | 1.59 × 10−51 | 6.03 × 10−210 | 4.19 × 10−134 | 1.27 × 10−139 |

| Standard deviation | 6.30 × 10−51 | 0 | 2.92 × 10−133 | 6.94 × 10−139 | |

| f3 | Mean value | 5.64 × 104 | 0 | 8.36 × 10−176 | 0 |

| Standard deviation | 1.32 × 104 | 0 | 0 | 0 | |

| f4 | Mean value | 2.80 × 101 | 2.83 × 101 | 2.86 × 101 | 2.77 × 101 |

| Standard deviation | 4.17 × 10−1 | 3.20 × 10−1 | 2.60 × 10−1 | 2.06 × 10−1 | |

| f5 | Mean value | −1.05 × 104 | −1.22 × 104 | −1.25 × 104 | −1.24 × 104 |

| Standard deviation | 1.74 × 103 | 1.04 × 103 | 1.18 × 102 | 3.03 × 102 | |

| f6 | Mean value | 1.89 × 10−15 | 0 | 0 | 0 |

| Standard deviation | 1.04 × 10−14 | 0 | 0 | 0 | |

| f7 | Mean value | 3.97 × 10−15 | 8.88 × 10−16 | 8.88 × 10−16 | 8.88 × 10−16 |

| Standard deviation | 2.59 × 10−15 | 1.00 × 10−31 | 1.00 × 10−31 | 1.00 × 10−31 | |

| f8 | Mean value | 3.66 × 10−2 | 0 | 0 | 0 |

| Standard deviation | 9.24 × 10−2 | 0 | 0 | 0 | |

| f9 | Mean value | 2.22 | 3.29 | 1.75 | 1.76 |

| Standard deviation | 2.02 | 3.57 | 1.87 | 8.52 × 10−1 | |

| f10 | Mean value | 7.12 × 10−4 | 6.52 × 10−4 | 3.98 × 10−4 | 3.72 × 10−4 |

| Standard deviation | 4.75 × 10−4 | 1.83 × 10−4 | 1.09 × 10−4 | 1.04 × 10−4 |

| Benchmark Function | Evaluation Indicator | WOA | DA | HHO | MWOA |

|---|---|---|---|---|---|

| f1 | Mean value | 3.98 × 10−73 | 2.03 × 103 | 4.57 × 10−93 | 0 |

| Standard deviation | 1.97 × 10−72 | 1.10 × 103 | 2.50 × 10−92 | 0 | |

| f2 | Mean value | 1.65 × 10−50 | 1.44 × 101 | 2.07 × 10−50 | 1.27 × 10−139 |

| Standard deviation | 7.67 × 10−50 | 5.58 | 1.09 × 10−49 | 6.94 × 10−139 | |

| f3 | Mean value | 4.16 × 104 | 1.42 × 104 | 1.88 × 10−70 | 0 |

| Standard deviation | 1.09 × 104 | 8.49 × 103 | 8.12 × 10−70 | 0 | |

| f4 | Mean value | 2.79 × 101 | 4.25 × 105 | 1.32 × 10−2 | 2.77 × 101 |

| Standard deviation | 3.35 × 10−1 | 3.93 × 105 | 1.92 × 10−2 | 2.06 × 10−1 | |

| f5 | Mean value | −9.83 × 103 | −5.36 × 103 | −1.26 × 104 | −1.24 × 104 |

| Standard deviation | 1.92 × 103 | 6.57 × 102 | 8.14 × 101 | 3.03 × 102 | |

| f6 | Mean value | 3.31 | 1.88 × 102 | 0 | 0 |

| Standard deviation | 1.82 × 101 | 4.36 × 101 | 0 | 0 | |

| f7 | Mean value | 4.45 × 10−15 | 1.05 × 101 | 8.88 × 10−16 | 8.88 × 10−16 |

| Standard deviation | 2.09 × 10−15 | 1.47 | 1.00 × 10−31 | 1.00 × 10−31 | |

| f8 | Mean value | 3.70 × 10−18 | 1.86 × 101 | 0 | 0 |

| Standard deviation | 2.03 × 10−17 | 1.15 × 101 | 0 | 0 | |

| f9 | Mean value | 2.50 | 1.23 | 1.29 | 1.76 |

| Standard deviation | 2.91 | 4.28 × 10−1 | 9.75 × 10−1 | 8.52 × 10−1 | |

| f10 | Mean value | 5.96 × 10−4 | 2.24 × 10−3 | 3.78 × 10−4 | 3.72 × 10−4 |

| Standard deviation | 2.98 × 10−4 | 3.42 × 10−3 | 2.27 × 10−4 | 1.04 × 10−4 |

| No. | Priority | Weight Coefficient Combination | Optimization Result I | Optimization Result II |

|---|---|---|---|---|

| 1 | Horizontal jumping distance | ω1 = 0.6132, ω2 = 0.2125, ω3 = 0.1743 | φ0 = 71.2°, v0 = 8 m/s | φ0 = 62.5°, v0 = 8 m/s |

| 2 | Vertical jumping distance | ω1 = 0.0315, ω2 = 0.8149, ω3 = 0.1536 | φ0 = 81.9°, v0 = 8 m/s | φ0 = 81.9°, v0 = 8 m/s |

| 3 | Landing safety | ω1 = 0.1852, ω2 = 0.0926, ω3 = 0.7222 | φ0 = 76.0°, v0 = 5.57 m/s | φ0 = 76.0°, v0 = 5.57 m/s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, J.; Yan, Z.; Li, B.; Xi, F.; Li, Y. Study of Obstacle-Crossing and Pitch Control Characteristic of a Novel Jumping Robot. Sensors 2021, 21, 2432. https://doi.org/10.3390/s21072432

Mo J, Yan Z, Li B, Xi F, Li Y. Study of Obstacle-Crossing and Pitch Control Characteristic of a Novel Jumping Robot. Sensors. 2021; 21(7):2432. https://doi.org/10.3390/s21072432

Chicago/Turabian StyleMo, Jixue, Ze Yan, Bing Li, Fengfeng Xi, and Yao Li. 2021. "Study of Obstacle-Crossing and Pitch Control Characteristic of a Novel Jumping Robot" Sensors 21, no. 7: 2432. https://doi.org/10.3390/s21072432

APA StyleMo, J., Yan, Z., Li, B., Xi, F., & Li, Y. (2021). Study of Obstacle-Crossing and Pitch Control Characteristic of a Novel Jumping Robot. Sensors, 21(7), 2432. https://doi.org/10.3390/s21072432