Design and Implementation of Universal Cyber-Physical Model for Testing Logistic Control Algorithms of Production Line’s Digital Twin by Using Color Sensor

Abstract

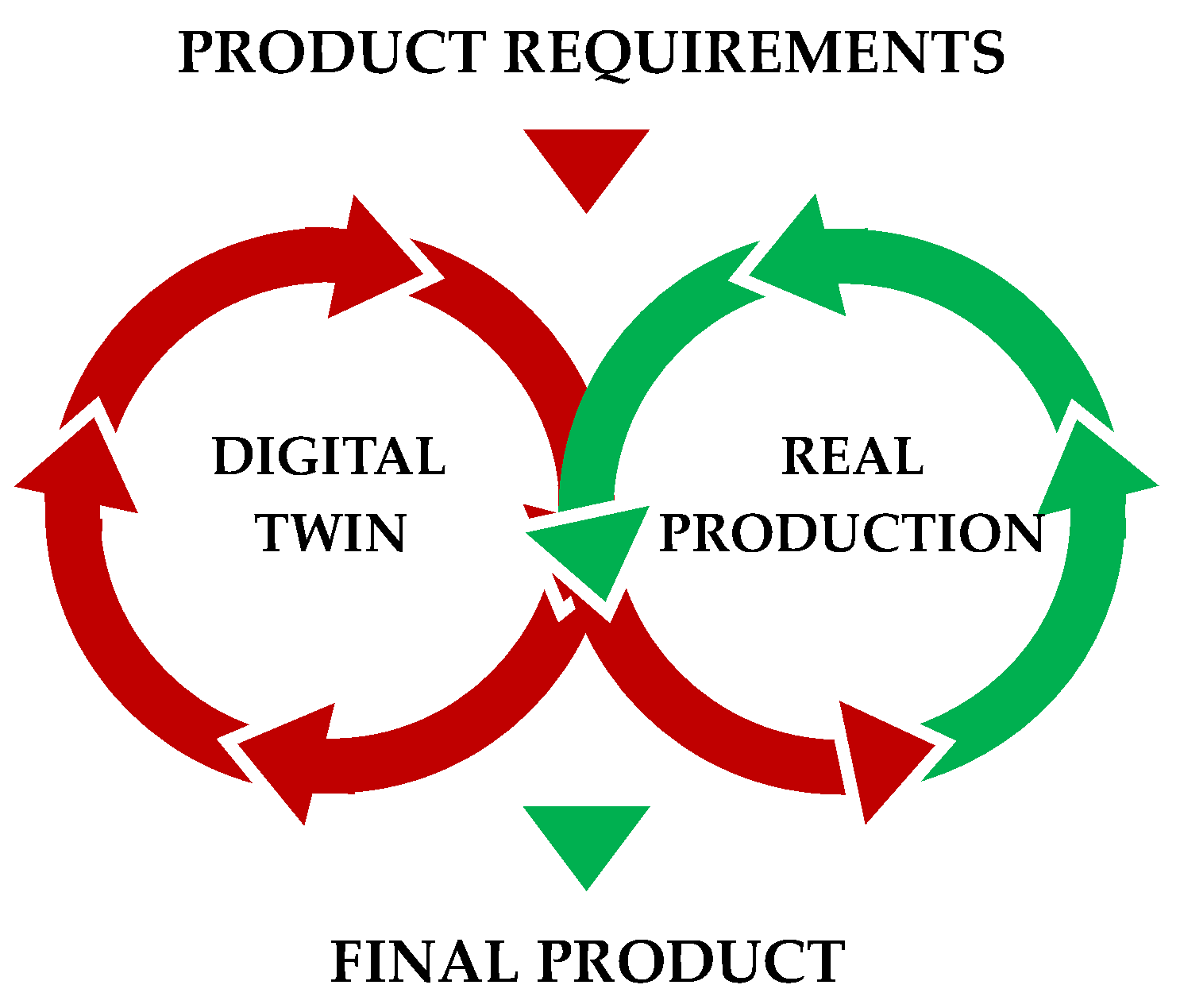

1. Introduction

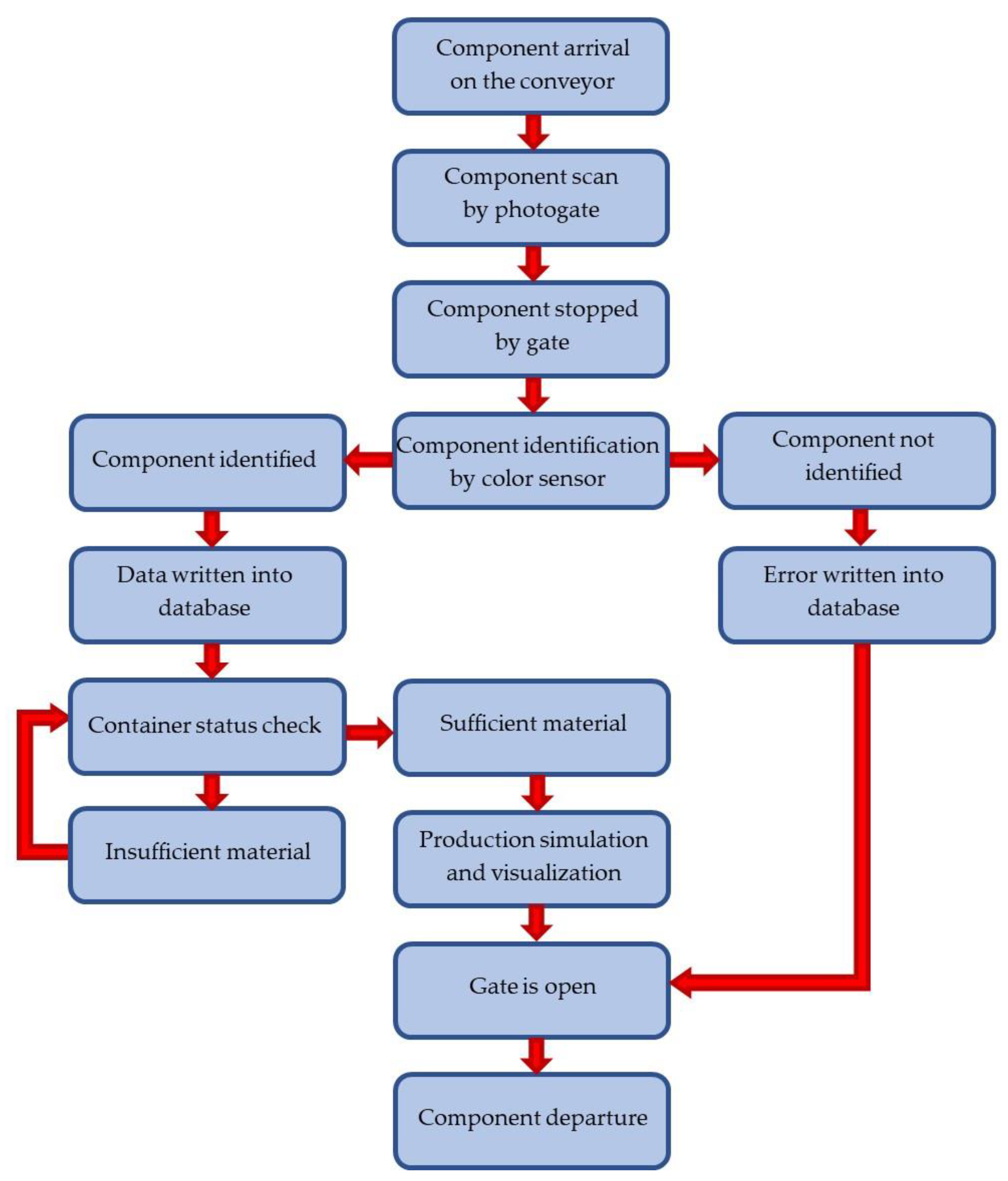

2. Methods and Materials

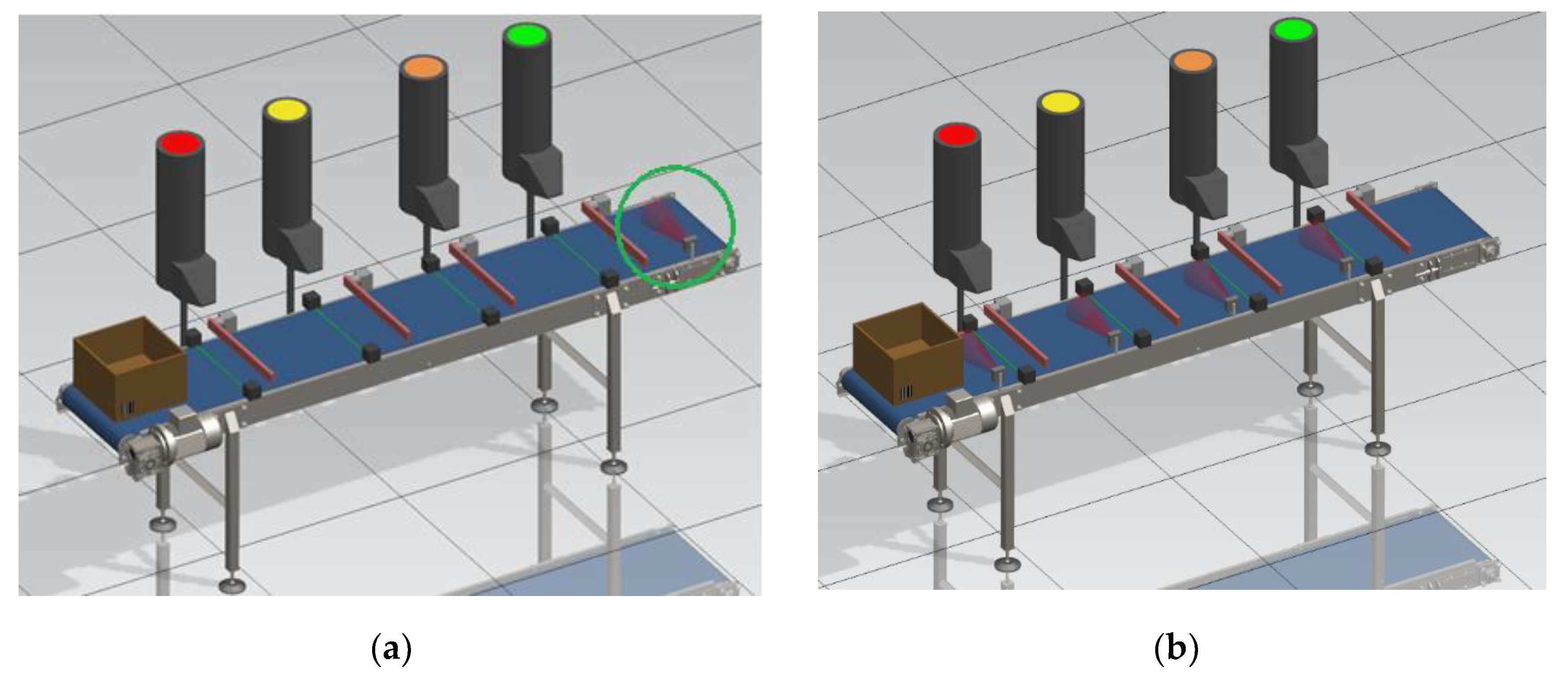

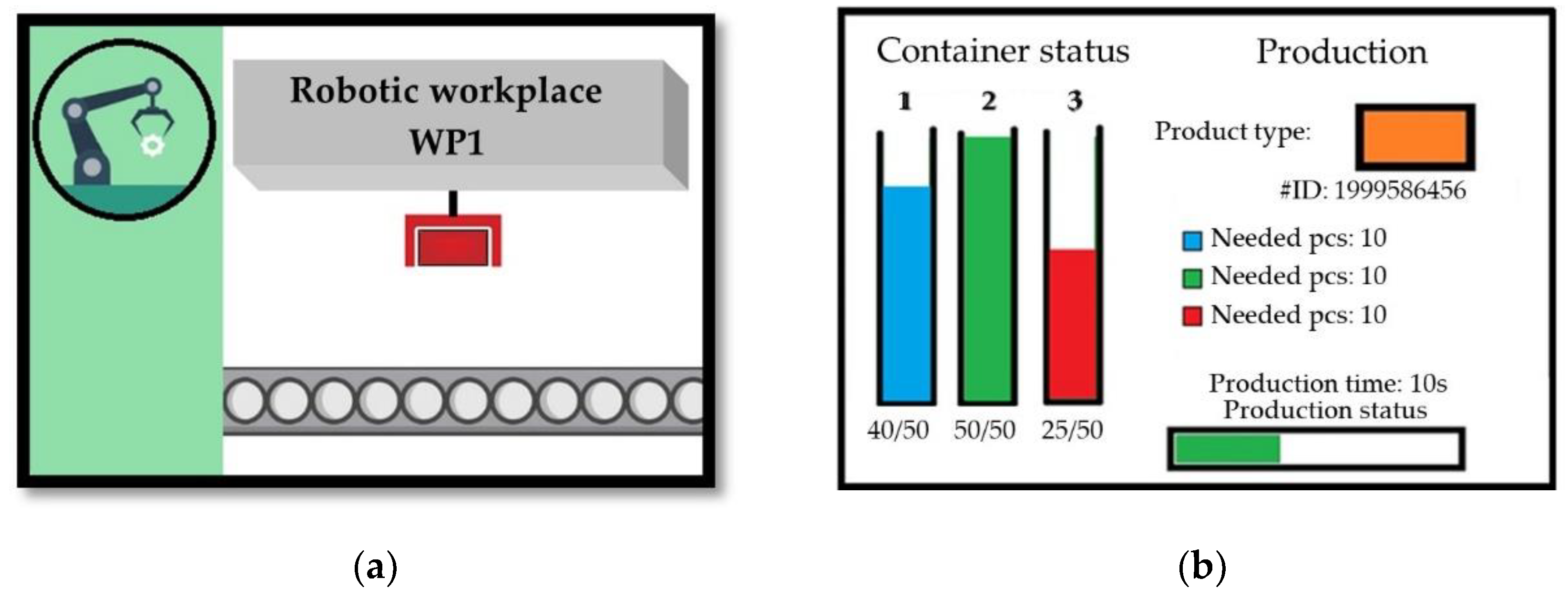

3. Functional Description of a Physical Model Workplace

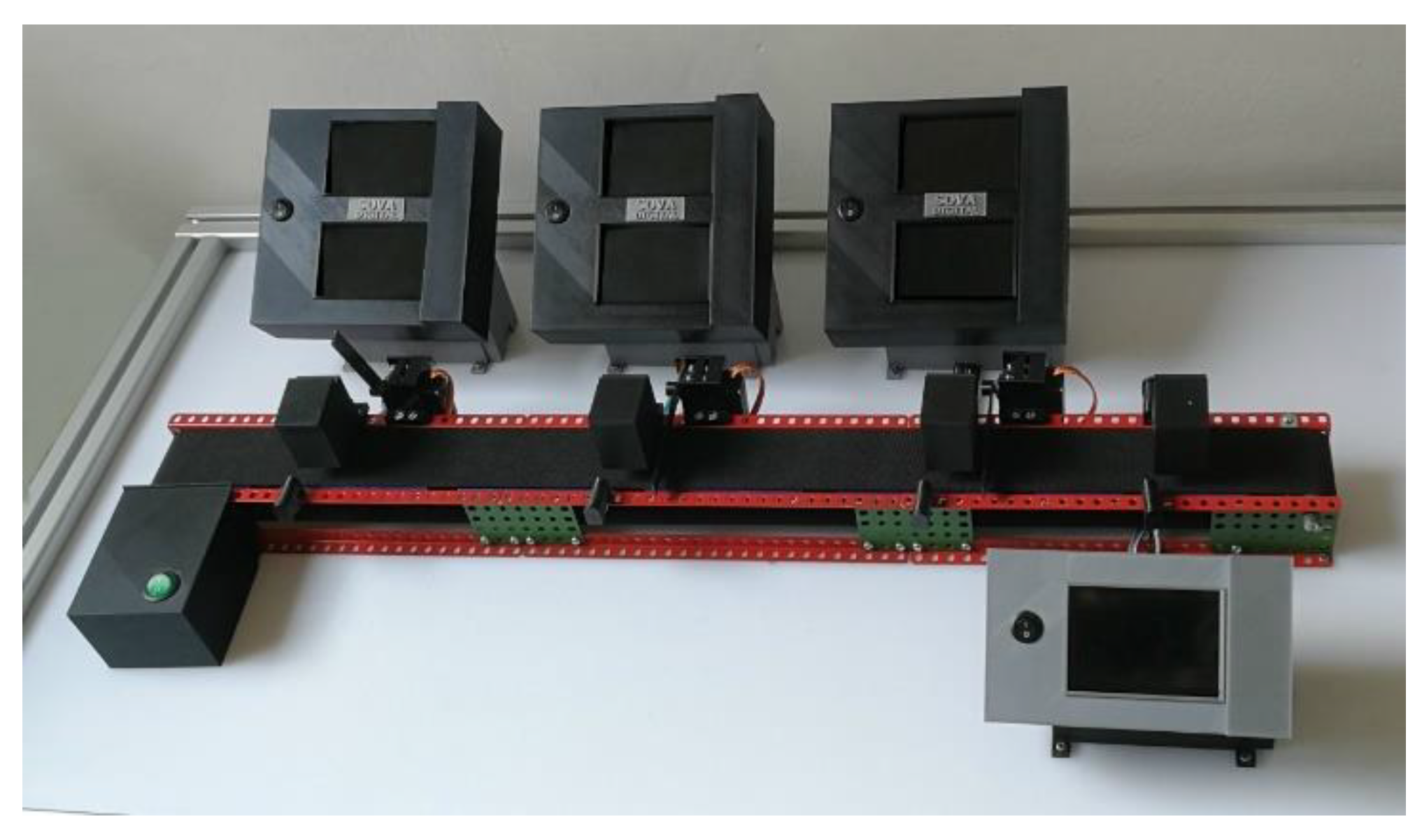

4. Design of a Physical (Real) Model of a Cyber-Physical System for Testing Control Algorithms

4.1. Product Identification

Color Sensor TCS 230

4.2. Process Visualization

4.3. Physical Model Control

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, W.D.; Low, Y.H.; Chong, Y.T.; Teo, C.L. Integrated Cyber Physical Simulation Modelling Environment for Manufacturing 4.0. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 6–12 December 2018; pp. 1861–1865. [Google Scholar] [CrossRef]

- Drath, R.; Horch, A. Industrie 4.0: Hit or Hype? IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Alqahtani, A.Y.; Gupta, S.M.; Nakashima, K. Warranty and maintenance analysis of sensor embedded products using internet of things in industry 4.0. Int. J. Prod. Econ. 2018, 208, 483–499. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113. [Google Scholar] [CrossRef]

- Tao, F.; Qinglin, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber-Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Valencia, E.T.; Lamouri, S.; Pellerin, R.; Dubois, P.; Moeuf, A. Production Planning in the Fourth Industrial Revolution: A Literature Review. IFAC PapersOnLine 2019, 52, 2158–2163. [Google Scholar] [CrossRef]

- Wittenberg, C. Human-CPS Interaction—Requirements and human-machine interaction methods for the Industry 4.0. IFAC PapersOnLine 2009, 49, 420–425. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The internet of things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Jones, M.; Zarzycki, L.; Murray, G. Does industry 4.0 Pose a Challenge for the SME machine builder? A Case Study and Reflection of Readiness for a UK SME. In Precision Assembly in the Digital Age, Proceeding of the 8th IFIP WG 5.5 International Precision Assembly Seminar, IPAS 2018, Chamonix, France, 14–16 January 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 183–197. [Google Scholar] [CrossRef]

- D’Orazio, L.; Messina, R.; Schiraldi, M.M. Industry 4.0 and World Class Manufacturing Integration: 100 Technologies for a WCM-I4.0 Matrix. Appl. Sci. 2020, 10, 4942. [Google Scholar] [CrossRef]

- Polge, J.; Robert, J.; Le Traon, Y. A Case Driven Study of the Use of Time Series Classification for Flexibility in Industry 4.0. Sensors 2020, 20, 7273. [Google Scholar] [CrossRef]

- Bellotti, F.; Osman, N.; Arnold, E.H.; Mozaffari, S.; Innamaa, S.; Louw, T.; Torrao, G.; Weber, H.; Hiller, J.; De Gloria, A.; et al. Managing Big Data for Addressing Research Questions in a Collaborative Project on Automated Driving Impact Assessment. Sensors 2020, 20, 6773. [Google Scholar] [CrossRef]

- Camarillo, A.; Ríos, J.; Althoff, K.-D. Product Lifecycle Management as Data Repository for Manufacturing Problem Solving. Materials 2018, 11, 1469. [Google Scholar] [CrossRef] [PubMed]

- Groover, M.P. Automation, Production Systems, and Computer-Integrated Manufacturing; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

- Ponis, S.T.; Efthymiou, O.K. Cloud and IoT Applications in Material Handling Automation and Intralogistics. Logistics 2020, 4, 22. [Google Scholar] [CrossRef]

- Fyraj, K.; Firsching, P. Using Augmented Reality to Enhance the Capabilities of Human-Machine Interaction in Industry. In Symposium Electronics and System Integration ESI 2018: From Sensors to Actuators in Interdisciplinary Application; Hochschule Landshut: Landshut, Germany, 2018; ISBN 978-3-9818439-1-0. [Google Scholar]

- Duchon, F.; Hubinsky, P.; Hanzel, J.; Babinec, A.; Tolgyessy, M. Intelligent Vehicles as the Robotic Applications. Procedia Eng. 2012, 48, 105–114. [Google Scholar] [CrossRef]

- Steck, J.; Morales-Ortega, R.; Currence, J.; Zhou, W. A Mobile Robot Gripper for Cooperative 3D Printing. In Solid Freeform Fabrication 2017, Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium an Additive Manufacturing Conference, SFF 2017, Austin, TX, USA, 7–9 August 2017; University of Texas at Austin: Austin, TX, USA, 2017; pp. 2664–2681. [Google Scholar]

- Prinsloo, J.; Sinha, S.; von Solms, B. A Review of Industry 4.0 Manufacturing Process Security Risks. Appl. Sci. 2019, 9, 5105. [Google Scholar] [CrossRef]

- Pawlewski, P.; Kosacka-Olejnik, M.; Werner-Lewandowska, K. Digital Twin Lean Intralogistics: Research Implications. Appl. Sci. 2021, 11, 1495. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Qi, Q.; Zhao, D.; Liao, T.W.; Tao, F. Modeling of Cyber-Physical Systems and Digital Twin Based on Edge Computing, Fog Computing and Cloud Computing Towards Smart Manufacturing. In Proceedings of the ASME 2018 13th International Manufacturing and Engineering Conference, College Station, TX, USA, 18–22 June 2018. [Google Scholar] [CrossRef]

- Pang, T.Y.; Restrepo, J.D.P.; Cheng, C.-T.; Yasin, A.; Lim, H.; Miletic, M. Developing a Digital Twin and Digital Thread Framework for an ‘Industry 4.0’ Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Lin, W.D.; Low, M.Y.H. Concept Design of a System Architecture for a Manufacturing Cyber-physical Digital Twin System. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; pp. 1320–1324. [Google Scholar] [CrossRef]

- Ciano, M.P.; Pozzi, R.; Rossi, T.; Strozzi, F. Digital twin-enabled smart industrial systems: A bibliometric review. Int. J. Comput. Integr. Manuf. 2020. [Google Scholar] [CrossRef]

- Schuh, G.; Kelzenberg, C.; Wiese, J.; Kessler, N. Creation of digital production twins for the optimization of value creation in single and small batch production. Procedia CIRP 2020, 93, 222–227. [Google Scholar] [CrossRef]

- Dos Santos, C.H.; De Queiroz, J.A.; Leal, F.; Montevechi, J.A.B. Use of simulation in the industry 4.0 context: Creation of a Digital Twin to optimise decision making on non-automated process. J. Simul. 2020, 1–14. [Google Scholar] [CrossRef]

- Bécue, A.; Maia, E.; Feeken, L.; Borchers, P.; Praça, I. A New Concept of Digital Twin Supporting Optimization and Resilience of Factories of the Future. Appl. Sci. 2020, 10, 4482. [Google Scholar] [CrossRef]

- Al-Sehrawy, R.; Kumar, B. Digital Twins in Architecture, Engineering, Construction and Operations. A Brief Review and Analysis. In Proceedings of the 18th International Conference on Computing in Civil and Building Engineering, Sao Paulo, Brazil, 18–20 August 2020; Springer: Cham, Switzerland, 2020; pp. 924–939. [Google Scholar] [CrossRef]

- Tvenge, N.; Ogorodnyk, O.; Østbø, N.P.; Martinsen, K. Added value of a virtual approach to simulation-based learning in a manufacturing learning factory. Procedia CIRP 2020, 88, 36–41. [Google Scholar] [CrossRef]

- Park, K.T.; Lee, J.; Kim, H.J.; Noh, S.D. Digital twin-based cyber physical production system architectural framework for personalized production. Int. J. Adv. Manuf. Technol. 2019, 106, 1787–1810. [Google Scholar] [CrossRef]

- Josifovska, K.; Yigitbas, E.; Engels, G. Reference Framework for Digital Twins within Cyber-Physical Systems. In Proceedings of the 2019 IEEE/ACM 5th International Workshop on Software Engineering for Smart Cyber-Physical Systems (SEsCPS), Montreal, QC, Canada, 28 May 2019; pp. 25–31. [Google Scholar] [CrossRef]

- Landolfi, G.; Barni, A.; Menato, S.; Cavadini, F.A.; Rovere, D.; Dal Maso, G. Design of a multi-sided platform supporting CPS deployment in the automation market. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), Saint Petersburg, Russia, 15–18 May 2018; pp. 684–689. [Google Scholar] [CrossRef]

- Zheng, N.; Lu, X. Comparative Study on Push and Pull Production System Based on Anylogic. In Proceedings of the International Conference on Electronic Commerce and Business Intelligence, Beijing, China, 6–7 June 2009; pp. 455–458. [Google Scholar] [CrossRef]

- Faccio, M.; Gamberi, M.; Bortolini, M.; Pilati, F. Macro and micro-logistic aspects in defining the parts-feeding policy in mixed-model assembly systems. Int. J. Serv. Oper. Manag. 2018, 31, 433–462. [Google Scholar] [CrossRef]

- Hanson, R. In-Plant Materials Supply: Supporting the Choice between Hitting and Continuous Supply; Chalmers Reproservice: Gothenburg, Sweden, 2012; ISBN 978-91-7385-654-6. [Google Scholar]

- Corakci, M.A. An Evaluation of Kitting Systems in Lean Production. Master’s Thesis, University College of Borås School of Engineering, Boras, Sweden, 2009. [Google Scholar]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: Cambridge, MA, USA, 1988; ISBN 97S-0915299140. [Google Scholar]

- Lai, K.; Cheng, T.C.E. Just-in-Time Logistics; CRC Press: Burlington, ON, Canada; Gower, UK, 2009; ISBN 97S-05OO0S900S. [Google Scholar]

- Mayer, A. Milk Run Design: Definitions, Concepts and Solution Approaches; KIT Scientific Publishing: Karlsruhe, Germany, 2015. [Google Scholar] [CrossRef]

- Regor, M.; Košturiak, J. Podnik v Roce 2001 Revoluce v Podnikové Kultuře; Grada: Prague, Czech Republic, 2001; ISBN S0-7109-003-1. [Google Scholar]

- Marhoulová, D. Japonské Systémy Řízení, 1st ed.; Svoboda: Prague, Czech Republic, 1989; ISBN S0-205-0033-2. [Google Scholar]

- Satoh, I. A format approach for Milk-run transport logistics. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2008, 91, 3261–3268. [Google Scholar] [CrossRef]

- Marchwinski, C.; Shook, J. Lean Lexicon; Lean Enterprise Institute: Cambridge, MA, USA, 2003; ISBN 0-9667843-6-7. [Google Scholar]

- Dorigo, M.; Gambardella, L.M. Ant colony system: A cooperative learning approach to the traveling salesman problem. IEEE Trans. Evol. Comput. 1997, 1, 53–66. [Google Scholar] [CrossRef]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2018, 13, 534–556. [Google Scholar] [CrossRef]

- Centomo, S.; Panato, M.; Fummi, F. Cyber-Physical Systems Integration in a Production Line Simulator. In Proceedings of the 26th IFIP/IEEE International Conference on Very Large Scale Integration (VLSI-SoC), Verona, Italy, 8–10 October 2018; pp. 237–242. [Google Scholar] [CrossRef]

- Chen, X.; Lu, F.; Ye, T.T. The “Weak Spots” in Stacked UHF RFID Tags in NFC Applications. In Proceedings of the IEEE International Conference on RFID (IEEE RFID 2010), Orlando, FL, USA, 14–16 April 2010; pp. 181–186. [Google Scholar] [CrossRef]

- Datasheet TCS230 Programmable Color Light-to-Frequency Converter. 2020. Available online: http://www.unihedron.com/projects/darksky/tcs230-e33.pdf. (accessed on 10 December 2020).

- Vachálek, J.; Šišmišová, D.; Vašek, P.; Rybář, J.; Slovák, J.; Šimovec, M. Intelligent Dynamic Identification of Industrial Products in a Robotic Workplace. Preprints 2021. [Google Scholar] [CrossRef]

- Arduino Mega 2560. 2020 Arduino. Available online: https://store.arduino.cc/arduino-mega-2560-rev3 (accessed on 16 December 2020).

- Babiuch, M.; Foltýnek, P.; Smutný, P. Using the ESP32 Microcontroller for Data Processing. In Proceedings of the 20th International Carpathian Control Conference (ICCC), Krakow-Wieliczka, Poland, 26–29 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Datta, S.K.; Bonnet, C. MEC and IoT Based Automatic Agent Reconfiguration in Industry 4.0. In Proceedings of the IEEE International Conference on Advanced Networks and Telecommunications Systems (ANTS), Indore, India, 16–19 December 2018; pp. 1–5. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vachálek, J.; Šišmišová, D.; Vašek, P.; Fiťka, I.; Slovák, J.; Šimovec, M. Design and Implementation of Universal Cyber-Physical Model for Testing Logistic Control Algorithms of Production Line’s Digital Twin by Using Color Sensor. Sensors 2021, 21, 1842. https://doi.org/10.3390/s21051842

Vachálek J, Šišmišová D, Vašek P, Fiťka I, Slovák J, Šimovec M. Design and Implementation of Universal Cyber-Physical Model for Testing Logistic Control Algorithms of Production Line’s Digital Twin by Using Color Sensor. Sensors. 2021; 21(5):1842. https://doi.org/10.3390/s21051842

Chicago/Turabian StyleVachálek, Ján, Dana Šišmišová, Pavol Vašek, Ivan Fiťka, Juraj Slovák, and Matej Šimovec. 2021. "Design and Implementation of Universal Cyber-Physical Model for Testing Logistic Control Algorithms of Production Line’s Digital Twin by Using Color Sensor" Sensors 21, no. 5: 1842. https://doi.org/10.3390/s21051842

APA StyleVachálek, J., Šišmišová, D., Vašek, P., Fiťka, I., Slovák, J., & Šimovec, M. (2021). Design and Implementation of Universal Cyber-Physical Model for Testing Logistic Control Algorithms of Production Line’s Digital Twin by Using Color Sensor. Sensors, 21(5), 1842. https://doi.org/10.3390/s21051842