Real-Time Detection of Fouling-Layer with a Non-Intrusive Continuous Sensor (NICS) during Thermal Processing in Food Manufacturing

Abstract

1. Introduction

2. Materials and Methods

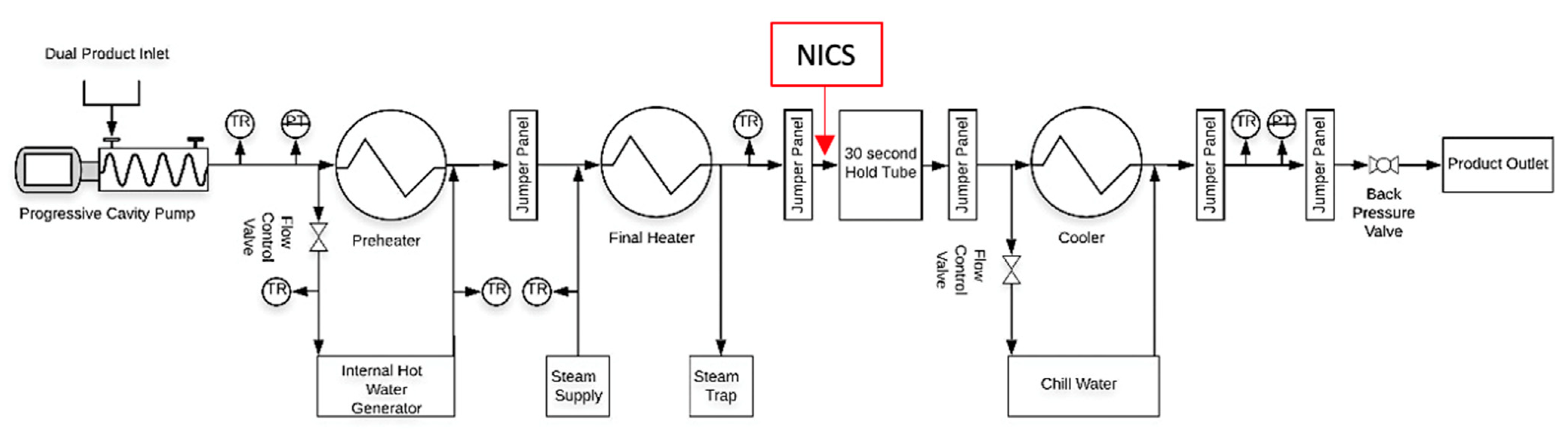

2.1. Product Description and Equipment Design

2.2. Fouling Layer Model

2.3. Sensor Calibration

2.4. Inverse Problem

2.5. Image Analysis

3. Results and Discussion

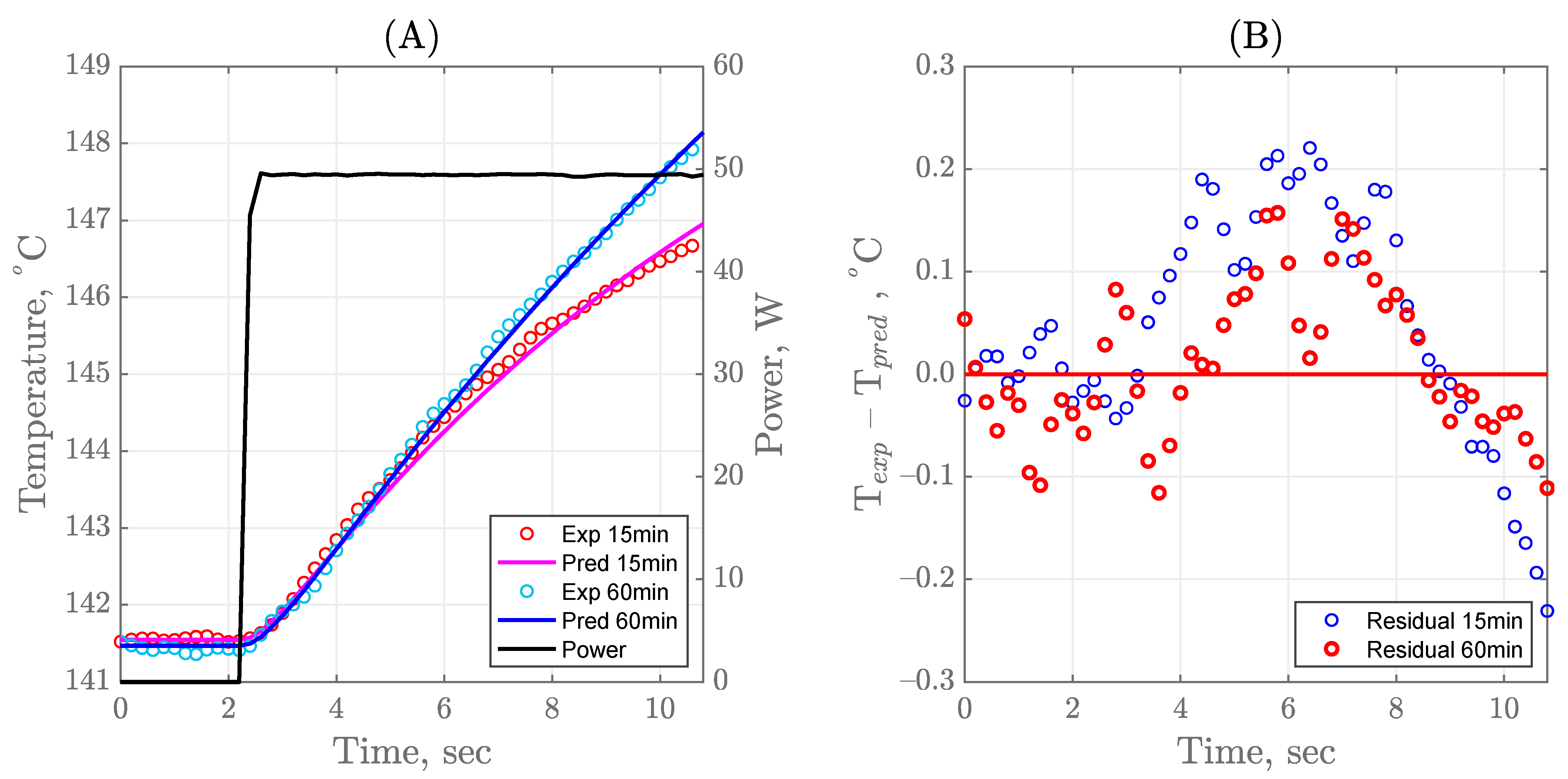

3.1. Sensor Calibration

3.2. Fouling Layer Image Analysis

3.3. Fouling Layer Thermal Conductivity Estimation

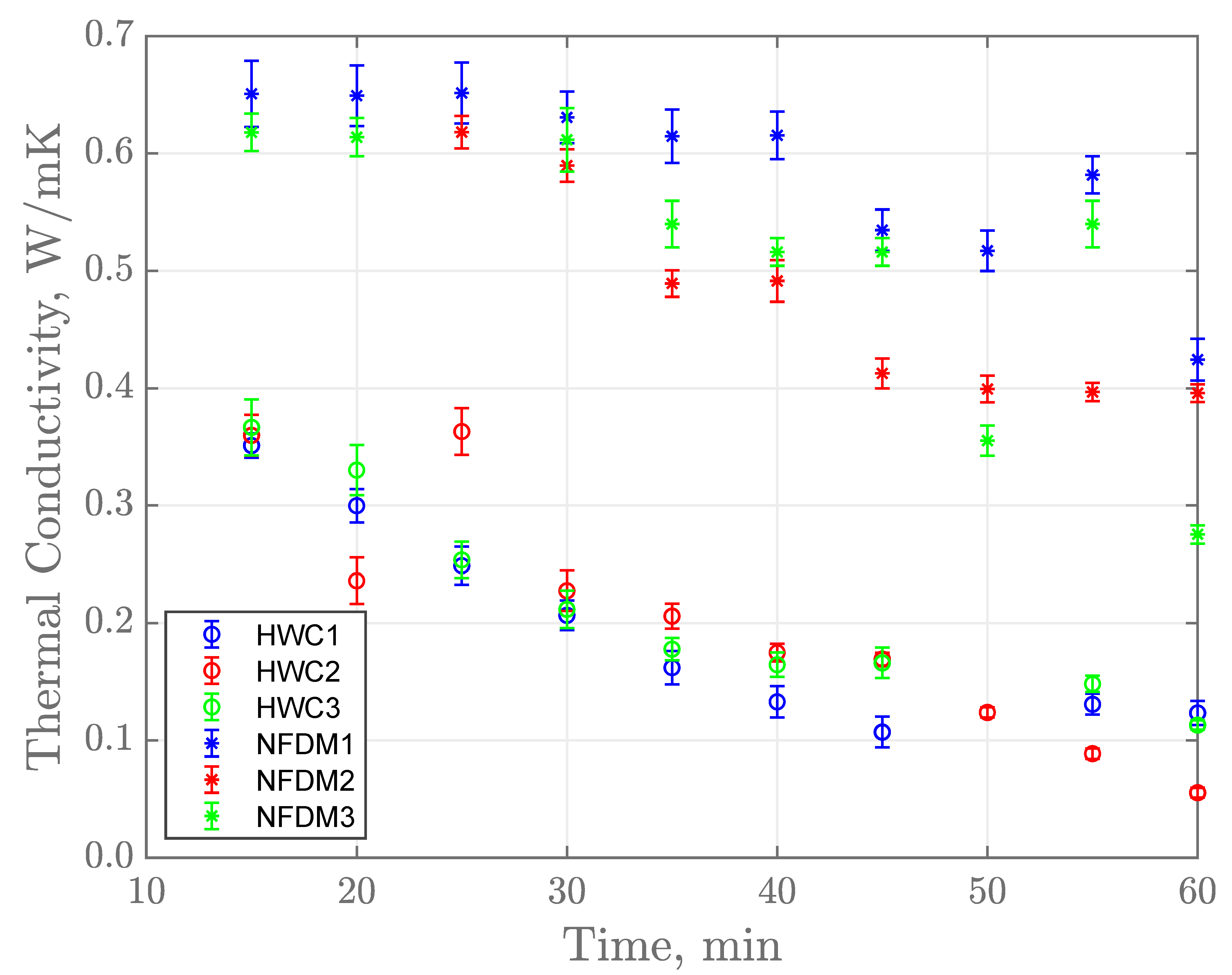

3.4. Fouling Layer Thermal Resistance Calculations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bott, T.R. Basic principles. In Fouling of Heat Exchangers; Bott, T.R., Ed.; Chemical Engineering Monographs; Elsevier: Amsterdam, The Netherlands, 1995; pp. 7–14. [Google Scholar]

- Awad, M.M. Fouling of Heat Transfer Surfaces; Intech Open Access Publisher: London, UK, 2011. [Google Scholar] [CrossRef]

- Ibrahim, H. Fouling in heat exchangers. In MATLAB—A Fundamental Tool for Scientific Computing and Engineering Applications; Katsikis, V.N., Ed.; Intech Open Access Publisher: London, UK, 2012; Volume 3. [Google Scholar]

- Schlüter, F.; Augustin, W.; Scholl, S. Modeling local fouling resistances. Heat Exch. Fouling Clean. 2019, 10, 20–30. [Google Scholar]

- Caruyer, C.; Minier, J.; Guingo, M.; Henry, C. A Stochastic model for particle deposition in turbulent flows and clogging effects. In Advances in Hydroinformatics; Springer: Singapore, 2016; pp. 451–466. ISBN 978-981-287-614-0. [Google Scholar]

- Tuoc, T.K. Fouling in Dairy Processes; Amjad, Z., Demadis, K.D.B.T.-M.S.D., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; Chapter 20; pp. 533–556. ISBN 978-0-444-63228-9. [Google Scholar]

- Gudmundsson, O.; Palsson, O.P.; Palsson, H.; Lalot, S. Online fouling detection of domestic hot water heat exchangers. Heat Transf. Eng. 2016, 37, 1231–1241. [Google Scholar] [CrossRef]

- Bansal, B.; Chen, X.D. A critical review of milk fouling in heat exchangers. Compr. Rev. Food Sci. Food Saf. 2006, 5, 27–33. [Google Scholar] [CrossRef]

- Gillham, C.R.; Fryer, P.J.; Hasting, A.P.M.; Wilson, D.I. Cleaning-in-place of whey protein fouling deposits: Mechanisms controlling cleaning. Food Bioprod. Process. 1999, 77, 127–136. [Google Scholar] [CrossRef]

- Wallhäußer, E.; Hussein, M.A.; Becker, T. Detection methods of fouling in heat exchangers in the food industry. Food Control 2012, 27, 1–10. [Google Scholar] [CrossRef]

- Crattelet, J.; Ghnimi, S.; Debreyne, P.; Zaid, I.; Boukabache, A.; Esteve, D.; Auret, L.; Fillaudeau, L. On-line local thermal pulse analysis sensor to monitor fouling and cleaning: Application to dairy product pasteurisation with an ohmic cell jet heater. J. Food Eng. 2013, 119, 72–83. [Google Scholar] [CrossRef]

- Cantarero Rivera, F.J.; Mishra, D.K.; Ozadali, F. A novel Non-Intrusive Continuous Sensor (NICS) to estimate thermal conductivity of food products in manufacturing systems. Food Bioprod. Process. 2020, 123, 390–397. [Google Scholar] [CrossRef]

- Hu, J.; Sari, O.; Eicher, S.; Rija Rakotozanakajy, A. Determination of specific heat of milk at different fat content between 1 °C and 59 °C using micro DSC. J. Food Eng. 2009, 90, 395–399. [Google Scholar] [CrossRef]

- Hayes, G.D. Food Engineering Data Handbook; Longman Scientific & Technical: Harlow, UK; Wiley: New York, NY, USA, 1987; ISBN 0-582-49505-9. [Google Scholar]

- AZO Materials Stainless Steel—Grade 316 (UNS S31600). Available online: https://www.azom.com/article.aspx?ArticleID=863 (accessed on 23 September 2019).

- Cardarelli, F. Ferrous metals and their alloys. In Materials Handbook; Springer: London, UK, 2008; pp. 59–157. ISBN 978-1-84628-669-8. [Google Scholar]

- COMSOL Multiphysics Heat Transfer Module. Available online: https://doc.comsol.com/5.4/doc/com.comsol.help.heat/HeatTransferModuleUsersGuide.pdf (accessed on 30 January 2021).

- COMSOL Multiphysics CFD Module User’s Guide. Comsol Multiphysics. 2016, p. 598. Available online: https://doc.comsol.com/5.4/doc/com.comsol.help.cfd/CFDModuleUsersGuide.pdf (accessed on 30 January 2021).

- Beck, J.V.; Arnold, K.J. Parameter Estimation in Engineering and Science; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1977; ISBN 0-471-06118-2. [Google Scholar]

- Mishra, D.K.; Dolan, K.D.; Beck, J.V.; Ozadali, F. A novel instrument for rapid measurement of temperature-dependent thermal properties of conduction-heated food up to 140 °C. J. Food Eng. 2016, 191, 19–27. [Google Scholar] [CrossRef]

- Vidyarthi, S.K.; Mishra, D.K.; Dolan, K.D.; Muramatsu, Y. Inverse estimation of fluid-to-particle heat transfer coefficient in aseptic processing of particulate foods. Biosyst. Eng. 2020, 198, 210–222. [Google Scholar] [CrossRef]

- Sulaiman, R.; Dolan, K.D.; Mishra, D.K. Simultaneous and sequential estimation of kinetic parameters in a starch viscosity model. J. Food Eng. 2012, 114, 313–322. [Google Scholar] [CrossRef]

- Srichantra, A.; Newstead, D.F.; Mccarthy, O.J.; Paterson, A.H.J. Effect of preheating on fouling of a pilot scale UHT sterilizing plant by recombined, reconstituted and fresh whole milks. Food Bioprod. Process. 2006, 84, 279–285. [Google Scholar] [CrossRef]

- Chaves, M.A.; De Almeida, A.O. Development of a microcontrolled instrument to determinate thermal conductivity of foods. Int. J. Food Eng. 2009, 5. [Google Scholar] [CrossRef]

- Kazi, S.N.; Teng, K.H.; Zakaria, M.S.; Sadeghinezhad, E.; Bakar, M.A. Study of mineral fouling mitigation on heat exchanger surface. Desalination 2015, 367, 248–254. [Google Scholar] [CrossRef]

- Prakash, S.; Datta, N.; Deeth, H.C. Methods of detecting fouling caused by heating of milk. Food Rev. Int. 2005, 21, 267–293. [Google Scholar] [CrossRef]

- Bouvier, L.; Delaplace, G.; Lalot, S. Continuous monitoring of whey protein fouling using a nonintrusive sensor. Heat Transf. Eng. 2018, 1–26. [Google Scholar] [CrossRef]

- Davies, T.J.; Henstridge, S.C.; Gillham, C.R.; Wilson, D.I. Investigation of whey protein deposit properties using heat flux sensors. Food Bioprod. Process. 1997, 75, 106–110. [Google Scholar] [CrossRef]

| Product/Material | Density (kg/m3) | Specific Heat (kJ/kg·K) | Thermal Conductivity (W/m·K) | Reference |

|---|---|---|---|---|

| Non-Fat Dry Milk (NFDM) | 1035 | 3.94 | 0.53 | [13,14] |

| Heavy Whipping Cream (HWC) | 1001 | 3.56 | 0.33 | [13,14] |

| 316L Stainless Steel | 8000 | 500.00 | 16.30 | [15] |

| Non-Intrusive Continuous Sensor (NICS) | 3110 | 862.90 | 37.30 | [16] |

| Product | Mean Thermal Conductivity (W/(m·K)) | Std. Error | Lower CI | Upper CI |

|---|---|---|---|---|

| Glycerol | 0.2919 | 0.0064 | 0.2887 | 0.2952 |

| Water | 0.6384 | 0.0125 | 0.6329 | 0.6439 |

| 4% Starch | 0.4873 | 0.0086 | 0.4835 | 0.4911 |

| 10% NFDM | 0.5977 | 0.0104 | 0.5934 | 0.6020 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivera, F.J.C.; Mishra, D.K.; Ozadali, F.; Benyathiar, P. Real-Time Detection of Fouling-Layer with a Non-Intrusive Continuous Sensor (NICS) during Thermal Processing in Food Manufacturing. Sensors 2021, 21, 1271. https://doi.org/10.3390/s21041271

Rivera FJC, Mishra DK, Ozadali F, Benyathiar P. Real-Time Detection of Fouling-Layer with a Non-Intrusive Continuous Sensor (NICS) during Thermal Processing in Food Manufacturing. Sensors. 2021; 21(4):1271. https://doi.org/10.3390/s21041271

Chicago/Turabian StyleRivera, Fernando José Cantarero, Dharmendra K Mishra, Ferhan Ozadali, and Patnarin Benyathiar. 2021. "Real-Time Detection of Fouling-Layer with a Non-Intrusive Continuous Sensor (NICS) during Thermal Processing in Food Manufacturing" Sensors 21, no. 4: 1271. https://doi.org/10.3390/s21041271

APA StyleRivera, F. J. C., Mishra, D. K., Ozadali, F., & Benyathiar, P. (2021). Real-Time Detection of Fouling-Layer with a Non-Intrusive Continuous Sensor (NICS) during Thermal Processing in Food Manufacturing. Sensors, 21(4), 1271. https://doi.org/10.3390/s21041271