Distributed Fibre Optic Sensor-Based Continuous Strain Measurement along Semicircular Paths Using Strain Transformation Approach

Abstract

:1. Introduction

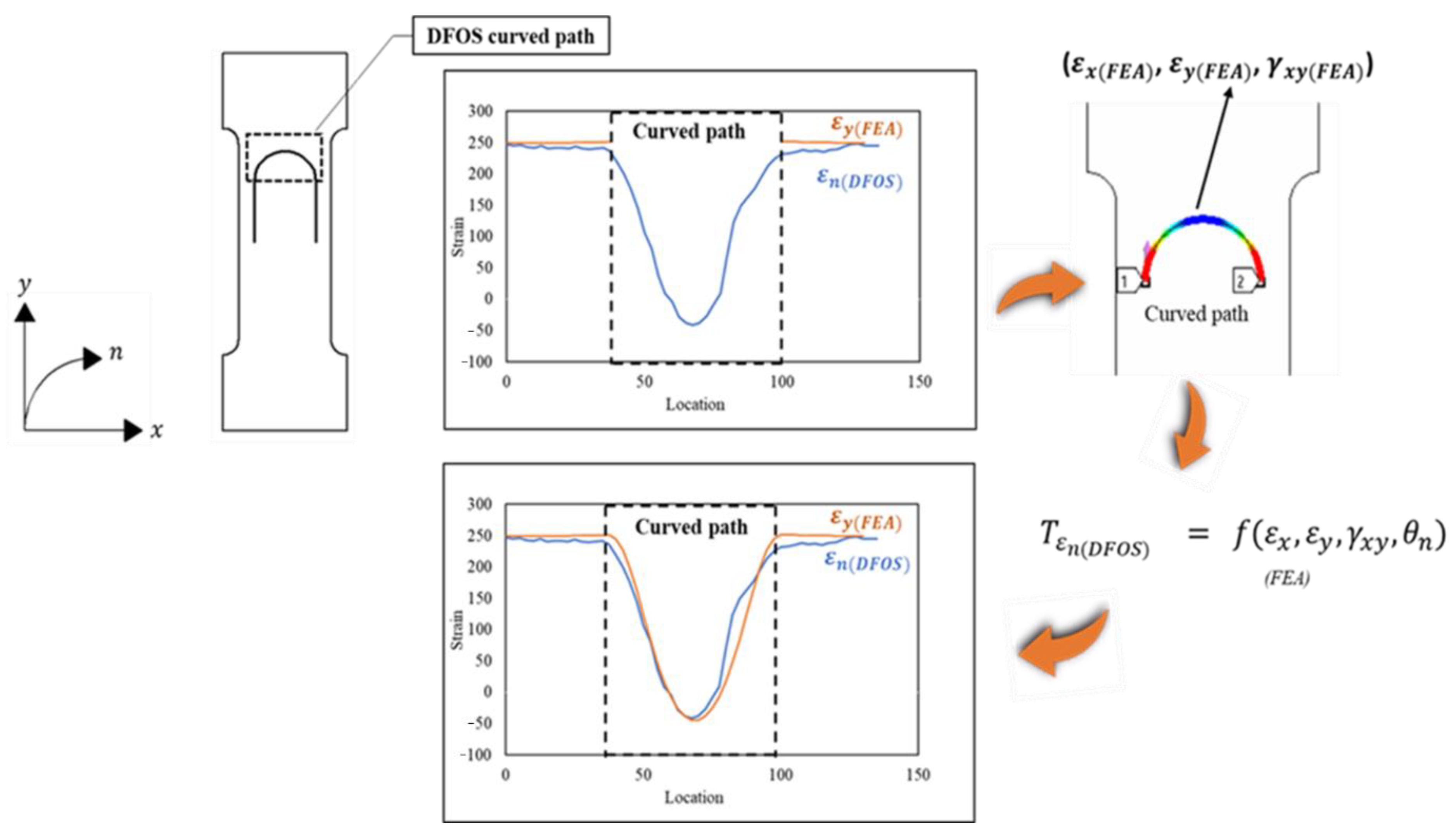

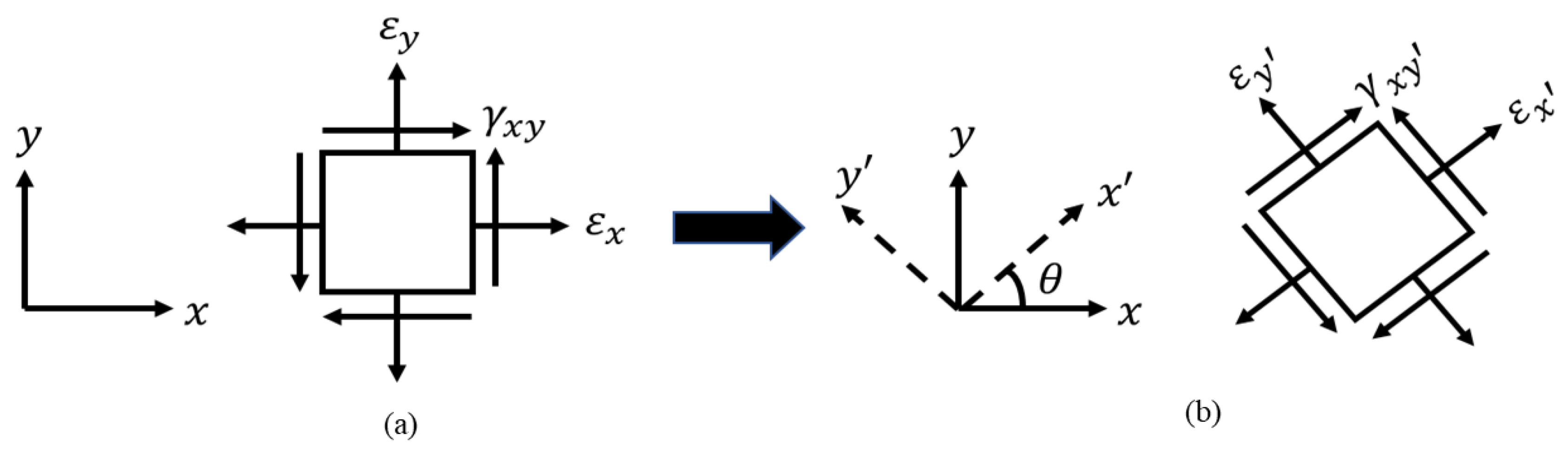

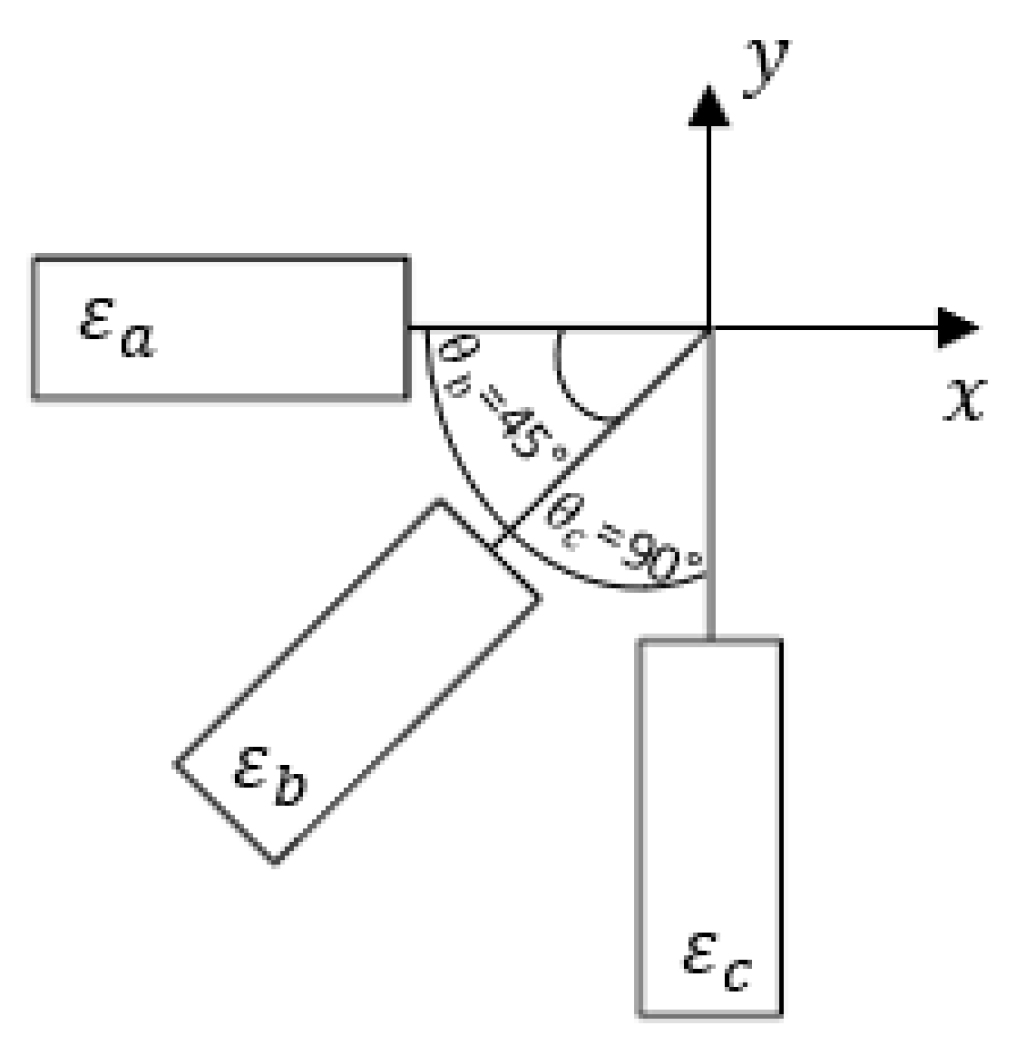

2. Formulation of Transformation Equation

3. Experimental Program

3.1. Finite Element Analysis (FEA)

3.2. Specimens for Experiments

3.2.1. Strain Rosette (SR) Installation

3.2.2. Instrumentation of the Distributed Fibre Optic Sensor (DFOS)

3.2.3. Experiments for Tensile and Flexural Loading

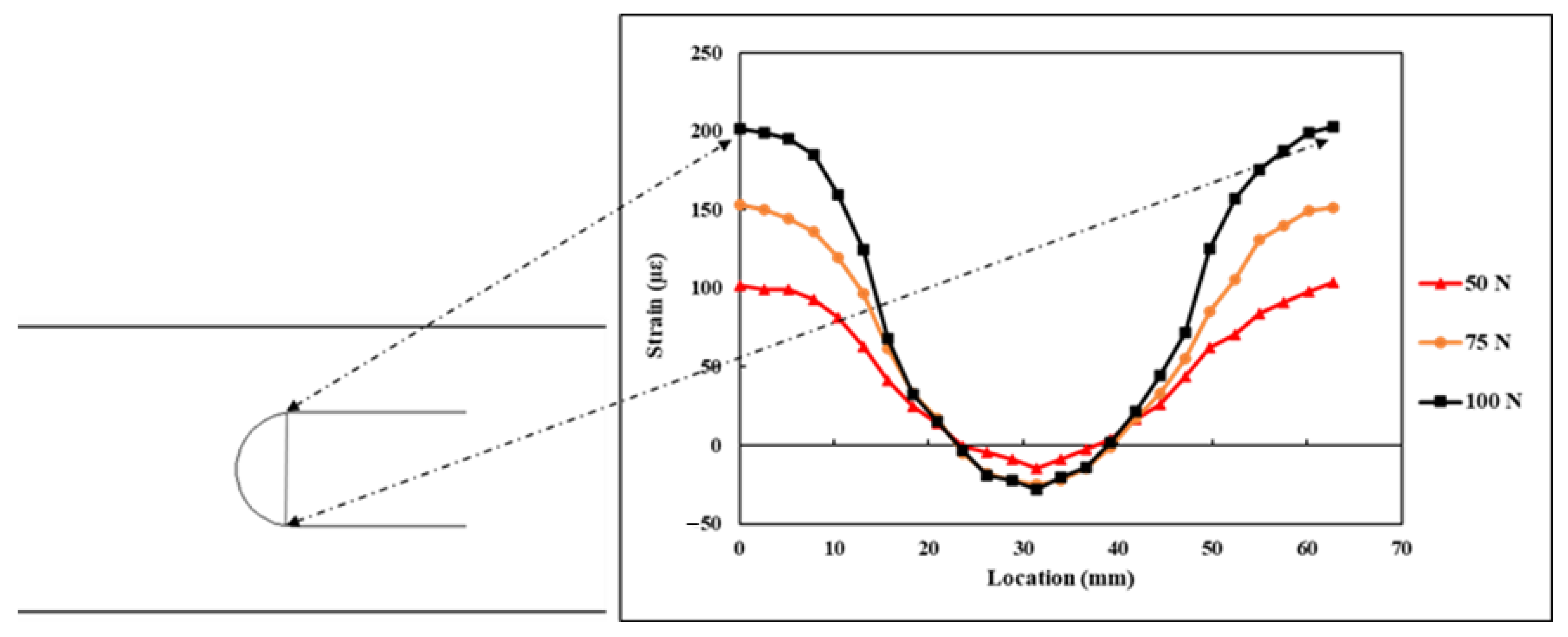

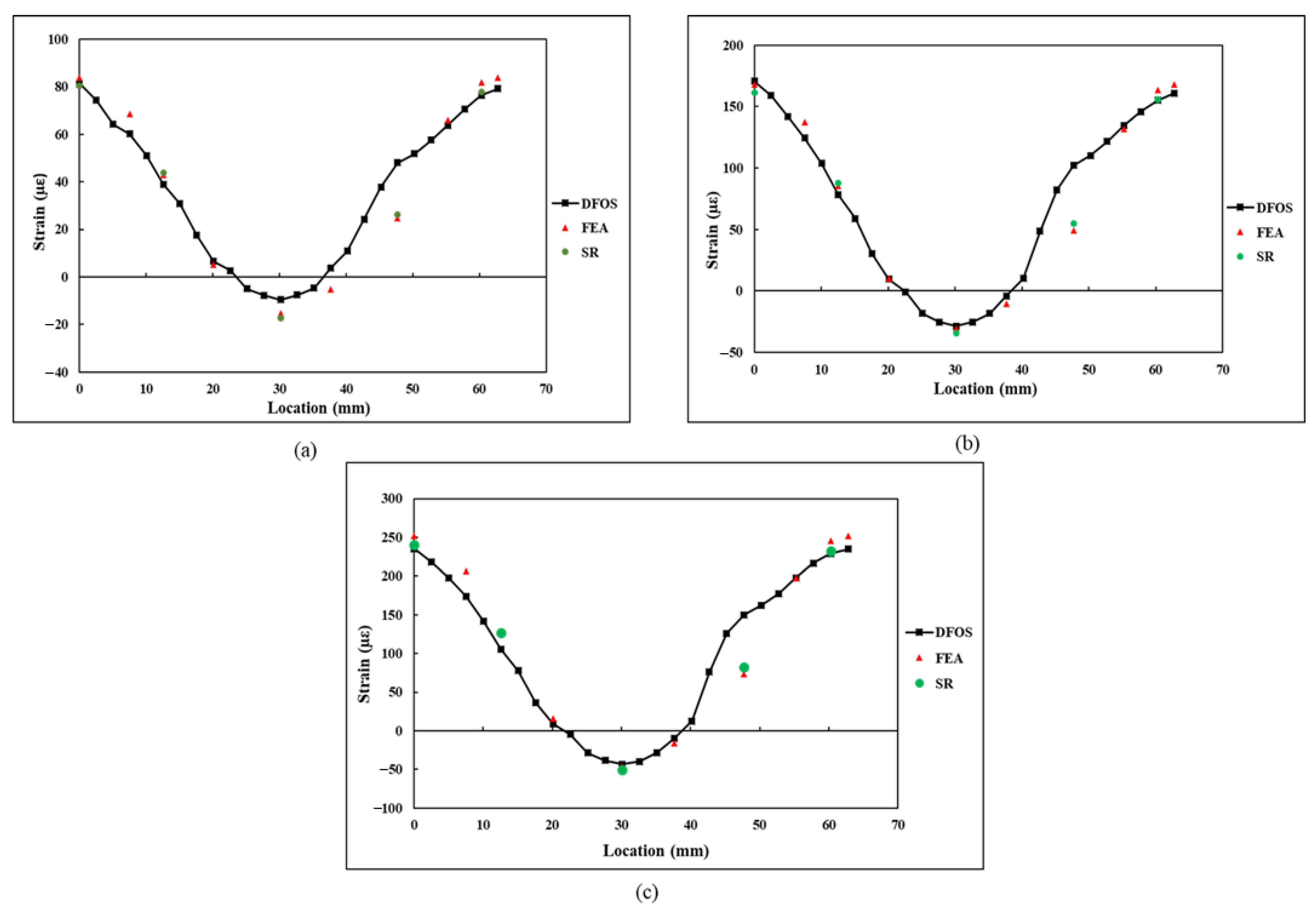

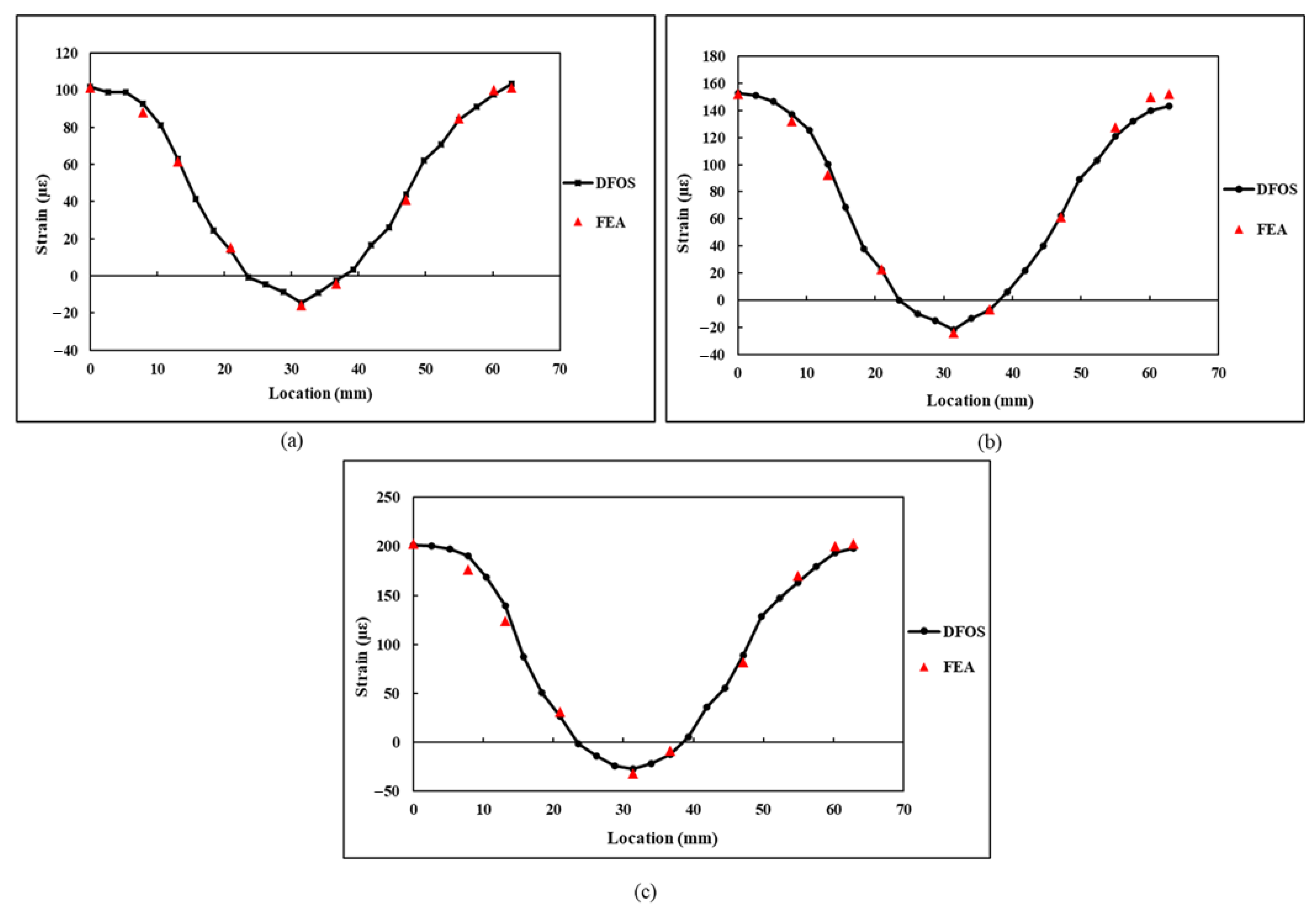

4. Results and Discussion

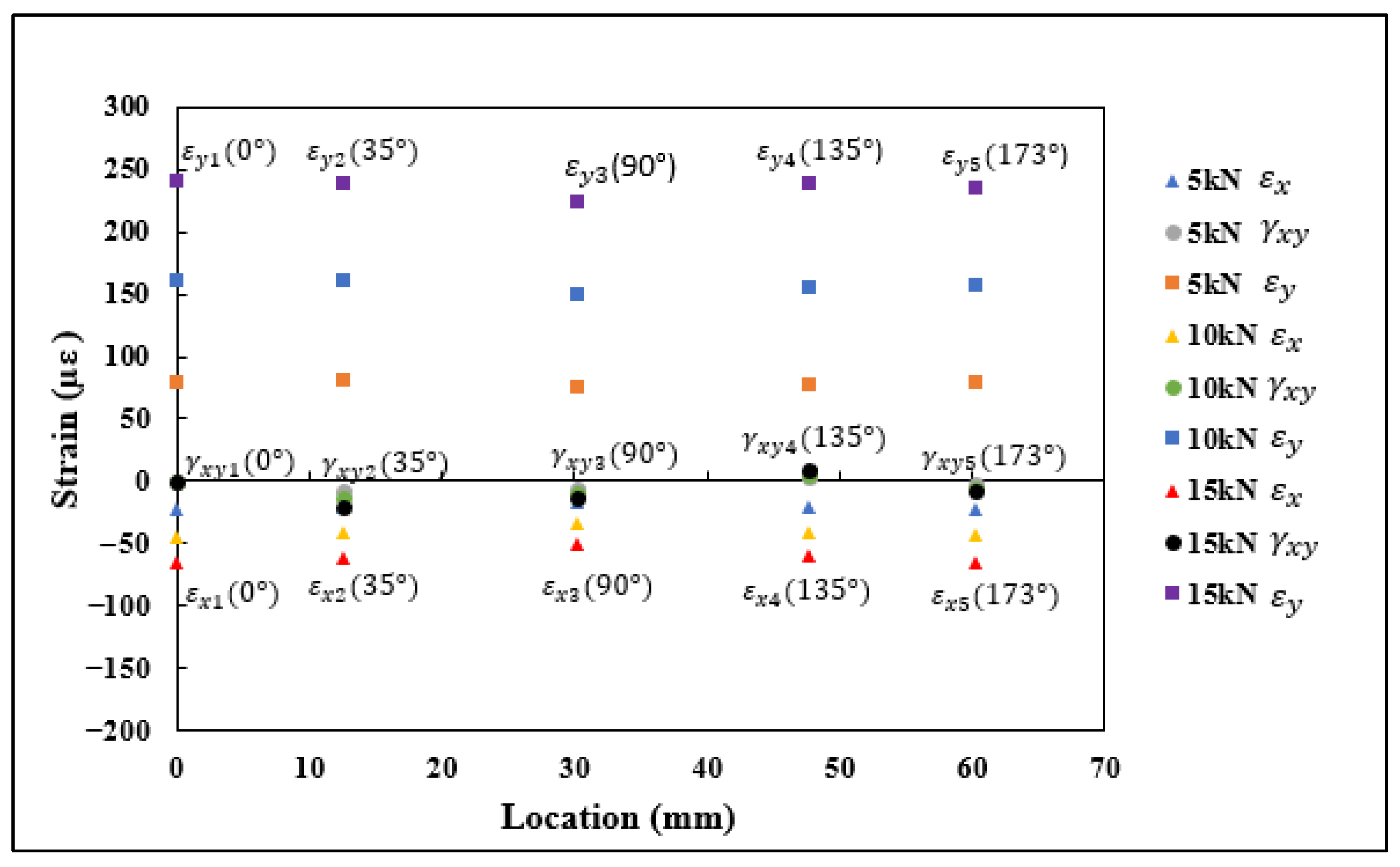

4.1. Strains Predicted from FEA

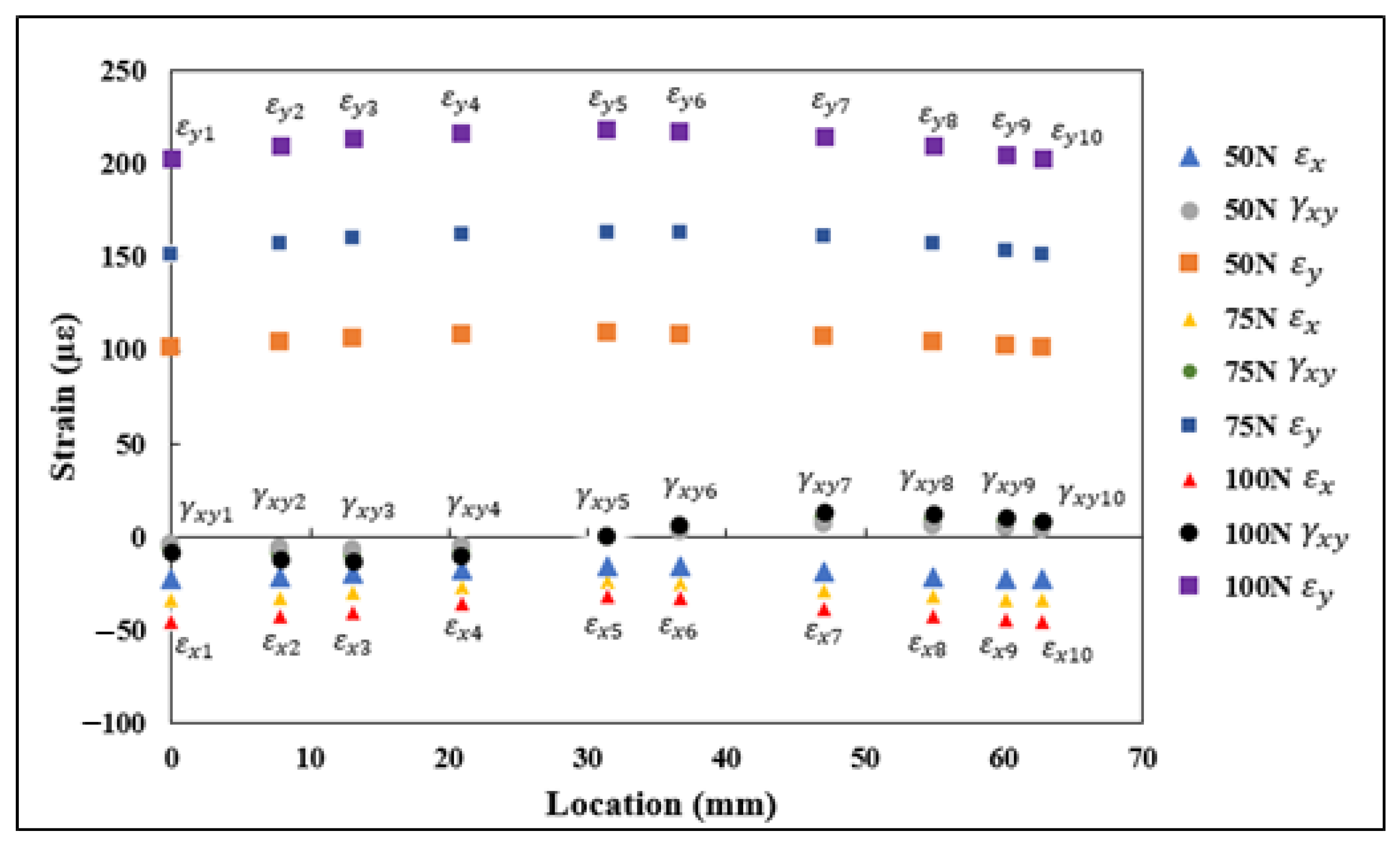

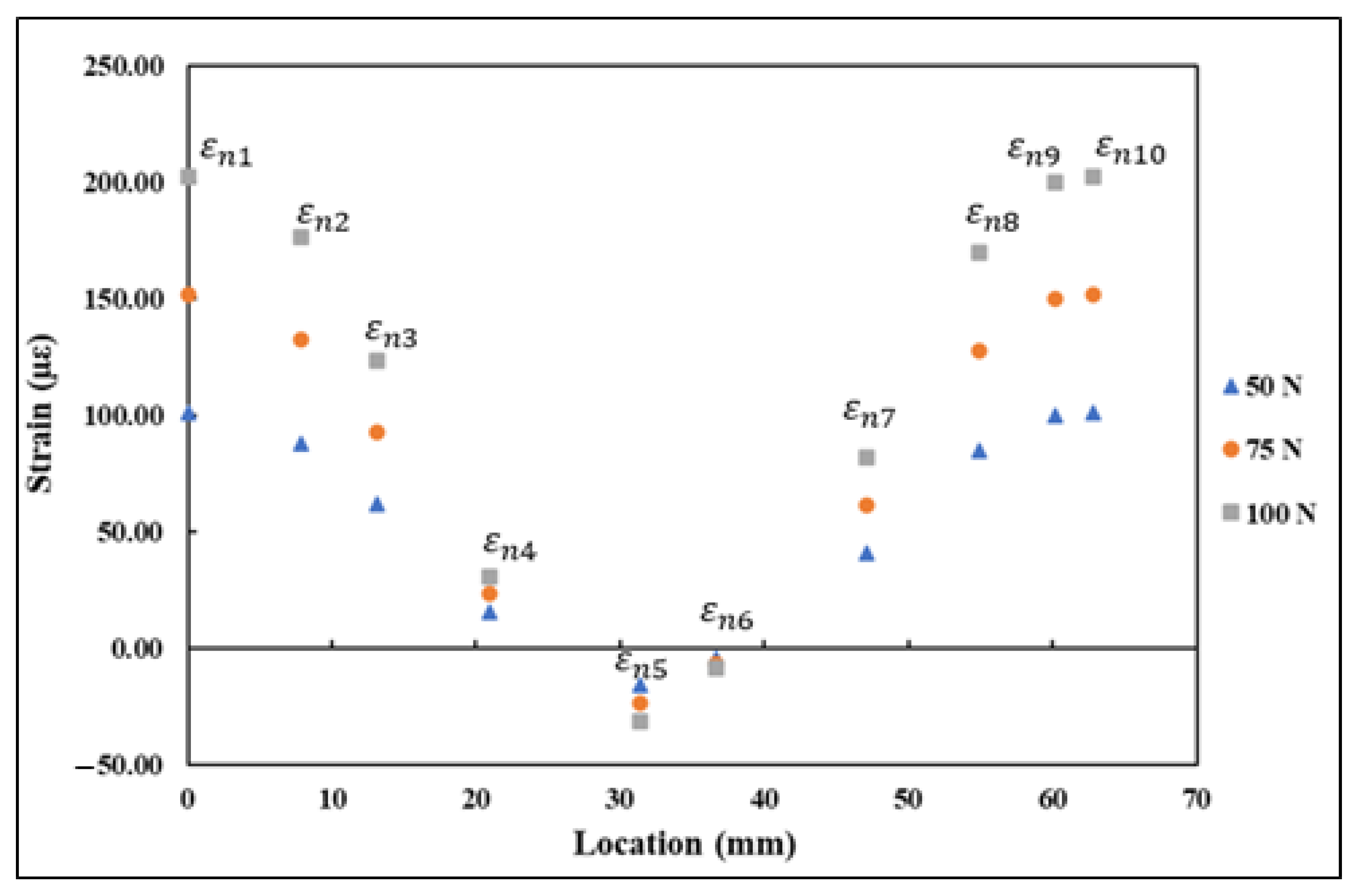

4.2. Strains Measured Using SR

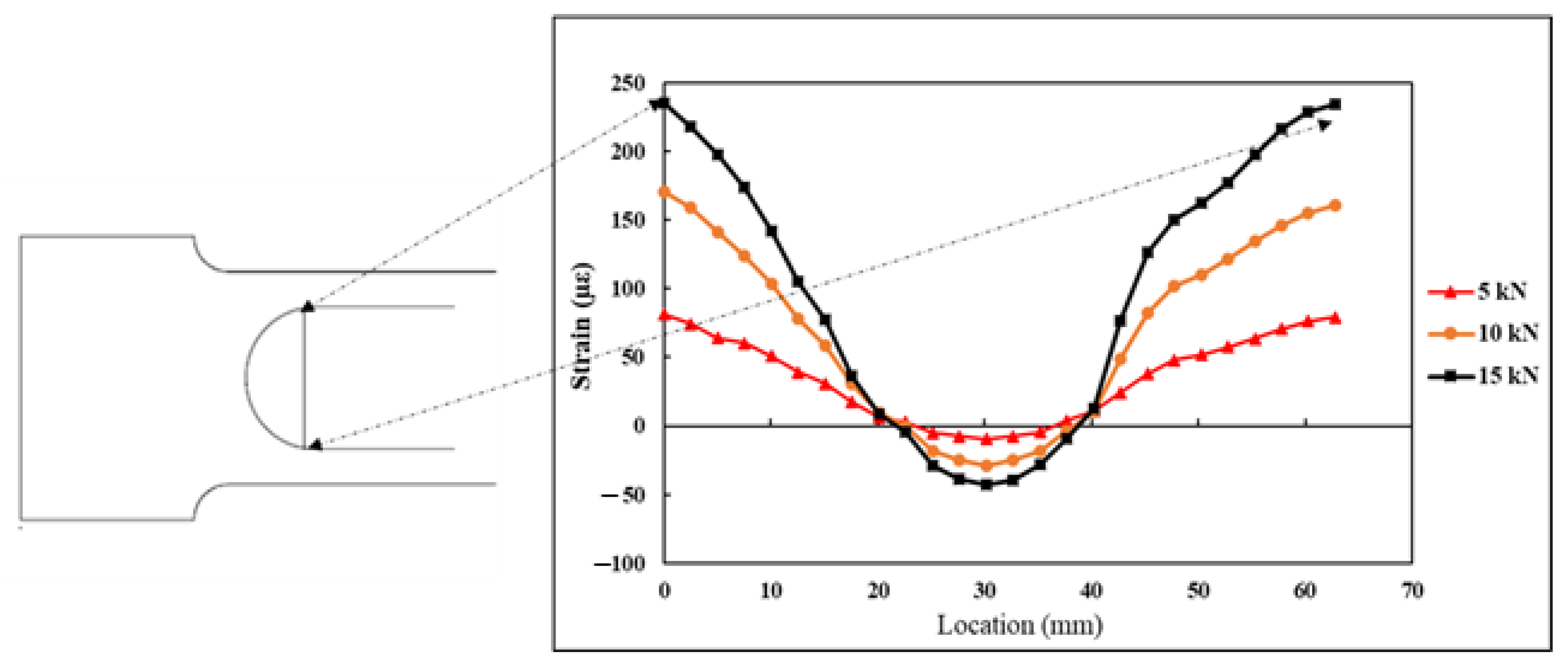

4.3. Strains Monitored Using DFOS

4.4. Comparison of the Strain Measurements between FEA, DFOS, and SR

5. Conclusions

- The transformed strain values derived through the strain transformation equation correlated well with the experiments under tensile and flexural loading scenarios.

- The DFOS strain field along a circular or semicircular curve follows a distinct sinusoidal pattern which is independent from the structure size and loading.

- A localised damage to the DFOS coating can influence the strain measurements at that location. However, deviations in DFOS readings are localised to the point of damage event under certain conditions, which is further evidence of the suitability of the DFOS in SHM applications.

- Overall, this study has successfully demonstrated that the proposed strain transformation equation can be used for transforming the horizontal and vertical strain components obtained through FEA along a semicircular geometry into a tangential component of the strain measured by the distributed fibre optic sensor along the curved semicircular paths.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Ou, J.; Li, H. Structural health monitoring research in China: Trends and applications. In Structural Health Monitoring of Civil Infrastructure Systems; Elsevier Inc.: Amsterdam, The Netherlands, 2009; pp. 463–516. ISBN 9781845693923. [Google Scholar]

- Cawley, P. Structural health monitoring: Closing the gap between research and industrial deployment. Struct. Health Monit. 2018, 17, 1225–1244. [Google Scholar] [CrossRef] [Green Version]

- Brownjohn, J.M.W. Structural health monitoring of civil infrastructure. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 589–622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giraldo, C.D.M. Development of Optical Fiber Sensors for the Structural Health Monitoring in Aeronautical Composite Structures. Ph.D. Thesis, Polytechnic University of Madrid, Madrid, Spain, 2018. [Google Scholar]

- Boller, C. State-of-the-art in structural health monitoring for aeronautics. In Proceedings of the International Symposium on NDT in Aerospace, Fürth, Germany, 3–5 December 2008; pp. 1–8. [Google Scholar]

- Tibaduiza Burgos, D.A.; Gomez Vargas, R.C.; Pedraza, C.; Agis, D.; Pozo, F. Damage Identification in Structural Health Monitoring: A Brief Review from Its Implementation to the Use of Data-Driven Applications. Sensors 2020, 20, 733. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guzman-Acevedo, G.M.; Vazquez-Becerra, G.E.; Millan-Almaraz, J.R.; Rodriguez-Lozoya, H.E.; Reyes-Salazar, A.; Gaxiola-Camacho, J.R.; Martinez-Felix, C.A. GPS, Accelerometer, and Smartphone Fused Smart Sensor for SHM on Real-Scale Bridges. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef]

- Moreno-Gomez, A.; Perez-Ramirez, C.A.; Dominguez-Gonzalez, A.; Valtierra-Rodriguez, M.; Chavez-Alegria, O.; Amezquita-Sanchez, J.P. Sensors Used in Structural Health Monitoring. Arch. Comput. Methods Eng. 2018, 25, 901–918. [Google Scholar] [CrossRef]

- Shan, Y.; Xu, H.; Zhou, Z.; Yuan, Z.; Xu, X.; Wu, Z. State sensing of composite structures with complex curved surface based on distributed optical fiber sensor. J. Intell. Mater. Syst. Struct. 2019, 30, 1951–1968. [Google Scholar] [CrossRef]

- Glisic, B.; Yao, Y.; Tung, S.T.E.; Wagner, S.; Sturm, J.C.; Verma, N. Strain Sensing Sheets for Structural Health Monitoring Based on Large-Area Electronics and Integrated Circuits. Proc. IEEE 2016, 104, 1513–1528. [Google Scholar] [CrossRef]

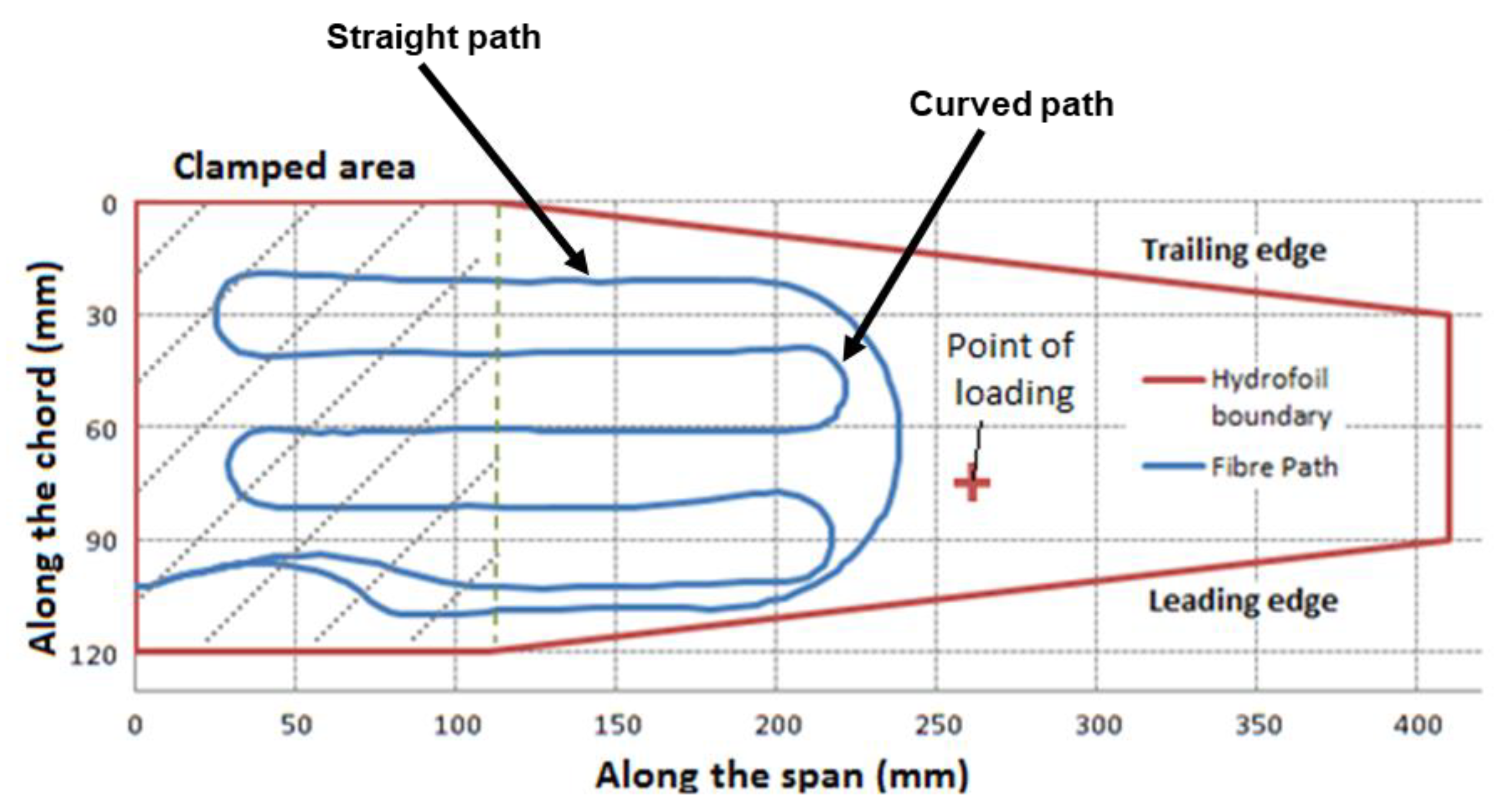

- Maung, P.T.; Prusty, B.G.; Rajan, G.; Li, E.; Phillips, A.W.; St John, N.A. Distributed strain measurement using fibre optics in a high performance composite hydrofoil. ICCM Int. Conf. Compos. Mater. 2017, 2017, 20–25. [Google Scholar]

- Yehia, S.; Abudayyeh, O.; Abdel-Qader, I.; Zalt, A.; Meganathan, V. Evaluation of sensor performance for concrete applications. Trans. Res. Rec. 2008, 101–110. [Google Scholar] [CrossRef]

- Rajan, G.; Prusty, G. Structural Health Monitoring of Composite Structures Using Fibre Optic Methods; CRC Press: Boca Raton, CA, USA, 2016. [Google Scholar]

- Wu, T.; Liu, G.; Fu, S.; Xing, F. Recent progress of fiber-optic sensors for the structural health monitoring of civil infrastructure. Sensors 2020, 20, 4517. [Google Scholar] [CrossRef] [PubMed]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Subash Chandra Mukhopadhyay. New Developments in Sensing Technology for Structural Health Monitoring; Springer: New York, NY, USA, 2011; ISBN 9783642210983. [Google Scholar]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of fiber optic sensor technologies for strain/temperature sensing applications in composite materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaur, A.; Jothibasu, S.; Anandan, S.; Du, Y.; Dhaliwal, G.; Huang, J.; Chandrashekhara, K.; Watkins, S. Strain monitoring using distributed fiber optic sensors embedded in carbon fiber composites. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10598. [Google Scholar] [CrossRef]

- Glisic, B.; Inaudi, D. Development of method for in-service crack detection based on distributed fiber optic sensors. Struct. Health Monit. 2011, 161–171. [Google Scholar] [CrossRef]

- Levin, K. Durability of Embedded Fibre Optic Sensors in Composites. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2008. [Google Scholar]

- Davis, C.; Knowles, M.; Rajic, N.; Swanton, G. Evaluation of a Distributed Fibre Optic Strain Sensing System for Full-Scale Fatigue Testing. Procedia Struct. Integr. 2016, 2, 3784–3791. [Google Scholar] [CrossRef] [Green Version]

- Castellucci, M.; Klute, S.; Lally, E.M.; Froggatt, M.E.; Lowry, D. Three-axis distributed fiber optic strain measurement in 3D woven composite structures. Ind. Commer. Appl. Smart Struct. Technol. 2013, 8690, 869006. [Google Scholar] [CrossRef] [Green Version]

- Saidi, M.; Gabor, A. Use of distributed optical fibre as a strain sensor in textile reinforced cementitious matrix composites. Meas. J. Int. Meas. Confed. 2019, 140, 323–333. [Google Scholar] [CrossRef]

- Drake, D.A.; Sullivan, R.W.; Wilson, J.C. Distributed strain sensing from different optical fiber configurations. Inventions 2018, 3, 67. [Google Scholar] [CrossRef] [Green Version]

- Gifford, D.K.; Froggatt, M.E.; Sang, A.K.; Kreger, S.T. Multiple fiber loop strain rosettes in a single fiber using high resolution distributed sensing. IEEE Sens. J. 2012, 12, 55–63. [Google Scholar] [CrossRef]

- Meadows, L.; Sullivan, R.W.; Vehorn, K. Distributed optical sensing in composite laminate adhesive bonds. In Proceedings of the 57th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, San Diego, CA, USA, 4–8 January 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Barker, C.; Hoult, N.A.; Le, H.; Tolikonda, V. Evaluation of a railway bridge using distributed and discrete strain sensors. In Proceedings of the International Conference on Smart Infrastructure and Construction 2019 (ICSIC): Driving Data-Informed Decision-Making, Cambridge, UK, 8–10 July 2019; pp. 533–539. [Google Scholar] [CrossRef] [Green Version]

- Zhu, P.; Xie, X.; Sun, X.; Soto, M.A. Distributed modular temperature-strain sensor based on optical fiber embedded in laminated composites. Compos. Part B Eng. 2019, 168, 267–273. [Google Scholar] [CrossRef]

- Glisic, B.; Huston, D.R.; Navarra, G.; Barrias, A.; Casas, J.R.; Villalba, S. SHM of Reinforced Concrete Elements by Rayleigh Backscattering DOFS. Front. Built Environ. 2019, 5, 30. [Google Scholar] [CrossRef]

- Gifford, D.K.; Sang, A.K.; Kreger, S.T.; Froggatt, M.E. Strain measurements of a fiber loop rosette using high spatial resolution Rayleigh scatter distributed sensing. Fourth Eur. Work Opt. Fibre Sens. 2010, 7653, 765333. [Google Scholar] [CrossRef]

- Nathan, I.; Meyendorf, N. Handbook of Advanced Nondestructive Evaluation; Nathan, I., Meyendorf, N., Eds.; Springer: Cham, The Netherlands, 2019; ISBN 9783319265520. [Google Scholar]

- Silva, A.L.; Varanis, M.; Mereles, A.G.; Oliveira, C.; Balthazar, J.M. A study of strain and deformation measurement using the Arduino microcontroller and strain gauges devices. Rev. Bras. Ensino Fis. 2019, 41. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, G. Strain distribution and crack detection in thin unbonded concrete pavement overlays with fully distributed fiber optic sensors. Opt. Eng. 2015, 55, 011008. [Google Scholar] [CrossRef]

- Okabe, Y.; Tanaka, N.; Takeda, N. Effect of fiber coating on crack detection in carbon fiber reinforced plastic composites using fiber Bragg grating sensors. Smart Mater. Struct. 2002, 11, 892–898. [Google Scholar] [CrossRef]

- Weisbrich, M.; Holschemacher, K. Comparison between different fiber coatings and adhesives on steel surfaces for distributed optical strain measurements based on Rayleigh backscattering. J. Sens. Sens. Syst. 2018, 7, 601–608. [Google Scholar] [CrossRef] [Green Version]

- De Oliveira, R.; Schukar, M.; Krebber, K.; Michaud, V. Distributed Strain Measurement in Cfrp Structures By Embedded Optical Fibres: Influence of the Coating. In Proceedings of the 6th International Conference on Composite Structures, ICCS 16, Porto, Portugal, 28–30 June 2011; pp. 2–3. [Google Scholar]

| Location | (°) | Arc Length (mm) |

|---|---|---|

| 0 | 0 | |

| 20 | 6.98 | |

| 35 | 12.21 | |

| 58 | 20.24 | |

| 90 | 31.41 | |

| 108 | 37.69 | |

| 135 | 47.12 | |

| 158 | 55.15 | |

| 173 | 60.38 | |

| 180 | 62.83 |

| Location | (°) |

|---|---|

| 90 | |

| 70 | |

| 55 | |

| 32 | |

| 0 | |

| −18 | |

| −45 | |

| −68 | |

| −83 | |

| −90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagulapally, P.; Shamsuddoha, M.; Rajan, G.; Djukic, L.; B. Prusty, G. Distributed Fibre Optic Sensor-Based Continuous Strain Measurement along Semicircular Paths Using Strain Transformation Approach. Sensors 2021, 21, 782. https://doi.org/10.3390/s21030782

Nagulapally P, Shamsuddoha M, Rajan G, Djukic L, B. Prusty G. Distributed Fibre Optic Sensor-Based Continuous Strain Measurement along Semicircular Paths Using Strain Transformation Approach. Sensors. 2021; 21(3):782. https://doi.org/10.3390/s21030782

Chicago/Turabian StyleNagulapally, Prashanth, Md Shamsuddoha, Ginu Rajan, Luke Djukic, and Gangadhara B. Prusty. 2021. "Distributed Fibre Optic Sensor-Based Continuous Strain Measurement along Semicircular Paths Using Strain Transformation Approach" Sensors 21, no. 3: 782. https://doi.org/10.3390/s21030782

APA StyleNagulapally, P., Shamsuddoha, M., Rajan, G., Djukic, L., & B. Prusty, G. (2021). Distributed Fibre Optic Sensor-Based Continuous Strain Measurement along Semicircular Paths Using Strain Transformation Approach. Sensors, 21(3), 782. https://doi.org/10.3390/s21030782