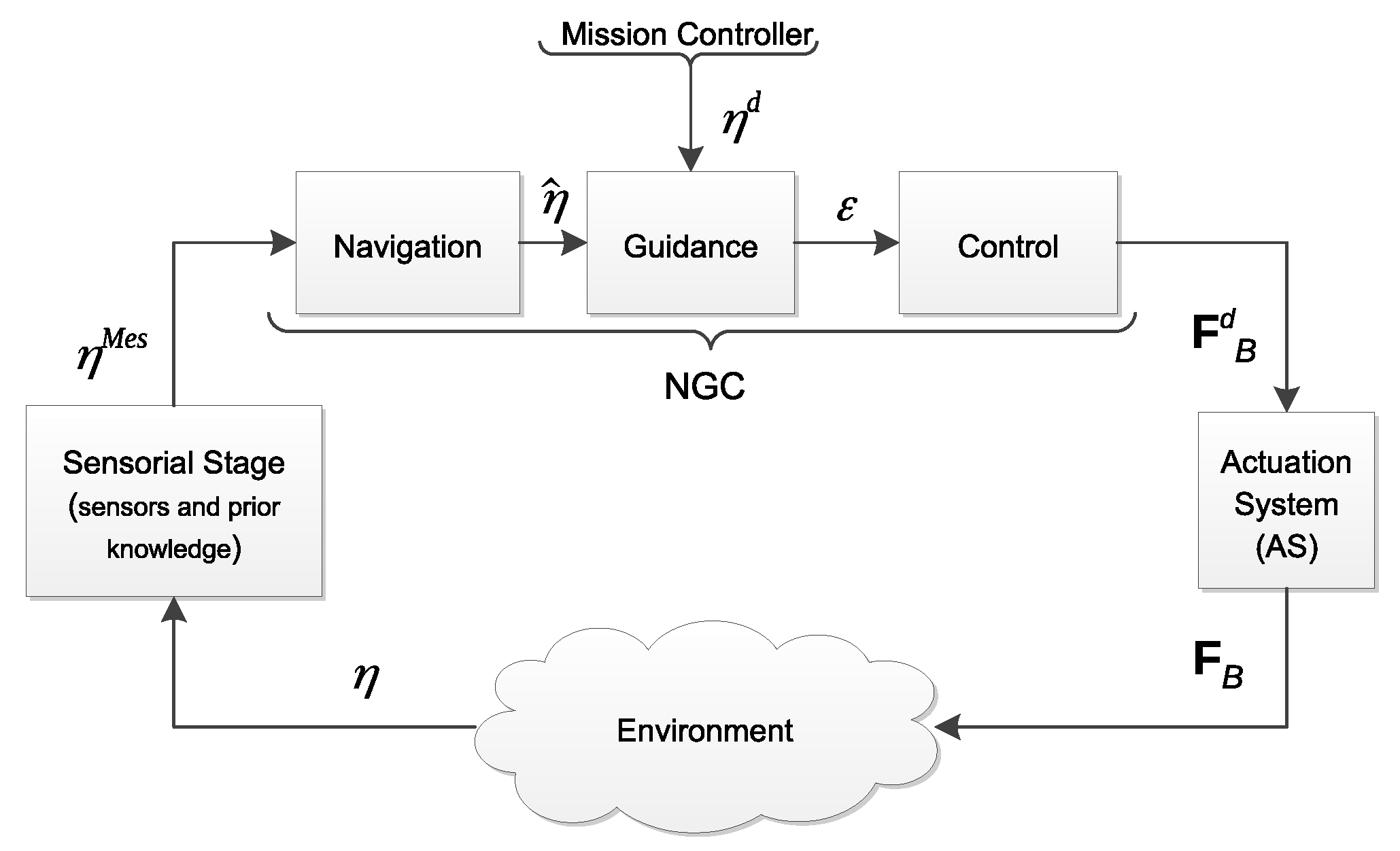

Following

Figure 1, the sensorial stage using sensors measurement and prior knowledge of the environment provides to the navigation system the necessary information to compute an estimation of the system state (

). Then, the guidance system uses this estimation and the reference system state (

) provided by the mission controller to compute the error function (

). The control system is then in charge of computing the desired force (

) in order to reduce the error function to zero. Note that classically, this desired force is expressed in the body-frame. Afterwards, the

actuation system produces in the environment a resulting force (

), which should be as close as possible to

. Note that, in this paper, the desired force (

) and resulting force (

) are (

) vectors and include force and torque elements. Inside the AS block, referring to

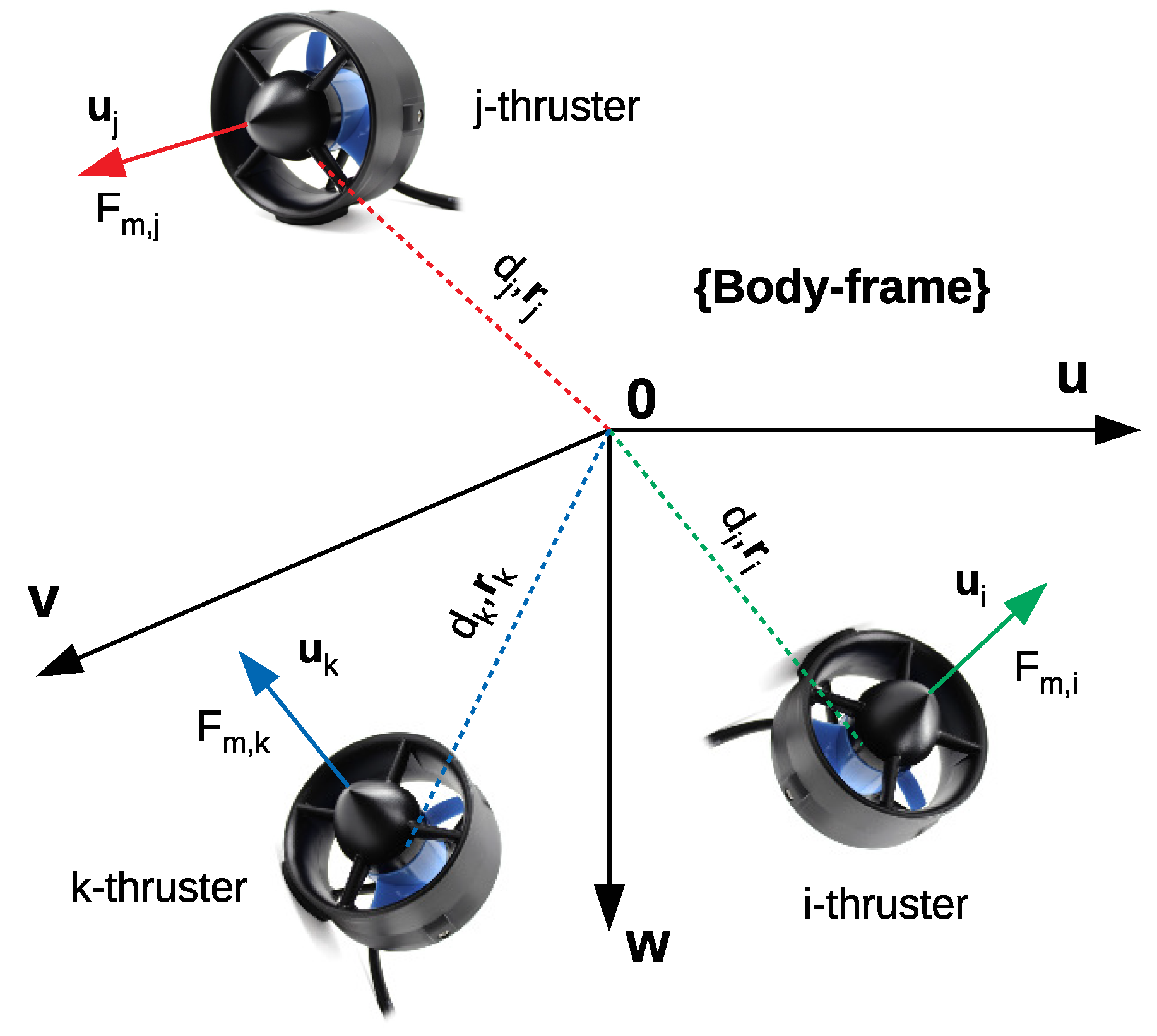

Figure 2, the desired force (

) is the output of the controller. Then, the dispatcher (

) considers the actuator allocation method (and eventually, redundancy management) to compute the desired actuator force (

) that each actuator has to produce. The inverse actuator characteristics are then considered in order to compute the actuator inputs (

). Once applied,

can produce actuator forces (

). The resulting force

is produced with respect to the actuator configuration (

). The properties of the AS are indeed dependent on the actuator configuration (position and attitude of the actuators with respect to the body-frame), actuator dynamics (response characteristics), and dispatcher (control allocation, redundancy management) (see

Figure 2) and afford the system different properties. Let us consider in the following that

n is the number of Degrees of Freedom (DoFs) of the system and

m is the number of actuators. If the system carries less actuators than DoFs, it is said to be

underactuated (in that case,

will be an (

) matrix where

). Long-range Autonomous Underwater Vehicles (AUVs) and, for the terrestrial case, unicycle wheeled vehicles belong to this category [

1]. In that case, specific nonlinear guidance strategies have to be used [

2]. If the system carries more actuators than DoFs, it is said to be

redundant (

). Then, there are different solutions (

) to produce an identical resulting force (

). Indeed,

is one of the multiple possible inverses of

, classically

, where

is the Moore–Penrose pseudo-inverse. The properties of the AS play a pivotal role in the system performances, in terms of achievable dynamics, maneuverability, robustness, and dependability. The properties of an

overactuated system have been studied in aerospace control, where critical safety is required [

3], and for marine vehicles [

4], where the harsh oceanic condition may easily produce actuator failure. Redundancy was also used in [

5] in order to compensate different and unknown actuator responses. The domain of robotic manipulators has also extensively studied this question of redundancy, especially with recent works on humanoid robotics, where the task function approach [

6] has been used to concurrently achieve equilibriums [

7], walking pattern following [

8], and multicontact management [

9].

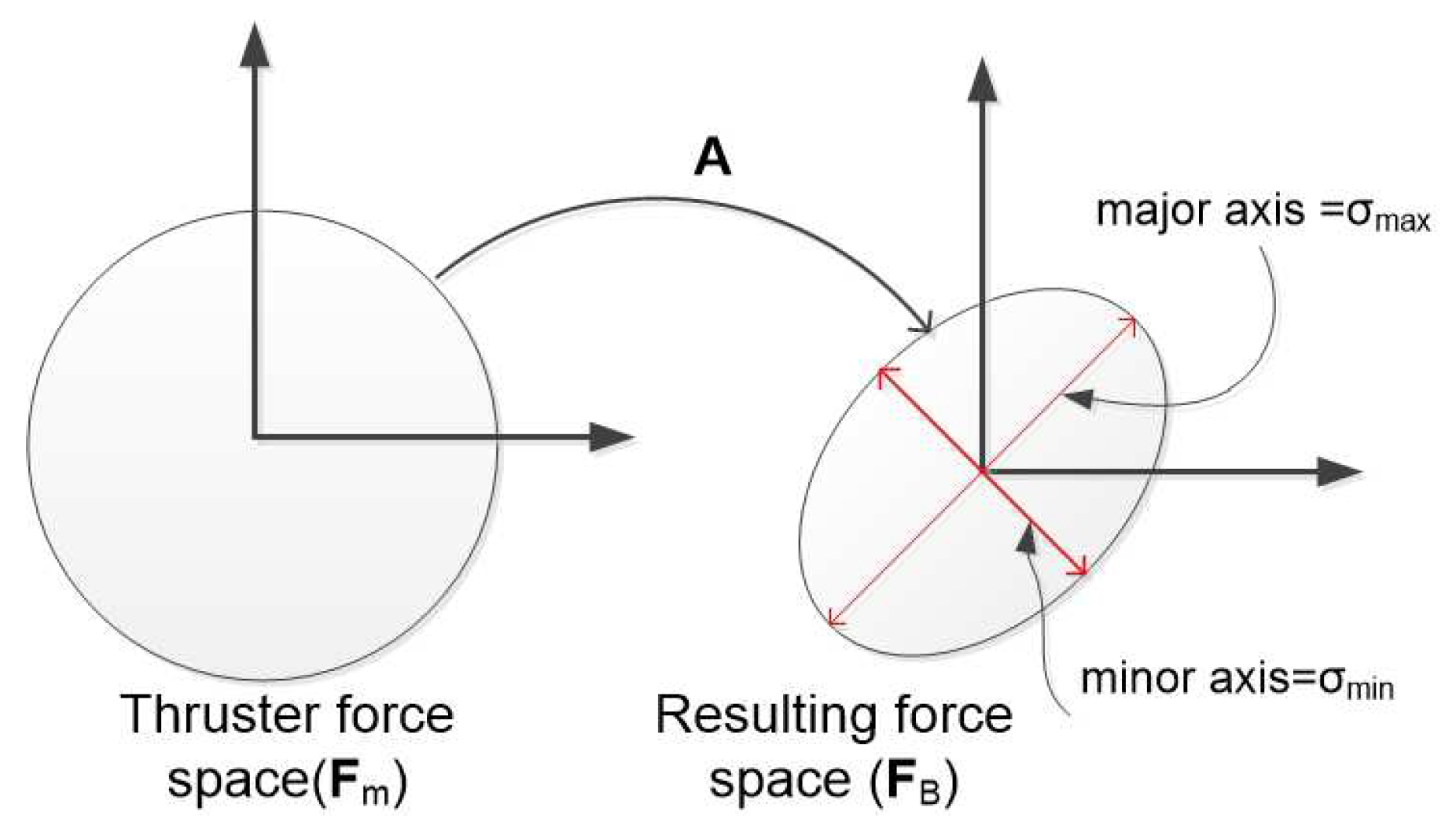

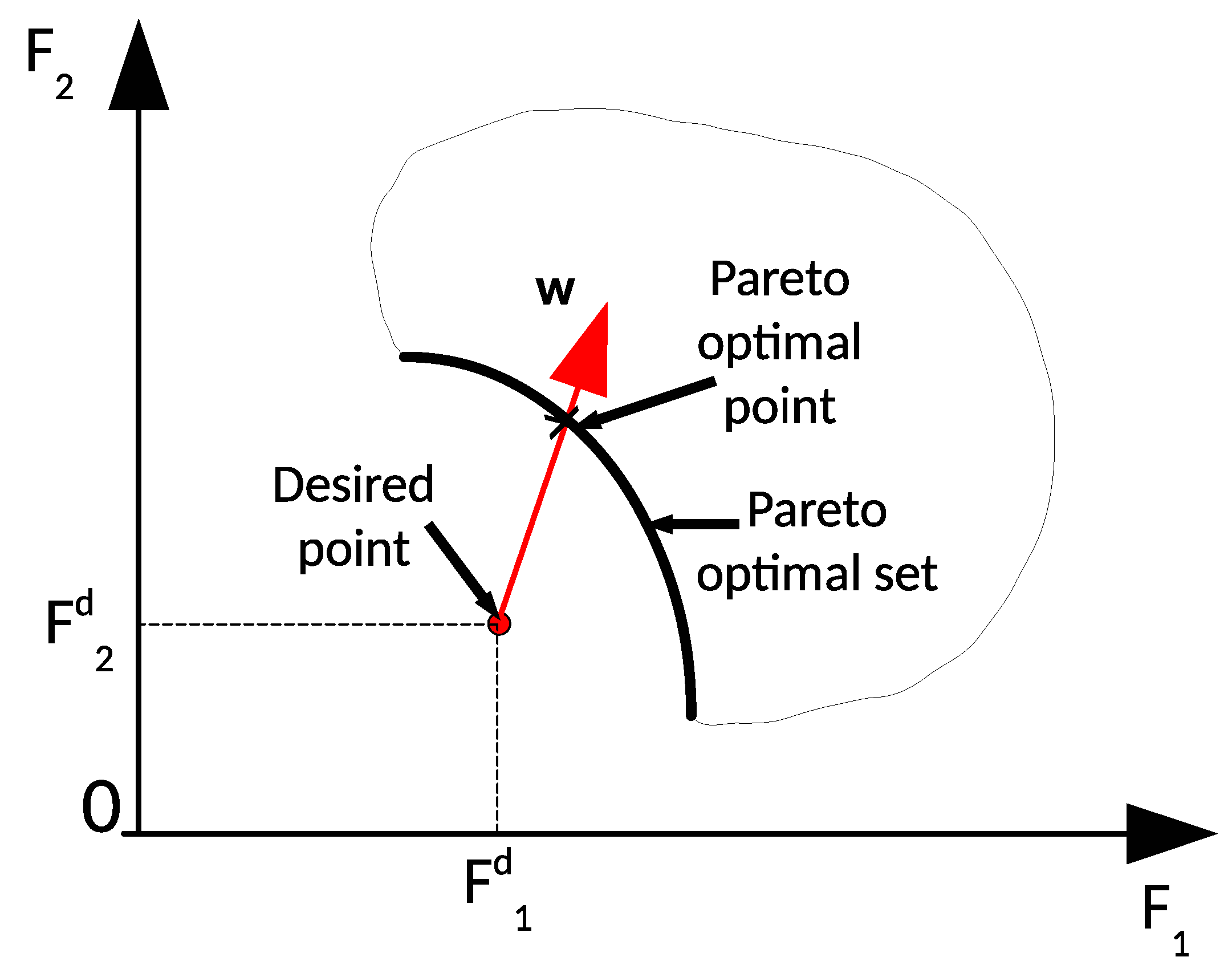

Different performance criteria related to the actuator configuration design have been proposed. For mobile manipulation, the

manipulability index [

10] measures the manipulation capability of the end-effector. Intuitively, this index regards the set of all end-effector velocities, which is realizable by joint velocities. This set is called the hyper-manipulability ellipsoid. This index is quantified by computing the hyper-manipulability ellipsoid’s properties. Based on these properties, there are different ways to quantify the manipulability index, including the volume of the hyper-manipulability ellipsoid, the ratio of the minimum and maximum radii of the hyperellipsoid, and the minimum radius of the hyperellipsoid. The selection depends on the purpose of evaluation. When the uniformity of manipulating ability is important, the ratio of two radii of the hyperellipsoid is chosen (the optimal value will be close to one). Otherwise, the minimum radius of the hyperellipsoid is suited for the case where the minimum manipulating ability might be critical [

11]. Another criterion,

attainability [

12,

13,

14], was studied using workspace volume estimation.

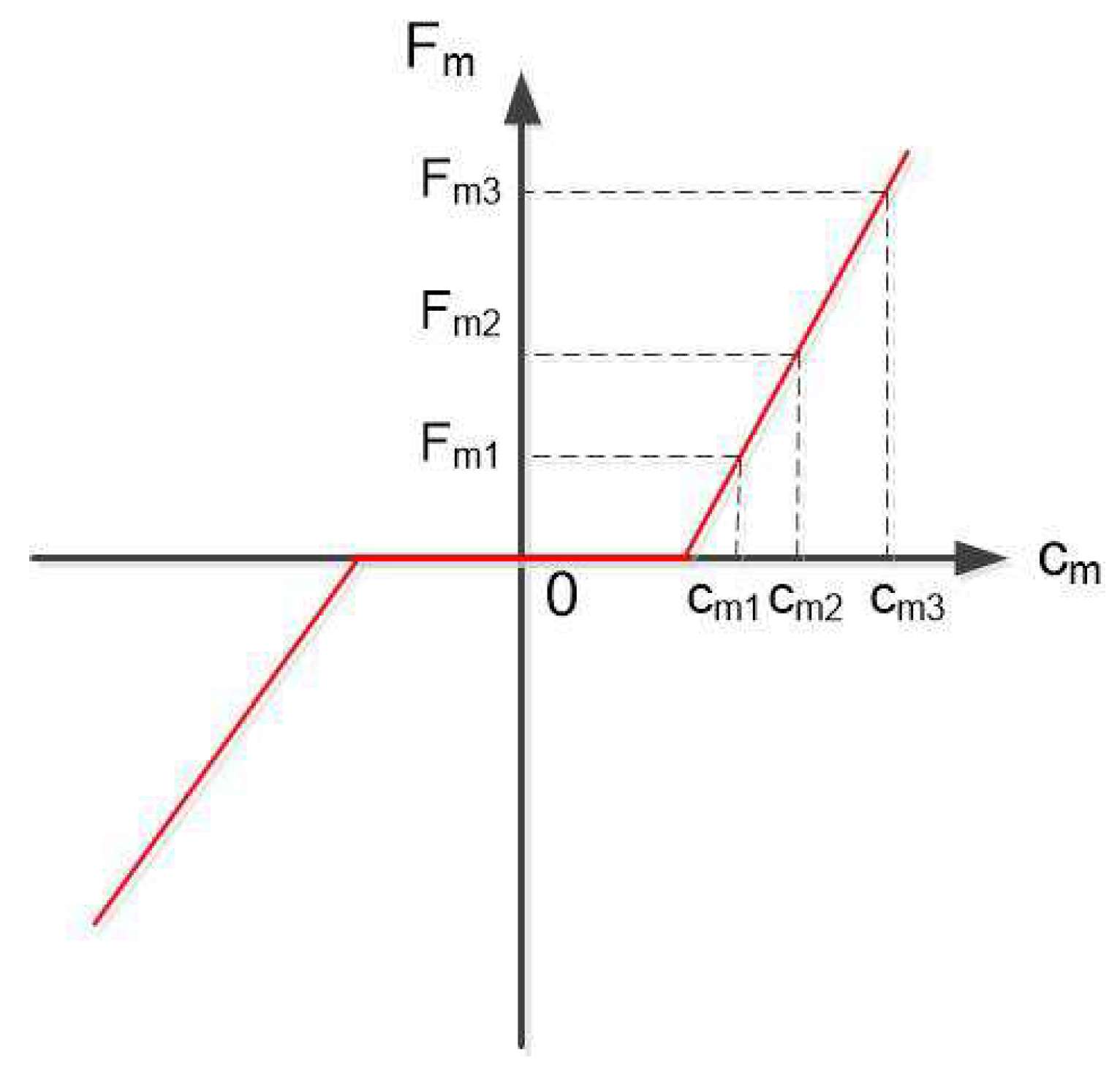

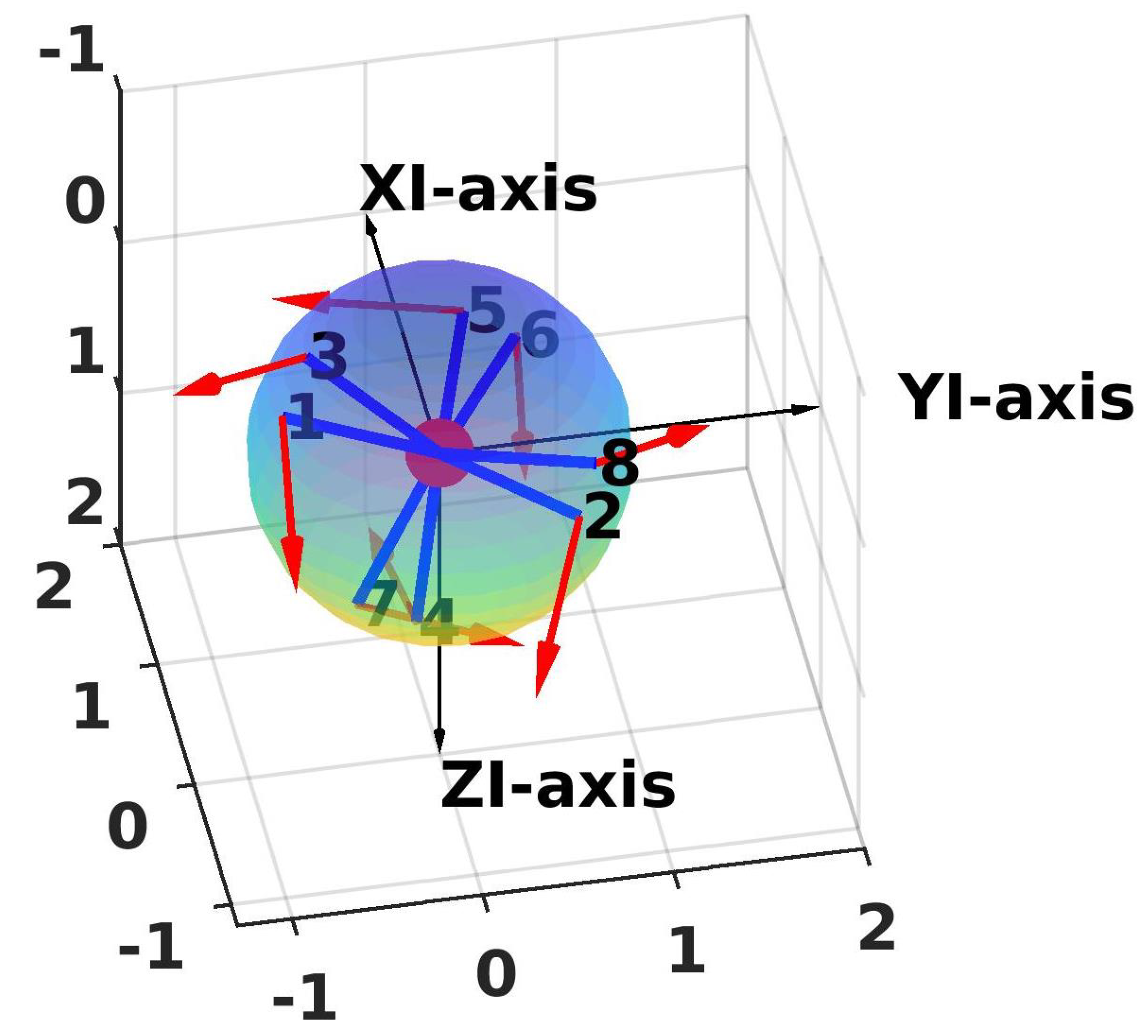

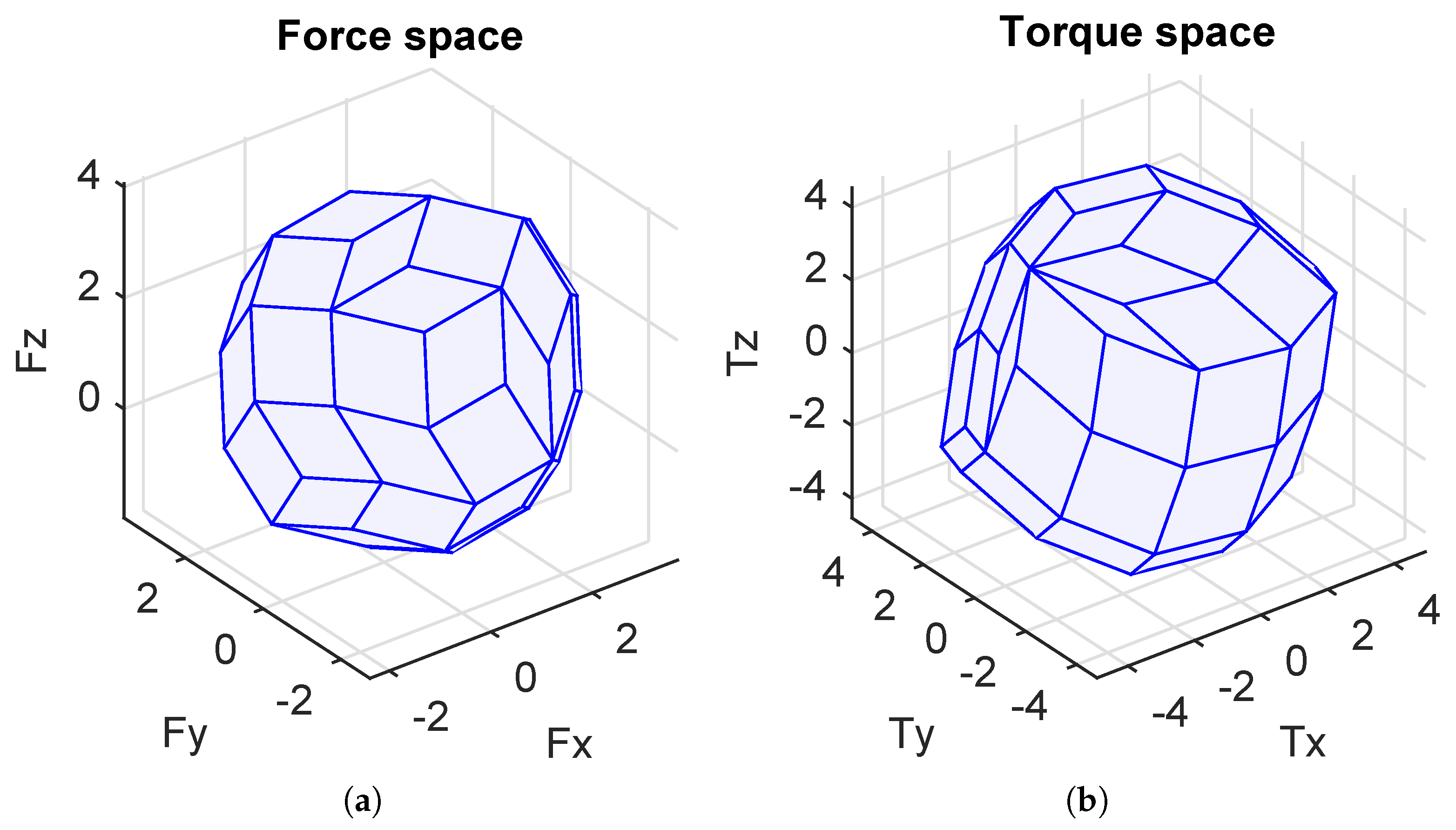

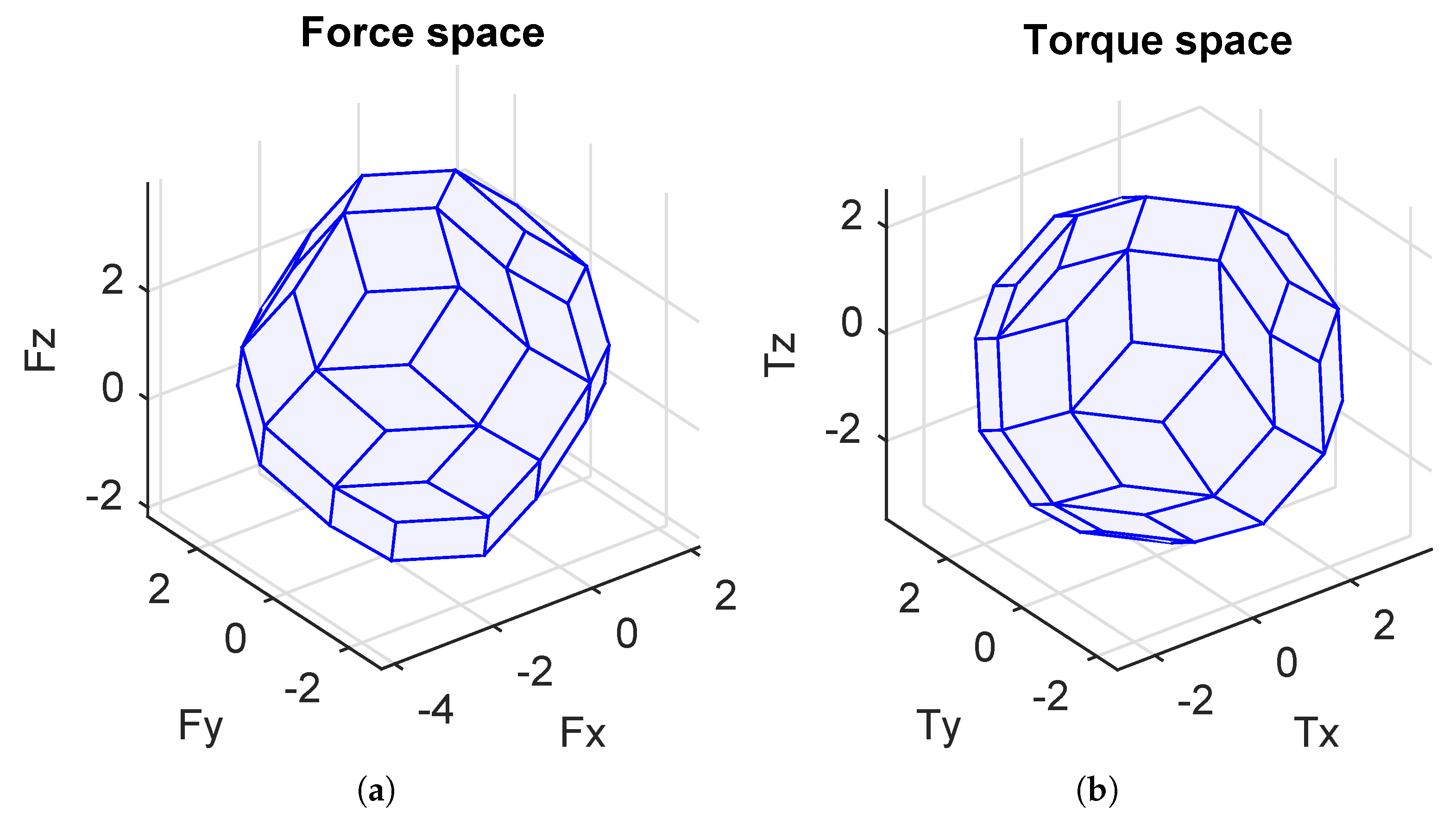

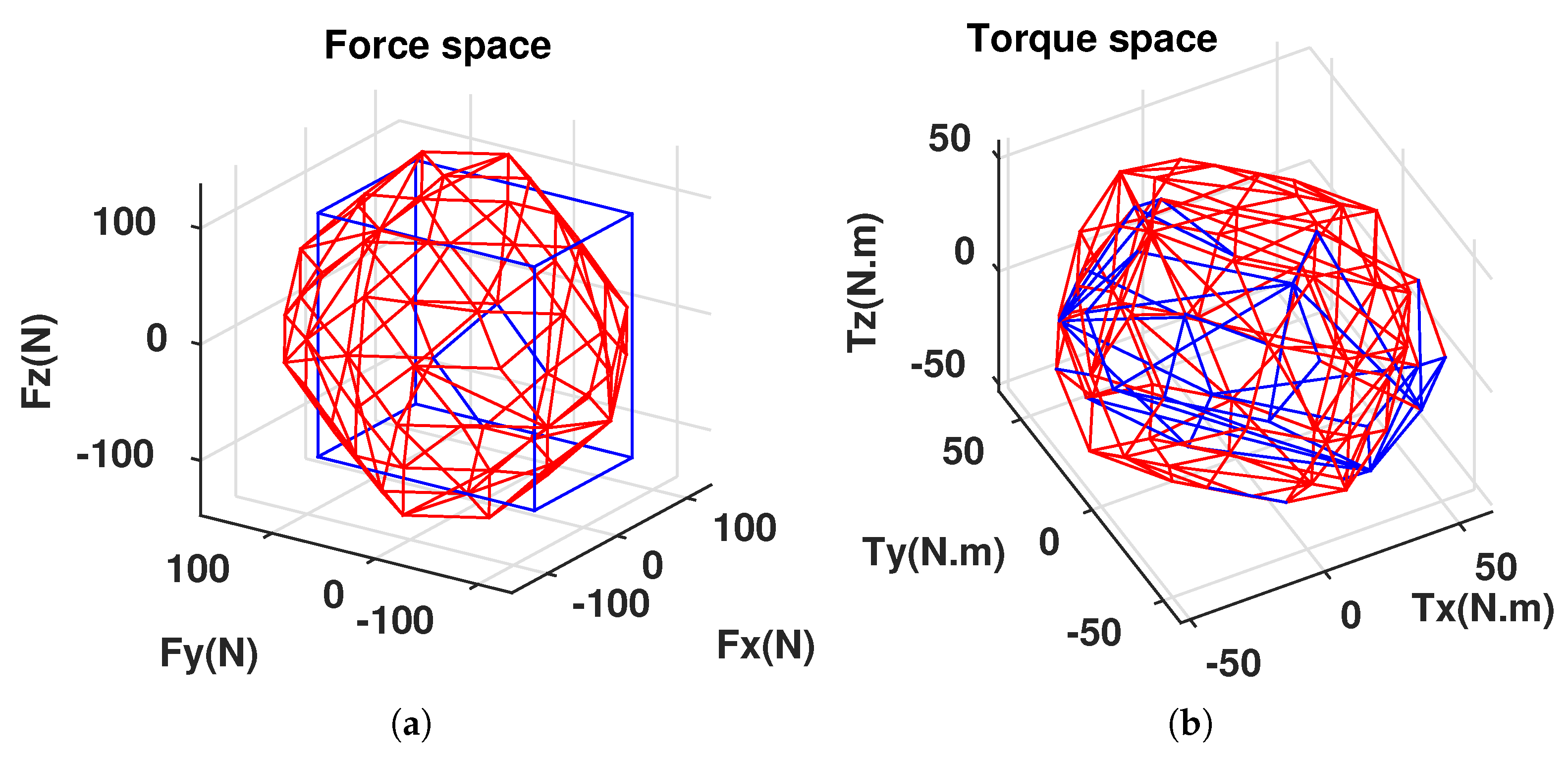

In the underwater robotics field, the

manipulability index,

energetic index, and

force index were introduced in [

15], and the manipulability index was applied in [

16]. Specifically, the

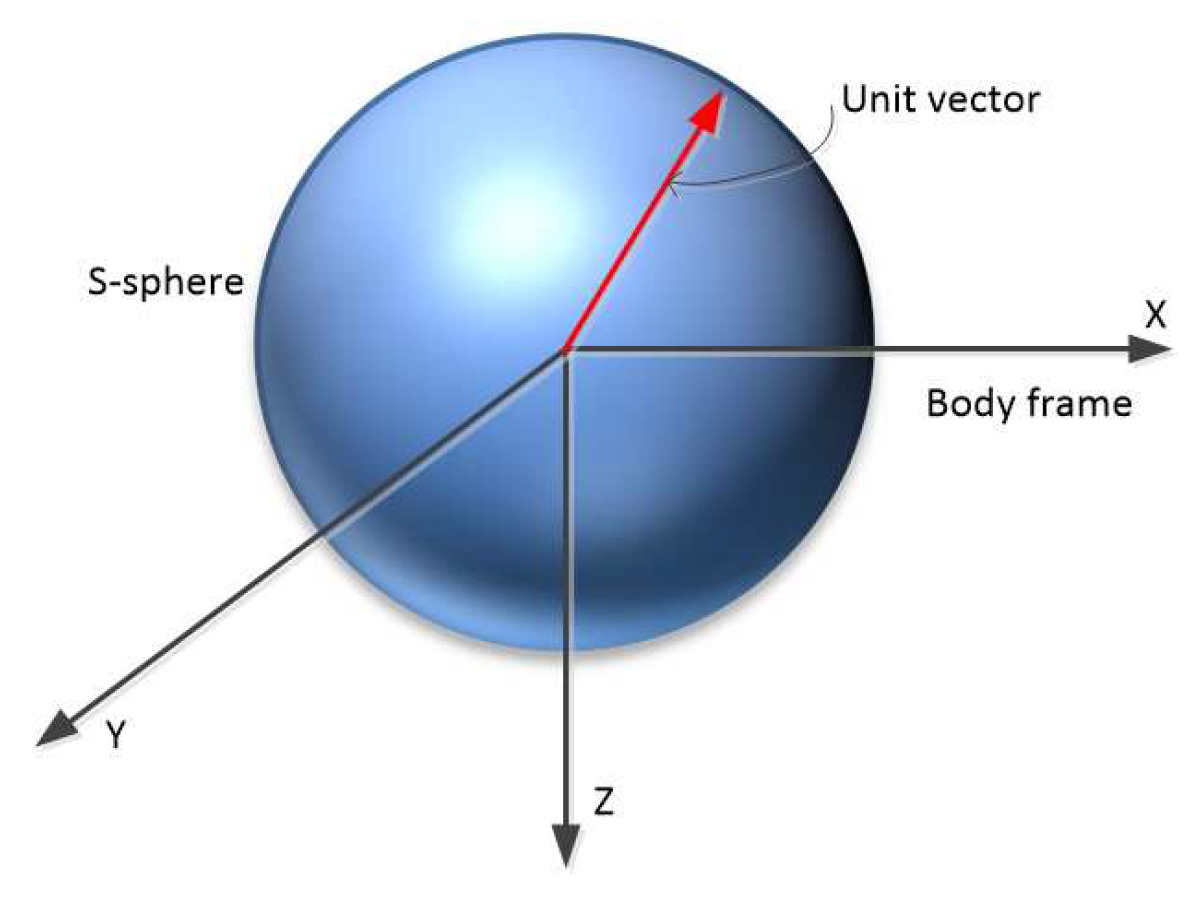

manipulability index is used to measure the system’s ability to exert a desired force with a specific actuator configuration. Therefore, the closer to one this index is, the better the robot’s isotropy is, i.e., the robot can exert the same forces/torques in any direction. The

energetic index is a measurement of the variation of system energy when the direction of the desired force changes. This is evaluated by measuring the energy consumption when the direction of a normalized desired force changes over a 3D sphere. The basic idea of the energetic index is to keep the system’s energy consumption constant and as low as possible when the direction of action changes. The

force index is used to measure the ratio between the actual maximum value and the minimum value of realizing forces. However, these studies only considered a given and fixed actuator configuration. Regarding the design of the actuator configuration of an overactuated underwater robot, a general problem is how to achieve an optimal configuration considering different performance indices. This is a challenging issue that raises two specific questions:

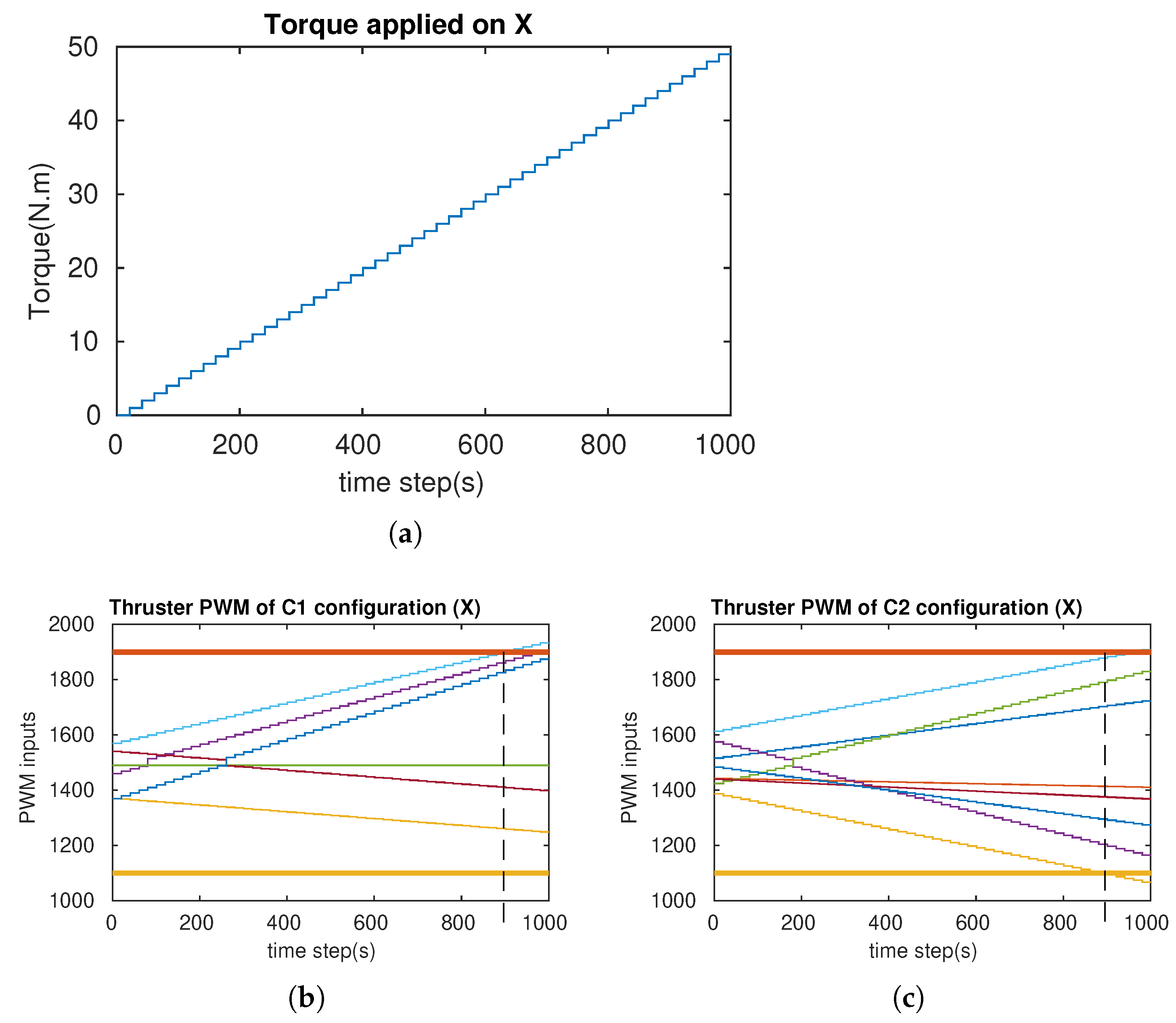

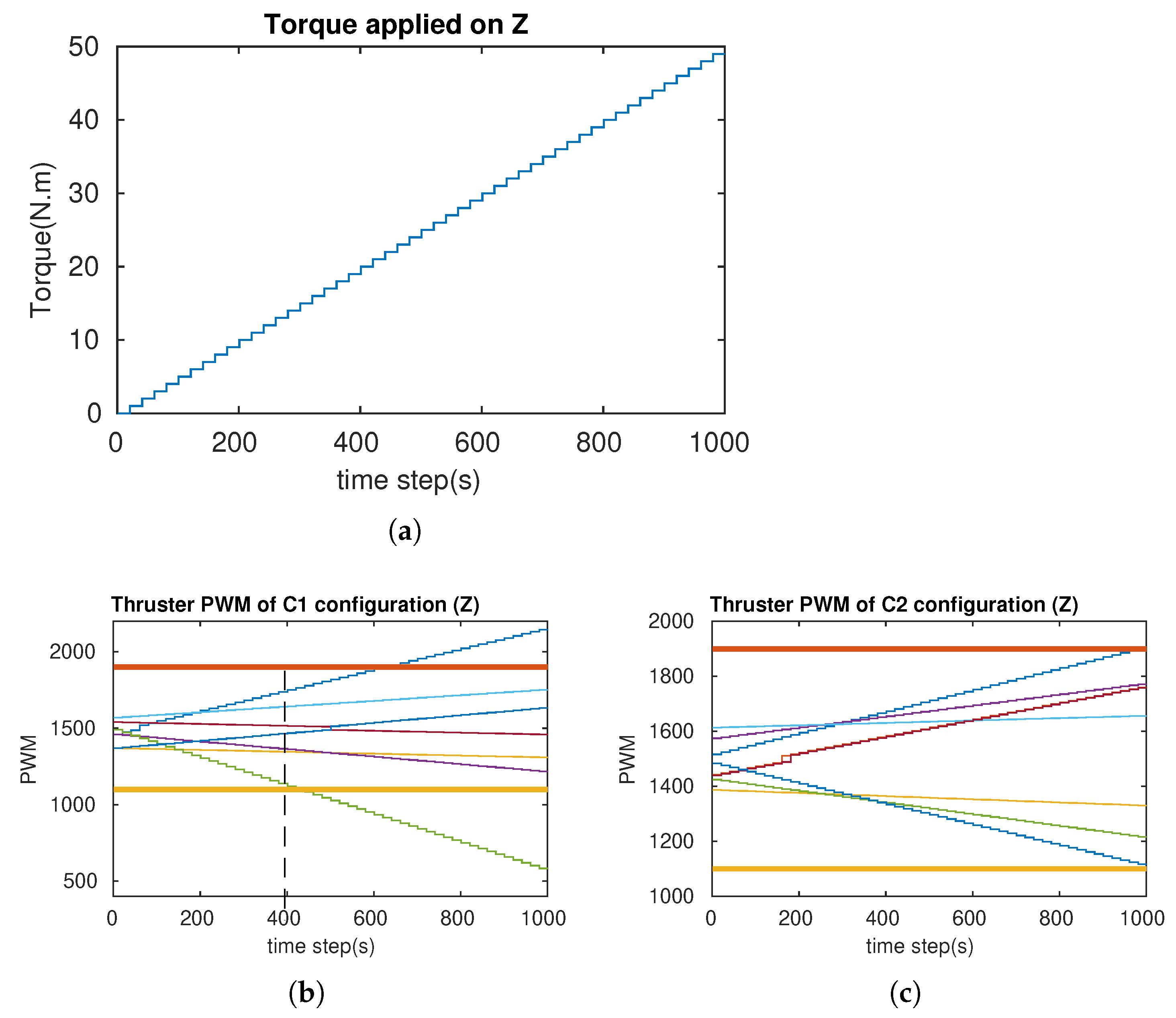

This paper focuses on the design of the actuator configuration for an overactuated underwater robot with the contributions outlined below:

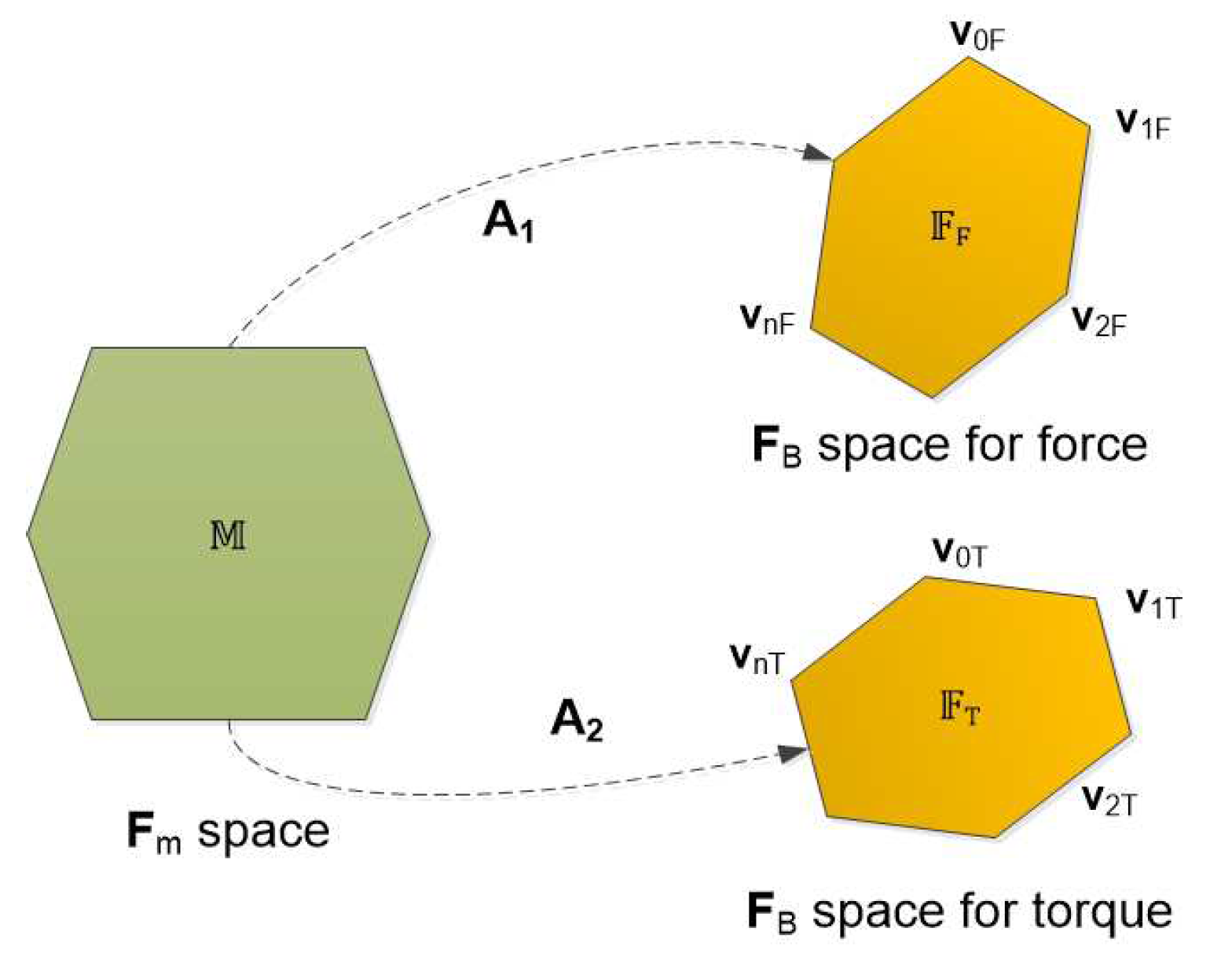

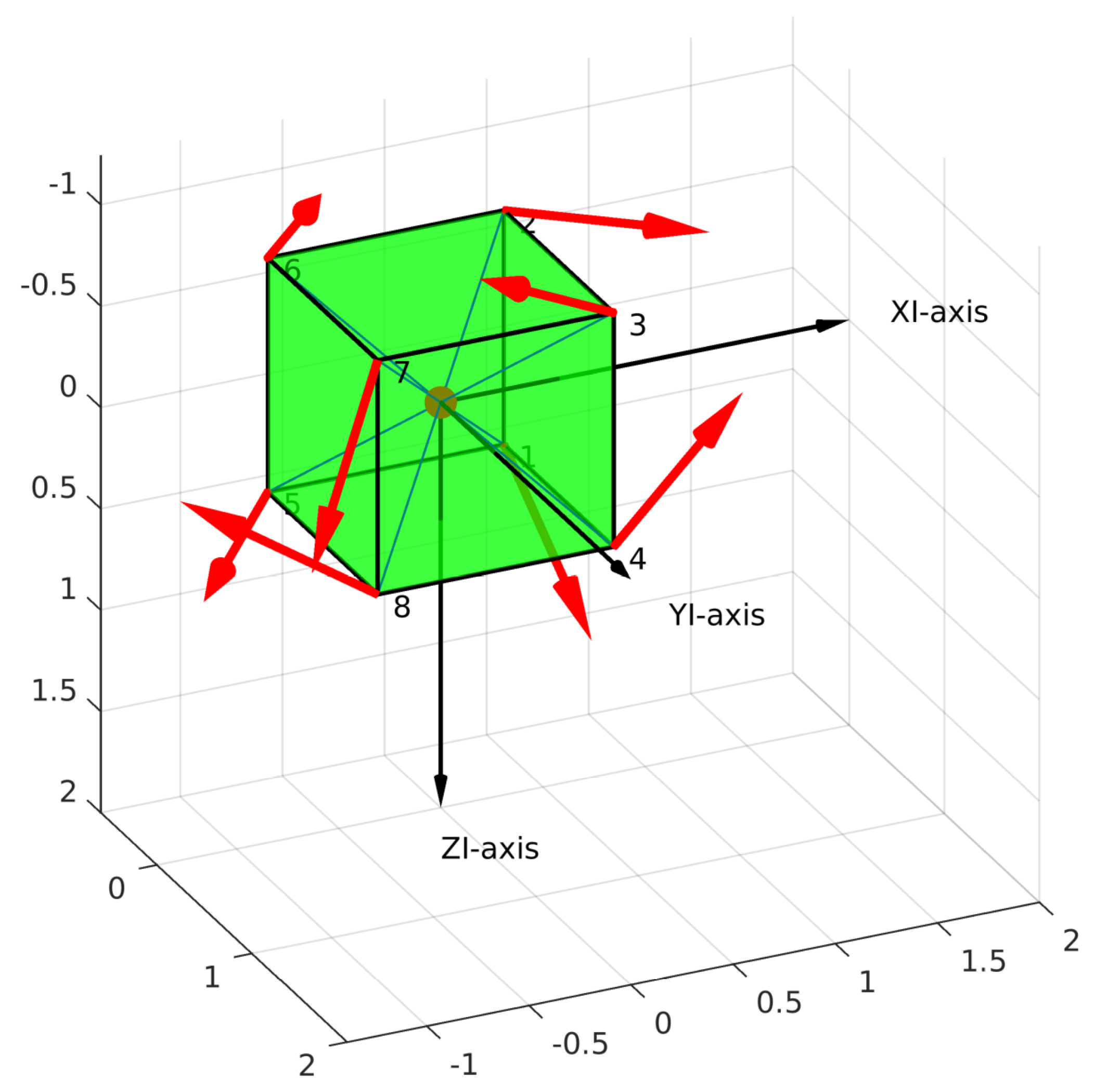

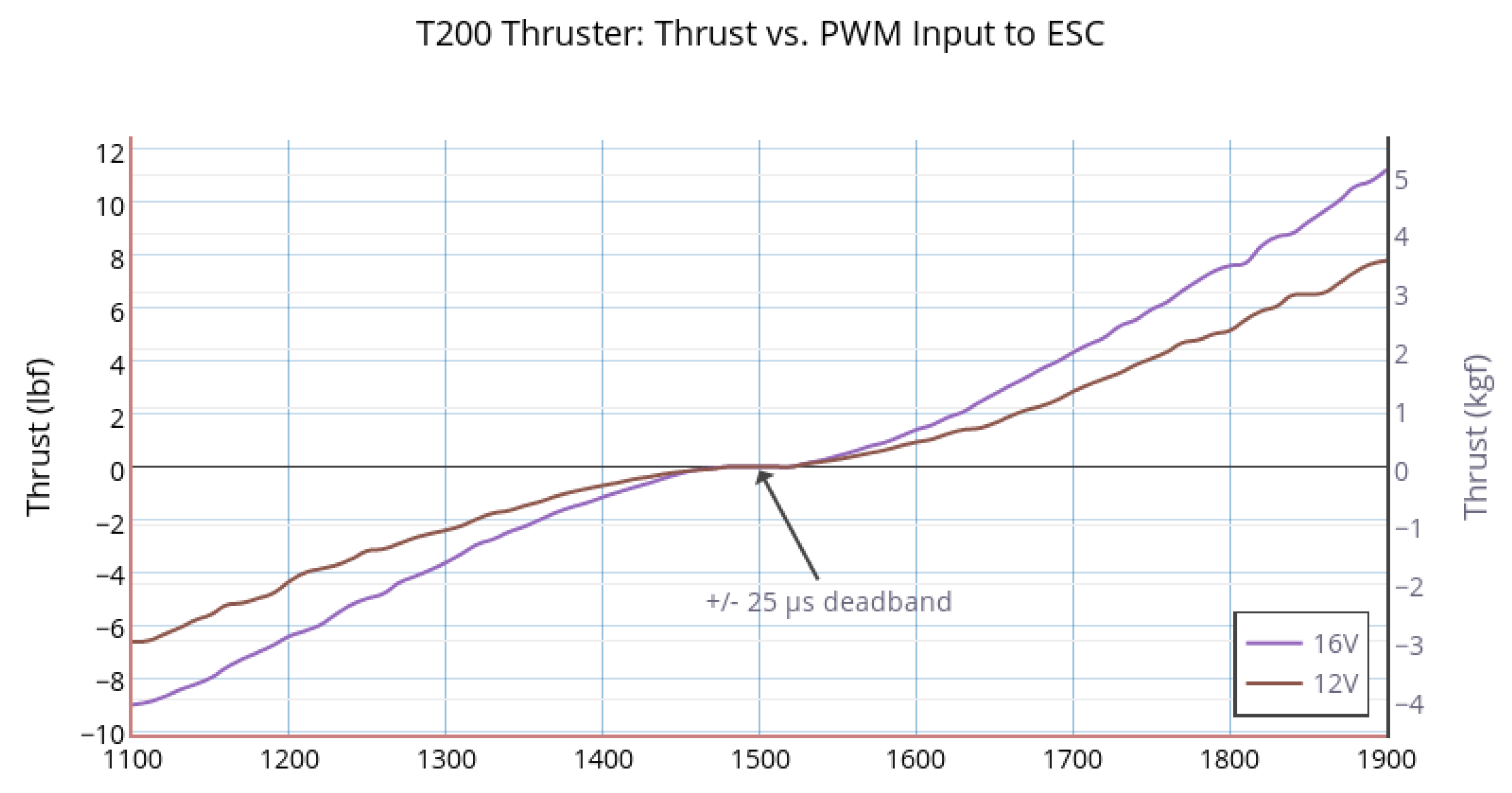

This paper focuses on the design of an actuator configuration of an overactuated underwater robot, which optimizes different performance indices. Mathematically, an actuator configuration is a mapping from an actuator force vector to a resulting force vector (

note that these vectors include force and torque elements). Since we considered an underwater robot equipped with thrusters, the mapping is from a thruster force vector (

space) to a body-frame vector (

space) (see

Figure 3). The mapping operator is a matrix, which has different names in the literature such as: control effectiveness matrix [

4,

17], static transformation matrix [

18], geometrical distribution of thrusters [

19], configuration matrix [

16]. In this paper, the mapping of an actuator configuration is called a

configuration matrix, denoted as

.