1. Introduction

Nowadays, the fourth industrial revolution, popularly known as Industry 4.0 [

1] or smart manufacturing [

2], has been fostering profound transformations in the traditional manufacturing landscape. It converges information and communication technologies (ICT), internet-based infrastructures (e.g., IoT), and web-based technologies (e.g., Web 3.0/4.0 or Semantic Web) for expediting high-level cognitive tasks such as monitoring and decision-making. Consequently, monitoring machining processes (e.g., milling, grinding, turning, and alike) and deciding the right course of action have become a remarkable research topic. Monitoring a machining process generally involves two aspects, namely machine-condition and process-condition monitoring [

3,

4]. Here, machine-condition monitoring means monitoring the machine parts (e.g., gears and bearings). On the other hand, process-condition monitoring means monitoring the process-relevant components (e.g., cutting tool and workpiece surface). In both aspects, sensor signals (e.g., cutting force, torque, surface roughness, vibration, acoustic emission (AE), and alike) obtained from the machining environment play a key role.

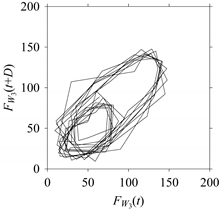

When a machining operation continues in a given smart manufacturing environment, as seen in

Figure 1, sensors collect signals. The signals are generally processed in the time [

5], frequency [

6,

7,

8], and time-frequency [

5,

6,

9] domains to extract the underlying features. In some cases, alternative processing methods, such as fractal-based [

10], Approximate Entropy (ApEn)-based, and Sampling Entropy (SampEn)-based [

11] methods, are used. Subsequently, the most relevant features are then selected using some computational arrangements (e.g., Principal Components Analysis (PCA) [

12]). The abovementioned feature extraction and selection result in some machine learning algorithms. These algorithms become the core of an intelligent monitoring system.

However, the conventional signal processing methods (time, frequency, and time-frequency domain-based processing) require high data acquisition rates [

13] and cannot mimic the dynamics underlying the signals [

11]. Now, complex communication networks underlying smart manufacturing entail a phenomenon called time latency (also known as time delay) [

14,

15], which results in a low data acquisition rate. In addition, a high data acquisition rate requires a high data storage capacity and energy-intensive sensor networks [

16]. Thus, a high data acquisition rate is not even desirable. As such, alternative methods are needed to tackle the abovementioned issues. Unfortunately, enough studies have not yet been conducted in this direction. This study fills this gap by adapting the delay domain-based signal processing method [

17]. In particular, this study investigates the implications of the time latency domain or delay domain for understanding the dynamics underlying a given sensor signal. In addition, real-life sensor signals collected while machining metallic workpieces are analyzed by both conventional and delay domain-based approaches. Moreover, the efficacy of the delay domain in identifying different machining situations is also elucidated.

For better understanding, the rest of this article is organized as follows.

Section 2 presents a literature review on sensor signal processing methods for machine- and process-condition monitoring.

Section 3 presents the significances of the delay domain-based signal processing since the delay domain directly incorporates time latency associated with sensor signals.

Section 4 presents a case study where delay domain-based signal processing is deployed to make sense of sensor signals of cutting force obtained from machining experiments.

Section 5 presents the efficacy of delay domain-based processing where it is shown that the delay domain can distinguish different machining situations more effectively than the frequency domain. Finally,

Section 6 provides the concluding remarks of this study.

2. Literature Review

Sensor signal processing is a mainspring for machine- and process-condition monitoring in manufacturing. Its role has been intensified due to the advent of Industry 4.0-centric embedded systems (cyber-physical systems and digital twins). Numerous researchers have been working on implementing the existing signal processing techniques or even developing new ones. For the sake of better understanding, some of the recent articles on signal processing are briefly described below.

First, consider the techniques used in sensor signal processing for manufacturing. Jáuregui et al. [

6] presented a method for tool condition monitoring (TCM) in high-speed micro-milling. It incorporates frequency and time-frequency analysis of cutting force and vibration signals, acquired at a sampling frequency of 38,200 Hz and 89,100 Hz, respectively. Zhou et al. [

18] introduced a sound signal-based TCM approach. The approach incorporates signal processing in a time-frequency domain called Wavelet Transform Modulus Maxima (WTMM). Chen et al. [

5] proposed a method for monitoring chatter under different cutting conditions in milling. It incorporates time series analysis (using Recurrence Quantitative Analysis or RQA) of cutting force signals acquired at a sampling frequency of 8 kHz. Bi et al. [

19] developed a method for monitoring grinding wheels while grinding brittle materials. The monitoring method acquires acoustic emission (AE) signals at a sampling frequency of 1 MHz and incorporates time and frequency analysis. Zhou and Xue [

8] stressed the importance of multiple sensor signal analysis for developing intelligent monitoring systems. They also developed a multi-sensory monitoring system for TCM in milling. The system acquires cutting force, vibration, and AE signals at a sampling frequency of 50 kHz. Then, the signals are analyzed in the time, frequency, and time-frequency (Wavelet Packet Transform or WPT) domains. Li et al. [

20] presented a multi-sensory system for identifying chatter in milling. It analyzes three signals, namely the cutting force, acceleration, and image ripple distance in the time and frequency domains (Wavelet Packet Decomposition or WPD). Segreto et al. [

9] developed a multi-sensory system for estimating tool wear while turning hard-to-machine nickel-based alloys. The system acquires cutting force, AE, and vibration acceleration signals at a sampling frequency of 10 kHz, 10 kHz, and 3 kHz, respectfully. Then it (the system) analyzes these signals in the time-frequency (WPT) domain. Abubakr et al. [

21] developed a model for detecting tool failure. The model acquires current, vibration, and AE signals at a sampling frequency of 250 Hz. Then it (the model) analyzes these signals in the time and frequency domains. Guo et al. [

7] developed a system for predicting surface roughness due to grinding. The system analyzes the grinding force, vibration, and AE signals in the time and frequency domains. The sampling frequency for the force and vibration signals is 3200 Hz, and for the AE signals, it is 2000 kHz. Segreto et al. [

22] presented a method for assessing surface roughness due to polishing. It analyzes the AE, strain, and current signals in time and time-frequency (WPT) domains. The corresponding sampling frequencies are 131 kHz, 16 kHz, and 0.1 kHz, respectively. Teti et al. [

10] developed an artificial neural network (ANN)-based approach for monitoring tool health in drilling. It incorporates time, frequency, and fractal analysis of the thrust force and torque signals acquired at a sampling frequency of 10 kHz. Wang et al. [

23] introduced an event-driven tool monitoring method for predicting the tools’ remaining useful life (RUL). It incorporates time and time-frequency analysis of cutting force signals to build the RUL prediction model. Jin et al. [

24] introduced a method for monitoring bearing health. It acquires vibration signals at a sampling rate of 25.6 kHz. Then it incorporates time-frequency features underlying these signals for developing health index (HI) and predicting the bearing RUL. Bhuiyan et al. [

25] investigated the relationship between tool wear and plastic deformation in turning. For this, AE signals are acquired at different sampling frequencies. The lowest sampling frequency studied was 50 kHz. The signals are analyzed in the frequency domain for the sake of investigation. Lee et al. [

26] introduced a Kernel Principal Component Analysis (KPCA)-driven method for TCM in milling. It monitors tool wear using Kernel Density Estimation (KDE)-based T2-statistic and Q-statistic control charts. For this, current, AE, and vibration acceleration signals are acquired (from NASA’s milling dataset [

27] at a minimum sampling frequency of 100 kHz) and analyzed.

In sum, the manufacturing-relevant sensor signals (e.g., cutting force, spindle load, AE, vibration, and alike) are commonly processed in the time, frequency, and time-frequency domains. Numerous authors have also studied the technical problems and limitations of the abovementioned sensor signal processing techniques. Some of the noteworthy studies are briefly described as follows.

Mahata et al. [

28] articulated that time or frequency domain-based signal processing is ineffective for analyzing non-linear signals (e.g., signals underlying grinding wheel wear). They proposed a novel method defined as the Hilbert-Huang transform (HHT). The HHT acquires spindle power and vibration signals at a sampling frequency of 67 Hz and 10 kHz, respectively, and analyzes them. Espinosa et al. [

11] articulated that traditional frequency analysis is not effective for unfolding the characteristics of non-linear signals, compared to the alternative analytics such as Approximate Entropy (ApEn) and Sampling Entropy (SampEn). Bayma et al. [

29] proposed a Non-linear Output Frequency Response Functions (NOFRFs)-based approach for analyzing non-linear systems from the contexts of condition monitoring, fault diagnosis, and non-linear modal analysis. Bernard et al. [

13] articulated that in the machine/process-condition monitoring research area, the methods used or introduced highly depend on high data acquisition rates. They emphasized the need for alternative methods that can perform with low data acquisition rates to meet some challenges of intelligent manufacturing, such as fast computation and low data storage. They also proposed a data-driven KDE function-based method for TCM. The method works with historical datasets of spindle load signals at a sampling frequency of 1/3 Hz. Cerna and Harvey [

30] demonstrated that processing a signal dataset—associated with low sampling frequency—in the frequency domain results in a misleading representation due to aliasing. Du et al. [

31] demonstrated that time latency and sampling rate must be synchronously optimized for improving control performance in a feedback control system. Lalouani et al. [

16] described that acquiring data at higher sampling rates and its (data) transmission cause significant energy dissipation from a sensor system. They also articulated that suppressing energy dissipation is a prime requirement for the sustainable operation of a sensor system. They developed an energy optimization method, which deploys in-network processing to reduce the number of data transmissions. Halgamuge et al. [

32] presented an overview of the sources of sensor power consumption. Some sources are: sensing signals at a sampling rate, signal conditioning, analog to digital conversion (ADC), reading/writing the sensed data in memory, and data transmitting. They also developed an energy model for estimating the life expectancy of wireless sensor networks (WSN). Wang and Chandrakasan [

33] articulated that both the communication and computing energy need to be suppressed for prolonging the lifetimes of the wireless sensors in a multi-sensory network. For this, they stressed the need for an efficient signal processing method to extract meaningful information from the sensed data. McIntire et al. [

34] described the requirements of Embedded Networked Sensor (ENS) systems from the viewpoint of critical environment monitoring. They articulated that the ENS must consume low energy. At the same time, the ENS must satisfy complex information processing to select proper sensor sampling. Marinkovic and Popovici [

35] developed a method for suppressing the communication energy dissipation in a Wireless Body Area Network (WBAN) sensor node. The method adapts wireless wake-up functionality enabled by a Wake-Up Receiver (WUR). Brunelli et al. [

36] articulated that computational tasks in a monitoring environment should consume less energy to guarantee an energy-efficient sensor network and data center.

In sum, conventional signal processing methods (time, frequency, and time-frequency domain-based methods) are inadequate for understanding the nature underlying non-linear and stochastic manufacturing signals. These methods highly depend on a higher data acquisition rate and complex computational arrangements, which create difficulties in storing the sensed data, consume more time to process the data, and cause energy dissipation from the sensor network. In addition, in reality, a low data acquisition rate is a possible outcome due to time latency (also known as delay) in complex communication networks underlying smart manufacturing systems [

14,

15,

37]. Therefore, apart from the conventional methods, alternative methods must be investigated and incorporated for signal processing and handling the abovementioned difficulties from the smart manufacturing context. This study addresses this issue by adapting delay domain-based signal processing, as follows.

3. Significances of Time Latency and Delay Domain

As mentioned in the previous section, alternative signal processing methods are needed for unfolding the effect of time latency. For this, one straightforward way might be to adapt delay domain-based signal processing [

17,

38]. Few authors have embarked on this issue—delay domain-based signal processing and its implication in smart manufacturing. For example, Ullah [

39] used delay domain-based processing for unfolding the dynamics underlying surface roughness signal datasets. Ullah and Harib [

40] proposed a rule-based knowledge extraction process for simulating surface roughness where the rules are derived from the delay domain-based processing of historical roughness datasets. Wang and Li [

41] used delay domain-based processing for the correlation analysis while developing a chaotic image encryption algorithm. Ghosh et al. [

42] demonstrated the impact of time latency in signal processing. The authors articulated that the delay domain effectively encapsulates the dynamics underlying sensor signals when time latency is concerned. The authors also proposed a delay domain-driven hidden Markov process for developing sensor signal-based digital twins from the viewpoint of smart manufacturing [

42,

43]. However, more comprehensive studies are required to articulate the significances of time latency in sensor signals fully. For this, delay domain-based signal processing must be considered along with the conventional approaches (e.g., time and frequency domain-based signal processing).

Delay domain-based signal processing means transferring a dataset (time series) to a space called the delay map [

17,

38]. The map considers a series of forward or backward values from the dataset based on a forward or backward delay parameter (a non-zero integer), respectively. For example, let {

A(

t) ∈ ℜ |

t = 0, Δ

t, 2Δ

t, …} be a signal dataset, where ∆

t is the sampling interval. Thus, (

t,

A(

t)) is the corresponding time series. Now, let

d be a non-zero integer to define the value of delay or time latency, i.e.,

d ∈ ℤ

+. As such, the dataset of ordered pairs {(

A(

t),

A(

t ±

D))|

D =

d × Δ

t,

t = 0, Δ

t, 2Δ

t, …} becomes the corresponding delay map. The time series can be represented by indexing its elements using a pointer, if preferred. In this case,

A(

t) is replaced by

A(

i) (=

A(

t)), where

t =

i × Δ

t and

i is the pointer,

i = 0, 1, …. As such, (

A(

i),

A(

i +

d)) becomes the corresponding delay map. For better understanding, consider the example in

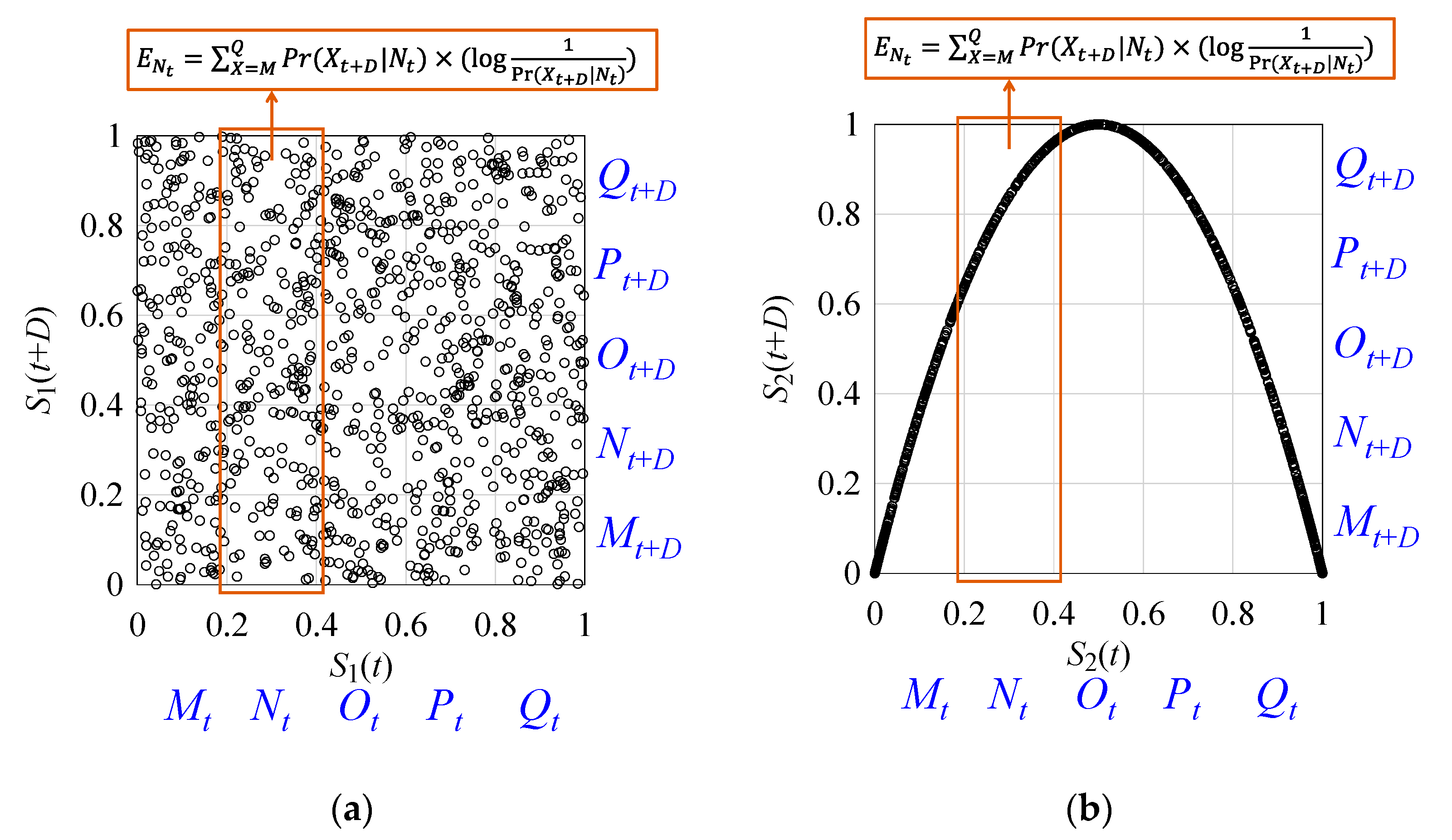

Figure 2.

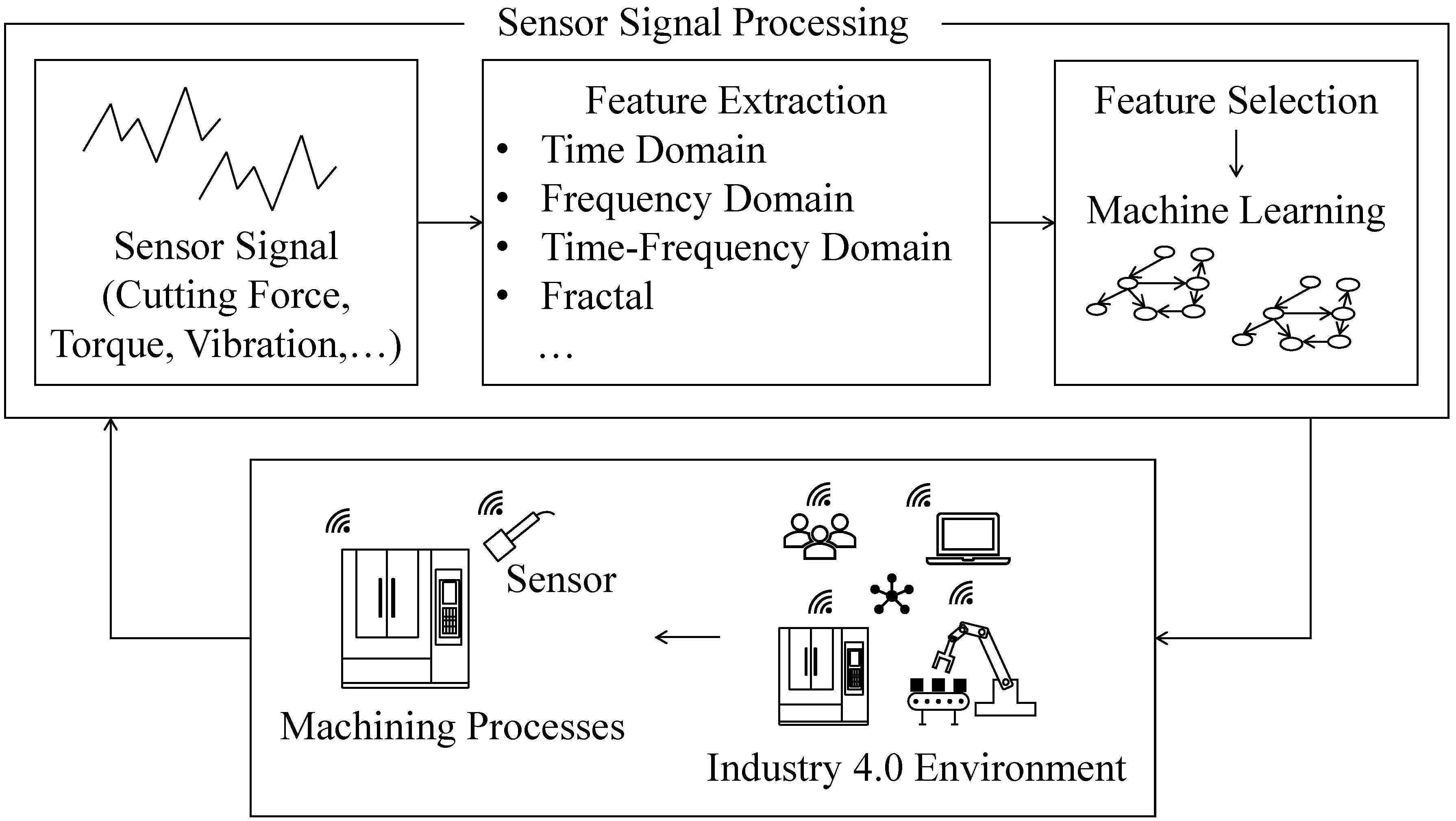

Let

S1 and

S2 be the time series of two arbitrary signals, where the signal values are

S1(

t),

S2(

t) ∈ [0,1],

t = 0, 1, …, as shown in

Figure 2. Thus, the plots shown in

Figure 2 are the time domain representations of the signals. Eight quantifiers (features) (

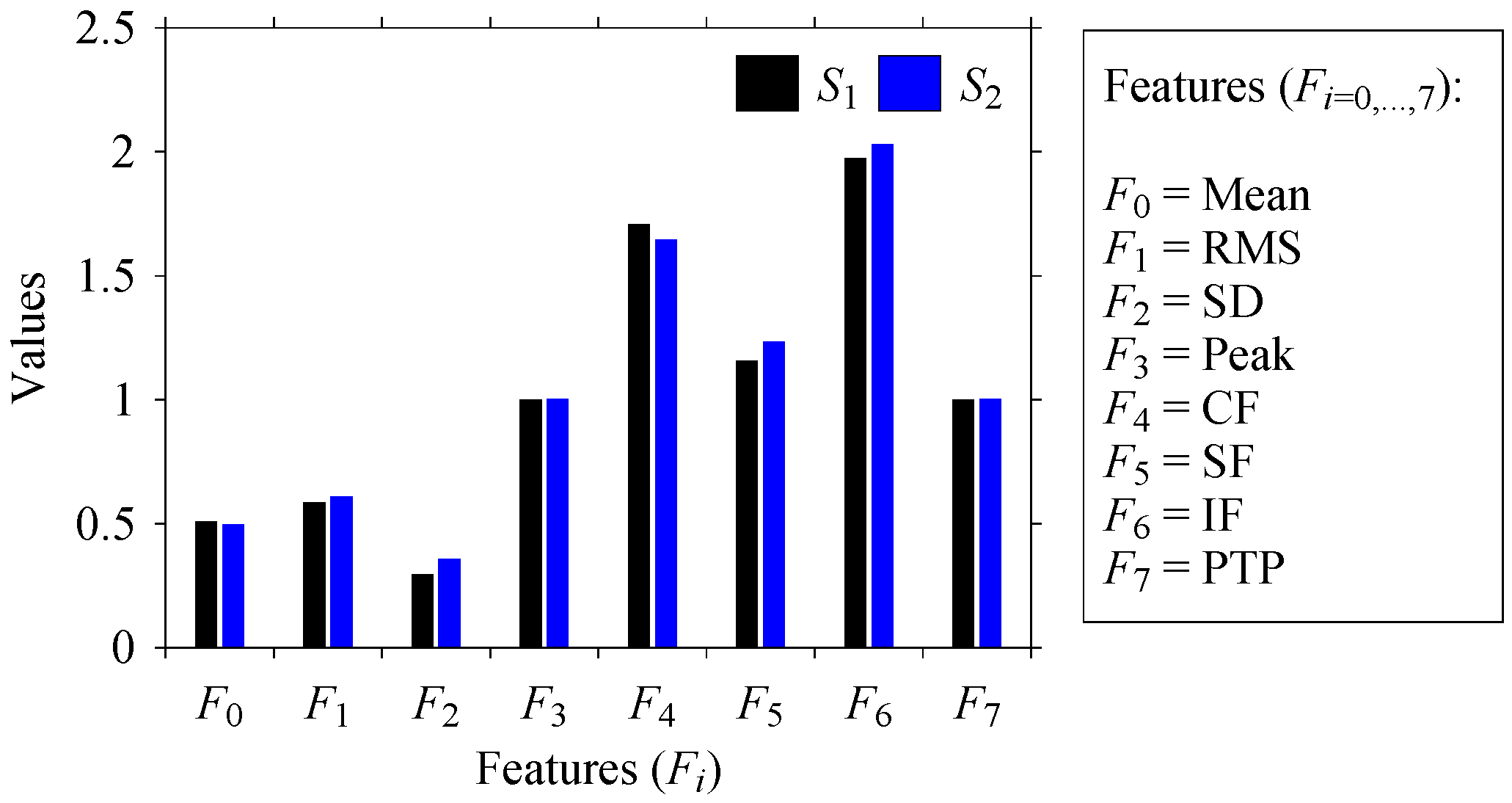

F0,

F1,

F2,

F3,

F4,

F5,

F6,

F7) = (Mean, Root Mean Square (RMS), Standard Deviation (SD), Peak, Crest Factor (CF), Shape Factor (SF), Impulse Factor (IF), and Peak to Peak (PTP)) are used to quantify

S1 and

S2 in the time domain. The values of the features are plotted in

Figure 3 for both signals. As seen in

Figure 3, the values of all features of

S1 and

S2 are almost the same. Therefore, as far as the time domain is concerned,

S1 and

S2 are two very similar signals.

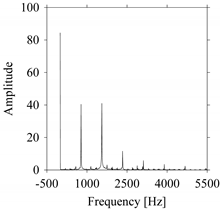

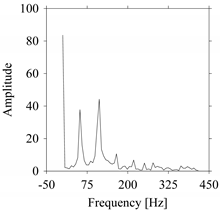

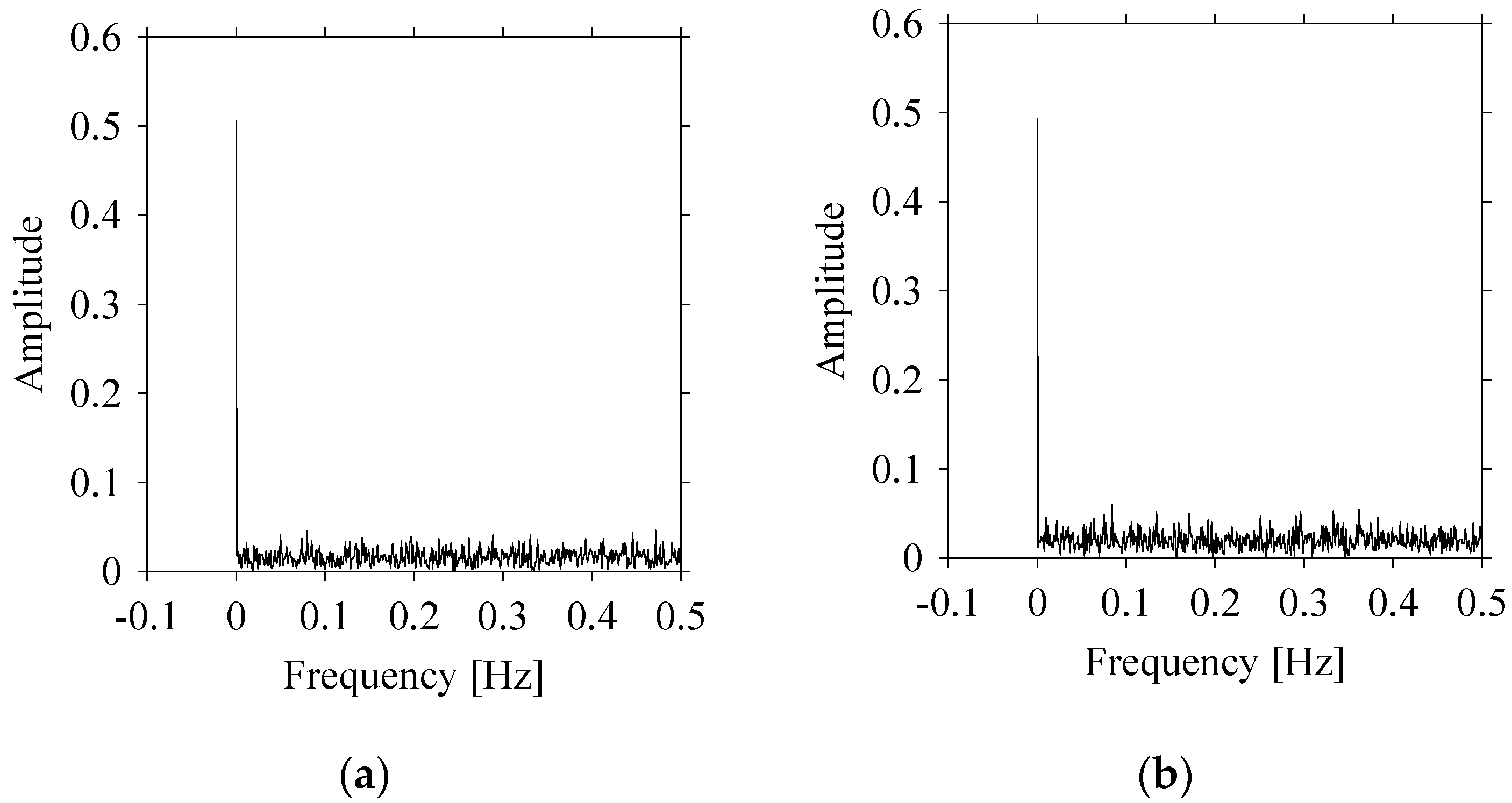

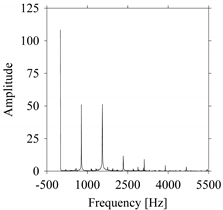

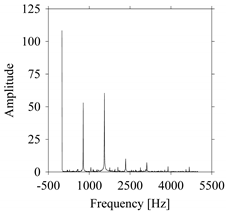

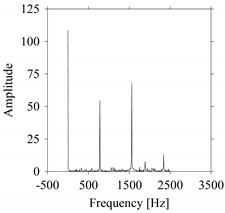

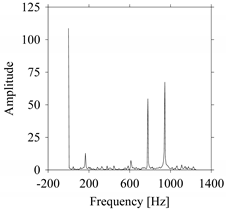

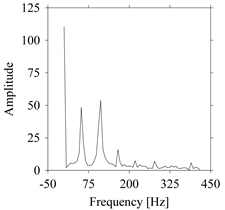

Let us quantify the signals in the frequency domain. For this, the Fast Fourier Transform (FFT) is performed on the datasets shown in

Figure 2 and the amplitude-frequency diagrams of

S1 and

S2 are constructed, as shown in

Figure 4. As seen in

Figure 4, the frequencies underlying

S1 (

Figure 4a) and

S2 (

Figure 4b) also exhibit a very similar pattern.

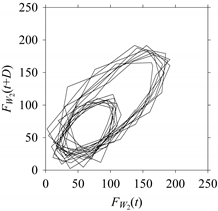

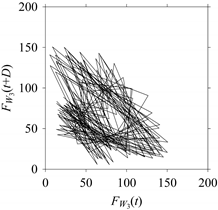

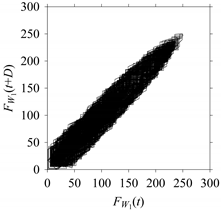

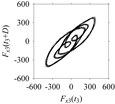

Finally, consider delay domain-based analysis of

S1 and

S2. For this, two delay maps, as shown in

Figure 5a,b for

S1 and

S2, respectively, are constructed. The

d (delay parameter) is set to be 1. Consider the delay map

S1 (

Figure 5a). In this case, the points are randomly distributed on the delay map, revealing the fact that the value of signal at a point of time,

S1(

t), can change to a value taken from the interval [0,1] randomly in the next point of time, (

S1(

t+1)). On the other hand, consider the delay map shown in

Figure 5b. A systematic pattern (the points are organized on parabolic curve) is shown in the delay map. This means that value of the signal at a point of time,

S2(

t), cannot change to a value taken from the interval [0,1] randomly in the next point of time, (

S2(

t+1)); it follows an order. This can also be described from the viewpoint of the entropy of information [

44]. As reported in

Appendix A, the entropy of information underlying the delay map of

S2 (

Figure 5b) is much less than that of

S1 (

Figure 5a), revealing the fact that

S2 follows a very systematic pattern whereas

S1 is random by nature. Note that the mathematical formulations for calculating the entropy of information are also described in detail in

Appendix A.

Nevertheless, from the above time domain, frequency domain, and delay domain analyses, it is clear that delay domain-based analysis is more informative compared to time domain and frequency domain-based analyses for understanding the dynamics underlying S1 and S2. Thus, the delay domain is a powerful means to process signals.

4. Manufacturing Signal Processing

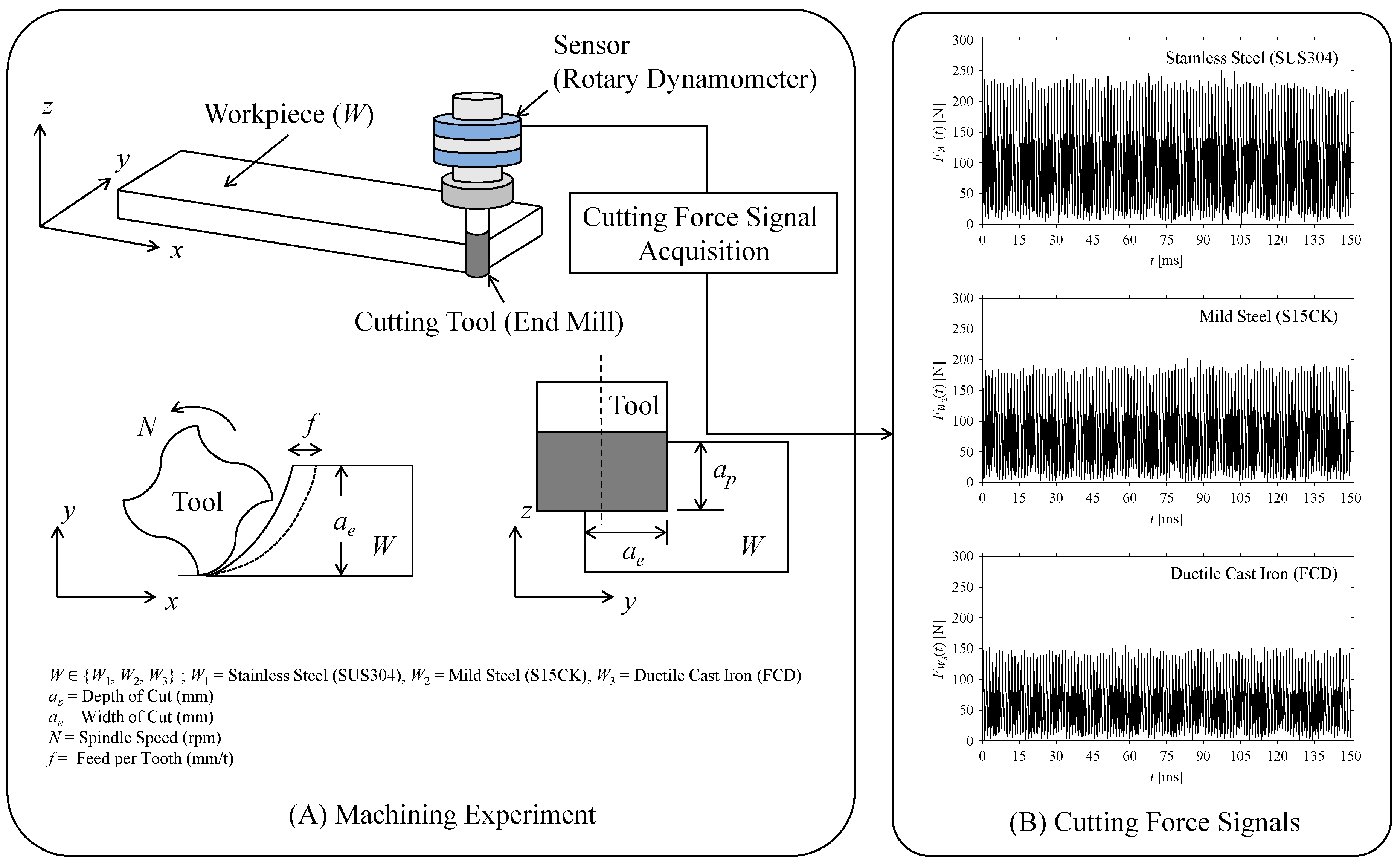

The previous section shows the significance of signal processing in the delay domain using two arbitrary signals. In this section, real-life signals are considered to see whether or not the delay domain remains significant in real-life settings. In particular, cutting force signals obtained by performing machining experiments according to the settings shown in

Table 1 are considered.

Consider a machining experiment, where a set of workpiece specimens denoted as

W, ∀

W ∈ {

W1,

W2,

W3} undergo end milling. Here,

W1,

W2, and

W3 refer to the workpiece specimens made of stainless steel (JIS: SUS304), mild steel (JIS: S15CK), and ductile cast iron (JIS: FCD), respectively.

Table 1 summarizes corresponding machining conditions (e.g., spindle speed

N (rpm), feed per tooth

f (mm/tooth), depth of cut

ap (mm), width of cut

ae (mm), and alike) in detail.

Figure 6 schematically illustrates the outline of the experiment and relative conditions (see the segment denoted as A).

As seen in

Figure 6, the corresponding cutting force signals are obtained using a sensor called rotary dynamometer (also described in

Table 1) while machining

W. Let,

FW(

t),

t = 0, Δ

t, 2Δ

t, …,

m × Δ

t, be the force signals of

W, as shown in the segment ‘B’ in

Figure 6. Here, Δ

t denotes a sampling period of 0.02 ms. The goal is to analyze the

FW under low data acquisition scenarios for understanding the underlying dynamics. Note that a low data acquisition scenario can evolve from two different cases: (1) a short sampling window and (2) a low sampling rate due to time latency or delay. For this, the

FW is analyzed considering both the abovementioned cases, as described in the following sub-sections, respectively.

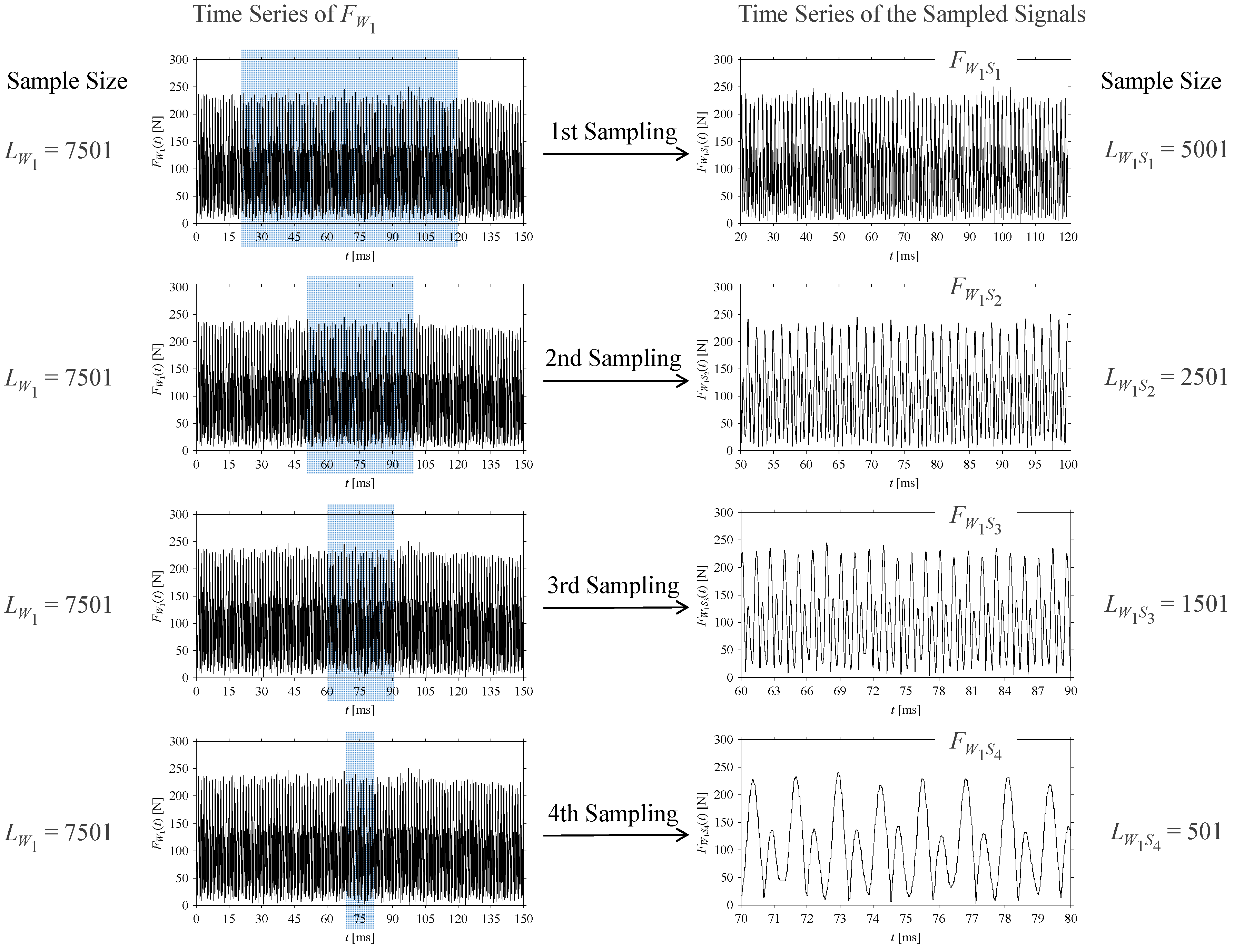

4.1. Analyzing Sensor Signals under Different Sampling Windows

In Industry 4.0-centric systems, the sensor signal sampling windows may vary due to physical limitations and suppressing energy dissipation. Therefore, signals sampled using different sampling windows must be considered. Each piece of sampled signals can then be analyzed in the time, frequency, and delay domains, respectively.

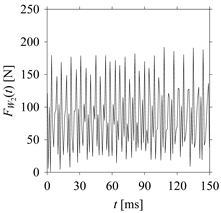

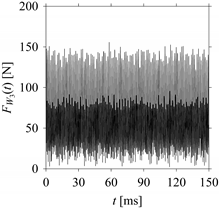

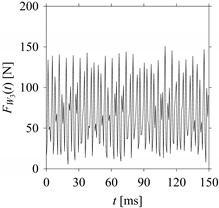

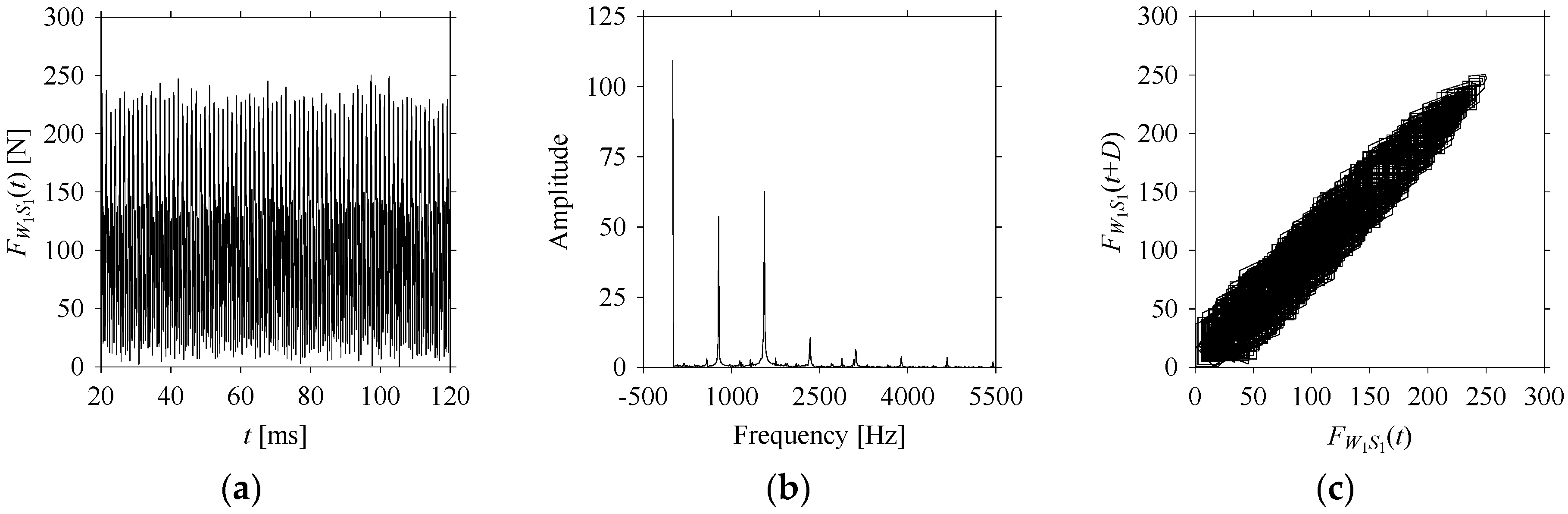

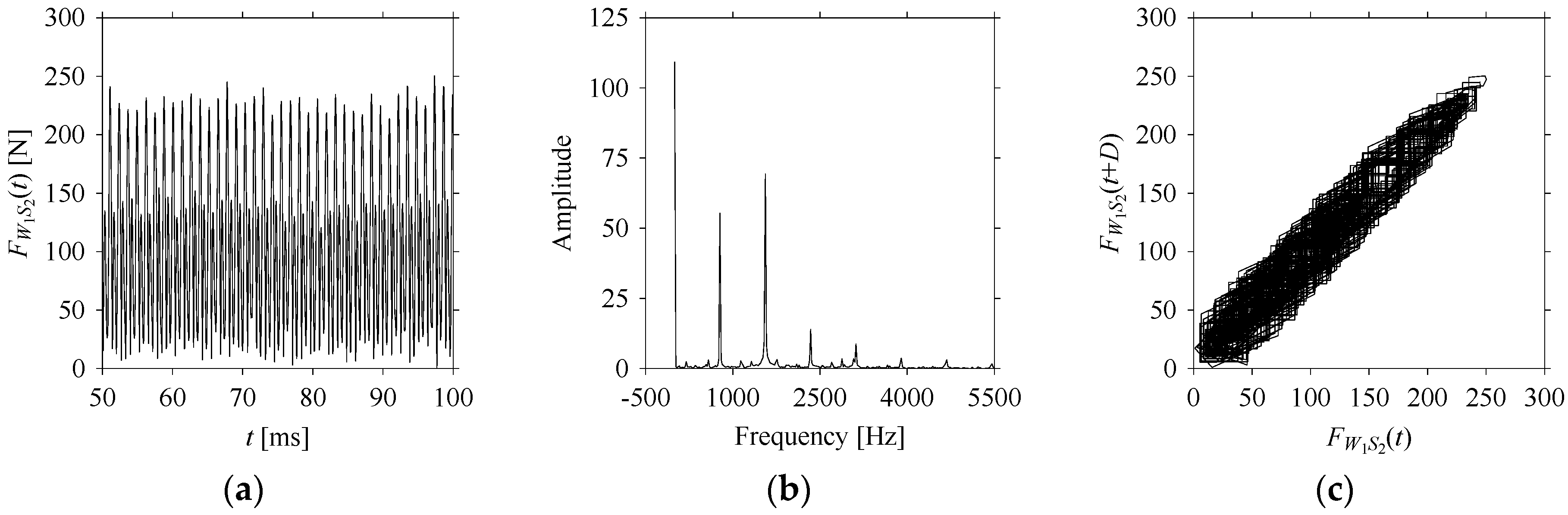

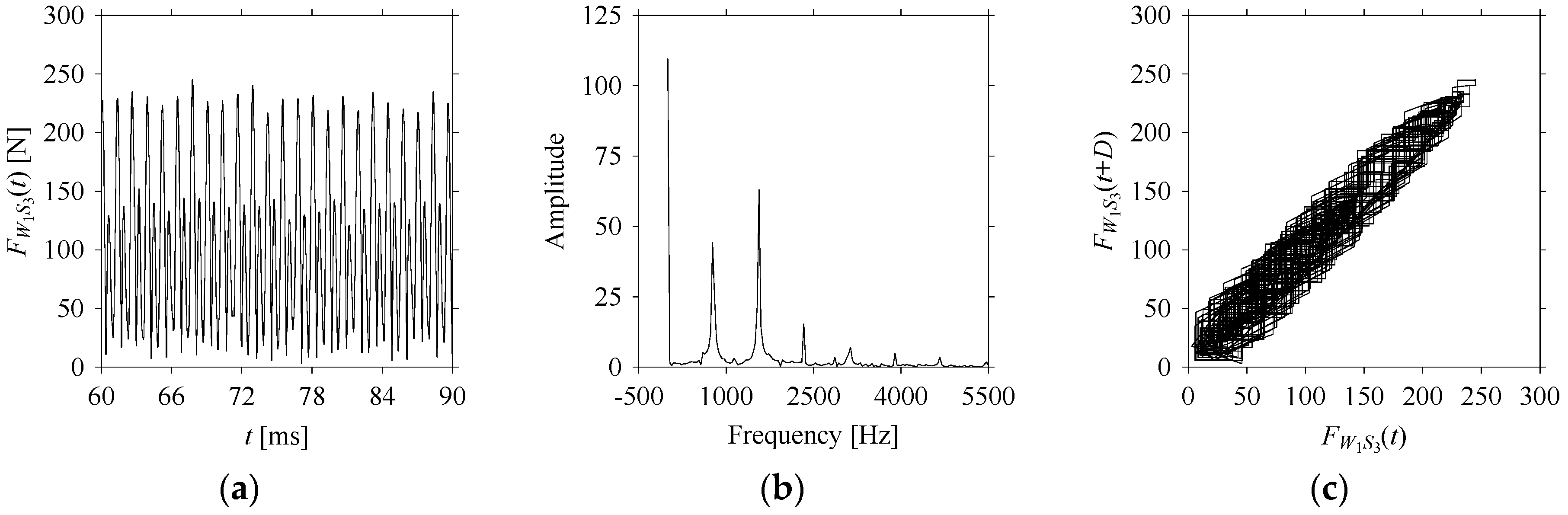

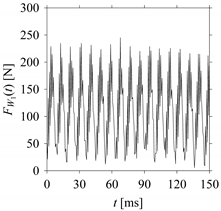

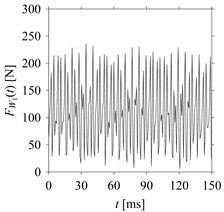

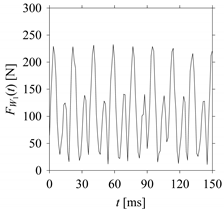

Consider the cutting force signal obtained while machining stainless steel (SUS304), i.e.,

FW1.

Figure 7 shows its time series. As seen in

Figure 7, the sample size of

FW1 is denoted as

LW1, where

LW1 = 7501.

FW1 is sampled four times using four different sampling windows (light blue colored regions in the time series of

FW1). This results in four new signals denoted as

FW1S1, …,

FW1S4. The corresponding sample sizes are denoted as

LW1S1, …,

LW1S4, where

LW1S1 = 5001,

LW1S2 = 2501,

LW1S3 = 1501, and

LW1S4 = 501.

For the sake of analysis, the signals

FW1 and

FW1S1, …,

FW1S4 are transferred to the frequency domain (using FFT) and delay domain (using

d = 1, as described in

Section 3). As such,

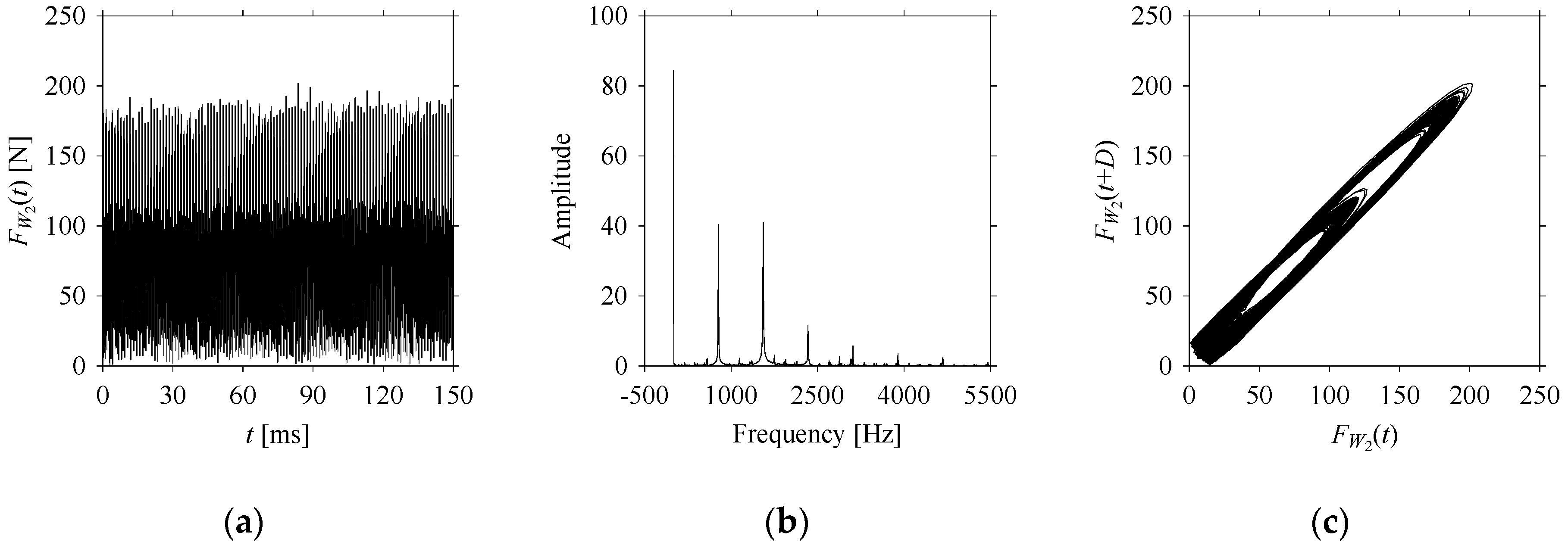

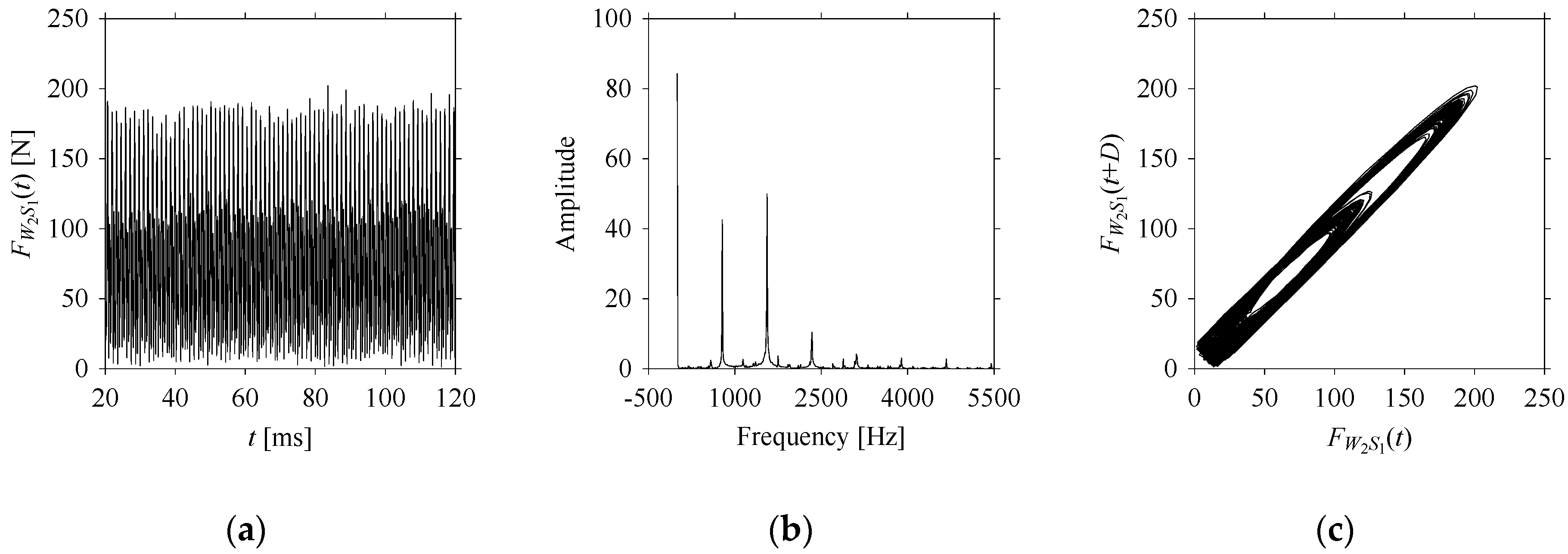

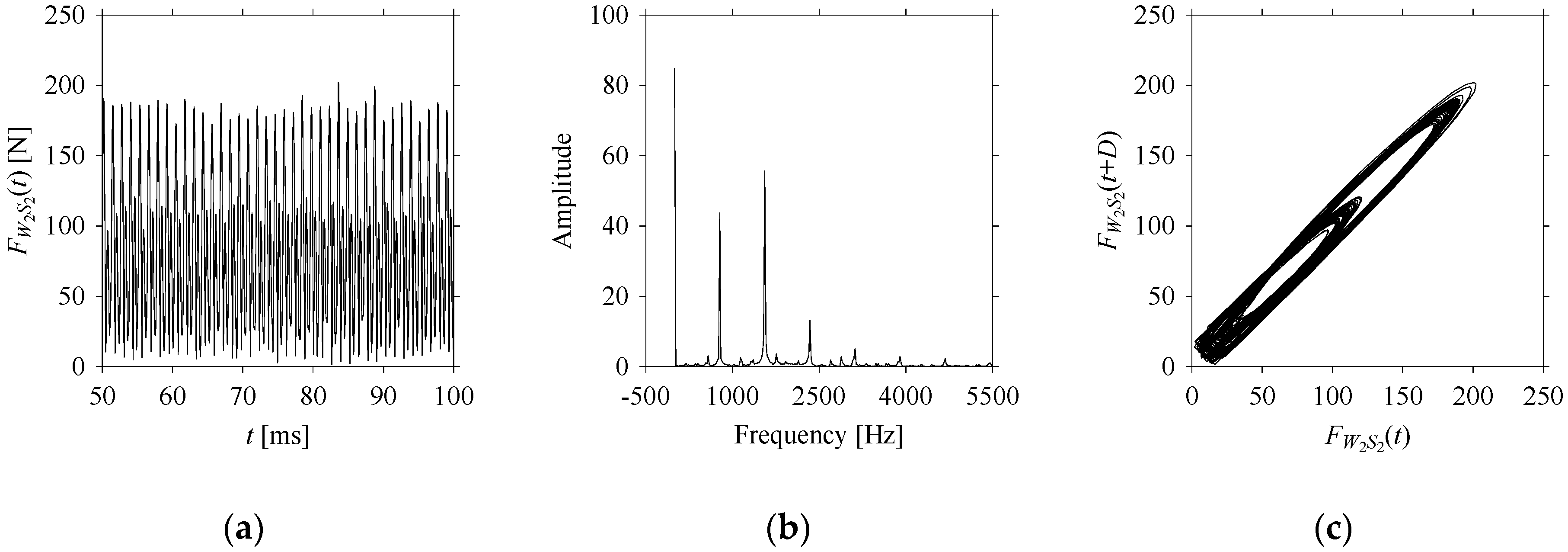

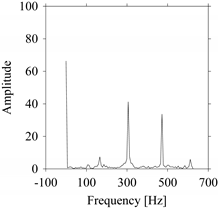

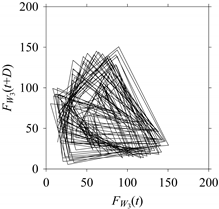

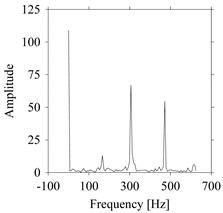

Figure 8 shows the time series, FFT, and delay map for

FW1.

Figure 9,

Figure 10,

Figure 11 and

Figure 12 show the time series, FFT, and delay map for

FW1S1, …,

FW1S4, respectively.

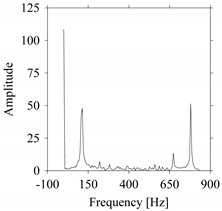

As seen in

Figure 8b, the prominent frequencies underlying

FW1 are 0 Hz, 780 Hz, 1560 Hz, 2333.333 Hz, 3113.333 Hz, 3893.333 Hz, and 4673.333 Hz. As seen in

Figure 9b, the prominent frequencies underlying

FW1S1 are 0 Hz, 780 Hz, 1560 Hz, 2340 Hz, 3110 Hz, 3890 Hz, and 4670 Hz. As seen in

Figure 10b, the prominent frequencies underlying

FW1S2 are 0 Hz, 780 Hz, 1560 Hz, 2340 Hz, and 3120 Hz. As seen in

Figure 11b, the prominent frequencies underlying

FW1S3 are 0 Hz, 766.6667 Hz, 1566.667 Hz, 2333.333 Hz, and 3133.333 Hz. As seen in

Figure 12b, the prominent frequencies underlying

FW1S4 are 0 Hz, 800 Hz, 1600 Hz, 2300 Hz, and 3100 Hz. This means that the frequency information varies with the sampling window. In addition, the FFT pattern gets affected when the sampling window is shorter (see

Figure 12b compared to

Figure 8b).

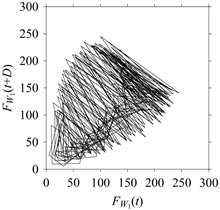

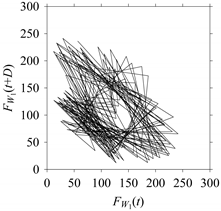

On the other hand, the delay maps shown in

Figure 8c,

Figure 9c,

Figure 10c,

Figure 11c and

Figure 12c exhibit similar characteristics under different sampling windows. In particular, the returns of points from one to another are identical. This means that the underlying nature of the

FW1 and

FW1S1, …,

FW1S4 are the same, regardless of the sample size. In addition, the density of points underlying the delay maps provides meaningful insight into the sample size of the signal. For example, the density of the delay map shown in

Figure 12c is lighter compared to that of in

Figure 8c, which mean the corresponding signal

FW1S4 (see

Figure 12a) undergoes a low sampling window compared to the

FW1 (see

Figure 8a).

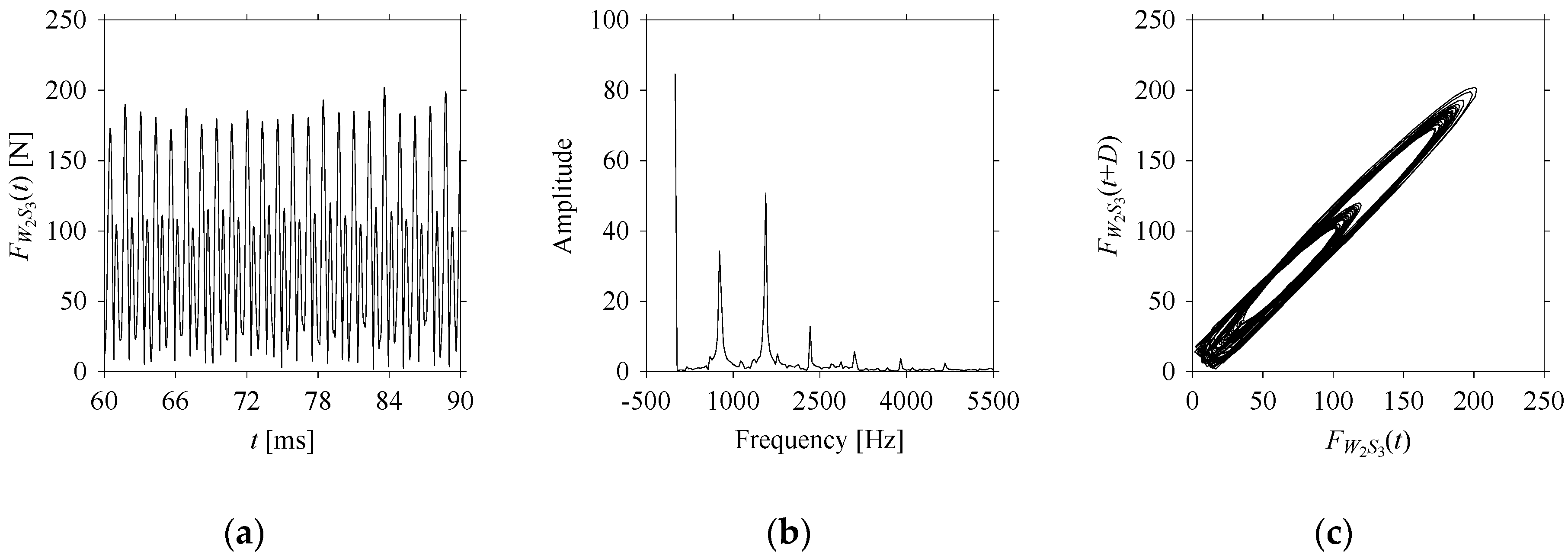

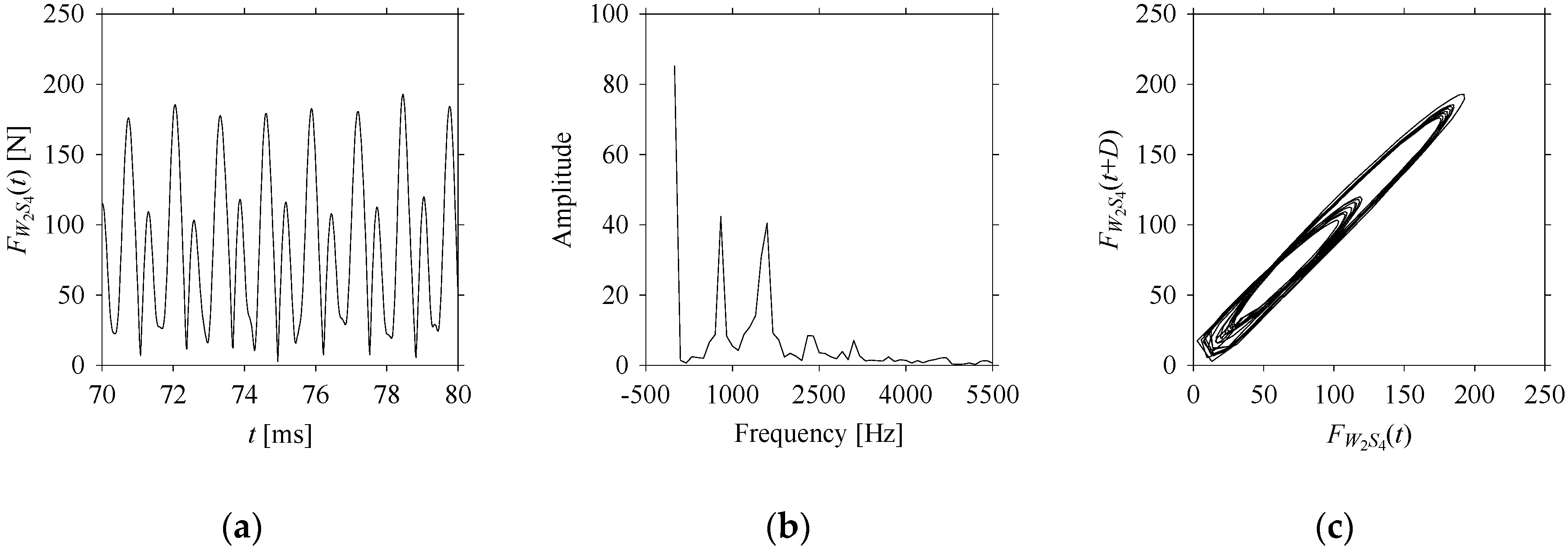

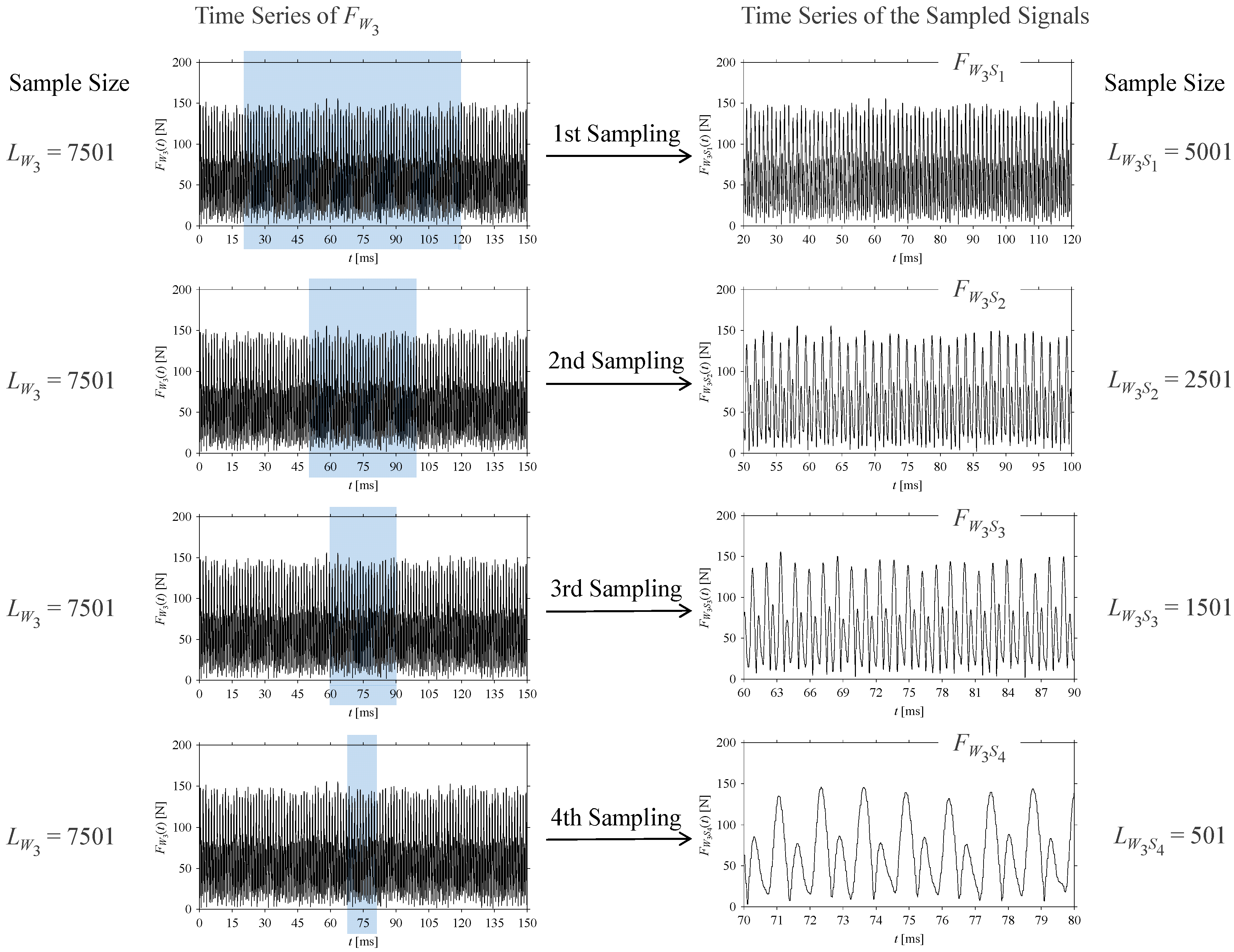

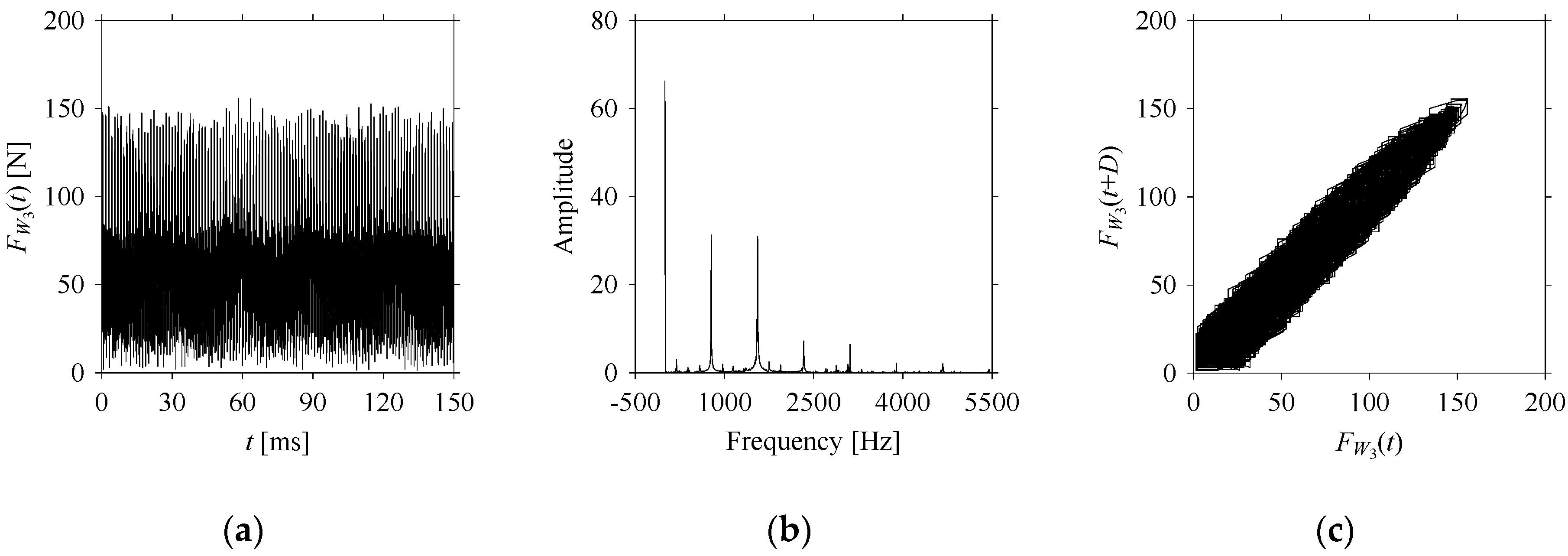

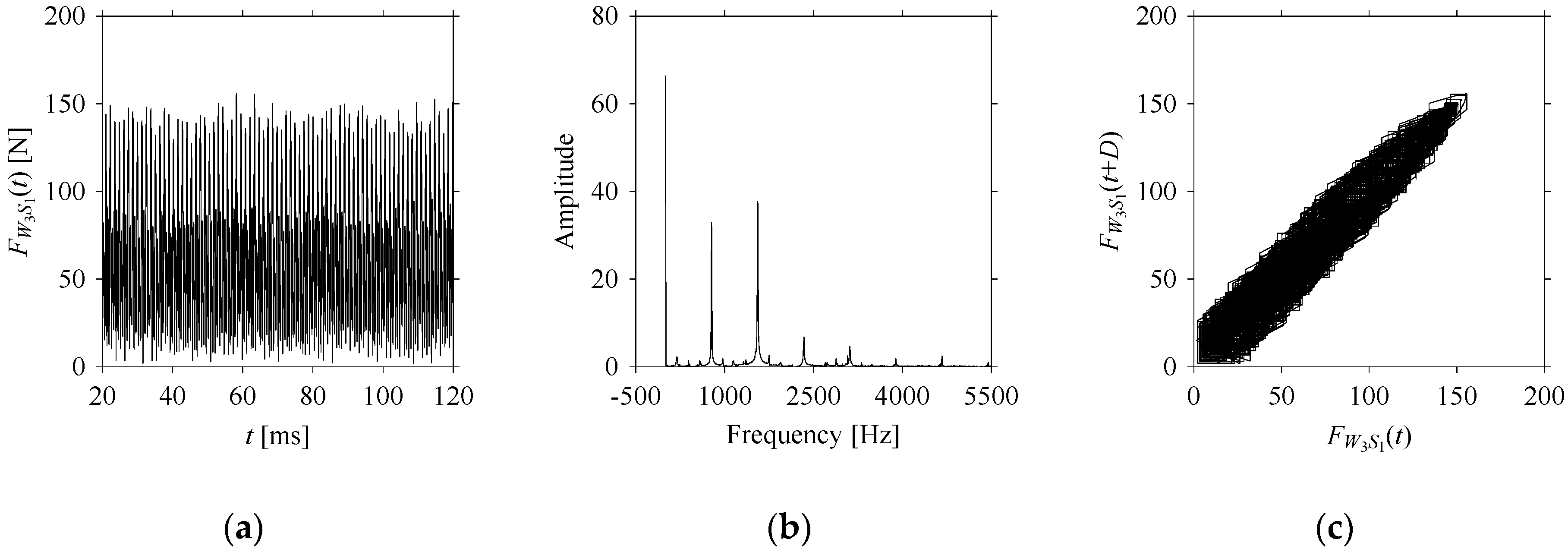

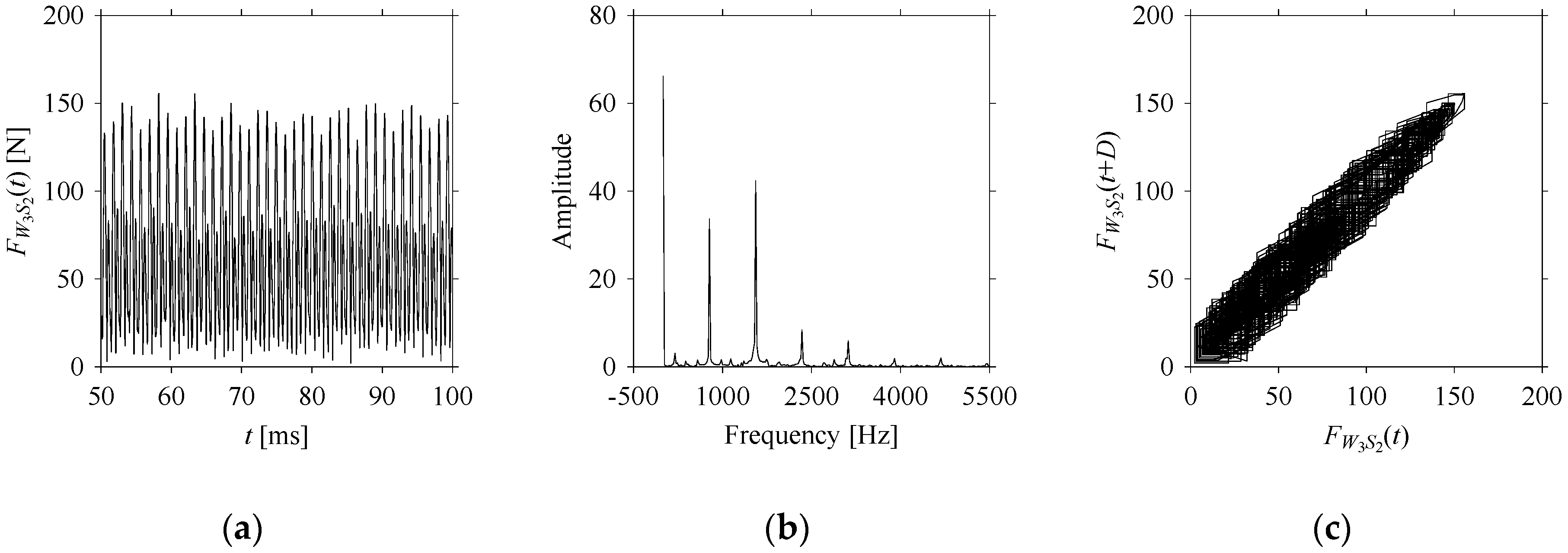

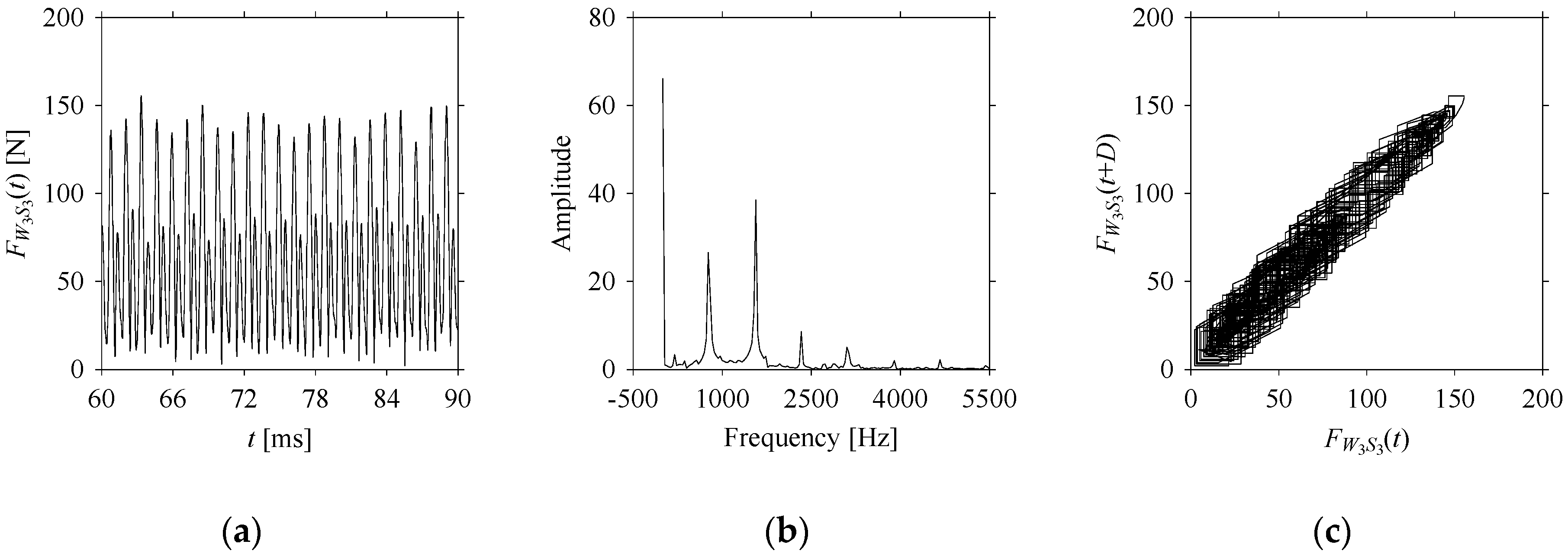

Nevertheless, similar outcomes are observed for the other two workpiece specimens, i.e.,

W2 = mild steel (S15CK) and

W3 = ductile cast iron (FCD), as described in

Appendix B and

Appendix C, respectively.

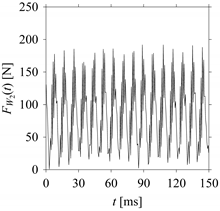

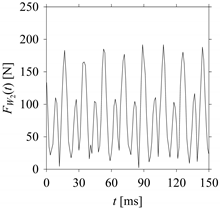

4.2. Analyzing Sensor Signals under Different Time Latencies

Consider the cutting force signal obtained while machining stainless steel (SUS304), i.e.,

FW1(

t),

t = 0, Δ

t, 2Δ

t, …,

m × Δ

t (which can also be seen in

Figure 6). As mentioned before, here Δ

t is the sampling period of 0.02 ms. To incorporate time latency or delay, Δ

t is increased using the delay parameter

d (non-zero integer), such as

d × Δ

t. For example, for

d = 1, the sampling period remains 1 × 0.02 = 0.02 ms; for

d = 2, the sampling period becomes 2 × 0.02 = 0.04 ms; and alike. As mentioned in

Section 3,

d × Δ

t is simplified using

D, where

D =

d × Δ

t. As such, a set of time series is generated using

D where

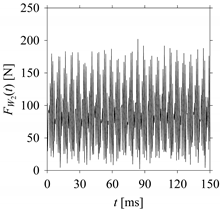

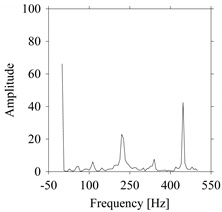

d = 1, 2, …. The goal is to understand the dynamics underlying the cutting force. For this, the time series datasets are transferred to the frequency domains (using FFT) and corresponding delay domains.

Table 2 shows the outcomes for some of the delays, i.e.,

d = 1, 5, 10, 20, 30, 40, 50, and 60.

As seen in

Table 2, when

d increases, the frequency information underlying the

FW1 gets affected. The prominent frequencies (see the FFT diagram for

d = 1) are gradually lost due to aliasing [

30] when

d > 5 (see the FFT diagrams for

d = 10, 20, 30, 40, 50, and 60).

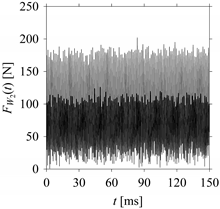

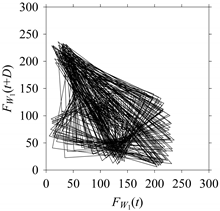

On the other hand, consider the delay maps consisting of the points (

FW1(

t),

FW1(

t+

D)) shown in

Table 2. When

d = 1, the delay map exhibits a very systematic pattern. When

d increases, the delay maps get more and more scattered (see the delay maps for

d = 5, 10, 20, 30, 40, and 50). This means that the signal gets more and more chaotic due to the presence of delay. However, when

d = 60, the corresponding delay map is somewhat systematic and similar to that of

d = 5. This means that the underlying natures of these two signals are similar, regardless of the difference in the sampling rate. It is worth mentioning that the corresponding FFTs (see the FFTs for

d = 5 and

d = 60 shown in

Table 2) are different and do not preserve the nature of the source signal. As such, delay domain-based representation is more informative for understanding the underlying nature of

FW1 under a low data acquisition rate due to time latency.

Nevertheless, similar outcomes are observed for the other two workpiece specimens, i.e.,

W2 = mild steel (S15CK) and

W3 = ductile cast iron (FCD), as described in

Appendix D and

Appendix E, respectively.

To summarize, as seen in

Table 3, real-life cutting force signals collected while machining different materials (stainless steel, mild steel, and ductile cast iron) are analyzed in the frequency and delay domains. This time, both the signal window and the amount of delay are varied to see their effect on signal processing. In the case of the signal window, it is found that both frequency and delay domains are effective for understanding the signals’ original nature for a larger window. On the other hand, the delay domain is more effective for smaller windows than the frequency domain. This is because frequency information gets lost or distorted when the sample size is smaller, whereas the delay domain retains the dynamics associated with the signals regardless of the sample size. In the case of varying delay, it is found that when delay increases, the frequency spectrum gets affected. The prominent frequencies of the original signal are gradually lost due to aliasing when the delay exceeds a critical value. On the other hand, when the delay increases, the delay domain gets more and more scattered. Furthermore, for some critical values of delay (one may be very high and the other may be very low), the delay domains exhibit similar characteristics, which is not the case for the frequency domains. Thus, when a very short window or low sampling rate (high delay) is used to analyze a signal, delay domains guarantee its (signal’s) original nature. This means that the delay domain-based representation is more robust in understating the nature of a sensor signal subjected to high time latency, a common phenomenon in Industry 4.0-relevant manufacturing environments.

5. Distinguishing Machining Situations Using Delay Maps

When machining is performed, the whole process undergoes different stages or situations. For example, at the onset and completion of machining, the cutting tool remains idle. Between the onset and completion, the tool machines the workpiece using a set of predefined cutting conditions. During cutting, the cutting conditions can be changed depending on the geometry or material of the workpiece. This creates the following situations: idle, idle to cutting, cutting with different cutting conditions/materials, cutting to idle, and idle. During this situation, an abnormality may happen (breakage of a tool, chatter vibration, and alike), adding other situations in the whole process. The Industry 4.0-centric systems must understand these situations on a real-time basis from sensor signals. Furthermore, the systems must coordinate among all machines under consideration and decide the right courses of action. Otherwise, the safety, economy, and quality of the other planning activities (e.g., maintenance scheduling) cannot be ensured [

45]. Since delay maps effectively understand a signal’s hidden characteristics even though the signals are subjected to time latency, and the signal sampling window is a short one (as shown in

Section 3 and

Section 4), these maps can be employed to distinguish different machining situations. This section explores this possibility showing the efficacy of the delay domain. For the sake of better understanding,

Section 5.1 describes the machining experiment and sensor signal acquisition. Afterward,

Section 5.2 describes the pre-processing of the acquired signal. Finally,

Section 5.3 describes the frequency and delay domain-based signal processing and the obtained results.

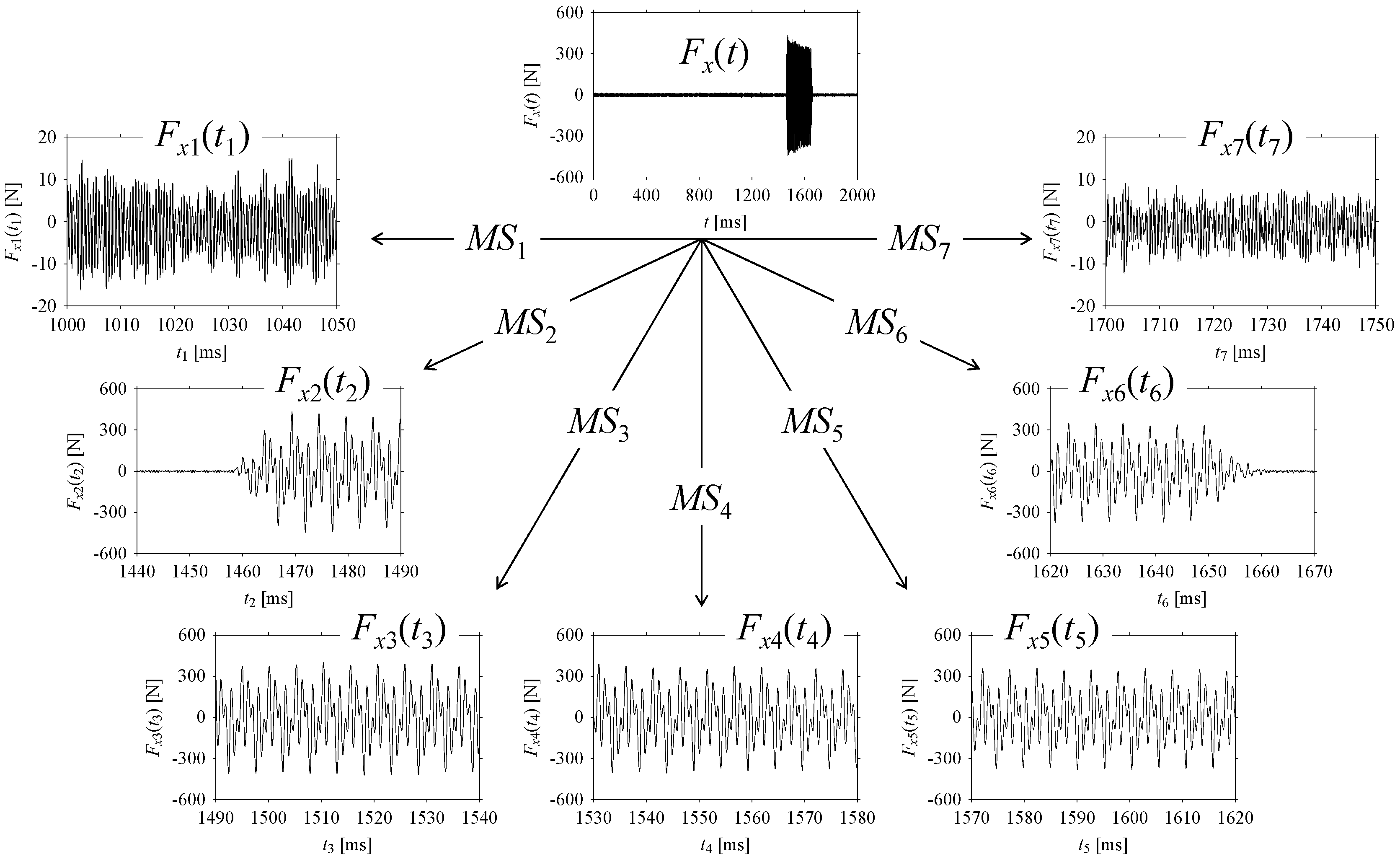

5.1. Sensor Signal Acquisition

As seen in

Figure 13, a multi-material workpiece made of stainless steel (JIS: SUS304) and mild steel (JIS: S15CK) is machined following an end milling process. The machining conditions are summarized in

Table 4. The reasons for choosing a multi-material workpiece over a mono-material workpiece are as follows: (1) the usage of multi-material objects is increasing because these perform better in terms of material efficiency compared to their mono-material counterparts [

44,

46], and (2) Machining a multi-material object underlies more complex machining situations compared to machining a mono-material object.

However, the multi-material workpiece is machined from the hard-to-soft material direction (i.e., SUS304 to S15CK), as shown in

Figure 13. As such, the machining involves a set of machining situations, denoted as

MS, ∀

MS ∈ {

MS1, …,

MS7}. Here,

MS1 denotes the situation when the cutting tool is idle just before the machining.

MS2 denotes the transition from an idle state to a machining state.

MS3 denotes the machining of SUS304 segment.

MS4 denotes the machining of the joint area (heat-affected area while joining SUS304 and S15CK).

MS5 denotes the machining of S15CK segment.

MS6 denotes the transition from a machining state to an idle state. Finally,

MS7 denotes the situation when the tool is idle after completing the machining.

While the cutting tool is passed through the abovementioned situations, the corresponding machining force signals are recorded using a rotary dynamometer (as reported in

Table 4). Let

Fo be the raw force signals, ∀

o ∈ {

x,

y,

z}. Here,

Fx,

Fy, and

Fz refer to the force signals along the

x-axis,

y-axis, and

z-axis, respectively. The force signals in the

x-axis, i.e.,

Fx, are reported here.

Figure 14 shows its time series, such as

Fx(

t),

t = 0, Δ

t, 2Δ

t, …. Here, Δ

t is a sampling period of 0.02 ms.

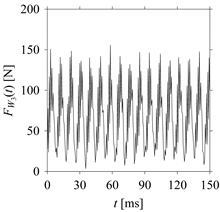

5.2. Signal Pre-Processing

As seen in

Figure 15,

Fx(

t) is sampled to seven (7) fragments based on the abovementioned machining situations (

MS). The fragments are denoted as

Fx1(

t1), …,

Fx7(

t7) corresponding to

MS1, …,

MS7, respectively. The sampling spans for

Fx1(

t1), …,

Fx7(

t7) are as follows:

t1 = [

tstart,

tend] = [1000,1050] ms,

t2 = [

tstart,

tend] = [1440,1490] ms,

t3 = [

tstart,

tend] = [1490,1540] ms,

t4 = [

tstart,

tend] = [1530,1580] ms,

t5 = [

tstart,

tend] = [1570,1620] ms,

t6 = [

tstart,

tend] = [1620,1670] ms, and

t7 = [

tstart,

tend] = [1700,1750] ms, respectively. Note that each fragment consists of 2501 samples.

Nevertheless, the sampled fragments (Fx1(t1), …, Fx7(t7)) are analyzed in the frequency and delay domains for distinguishing the corresponding machining situations (MS1, …, MS7).

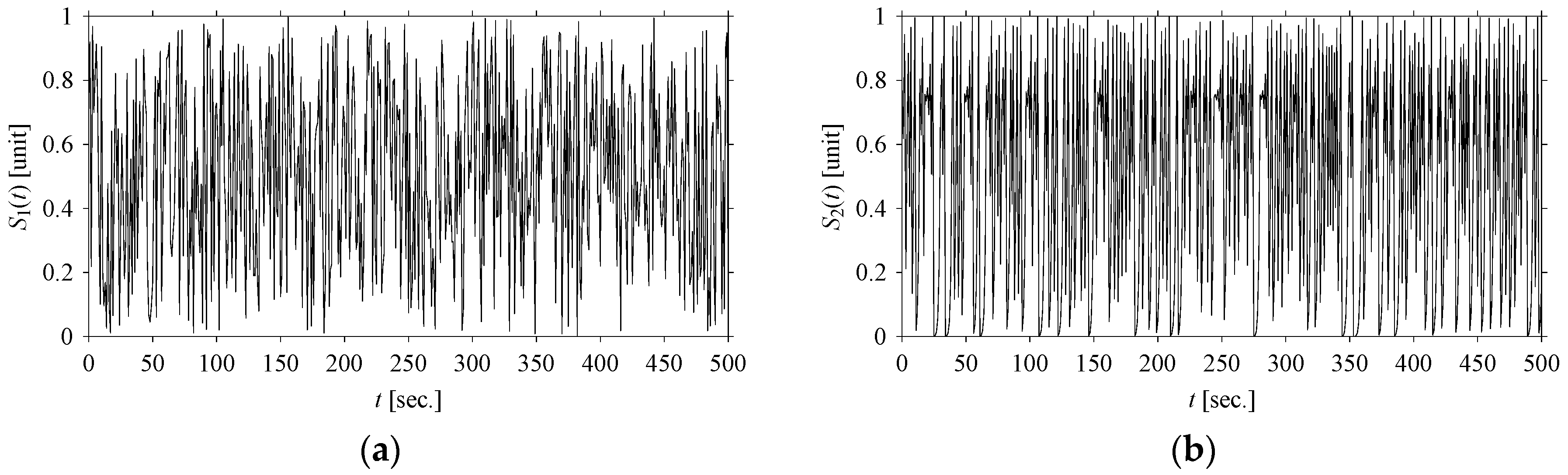

5.3. Analysis in the Frequency and Delay Domains

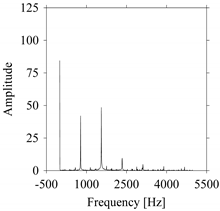

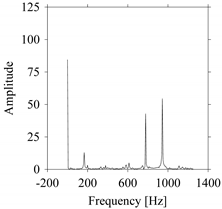

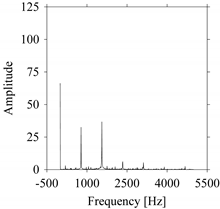

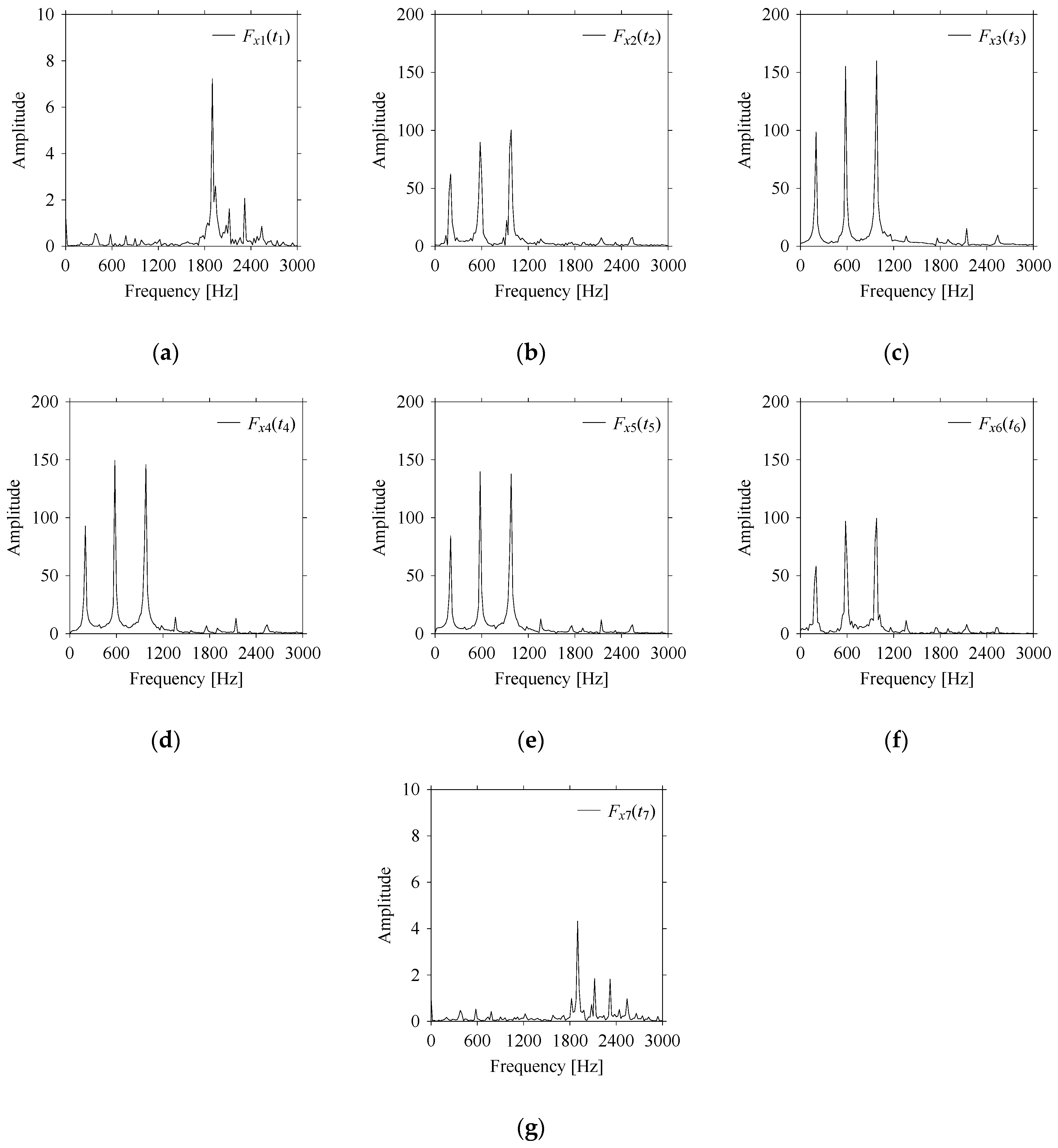

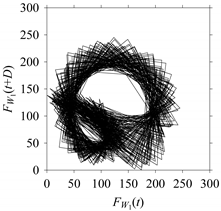

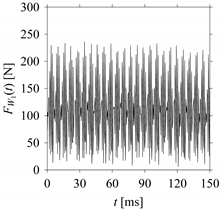

First, consider the frequency domain-based analysis.

Figure 16a–g shows the frequency domain representations (FFT) of

Fx1(

t1), …,

Fx7(

t7) corresponds to

MS1, …,

MS7, respectively.

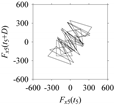

As seen in

Figure 16a,g, the frequency components underlying

Fx1(

t1) and

Fx7(

t7) are the same, respectively. These frequency components are different from the frequency components underlying

Fx2(

t2), …,

Fx6(

t6), as shown in

Figure 16b–f, respectively. In addition, the frequency components underlying

Fx2(

t2), …,

Fx6(

t6) are the same (see

Figure 16b–f, respectively). This means that the frequency domain-based analysis is effective only for distinguishing the situations

MS1 (underlying

Fx1(

t1)) and

MS7 (underlying

Fx7(

t7)) from others (

MS2, …,

MS6 underlying

Fx2(

t2), …,

Fx6(

t6), respectively). It is not effective for distinguishing the situations

MS2, …,

MS6 (underlying

Fx2(

t2), …,

Fx6(

t6), respectively) from each other.

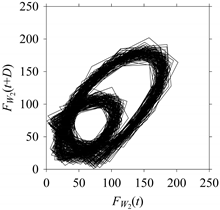

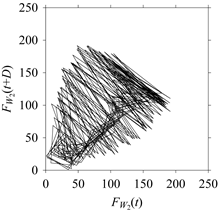

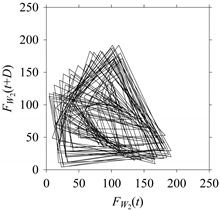

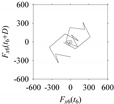

Now, consider the delay domain-based analysis. For this, a set of delay maps are constructed for each signals

Fx1(

t1), …,

Fx7(

t7) by varying the delay parameter

d = 1, …, 100. Note that the delay maps are generated following the methodology described in

Section 3 (which can also be seen in

Section 4.2).

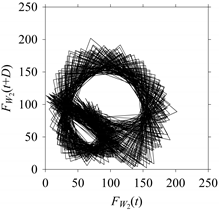

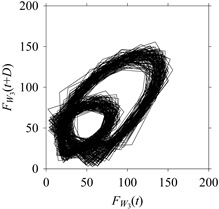

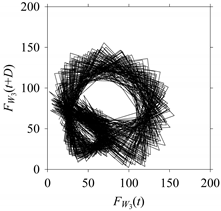

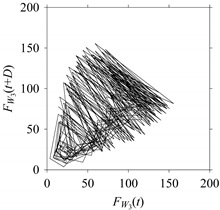

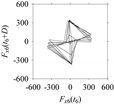

Table 5 shows some of the delay maps corresponding to

d = 1, 2, 5, 50, and 100.

As seen in

Table 5, the delay maps of

Fx1(

t1), …,

Fx7(

t7) exhibit similar patterns when

d is very small (

d = 1 and 2). The maps become more and more chaotic with the increase in

d, as observed in

Table 5. For some specific delay parameter values, a delay map corresponding to a given machining situation exhibits a distinct pattern, although it is not usually the case. Nevertheless, the specific values of delay for which each delay map exhibits a distinct pattern are valuable for Industry 4.0-centric systems. In this case, the systems make a one-to-one correspondence between a given machining situation and its delay map, which is ideal for pattern recognition. This means that a delay map can be a signature of a machining situation. For example, for the signals reported in

Figure 15, the delay maps exhibit unique patterns when

d = 43, as shown in

Table 6. In other words, the delay maps corresponding to

d = 43 are the signatures of the machining situations

MS1, …,

MS7.

6. Concluding Remarks

This study elucidates the implications of time latency or delay in signal processing from the perspective of smart manufacturing. In smart manufacturing, signal processing frameworks mostly follow time and frequency analyses. In addition, there is no systematic study from the viewpoint of manufacturing practices where delay-related issues are addressed adequately. This study fills this gap by analyzing manufacturing-centric sensor signals (cutting force signals) in the delay domain in addition to time and frequency domains.

This study first studies two arbitrary chaotic signals that look alike in the time and frequency domains. However, their differences could not be understood delay until they are represented in the delay domain. This means that the delay domain must be incorporated to make sense of chaotic sensor signals. Chaotic sensor signals are common in smart manufacturing.

In the next step, real-life sensor signals relevant to manufacturing, particularly cutting force signals collected while machining different materials (stainless steel, mild steel, and ductile cast iron), are analyzed in frequency and delay domains. This time, both signal window and the amount of delay are varied to see their effect on signal processing. It is found that when delay increases, the frequency spectrum gets affected. The prominent frequencies of the original signal are gradually lost due to aliasing when the delay exceeds a critical value. On the other hand, when the delay increases, the delay domain gets more and more scattered. For some critical values of delay (one may be very high and the other may be very low), the delay domains exhibit similar characteristics, which is not the case for the frequency domains. Thus, when a very short window or low sampling rate (high delay) is unavoidable, the delay domains guarantee its (signal’s) original nature. This means that the delay domain-based signal processing is more robust in understating the nature of a sensor signal subjected to high time latency.

Lastly, the potential of the delay domain becoming a signature of a machining situation is studied using real-life signals. For this, sensor signals are sampled exhibiting seven different machining situations. The situations represent the onset of machining, completion of machining, machining of different materials, and transitions situations. For some specific delays, the delay maps make one-to-one correspondence with machining situations. This means that a delay domain of a machine situation is different from the delay domains of other machining situations for a critical delay. Consequently, a delay domain can be used as a signature of a machining situation.

In synopsis, computational arrangements enabling delay domain-based signal processing must accompany the smart manufacturing-centric embedded systems because such systems (CNC machine tools, PLC, robots, digital measuring instruments, cyber-physical systems, and digital twins) are subjected to acute time latency.

Thus, the outcomes of this study contribute to the advancement of smart manufacturing.