Image Processing Technique for Improving the Sensitivity of Mechanical Register Water Meters to Very Small Leaks †

Abstract

:1. Introduction

- (i)

- The daily or weekly users’ consumption profiles are the basis for most leakage detection algorithms developed in recent years. However, a water leak can be sudden or small: while the former generates a significant detachment from the consumption profile, the latter often is submerged in the “floor” of small intakes. For this reason, to develop a new algorithm able to deal with small water leaks, useful metrics must be defined.

- (ii)

- There are two principal categories of water sensors: mechanical or static. Usually, mechanical water sensors are based on pistons or turbines, providing starting flow rates ranging from 1 L/h to 12 L/h. This aspect has a significant impact on the performance of small leakage detection aims. On the other hand, static sensors are mainly electronic devices based on ultrasound. An important aspect is that static sensors provide digital output data, while the mechanical ones run digits and needles on a hardware register.

- (iii)

- To feed the water leaks detection algorithm with valuable data about the phenomena, the water meters must have smart capabilities and be integrated into a communication network. While static meters are electronic digital devices, mechanical water meters need an electronic add-on device to count magnetic pulses or obtain other consumption readings. In addition, the coverage range and bandwidth of the wireless communication channel must be appropriately chosen to satisfy application requirements.

- (iv)

- Long-life batteries must power smart water meters, resulting in weight and dimensions compatible with domestic applications. Data processing and communication features must deal with these rigid constraints.

2. Smart Add-on Device for Classical Mechanical Register

- The camera module is an OV7670 provided by a low voltage CMOS image sensor. In a tiny footprint, it allows all the functionality of a single-chip image processor and VGA camera. The OV7670 makes available full-frame, sub-sampled, or windowed 8-bit pictures in different formats. The module is controlled via the Serial Camera Control Bus (SCCB) interface. The raw output image can be transferred to a suitable microcontroller using the Digital Camera Module Interface (DCMI). In addition, the consumption of the camera module is low: considering a 30 fps, its current consumption is less than 20 mA at 3 V in the active state and less than 100 μA in standby.

- The processing unit employed is a high-performance microcontroller STM32F4. It belongs to a microcontrollers’ family based on the general-purpose ARM®Cortex®-M4. The STM32F4 is widely employed in many fields such as entertainment, powertrain, industrial automation, etc. In more detail, the microcontroller is based on a RISC core architecture at 32-bit operating up to 168 MHz. In addition, the Cortex M4 core implements full DSP set instructions and provides a Floating-Point Unit (FPU) single precision. The microcontroller offers, in addition, three 12-bit ADCs, two DACs, one SCCB, and one DCMI. Its memory features include a high-speed Flash memory RAM of up to 1 Mbyte and an SRAM of up to 192 Kbytes.

- The hardware responsible for the low-range communication is in charge of the transceiver CC1120 manufactured by Texas Instruments, with the power front-end module SKY65367-11 manufactured by SKYWORKS. The CC1120 transceiver conforms with EN 13757-4:2013 standard, regulating in a short-range network the WM-Bus operation. In more detail, the prototype has been set up to operate at maximum transfer power in N2a mode. In addition, the SKY65367-11 has been adapted to enhance the power provided to the antenna at up to 27 dBm.

- The smart add-on is battery-powered, utilizing two low discharge lithium batteries at a total capacity of 7000 mAh (3.6 V).

3. Image Processing Techniques and Metrics

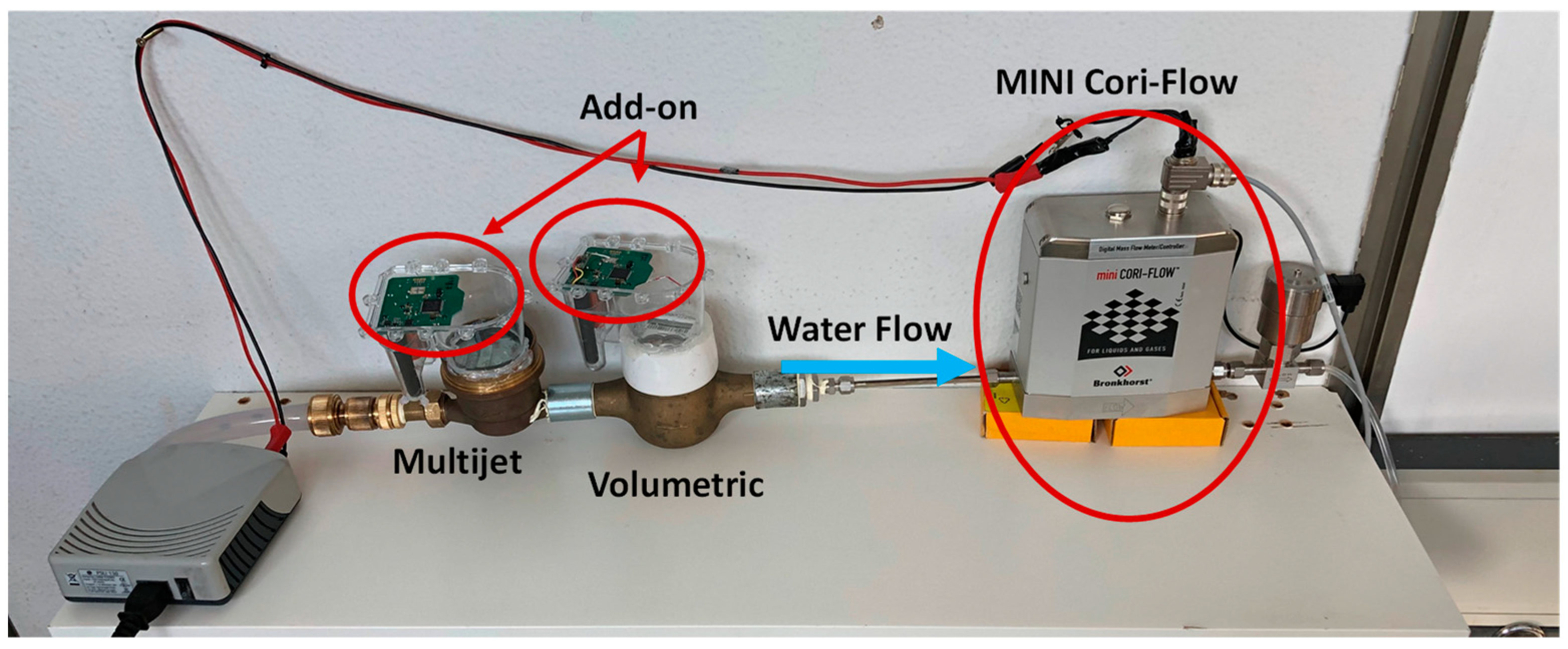

4. The Test Rig

4.1. The Measurement System

4.2. The Water Meters

5. Experimental Results

5.1. Static Profile

5.2. Dynamic Profile

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gato-Trinidad, S.; Jayasuriya, N.; Roberts, P. Understanding urban residential end uses of water. Water Sci. Technol. 2011, 64, 36–42. [Google Scholar] [CrossRef] [PubMed]

- Gabaldon, A.; Molina, R.; Marin-Parra, A.; Valero-Verdu, S.; Álvarez, C. Residential end-uses disaggregation and demand response evaluation using integral transforms. J. Mod. Power Syst. Clean Energy 2017, 5, 91–104. [Google Scholar] [CrossRef] [Green Version]

- Farah, E.; Shahrour, I. Smart water for leakage detection: Feedback about the use of automated meter reading technology. In Proceedings of the 2017 Sensors Networks Smart and Emerging Technologies (SENSET), Beiriut, Lebanon, 12–14 September 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Mudumbe, M.J.; Abu-Mahfouz, A.M. Smart water meter system for user-centric consumption measurement. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; pp. 993–998. [Google Scholar] [CrossRef]

- Purwar, A.; Patel, M.; Garg, M.; Ahuja, K. A Novel Approach for Water Leakage Detection and Localization. In Proceedings of the 2018 7th International Conference on Reliability, Infocom Technologies and Optimization (Trends and Future Directions) (ICRITO), Noida, India, 29–31 August 2018; pp. 373–377. [Google Scholar] [CrossRef]

- Boudhaouia, A.; Wira, P. Water Consumption Analysis for Real-Time Leakage Detection in the Context of a Smart Tertiary Building. In Proceedings of the 2018 International Conference on Applied Smart Systems (ICASS), Medea, Algeria, 24–25 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Al Qahtani, T.; Yaakob, M.S.; Yidris, N.; Sulaiman, S.; Ahmad, K.A. A Review on Water Leakage Detection Method in the Water Distribution Network. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 68, 152–163. [Google Scholar] [CrossRef]

- Available online: https://leakdefensesystem.com/2019/05/26/commercial-leak-detection-system/ (accessed on 27 October 2021).

- Available online: https://www.cmrelectrical.com/products/breeam-water-leak-detection-systems/water-leak-watch-for-houses-and-flats/ (accessed on 27 October 2021).

- Available online: https://fois.com/water-leak-detection/ (accessed on 27 October 2021).

- Available online: https://www.bartec.de/en/products/heating-technology/water-detection/monitoring/ (accessed on 27 October 2021).

- Available online: https://www.moen.com/products/Flo-by-Moen/Flo-by-Moen-3-4-Smart-Home-Water-Monitoring-And-Leak-Detection-System/900-001 (accessed on 27 October 2021).

- Ferrigno, L.; Pietrosanto, A.; Paciello, V. Low-cost visual sensor node for bluetooth-based measurement networks. IEEE Trans. Instrum. Meas. 2006, 55, 521–527. [Google Scholar] [CrossRef]

- Di Leo, G.; Liguori, C.; Paciello, V.; Pietrosanto, A.; Sommella, P. Smart meters in smart cities: An application of DLMS-COSEM on 169 MHz WM-Bus. In Advanced Computer and Communication Engineering Technology; Springer: Cham, Switzerland, 2016; Volume 362, pp. 735–746. [Google Scholar]

- Carratù, M.; Ferro, M.; Pietrosanto, A.; Sommella, P. Adopting smart metering RF networks for particulate matter distributed measurements. In Proceedings of the 7th IMEKO TC19 Symposium on Environmental Instrumentation and Measurements (EnvIMEKO 2017), Aguascalientes, Mexico, 3–4 August 2017; pp. 50–55. [Google Scholar]

- Pietrosanto, A.; Carratù, M.; Liguori, C. Sensitivity of Water Meters to Small Leakage. Measurement 2021, 168, 108479. [Google Scholar] [CrossRef]

- Abate, F.; Carratù, M.; Liguori, C.; Pietrosanto, A. Smart meters and water leakage detection: A preliminary study. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; pp. 1–6. [Google Scholar]

- Carratù, M.; Iacono, S.D.; Di Leo, G.; Liguori, C.; Pietrosanto, A. Image based similarity detection in mechanical registers. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Mojsilovic, A.; Hu, H.; Soljanin, E. Extraction of perceptually important colors and similarity measurement for image matching, retrieval and analysis. IEEE Trans. Image Process. 2002, 11, 1238–1248. [Google Scholar] [CrossRef] [PubMed]

- Di Leo, G.; Liguori, C.; Paolillo, A.; Pietrosanto, A. Machine vision systems for on line quality monitoring in industrial applications. Acta IMEKO 2015, 4, 121–127. [Google Scholar] [CrossRef]

- Long, F.; Zhang, H.; Feng, D.D. Fundamentals of Content-Based Image Retrieval. In Multimedia Information Retrieval and Management; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Available online: https://www.bronkhorst.com/int/products/liquid-flow/mini-cori-flow/m15/ (accessed on 27 October 2021).

- Jakubczyk-Galczynska, A.; Jankowski, R. Traffic-induced vibrations. The impact on buildings and people. In Proceedings of the 9th International Conference on Environmental Engineering, Vilnius, Lithuania, 22–23 May 2014. [Google Scholar] [CrossRef] [Green Version]

| Flow range (intermediate ranges available) | min. 0.2…5 kg/h; max. 3…300 kg/h |

| Mass flow accuracy | 0.2% of rate; |

| Repeatability | Liquid: 0,2% of rate; |

| Zero stability (ZS) | 0.5% of rate ± ½(ZS * × 100/actual flow)% |

| Response time (sensor) | ≤200 ms |

| Temperature accuracy | on zero: <5 g/h/°C; |

| Density accuracy | on span: <0.001% Rd/°C; |

| METER | Size [inch] | Starting Flow [L/h] | Q1 [L/h] | Q2 [L/h] | Q3 [L/h] | Q4 [L/h] |

|---|---|---|---|---|---|---|

| Multi-jet | 1/2" | 7-8 | 15.6 | 25 | 2500 | 3130 |

| Volumetric | 1/2" | 1 | 16 | 25.6 | 1600 | 2000 |

| Multijet Water Meter | Piston Water Meter | ||||||

|---|---|---|---|---|---|---|---|

| Flow Rate [L/h] | Min (r0) | Max(σ r0w) | Flow Rate [L/h] | Min (r0) | Max(σ r0w) | ||

| Zero Flow Rate | 0 | 0.986 | 0.0002 | Zero Flow Rate | 0 | 0.987 | 0.0002 |

| Under Starting Flow Rate | 1 | 0.940 | 0.012 | Under Starting Flow Rate | 0.25 | 0.990 | 0.001 |

| 3 | 0.950 | 0.011 | 0.5 | 0.986 | 0.003 | ||

| 6 | 0.934 | 0.011 | 0.75 | 0.970 | 0.003 | ||

| Starting Flow Rate | 8 | 0.901 | 0.042 | Starting Flow Rate | 1 | 0.960 | 0.013 |

| Over Starting Flow Rate | 10 | 0.891 | 0.034 | Over Starting Flow Rate | 10 | 0.784 | 0.080 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carratù, M.; Dello Iacono, S.; Di Leo, G.; Liguori, C.; Pietrosanto, A. Image Processing Technique for Improving the Sensitivity of Mechanical Register Water Meters to Very Small Leaks. Sensors 2021, 21, 7251. https://doi.org/10.3390/s21217251

Carratù M, Dello Iacono S, Di Leo G, Liguori C, Pietrosanto A. Image Processing Technique for Improving the Sensitivity of Mechanical Register Water Meters to Very Small Leaks. Sensors. 2021; 21(21):7251. https://doi.org/10.3390/s21217251

Chicago/Turabian StyleCarratù, Marco, Salvatore Dello Iacono, Giuseppe Di Leo, Consolatina Liguori, and Antonio Pietrosanto. 2021. "Image Processing Technique for Improving the Sensitivity of Mechanical Register Water Meters to Very Small Leaks" Sensors 21, no. 21: 7251. https://doi.org/10.3390/s21217251

APA StyleCarratù, M., Dello Iacono, S., Di Leo, G., Liguori, C., & Pietrosanto, A. (2021). Image Processing Technique for Improving the Sensitivity of Mechanical Register Water Meters to Very Small Leaks. Sensors, 21(21), 7251. https://doi.org/10.3390/s21217251