Pultruded FRP Beams with Embedded Fibre Bragg Grating Optical Sensors for Strain Measurement and Failure Detection

Abstract

:1. Introduction

2. Materials and Methods

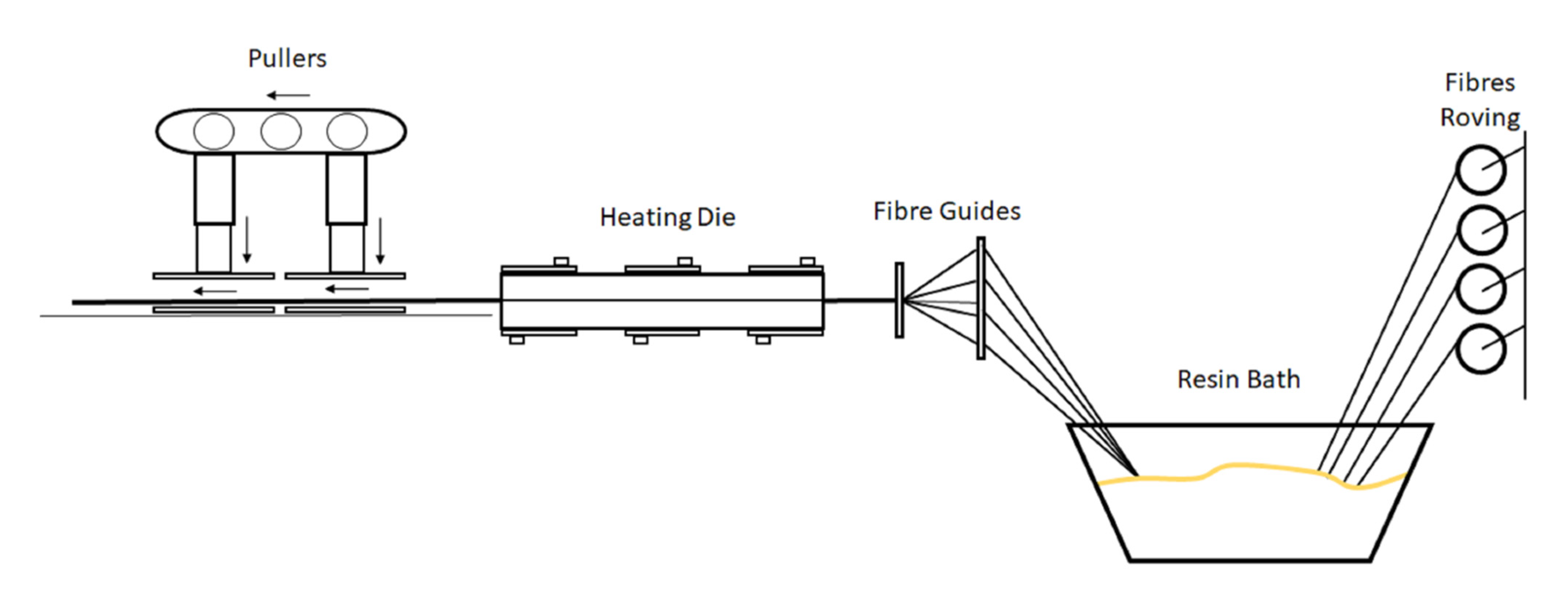

2.1. FRP Beam Fabrication

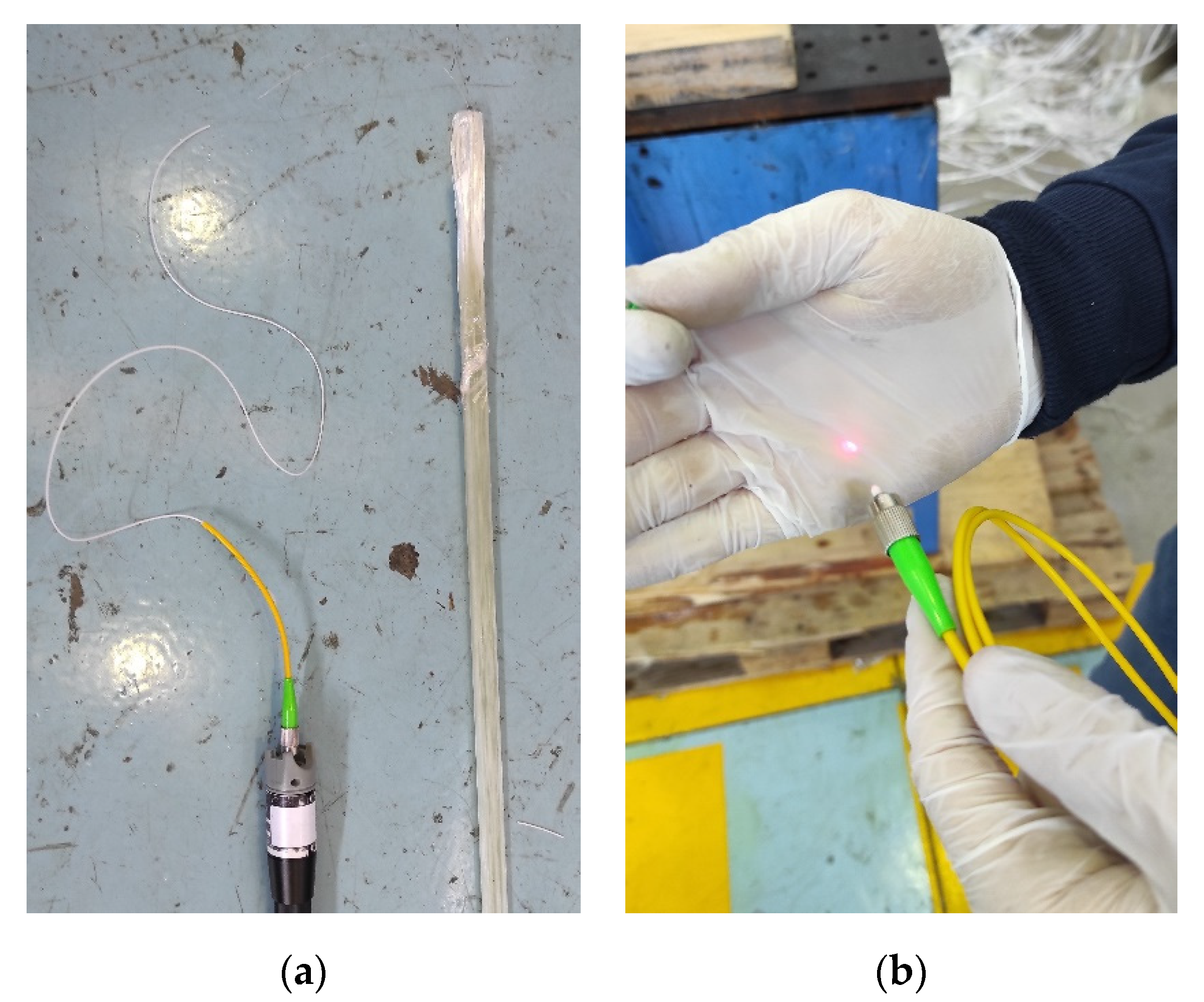

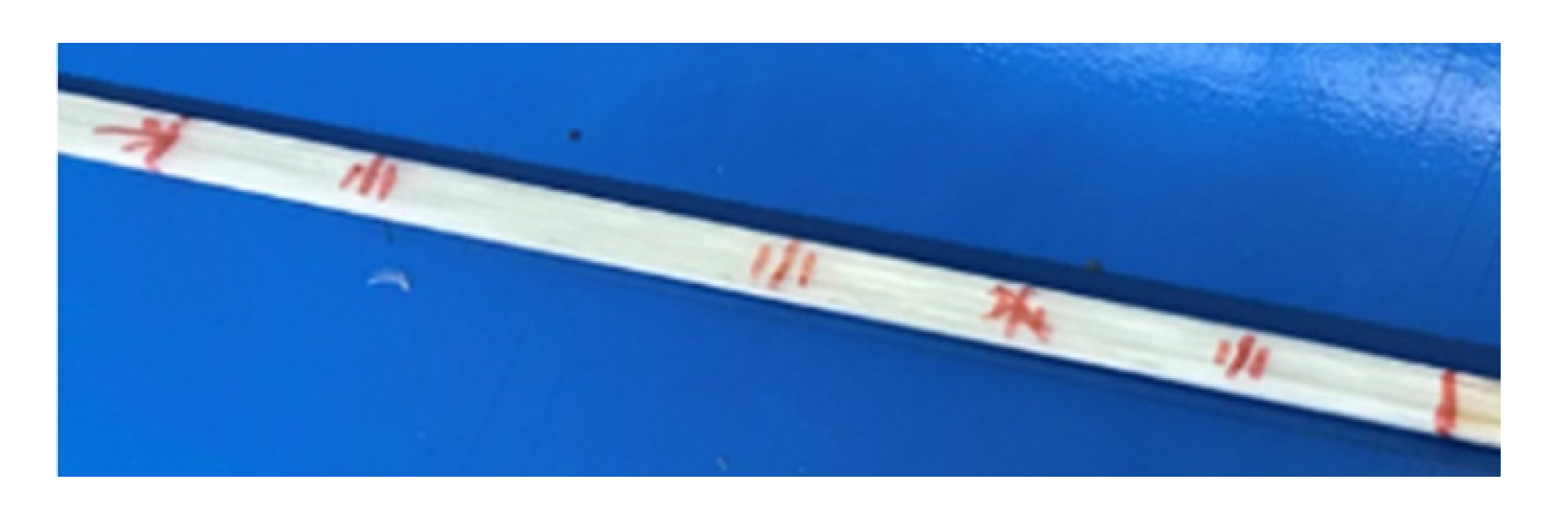

2.2. Fibre Optic Embedded Integration

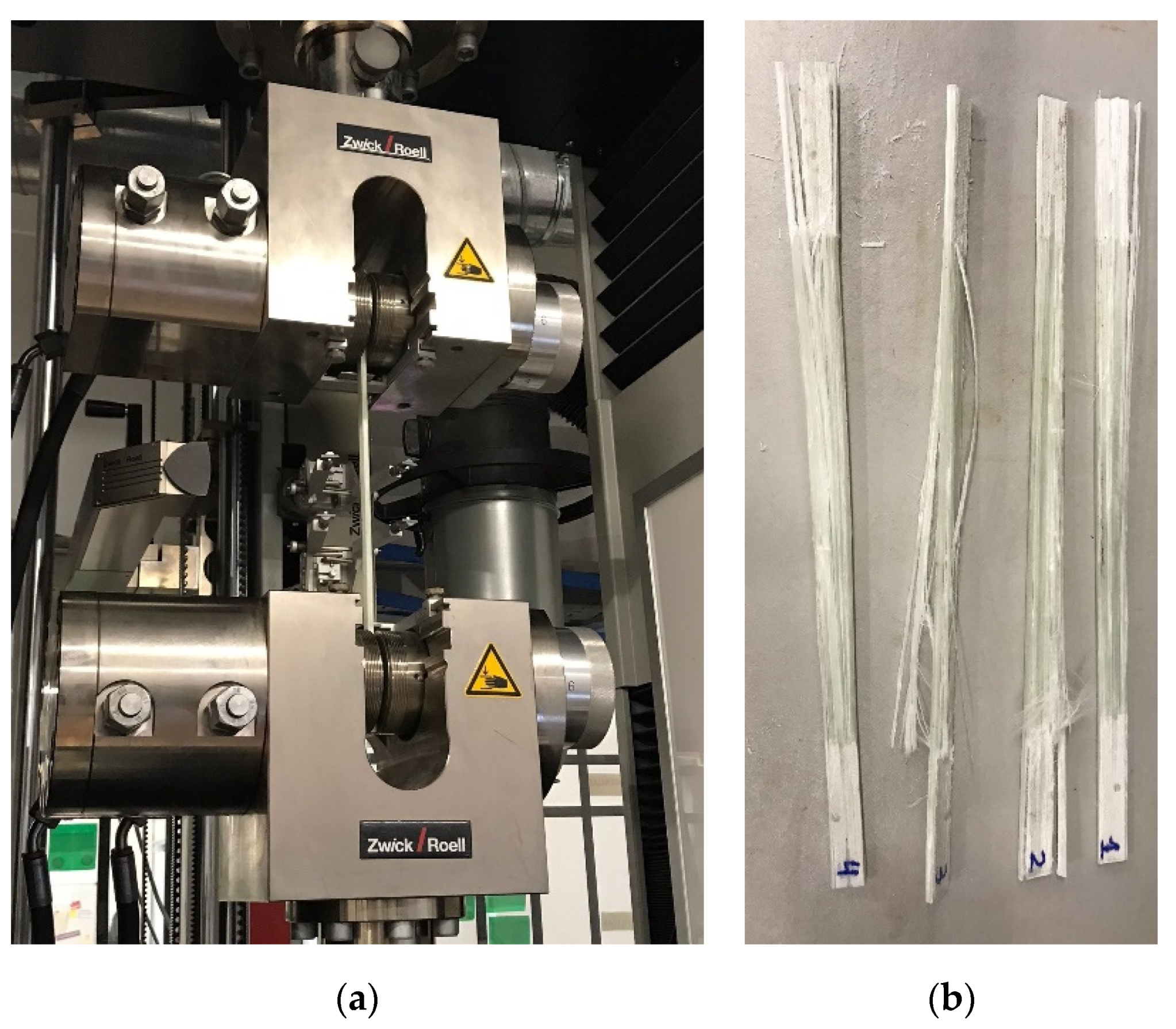

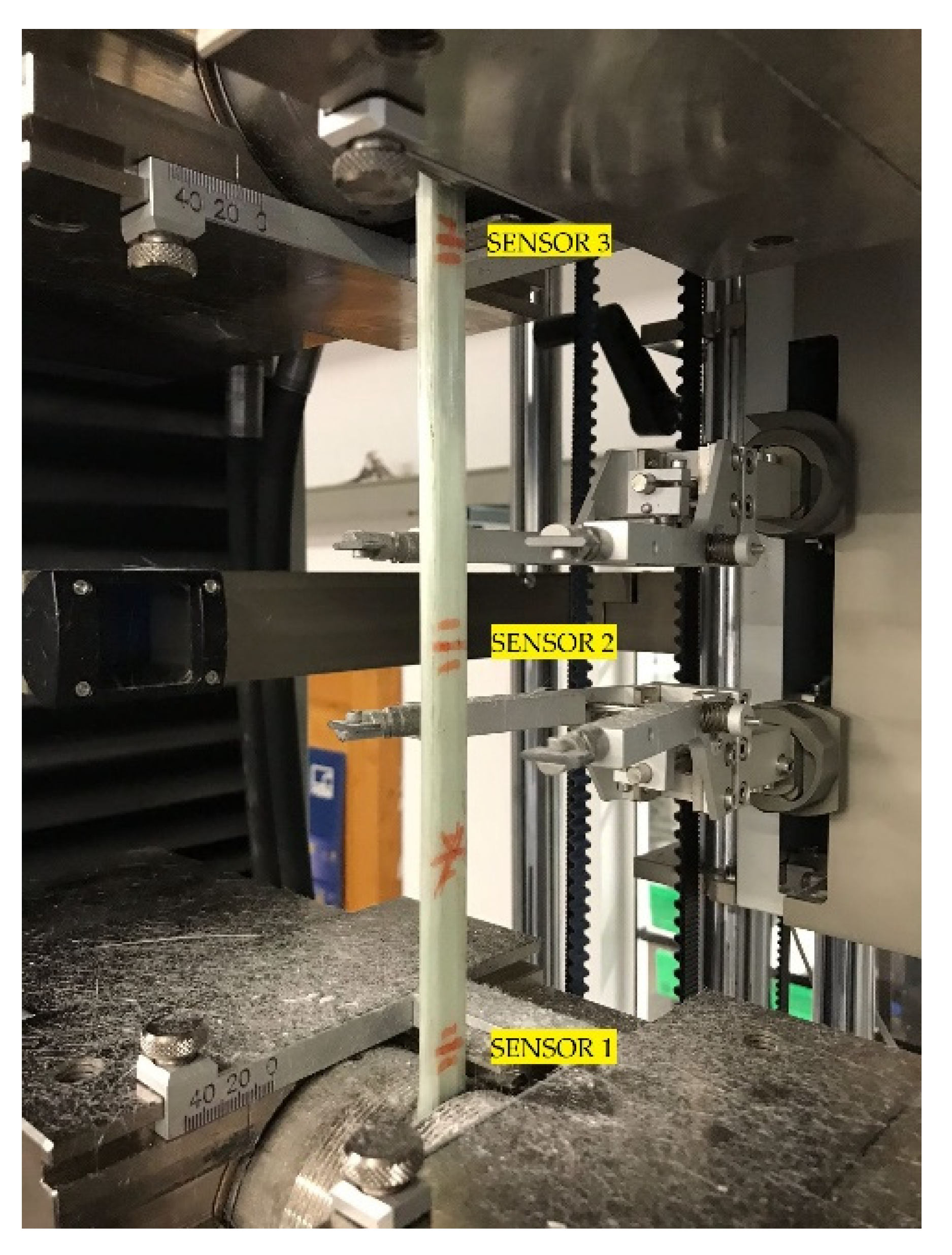

2.3. Beam Testing

2.4. FBG Strain Sensing Principle

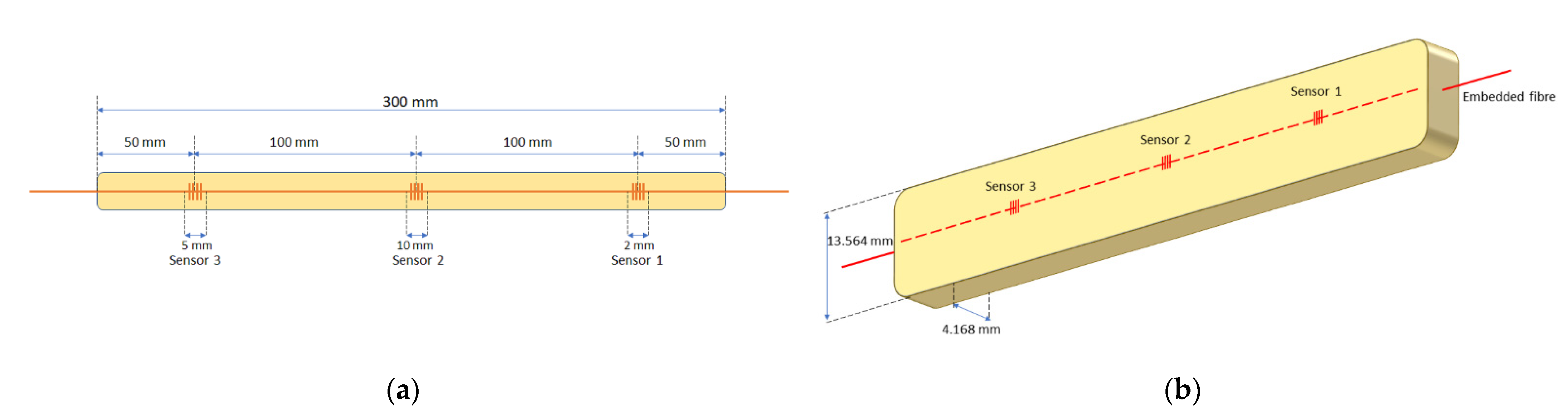

2.5. FBG Sensors Integration

3. Results

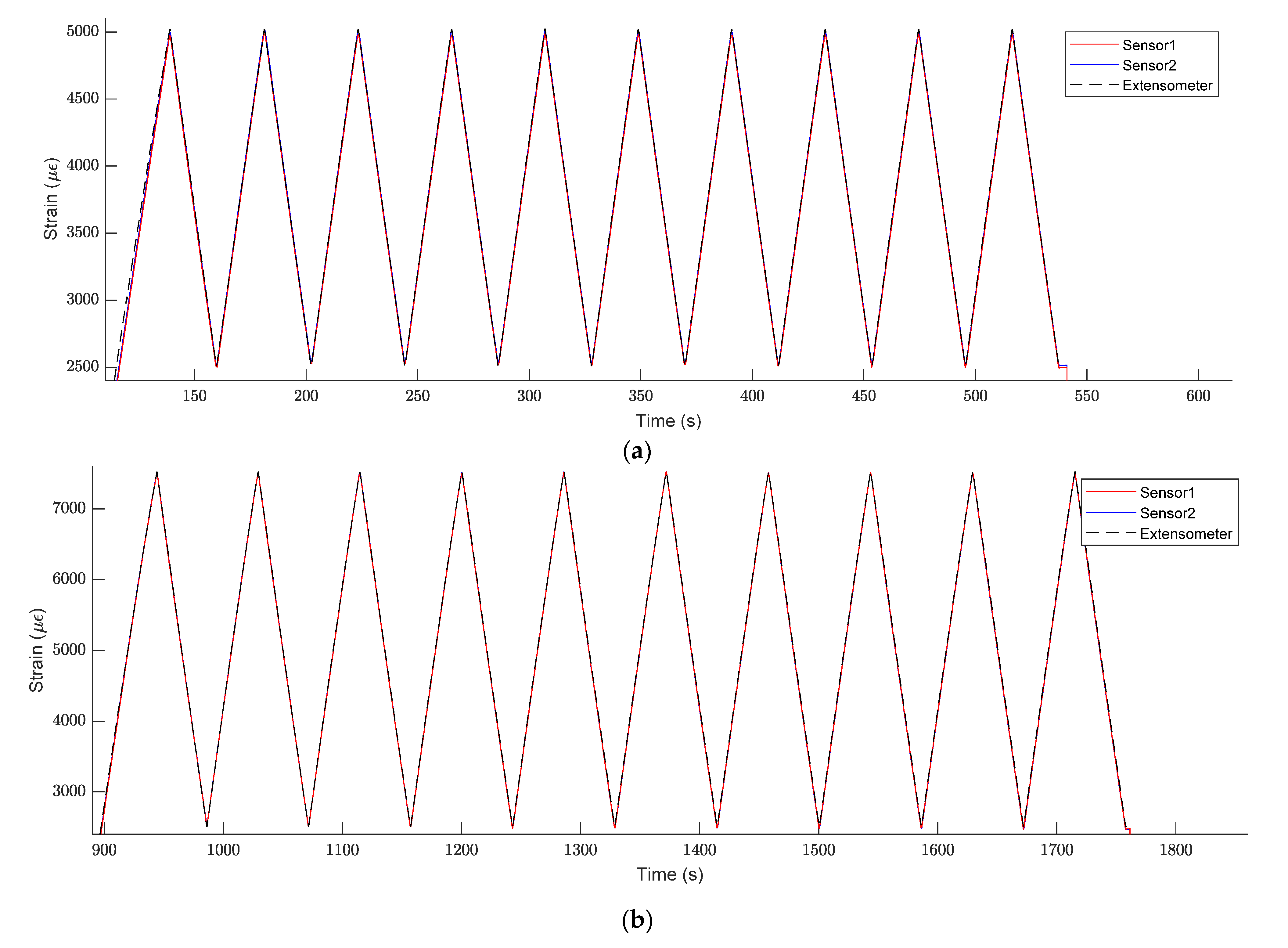

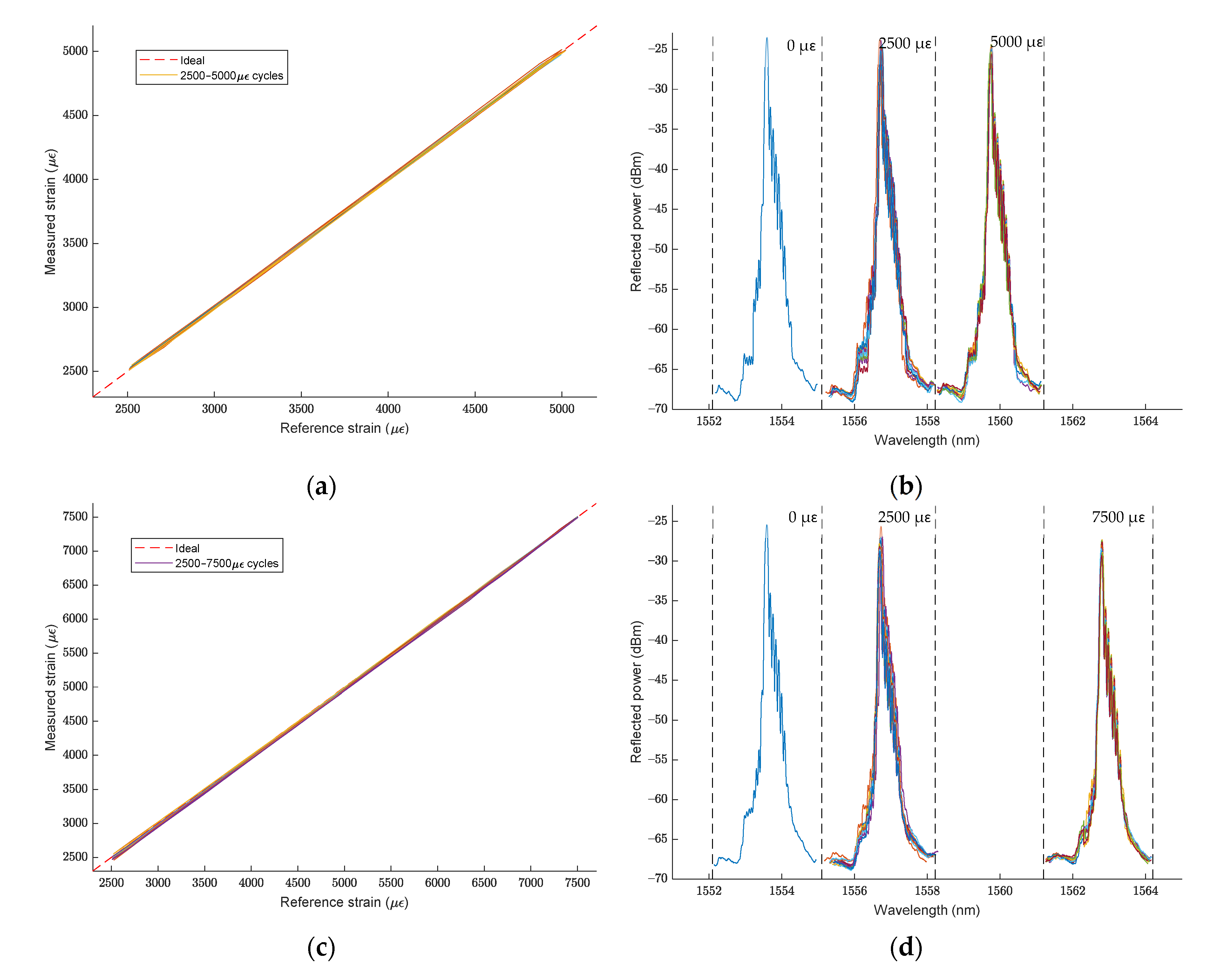

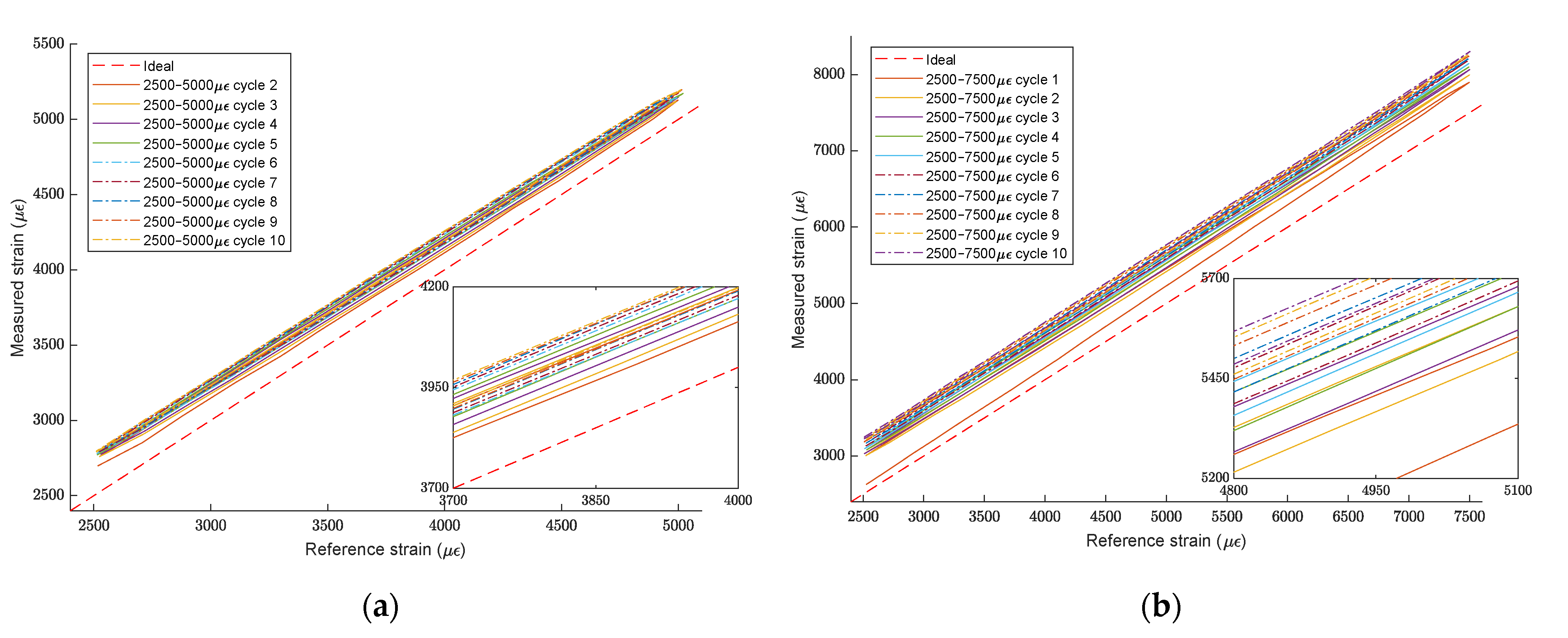

3.1. Embedded FBG Sensors Strain Measurement

- As sensors survived and information was useful, the procedure used to embed a standard SMF optical fibre with FBG sensors during FRP pultrusion for sensorized beam manufacturing was successful.

- The standard SMF shows enough adherence to transfer strain from the piece to the fibre sensor. No slippery was detected in any cycle.

- This embedding of optical sensors in the part itself in its manufacturing process provides great benefits, such as insulation of the sensors against external agents since they are found inside the beam. Additionally, the FBG sensor built in a standard optical fibre was able to read a strain of up to 7500 µɛ, which is 65% higher than the normal guaranteed strain reading before slippering of that kind of optical fibre [38].

3.2. Beam Failure Detection

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Johnson, T. History of composites. The Evolution of Lightweight Composite Materials. 2018. Available online: https://www.thoughtco.com/history-of-composites-820404 (accessed on 30 September 2021).

- Williams, J. The Science and Technology of Composite Materials; AM FAA FTSE, Research School of Physics and Engineering, The Australian National University: Canberra, Australia, 2015; Available online: https://www.science.org.au/curious/technology-future/composite-materials (accessed on 30 September 2021).

- Kumar, A.M.; Hakeem, S.A. Optimum design of symmetric composite patch repair to centre cracked metallic sheet. Compos. Struct. 2000, 49, 285–292. [Google Scholar] [CrossRef]

- Knigh, M.; Curliss, D. Encyclopedia of Physical Science and Technology, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 455–468. [Google Scholar] [CrossRef]

- Hancox, H.N.L. Fibre Composite Hybrid Materials; Applied Science Publishers Ltd.: London, UK, 1981; pp. 96–117. [Google Scholar]

- Koniuszewska, A.G.; Kaczmar, J.W. Application of polymer based composite materials in transportation. Prog. Rubber Plast. Recycl. Technol. 2016, 32, 1–24. [Google Scholar] [CrossRef]

- Zhang, L. The application of composite fiber materials in sports equipment. In Proceedings of the 2015 International Conference on Education, Management, Information and Medicine, Shenyang, China, 24–26 April 2015; pp. 450–453. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, Q.; Ngo, T.; Mendis, P.; Tran, P. Composite Materials for Next Generation Building Façade Systems. Civ. Eng. Archit. 2013, 1, 88–95. [Google Scholar] [CrossRef]

- Chachad, Y.R.; Roux, J.A.; Vaughan, J.G.; Arafat, E. Three-dimensional characterization of pultruded fiberglass-epoxy composite materials. J. Reinf. Plast. Compos. 1995, 14, 495–512. [Google Scholar] [CrossRef]

- Valliappan, M.; Roux, J.A.; Vaughan, J.G.; Arafat, E.S. Die and post-die temperature and cure in graphite/epoxy composites. Compos. Part B Eng. 1996, 27, 1–9. [Google Scholar] [CrossRef]

- Liu, X.L.; Crouch, I.G.; Lam, Y.C. Simulation of heat transfer and cure in pultrusion with a general-purpose finite element package. Compos. Sci. Technol. 2000, 60, 857–864. [Google Scholar] [CrossRef]

- Ding, Z.; Li, S.; Lee, L.J. Influence of heat transfer and curing on the quality of pultruded composites. ii: Modeling and simulation. Polym. Compos. 2002, 23, 957–969. [Google Scholar] [CrossRef]

- Joshi, S.C.; Lam, Y.C.; Tun, U.W. Improved cure optimization in pultrusion with pre-heating and die-cooler temperature. Compos. Part A Appl. Sci. Manuf. 2003, 34, 1151–1159. [Google Scholar] [CrossRef]

- Carlone, P.; Palazzo, G.S.; Pasquino, R. Pultrusion manufacturing process development by computational modelling and methods. Math. Comput. Model. 2006, 44, 701–709. [Google Scholar] [CrossRef]

- Baran, I.; Tutum, C.C.; Hattel, J.H. Optimization of the thermosetting pultrusion process by using hybrid and mixed integer genetic algorithms. Appl. Compos. Mater. 2013, 20, 449–463. [Google Scholar] [CrossRef]

- Baran, I.; Tutum, C.C.; Hattel, J.H. Reliability estimation of the pultrusion process using the first-order reliability method (FORM). Appl. Compos. Mater. 2013, 20, 639–653. [Google Scholar] [CrossRef]

- Baran, I.; Tutum, C.C.; Hattel, J.H. Probabilistic thermo-chemical analysis of a pultruded composite rod. In Proceedings of the 15th European Conference on Composite Materials, ECCM-15, Venice, Italy, 24–28 June 2012; Volume 24, p. 28. Available online: https://research.utwente.nl/en/publications/probabilistic-thermo-chemical-analysis-of-a-pultruded-composite-r (accessed on 30 September 2021).

- Baran, I.; Tutum, C.C.; Hattel, J.H. The effect of thermal contact resistance on the thermosetting pultrusion process. Compos. Part B Eng. 2013, 45, 995–1000. [Google Scholar] [CrossRef]

- Baran, I.; Tutum, C.C.; Nielsen, M.W.; Hattel, J.H. Process induced residual stresses and distortions in pultrusion. Compos. Part B Eng. 2013, 51, 148–161. [Google Scholar] [CrossRef]

- Kalamkarov, A.L.; Fitzgerald, S.B.; MacDonald, D.O. The use of Fabry Perot fiber optic sensors to monitor residual strains during pultrusion of FRP composites. Compos. Part B Eng. 1999, 30, 167–175. [Google Scholar] [CrossRef]

- Willberry, J.O.; Papaelias, M.; Franklyn Fernando, G. Structural Health Monitoring Using Fibre Optic Acoustic Emission Sensors. Sensors 2020, 20, 6369. [Google Scholar] [CrossRef]

- Palizvan, P.; Olyaee, S.; Seifouri, M. High Sensitive Optical Pressure Sensor Using Nano-Scale Plasmonic Resonator and Metal-Insulator-Metal Waveguides. J. Nanoelectron. Optoelectron. 2018, 13, 1449–1453. [Google Scholar] [CrossRef]

- Gabler, M.; Tkachenko, V.; Küppers, S.; Kuka, G.G.; Habel, W.R.; Milwich, M.; Knippers, J. Automatically produced FRP beams with embedded FOS in complex geometry: Process, material compatibility, micromechanical analysis, and performance tests. In Smart Sensor Phenomena, Technology, Networks, and Systems Integration 2012; International Society for Optics and Photonics: Bellingham, WA, USA, 2012; Volume 8346, p. 83460B. [Google Scholar] [CrossRef]

- Gabler, M.; Knippers, J. Pultruded FRP Girder with Embedded Optical Sensor Network. Book of Abstracts of the 7th International Conference on FRP Composites in Civil Engineering (CICE 2014). 2014. Available online: https://www.researchgate.net/publication/265786284_Pultruded_FRP_Girder_with_Embedded_Optical_Sensor_Network (accessed on 30 September 2021).

- Hasan, Z.; Atmeh, G. A Structural Health Monitoring System for Composite Beams with Coupled Bending-Torsion. In Smart Materials, Adaptive Structures and Intelligent Systems, Proceedings of the ASME 2012 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Stone Mountain, GA, USA, 19–21 September 2012; ASME: New York, NY, USA, 2012; Volume 45097, pp. 653–664. [Google Scholar] [CrossRef]

- Di Sante, R. Fibre optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Takeda, S.; Aoki, Y.; Ishikawa, T.; Takeda, N.; Kikukawa, H. Structural health monitoring of composite wing structure during durability test. Compos. Struct. 2007, 79, 133–139. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg gratings in structural health monitoring—Present status and applications. Sens. Actuators A Phys. 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Cusano, A.; Cutolo, A.; Albert, J. (Eds.) Fiber Bragg Grating Sensors: Recent Advancements, Industrial Applications and Market Exploitation; Bentham Science Publishers: Sharjah, United Arab Emirates, 2011. [Google Scholar] [CrossRef] [Green Version]

- de la Torre, O.; Floris, I.; Sales, S.; Escaler, X. Fiber Bragg Grating Sensors for Underwater Vibration Measurement: Potential Hydropower Applications. Sensors 2021, 21, 4272. [Google Scholar] [CrossRef]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef] [Green Version]

- Mulle, M.; Yudhanto, A.; Lubineau, G.; Yaldiz, R.; Schijve, W.; Verghese, N. Internal strain assessment using FBGs in a thermoplastic composite subjected to quasi-static indentation and low-velocity impact. Compos. Struct. 2019, 215, 305–316. [Google Scholar] [CrossRef]

- Miguel Giraldo, C. Desarrollo de Sensores de Fibra Óptica para su Aplicación a la Monitorización de la Integridad Estructural en Estructuras Aeronáuticas de Material Compuesto. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2018. [Google Scholar]

- Micron Optics Is Now Luna. Available online: https://lunainc.com/sites/default/files/assets/files/resource-library/sm125.pdf (accessed on 30 September 2021).

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg Grating Sensors toward Structural Health Monitoring in Composite Materials: Challenges and Solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef]

- Di Sante, R.; Bastianini, F. Temperature-compensated fibre Bragg grating-based sensor with variable sensitivity. Opt. Lasers Eng. 2015, 75, 5–9. [Google Scholar] [CrossRef]

- Van Roosbroeck, J.; Ibrahim, S.K.; Lindner, E.; Schuster, K.; Vlekken, J. Stretching the Limits for the Decoupling of Strain and Temperature with FBG based sensors. In Proceedings of the 24th International Conference on Optical Fibre Sensors (OFS24), Curitiba, Brazil, 28 September 2015; Volume 9634, p. 96343S. [Google Scholar] [CrossRef]

- Kim, J.M.; Kim, C.M.; Choi, S.Y.; Lee, B.Y. Enhanced strain measurement range of an FBG sensor embedded in seven-wire steel strands. Sensors 2017, 17, 1654. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.F.; Mikkelsen, L.P.; McGugan, M. Crack detection in fibre reinforced plastic structures using embedded fibre Bragg grating sensors: Theory, model development and experimental validation. PLoS ONE 2015, 10, e0141495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lau, K.T.; Zhou, L.M.; Wu, J.S. Investigation on strengthening and strain sensing techniques for concrete structures using FRP composites and FBG sensors. Mater. Struct. 2001, 34, 42–50. [Google Scholar] [CrossRef]

| Series | Thickness | Width | Modulus of Elasticity | Tensile Strength | Deformation at Tensile Strength |

|---|---|---|---|---|---|

| n = 4 | mm | mm | MPa | MPa | % |

| Mean value | 4.168 | 13.564 | 52,900 | 740 | 1.42 |

| Standard deviation | 0.045 | 0.069 | 2360 | 22.3 | 0.0263 |

| Series | Thickness | Width | Modulus of Elasticity | Tensile Strength | Deformation at Tensile Strength |

|---|---|---|---|---|---|

| n = 5 | mm | mm | MPa | MPa | % |

| Mean value | 4.958 | 14.805 | 38,400 | 584 | 1.44 |

| Standard deviation | 0.141 | 0.075 | 1900 | 27 | 0.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maldonado-Hurtado, D.; Madrigal, J.; Penades, A.; Ruiz, R.; Crespo, A.I.; Sales, S. Pultruded FRP Beams with Embedded Fibre Bragg Grating Optical Sensors for Strain Measurement and Failure Detection. Sensors 2021, 21, 7019. https://doi.org/10.3390/s21217019

Maldonado-Hurtado D, Madrigal J, Penades A, Ruiz R, Crespo AI, Sales S. Pultruded FRP Beams with Embedded Fibre Bragg Grating Optical Sensors for Strain Measurement and Failure Detection. Sensors. 2021; 21(21):7019. https://doi.org/10.3390/s21217019

Chicago/Turabian StyleMaldonado-Hurtado, Daniel, Javier Madrigal, Antonio Penades, Rocío Ruiz, Ana Isabel Crespo, and Salvador Sales. 2021. "Pultruded FRP Beams with Embedded Fibre Bragg Grating Optical Sensors for Strain Measurement and Failure Detection" Sensors 21, no. 21: 7019. https://doi.org/10.3390/s21217019

APA StyleMaldonado-Hurtado, D., Madrigal, J., Penades, A., Ruiz, R., Crespo, A. I., & Sales, S. (2021). Pultruded FRP Beams with Embedded Fibre Bragg Grating Optical Sensors for Strain Measurement and Failure Detection. Sensors, 21(21), 7019. https://doi.org/10.3390/s21217019