Strain Transfer Characteristics of Multi-Layer Optical Fiber Sensors with Temperature-Dependent Properties at Low Temperature

Abstract

1. Introduction

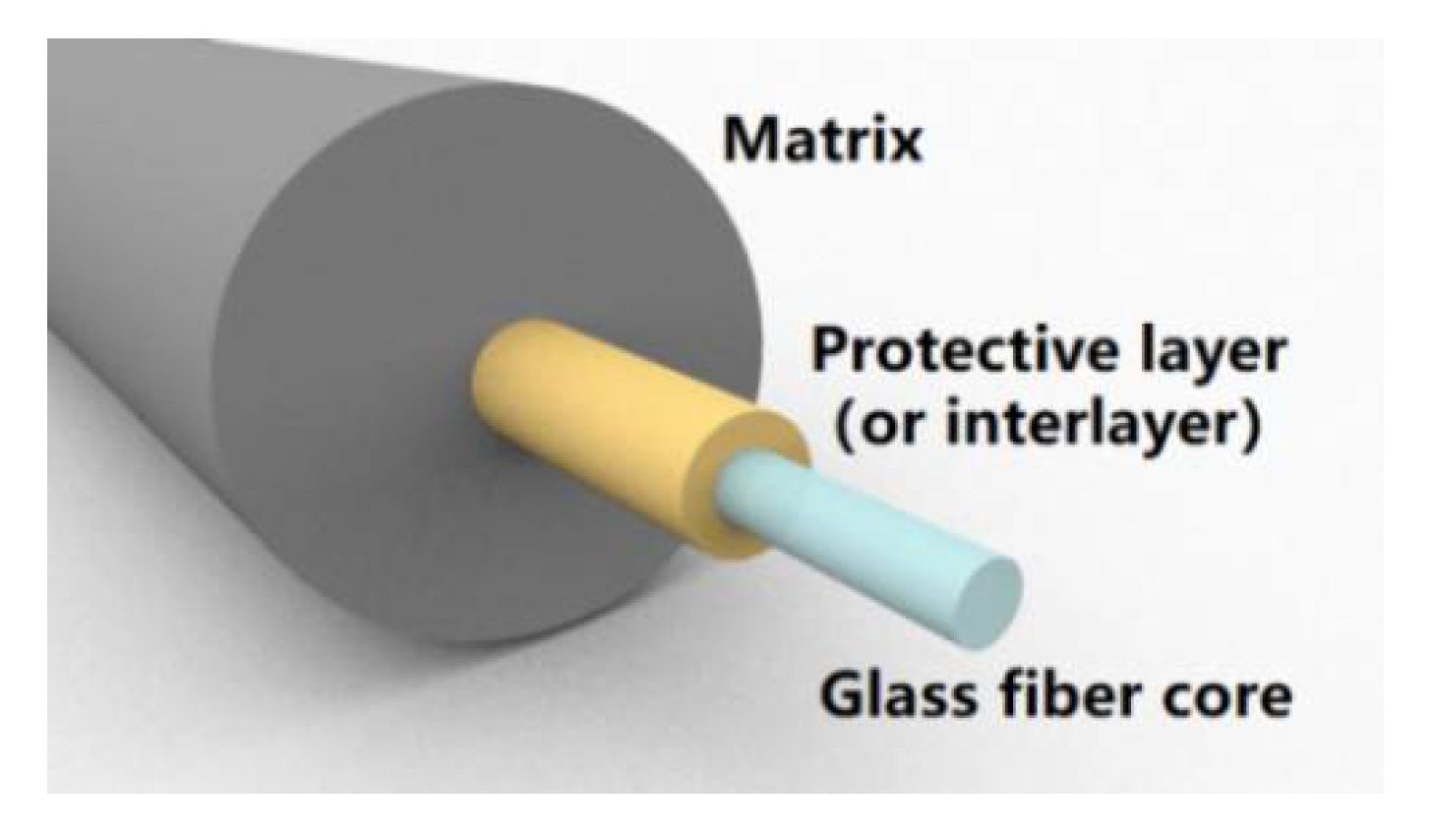

2. Multi-Layer Strain Transfer Model and Analysis

2.1. Fundamental Equations

2.2. Nondimensional Forms of Equations

2.3. Numerical Solution to the ODE

3. Results and Discussions

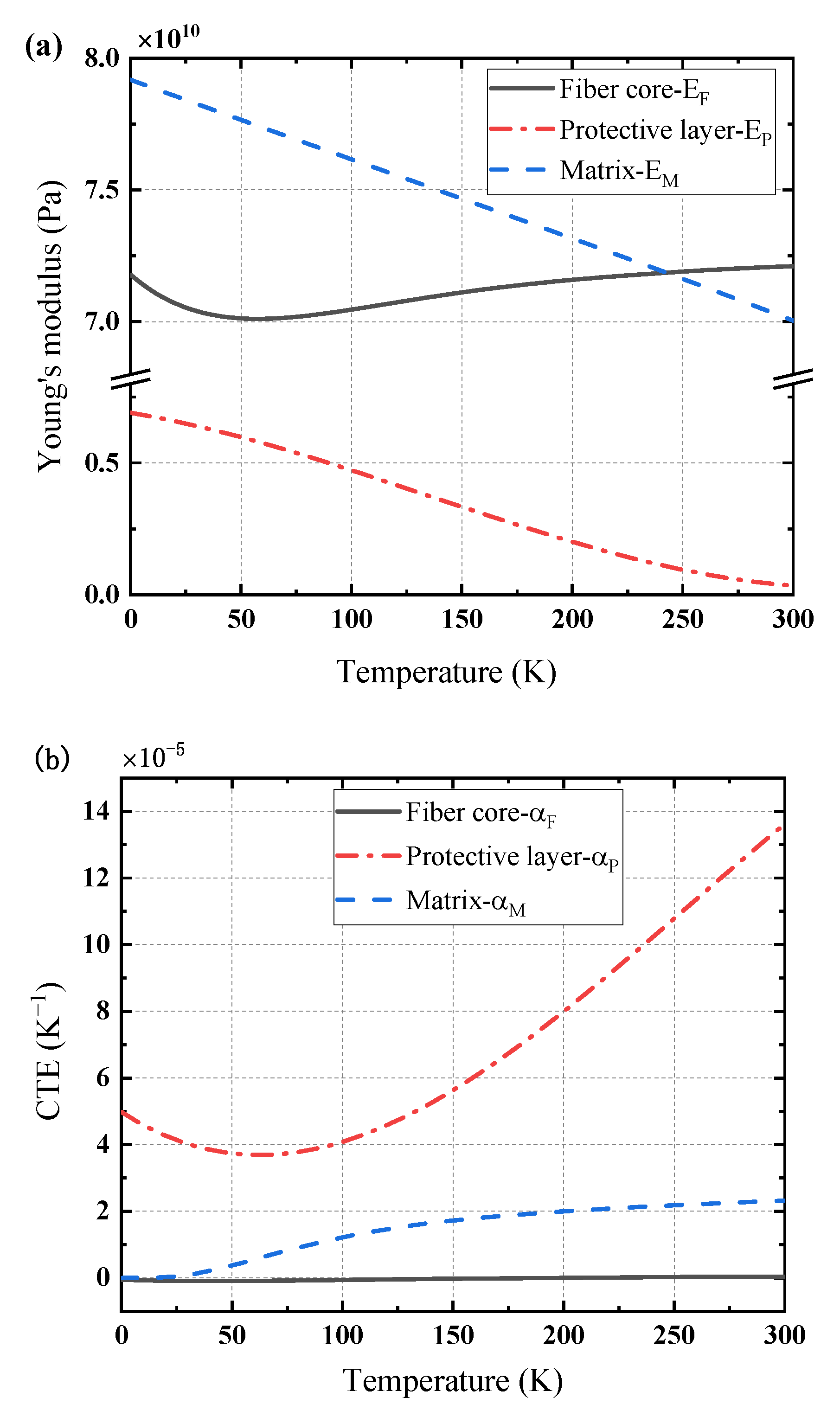

3.1. Temperature-Dependent Material Properties

3.2. Different Temperature Loads

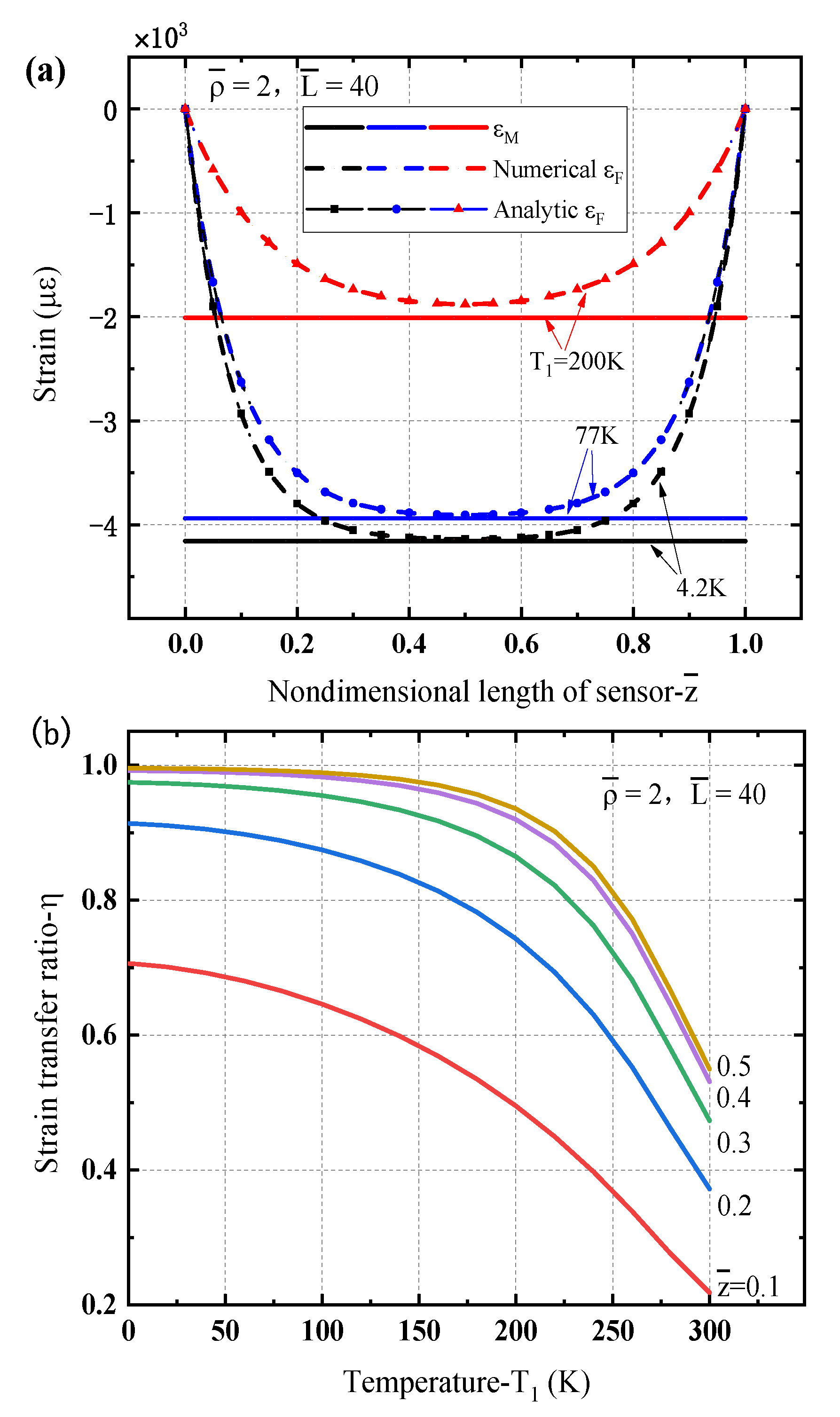

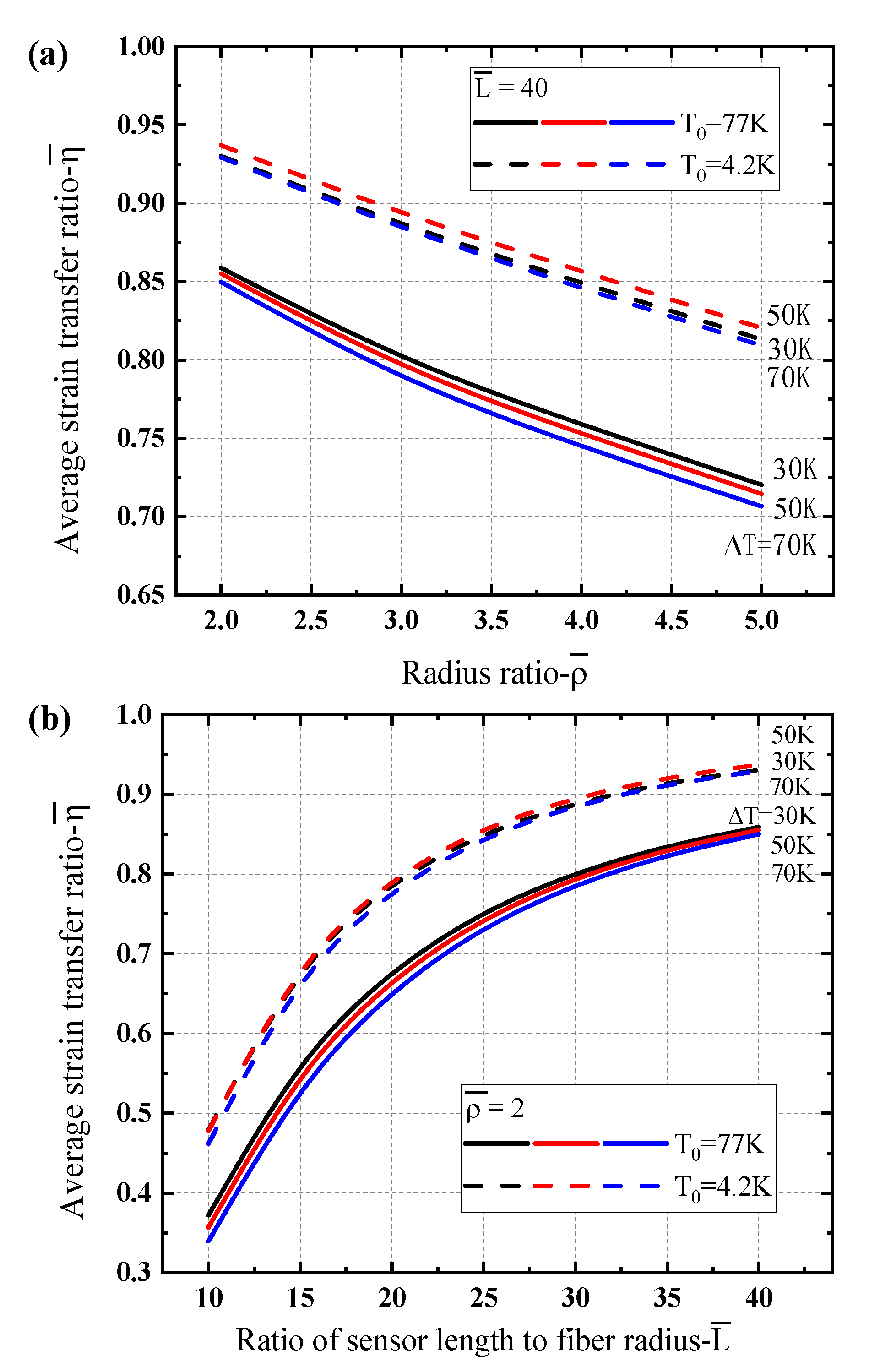

3.2.1. Uniform Temperature Load

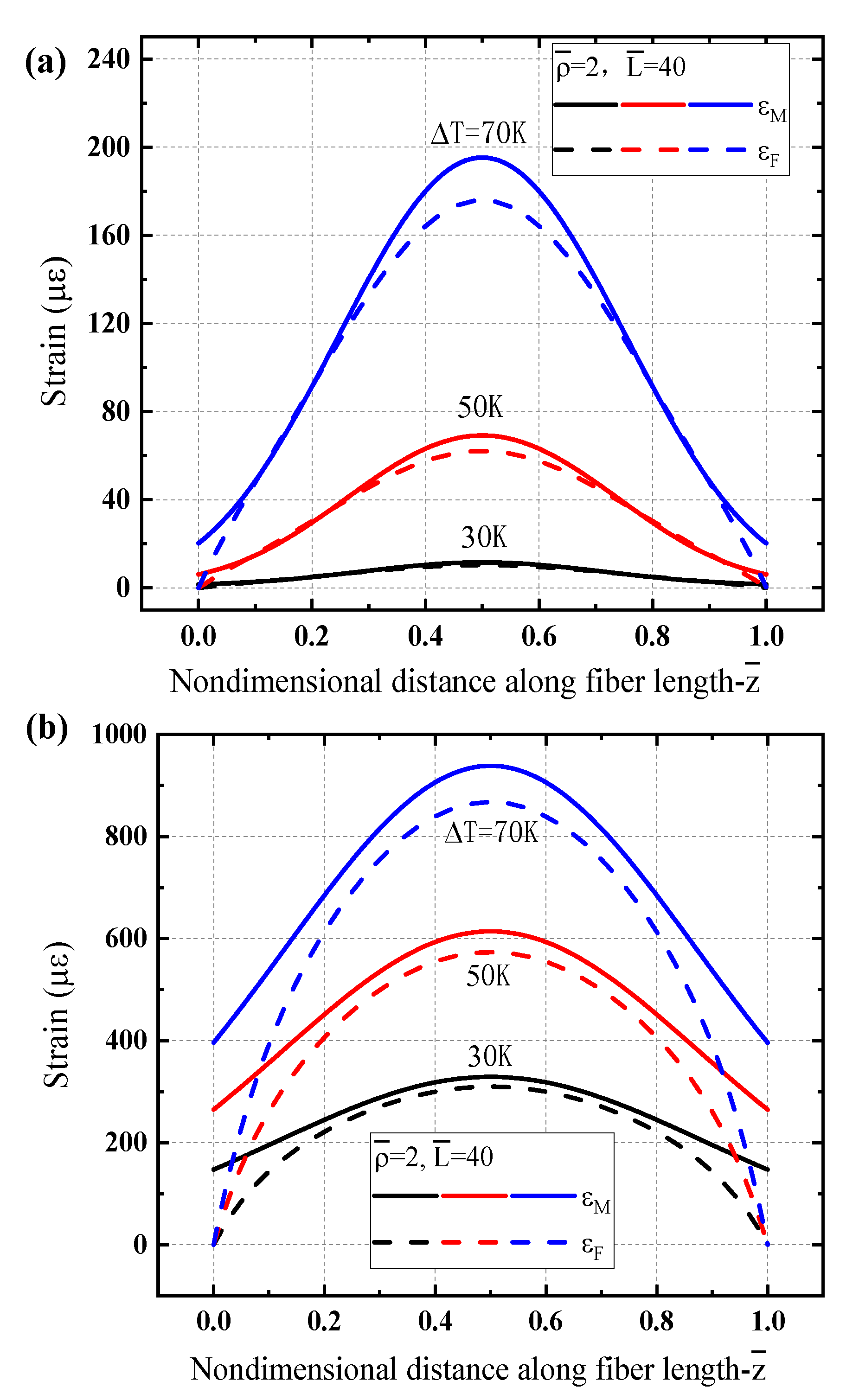

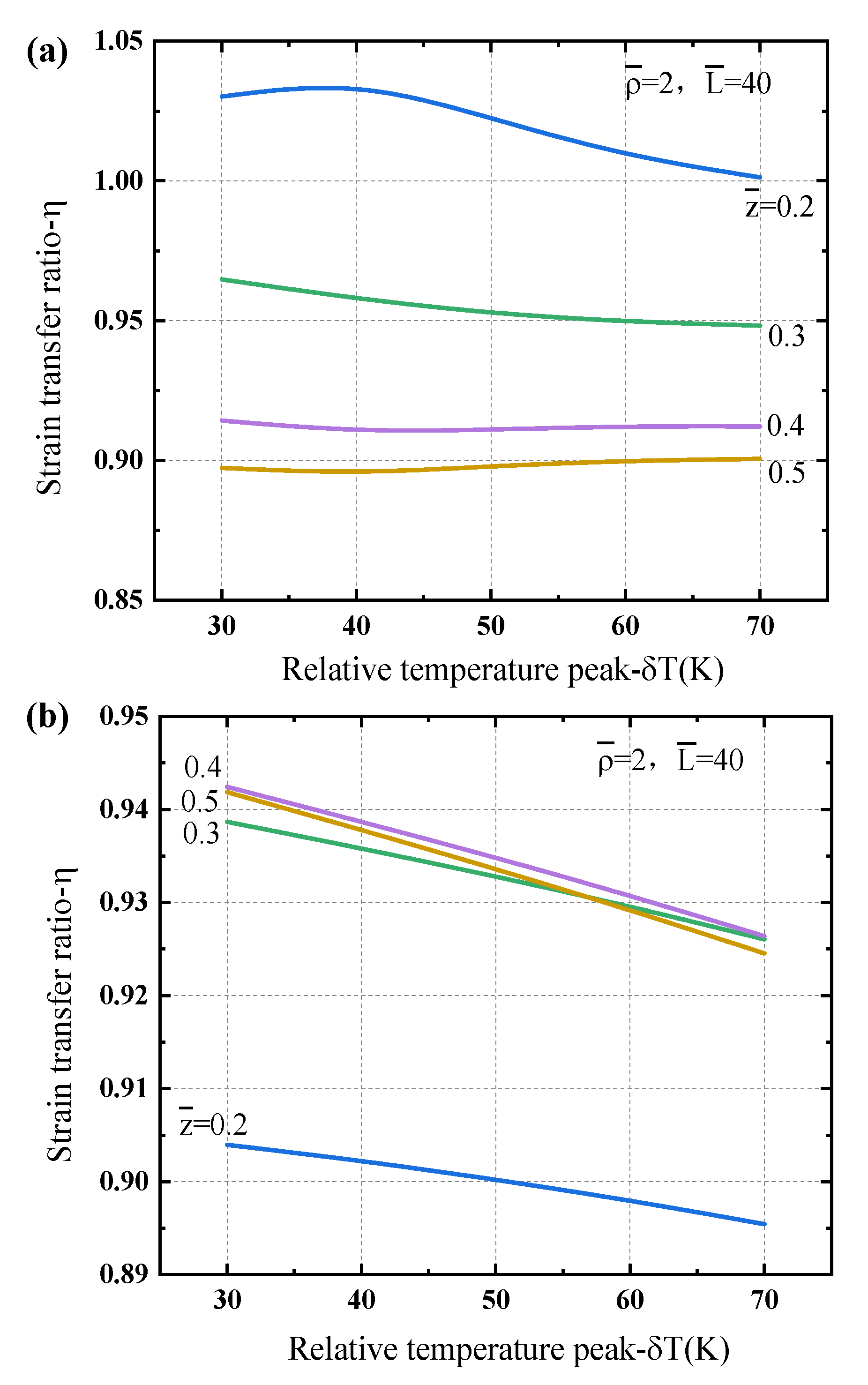

3.2.2. Gradient Temperature Load

4. Experiment Investigation at Low Temperature

4.1. Uniform Temperature Change

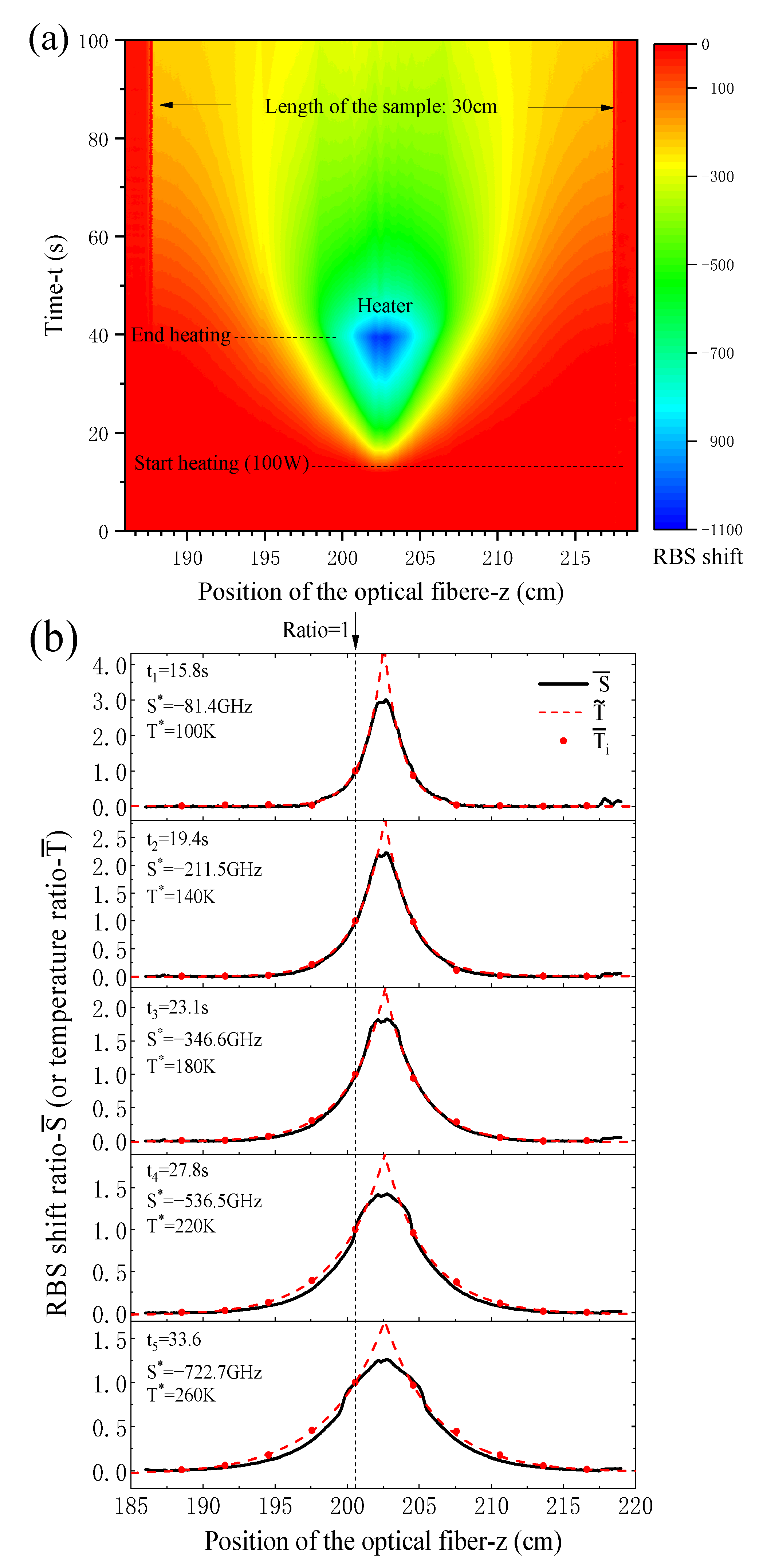

4.2. Temperature with Great Gradient

5. Conclusions

- (1)

- The proposed sensing model can successfully capture the strain transfer characteristics of the three-layer optical sensor structure as a temperature gradient exists, and the deformation in the different layers were accurately obtained. Meanwhile, a traditional model under uniform temperature loading for strain transfer analysis has been gained by the proposed model as a degradation form.

- (2)

- With temperature decreasing, the Young’s modulus of the protective layer of the optical sensor always increases so that a quite good strain transfer performance is achieved. It results in the measurement of optical fiber strain sensor being more reliable and accurate under low temperature than that at room temperature.

- (3)

- Since the temperature-dependent properties of layers of the fiber sensor, the strain transfer ratios are even larger than 1.0 near the sensor ends at low temperature and a high gradient temperature load, while the average strain transfer ratios are commonly less than 1.0. The protective layer always plays a main role for the strain transfer for the global performance of the optical fiber sensing structure, and the optimization geometrical parameters should be carefully designed which can be improved by reducing thickness of the protective layer and increasing sensor length of the multi-layer sensing structure.

- (4)

- The experiments on a sample embedded with an optical fiber sensor were conducted. The thermal strains related to RBS shifts of the optical fiber for a uniform temperature variation and a temperature gradient load heated by a resistance heater were measured, to qualitatively verify the theoretical predictions on the main characteristics under low temperature condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber grating sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Udd, E.; Schulz, W.L.; Seim, J.M.; Haugse, E.; Trego, A.; Johnson, P.E.; Bennett, T.E.; Nelson, D.V.; Makino, A. Multidimensional strain field measurements using fiber optic grating sensors. Proc. SPIE 2000, 254, 3986. [Google Scholar]

- Leal-Junior, A.G.; Díaz, C.R.; Leitão, C.; Pontes, M.J.; Marques, C.; Frizera, A. Polymer optical fiber-based sensor for simultaneous measurement of breath and heart rate under dynamic movements. Opt. Laser Technol. 2019, 109, 429–436. [Google Scholar] [CrossRef]

- Leal-Junior, A.; Avellar, L.; Frizera, A.; Marques, C. Smart textiles for multimodal wearable sensing using highly stretchable multiplexed optical fiber system. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Lu, X.; Thomas, P.J.; Hellevang, J.O. A review of methods for fibre-optic distributed chemical sensing. Sensors 2019, 19, 2876. [Google Scholar] [CrossRef]

- Rajan, G. Optical Fiber Sensors: Advanced Techniques and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Barrias, A.; Casas, J.R.; Villalba, S. A review of distributed optical fiber sensors for civil engineering applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef]

- Leung, C.K.; Wan, K.T.; Inaudi, D.; Bao, X.; Habel, W.; Zhou, Z.; Imai, M. Optical fiber sensors for civil engineering applications. Mater. Struct. 2015, 48, 871–906. [Google Scholar] [CrossRef]

- Campanella, C.E.; Cuccovillo, A.; Campanella, C.; Yurt, A.; Passaro, V. Fibre Bragg grating based strain sensors: Review of technology and applications. Sensors 2018, 18, 3115. [Google Scholar] [CrossRef]

- Mihailov, S.J.; Grobnic, D.; Hnatovsky, C.; Walker, R.B.; Lu, P.; Coulas, D.; Ding, H. Extreme environment sensing using femtosecond laser-inscribed fiber Bragg gratings. Sensors 2017, 17, 2909. [Google Scholar] [CrossRef]

- Yang, S.; Homa, D.; Heyl, H.; Theis, L.; Beach, J.; Dudding, B.; Wang, A. Application of sapphire-fiber-Bragg-grating-based multi-point temperature sensor in boilers at a commercial power plant. Sensors 2019, 19, 3211. [Google Scholar] [CrossRef]

- Laffont, G.; Cotillard, R.; Roussel, N.; Desmarchelier, R.; Rougeault, S. Temperature resistant fiber Bragg gratings for on-line and structural health monitoring of the next-generation of nuclear reactors. Sensors 2018, 18, 1791. [Google Scholar] [CrossRef] [PubMed]

- Latka, I.; Ecke, W.; Höfer, B.; Chojetzki, C.; Reutlinger, A. Fiber optic sensors for the monitoring of cryogenic spacecraft tank structures. Proc. SPIE 2004, 5579, 195–204. [Google Scholar]

- Rajinikumar, R.; Narayankhedkar, K.G.; Krieg, G.; Suber, M.; Nyilas, A.; Weiss, K.P. Fiber Bragg gratings for sensing temperature and stress in superconducting coils. IEEE Trans. Appl. Supercond. 2006, 16, 1737–1740. [Google Scholar] [CrossRef]

- Gupta, S.; Mizunami, T.; Yamao, T.; Shimomura, T. Fiber Bragg grating cryogenic temperature sensors. Appl. Opt. 1996, 35, 5202–5205. [Google Scholar] [CrossRef]

- Mizunami, T.; Tatehata, H.; Kawashima, H. High-sensitivity cryogenic fibre-Bragg-grating temperature sensors using Teflon substrates. Meas. Sci. Technol. 2001, 12, 914. [Google Scholar]

- Chen, T.; Wang, Q.; Chen, R.; Zhang, B.; Lin, Y.; Chen, K.P. Distributed liquid level sensors using self-heated optical fibers for cryogenic liquid management. Appl. Opt. 2012, 51, 6282–6289. [Google Scholar] [CrossRef]

- Hahn, S.; Kim, K.; Kim, K.; Hu, X.; Painter, T.; Dixon, I.; Larbalestier, D.C. 45.5-tesla direct-current magnetic field generated with a high-temperature superconducting magnet. Nature 2019, 570, 496–499. [Google Scholar] [CrossRef]

- Wang, X.; Guan, M.; Ma, L. Strain-based quench detection for a solenoid superconducting magnet. Supercond. Sci. Technol. 2012, 25, 095009. [Google Scholar] [CrossRef]

- Willsch, M.; Hertsch, H.; Bosselmann, T.; Oomen, M.; Ecke, W.; Latka, I.; Höfer, H. Fiber optical temperature and strain measurements for monitoring and quench detection of superconducting coils. Proc. SPIE 2008, 7004, 70045G. [Google Scholar]

- Chiuchiolo, A.; Palmieri, L.; Consales, M.; Giordano, M.; Borriello, A.; Bajas, H.; Cusano, A. Cryogenic-temperature profiling of high-power superconducting lines using local and distributed optical-fiber sensors. Opt. Lett. 2015, 40, 4424–4427. [Google Scholar] [CrossRef]

- Scurti, F.; Ishmael, S.; Flanagan, G.; Schwartz, J. Quench detection for high temperature superconductor magnets: A novel technique based on Rayleigh-backscattering interrogated optical fibers. Supercond. Sci. Technol. 2016, 29, 03LT01. [Google Scholar] [CrossRef]

- Jiang, J.; Zhao, Y.; Hong, Z.; Zhang, J.; Li, Z.; Hu, D.; Qiu, D.; Zhao, A.; Ryu, K.; Jin, Z. Experimental study on quench detection of a no-insulation HTS coil based on Raman-scattering technology in optical fiber. IEEE Trans. Appl. Supercond. 2018, 28, 4702105. [Google Scholar] [CrossRef]

- Pak, Y.E. Longitudinal shear transfer in fiber optic sensors. Smart Mater. Struct. 1992, 1, 57–62. [Google Scholar] [CrossRef]

- Ansari, F.; Yuan, L.B. Mechanics of bond and interface shear transfer in optical fiber sensors. J. Eng. Mech. 1998, 124, 385–394. [Google Scholar] [CrossRef]

- LeBlanc, M. Interaction Mechanics of Embedded Single-Ended Optical Fibre Sensors Using Novel In Situ Measurement Techniques; University of Toronto: Toronto, ON, Canada, 1999. [Google Scholar]

- Li, H.N.; Zhou, G.D.; Liang, R.; Li, D.S. Strain transfer analysis of embedded fiber Bragg grating sensor under nonaxial stress. Opt. Eng. 2007, 46, 054402. [Google Scholar] [CrossRef]

- Li, H.N.; Zhou, G.D.; Ren, L.; Li, D.S. Strain transfer coefficient analyses for embedded fiber Bragg grating sensors in different host materials. J. Eng. Mech. 2009, 35, 1343–1353. [Google Scholar] [CrossRef]

- Feng, X.; Zhou, J.; Sun, C.; Zhang, X.; Ansari, F. Theoretical and experimental investigations into crack detection with BOTDR-distributed fiber optic sensors. J. Eng. Mech. 2013, 139, 1797–1807. [Google Scholar] [CrossRef]

- Sun, L.; Li, C.; Zhang, C.; Liang, T.; Zhao, Z. The Strain Transfer Mechanism of Fiber Bragg Grating Sensor for Extra Large Strain Monitoring. Sensors 2019, 19, 1851. [Google Scholar] [CrossRef]

- Wang, H.P.; Xiang, P.; Jiang, L.Z. Strain transfer theory of industrialized optical fiber-based sensors in civil engineering: A review on measurement accuracy, design and calibration. Sens. Actuators A Phys. 2019, 285, 414–426. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, X.; Guan, M.; Wu, B. Strain responses of superconducting magnets based on embedded polymer-FBG and cryogenic resistance strain gauge measurements. IEEE Trans. Appl. Supercond. 2018, 29, 1–7. [Google Scholar] [CrossRef]

- Naimon, E.R.; Ledbetter, H.M.; Weston, W.F. Low-temperature elastic properties of four wrought and annealed aluminium alloys. J. Mater. Sci. 1975, 10, 1309–1316. [Google Scholar] [CrossRef]

- Scott, R.B. Cryogenic Engineering; D. Van Nostrand Co., Inc.: Princeton, NJ, USA, 1959. [Google Scholar]

- Miniewicz, A.; Bartkiewicz, S.; Orlikowska, H.; Dradrach, K. Marangoni effect visualized in two-dimensions Optical tweezers for gas bubbles. Sci. Rep. 2016, 6, 34787. [Google Scholar] [CrossRef] [PubMed]

- Jothibasu, S.; Du, Y.; Anandan, S.; Dhaliwal, G.S.; Gerald, R.E.; Watkins, S.E.; Huang, J. Spatially continuous strain monitoring using distributed fiber optic sensors embedded in carbon fiber composites. Opt. Eng. 2019, 58, 072004. [Google Scholar] [CrossRef]

- Roman, M.; Balogun, D.; Zhuang, Y.; Gerald, R.E., II; Bartlett, L.; O’Malley, R.J.; Huang, J. A spatially distributed fiber-optic temperature sensor for applications in the steel industry. Sensors 2020, 20, 3900. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, T.; Wang, H.; Wang, X. Strain Transfer Characteristics of Multi-Layer Optical Fiber Sensors with Temperature-Dependent Properties at Low Temperature. Sensors 2021, 21, 495. https://doi.org/10.3390/s21020495

Yang T, Wang H, Wang X. Strain Transfer Characteristics of Multi-Layer Optical Fiber Sensors with Temperature-Dependent Properties at Low Temperature. Sensors. 2021; 21(2):495. https://doi.org/10.3390/s21020495

Chicago/Turabian StyleYang, Taolue, Huaping Wang, and Xingzhe Wang. 2021. "Strain Transfer Characteristics of Multi-Layer Optical Fiber Sensors with Temperature-Dependent Properties at Low Temperature" Sensors 21, no. 2: 495. https://doi.org/10.3390/s21020495

APA StyleYang, T., Wang, H., & Wang, X. (2021). Strain Transfer Characteristics of Multi-Layer Optical Fiber Sensors with Temperature-Dependent Properties at Low Temperature. Sensors, 21(2), 495. https://doi.org/10.3390/s21020495