Optimal Material Search for Infrared Markers under Non-Heating and Heating Conditions

Abstract

:1. Introduction

- 1.

- We propose four requirements of infrared markers for engineering applications (e.g., device calibration and structural health monitoring), and investigate the appropriate combinations of materials based on these requirements.

- 2.

- We qualitatively and quantitatively compare the clearance of the thermal imaging of the markers under both non-heating and heating conditions in the MWIR region.

- 3.

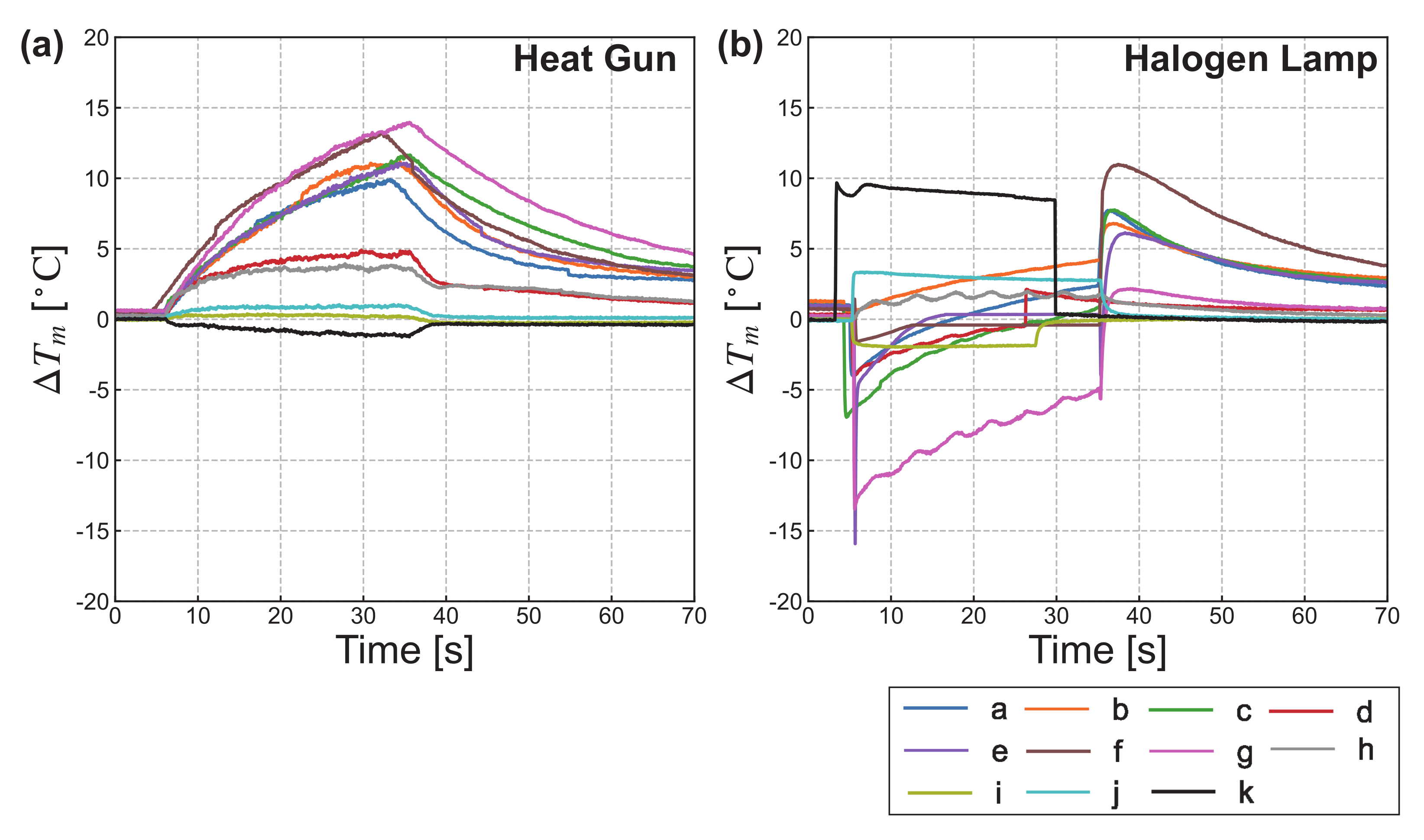

- We evaluate how the difference in heat sources affects the imaging performance of the markers by comparing a hot-air heating with optical radiation heating.

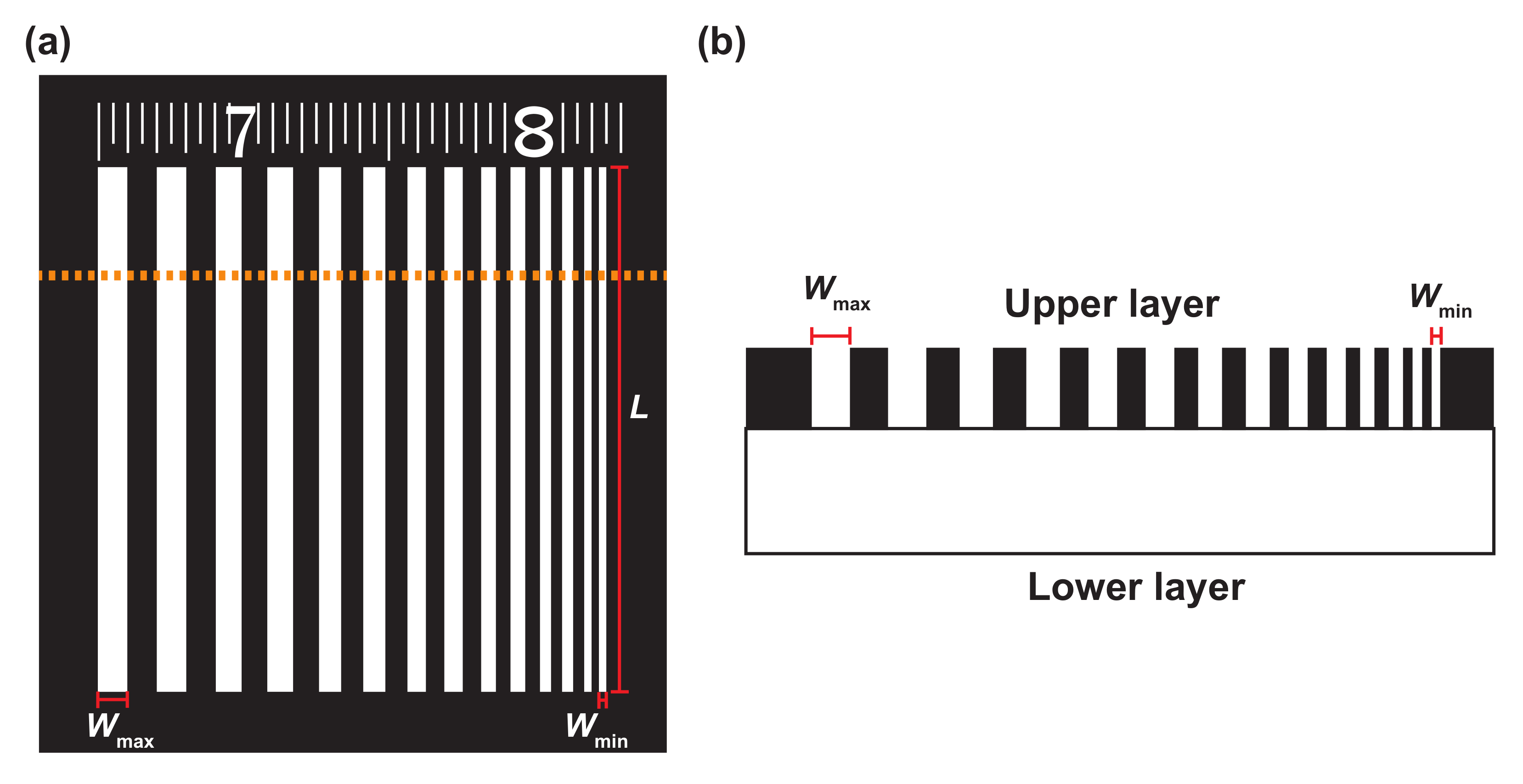

2. Marker Design Requirements and Production

2.1. Design and Evaluation Requirements

- 1.

- Available under both non-heating and heating conditions: the images are available under both conditions

- 2.

- Highly accurate production for imaging: the production of the markers is sufficiently accurate to capture clear images.

- 3.

- Compatible with both MWIR and visible cameras: the images can be captured using both cameras.

- 4.

- Easy to attach and detach: the markers should be easily attached and detached at the beginning and end of their utilization.

2.2. Marker Production Procedures

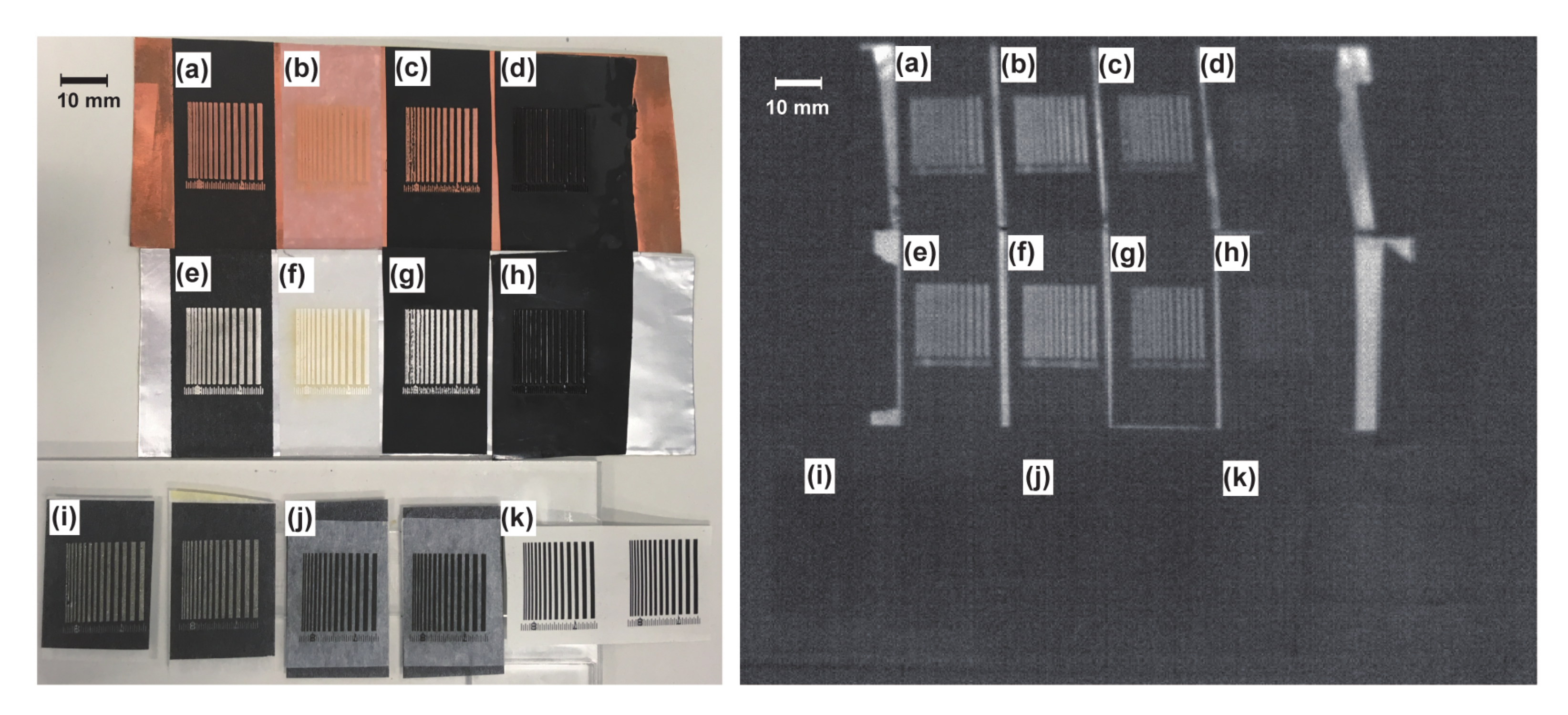

2.3. Produced Marker Images and Qualitative Evaluation

2.3.1. Comparisons of Upper-Layer Insulators

2.3.2. Comparisons of Lower-Layer Metals

2.3.3. Comparisons of Metal–Insulator and Insulator–Insulator Markers

2.3.4. Production Reproducibility under Identical Conditions

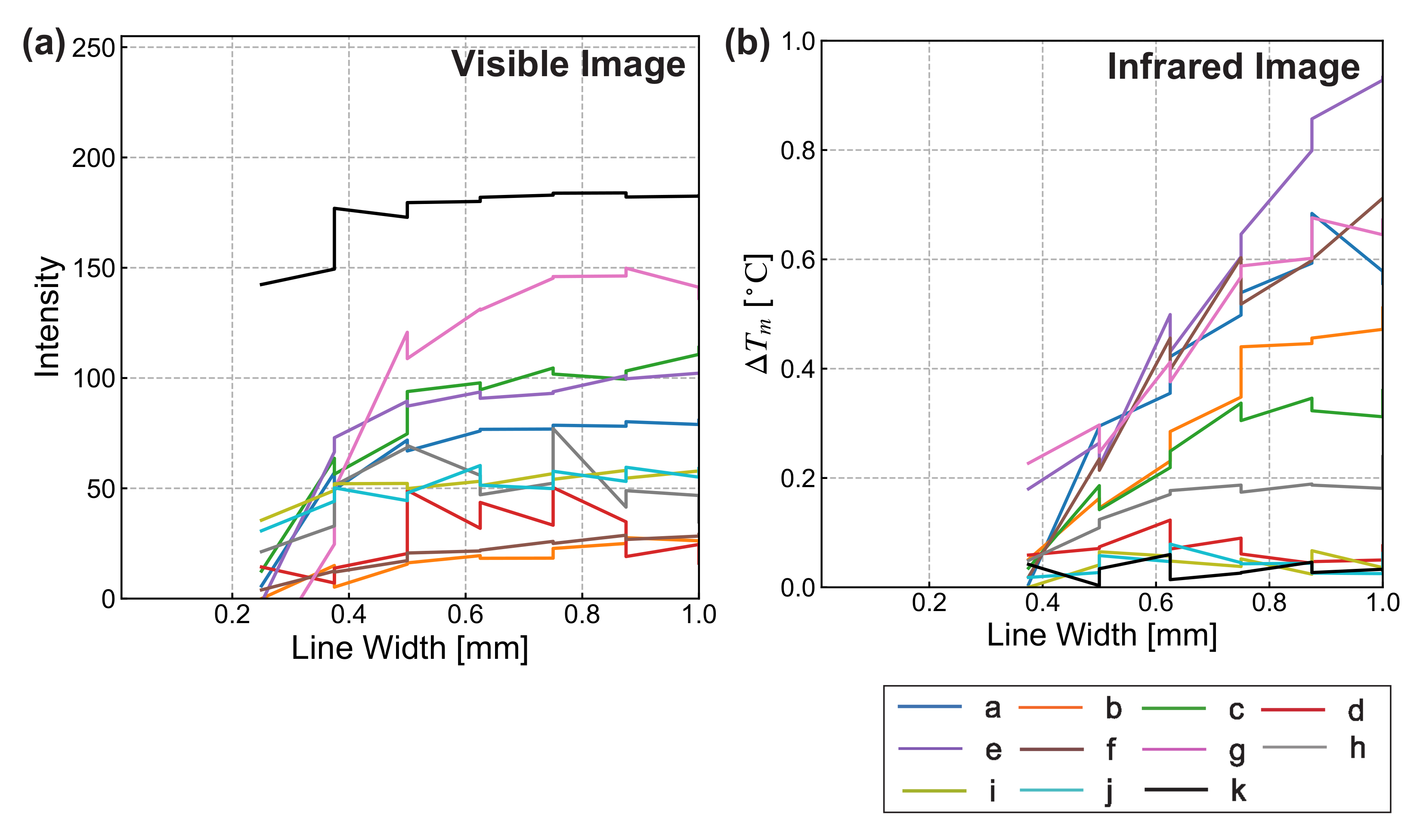

3. Experiment 1: Marker Performance Evaluation under Non-Heating Conditions

3.1. Performance Evaluation Procedures

3.2. Results

4. Experiment 2: Marker Performance Evaluation under Heating Conditions

4.1. Experimental Procedures

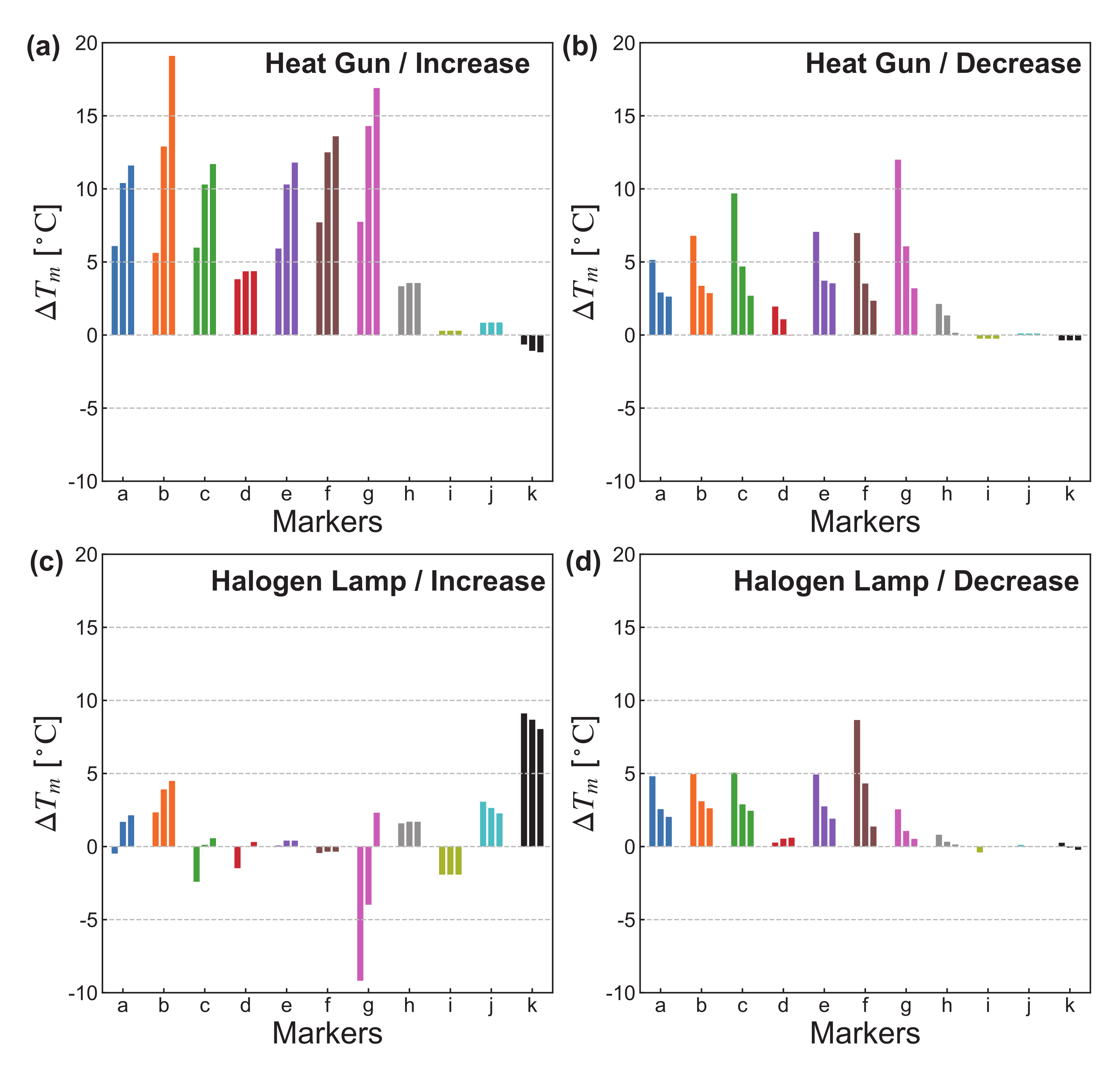

4.2. Results

5. Discussion

5.1. Marker Characteristics from Thermal Radiation Theory

5.2. Evaluation of Marker Selection

- 1.

- Production accuracy

- 2.

- Clearance of visible-light imaging

- 3.

- Clearance of infrared imaging under the non-heating condition

- 4.

- Clearance of infrared imaging during heating under the hot air heating conditions

- 5.

- Clearance of infrared imaging after heating under the hot air heating conditions

- 6.

- Clearance of infrared imaging during heating under the optical radiation heating conditions

- 7.

- Clearance of infrared imaging after heating under the optical radiation heating conditions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Thermal Radiation Theory of Material Heating

Appendix A.1. Kirchhoff’s Law and Energy Conservation

Appendix A.2. Thermal Imaging under Non-Heating Conditions

Appendix A.3. Thermal Imaging under Heating Conditions

Appendix B. Fitting Results under Heating Condition

References

- Rangel, J.; Soldan, S.; Kroll, A. 3D thermal imaging: Fusion of thermography and depth cameras. In Proceedings of the 12th Quantitative InfraRed Thermography Conference (QIRT 2014), Bordeaux, France, 7–11 July 2014. [Google Scholar]

- Wang, Y.; Gao, B.; Woo, W.L.; Tian, G.; Maldague, X.; Zheng, L.; Guo, Z.; Zhu, Y. Thermal Pattern Contrast Diagnostic of Microcracks With Induction Thermography for Aircraft Braking Components. IEEE Trans. Ind. Inform. 2018, 14, 5563–5574. [Google Scholar] [CrossRef] [Green Version]

- Washer, G.; Fenwick, R.; Bolleni, N. Effects of solar loading on infrared imaging of subsurface features in concrete. J. Bridge Eng. 2010, 15, 384–390. [Google Scholar] [CrossRef]

- Kubota, Y.; Hayakawa, T.; Ke, Y.; Moko, Y.; Ishikawa, M. High-speed motion blur compensation system in infrared region using galvanometer mirror and thermography camera. Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2020. Int. Soc. Opt. Photonics 2020, 11379, 1137919. [Google Scholar]

- St-Laurent, L.; Mikhnevich, M.; Bubel, A.; Prévost, D. Passive calibration board for alignment of VIS-NIR, SWIR and LWIR images. QIRT J. 2017, 14, 193–205. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Garcia, D.; Ibarra-Castanedo, C.; Maldague, X. Highly accurate geometric calibration for infrared cameras using inexpensive calibration targets. Measurement 2017, 112, 105–116. [Google Scholar] [CrossRef]

- Yang, R.; He, Y. Optically and non-optically excited thermography for composites: A review. Infrared Phys. Technol. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Holland, S.D.; Reusser, R.S. Material evaluation by infrared thermography. Annu. Rev. Mater. Res. 2016, 46, 287–303. [Google Scholar] [CrossRef]

- Hiasa, S.; Birgul, R.; Catbas, F.N. Infrared thermography for civil structural assessment: Demonstrations with laboratory and field studies. J. Civil Struct. Health Monit. 2016, 6, 619–636. [Google Scholar] [CrossRef]

- Vidas, S.; Lakemond, R.; Denman, S.; Fookes, C.; Sridharan, S.; Wark, T. A mask-based approach for the geometric calibration of thermal-infrared cameras. IEEE Trans. Instrum. Meas. 2012, 61, 1625–1635. [Google Scholar] [CrossRef] [Green Version]

- Cheng, S.Y.; Park, S.; Trivedi, M.M. Multiperspective thermal IR and video arrays for 3D body tracking and driver activity analysis. In Proceedings of the 2005 IEEE Conference on Computer Vision and Pattern Recognition, San Diego, CA, USA, 20–26 June 2005; p. 3. [Google Scholar]

- Prakash, S.; Lee, P.Y.; Caelli, T.; Raupach, T. Robust thermal camera calibration and 3D mapping of object surface temperatures. Proc. SPIE 2006, 6205, 62050J. [Google Scholar]

- Hilsenstein, V. Surface reconstruction of water waves using thermographic stereo imaging. In Proceedings of the Image and Vision Computing New Zealand, Dunedin, New Zealand, 28–29 November 2005; pp. 102–107. [Google Scholar]

- Acampora, L.; De Filippis, F.; Martucci, A.; Sorgi, L. 3D reconstruction of thermal images. In Proceedings of the 26th Aerospace Testing Seminar, Los Angeles, CA, USA, 29–31 March 2011; pp. 263–277. [Google Scholar]

- Rzeszotarski, D.; Wiecek, B. Calibration for 3D reconstruction of thermal images. In Proceedings of the 9th Quantitative InfraRed Thermography conference (QIRT 2008), Krakow, Poland, 2–5 July 2008; pp. 563–566. [Google Scholar]

- Ming, Y.; Ng, H.; Du, R. Acquisition of 3D surface temperature distribution of a car body. In Proceedings of the 2005 IEEE International Conference on Information Acquisition, Hong Kong, China, 27 June–3 July 2005; pp. 16–20. [Google Scholar]

- Cardone, G.; Ianiro, A.; Dello Ioio, G.; Passaro, A. Temperature maps measurements on 3D surfaces with infrared thermography. Exp. Fluids 2012, 52, 375–385. [Google Scholar] [CrossRef]

- Skala, K.; Lipić, T.; Sović, I.; Gjenero, L.; Grubišić, I. 4D thermal imaging system for medical applications. Period. Biol. 2011, 113, 407–416. [Google Scholar]

- Gschwandtner, M.; Kwitt, R.; Uhl, A.; Pree, W. Infrared camera calibration for dense depth map construction. In Proceedings of the 2011 IEEE Intelligent Vehicles Symposium, Barden-barden, Germany, 5–9 June 2011; pp. 857–862. [Google Scholar]

- Lagüela, S.; Martínez, J.; Armesto, J.; Arias, P. Energy efficiency studies through 3D laser scanning and thermographic technologies. Energy Build. 2011, 43, 1216–1221. [Google Scholar] [CrossRef]

- Yang, R.; Yang, W.; Chen, Y.; Wu, X. Geometric calibration of IR camera using trinocular vision. J. Light. Technol. 2011, 29, 3797–3803. [Google Scholar] [CrossRef]

- Ellmauthaler, A.; da Silva, E.A.; Pagliari, C.L.; Gois, J.N.; Neves, S.R. A novel iterative calibration approach for thermal infrared cameras. In Proceedings of the 2013 IEEE International Conference on Image Processing, Melbourne, Australia, 15–18 September 2013; pp. 2182–2186. [Google Scholar]

- Yu, Z.; Lincheng, S.; Dianle, Z.; Daibing, Z.; Chengping, Y. Camera calibration of thermal-infrared stereo vision system. In Proceedings of the 2013 Fourth International Conference on Intelligent Systems Design and Engineering Applications, Zhangjiajie, China, 6–7 November 2013; pp. 197–201. [Google Scholar]

- Stierwalt, D.L. Infrared spectral emittance measurements of optical materials. Appl. Opt. 1966, 5, 1911–1915. [Google Scholar] [CrossRef]

- Bauer, W.; Moldenhauer, A.; Oertel, H. Thermal radiation properties of different metals. Proc. SPIE 2006, 6205, 62050E. [Google Scholar]

- Saponaro, P.; Sorensen, S.; Rhein, S.; Kambhamettu, C. Improving calibration of thermal stereo cameras using heated calibration board. In Proceedings of the 2015 IEEE International Conference on Image Processing, Quebec City, QC, Canada, 27 September–1 October 2015; pp. 4718–4722. [Google Scholar]

- Gao, B.; Woo, W.L.; He, Y.; Tian, G.Y. Unsupervised sparse pattern diagnostic of defects with inductive thermography imaging system. IEEE Trans. Ind. Inform. 2015, 12, 371–383. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Piau, J.M.; Guilbert, S.; Avdelidis, N.P.; Genest, M.; Bendada, A.; Maldague, X.P. Comparative study of active thermography techniques for the nondestructive evaluation of honeycomb structures. Res. Nondestruct. Eval. 2009, 20, 1–31. [Google Scholar] [CrossRef]

- Ju, X.; Nebel, J.C.; Siebert, J.P. 3D thermography imaging standardization technique for inflammation diagnosis. Infrared Components and Their Applications. Int. Soc. Opt. Photonics 2005, 5640, 266–273. [Google Scholar]

- Sinha, A.; Sastry, O.; Gupta, R. Detection and characterisation of delamination in PV modules by active infrared thermography. Nondestruct. Test. Eval. 2016, 31, 1–16. [Google Scholar] [CrossRef]

- Spencer, C.A.; Bond, J.W. A calibration test for latent fingerprint development on thermal paper. J. Forensic Sci. 2014, 59, 1635–1637. [Google Scholar] [CrossRef] [PubMed]

- Hayakawa, T.; Ishikawa, M. Motion-blur-compensated structural health monitoring system for tunnels at a speed of 100 km/h. Proc. SPIE 2017, 10169, 101692G. [Google Scholar]

- Suzuki, S.; Ogasawara, N. Infrared thermographic test for removing background reflection based on polarization theory. NDT E Int. 2019, 103, 19–25. [Google Scholar] [CrossRef]

| Index | a | b | c | d | e | f | g | h | i | j | k |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Upper | BJP | WJP | PE-1 | PE-2 | BJP | WJP | PE-1 | PE-2 | BJP | WJP | Ink |

| Lower | Cu | Cu | Cu | Cu | Al | Al | Al | Al | WJP | BJP | Paper |

| Abbreviation | Material | Manufacturer and Product Number |

|---|---|---|

| Cu | Copper foil (Metal) | Nitoms, copper foil tape J3170 |

| Al | Aluminum foil (Metal) | Nitoms, thick aluminum tape, J3090 |

| BJP | Black Japanese paper (Insulator) | Kamoi masking tape, Japanese paper adhesive tape 220 color |

| WJP | White Japanese paper (Insulator) | Monotaro, masking tape for architecture and painting |

| PE-1 | Black polyethylene tape (Insulator) | Diatex, MT-08-BK-50MM |

| PE-2 | Black polyethylene tape (Insulator) | Nitto Denko, PE corrosion-proof tape No. 55 |

| Paper | Copier paper (Insulator) | Daio Paper, recycled plain copier paper |

| Ink | Toner (Insulator) | Canon, toner cartridge CRG-040HBLK |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubota, Y.; Ke, Y.; Hayakawa, T.; Moko, Y.; Ishikawa, M. Optimal Material Search for Infrared Markers under Non-Heating and Heating Conditions. Sensors 2021, 21, 6527. https://doi.org/10.3390/s21196527

Kubota Y, Ke Y, Hayakawa T, Moko Y, Ishikawa M. Optimal Material Search for Infrared Markers under Non-Heating and Heating Conditions. Sensors. 2021; 21(19):6527. https://doi.org/10.3390/s21196527

Chicago/Turabian StyleKubota, Yuki, Yushan Ke, Tomohiko Hayakawa, Yushi Moko, and Masatoshi Ishikawa. 2021. "Optimal Material Search for Infrared Markers under Non-Heating and Heating Conditions" Sensors 21, no. 19: 6527. https://doi.org/10.3390/s21196527

APA StyleKubota, Y., Ke, Y., Hayakawa, T., Moko, Y., & Ishikawa, M. (2021). Optimal Material Search for Infrared Markers under Non-Heating and Heating Conditions. Sensors, 21(19), 6527. https://doi.org/10.3390/s21196527