Use of the Ferroelectric Ceramic Bismuth Titanate as an Ultrasonic Transducer for High Temperatures and Nuclear Radiation

Abstract

:1. Introduction

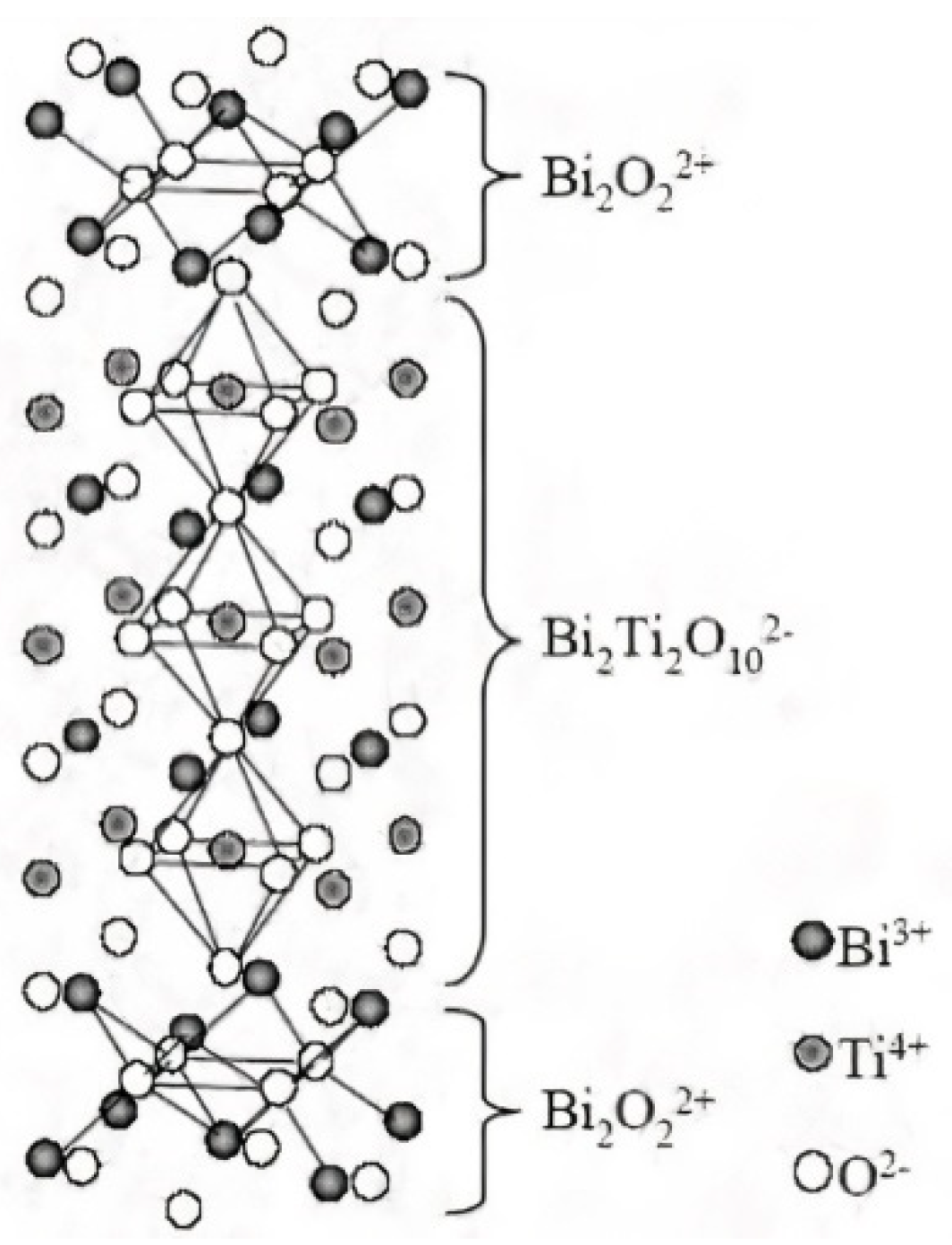

2. Bismuth Titanate (BiTi)—Material Properties

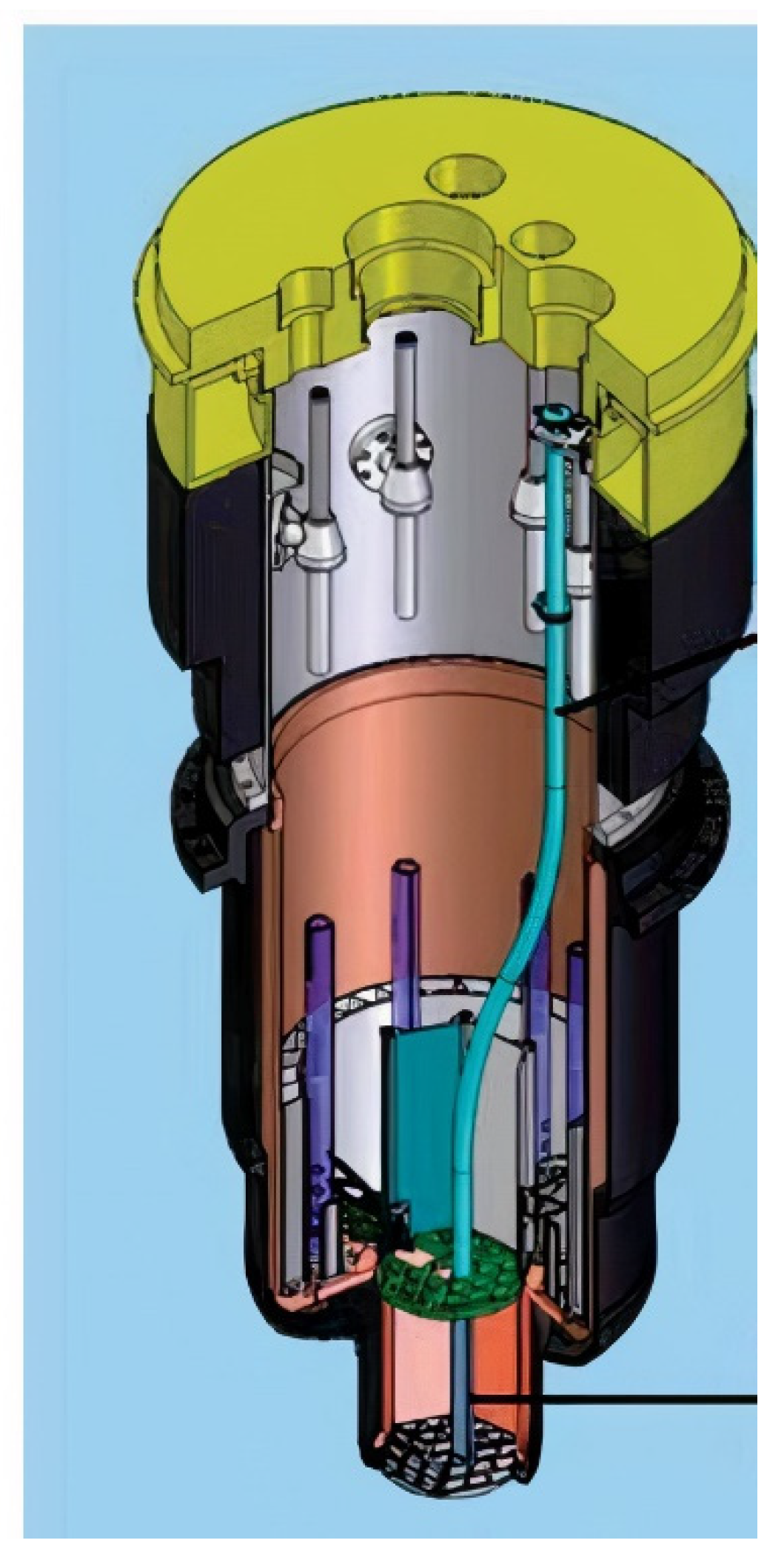

3. Overview of Reactor Project

4. Reactor Environment

5. Capsule Environmental Characterization

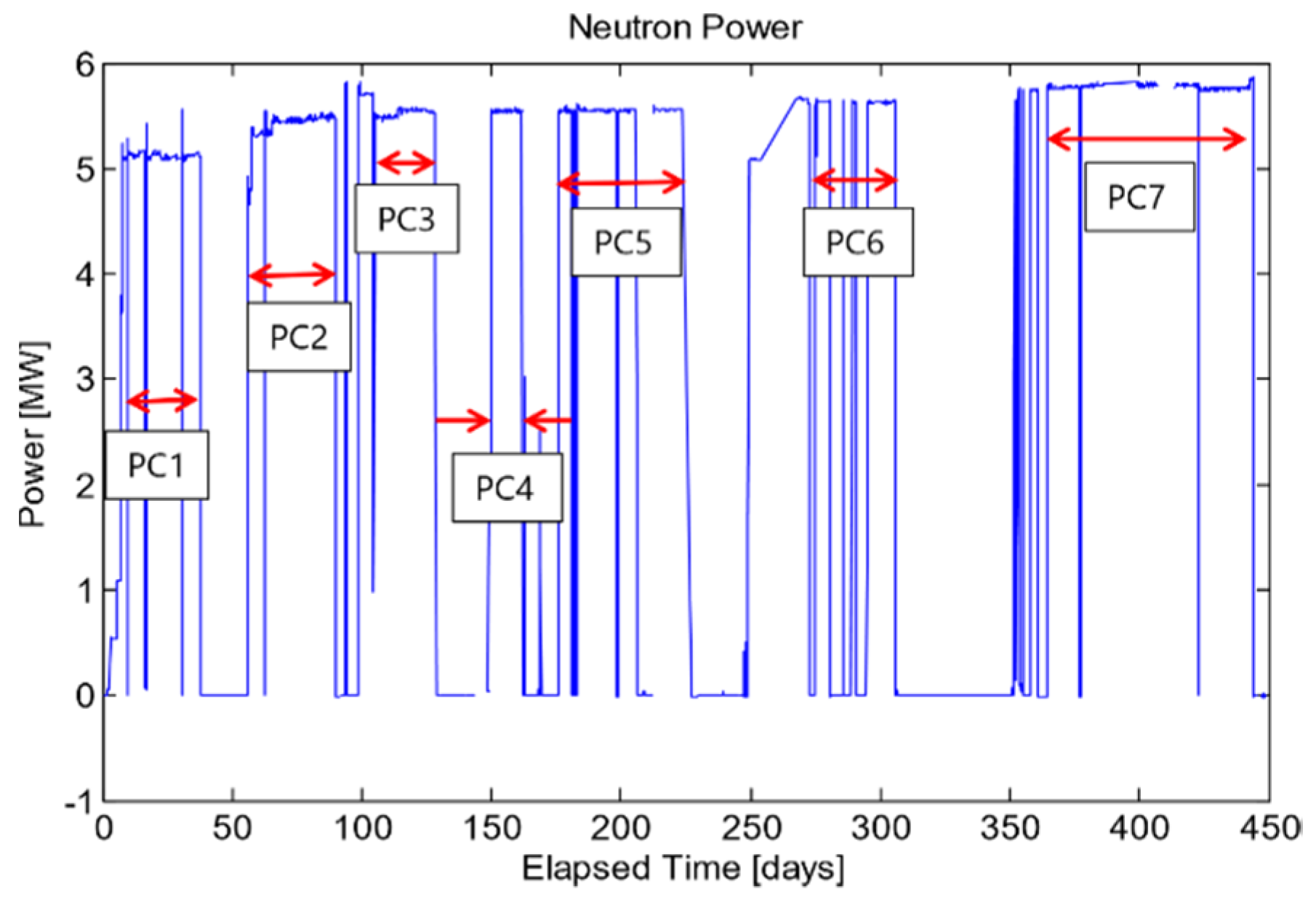

6. Neutron Power

6.1. Neutron Fluence

6.2. Gamma Fluence

7. Measurement Process

7.1. Insertion Capsule

7.2. In-Pile Ultrasonic Measurement Equipment

7.3. Out-of-Pile Optical Inspection and Ultrasonic Measurements

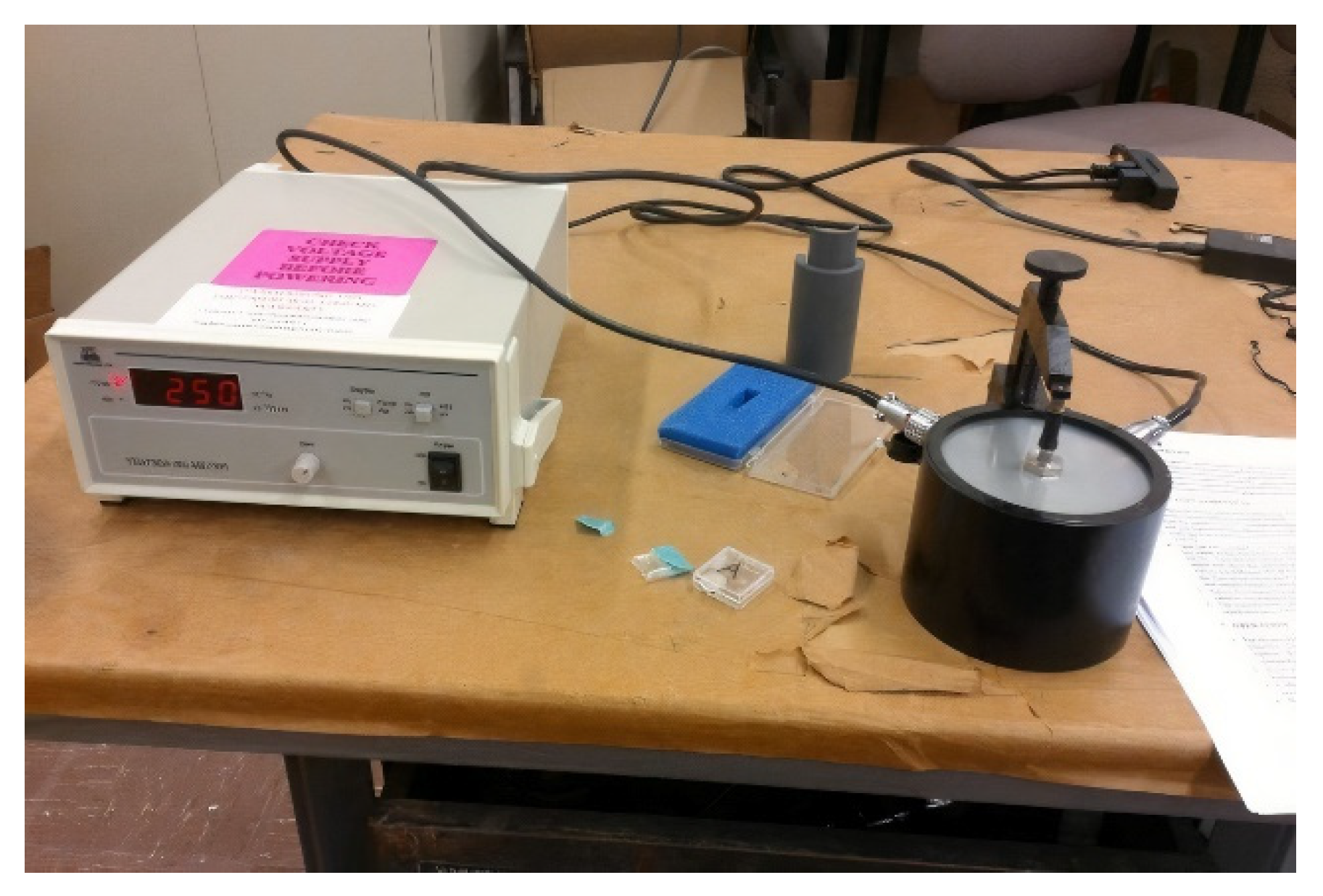

8. Out-of-Pile Measurements of Piezoelectric Coefficient, d33

9. Data Processing

10. Bismuth Titanate (BiTi) Sensor Results

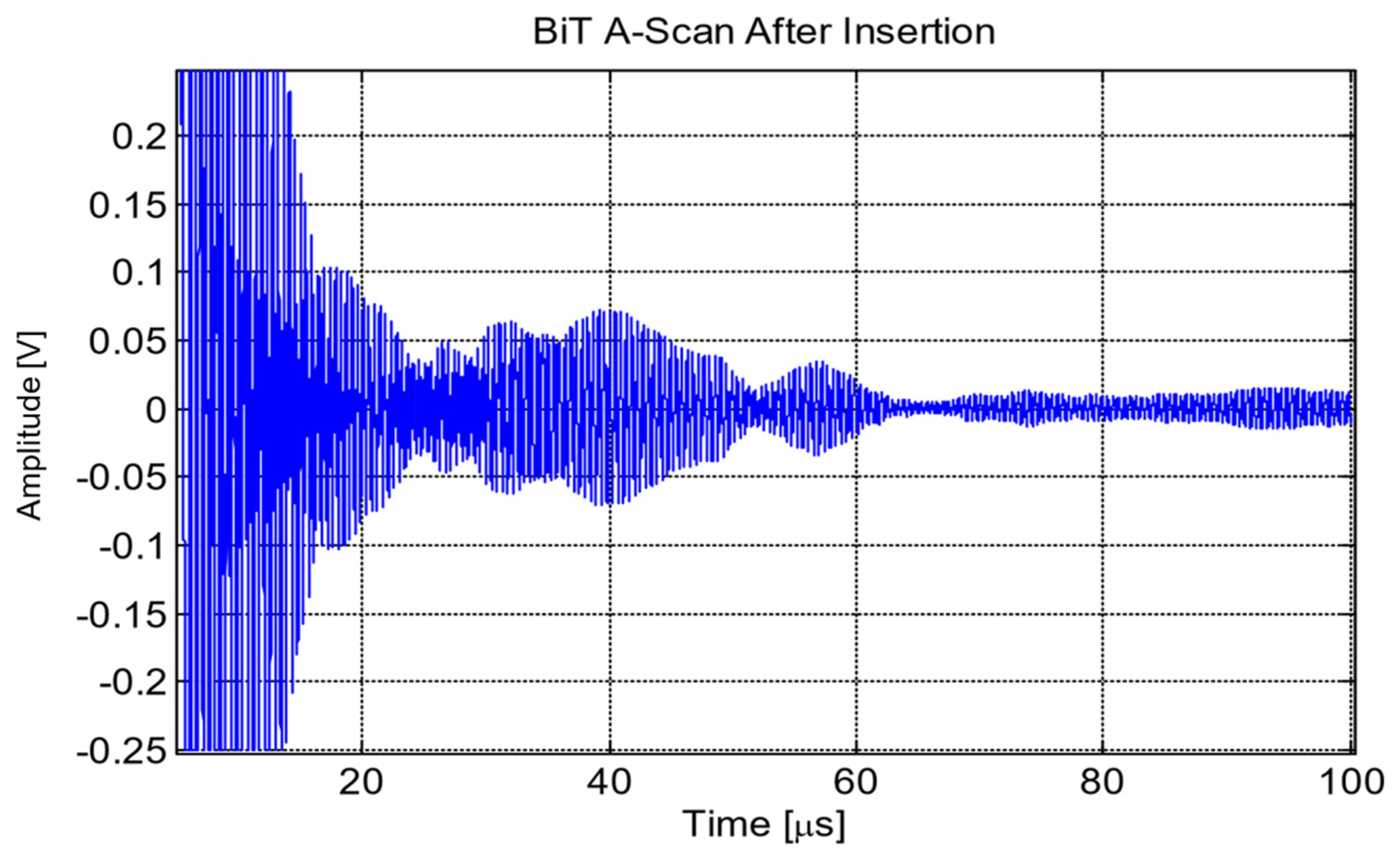

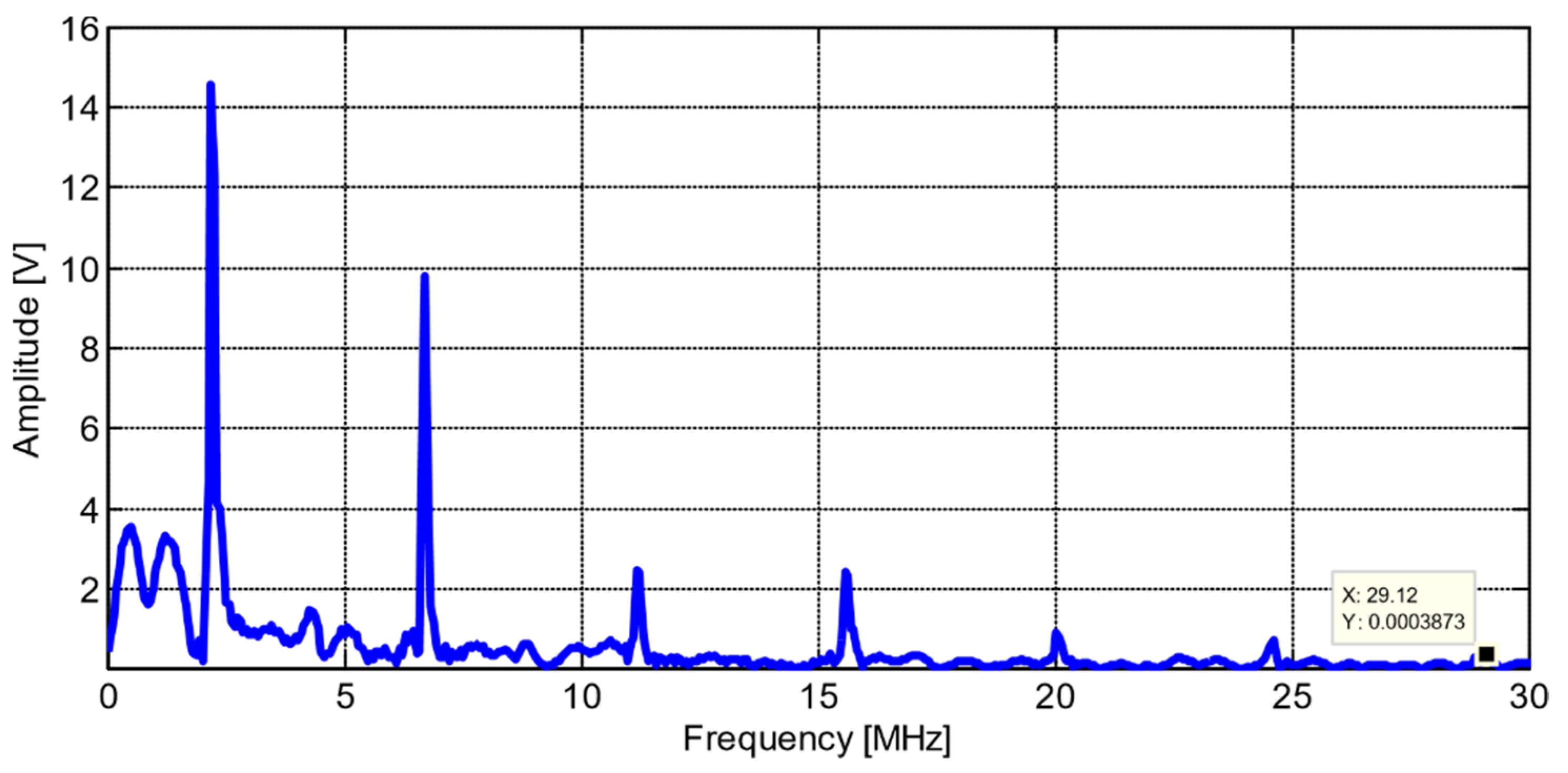

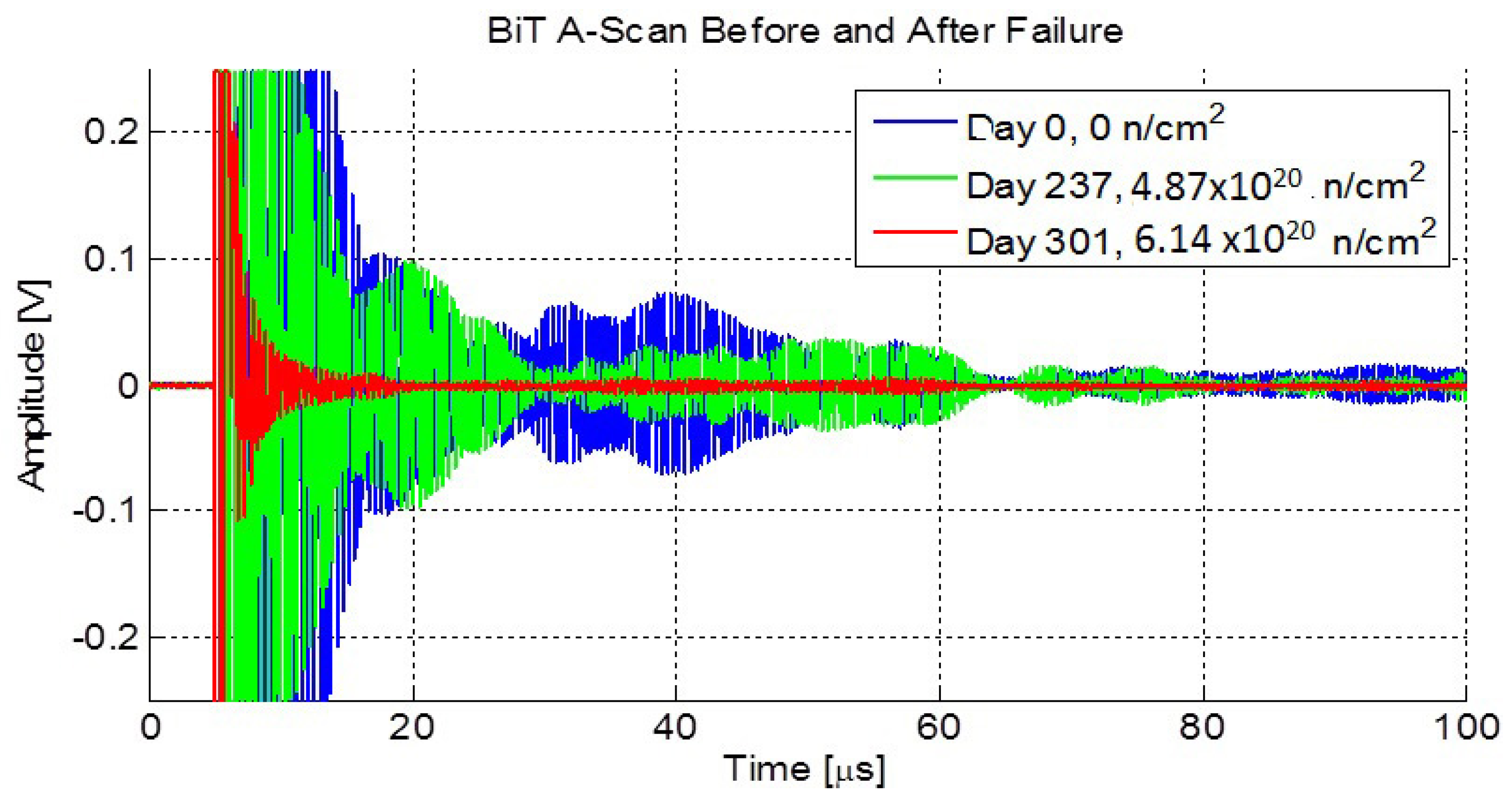

10.1. Ultrasonic Measurements

10.2. Performance during Irradiation

11. Bismuth Titanate (BiTi) Drop-In Sample

11.1. Overview

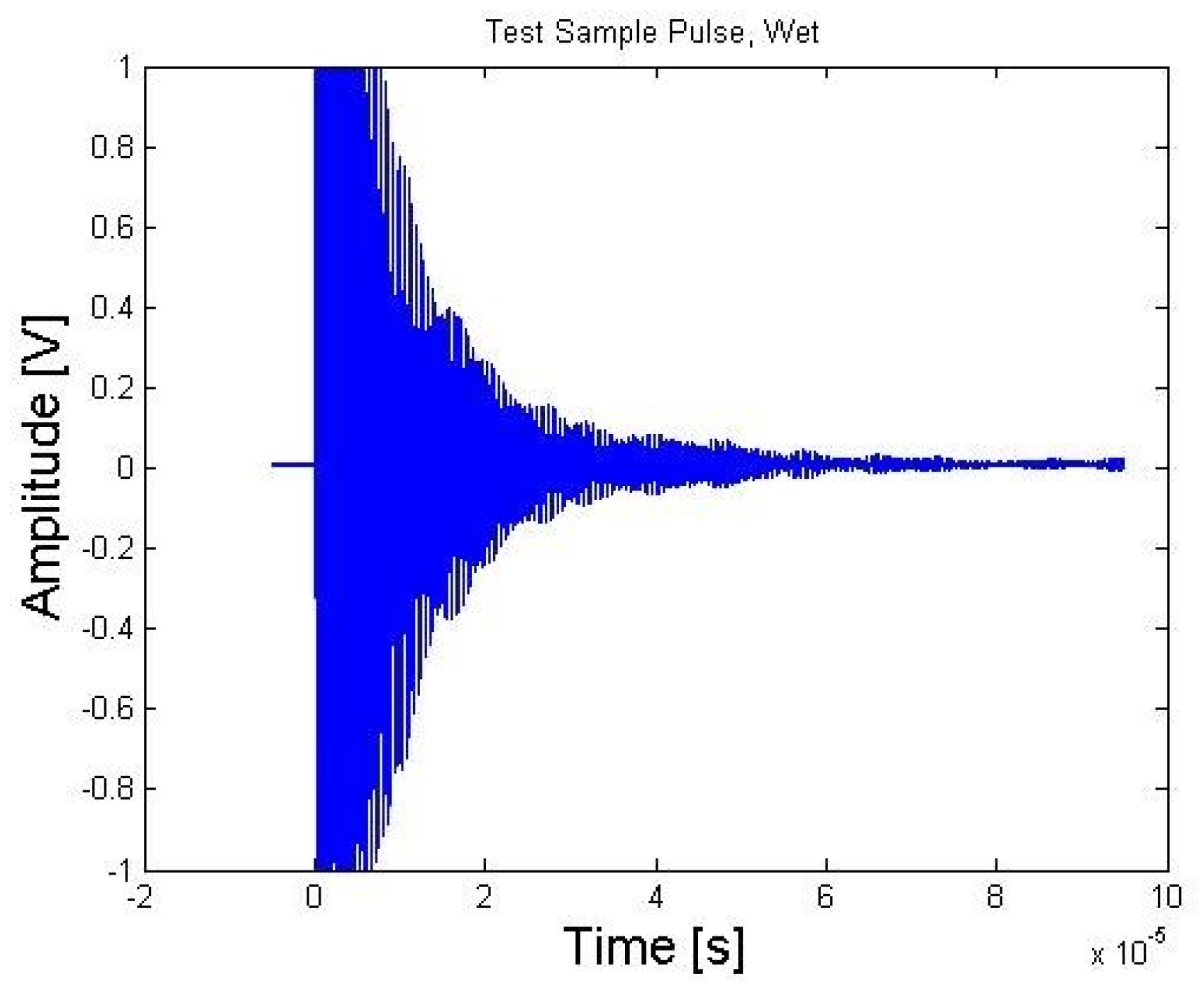

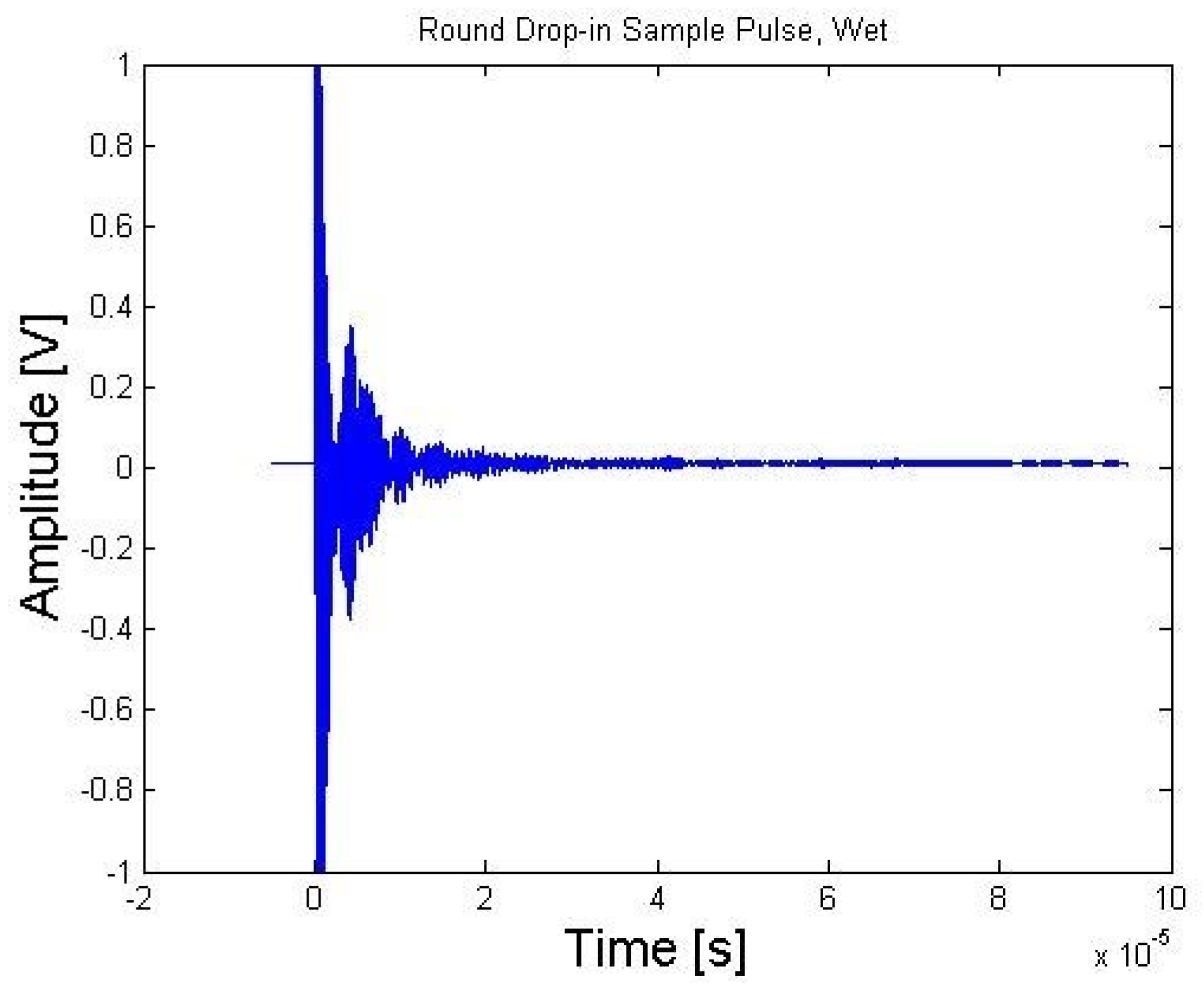

11.2. Ultrasonic Measurements on Drop-In Sample of Bismuth Titanate

12. Measurements of Piezoelectric Coefficient, d33

13. Radiation Damage

- De-poling via thermal spike processes;

- Amorphization/metamictization due to displacement spikes or high concentration of point defects;

- Increase in point defect concentration;

- Development of defect aggregates.

14. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sinclair, A.N.; Chertov, A.M. Radiation endurance of piezoelectric ultrasonic transducers—A review. Ultrasonics 2014, 57, 1–10. [Google Scholar] [CrossRef]

- Aurivillius, B. Mixed bismuth oxides with layer lattices II. Structure of Bi4Ti3O12. Arkiv Kemi 1949, 1, 499–512. [Google Scholar]

- Lazarevic, Z.; Stojanoic, B.D.; Varela, J.A. An Approach to Analyzing Synthesis, Structure, and Properties of Bismuth Titanate Ceramics. Sci. Sinter. 2005, 37, 199–216. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, F. Piezoelectric Materials for High Temperature Sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Smolenskii, G.A.; Bokov, V.A.; Isupov, V.A.; Krainik, N.N.; Pasynkov, R.E.; Sokolov, A.I. Ferroelectrics and Related Materials; Gordon and Breach Science Publishers: New York, NY, USA; London, UK; Paris, France; Montreux, Switzerland; Tokio, Japan, 1984; p. 18. [Google Scholar]

- Shulman, H.S.; Testorf, M.; Damjanovic, D.; Setter, N. Microstructure, Electrical Conductivity, and Piezoelectric Properties of Bismuth Titanate. J. Am. Ceram. Soc. 1996, 79, 3124–3128. [Google Scholar] [CrossRef]

- Cummins, S.E.; Cross, L.E. Crystal symmetry, optical properties and Ferroelectric Polarization of Bi4Ti3O12 Single Crystals. Appl. Phys. Lett. 1967, 10, 14–16. [Google Scholar] [CrossRef]

- Del Piezo Specialties, LLC. (350 Tall Pines Road, Suite H & I. West Palm Beach, FL 33413. Tel: 561-309-7170. Fax: 561-478-8822. E-mail: sales@delpiezo.com). Available online: https://www.delpiezo.com (accessed on 23 June 2021).

- Wang, W.; Zheng, K.; Sun, S.; Qin, L.; Tang, L.; Li, Z. Characterization of the full matrix constants of Bi4Ti3O12 ceramics. Ceram. Int. 2021, 47, 23518–23527. [Google Scholar] [CrossRef]

- Meleshko, Y.P.; Babaev, S.V.; Karpechko, S.G.; Nalivaev, V.I.; Safin, Y.A.; Smirnov, V.M. A study of the electrophysical parameters of various types of piezoceramics in an IVV-2M reactor. Sov. At. Energy 1984, 57, 111–113. [Google Scholar] [CrossRef]

- Kazys, R.; Voleisis, A.; Sliteris, R.; Voleisiene, B.; Mazeika, L.; Kupschus, P.H.; Abderrahim, H.A. Development of ultrasonic 1254 sensors for operation in a heavy liquid metal. IEEE Sens. J. 2006, 6, 1134–1143. [Google Scholar] [CrossRef]

- Kažys, R.; Vaškelienė, B. High temperature ultrasonic transducers: A review. Sensors 2021, 21, 3200. [Google Scholar] [CrossRef] [PubMed]

- Ferrandis, J.Y.; Gatsa, O.; Combette, P.; Fourmentel, D.; Destouches, C.; Radulovic, V.; Snoj, L. Acoustic instrumentation of the new generation of MTR: Effect of nuclear radiation on modified Bismuth Titanate piezoelectric elements. ANIMMA 2019, 225, 04012. [Google Scholar] [CrossRef]

- Reinhardt, B. Nonlinear Ultrasonic Measurements in Nuclear Reactor Environments. Ph.D. Thesis, The Pennsylvania State University, Stecker Ridge, PA, USA, 2016. [Google Scholar]

- Daw, J.; Tittmann, B.R.; Reinhardt, B.; Kohse, G.; Ramuhali, P.; Montgomery, R.; Chien, H.-T.; Villard, J.-F.; Palmer, J.; Rempe, J. Irradiation testing of ultrasonic transducers. Presented at the International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and their Applications, Marseille, France, 23–27 June 2013. [Google Scholar]

- Daw, J.E.; JRempe, L.; Palmer, J.; Tittmann, B.R.; Reinhardt, B.; Kohse, G.; Ramuhalli, P.; Chien, H.T. Assessment of survival or ultrasonic transducers under neutron irradiation. In Nuclear Fuels and Materials Spotlight; Byrd, L., Ed.; Idaho National Laboratory: Idaho Falls, ID, USA, 2014; Volume 4. [Google Scholar]

- Reinhardt, B.; Tittmann, B.; Rempe, J.; Daw, J.; Kohse, G.; Carpenter, D.; Ames, M.; Ostrovsky, Y.; Ramuhalli, P.; Montgomery, R.; et al. Progress towards developing neutron tolerant magnetostrictive and piezoelectric transducers. In Proceedings of the 41st Annual Review of Progress in Quantitative Nondestructive Evaluation, Centre County, PE, USA, 20–24 July 2015; Chimenti, D.E., Bond, L.J., Eds.; AIP Publishing: Melville, NY, USA, 2015; 1650, pp. 1512–1520. [Google Scholar]

- Reinhardt, B.; Tittmann, B.R.; Suprock, A. Nuclear radiation tolerance of single crystal aluminum nitride ultrasonic transonic. In Proceedings of the 2015 ICU International Congress on Ultrasonics, Metz, France, 15–24 May 2015; Volume 70, pp. 609–613. [Google Scholar]

- Tittmann, B.R. Transducers for in-pile ultrasonic measurement of the evolution of fuels and materials. In Nuclear Science User Facilities 2014 Annual Report; Department of Energy: Idaho Falls, ID, USA, 2015. [Google Scholar]

- Reinhardt, B.T.; Suprock, A.; Tittmann, B.R. Testing piezoelectric sensors in a nuclear reactor environment. In 43rd Annual Review of Progress in Quantitative Nondestructive Evaluation; Chimenti, D.E., Bond, L.J., Eds.; AIP Publishing: Melville, NY, USA, 2017. [Google Scholar]

- Reinhardt, B.; Daw, J.; Tittmann, B.R. Irradiation Testing of Piezoelectric Aluminum Nitride, Zinc Oxide, Bismuth Titanate and Magnetostrictive Sensors (Remendur and Galfenol). IEEE Trans. Nucl. Sci. 2018, 65, 533–538. [Google Scholar] [CrossRef]

- Herskovitz, M.B.; Hubbell, H.H. Effect of Fast-Neutron Irradiation on Sheather Chromel/Alumel Thermocouples; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1976. [Google Scholar]

- Burrows, S.; Ramadas, S.N.; Eriksson, T.J.R.; Kang, L.; Dixon, S.M.; Unger, A.; Kupnik, M. High temperature flexural ultrasonic 1392 transducer for non-contact measurement applications. In Proceedings of the 2016 Joint IEEE International Symposium on the Applications of Ferroelectrics, European Conference on Application of Polar Dielectrics, and Piezoelectric Force Microscopy Workshop (ISAF/ECAPD/PFM), Darmstadt, Germany, 21–25 August 2016. [Google Scholar] [CrossRef]

- Yan, H.; Ning, H.; Kan, Y.; Wang, P.; Reece, M.J. Piezoelectric Ceramics with Super-High Curie Points. J. Am. Ceram. Soc. 2009, 92, 2270–2275. [Google Scholar] [CrossRef]

- Gao, Z.; Lu, C.; Wang, Y.; Yang, S.; Yu, Y.; He, H. Super Stable Ferroelectrics with High Curie Point. Sci. Rep. 2016, 6, 24139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barrow, D.; Petroff, T.; Sayer, M. Thick ceramic coatings using a sol gel-based ceramic-ceramic 0–3 composite. Surf. Coat. Technol. 1995, 76, 113–118. [Google Scholar] [CrossRef]

- Kobayashi, M.; Olding, T.R.; Zou, L.; Sayer, M.; Jen, C.K.; Rehmen, A.U. Piezoelectric Thick Film Ultrasonic Transducers Fabricated by a Spray Technique. In Proceedings of the IEEE Ultrasonics Symposium, San Juan, PR, USA, 22–25 October 2000; pp. 985–989. [Google Scholar]

- Kobayashi, M.; Jen, C.K. Piezoelectric thick bismuth titanate/lead zirconate titanate composite film transducers for smart NDE of metals. Smart Mater. Struct. 2004, 13, 951–956. [Google Scholar] [CrossRef]

- Kobayashi, M.; Jen, C.K.; Nagata, H.; Hiruma, Y.; Tokutsu, T.; Takenaka, T. 10F-5 integrated ultrasonic transducers above 500 °C. In Proceedings of the 2007 IEEE Ultrasonics Symposium, New York, NY, USA, 28–31 October 2007; pp. 953–956. [Google Scholar]

- Kobayashi, M.; Jen, C.K.; Ono, Y.; Krüger, S. Lead-free thick piezoelectric films as miniature high temperature ultrasonic transducer. In Proceedings of the IEEE Ultrasonic Symposium, Montreal, QC, Canada, 23–27 August 2004; pp. 910–913. [Google Scholar]

- Kobayashi, M.; Ono, Y.; Jen, C.K.; Cheng, C.C. High-Temperature Piezoelectric Film Ultrasonic Transducers by a Sol-Gel Spray Technique and Their Application to Process Monitoring of Polymer Injection Molding. IEEE Sens. J. 2006, 6, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Searfass, C.T.; Baba, A.; Tittmann, B.R.; Agrawal, D.K. Fabrication and testing of microwave sintered sol-gel spray-on bismuth titanate-lithium niobate based piezoelectric composite for use as a high temperature (>500 °C) ultrasonic transducer. In Review of Progress in Quantitative Nondestructive Evaluation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; pp. 1035–1042. [Google Scholar]

- Searfass, C.T.; Tittmann, B.R.; Agrawal, D.K. Sol-gel deposited thick film bismuth titanate based transducer achieves operation of 600 °C. In Review of Progress in Quantitative Nondestructive Evaluation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; pp. 1751–1758. [Google Scholar]

- Searfass, C.T.; Parks, D.A.; Baba, A.; Tittmann, B.R. Testing of single crystal and oriented polycrystalline piezoelectric materials for use as high temperature (>500 °C) ultrasonic transducers. In Proceedings of the 12th International Symposium on Nondestructive Characterization of Materials (NDCM-XII), Blacksburg, VA, USA, 19–24 June 2011. [Google Scholar]

- Searfass, C.T.; Baba, A.; Tittmann, B.R.; Agrawal, D.K. Spray-on piezoelectric bismuth titanate and bismuth titanate-lithium niobate transducers for high temperature (>500 °C). In Proceedings of the 12th International Symposium on Nondestructive Characterization of Materials (NDCM-XII), Blacksburg, VA, USA, 19–24 June 2011. [Google Scholar]

- Ledford, K.R. Practical Sprayed-on Transducer Composites for High Temperature Applications. Master’s Thesis, The Pennsylvania State University, Stecker Ridge, PA, USA, 2015. [Google Scholar]

- Cho, S.W.; Lee, J.I.; Jeong, Y.H. Microstructure, Ferroelectric and Piezoelectric Properties of Bi4Ti3O12 Platelet Incorporated 0.36BiScO3-0.64PbTiO3 Thick Films for High Temperature Piezoelectric Device Applications. Ceram. Int. 2012. [Google Scholar] [CrossRef]

- Trivedi, Y. Field-Deployable Guided Wave Transducers for High-Temperature Applications. Master’s Thesis, The Pennsylvania State University, Stecker Ridge, PA, USA, 2016. [Google Scholar]

- Anonymous. Evaluation of irradiation test results for candidate NERVA. In Piezoelectric Accelerometers, Ground Test Reactor Irradiation Test No. 22; Aerojet Nuclear Systems Company: Huntsville, AL, USA, 1971. [Google Scholar]

- Hobbs, L.W.; Jesurum, C.E.; Berger, B. Rigidity constraints in amorphization of singly and multiply-polytopic structures. In Rigidity Theory and Applications; Kluwer Academic/Plenium Publishers: New York, NY, USA, 1999; pp. 191–216. [Google Scholar]

- Trachenko, K. Understanding resistance to amorphization by radiation damage. J. Phys. Condens. Matter 2004, 16, R1491–R1515. [Google Scholar] [CrossRef]

- Glower, D. Effects of Radiation-Induced Damage Centers in Lead Zirconate Titanate Ceramics. J. Am. Ceram. Soc. 1965, 48, 417–421. [Google Scholar] [CrossRef]

- Primak, W.; Anderson, T. Metamimictization of Lithium Niobate by Thermal Neutrons. Nucl. Technol. 1975, 23, 235. [Google Scholar]

- Hobbs, L.W.; Clinard, F.W.; Zinkle, S.J.; Ewing, R.C. Radiation effects in ceramics. J. Nucl. Mater. 1994, 216, 291–321. [Google Scholar] [CrossRef]

- Baranov, V.M.; Martynenko, S.P. Durability of ZTL Piezoceramic Under the Action of Reactor Irradiation. Atomnaya Energiya 1982, 53, 803–804. [Google Scholar]

- Lefkowitz, I. Radiation-Induced Changes in the Ferroelectric Properties of Some Barium Titanate-Type Materials. J. Phys. Chem. Solids 1958, 10, 169–173. [Google Scholar] [CrossRef]

- Szenes, G. Ion-induced amorphization in ceramic materials. J. Nucl. Mater. 2005, 336, 81–89. [Google Scholar] [CrossRef]

- Szenes, G. Thermal spike analysis of ion-induced tracks in semiconductors. Nuclear Inst. Methods Phys. Res. B 2011, 269, 2075–2079. [Google Scholar] [CrossRef]

- Miclea, A.; Tanasoiu, C.; Miclea, C.F.; Spanulescu, I.; Cioangher, M. Effect of neutron irradiation on some piezoelectric properties of PZT type ceramics. Romania 2005, 128, 115–120. [Google Scholar] [CrossRef]

- Kazys, R.; Voleisis, A.; Sliteris, R.; Mazeika, L.; Van Nieuwenhove, R.; Kupschus, P.; Abderrahim, H.A. High Temperature Ultrasonic Transducers for Imaging and Measurements in a Liquid Pb/Bi Eutectic Alloy. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2005, 52, 525–537. [Google Scholar] [CrossRef]

- Friedland, E. Influence of electronic stopping on amorphization energies. Surf. Coat. Technol. 2006, 201, 8220–8224. [Google Scholar] [CrossRef]

- Dienes, G.J.; Vineyard, G.H. Radiation Effects in Solids. N. Y. Intersci. Publ. Inc. 1957, 2, 25–56. [Google Scholar] [CrossRef]

- Brinkman, J.A. On the Nature of Radiation Damage in Metals. J. Appl. Phys. 1954, 25, 961. [Google Scholar] [CrossRef]

- Trachenko, K.; Pruneda, J.M.; Artacho, E.; Dove, M.T. How the nature of the chemical bond governs resistance to amorphization by radiation damage. Phys. Rev. B 2005, 71, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Yano, T.; Inokuchi, K.; Shikama, M.; Ukai, J. Neutron irradiation effects on isotope tailored aluminum nitride ceramics by a fast reactor up to 2E l026 n/m2. J. Nucl. Mater. 2004, 329–333, 1471–1475. [Google Scholar] [CrossRef]

- Parks, D.A.; Tittmann, B.R.; Kropf, M.M. Aluminum Nitride as a High Temperature Transducer. Quant. Nondestruct. Eval. 2009, 1211, 1029–1034. [Google Scholar]

| Material | Structure | Transition Temp (°C) | Transition Type | d33 (pC/N) | K33 |

|---|---|---|---|---|---|

| Bi4O12T3 | Perovskite | 650 | Curie Temp | 20 | 0.23 |

| Post-Irradiated d33 (pC/N) | Pre-Irradiated d33 (pC/N) |

|---|---|

| 10.8–11.3 | 20 |

| Nuclei | Cross-Section Barnes (10−24 cm2) |

|---|---|

| Bismuth (Bi) | 9.16 |

| Titanium (Ti) | 4.35 |

| Oxygen (O) | 4.23 |

| Lead (Pb) | 11.2 |

| Radiation Source | Exposure |

|---|---|

| Thermal flux (<0.4 eV) | 2.27 × 1020 (n/cm2) |

| Epithermal flux (0.4 eV, 0.1 MeV) | 1.72 × 1021 (n/cm2) |

| Fast flux 1 (>0.1 MeV) | 1.88 × 1021 (n/cm2) |

| Fast flux 2 (>1 MeV) | 8.68 × 1021 (n/cm2) |

| Total (Full range) | 4.05 × 1021 (n/cm2) |

| Gamma | 7.23 × 1021 (gamma/cm2) |

| Fast Fluence (n/cm2) | % Change in Amp | % Change in fc |

|---|---|---|

| 5 × 1020 | –80% | 0.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reinhardt, B.T.; Tittmann, B.R. Use of the Ferroelectric Ceramic Bismuth Titanate as an Ultrasonic Transducer for High Temperatures and Nuclear Radiation. Sensors 2021, 21, 6094. https://doi.org/10.3390/s21186094

Reinhardt BT, Tittmann BR. Use of the Ferroelectric Ceramic Bismuth Titanate as an Ultrasonic Transducer for High Temperatures and Nuclear Radiation. Sensors. 2021; 21(18):6094. https://doi.org/10.3390/s21186094

Chicago/Turabian StyleReinhardt, Brian T., and Bernhard R. Tittmann. 2021. "Use of the Ferroelectric Ceramic Bismuth Titanate as an Ultrasonic Transducer for High Temperatures and Nuclear Radiation" Sensors 21, no. 18: 6094. https://doi.org/10.3390/s21186094

APA StyleReinhardt, B. T., & Tittmann, B. R. (2021). Use of the Ferroelectric Ceramic Bismuth Titanate as an Ultrasonic Transducer for High Temperatures and Nuclear Radiation. Sensors, 21(18), 6094. https://doi.org/10.3390/s21186094