A Multichannel Strain Measurement Technique for Nanomodified Smart Cement-Based Sensors in Reinforced Concrete Structures

Abstract

:1. Introduction

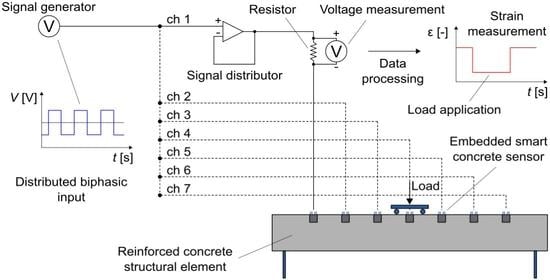

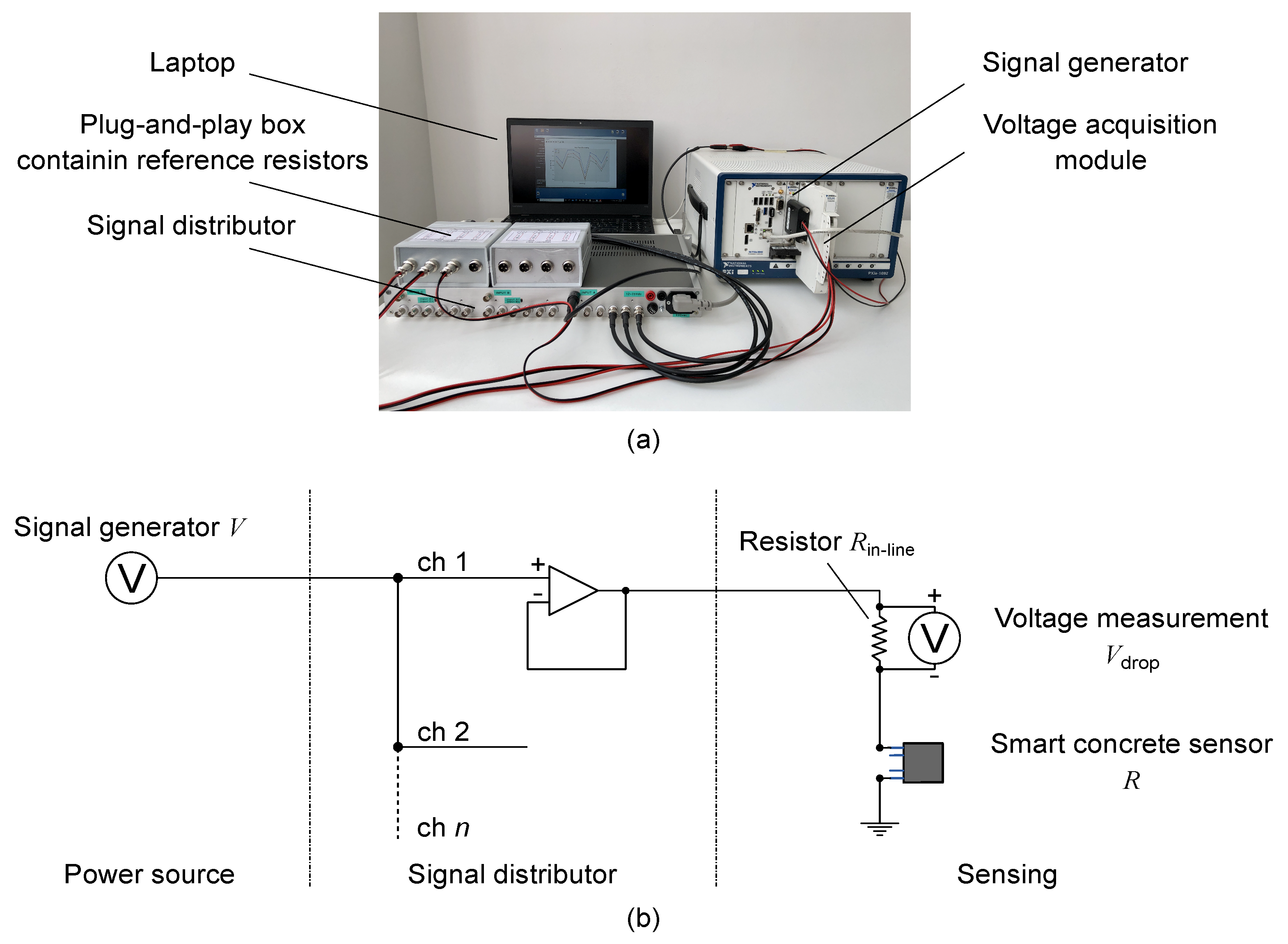

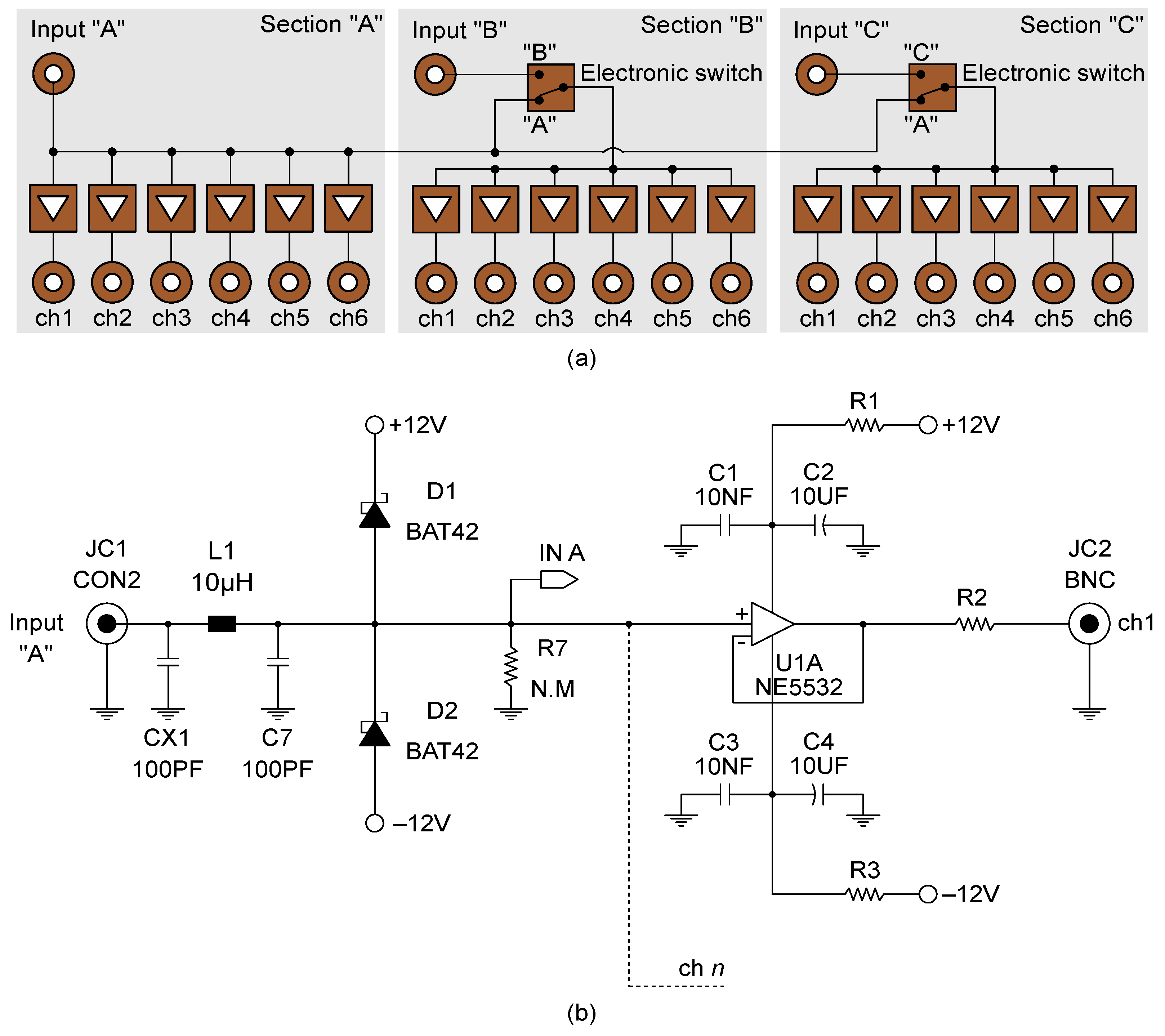

2. Multichannel Strain Measurement Technique

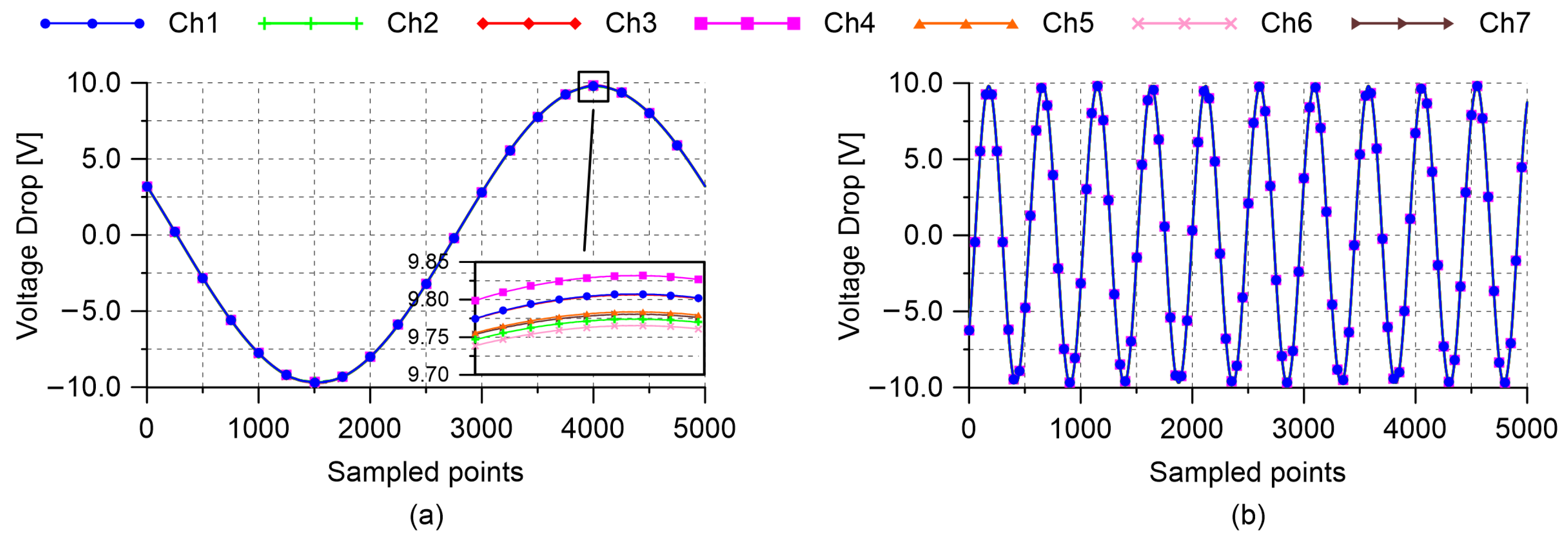

2.1. Input–Output Simultaneity Assessment

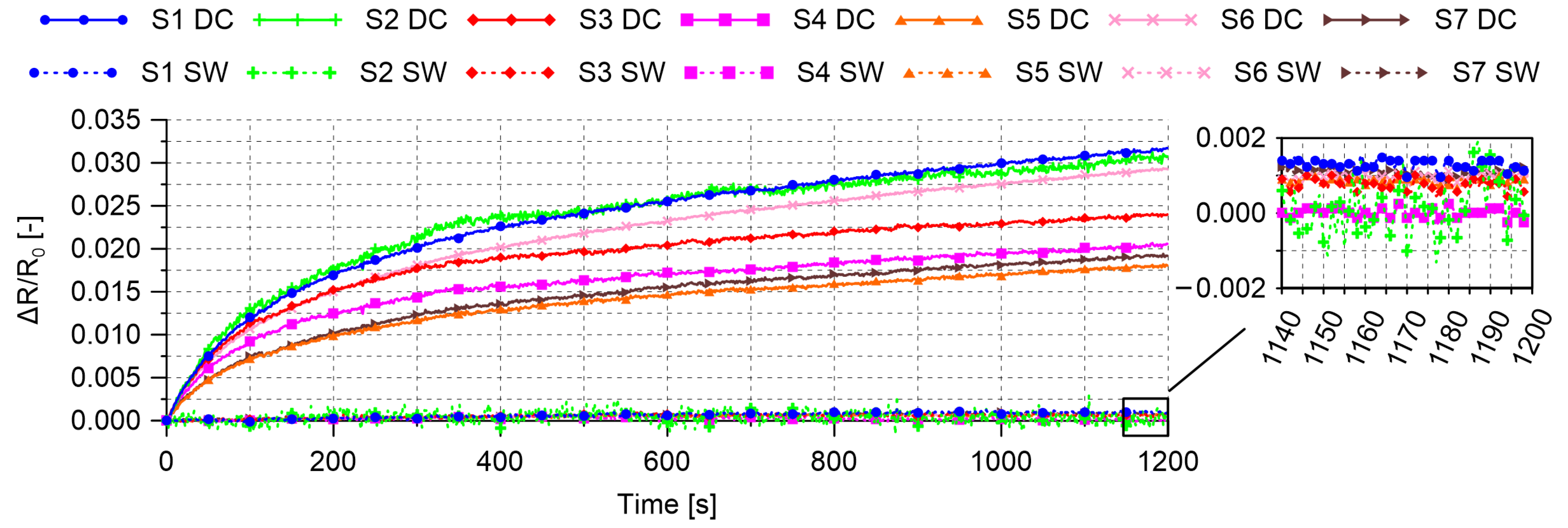

2.2. Stability of the Electrical Measurements

3. Methodology for Validation

3.1. Tested Specimens

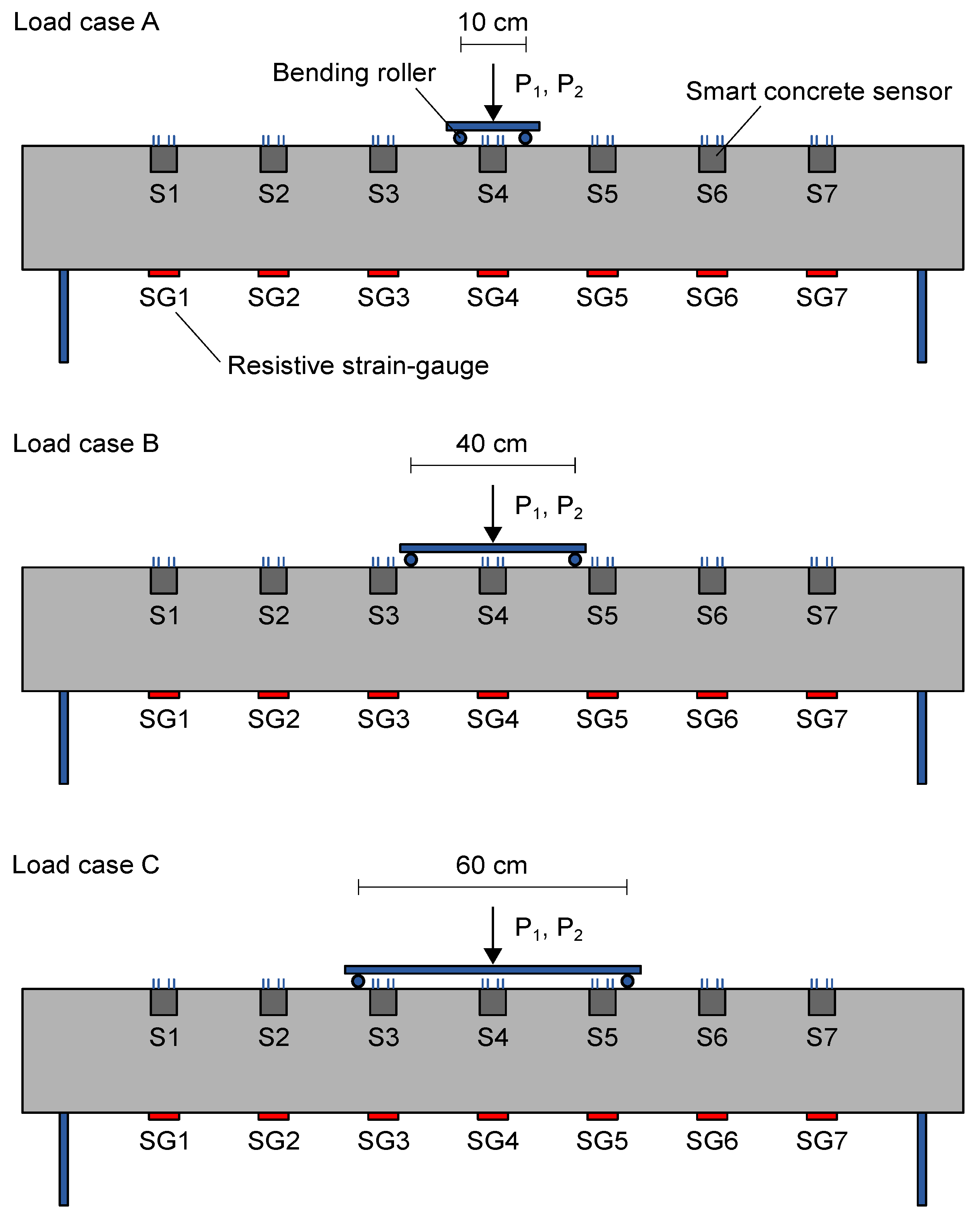

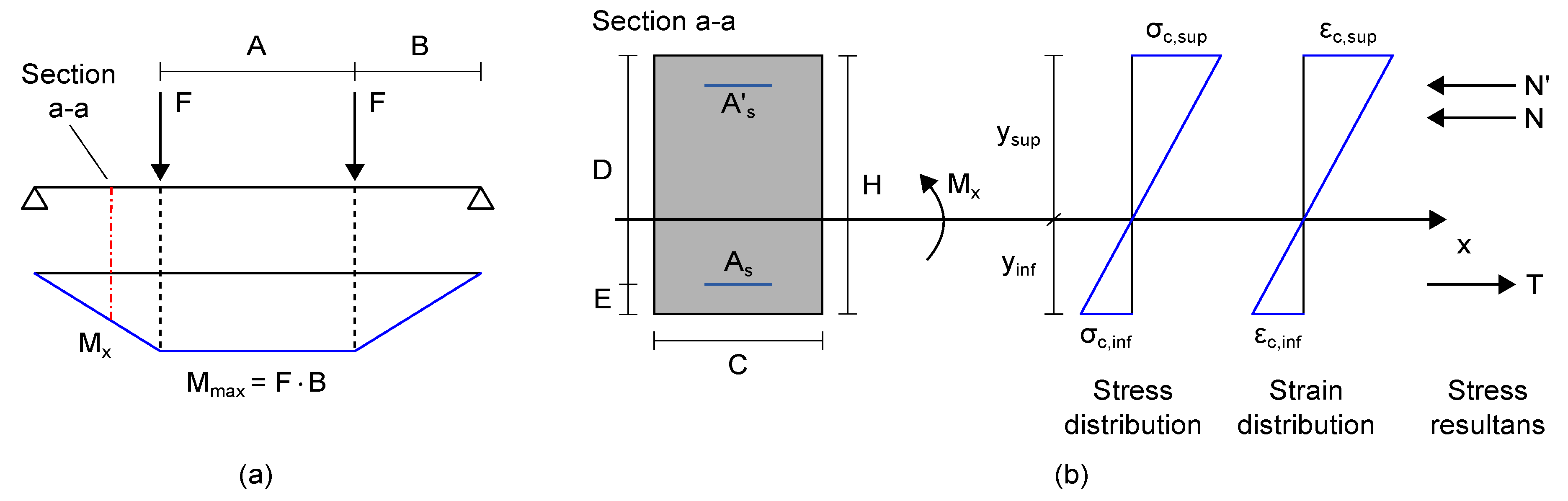

3.2. Four-Point Bending Tests on an RC Beam Specimen

Post-Embedding Calibration Algorithm for Smart Cement-Based Sensors Integrated in RC Beams

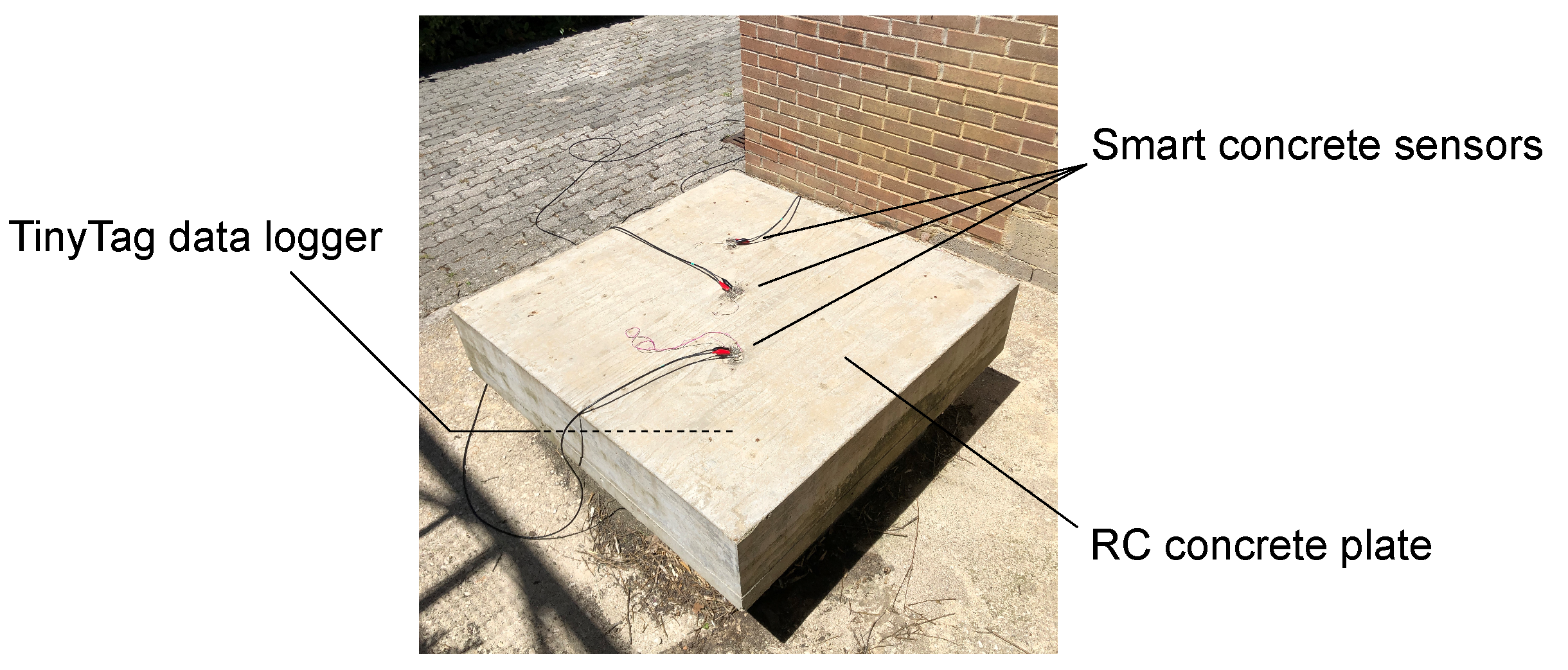

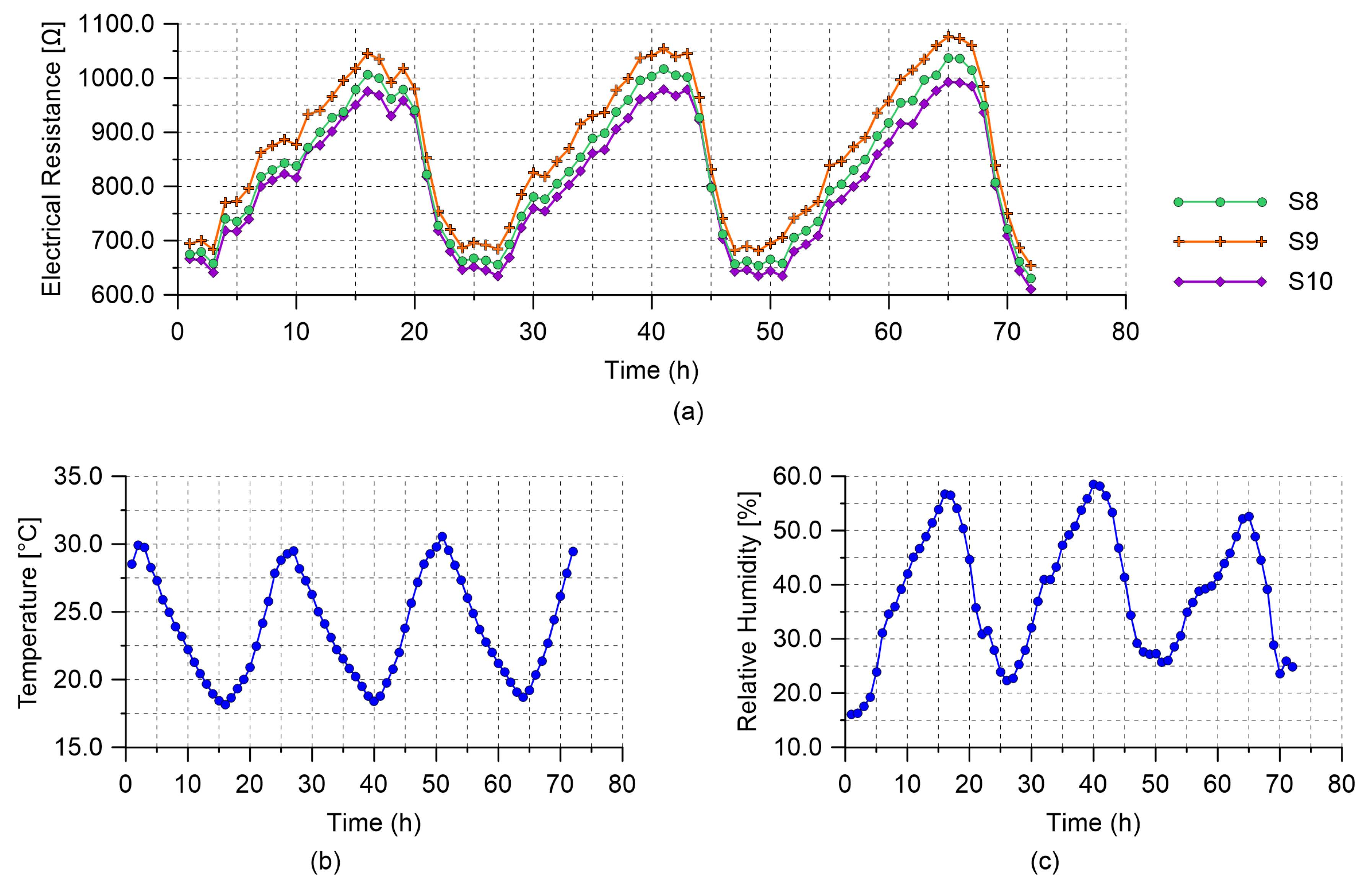

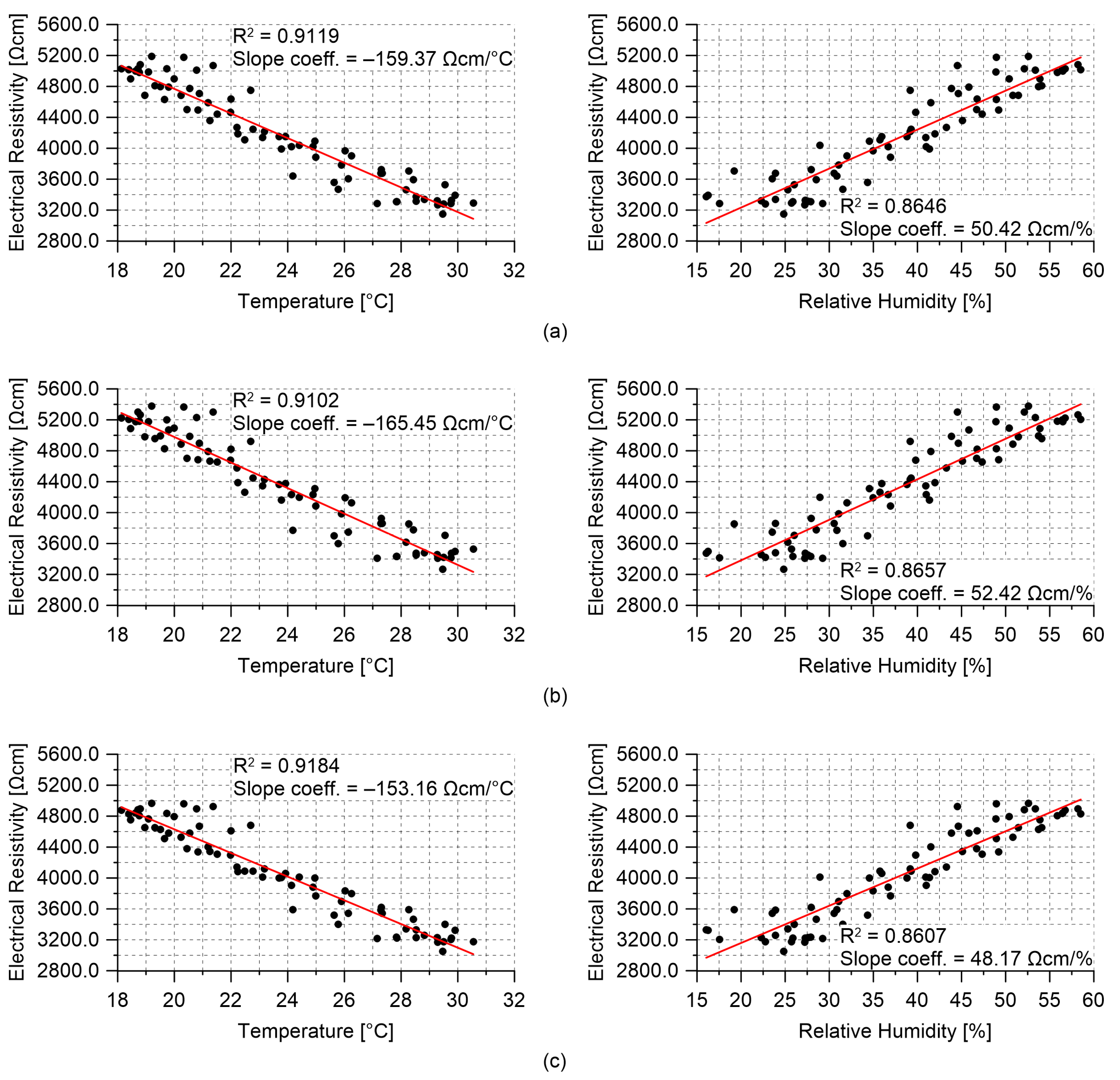

3.3. RC Plate Specimen Subjected to Changing Environmental Conditions

4. Results

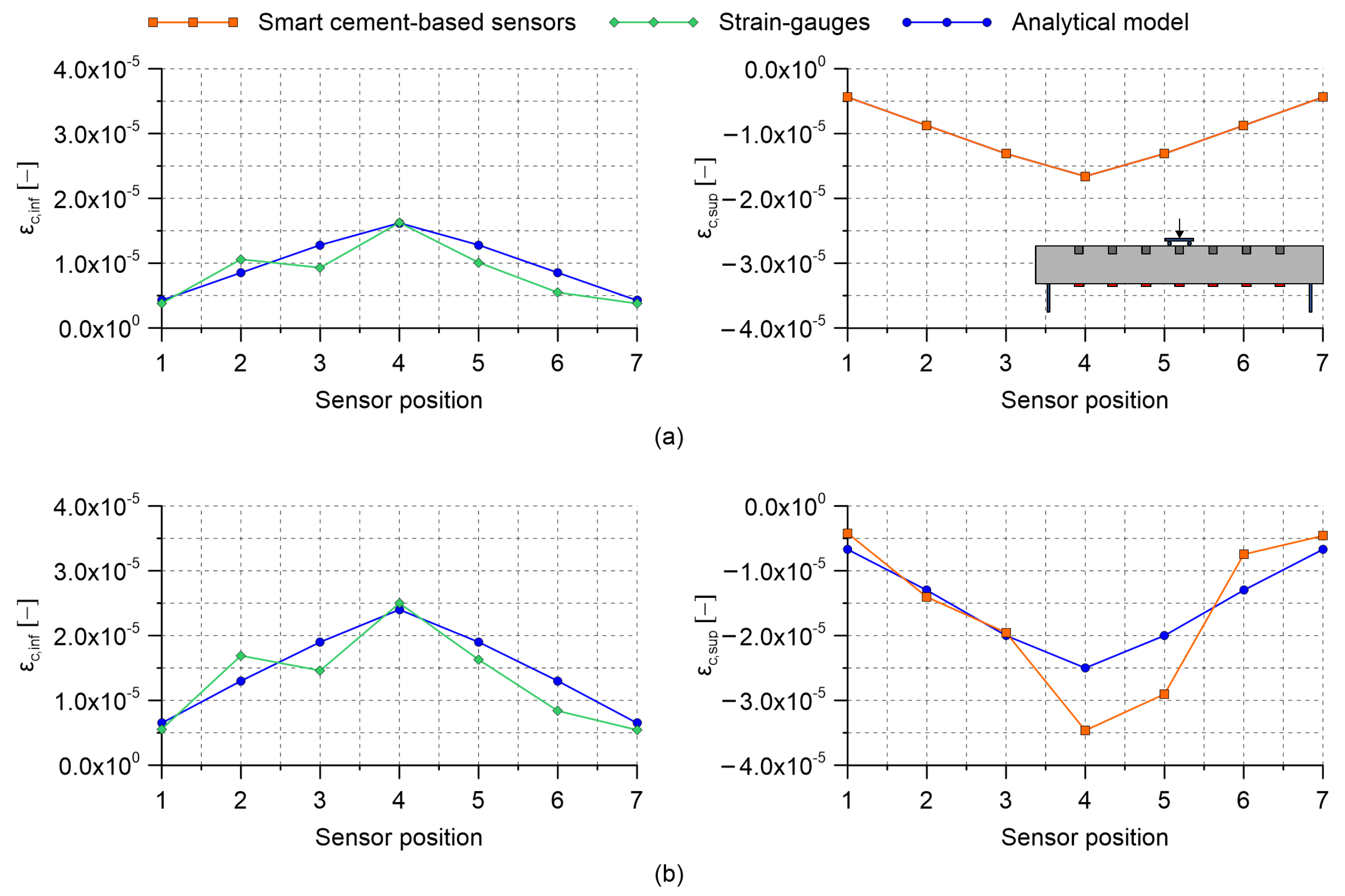

4.1. Four-Point Bending Tests on an RC Beam Specimen

4.2. RC Plate Specimen Subjected to Changing Environmental Conditions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, B.; Yu, X.; Ou, J. Self-Sensing Concrete in Smart Structures; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- D’Alessandro, A.; Materazzi, A.L.; Ubertini, F. Nanotechnology in Cement-Based Construction; Jenny Stanford Publishing: Singapore, 2020. [Google Scholar]

- American Concrete Institute, C. Structural Health Monitoring Technologies for Concrete Structures—Report; American Concrete Institute: Farmington Hills, MI, USA, 2021; p. 114. [Google Scholar]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self sensing carbon nanotube (CNT) and nanofiber (CNF) cementitious composites for real time damage assessment in smart structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Han, B.; Wang, Y.; Dong, S.; Zhang, L.; Ding, S.; Yu, X.; Ou, J. Smart concretes and structures: A review. J. Intell. Mater. Syst. Struct. 2015, 26, 1303–1345. [Google Scholar] [CrossRef]

- Camacho-Ballesta, C.; Zornoza, E.; Garcés, P. Performance of cement-based sensors with CNT for strain sensing. Adv. Cem. Res. 2016, 28, 274–284. [Google Scholar] [CrossRef] [Green Version]

- Hou, T.C.; Lynch, J.P. Electrical impedance tomographic methods for sensing strain fields and crack damage in cementitious structures. J. Intell. Mater. Syst. Struct. 2009, 20, 1363–1379. [Google Scholar] [CrossRef] [Green Version]

- Han, B.; Yu, X.; Ou, J. Multifunctional and smart carbon nanotube reinforced cement-based materials. In Nanotechnology in Civil Infrastructure; Springer Science+Business Media: Berlin, Germany, 2011; pp. 1–47. [Google Scholar]

- Rana, S.; Subramani, P.; Fangueiro, R.; Correia, A.G. A review on smart self-sensing composite materials for civil engineering applications. AIMS Mater. Sci. 2016, 3, 357–379. [Google Scholar] [CrossRef]

- Birgin, H.; D’Alessandro, A.; Ubertini, F. Smart Graphite–Cement Composite for Roadway-Integrated Weigh-In-Motion Sensing. Sensors 2020, 20, 4518. [Google Scholar] [CrossRef]

- Shah, S.P.; Konsta-Gdoutos, M.; Metaxa, Z.; Mondal, P. Nanoscale modification of cementitious materials. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 125–130. [Google Scholar]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Strain and damage sensing properties on multifunctional cement composites with CNF admixture. Cem. Concr. Compos. 2014, 46, 90–98. [Google Scholar] [CrossRef] [Green Version]

- Yang, Q.; Liu, P.; Ge, Z.; Wang, D. Self-Sensing Carbon Nanotube-Cement Composite Material for Structural Health Monitoring of Pavements. J. Test. Eval. 2020, 48, 1990–2002. [Google Scholar] [CrossRef]

- Baeza, F.; Zornoza, E.; Andión, L.G.; Ivorra, S.; Garcés, P. Variables affecting strain sensing function in cementitious composites with carbon fibers. Comput. Concr. 2011, 8, 229–241. [Google Scholar] [CrossRef]

- Coppola, L.; Buoso, A.; Corazza, F. Electrical properties of carbon nanotubes cement composites for monitoring stress conditions in concrete structures. Appl. Mech. Mater. 2011, 82, 118–123. [Google Scholar] [CrossRef] [Green Version]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Meoni, A.; D’Alessandro, A.; Downey, A.; García-Macías, E.; Rallini, M.; Materazzi, A.; Torre, L.; Laflamme, S.; Castro-Triguero, R.; Ubertini, F. An experimental study on static and dynamic strain sensitivity of embeddable smart concrete sensors doped with carbon nanotubes for SHM of large structures. Sensors 2018, 18, 831. [Google Scholar] [CrossRef] [Green Version]

- Saafi, M. Wireless and embedded carbon nanotube networks for damage detection in concrete structures. Nanotechnology 2009, 20, 395502. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Ubertini, F.; García-Macías, E.; Castro-Triguero, R.; Downey, A.; Laflamme, S.; Meoni, A.; Materazzi, A.L. Static and dynamic strain monitoring of reinforced concrete components through embedded carbon nanotube cement-based sensors. Shock Vib. 2017, 2017, 3648403. [Google Scholar] [CrossRef]

- Ding, S.; Ruan, Y.; Yu, X.; Han, B.; Ni, Y.Q. Self-monitoring of smart concrete column incorporating CNT/NCB composite fillers modified cementitious sensors. Constr. Build. Mater. 2019, 201, 127–137. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Luo, Z.; Long, G.; Vessalas, K.; Sheng, D. Structural response monitoring of concrete beam under flexural loading using smart carbon black/cement-based sensors. Smart Mater. Struct. 2020, 29, 065001. [Google Scholar] [CrossRef]

- Castañeda-Saldarriaga, D.L.; Alvarez-Montoya, J.; Martínez-Tejada, V.; Sierra-Pérez, J. Toward Structural Health Monitoring of Civil Structures Based on Self-Sensing Concrete Nanocomposites: A Validation in a Reinforced-Concrete Beam. Int. J. Concr. Struct. Mater. 2021, 15, 1–18. [Google Scholar] [CrossRef]

- Han, B.; Guan, X.; Ou, J. Electrode design, measuring method and data acquisition system of carbon fiber cement paste piezoresistive sensors. Sens. Actuators A Phys. 2007, 135, 360–369. [Google Scholar] [CrossRef]

- Machan, L.; Steffan, P. Multichannel Laboratory Device for Measurement of Smart Concrete Material Properties. In Advanced Materials Research; Trans Tech Publications: Stafa-Zurich, Switzerland, 2015; Volume 1124, pp. 249–254. [Google Scholar]

- Downey, A.; D’Alessandro, A.; Ubertini, F.; Laflamme, S.; Geiger, R. Biphasic DC measurement approach for enhanced measurement stability and multi-channel sampling of self-sensing multi-functional structural materials doped with carbon-based additives. Smart Mater. Struct. 2017, 26, 065008. [Google Scholar] [CrossRef] [Green Version]

- Downey, A.; D’Alessandro, A.; Baquera, M.; García-Macías, E.; Rolfes, D.; Ubertini, F.; Laflamme, S.; Castro-Triguero, R. Damage detection, localization and quantification in conductive smart concrete structures using a resistor mesh model. Eng. Struct. 2017, 148, 924–935. [Google Scholar] [CrossRef] [Green Version]

- Kang, M.S.; Lee, H.; Yim, H.J.; An, Y.K.; Kim, D.J. Multi-channel electrical impedance-based crack localization of fiber-reinforced cementitious composites under bending conditions. Appl. Sci. 2018, 8, 2582. [Google Scholar] [CrossRef]

- Yu, X.; Kwon, E. A carbon nanotube/cement composite with piezoresistive properties. Smart Mater. Struct. 2009, 18, 055010. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Zi, G.; Lee, S.J. Effects of carbon nanomaterial type and amount on self-sensing capacity of cement paste. Measurement 2019, 134, 750–761. [Google Scholar] [CrossRef]

| Reinforcing Steel Bar B450C | Concrete Rck30 | ||

|---|---|---|---|

| A | 200 mm | E | 20,750 MPa |

| A | 100 mm | n = E/E | 10.12 |

| E | 210,000 MPa | ||

| Sensor | Sensor | ||

|---|---|---|---|

| S1 | 59 | S5 | 28 |

| S2 | 594 | S6 | 39 |

| S3 | 45 | S7 | 46 |

| S4 | 28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meoni, A.; D’Alessandro, A.; Mancinelli, M.; Ubertini, F. A Multichannel Strain Measurement Technique for Nanomodified Smart Cement-Based Sensors in Reinforced Concrete Structures. Sensors 2021, 21, 5633. https://doi.org/10.3390/s21165633

Meoni A, D’Alessandro A, Mancinelli M, Ubertini F. A Multichannel Strain Measurement Technique for Nanomodified Smart Cement-Based Sensors in Reinforced Concrete Structures. Sensors. 2021; 21(16):5633. https://doi.org/10.3390/s21165633

Chicago/Turabian StyleMeoni, Andrea, Antonella D’Alessandro, Massimo Mancinelli, and Filippo Ubertini. 2021. "A Multichannel Strain Measurement Technique for Nanomodified Smart Cement-Based Sensors in Reinforced Concrete Structures" Sensors 21, no. 16: 5633. https://doi.org/10.3390/s21165633

APA StyleMeoni, A., D’Alessandro, A., Mancinelli, M., & Ubertini, F. (2021). A Multichannel Strain Measurement Technique for Nanomodified Smart Cement-Based Sensors in Reinforced Concrete Structures. Sensors, 21(16), 5633. https://doi.org/10.3390/s21165633