The Effect of Sleeve Pattern and Fit on E-Textile Electromyography (EMG) Electrode Performance in Smart Clothing Design

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Material Characterization

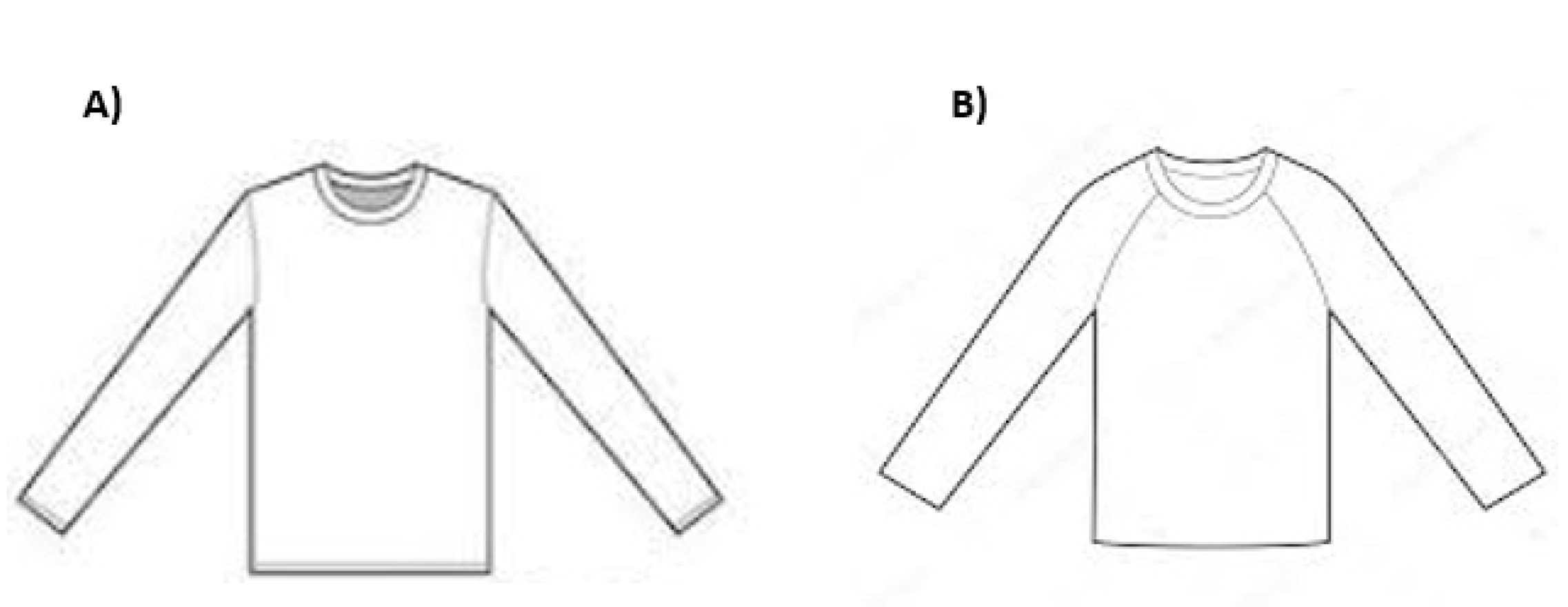

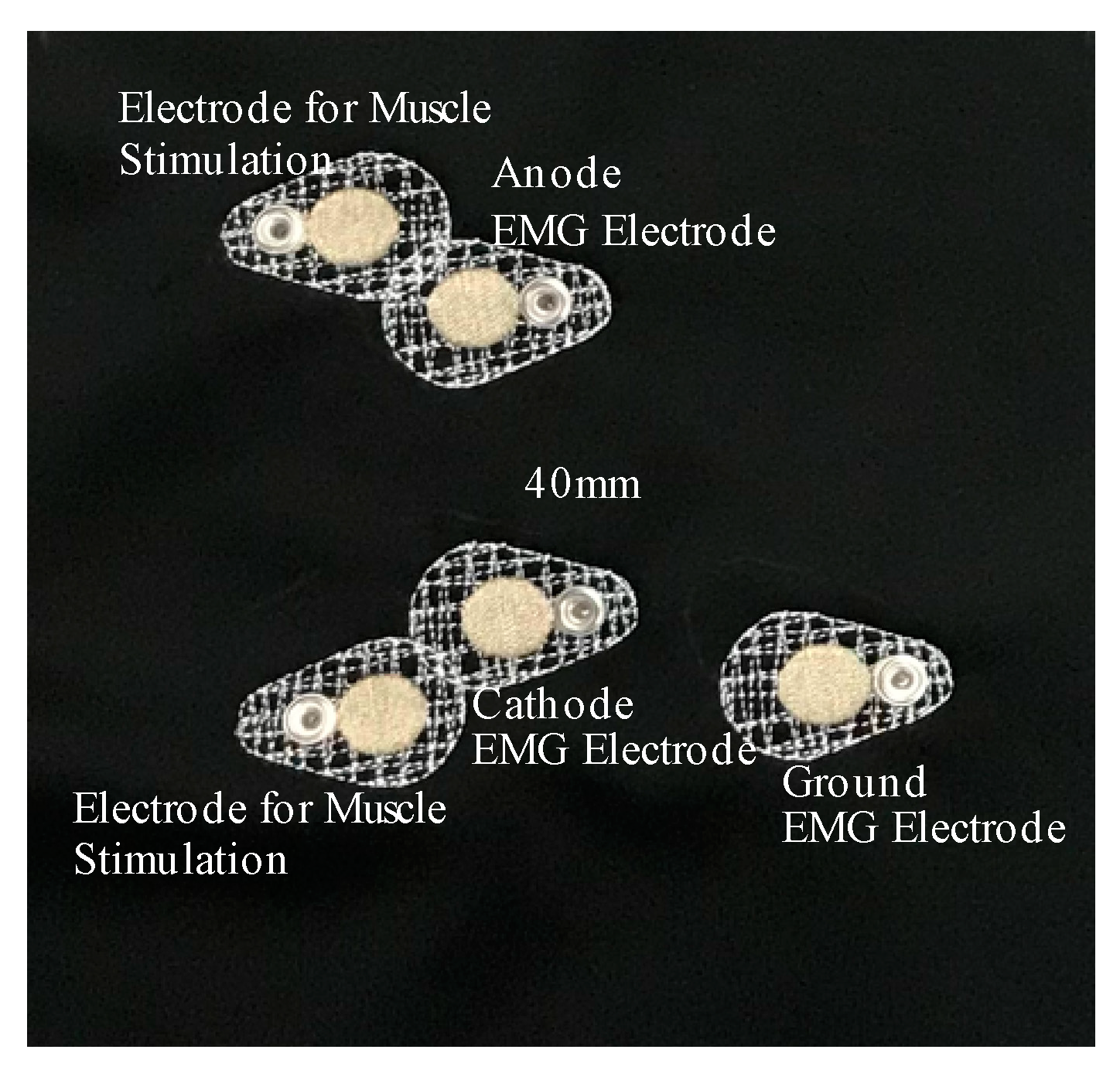

2.3. Prototype Development

2.4. Experimental Protocol

2.5. Data Analysis

3. Results and Discussion

3.1. Material Characterization

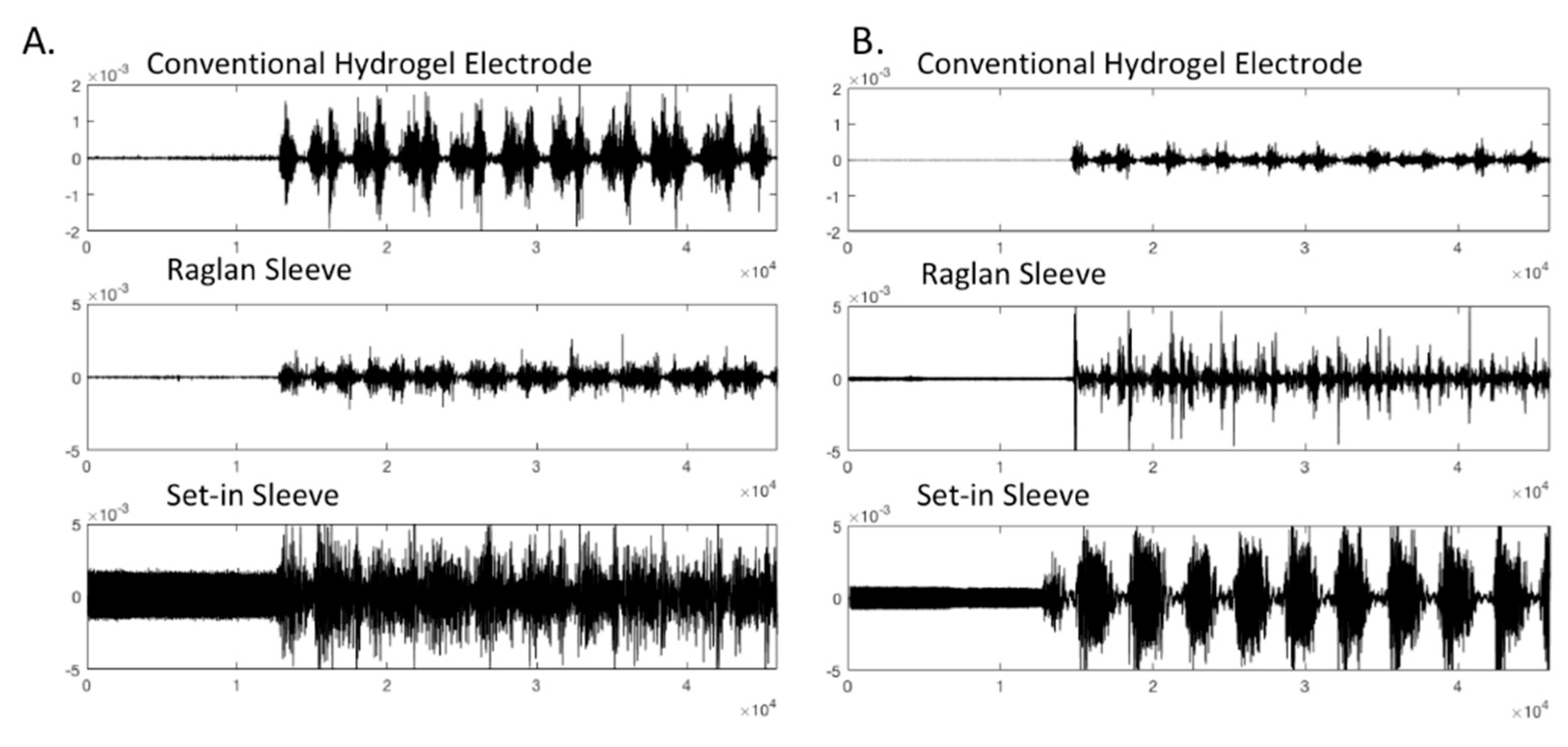

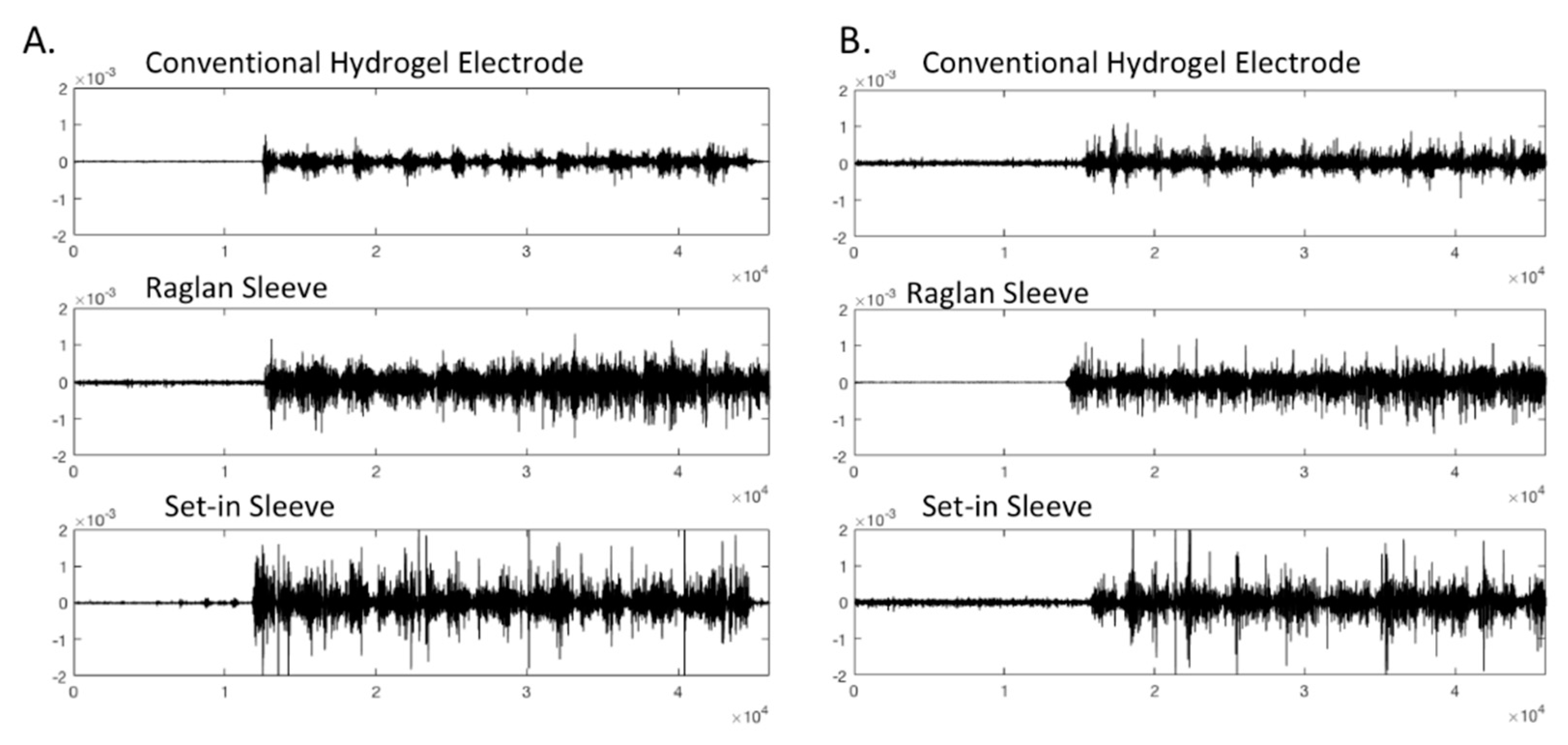

3.2. EMG Measurements

4. Conclusions

- Embroidered e-textile EMG electrode performance is directly related to clothing pattern and cut. The raglan sleeve pattern, which does not have a seam directly on the shoulder joint, shows significantly higher signal-to-noise ratio and gets less affected from the arm movement.

- The frequency distribution of the PSD analysis indicated that the e-textile electrodes might detect muscle fatigue more sensitively; however, this finding requires further research.

- The electrode–skin impedance spectrum analysis of e-textile electrodes in raglan sleeve condition shows a more consistent impedance spectrum across different frequencies and therefore relates to considerably higher signal-to-noise ratio of the measured EMG signal.

- Embroidered e-textile EMG electrode performance is directly related to how clothing fits on the body. Analysis done in comparison to custom-fit set-in and raglan sleeve pattern conditions revealed that slightly snug or slightly loose fit conditions within the same clothing size range results in decline in the EMG signal quality for the raglan-sleeve pattern style. On the other hand, the set-in sleeve pattern style performs better when the fit is more snig and the EMG signal quality significantly declines in loose conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Guo, L.; Sandsjö, L.; Ortiz-Catalan, M.; Skrifvars, M. Systematic review of textile-based electrodes for long-term and continuous surface electromyography recording. Text. Res. J. 2020, 90, 227–244. [Google Scholar] [CrossRef] [Green Version]

- Catrysse, M.; Puers, R.; Hertleer, C.; van Langenhove, L.; van Egmond, H.; Matthys, D. Towards the integration of textile sensors in a wireless monitoring suit. Sens. Actuators A Phys. 2004, 114, 302–311. [Google Scholar] [CrossRef]

- Paradiso, R.; Loriga, G.; Taccini, N. A wearable health care system based on knitted integrated sensors. IEEE Trans. Inf. Technol. Biomed. 2005, 9, 337–344. [Google Scholar] [CrossRef] [PubMed]

- An, X.; Tangsirinaruenart, O.; Stylios, G.K. Investigating the performance of dry textile electrodes for wearable end-uses. J. Text. Inst. 2019, 110, 151–158. [Google Scholar] [CrossRef]

- Oliveira, C.C.; da Silva, J.M.; Trindade, I.G.; Martins, F. Characterization of the electrode-skin impedance of textile electrodes. In Proceedings of the Conference on Design of Circuits and Integrated Circuits (DCIS), Madrid, Spain, 26–28 November 2014; pp. 1–6. [Google Scholar]

- Catarino, A.; Carvalho, H.; Barros, L.; Dias, M.J. Surface Electromyography Using Textile-Based Electrodes. In Proceedings of the Fiber Society 2012 Fall Meeting and Technical Conference, Boston, MA, USA, 7–9 November 2012. [Google Scholar]

- Martin, T.; Jones, M.T.; Edmison, J.N.; Shenoy, R. Towards a design framework for wearable electronic textiles. ISWC 2003, 3, 190–200. [Google Scholar]

- Finni, T.; Hu, M.; Kettunen, P.; Vilavuo, T.; Cheng, S. Measurement of EMG activity with textile electrodes embedded into clothing. Physiol. Meas. 2007, 28, 1405. [Google Scholar] [CrossRef] [PubMed]

- Joachim, T.; Adriaensen, T.; van der Horst, C.; Linz, T.; Spaepen, A. Textile integrated contactless EMG sensing for stress analysis. In Proceedings of the 2007 29th annual international conference of the IEEE Engineering in Medicine and Biology Society, Lyon, France, 22–26 August 2007; pp. 3966–3969. [Google Scholar]

- Kim, S.; Lee, S.; Jeong, W. Emg measurement with textile-based electrodes in different electrode sizes and clothing pressures for smart clothing design optimization. Polymers 2020, 12, 2406. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Zhu, X.; Xia, Q. An Integrated Design of Multi-Channel ECG Sensor on Smart Garment. In Proceedings of the 2020 10th International Conference on Biomedical Engineering and Technology, Tokyo, Japan, 15–18 September 2020; pp. 316–320. [Google Scholar]

- Comert, A.; Honkala, M.; Hyttinen, J. Effect of pressure and padding on motion artifact of textile electrodes. Biomed. Eng. Online 2013, 12, 1–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cho, G.; Jeong, K.; Paik, M.J.; Kwun, Y.; Sung, M. Performance evaluation of textile-based electrodes and motion sensors for smart clothing. IEEE Sens. J. 2011, 11, 3183–3193. [Google Scholar] [CrossRef]

- Kanakaraj, P.; Ramachandran, R. Selective utility characteristics of knitted fabrics for sports application. J. Text. Appar. Technol. Manag. 2015, 9, 1–11. [Google Scholar]

- Troynikov, O.; Wardiningsih, W. Moisture management properties of wool/polyester and wool/bamboo knitted fabrics for the sportswear base layer. Text. Res. J. 2011, 81, 621–631. [Google Scholar] [CrossRef]

- Varshney, R.K.; Kothari, V.K.; Dhamija, S. A study on thermophysiological comfort properties of fabrics in relation to constituent fibre fineness and cross-sectional shapes. J. Text. Inst. 2010, 101, 495–505. [Google Scholar] [CrossRef]

- Berk, G.G. Design of a wearable pain management system with embroidered TENS electrodes. Int. J. Cloth. Sci. Technol. 2018, 30, 38–48. [Google Scholar] [CrossRef]

- Ashdown, S.P. An investigation of the structure of sizing systems: A comparison of three multidimensional optimized sizing systems generated from anthropometric data with the ASTM standard D5585-94. Int. J. Cloth. Sci. Technol. 1998, 10, 324–341. [Google Scholar] [CrossRef]

- Stamper, A.A.; Sharp, S.H.; Donnell, L.B. Evaluating Apparel Quality; Fairchild Fashion Group: New York, NY, USA, 1991. [Google Scholar]

- Pisut, G.; Connell, L.J. Fit preferences of female consumers in the USA. J. Fash. Mark. Manag. Int. J. 2007, 11, 366–379. [Google Scholar] [CrossRef]

- Keiser, S.; Garner, M.B.; Vandermar, D. Beyond Design: The Synergy of Apparel product Development; Bloomsbury Publishing: New York, NY, USA, 2017. [Google Scholar]

- Marquez, J.C. On the Feasibility of Using Textile Electrodes for Electrical Bioimpedance Measurements. Ph.D. Thesis, Skolan för teknik och hälsa, Kungliga Tekniska högskolan, Stockholm, Sweden, 2011. [Google Scholar]

- Ankhili, A.; Tao, X.; Cochrane, C.; Koncar, V.; Coulon, D.; Tarlet, J. Ambulatory evaluation of ECG signals obtained using washable textile-based electrodes made with chemically modified PEDOT: PSS. Sensors 2019, 19, 416. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oskoei, M.A.; Hu, H.; Gan, J.Q. Manifestation of fatigue in myoelectric signals of dynamic contractions produced during playing PC games. In Proceedings of the 2008 30th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Vancouver, BC, Canada, 20–24 August 2008; pp. 315–318. [Google Scholar]

- Phinyomark, A.; Phukpattaranont, P.; Limsakul, C. Feature reduction and selection for EMG signal classification. Expert Syst. Appl. 2012, 39, 7420–7431. [Google Scholar] [CrossRef]

- Phinyomark, A.; Thongpanja, S.; Hu, H.; Phukpattaranont, P.; Limsakul, C. The usefulness of mean and median frequencies in electromyography analysis. In Computational Intelligence in Electromyography Analysis—A Perspective on Current Applications and Future Challenges; InTech: Rijeka, Croatia, 2012; pp. 195–220. [Google Scholar]

- Ankhili, A.; Tao, X.; Cochrane, C.; Coulon, D.; Koncar, V. Study on the measurement method of skin textile electrodes contact impedance. J. Fash. Technol. Text. Eng. 2018, 5, 4. [Google Scholar] [CrossRef]

- Rattfält, L.; Björefors, F.; Nilsson, D.; Wang, X.; Norberg, P.; Ask, P. Properties of screen printed electrocardiography smartware electrodes investigated in an electro-chemical cell. Biomed. Eng. Online 2013, 12, 64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiong, F.; Chen, D.; Chen, Z.; Jin, C.; Dai, S. Impedance characteristics of the skin-electrode interface of dry textile electrodes for wearable electrocardiogram. In Advances in Body Area Networks I; Springer: Cham, Switzerland, 2019; pp. 343–356. [Google Scholar]

| Participant | Gender | Age | BMI | Clothing Size | Prototype Fit Condition | Armhole Girth (cm) | Bicep Girth (cm) | Shoulder Width (cm) | Chest/Bust Girth (cm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Male | 39 | 25.2 | M | Custom Fit | 53.84 | 31.95 | 51.38 | 99.08 |

| 2 | Female | 26 | 23.4 | S | Custom Fit | 41.19 | 11.64 | 37.84 | 92.07 |

| 3 | Male | 43 | 25.8 | M | Snug compared to Participant 1 | 54.62 | 32.58 | 51.76 | 101.08 |

| 4 | Female | 22 | 19.8 | S | Custom Fit | 39.49 | 10.49 | 36.65 | 85.09 |

| 5 | Female | 38 | 21.1 | S | Loose compared to Participant 2 | 40.79 | 10.72 | 37.16 | 83.21 |

| Participant | Gender | Age | BMI | Clothing Size | Prototype Fit Condition | Armhole Girth (cm) | Bicep Girth (cm) | Shoulder Width (cm) | Chest/Bust Girth (cm) |

| 1 | Male | 39 | 25.2 | M | Custom Fit | 53.84 | 51.38 | 99.08 | |

| 2 | Female | 26 | 23.4 | S | Custom Fit | 41.19 | 37.84 | 92.07 | |

| 3 | Male | 43 | 25.8 | M | Snug compared to Participant 1 | 54.62 | 51.76 | 101.08 | |

| 4 | Female | 22 | 19.8 | S | Custom Fit | 39.49 | 36.65 | 85.09 | |

| 5 | Female | 38 | 21.1 | S | Loose compared to Participant 2 | 40.79 | 37.16 | 83.21 |

| Thickness (μm) | Weight (g/m2) | Elasticity (%) | Residual Elasticity (%) | Bursting Strength (kPa) | ||

|---|---|---|---|---|---|---|

| Wale | Course | Wale | Course | |||

| 51.6 | 182.3 | 120.8 | 138.3 | 10 | 14 | 12.34 |

| Mean R (Ω) | SNR (dB) | |

|---|---|---|

| Embroidered Electrode | 0.087 ± 0.005 | 70.83 |

| Conventional Electrode | 649.33 ± 145.14 | 60.63 |

| SNR (dB) | Maximum Frequency in PSD (Hz) | |

|---|---|---|

| Conventional Hydrogel Electrode | 21.8 ± 8.9 | 45 ± 4 |

| Raglan Sleeve t-shirt, Embroidered Electrode | 22.5 ± 8.1 | 25 ± 7 * |

| Set-in Sleeve t-shirt, Embroidered Electrode | 14.0 ± 7.6 * | 37 ± 2 |

| Mean Difference | Std. Error | Significance | 95% Lower Bound | 95% Upper Bound | ||

|---|---|---|---|---|---|---|

| Conventional Electrode | Raglan Sleeve Embroidered Electrode | −0.675 | 3.669 | 0.855 | −8.17 | 6.82 |

| Set-in Sleeve Embroidered Electrode | 7.742 * | 3.533 | 0.037 | 0.51 | 14.96 | |

| Raglan Sleeve Embroidered Electrode | Conventional Electrode | 0.675 | 3.669 | 0.855 | −6.82 | 8.17 |

| Set-in Sleeve Embroidered Electrode | 8.418 * | 4.072 | 0.048 | 0.089 | 16.74 | |

| Set-in Sleeve Embroidered Electrode | Conventional Electrode | −7.742 * | 3.533 | 0.037 | −14.96 | −0.51 |

| Raglan Sleeve Embroidered Electrode | −8.418 * | 4.072 | 0.048 | −16.74 | −0.08 |

| Mean Difference | Std. Error | Significance | 95% Lower Bound | 95% Upper Bound | ||

|---|---|---|---|---|---|---|

| Conventional Electrode | Raglan Sleeve Embroidered Electrode | −1212.79 | 922.079 | 0.201 | −3115.87 | 690.28 |

| Set-in Sleeve Embroidered Electrode | −4134.92 * | 922.079 | 0.000 | −6038.00 | −2231.84 | |

| Raglan Sleeve Embroidered Electrode | Conventional Electrode | 1212.79 | 922.079 | 0.201 | −690.28 | 3115.87 |

| Set-in Sleeve Embroidered Electrode | −2922.13 * | 922.079 | 0.004 | −4825.20 | −1019.05 | |

| Set-in Sleeve Embroidered Electrode | Conventional Electrode | 4134.92 * | 922.079 | 0.000 | 2231.84 | 6038.00 |

| Raglan Sleeve Embroidered Electrode | 2922.12 * | 922.079 | 0.004 | 1019.05 | 4825.20 |

| Raglan Sleeve T-Shirt SNR (dB) | Set-in Sleeve T-Shirt SNR (dB) | |

|---|---|---|

| Participant 2 (custom fit condition, clothing size S) | 22.2 ± 8.8 | 16.4 ± 7.7 |

| Participant 5 (slightly loose condition, clothing size S) | 17.3 ± 5.5 | 5.1 ± 2.0 |

| Raglan Sleeve T-Shirt SNR (dB) | Set-in Sleeve T-Shirt SNR (dB) | |

|---|---|---|

| Participant 1 (custom fit condition, clothing size M) | 26.2 ± 2.4 | 17 ± 1.9 |

| Participant 3 (slightly snug condition, clothing size M) | 22.1 ± 3.4 | 22.1 ± 1.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goncu-Berk, G.; Tuna, B.G. The Effect of Sleeve Pattern and Fit on E-Textile Electromyography (EMG) Electrode Performance in Smart Clothing Design. Sensors 2021, 21, 5621. https://doi.org/10.3390/s21165621

Goncu-Berk G, Tuna BG. The Effect of Sleeve Pattern and Fit on E-Textile Electromyography (EMG) Electrode Performance in Smart Clothing Design. Sensors. 2021; 21(16):5621. https://doi.org/10.3390/s21165621

Chicago/Turabian StyleGoncu-Berk, Gozde, and Bilge Guvenc Tuna. 2021. "The Effect of Sleeve Pattern and Fit on E-Textile Electromyography (EMG) Electrode Performance in Smart Clothing Design" Sensors 21, no. 16: 5621. https://doi.org/10.3390/s21165621

APA StyleGoncu-Berk, G., & Tuna, B. G. (2021). The Effect of Sleeve Pattern and Fit on E-Textile Electromyography (EMG) Electrode Performance in Smart Clothing Design. Sensors, 21(16), 5621. https://doi.org/10.3390/s21165621