Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset

Abstract

:1. Introduction

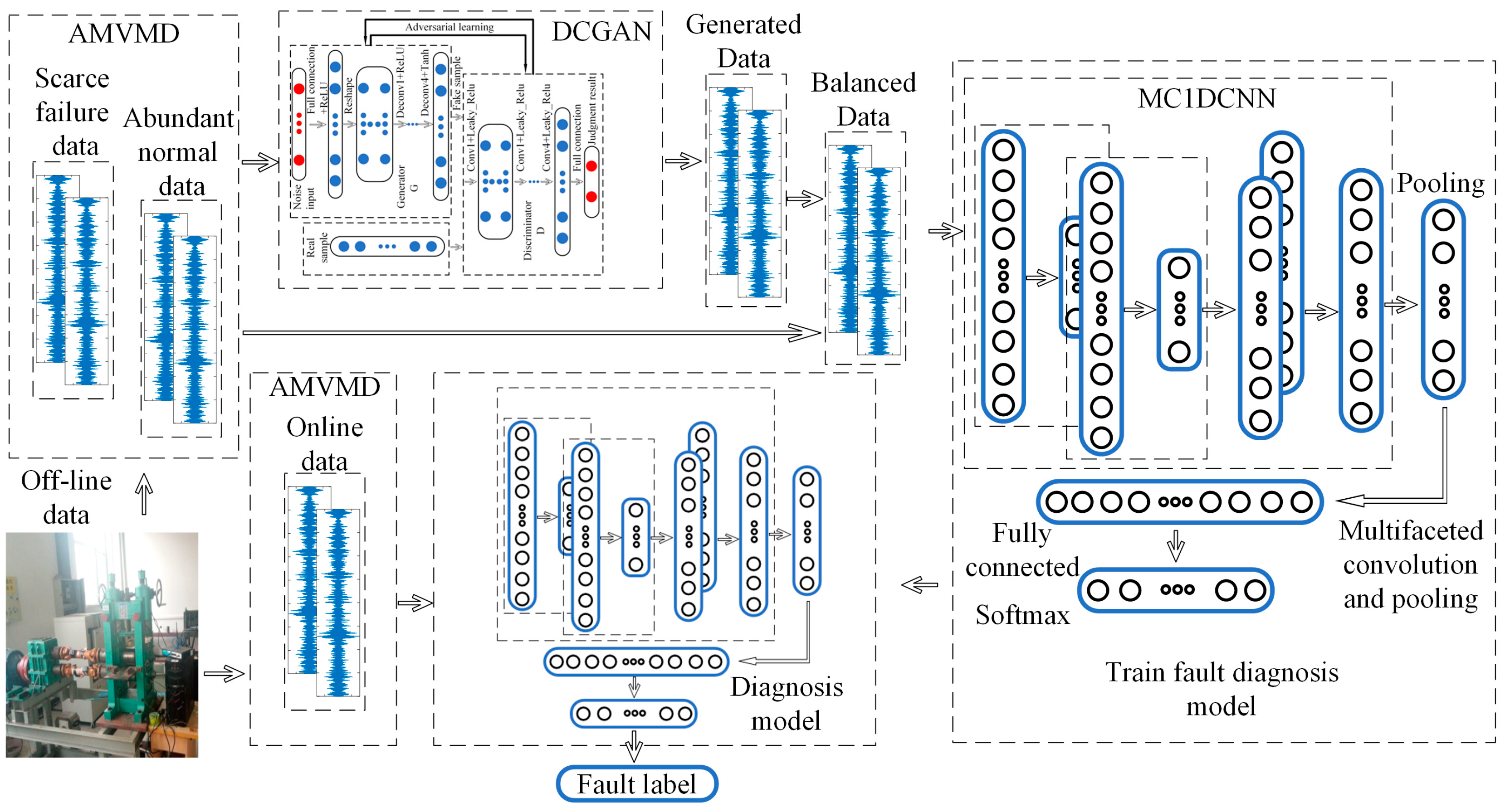

2. AMVMD Signal Processing and Unbalanced Data Generation

2.1. Iterative Acceleration of MVMD

- (1)

- Initialize ,,, set , .

- (2)

- Set , and execute a loop to update , and until iterative precision is reached.Update for all ω > 0

- (3)

- Stop the iteration when the iteration accuracy is satisfied and output the set of modes uK and the center frequency ωK.

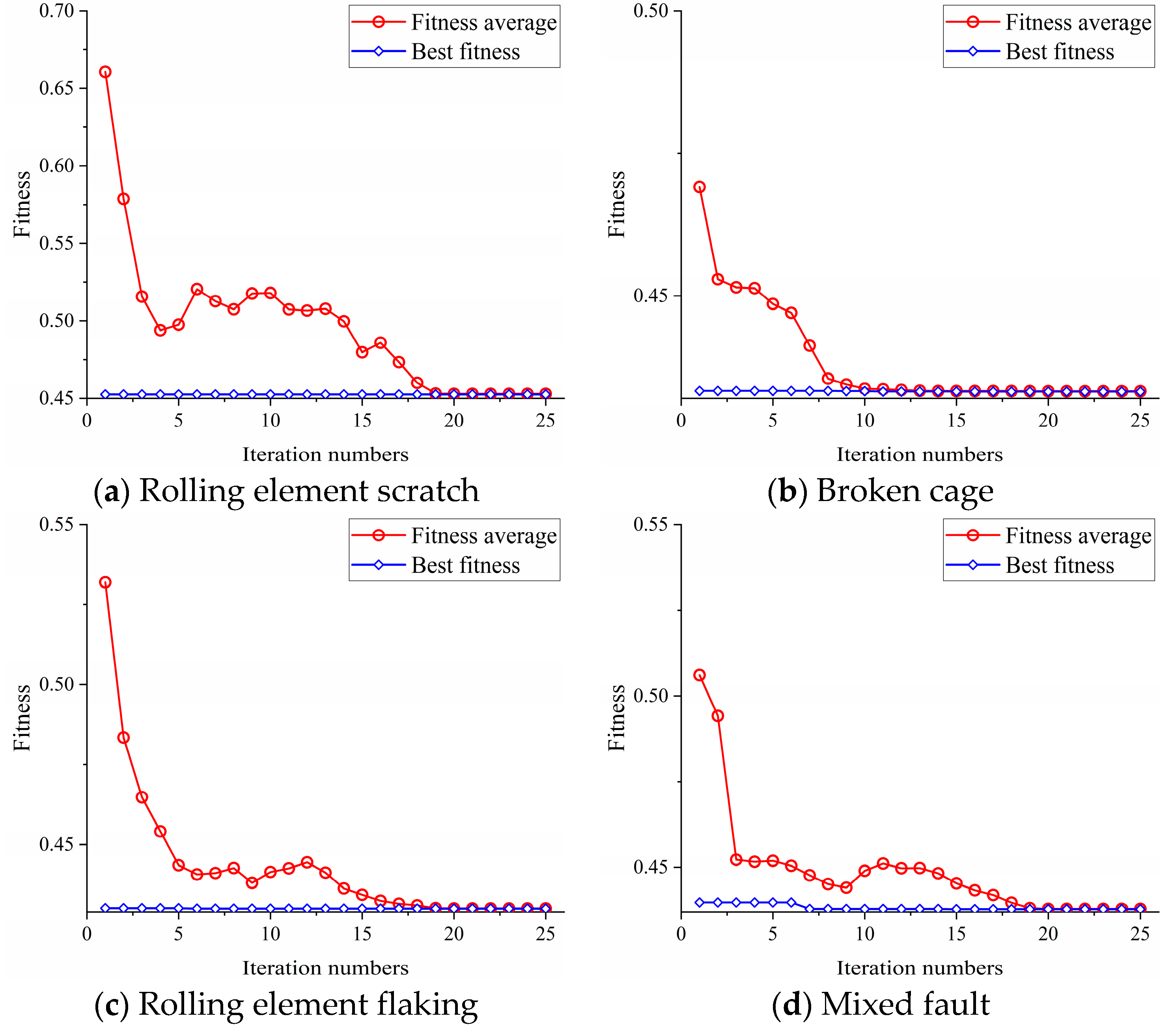

2.2. Parameter Optimization Based on GA

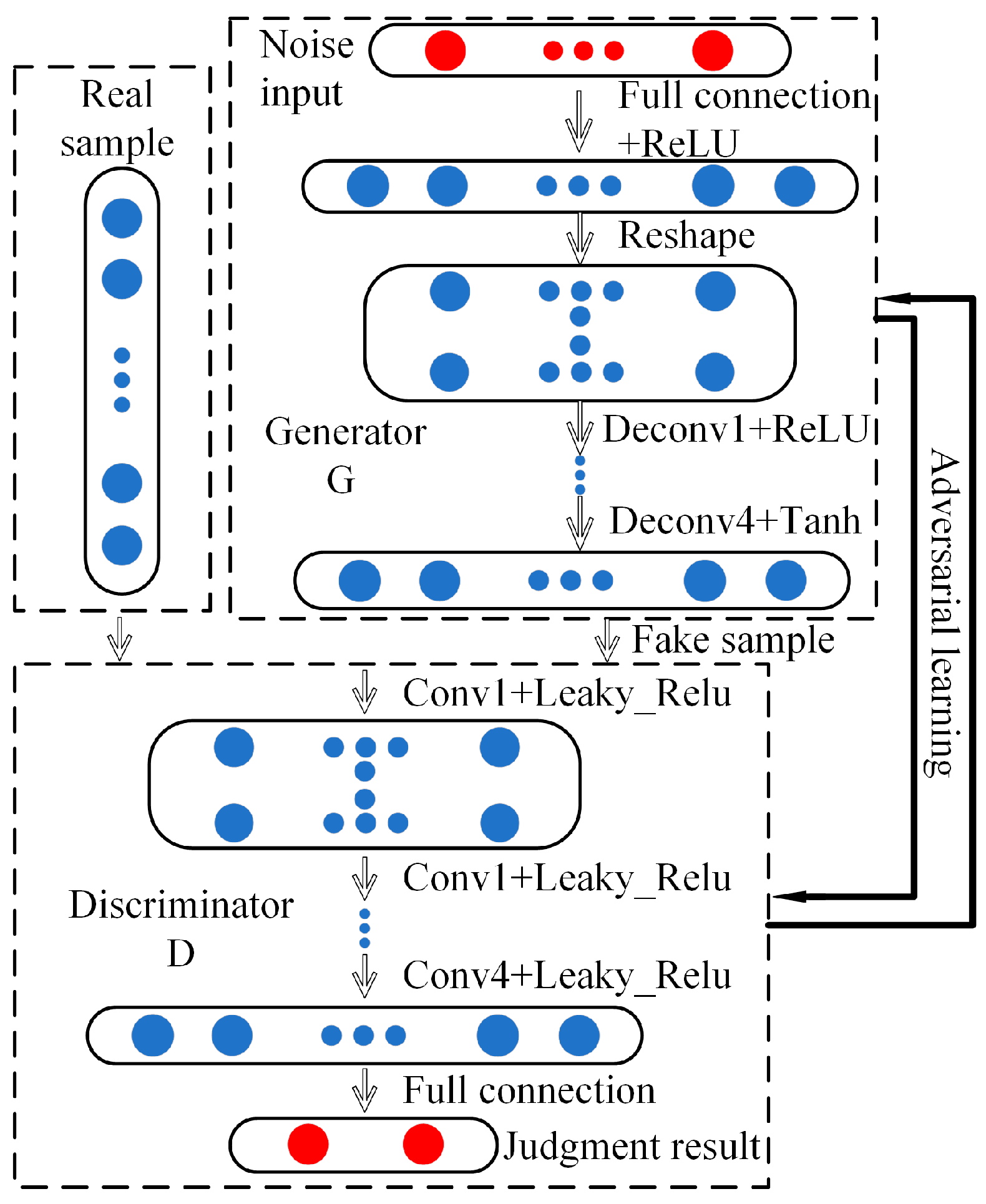

2.3. Unbalanced Data Generation Based on DCGAN

3. Analysis of Simulated Signals

3.1. Construction of Simulation Signal

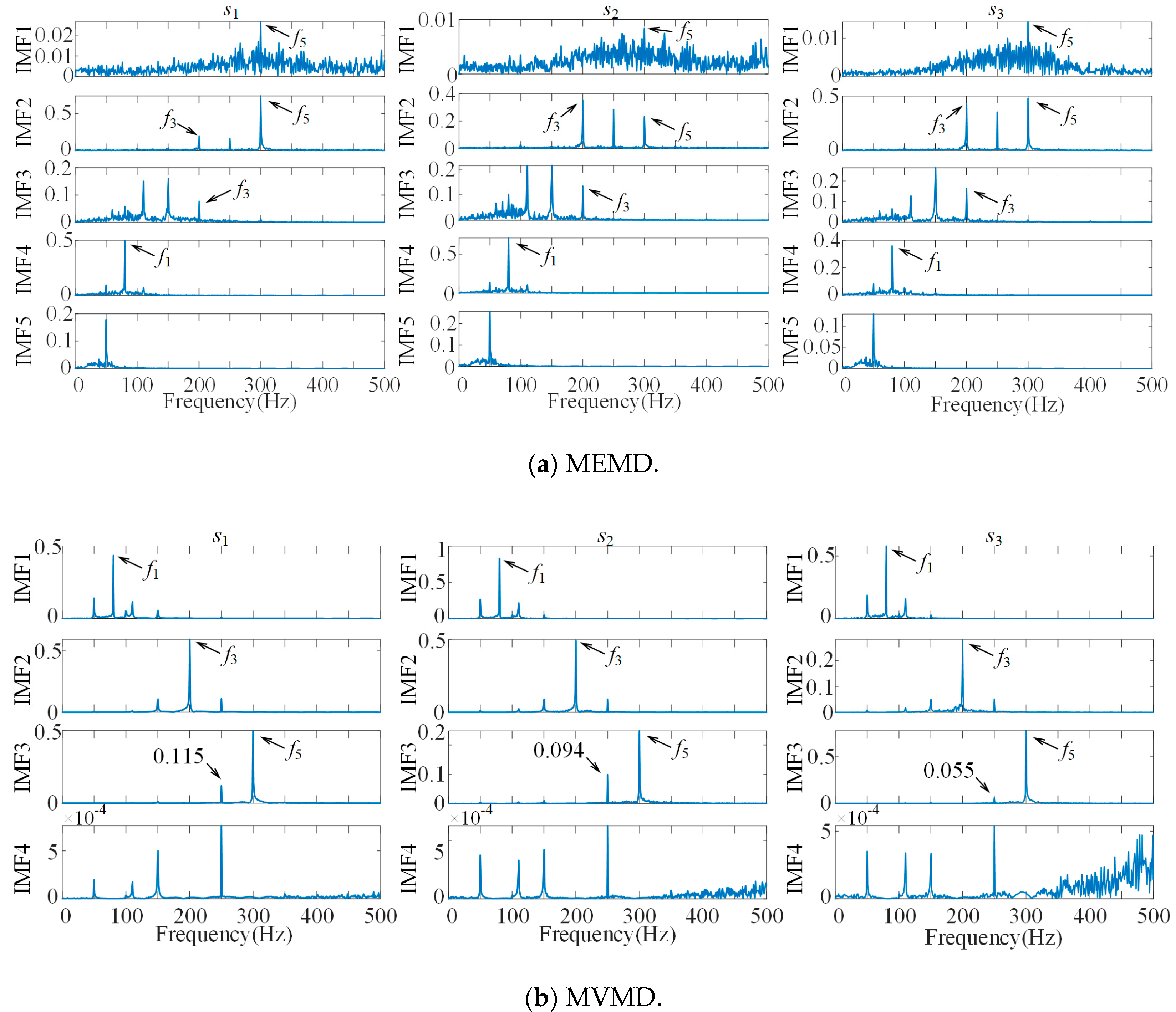

3.2. Algorithm Performance Comparison

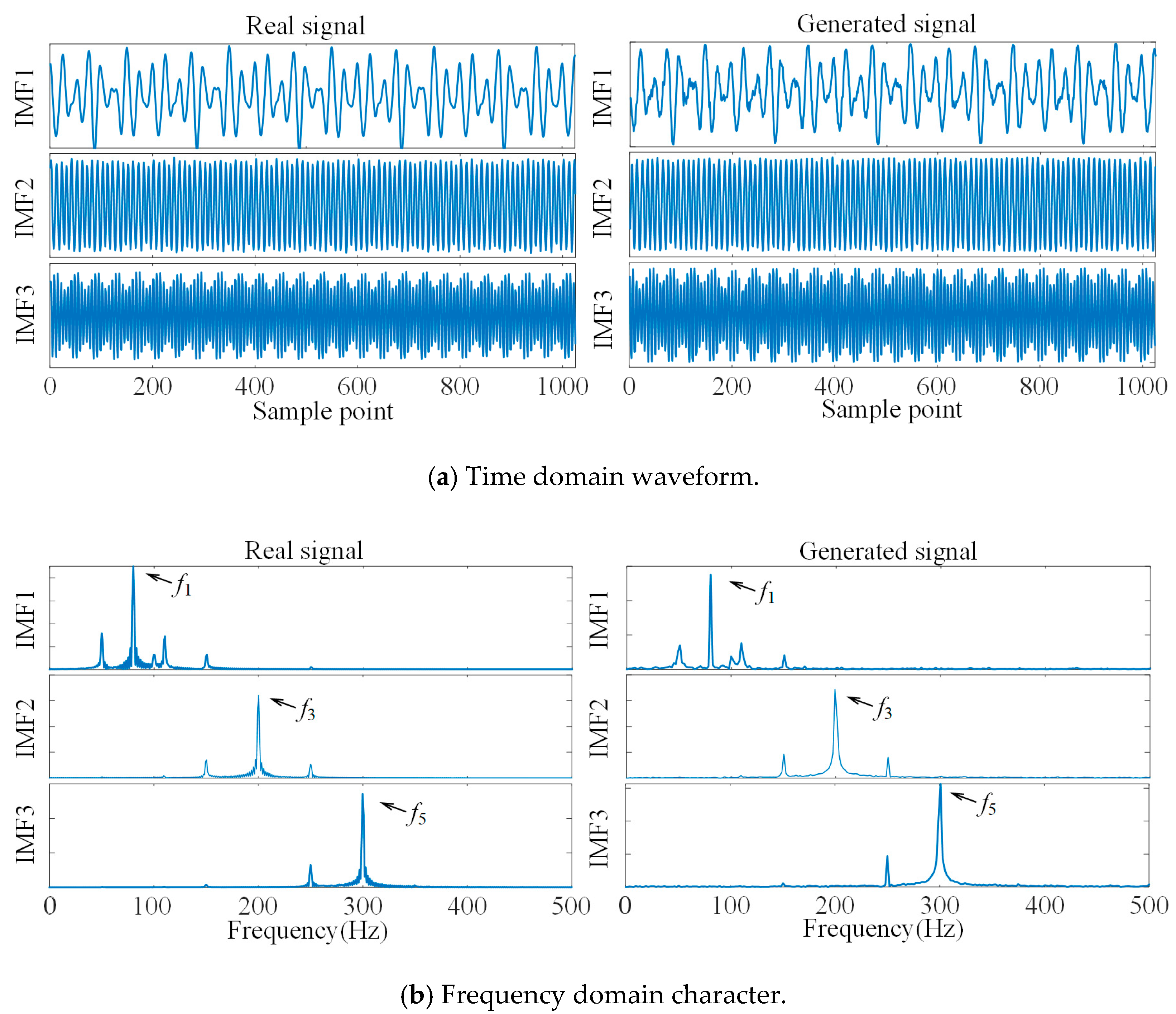

3.3. Generation of Simulation Data

4. Fault Diagnosis Model Based on AMVMD-MC1DCNN

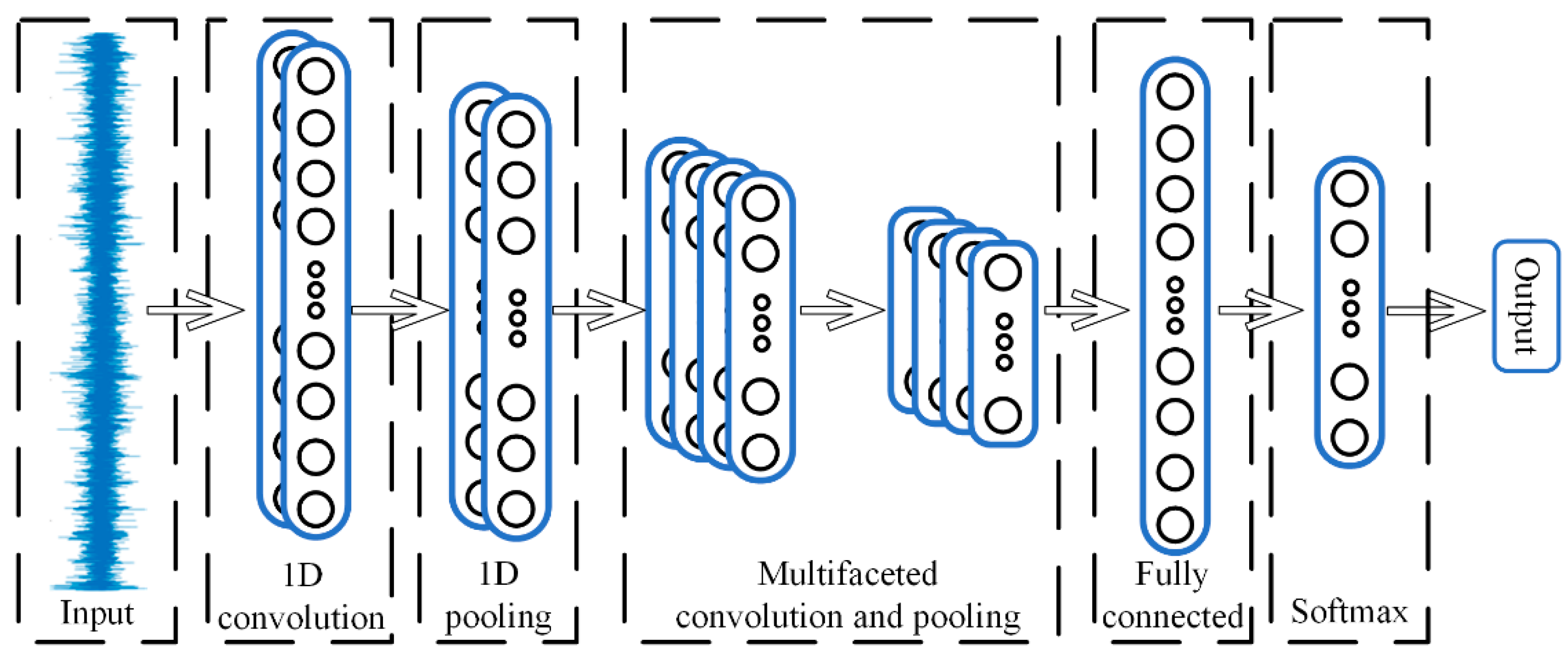

4.1. One-Dimension Convolutional Neural Network

4.2. Multi-Channel One-Dimension Convolutional Neural Network

4.3. Fault Diagnosis Model

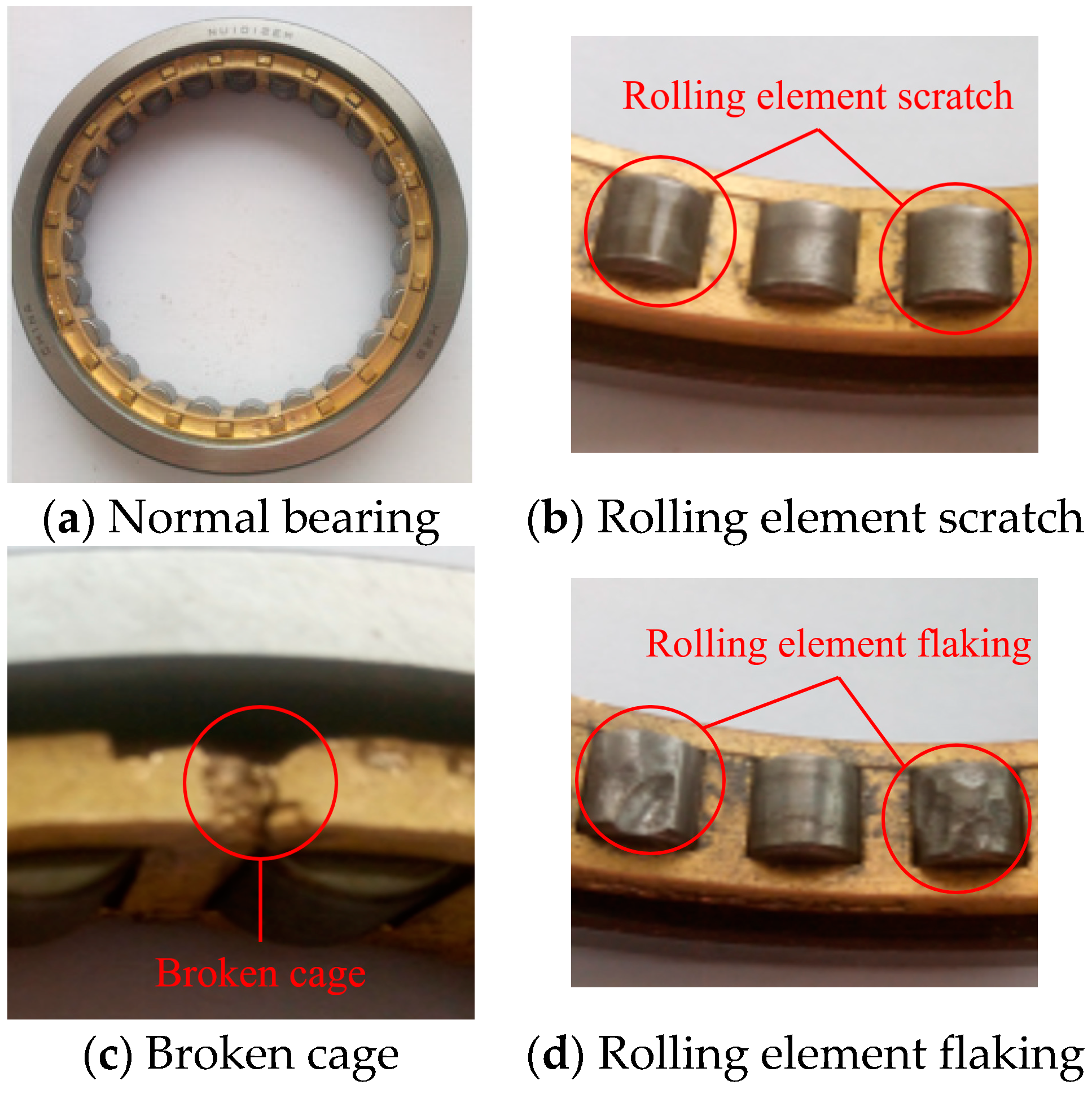

5. Experiments and Results Analysis

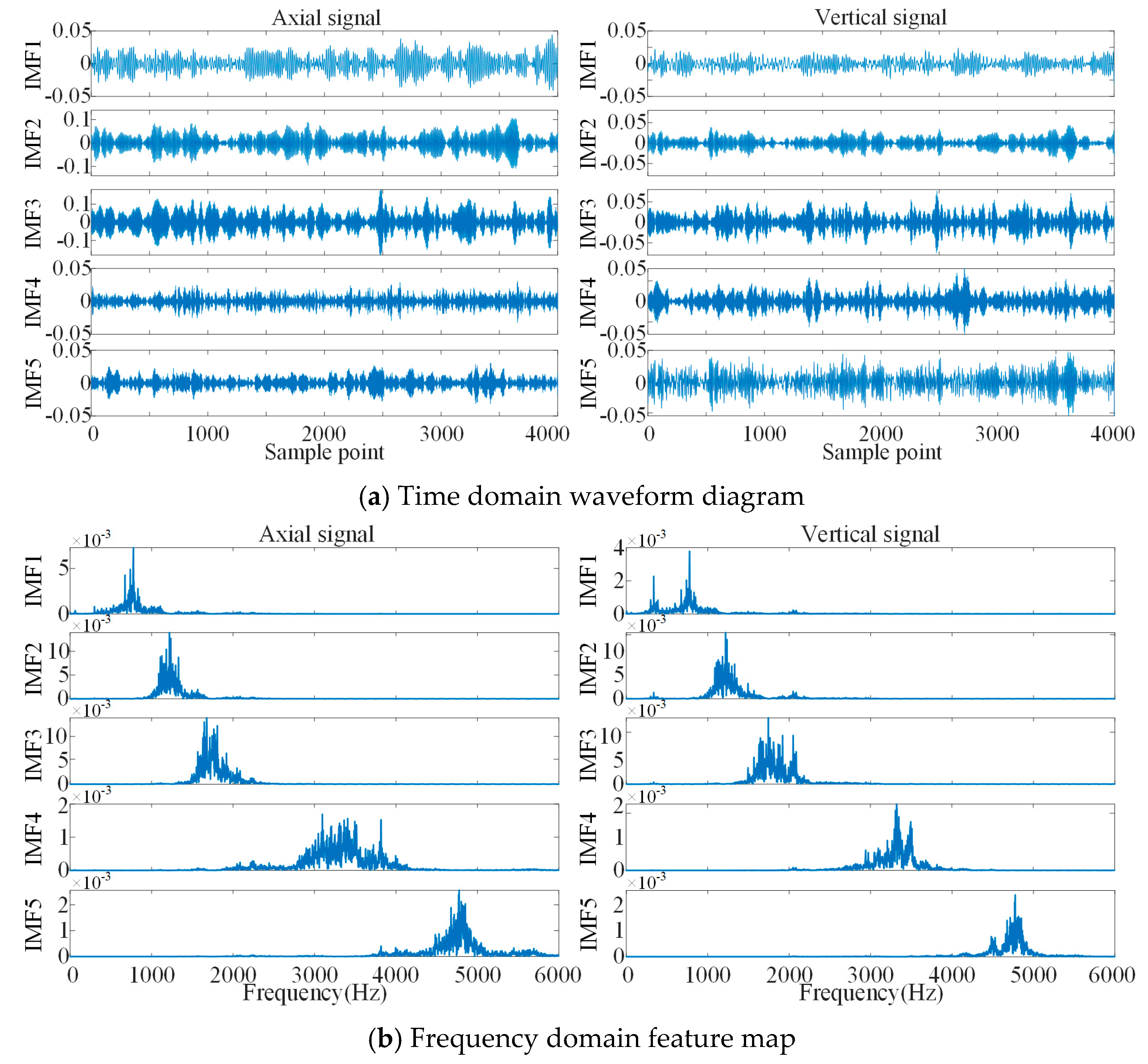

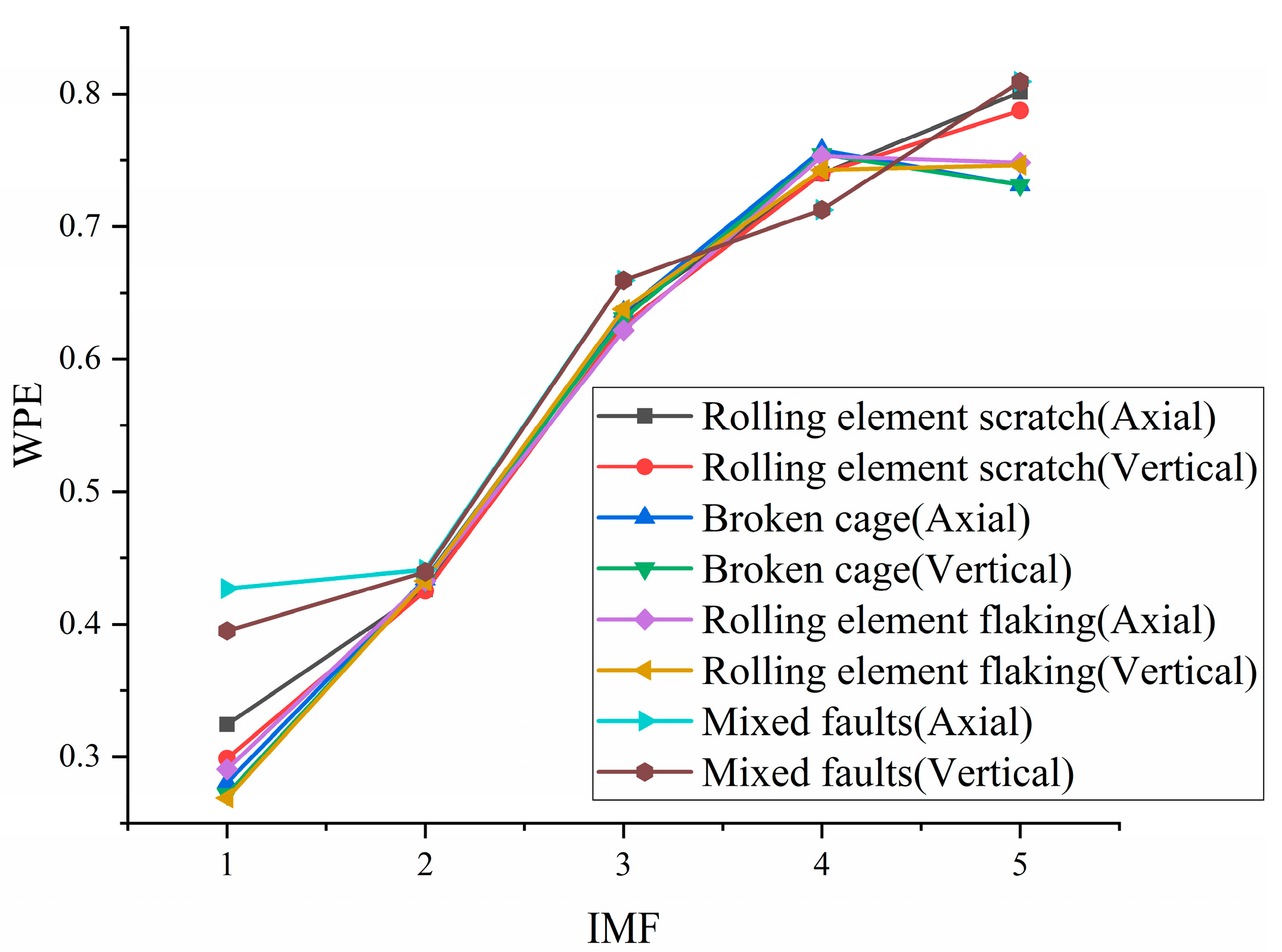

5.1. Signal Processing by AMVMD

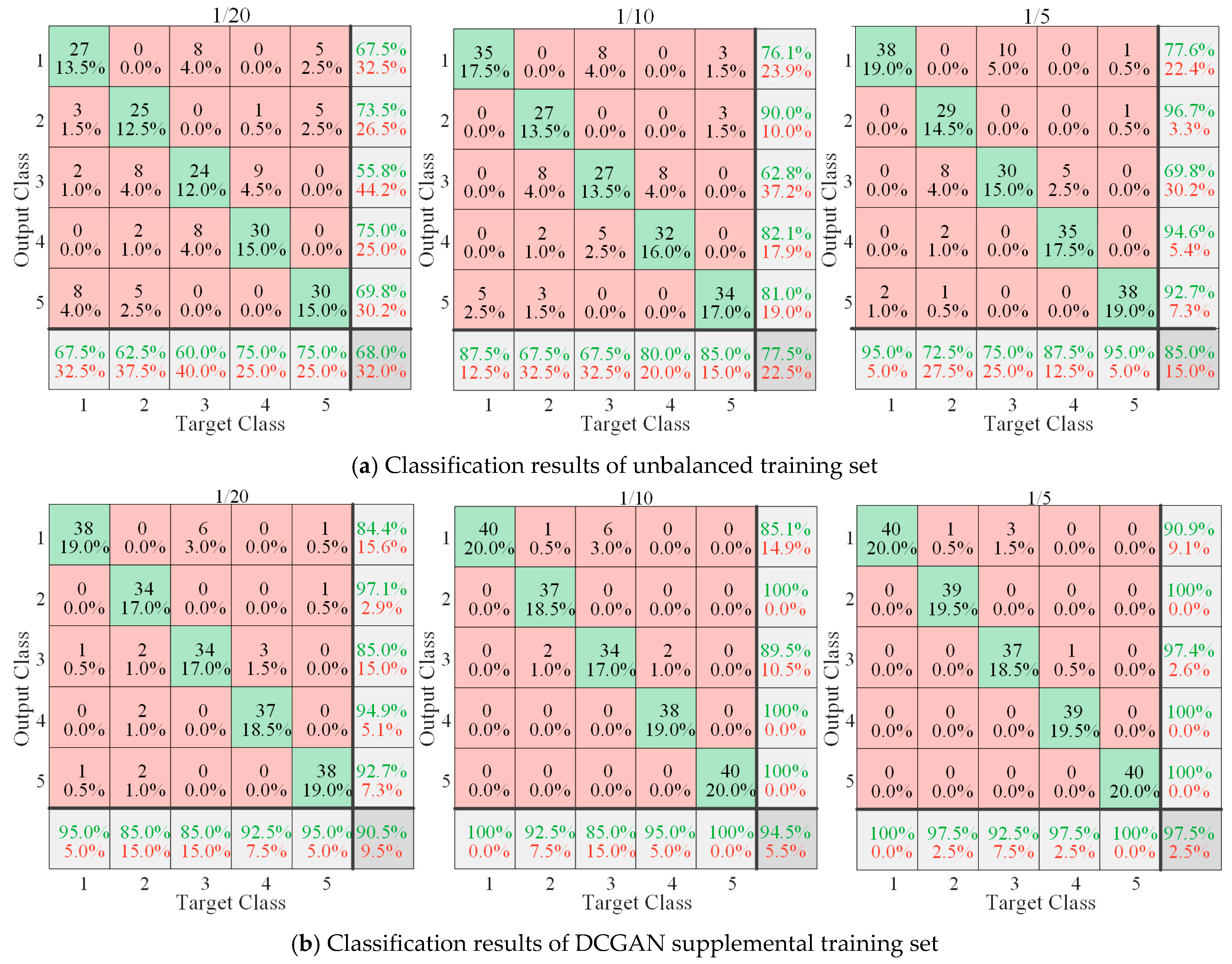

5.2. Generate Reconstructed Data by DCGAN

5.3. Fault Diagnosis by MC1DCNN

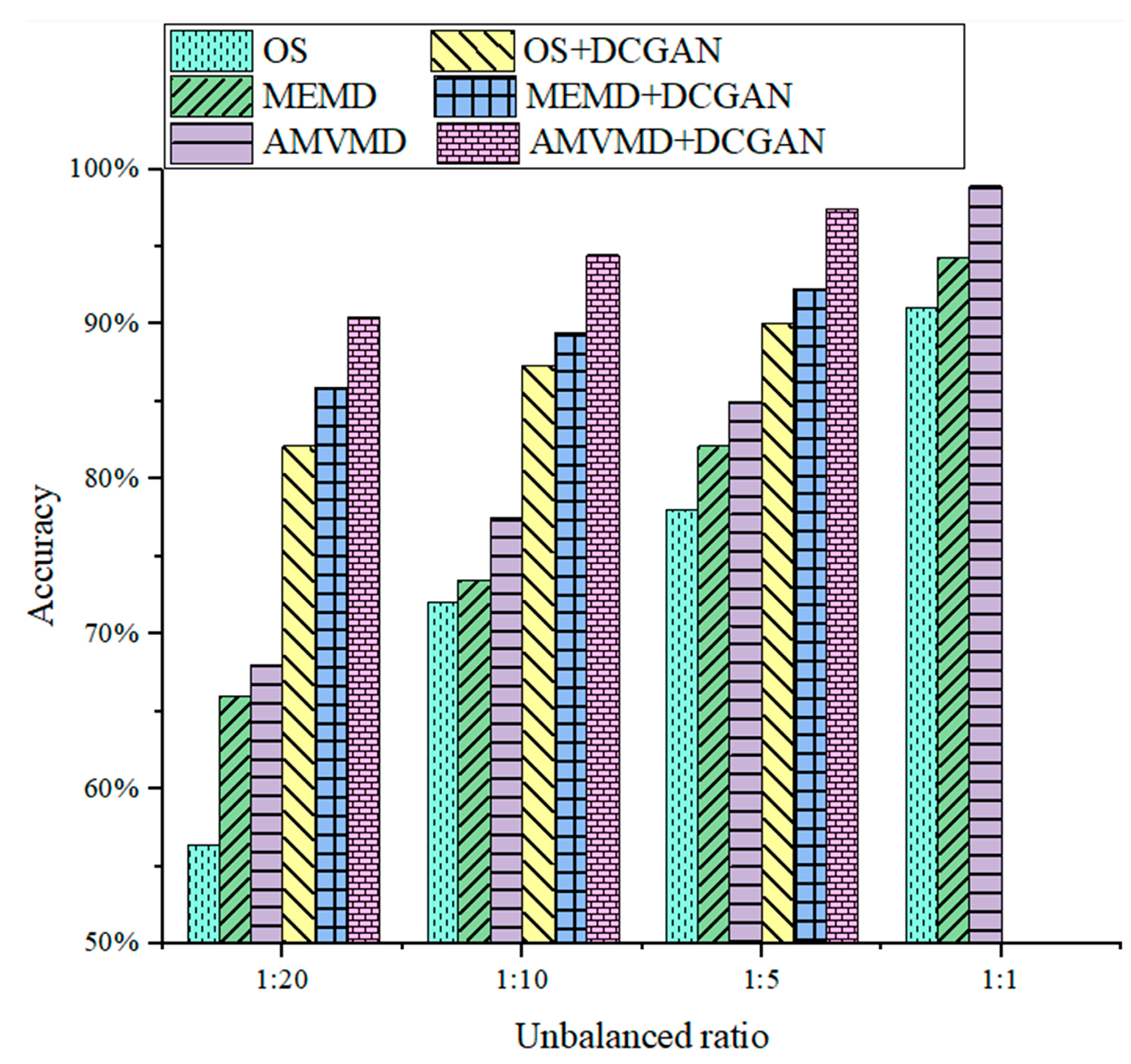

5.4. Comparison Experiments

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nandi, S.; Toliyat, H.A.; Li, X. Condition Monitoring and Fault Diagnosis of Electrical Motors—A Review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Zhu, H.; He, Z.; Wei, J.; Wang, J.; Zhou, H. Bearing Fault Feature Extraction and Fault Diagnosis Method Based on Feature Fusion. Sensors 2021, 21, 2524. [Google Scholar] [CrossRef]

- Feng, Z.; Chen, X.; Wang, T. Time-varying demodulation analysis for rolling bearing fault diagnosis under variable speed conditions. J. Sound Vib. 2017, 400, 71–85. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Wang, X.; Liu, B.; Liang, X. Early fault diagnosis of rolling bearings based on hierarchical symbol dynamic entropy and binary tree support vector machine. J. Sound Vib. 2018, 428, 72–86. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal. Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Liu, W.Y.; Zhang, W.H.; Han, J.G.; Wang, G.F. A new wind turbine fault diagnosis method based on the local mean decomposition. Renew. Energy 2012, 48, 411–415. [Google Scholar] [CrossRef]

- Zhao, H.; Zuo, S.; Hou, M.; Liu, W.; Yu, L.; Yang, X.; Deng, W. A Novel Adaptive Signal Processing Method Based on Enhanced Empirical Wavelet Transform Technology. Sensors 2018, 18, 3323. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Zi, Y.; Pan, J. Independence-oriented VMD to identify fault feature for wheel set bearing fault diagnosis of highspeed locomotive. Mech. Syst. Signal. Process. 2017, 85, 512–529. [Google Scholar] [CrossRef]

- Aneesh, C.; Kumar, S.; Hisham, P.M.; Soman, K.P. Performance Comparison of Variational Mode Decomposition over Empirical Wavelet Transform for the Classification of Power Quality Disturbances Using Support Vector Machine. Procedia Comput. Sci. 2015, 46, 372–380. [Google Scholar] [CrossRef] [Green Version]

- Rehman, N.; Mandic, D.P. Multivariate empirical mode decomposition. Proc. R. Soc. A Math. Phys. 2010, 466, 1291–1302. [Google Scholar] [CrossRef]

- Rehman, N.; Aftab, H. Multivariate Variational Mode Decomposition. IEEE Trans. Signal Process. 2019, 67, 6039–6052. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Zhou, X.; Yu, W.; Hou, Y.; Mechefske, C.K. Adaptive variational mode decomposition and its application to multi-fault detection using mechanical vibration signals. ISA Trans. 2020, 111, 360–375. [Google Scholar] [CrossRef]

- Cao, P.; Wang, H.; Zhou, K. Multichannel Signal Denoising using Multivariate Variational Mode Decomposition with Subspace Projection. IEEE Access 2020, 8, 74039–74047. [Google Scholar] [CrossRef]

- Isham, M.F.; Leong, M.S.; Lim, M.H.; Ahmad, B.; Asrar, Z. Intelligent wind turbine gearbox diagnosis using VMDEA and ELM. Wind Energy 2019, 22, 813–833. [Google Scholar] [CrossRef]

- Akyol, K. Comparing of deep neural networks and extreme learning machines based on growing and pruning approach. Expert Syst. Appl. 2020, 140, 112875. [Google Scholar] [CrossRef]

- Gu, C.; Qiao, X.; Jin, Y.; Liu, Y. A Novel Fault Diagnosis Method for Diesel Engine Based on MVMD and Band Energy. Shock Vib. 2020, 2020, 8247194. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, L.; Cai, Y. Rolling bearing fault diagnosis using generalized refined composite multiscale sample entropy and optimized support vector machine. Measurement 2020, 156, 107574. [Google Scholar] [CrossRef]

- Yang, C.; Lu, G. Deeply Recursive Low- and High-Frequency Fusing Networks for Single Image Super-Resolution. Sensors 2020, 20, 7268. [Google Scholar] [CrossRef]

- Chen, R.; Huang, X.; Yang, L.; Xu, X.; Zhang, X.; Zhang, Y. Intelligent Fault Diagnosis Method of Planetary Gearboxes Based on Convolution Neural Network and Discrete Wavelet Transform. Comput. Ind. 2019, 106, 48–59. [Google Scholar] [CrossRef]

- Xu, Z.; Li, C.; Yang, Y. Fault diagnosis of rolling bearing of wind turbines based on the Variational Mode Decomposition and Deep Convolutional Neural Networks. Appl. Soft Comput. 2020, 95, 106515. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, G.; Wang, R.; Tang, S.; Su, H.; Cao, K. Intelligent Fault Diagnosis of Hydraulic Piston Pump Based on Wavelet Analysis and Improved AlexNet. Sensors 2021, 21, 549. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Yang, S.; Li, Q.; Liu, Y.; Liu, W. A New Bearing Fault Diagnosis Method Based on Signal-to-Image Mapping and Convolutional Neural Network. Measurement 2021, 176, 109088. [Google Scholar] [CrossRef]

- Levent, E. Bearing Fault Detection by One-Dimensional Convolutional Neural Network. Math. Probl. Eng. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.; Jiang, P.; Ding, C.; Feng, F.; Chen, T. Intelligent Fault Diagnosis of Rotating Machinery Based on One-dimensional Convolutional Neural Network. Comput. Ind. 2019, 108, 53–61. [Google Scholar] [CrossRef]

- Pascual, S.; Serrà, J.; Bonafonte, A. Time-domain speech enhancement using generative adversarial networks—ScienceDirect. Speech Commun. 2019, 114, 10–21. [Google Scholar] [CrossRef]

- Zeng, H.; Li, X.; Borghini, G.; Zhao, Y.; Aricò, P.; Flumeri, G.D.; Sciaraffa, N.; Zakaria, W.; Kong, W.; Babiloni, F. An EEG-Based Transfer Learning Method for Cross-Subject Fatigue Mental State Prediction. Sensors 2021, 21, 2369. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Jiang, H.; Wu, Z.; Li, X. Data synthesis using deep feature enhanced generative adversarial networks for rolling bearing imbalanced fault diagnosis. Mech. Syst. Signal. Process. 2022, 163, 108139. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, S.; Chen, Z.; Li, W. Enhanced generative adversarial network for extremely imbalanced fault diagnosis of rotating machine. Measurement 2021, 180, 109467. [Google Scholar] [CrossRef]

- Radford, A.; Metz, L.; Chintala, S. Unsupervised Representation Learning with Deep Convolutional Generative Adversarial Network. In Proceedings of the 4th International Conference on Learning Representations (ICLR), San Juan, Puerto Rico, 2–4 May 2016. [Google Scholar]

- Guo, Q.; Li, Y.; Song, Y.; Wang, D.; Chen, W. Intelligent Fault Diagnosis Method Based on Full 1D Convolutional Generative Adversarial Network. IEEE Trans. Ind. Inform. 2019, 16, 2044–2053. [Google Scholar] [CrossRef]

- Gao, S.; Wang, X.; Miao, X.; Su, C.; Li, Y. ASM1D-GAN: An Intelligent Fault Diagnosis Method Based on Assembled 1D Convolutional Neural Network and Generative Adversarial Network. J. Signal Process Syst. 2019, 91, 1237–1247. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, C.; Hu, Z.; Kong, F.; Liu, X. Adaptive variational mode decomposition based on artificial fish swarm algorithm for fault diagnosis of rolling bearings. Proc. Inst. Mech. Eng. C J. Mech. 2015, 231, 635–654. [Google Scholar] [CrossRef]

- Wang, J.; Han, B.; Bao, H.; Wang, M.; Chu, Z.; Shen, Y. Data augment method for machine fault diagnosis using conditional generative adversarial networks. Proc. Inst. Mech. Eng. D J. Automob. 2020, 234, 2719–2727. [Google Scholar] [CrossRef]

- Zhou, F.; Yang, S.; Fujita, H.; Chen, D.; Wen, C. Deep learning fault diagnosis method based on global optimization GAN for unbalanced data. Knowl. Based Syst. 2020, 187, 104837. [Google Scholar] [CrossRef]

- Mirza, M.; Osindero, S. Conditional Generative Adversarial Nets. arXiv 2014, arXiv:1411.1784. Available online: https://arxiv.org/abs/1411.1784 (accessed on 2 August 2021).

- Traore, B.B.; Kamsu-Foguem, B.; Tangara, F. Deep convolution neural network for image recognition. Ecol. Inform. 2018, 48, 257–268. [Google Scholar] [CrossRef] [Green Version]

- Celona, L.; Bianco, S.; Schettini, R. Fine-grained face annotation using deep Multi-Task CNN. Sensors 2018, 18, 2666. [Google Scholar] [CrossRef] [Green Version]

| Length of Signal | Computation Time of MVMD(s) | Calculation Time of AMVMD (s) |

|---|---|---|

| 2000 | 0.737 | 0.506 |

| 4000 | 3.345 | 2.001 |

| 6000 | 8.185 | 5.020 |

| 8000 | 11.887 | 7.241 |

| 10,000 | 15.817 | 9.642 |

| 12,000 | 22.567 | 14.037 |

| 14,000 | 30.682 | 19.367 |

| 16,000 | 41.052 | 26.477 |

| Types of Faults | Number of IMF | Penalty Factor α |

|---|---|---|

| Rolling element scratch | 5 | 2658 |

| Broken cage | 6 | 2941 |

| Rolling element flaking | 5 | 2931 |

| Mixed faults | 6 | 2137 |

| Network Structure | Convolution Kernel | Input Channel | Output Channel | Step | Activation Function |

|---|---|---|---|---|---|

| Convolutional layer 1 | 32 × 1 | 2 | 32 | 2 | Tanh |

| Convolutional layer 2 | 4 × 1 | 32 | 64 | 2 | ReLU |

| Convolutional layer 3 | 4 × 1 | 64 | 128 | 2 | ReLU |

| Convolutional layer 4 | 4 × 1 | 128 | 128 | 2 | ReLU |

| Input Signal | Classification Model | Accuracy |

|---|---|---|

| Original signal (Vertical) | DBN | 81.4% |

| Original signal (Axial) | DBN | 84.2% |

| Original signal (Mixed) | DBN | 89.8% |

| Original signal (Vertical) | 1DCNN | 84.3% |

| Original signal (Axial) | 1DCNN | 87.4% |

| Original signal (Mixed) | 1DCNN | 91.7% |

| MEMD reconstructed signal (Vertical) | DBN | 87.3% |

| MEMD reconstructed signal (Axial) | DBN | 89.5% |

| MEMD reconstructed signal (Mixed) | DBN | 91.6% |

| MEMD reconstructed signal (Vertical) | 1DCNN | 87.5% |

| MEMD reconstructed signal (Axial) | 1DCNN | 90.1% |

| MEMD reconstructed signal (Mixed) | 1DCNN | 94.3% |

| AMVMD reconstructed signal (Vertical) | DBN | 89.8% |

| AMVMD reconstructed signal (Axial) | DBN | 91.3% |

| AMVMD reconstructed signal (Mixed) | DBN | 95.4% |

| AMVMD reconstructed signal (Vertical) | 1DCNN | 93.2% |

| AMVMD reconstructed signal (Axial) | 1DCNN | 94.7% |

| AMVMD reconstructed signal (Mixed) | 1DCNN | 96.1% |

| AMVMD reconstructed signal | MC1DCNN | 98.2% |

| Vibration Signal | Classification Model | Model Input | Accuracy |

|---|---|---|---|

| Vertical signal | VMD-ELM | Multidomain features | 90.4% |

| Axial signal | VMD-ELM | Multidomain features | 92.6% |

| Mixed signal | VMD-ELM | Multidomain features | 94.5% |

| Vertical signal | MVMD-SVM | MWPE | 90.2% |

| Axial signal | MVMD-SVM | MWPE | 91.4% |

| Mixed signal | MVMD-SVM | MWPE | 94.7% |

| Vertical signal | VMD-CNN | The reconstructed signal | 92.3% |

| Axial signal | VMD-CNN | The reconstructed signal | 93.4% |

| Mixed signal | VMD-CNN | The reconstructed signal | 95.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Sun, J.; Lin, S.; Peng, Y. Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset. Sensors 2021, 21, 5494. https://doi.org/10.3390/s21165494

Zhao C, Sun J, Lin S, Peng Y. Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset. Sensors. 2021; 21(16):5494. https://doi.org/10.3390/s21165494

Chicago/Turabian StyleZhao, Chen, Jianliang Sun, Shuilin Lin, and Yan Peng. 2021. "Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset" Sensors 21, no. 16: 5494. https://doi.org/10.3390/s21165494

APA StyleZhao, C., Sun, J., Lin, S., & Peng, Y. (2021). Fault Diagnosis Method for Rolling Mill Multi Row Bearings Based on AMVMD-MC1DCNN under Unbalanced Dataset. Sensors, 21(16), 5494. https://doi.org/10.3390/s21165494