Monitoring Soil and Ambient Parameters in the IoT Precision Agriculture Scenario: An Original Modeling Approach Dedicated to Low-Cost Soil Water Content Sensors

Abstract

:1. Introduction

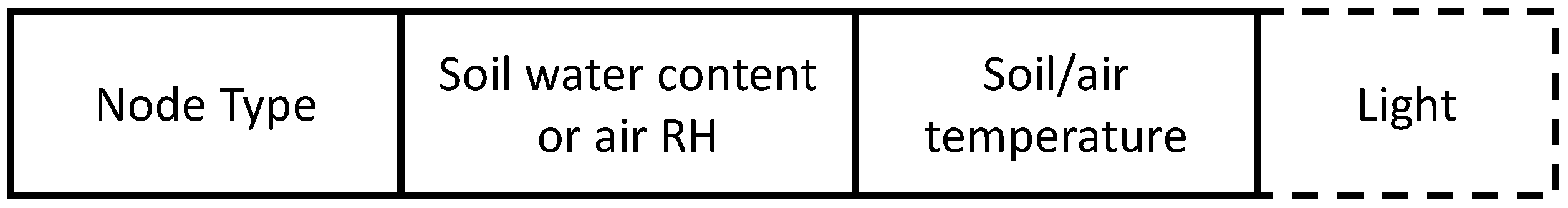

- Acquisition of basic physical parameters of plants and ambient with low-cost sensors: soil water content and temperature, greenhouse ambient RH, temperature, and light. Even if the present paper will mostly be focused on soil water content and most parameters will not be discussed, the availability of multiple parameters could be exploited in the future to build a more intelligent system by using machine learning algorithms.

- Availability of a modular system built with cheap off-the-shelf components also providing capabilities for automation and management of plant irrigation.

- Comparison of the performance of a very low-cost soil moisture sensor with a commercially available expensive system using two different types of soil with an original modeling approach which helps us to compare measurement results taken at different soil depths.

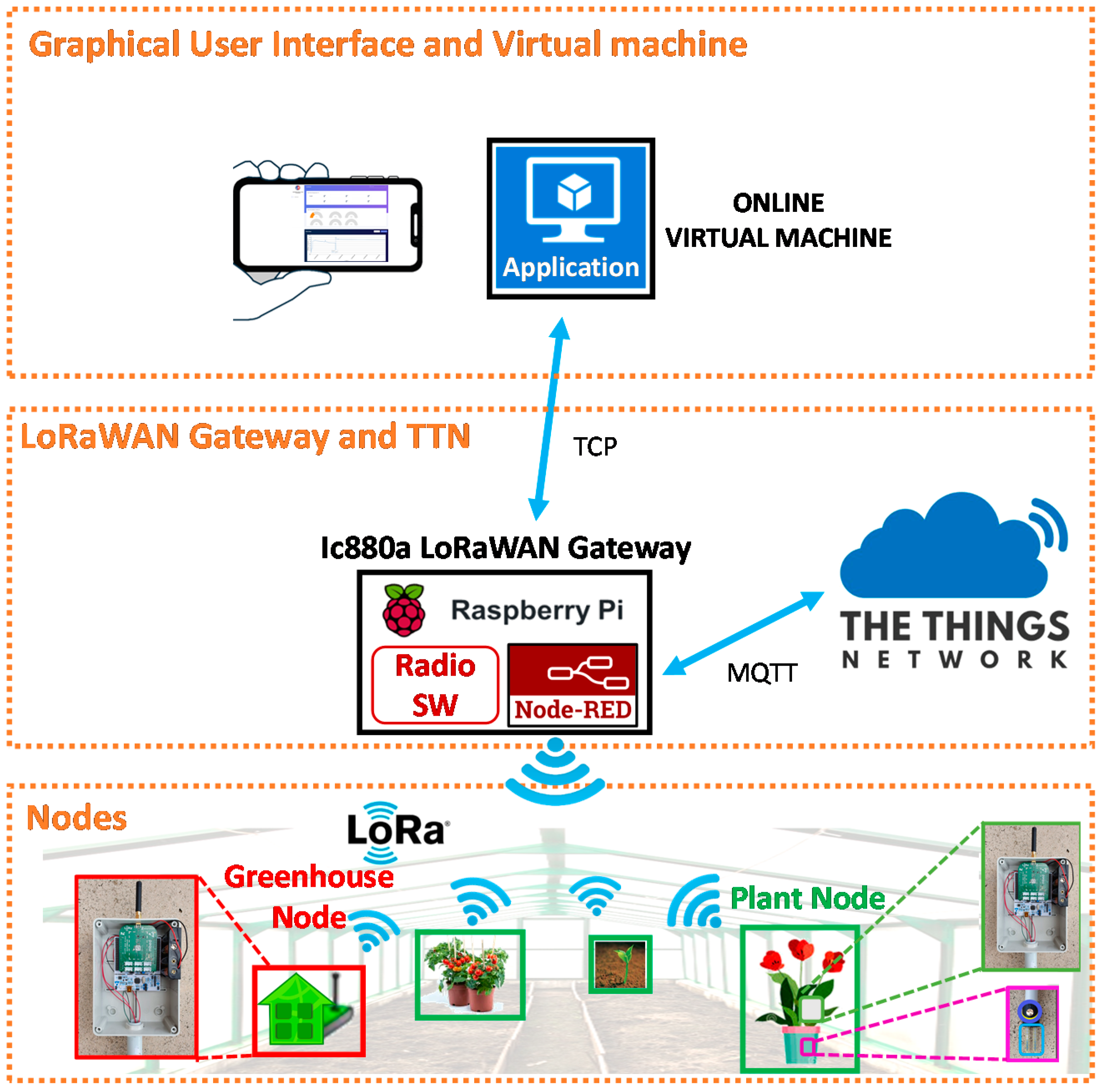

2. IoT Architecture in Precision Agriculture Scenario

2.1. Water Waste and Agriculture

2.2. IoT Architectures

2.3. Radio and Wireless Protocols in PA

3. System Architecture

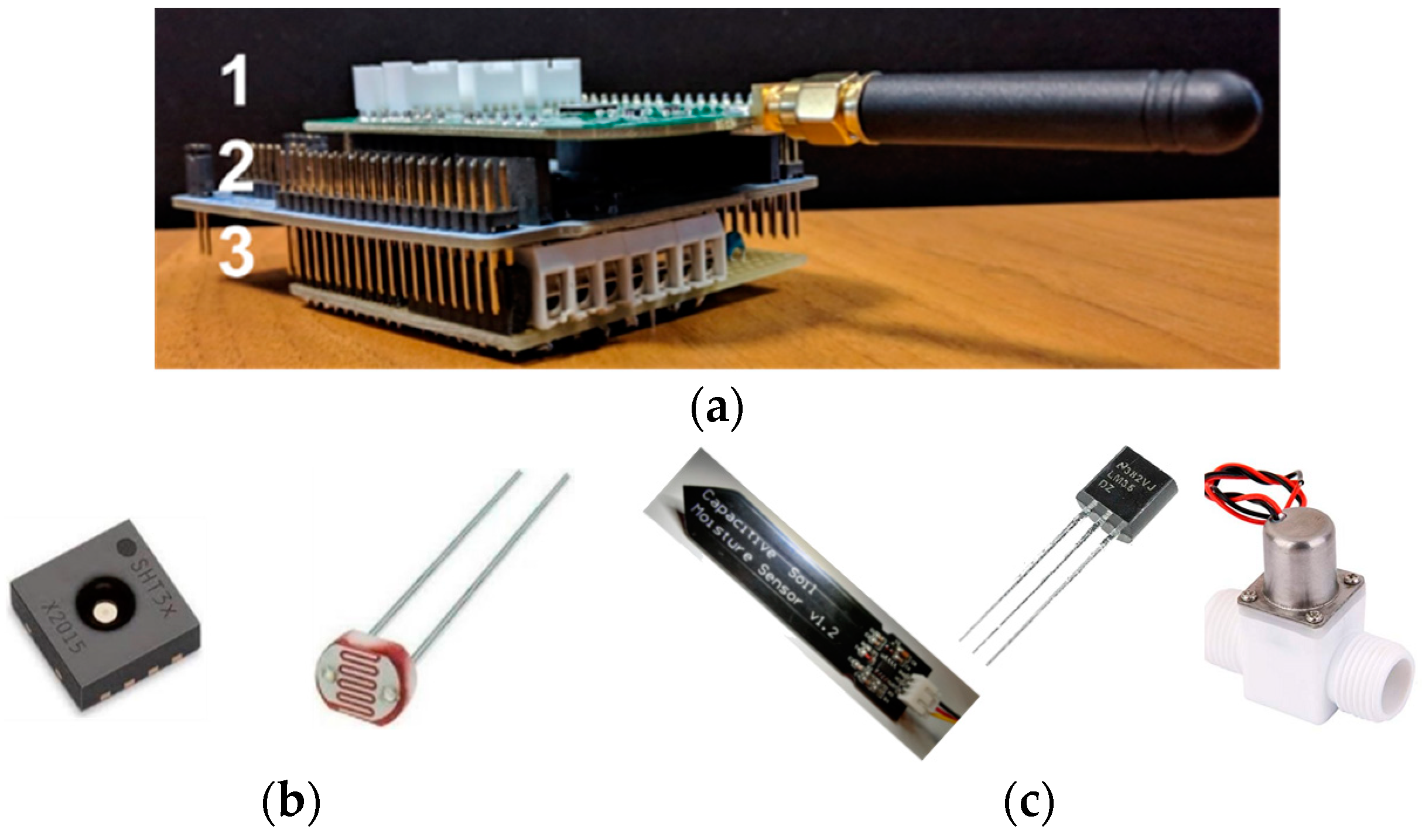

3.1. Nodes

3.1.1. Soil Volumetric Water Content Fitting Equations

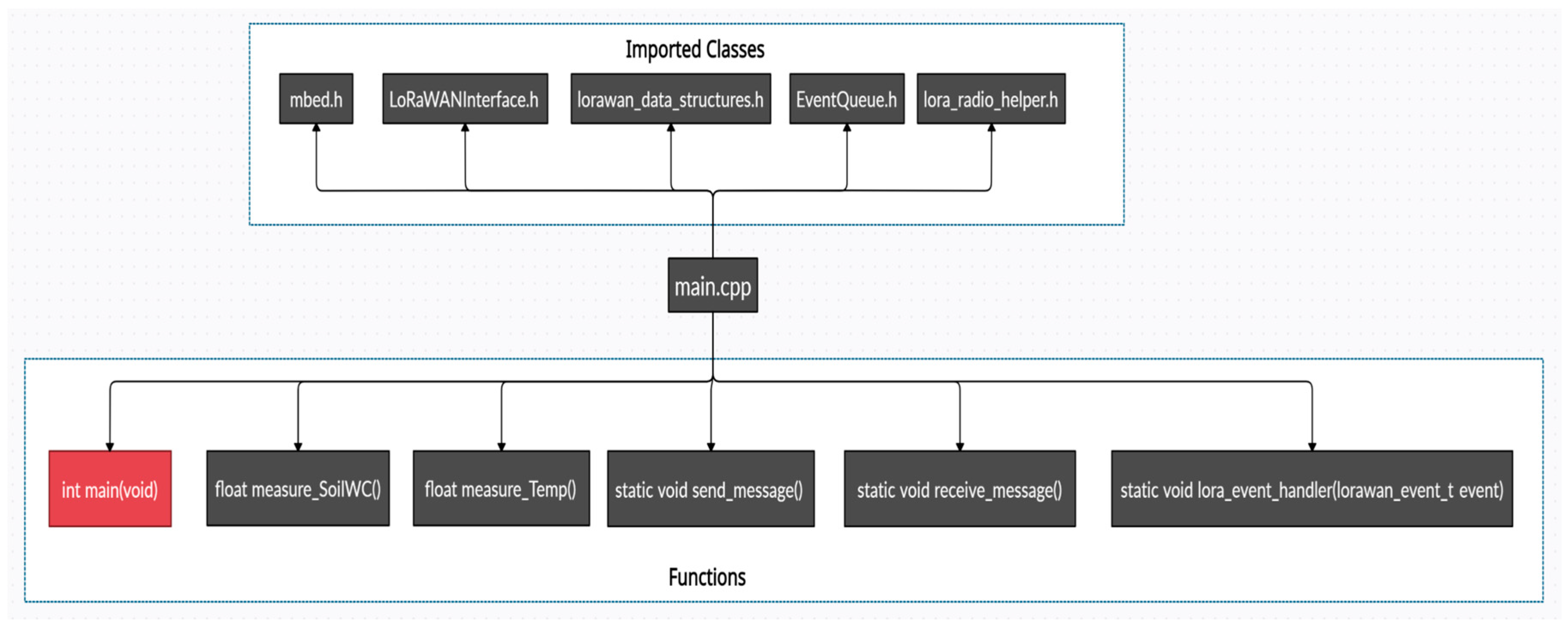

3.1.2. Embedded Software Implementation of Nodes

3.2. The Things Network and Connection to the LoRaWAN™ Gateway

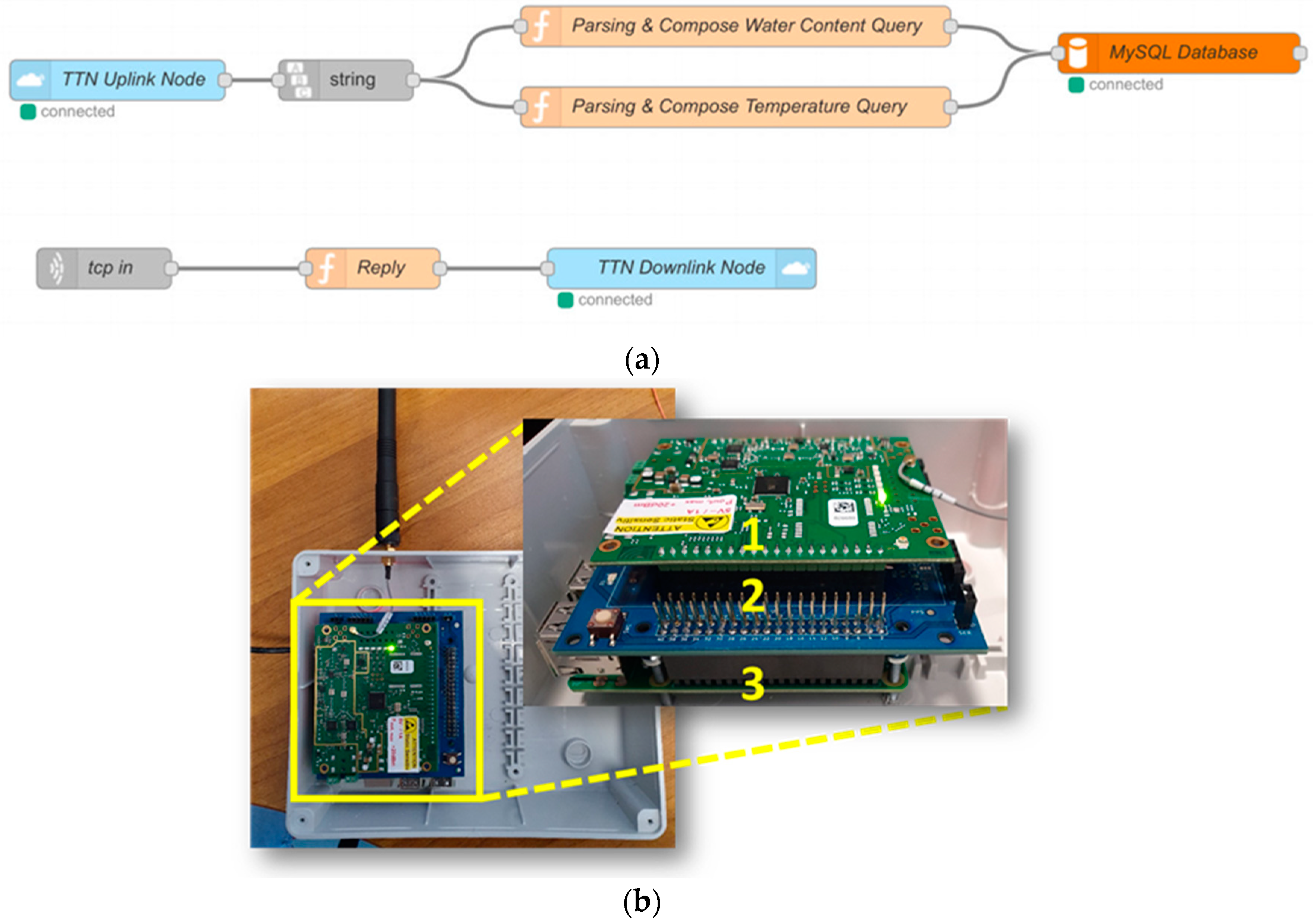

- Retrieving through the internet the data received and published by the TTN broker exploiting the light blue TTN Uplink Node producing an output Node.js buffer;

- Converting this Node.js buffer to a string;

- Parsing this string by exploiting two function nodes featuring JavaScript codes, dedicated to Water Content and Temperature, respectively, which also compose the query for the database;

- Sending the query to the MySQL database running on the Virtual Machine through a dedicated TCP port (internet connection through MySQL 3306 port) employing the orange node.

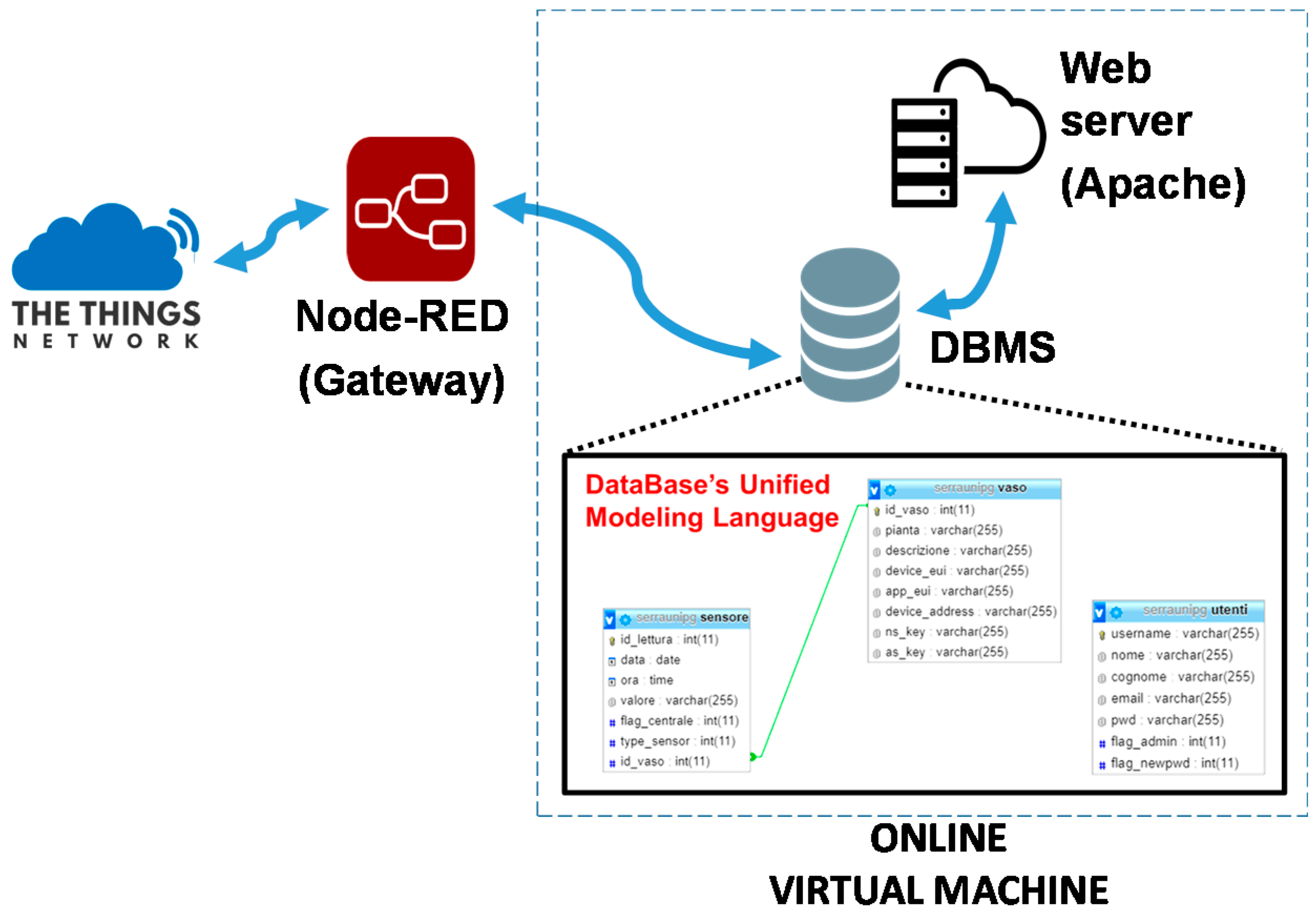

3.3. The Virtual Machine in the Cloud, Database Application, and Graphical User Interface

- Web site (HTML, PHP, CSS, and JavaScript) within a web server;

- MySQL Database Management System (DBMS) server.

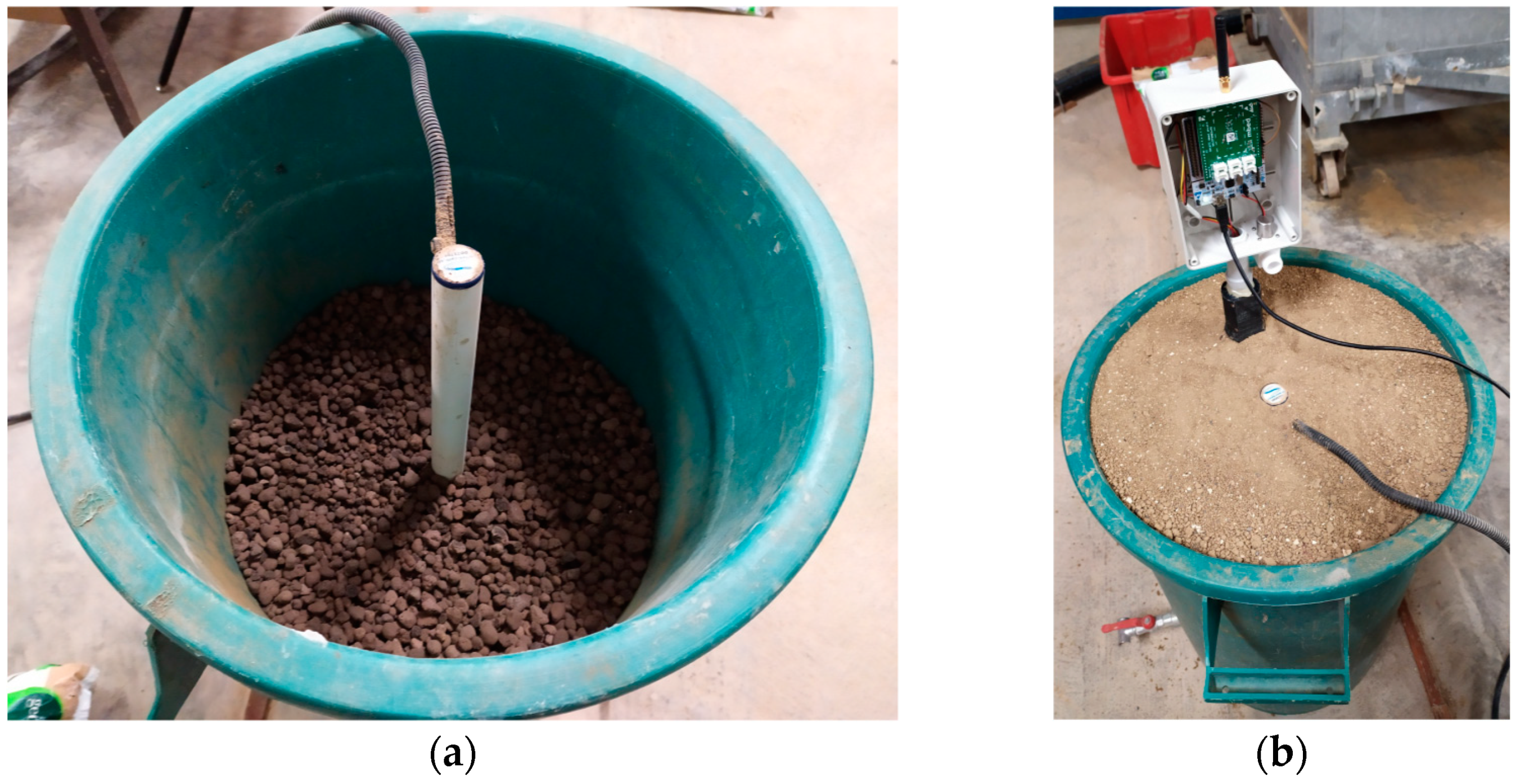

4. Materials

5. Methods, Tests, and Results

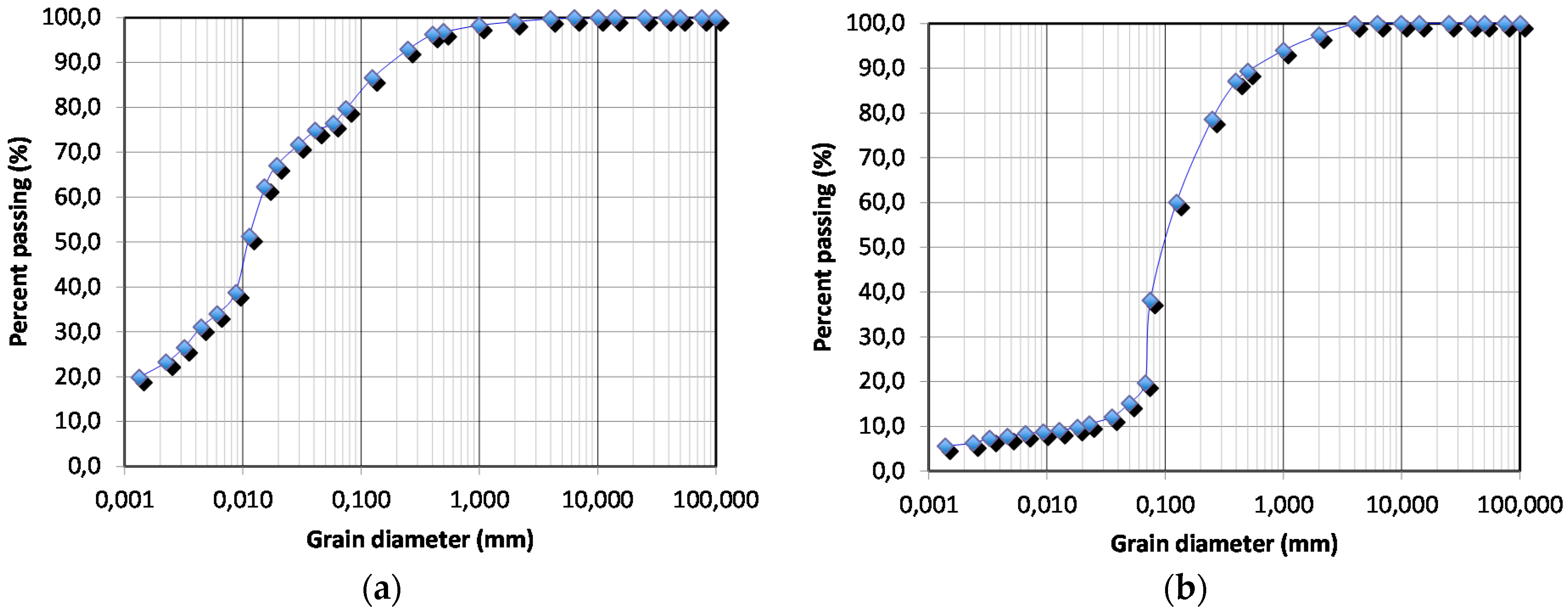

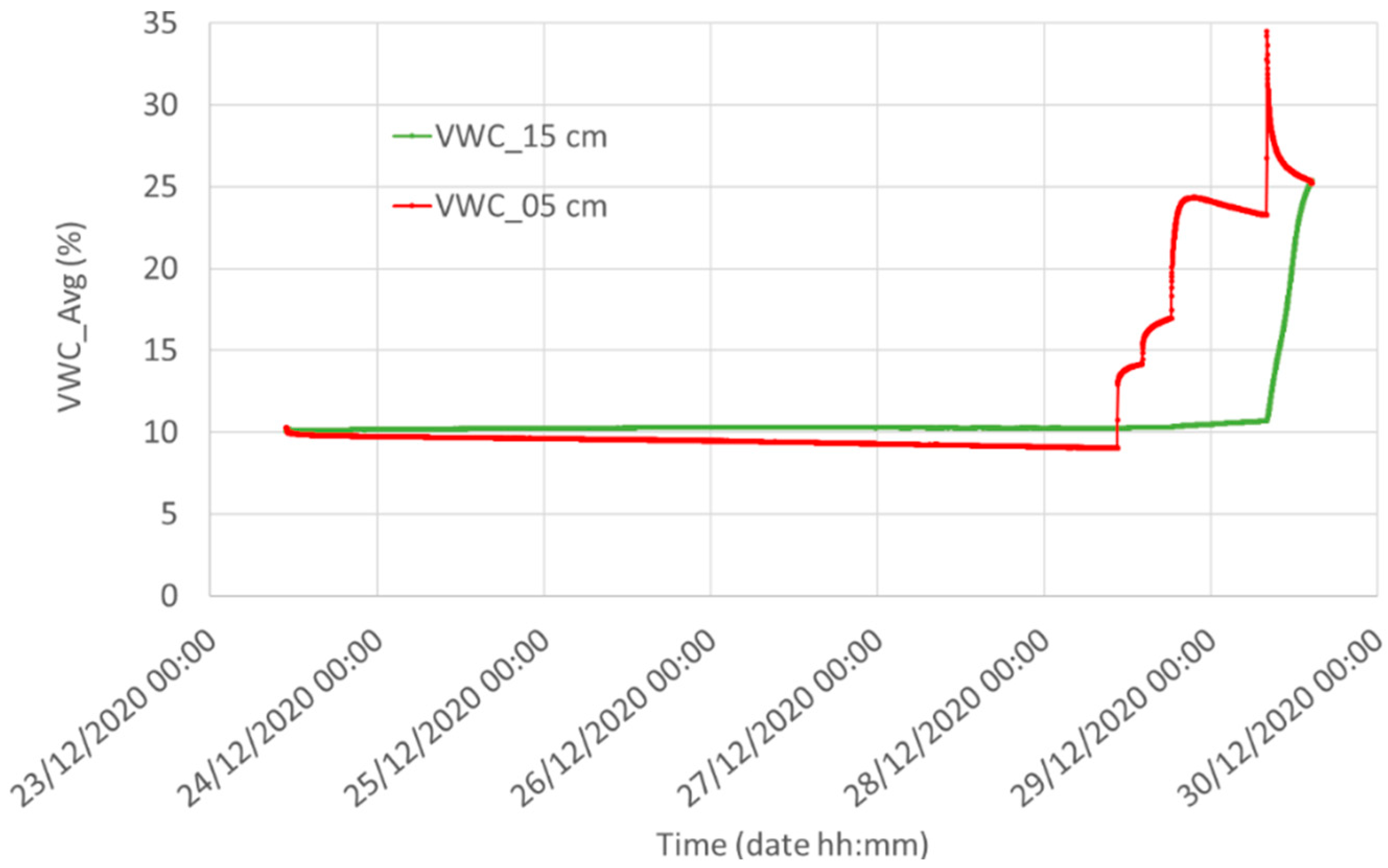

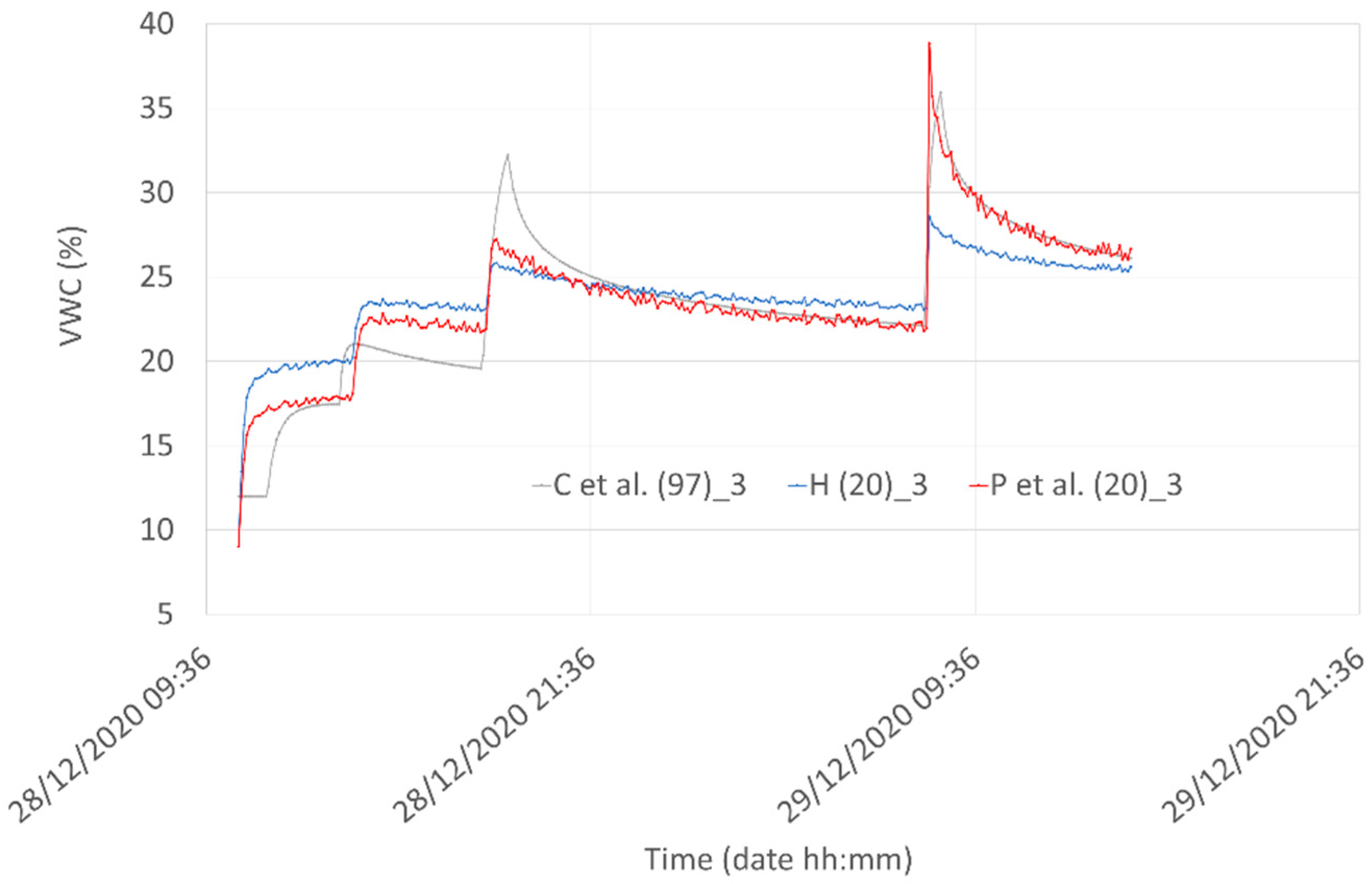

5.1. Measurements in Silty Loam

5.2. Measurements in Loamy Sand

6. Discussion

- Node #1 is 10 cm far from the reference sensor and soil compaction and watering could not be perfectly uniform in that area;

- Measurement results from Node #1 could be influenced by temperature variations;

- The Capacitive Soil Moisture Sensor v1.2 measures an average water content of approximately the first 5 cm of the soil where it is inserted, while the reference sensor is placed at 5 cm from the soil surface with a wider thickness of influence (spanning a depth between 0 and 10 cm).

6.1. The Modeling Infiltration and Redistribution of Water

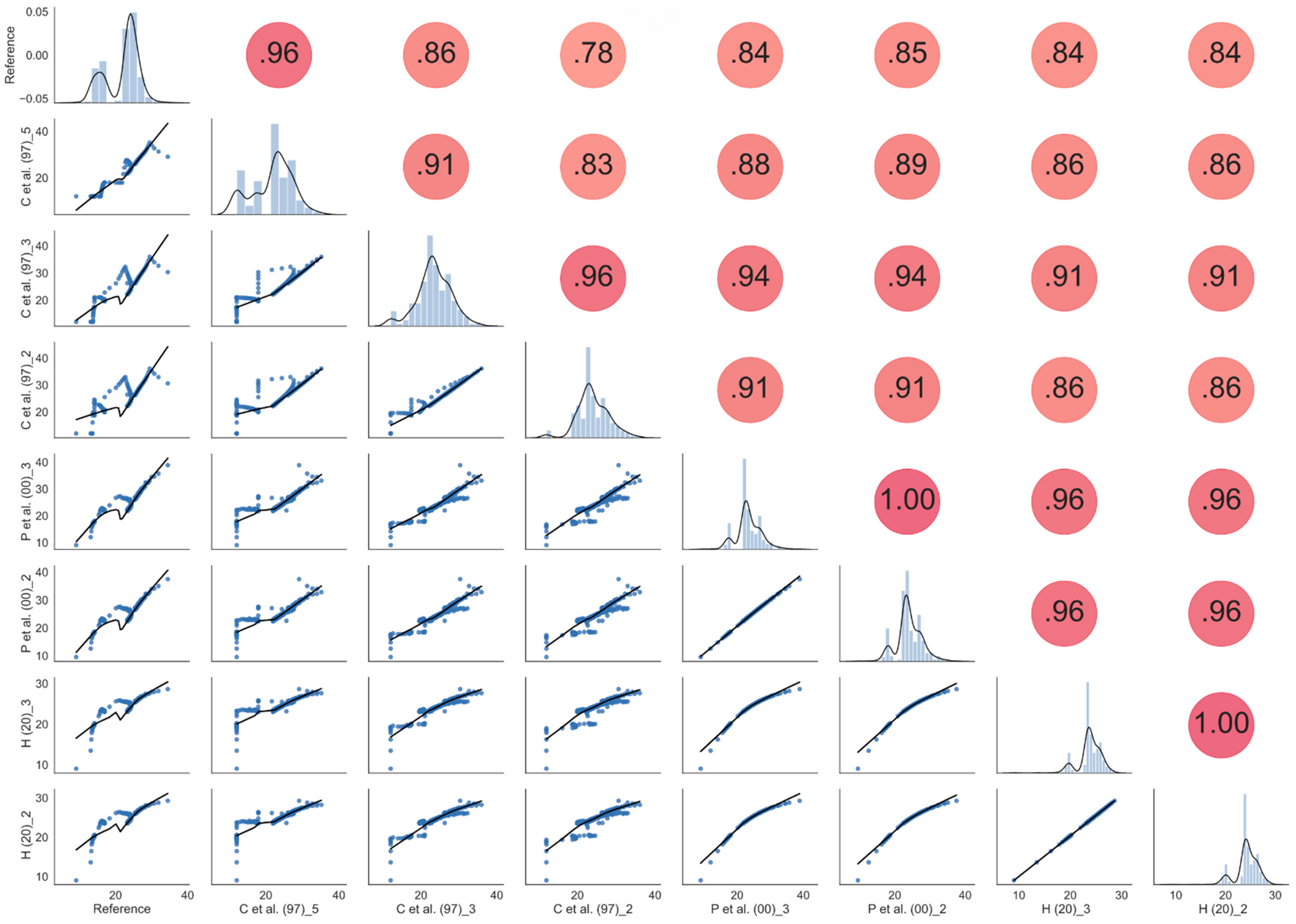

6.2. Correlation of the Capacitive Soil Moisture Sensor v1.2 Output Voltage with the Prediction of the Hydraulic Model

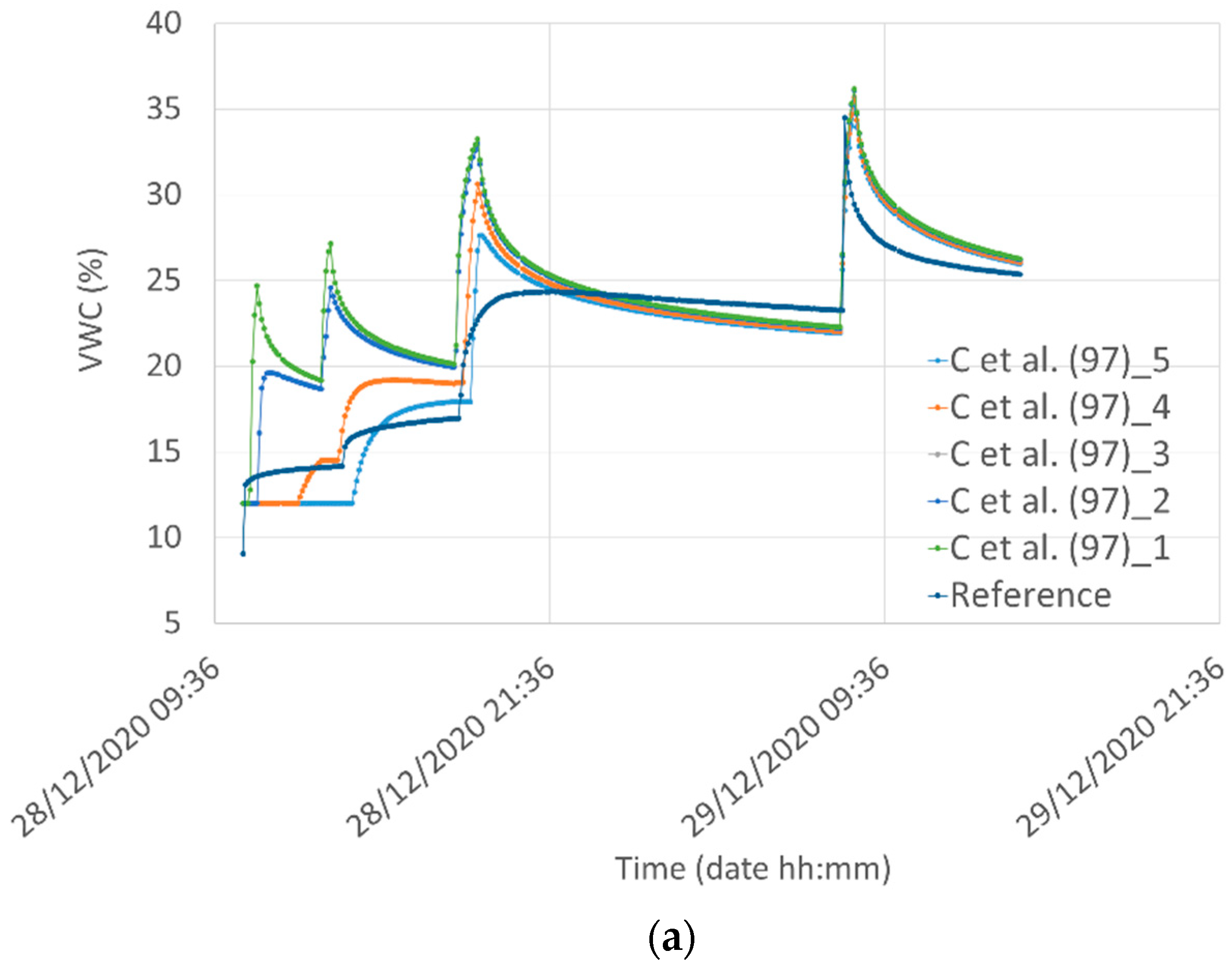

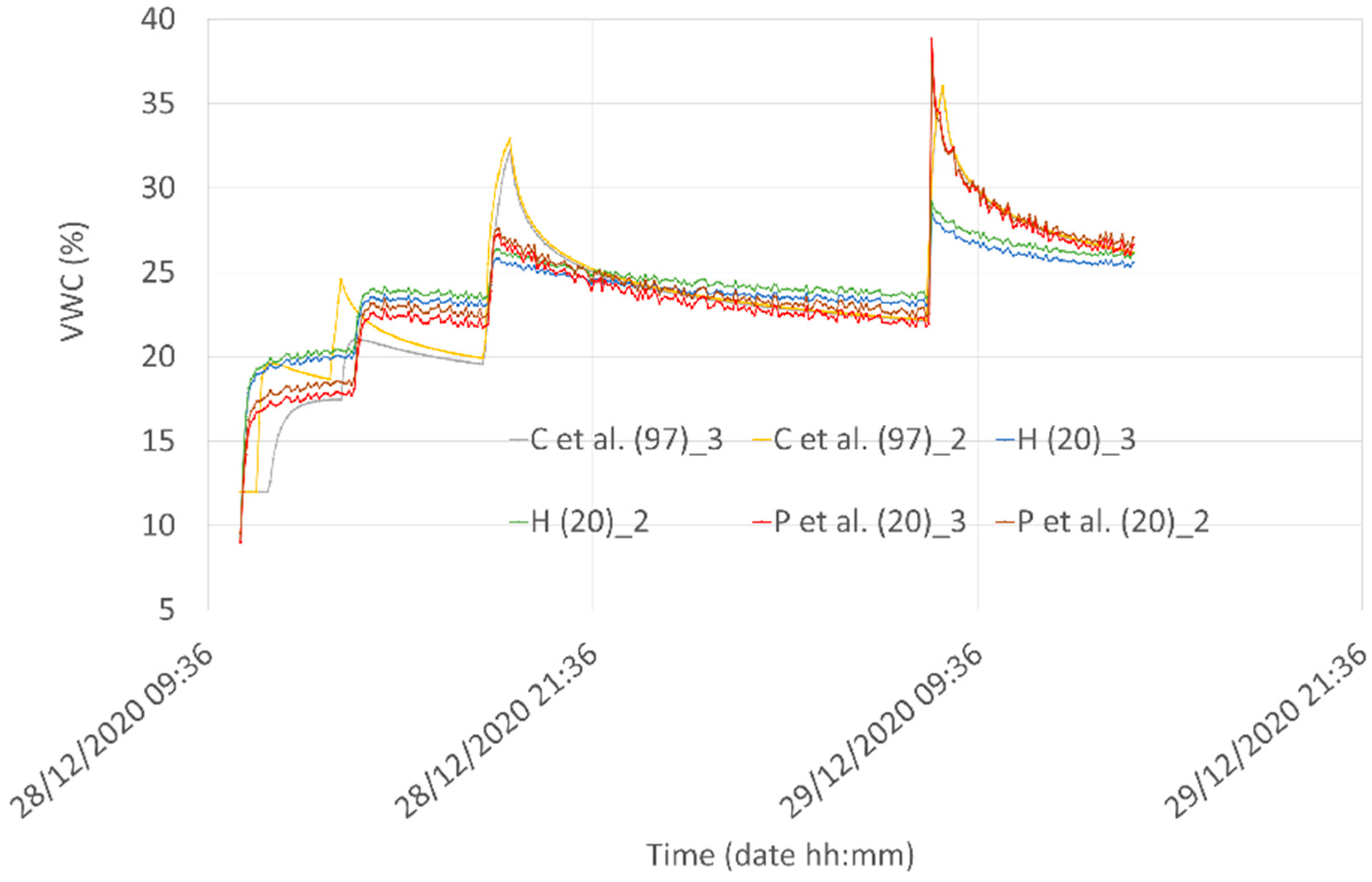

6.2.1. Water Content in Silty Loam

6.2.2. Water Content in Loamy Sand

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Banđur, Đ.; Jakšić, B.; Banđur, M.; Jović, S. An analysis of energy efficiency in Wireless Sensor Networks (WSNs) applied in smart agriculture. Comput. Electron. Agric. 2019, 156, 500–507. [Google Scholar] [CrossRef]

- Kochhar, A.; Kumar, N. Wireless sensor networks for greenhouses: An end-to-end review. Comput. Electron. Agric. 2019, 163, 104877. [Google Scholar] [CrossRef]

- Castañeda-Miranda, A.; Castaño, V.M. Internet of things for smart farming and frost intelligent control in greenhouses. Comput. Electron. Agric. 2020, 176, 105614. [Google Scholar] [CrossRef]

- Pradeepkumar, D.; Ravi, V. Soft computing hybrids for FOREX rate prediction: A comprehensive review. Comput. Oper. Res. 2018, 99, 262–284. [Google Scholar] [CrossRef]

- Panigrahi, S.; Behera, H.S. A hybrid ETS–ANN model for time series forecasting. Eng. Appl. Artif. Intell. 2017, 66, 49–59. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, Y.; Chen, Z.; Wang, X.; Huang, B. Comprehensive assessments of soil fertility and environmental quality in plastic greenhouse production systems. Geoderma 2021, 385, 114899. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, H.; Zhang, S.; Wang, Y.; Chow, D. Modeling and optimization of environment in agricultural greenhouses for improving cleaner and sustainable crop production. J. Clean. Prod. 2021, 285, 124843. [Google Scholar] [CrossRef]

- Placidi, P.; Gasperini, L.; Grassi, A.; Cecconi, M.; Scorzoni, A. Characterization of Low-Cost Capacitive Soil Moisture Sensors for IoT Networks. Sensors 2020, 20, 3585. [Google Scholar] [CrossRef]

- Syafrudin, M.; Alfian, G.; Fitriyani, N.L.; Rhee, J. Performance Analysis of IoT-Based Sensor, Big Data Processing, and Machine Learning Model for Real-Time Monitoring System in Automotive Manufacturing. Sensors 2018, 18, 2946. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castañeda, A.; Castaño, V.M. Smart frost measurement for anti-disaster intelligent control in greenhouses via embedding IoT and hybrid AI methods. Measurement 2020, 164, 108043. [Google Scholar] [CrossRef]

- Rizzi, M.; Ferrari, P.; Flammini, A.; Sisinni, E. Evaluation of the IoT LoRaWAN Solution for Distributed Measurement Applications. IEEE Trans. Instrum. Meas. 2017, 66, 12. [Google Scholar] [CrossRef]

- Zamora-Izquierdo, M.A.; Santa, J.; Martínez, J.A.; Martínez, V.; Skarmeta, A.F. Smart farming IoT platform based on edge and cloud computing. Biosyst. Eng. 2019, 177, 4–17. [Google Scholar] [CrossRef]

- Iyengar, S.S.; Boroojeni, K.G.; Balakrishnan, N. Mathematical Theories of Distributed Sensor Networks; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Benos, L.; Tagarakis, A.; Dolias, G.; Berruto, R.; Kateris, D.; Bochtis, D. Machine Learning in Agriculture: A Comprehensive Updated Review. Sensors 2021, 21, 3758. [Google Scholar] [CrossRef]

- Patrício, D.I.; Rieder, R. Computer vision and artificial intelligence in precision agriculture for grain crops: A systematic re-view. Comput. Electron. Agric. 2018, 153, 69–81. [Google Scholar] [CrossRef] [Green Version]

- van Klompenburg, T.; Kassahun, A.; Catal, C. Crop yield prediction using machine learning: A systematic literature review. Comput. Electron. Agric. 2020, 177, 105709. [Google Scholar] [CrossRef]

- Liakos, K.G.; Busato, P.; Moshou, D.; Pearson, S.; Bochtis, D. Machine learning in agriculture: A review. Sensors 2018, 18, 2674. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, Y.; Chen, L.; Wu, H.; Li, L. Advanced agricultural disease image recognition technologies: A review. Inf. Process. Agric. 2021, 8, 1–12. [Google Scholar] [CrossRef]

- Akbar, A.; Kuanar, A.; Patnaik, J.; Mishra, A.; Nayak, S. Application of Artificial Neural Network modeling for optimization and prediction of essential oil yield in turmeric (Curcuma longa L.). Comput. Electron. Agric. 2018, 148, 160–178. [Google Scholar] [CrossRef]

- Vij, A.; Vijendra, S.; Jain, A.; Bajaj, S.; Bassi, A.; Sharma, A. IoT and Machine Learning Approaches for Automation of Farm Irrigation System. Procedia Comput. Sci. 2020, 167, 1250–1257. [Google Scholar] [CrossRef]

- Rehman, A.U.; Abbasi, A.Z.; Islam, N.; Shaikh, Z.A. A review of wireless sensors and networks’ applications in agriculture. Comput. Stand. Interfaces 2014, 36, 263–270. [Google Scholar] [CrossRef]

- Farooq, M.S.; Riaz, S.; Abid, A.; Umer, T.; Bin Zikria, Y. Role of IoT Technology in Agriculture: A Systematic Literature Review. Electronics 2020, 9, 319. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; An, X.; Zhao, Q.; Liu, H.; Xia, L.; Sun, X.; Guo, Y. State-of-the-Art Internet of Things in Protected Agriculture. Sensors 2019, 19, 1833. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sagheer, A.; Mohammed, M.; Riad, K.; Alhajhoj, M. A Cloud-Based IoT Platform for Precision Control of Soilless Greenhouse Cultivation. Sensors 2020, 21, 223. [Google Scholar] [CrossRef] [PubMed]

- Shafi, U.; Mumtaz, R.; García-Nieto, J.; Hassan, S.A.; Zaidi, S.A.R.; Iqbal, N. Precision Agriculture Techniques and Practices: From Considerations to Applications. Sensors 2019, 19, 3796. [Google Scholar] [CrossRef] [Green Version]

- Messina, G.; Modica, G. Applications of UAV Thermal Imagery in Precision Agriculture: State of the Art and Future Research Outlook. Remote. Sens. 2020, 12, 1491. [Google Scholar] [CrossRef]

- Gnecchi, J.A.G.; Tirado, L.F.; Campos, G.M.C.; Ramirez, R.D.; Gordillo, C.F.E. Design of a Soil Moisture Sensor with Temperature Compensation Using a Backpropagation Neural Network. In Proceedings of the 2008 Electronics, Robotics and Automotive Mechanics Conference, Cuernavaca, Mexico, 30 September–3 October 2008; pp. 553–558. [Google Scholar]

- Danita, M.; Mathew, B.; Shereen, N.; Sharon, N.; Paul, J.J. IoT Based Automated Greenhouse Monitoring System. In Proceedings of the 2018 Second International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 14–15 June 2018; pp. 1933–1937. [Google Scholar]

- Ruiz-Garcia, L.; Lunadei, L.; Barreiro, P.; Robla, J.I. A Review of Wireless Sensor Technologies and Applications in Agriculture and Food Industry: State of the Art and Current Trends. Sensors 2009, 9, 4728–4750. [Google Scholar] [CrossRef] [Green Version]

- BeechamRes. Towards Smart Farming Agriculture Embracing the IoT Vision. Available online: http://www.beechamresearch.com/files/BRL%20Smart%20Farming%20Executive%20Summary.pdf (accessed on 12 May 2020).

- SU, S.L.; Singh, D.N.; Baghini, M.S. A critical review of soil moisture measurement. Measurement 2014, 54, 92–105. [Google Scholar] [CrossRef]

- Nagahage, E.A.A.D.; Nagahage, I.S.P.; Fujino, T. Calibration and Validation of a Low-Cost Capacitive Moisture Sensor to Integrate the Automated Soil Moisture Monitoring System. Agriculture 2019, 9, 141. [Google Scholar] [CrossRef] [Green Version]

- Hrisko, J. Capacitive Soil Moisture Sensor Theory, Calibration, and Testing. Tech. Rep. 2020, 2, 1–12. [Google Scholar] [CrossRef]

- Morais, R.; Mendes, J.; Silva, R.; Silva, N.; Sousa, J.; Peres, E. A Versatile, Low-Power and Low-Cost IoT Device for Field Data Gathering in Precision Agriculture Practices. Agriculture 2021, 11, 619. [Google Scholar] [CrossRef]

- Figorilli, S.; Pallottino, F.; Colle, G.; Spada, D.; Beni, C.; Tocci, F.; Vasta, S.; Antonucci, F.; Pagano, M.; Fedrizzi, M.; et al. An Open Source Low-Cost Device Coupled with an Adaptative Time-Lag Time-Series Linear Forecasting Modeling for Apple Trentino (Italy) Precision Irrigation. Sensors 2021, 21, 2656. [Google Scholar] [CrossRef]

- Escriba, C.; Bravo, E.G.A.; Roux, J.; Fourniols, J.-Y.; Contardo, M.; Acco, P.; Soto-Romero, G. Toward Smart Soil Sensing in v4.0 Agriculture: A New Single-Shape Sensor for Capacitive Moisture and Salinity Measurements. Sensors 2020, 20, 6867. [Google Scholar] [CrossRef] [PubMed]

- Kojima, Y.; Shigeta, R.; Miyamoto, N.; Shirahama, Y.; Nishioka, K.; Mizoguchi, M.; Kawahara, Y. Low-Cost Soil Moisture Profile Probe Using Thin-Film Capacitors and a Capacitive Touch Sensor. Sensors 2016, 16, 1292. [Google Scholar] [CrossRef]

- Ferrández-Pastor, F.J.; García-Chamizo, J.M.; Nieto-Hidalgo, M.; Pascual, J.M.M.; Mora-Martínez, J. Developing Ubiquitous Sensor Network Platform Using Internet of Things: Application in Precision Agriculture. Sensors 2016, 16, 1141. [Google Scholar] [CrossRef] [Green Version]

- Ferrández-Pastor, F.J.; García-Chamizo, J.M.; Nieto-Hidalgo, M.; Mora-Martínez, J. Precision Agriculture Design Method Using a Distributed Computing Architecture on Internet of Things Context. Sensors 2018, 18, 1731. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Coping with Water Scarcity. UN—Water Thematic Initiatives. A Strategic Issue and Priority for System-Wide Action. 2006. Available online: http://www.unwater.org/publications/coping-water-scarcity/ (accessed on 3 January 2021).

- Hanak, E.; Mount, J.; Chappelle, C.; Lund, J.; Medellín-Azuara, J.; Moyle, P. Public Policy Institute of California, Water Policy Center. What If California’s Drought Continues? 2015. Available online: http://www.ppic.org/publication/what-if-californias-drought-continues/ (accessed on 3 January 2021).

- Yuanyuan, C.; Zuozhuang, Z. Research and Design of Intelligent Water-saving Irrigation Control System Based on WSN. In Proceedings of the 2020 IEEE International Conference on Artificial Intelligence and Computer Applications (ICAICA), Dalian, China, 27–29 June 2020. [Google Scholar]

- Mohanraj, I.; Gokul, V.; Ezhilarasie, R.; Umamakeswari, A. Intelligent drip irrigation and fertigation using wireless sensor networks. In Proceedings of the 2017 IEEE Technological Innovations in ICT for Agriculture and Rural Development (TIAR), Chennai, India, 7–8 April 2017. [Google Scholar]

- Walker, J.P.; Willgoose, G.R.; Kalma, J.D. In Situ measurement of soil moisture: A comparison of techniques. J. Hydrol. 2004, 293, 85–99. [Google Scholar] [CrossRef]

- Tremsin, V.A. Real-Time Three-Dimensional Imaging of Soil Resistivity for Assessment of Moisture Distribution for Intelligent Irrigation. Hydrology 2017, 4, 54. [Google Scholar] [CrossRef] [Green Version]

- Subahi, F.; Bouazza, K.E. An Intelligent IoT-Based System Design for Controlling and Monitoring Greenhouse Temperature. IEEE Access 2020, 8, 125488–125500. [Google Scholar] [CrossRef]

- Pawlowski, A.; Guzman, J.L.; Rodríguez, F.; Berenguel, M.; Sánchez, J.; Dormido, S. Simulation of Greenhouse Climate Monitoring and Control with Wireless Sensor Network and Event-Based Control. Sensors 2009, 9, 232–252. [Google Scholar] [CrossRef] [Green Version]

- Germani, L.; Mecarelli, V.; Baruffa, G.; Rugini, L.; Frescura, F. An IoT Architecture for Continuous Livestock Monitoring Using LoRa LPWAN. Electronics 2019, 8, 1435. [Google Scholar] [CrossRef] [Green Version]

- Wang, N.; Zhang, N.; Wang, M. Wireless sensors in agriculture and food industry—Recent development and future perspective. Comput. Electron. Agric. 2006, 50, 1–14. [Google Scholar] [CrossRef]

- Haseeb, K.; Ud Din, I.; Almogren, A.; Islam, N. An Energy Efficient and Secure IoT-Based WSN Framework: An Application to Smart Agriculture. Sensors 2020, 20, 2081. [Google Scholar] [CrossRef] [PubMed]

- Yelamarthi, K.; Aman, M.S.; Abdelgawad, A. An Application-Driven Modular IoT Architecture. Wirel. Commun. Mob. Comput. 2017, 2017, 1350929. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, J.; Villa-Medina, J.F.; Nieto-Garibay, A.; Porta-Gándara, M.Á. Automated Irrigation System Using a Wireless Sensor Network and GPRS Module. IEEE Trans. Instrum. Meas. 2014, 63, 1. [Google Scholar] [CrossRef]

- LoRa Alliance. What is LoRaWAN® Specification. Available online: https://lora-alliance.org/about-lorawan/ (accessed on 1 February 2021).

- Zourmand, A.; Hing, A.L.K.; Hung, C.W.; Abdulrehman, M. Internet of Things (IoT) using LoRa technology. In Proceedings of the Conference I2CACIS 2019, Selangor, Malaysia, 29 June 2019. [Google Scholar]

- Gu, C.; Tan, R.; Huang, J. SoftLoRa—A LoRa-Based Platform for Accurate and Secure Timing. In Proceedings of the IPSN 19, Montreal, QC, Canada, 16–18 April 2019; pp. 309–310. [Google Scholar]

- Van Torre, P.; Ameloot, T.; Rogier, H. Long-range body-to-body LoRa link at 868 MHz. In Proceedings of the 13th European Conference on Antennas and Propagation (EuCAP 2019), Krakow, Polland, 31 March–15 April 2019. [Google Scholar]

- Lavric, A.; Popa, V. Internet of Things and LoRa™ Low-Power Wide-Area Networks: A survey. In Proceedings of the International Symposium on Signals, Circuits and Systems (ISSCS), Iasi, Romania, 3–14 July 2017. [Google Scholar]

- Mikhaylov, K.; Petaejaejaervi, J.; Haenninen, T. Analysis of capacity and scalability of the LoRa low power wide area network technology. In Proceedings of the 22nd European Wireless Conference, Oulu, Finland, 1–6 May 2016. [Google Scholar]

- Thethingsnetwork.org. Available online: https://www.thethingsnetwork.org/docs/network/architecture.html (accessed on 2 May 2019).

- FarmBot. Available online: https://farm.bot/ (accessed on 2 May 2019).

- SKU:SEN0193. Available online: https://wiki.dfrobot.com/Capacitive_Soil_Moisture_Sensor_SKU_SEN0193 (accessed on 10 December 2020).

- A WiFi Enabled Soil Moisture Sensor. Available online: https://www.hackster.io/rbaron/a-wifi-enabled-soil-moisture-sensor-49912b (accessed on 2 May 2021).

- Munyaradzi, M.; Rupere, T.; Nyambo, B.; Mukute, S.; Chinyerutse, M.; Hapanga, T.; Mashonjowa, E. A Low Cost Automatic Irrigation Controller Driven by Soil Moisture Sensors. Int. J. Agric. Innov. Res. 2013, 2, 1–7. [Google Scholar]

- Nemali, K.S.; Montesano, F.; Dove, S.K.; van Iersel, M.W. Calibration and performance of moisture sensors in soilless substrates:ECH2O and Theta probes, Scientia. Horticulturae 2007, 112, 227–234. [Google Scholar] [CrossRef]

- Qu, W.; Bogena, H.R.; Huisman, J.A.; Vereecken, H. Calibration of a Novel Low-Cost Soil Water Content Sensor Based on a Ring Oscillator. Vadose Zone J. 2013, 12, vzj2012.0139. [Google Scholar] [CrossRef]

- Bogena, H.R.; Huisman, J.A.; Schilling, B.; Weuthen, A.; Vereecken, H. Effective Calibration of Low-Cost Soil Water Content Sensors. Sensors 2017, 17, 208. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Node-RED. Available online: https://nodered.org/ (accessed on 3 January 2021).

- Linsley, R.K.; Franzini, J.B.; Freyberg, D.L.; Tchobanoglous, G. Water–Resources Engineering; McGraw-Hill Singapore: Singapore, 1992. [Google Scholar]

- Morbidelli, R.; Saltalippi, C.; Flammini, A.; Cifrodelli, M.; Picciafuoco, T.; Corradini, C.; Govindaraju, R.S. In-situ measurements of soil saturated hydraulic conductivity: Assessment of reliability trough rainfall-runoff experiments. Hydrol. Process. 2017, 31, 3084–3094. [Google Scholar] [CrossRef]

- Melone, F.; Corradini, C.; Morbidelli, R.; Saltalippi, C. Laboratory experimental check of a conceptual model for infiltration under complex rainfall patterns. Hydrol. Proc. 2006, 20, 439–452. [Google Scholar] [CrossRef]

- Melone, F.; Corradini, C.; Morbidelli, R.; Saltalippi, C.; Flammini, A. Comparison of theoretical and experimental soil moisture profiles under complex rainfall patterns. J. Hydrol. Eng. 2008, 13, 1170–1176. [Google Scholar] [CrossRef]

- Corradini, C.; Melone, F.; Smith, E.R. A unified model for infiltration and redistribution during complex rainfall patterns. J. Hydrol. 1997, 192, 104–124. [Google Scholar] [CrossRef]

- Waskom, M.; Botvinnik, O.; O’Kane, D.; Hobson, P.; Ostblom, J.; Lukauskas, S.; Gemperline, D.C.; Augspurger, T.; Halchenko, Y.; Cole, J.B.; et al. mwaskom/seaborn: v0.9.0 (July 2018). Available online: http://seaborn.pydata.org/ (accessed on 25 November 2019).

- Silverman, B.W. Density Estimation for Statistics and Data Analysis; Routledge: New York, NY, USA, 1998. [Google Scholar]

- Fan, J. Local Polynomial Modelling and Its Applications: Monographs on Statistics and Applied Probability 66; Routledge: New York, NY, USA, 1996. [Google Scholar]

| Sample ID | DC/% | f/MHz |

|---|---|---|

| S1 | 37.12 | 1.221 |

| S2 | 35.58 | 1.533 |

| S5 | 34.36 | 1.533 |

| S6 | 32.93 | 1.524 |

| S7 | 34.78 | 1.552 |

| S9 | 34.36 | 1.533 |

| S10 | 35.00 | 1.510 |

| S13 | 35.12 | 1.535 |

| S14 | 34.02 | 1.527 |

| Fine-Textured Soil (Silty Loam) | Coarse-Textured Soil (Loamy Sand) | |

|---|---|---|

| Ks (mmh−1) | 10.0 | 30.0 |

| θs | 0.420 | 0.295 |

| θr | 0.057 | 0.035 |

| bd (gcm−3) | 2.628 | 2.669 |

| P et al. (20)_3 | P et al. (20)_2 | |

| A | 0.711 | 0.731 |

| B | 9.72 | 10.2 |

| C | 0.864 | 0.859 |

| H (20)_3 | H (20)_2 | |

| P | 73.4 | 75.8 |

| Q | 55.1 | 57.2 |

| P et al. (20)_3 | P et al. (20)_2 | |

| A | 1.64 | 1.65 |

| B | 8.16 | 8.41 |

| C | 0.85 | 0.85 |

| H (20)_3 | H (20)_2 | |

| P | 17.44 | 17.54 |

| Q | 2.37 | 2.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Placidi, P.; Morbidelli, R.; Fortunati, D.; Papini, N.; Gobbi, F.; Scorzoni, A. Monitoring Soil and Ambient Parameters in the IoT Precision Agriculture Scenario: An Original Modeling Approach Dedicated to Low-Cost Soil Water Content Sensors. Sensors 2021, 21, 5110. https://doi.org/10.3390/s21155110

Placidi P, Morbidelli R, Fortunati D, Papini N, Gobbi F, Scorzoni A. Monitoring Soil and Ambient Parameters in the IoT Precision Agriculture Scenario: An Original Modeling Approach Dedicated to Low-Cost Soil Water Content Sensors. Sensors. 2021; 21(15):5110. https://doi.org/10.3390/s21155110

Chicago/Turabian StylePlacidi, Pisana, Renato Morbidelli, Diego Fortunati, Nicola Papini, Francesco Gobbi, and Andrea Scorzoni. 2021. "Monitoring Soil and Ambient Parameters in the IoT Precision Agriculture Scenario: An Original Modeling Approach Dedicated to Low-Cost Soil Water Content Sensors" Sensors 21, no. 15: 5110. https://doi.org/10.3390/s21155110

APA StylePlacidi, P., Morbidelli, R., Fortunati, D., Papini, N., Gobbi, F., & Scorzoni, A. (2021). Monitoring Soil and Ambient Parameters in the IoT Precision Agriculture Scenario: An Original Modeling Approach Dedicated to Low-Cost Soil Water Content Sensors. Sensors, 21(15), 5110. https://doi.org/10.3390/s21155110