Field Representation Microwave Thermography Utilizing Lossy Microwave Design Materials

Abstract

:1. Introduction

2. Fundamentals

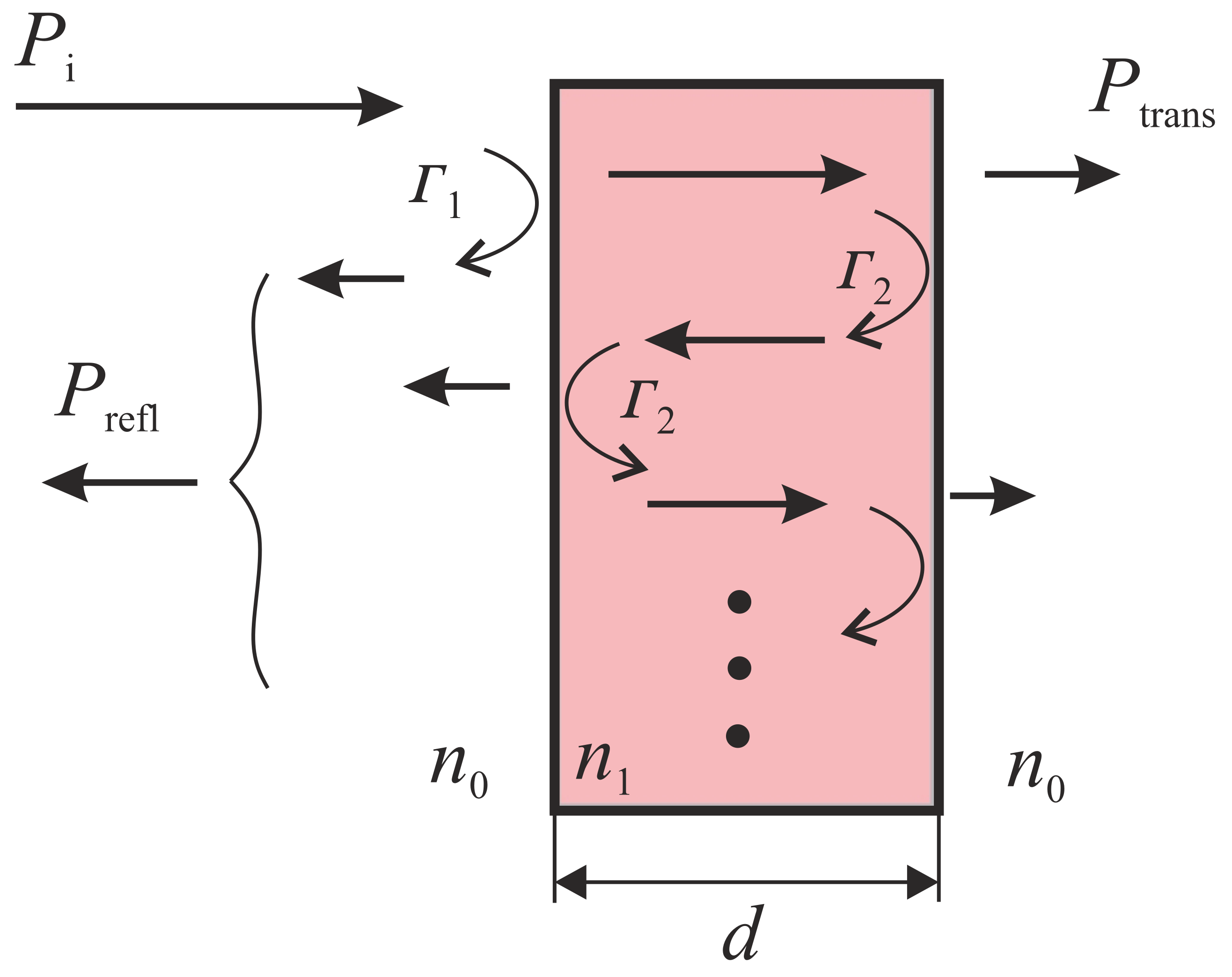

2.1. Wave Interaction and Dielectric Heating

2.2. Thermal Losses

2.3. Design Materials and Mixing

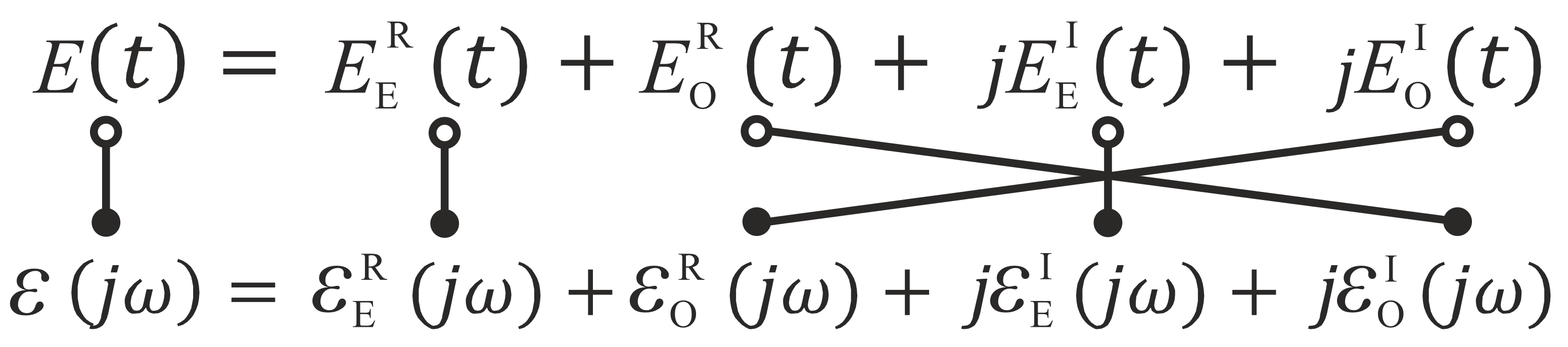

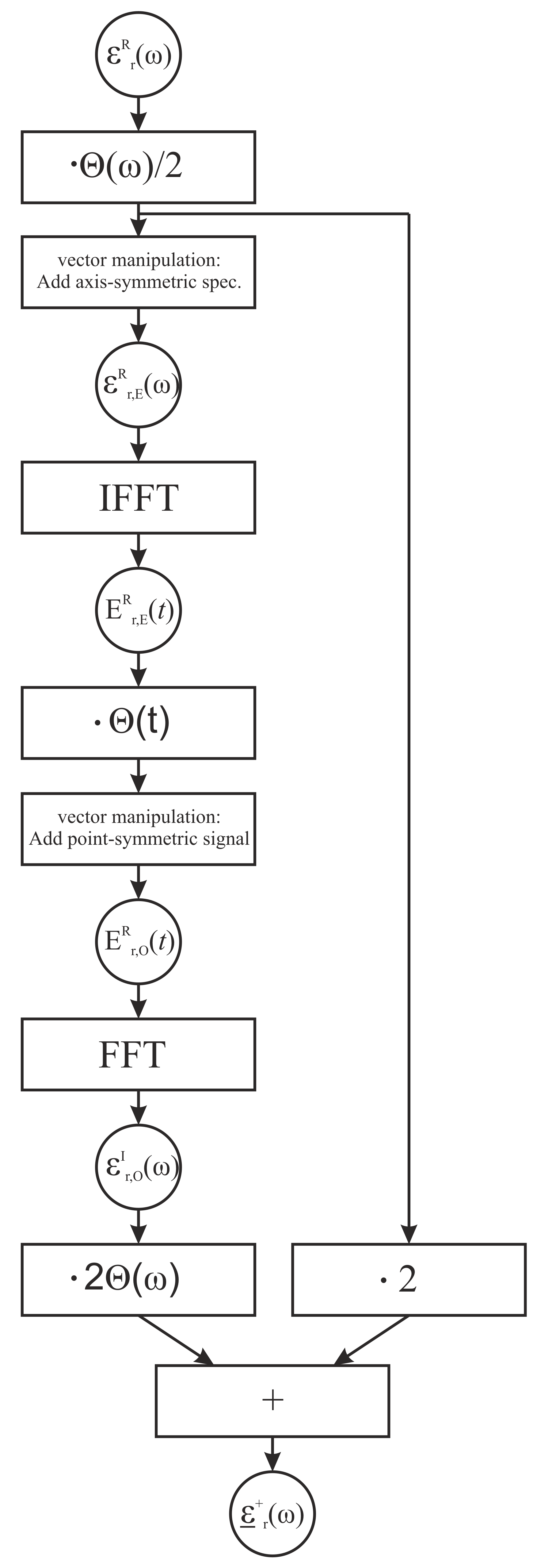

indicates the Fourier transformation from time (∘) to frequency domain (•). Moreover, the indices E and O represent even and odd signal and spectral parts, while the superscripts R and I indicate real and imaginary parts. As initial point, we consider a measured broadband, real part permittivity. As this quantity depends on frequency, we can regard it as a spectrum. Moreover, any commercial measuring probe will deliver measurement values for positive frequencies only. Therefore, the measured permittivity is the combination of its even and odd part:

indicates the Fourier transformation from time (∘) to frequency domain (•). Moreover, the indices E and O represent even and odd signal and spectral parts, while the superscripts R and I indicate real and imaginary parts. As initial point, we consider a measured broadband, real part permittivity. As this quantity depends on frequency, we can regard it as a spectrum. Moreover, any commercial measuring probe will deliver measurement values for positive frequencies only. Therefore, the measured permittivity is the combination of its even and odd part:3. Transient FRMWT Model

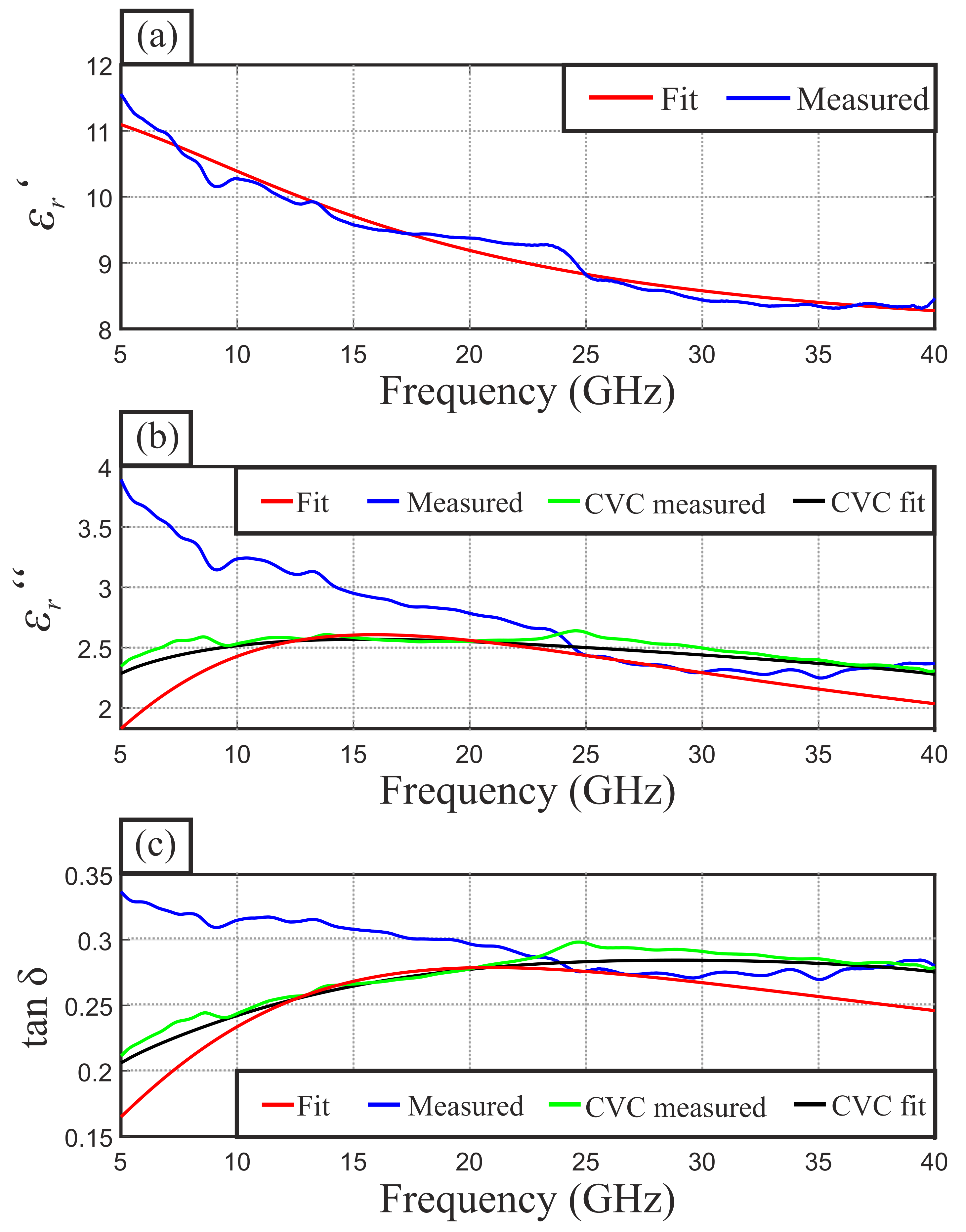

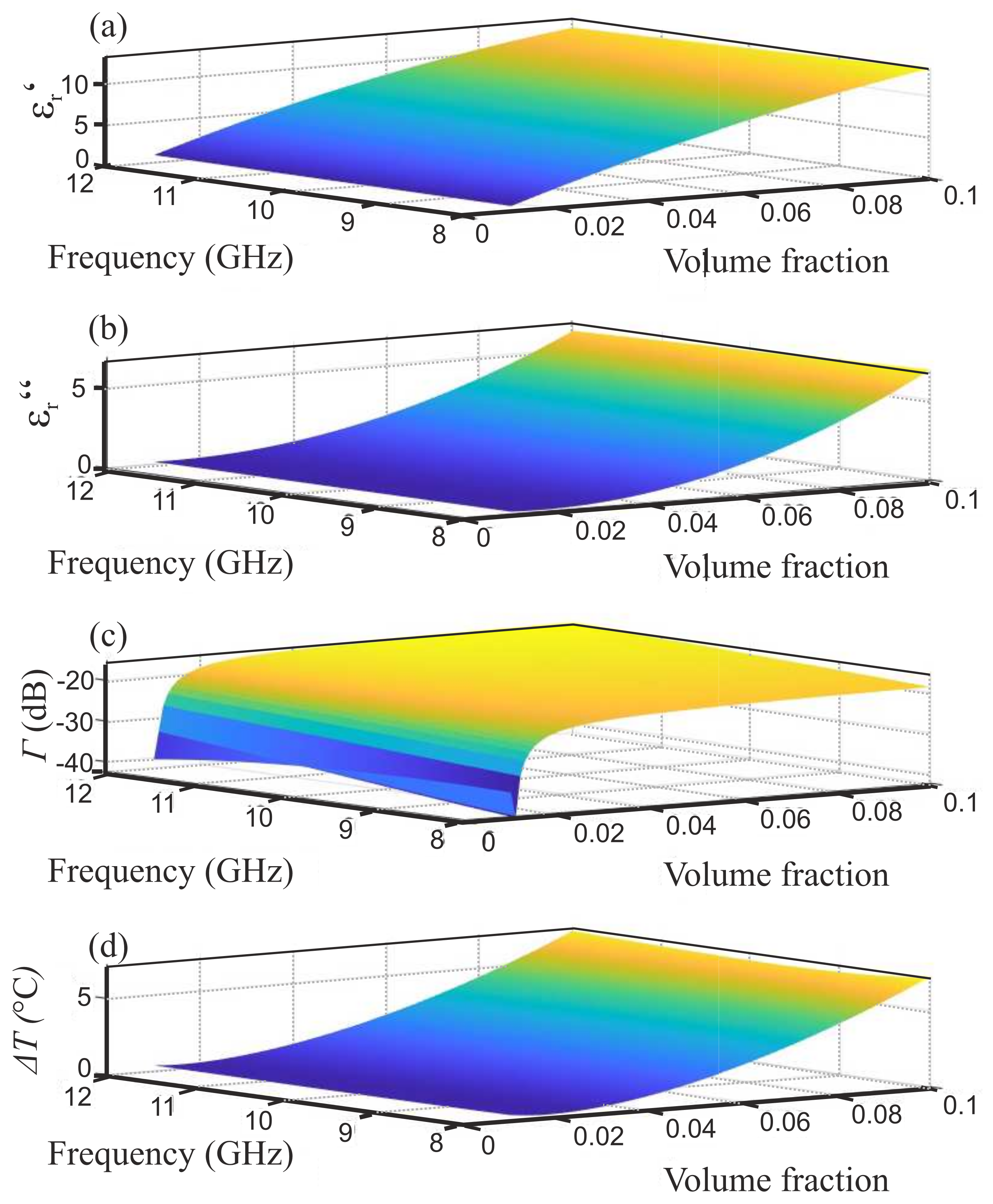

4. Design Materials

5. Results

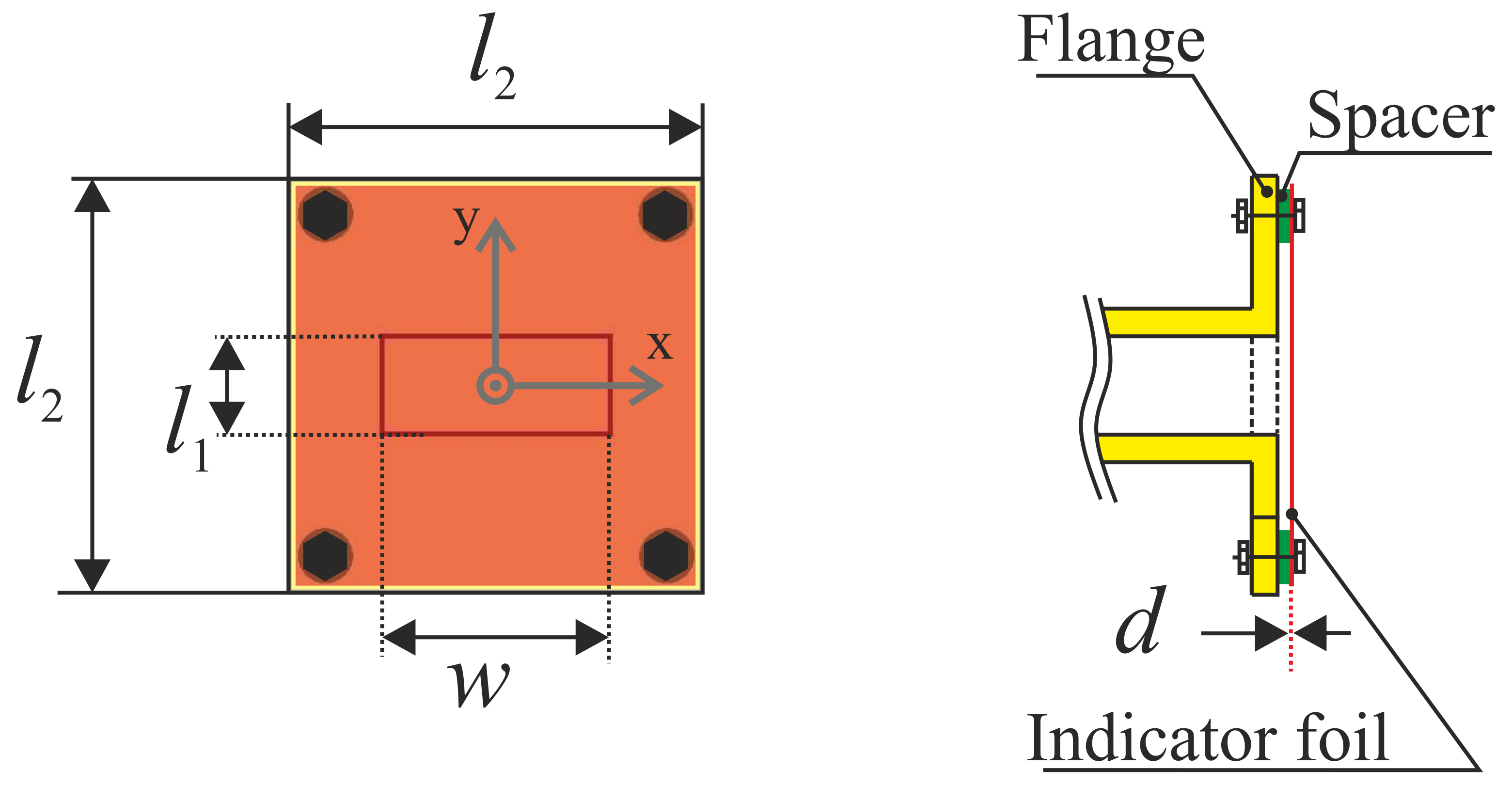

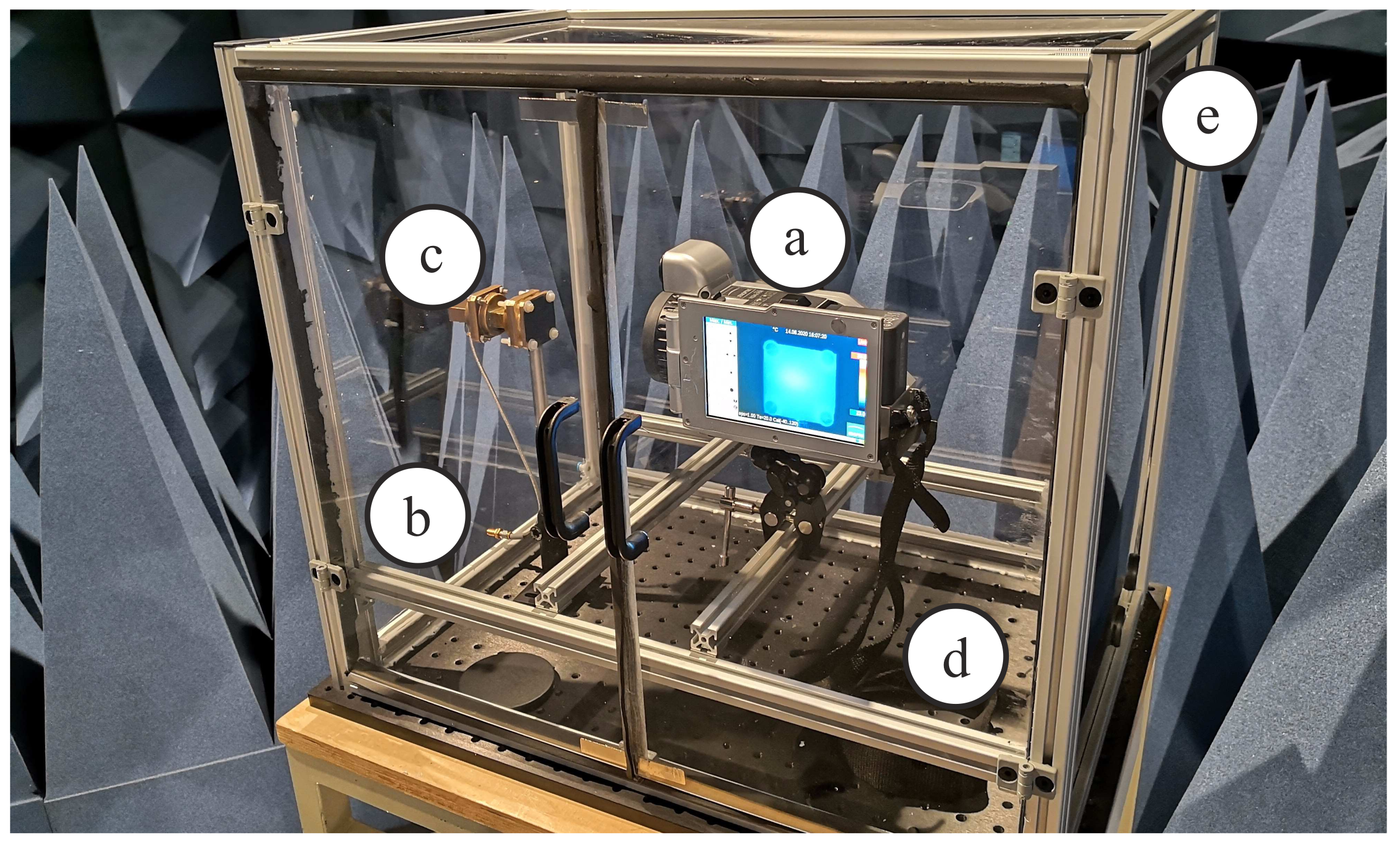

5.1. Measurement Setup

- Housing:The measurement chamber needs to be closed and air tight for enabling different measurement environments such as gases. Moreover, it must prevent forced convection.

- Utilized Materials:The housing should be impervious for infrared radiation for preventing disturbing environmental reflections. The metal content should be kept low or needs a microwave absorber covering in order to avoid disturbing reflections.

- Peripheral Connections:Gas in- and outlets allow for FRMWT in different surrounding gases. Microwave connectors are necessary for feeding the structure under test.

5.2. Simulation and Measurement Results

6. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRMWT | Field Representation Microwave Thermography |

| CVC | Complex Valued Completion |

References

- Thompson, J.E.; Kristiansen, M.; Hagler, M.O. Optical measurement of high electric and magnetic fields. IEEE Trans. Instrum. Meas. 1976, IM-25, 1–7. [Google Scholar] [CrossRef]

- Cecelja, F.; Balachandran, W. Electrooptic sensor for near-field measurement. IEEE Trans. Instrum. Meas. 1999, 48, 650–653. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, H.; Cui, Y.; Ding, Z.; Zhao, L. Measurement of Distorted Power-Frequency Electric Field With Integrated Optical Sensor. IEEE Trans. Instrum. Meas. 2019, 68, 1132–1139. [Google Scholar] [CrossRef]

- Puranen, L.; Jokela, K. Simultaneous measurements of RF electric and magnetic near fields-theoretical considerations. IEEE Trans. Instrum. Meas. 1993, 42, 1001–1008. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, J.; Zhang, W.; Wang, Y.; Fan, J. A Miniature Ultrawideband Electric Field Probe Based on Coax-Thru-Hole via Array for Near-Field Measurement. IEEE Trans. Instrum. Meas. 2017, 66, 2762–2770. [Google Scholar] [CrossRef]

- Pokovic, K.; Schmid, T.; Kuster, N. Millimeter-resolution E-field probe for isotropic measurement in lossy media between 100 MHz and 20 GHz. IEEE Trans. Instrum. Meas. 2000, 49, 873–878. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, R.; He, Y.; Foudazi, A.; Chengand, L.; Tian, G. A Review of Microwave Thermography Nondestructive Testing and Evaluation. Sensors 2017, 17, 1123. [Google Scholar] [CrossRef] [PubMed]

- Baghdasaryan, Z.; Babajanyan, A.; Pdabashyan, L.; Lee, H.; Firedmann, B.; Lee, K. Visualization of Microwave Heating for mesh-Patterned Indium-tin-Oxide by a Thermo-Elastic Optical Indicator Microscope. Armen. J. Phys. 2018, 11, 175–179. [Google Scholar]

- Lee, H.; Arakelyan, S.; Friedman, B.; Lee, K. Temperature and microwave near field imaging by thermo-elastic optical indicator microscopy. Sci. Rep. 2016, 6, 39696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, B.; Dong, Y.; Hu, Z.; Liu, G.; Wang, Y.; Du, G. Noninvasive Imaging Method of Microwave Near Field Based on Solid-State Quantum Sensing. IEEE Trans. Microw. Theory Tech. 2018, 66, 2276–2283. [Google Scholar] [CrossRef] [Green Version]

- Faure, S.; Bobo, J.F.; Carrey, J.; Issac, F.; Prost, D. Composant Sensible Pour Dispositif de Mesure de Champ Electromagnétique par Thermofluorescence, Procédés de Mesure et de Fabrication Correspondants. French Patent 1758907, 26 September 2017. [Google Scholar]

- Ragazzo, H.; Faure, S.; Carrey, J.; Issac, F.; Prost, D.; Bobo, J.F. Detection and Imaging of Magnetic Field in the Microwave Regime With a Combination of Magnetic Losses Material and Thermofluorescent Molecules. IEEE Trans. Magn. 2019, 55, 6500104. [Google Scholar] [CrossRef] [Green Version]

- Ragazzo, H.; Prost, D.; Bobo, J.-F.; Faure, S. Characterization of electromagnetic fields of radiating systems by thermo-fluorescence. In Proceedings of the 2020 International Symposium on Electromagnetic Compatibility—EMC EUROPE, Rome, Italy, 23–25 September 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Birle, M.; Leu, C. Dielectric Heating in Insultaning Materials at High DC and AC Voltages Superimposed by High Frequency High Voltages. In Proceedings of the International Symposium on High Volatage Engineering, Seoul, Korea, 25–30 August 2013. [Google Scholar]

- Incropera, F.P.; de Witt, D.P. Fundamentals of Heat and Mass Transfer; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Herwig, H.; Schäfer, P. A Combined pertubation/finite-difference procedure applied to temperature effects and stability in laminar boundary layer. Arch. Appl. Mech. 1996, 66, 264–272. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N. Fundamentals of Engineering Thermodynamics; Wiley: New York, NY, USA, 1995. [Google Scholar]

- VDI-GVC (Ed.) Heat Transfer Modes and Basic Principles of Their Description. In VDI Heat Atlas; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- VDI-GVC (Ed.) Heat Conduction and Overall Heat Resistances. In VDI Heat Atlas; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Hattenhorst, B.; Mallach, M.; Baer, C.; Musch, T.; Barowski, J.; Rolfes, I. Dielectric phantom materials for broadband biomedical applications. In Proceedings of the 2017 First IEEE MTT-S International Microwave Bio Conference (IMBIOC), Gothenburg, Sweden, 15–17 May 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Gutierrez, S.; Just, T.; Sachs, J.; Baer, C.; Vega, F. Field-Deployable System for the Measurement of Complex Permittivity of Improvised Explosives and Lossy Dielectric Materials. IEEE Sens. J. 2018, 18, 6706–6714. [Google Scholar] [CrossRef]

- Sihvola, A. Electromagnetic Mixing and Formulas and Applications; IET Electromagnetic Waves Series 47; IET: England, UK, 2008. [Google Scholar]

- Chester, G.V.; Thellung, A. The law of Wiedemann and Franz. Proc. Phys. Soc. 1961, 77, 1005–1013. [Google Scholar] [CrossRef]

- Jackson, J.D. Classical Electrodynamics, 3rd ed.; John Wiley& Sons: New York, NY, USA, 1999. [Google Scholar]

- Weerasundara, R.; Raju, G.G. An efficient algorithm for numerical computation of the complex dielectric permittivity using Hilbert transform and FFT techniques through Kramers Kronig relation. In Proceedings of the 2004 IEEE International Conference on Solid Dielectrics, ICSD 2004, Toulouse, France, 5–9 July 2004; Volume 2, pp. 558–561. [Google Scholar] [CrossRef]

- Leistner, C.; Löffelholz, M.; Hartmann, S. Model validation of polymer curing processes using thermography. Polym. Test. 2009, 77, 105893. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baer, C.; Orend, K.; Hattenhorst, B.; Musch, T. Field Representation Microwave Thermography Utilizing Lossy Microwave Design Materials. Sensors 2021, 21, 4830. https://doi.org/10.3390/s21144830

Baer C, Orend K, Hattenhorst B, Musch T. Field Representation Microwave Thermography Utilizing Lossy Microwave Design Materials. Sensors. 2021; 21(14):4830. https://doi.org/10.3390/s21144830

Chicago/Turabian StyleBaer, Christoph, Kerstin Orend, Birk Hattenhorst, and Thomas Musch. 2021. "Field Representation Microwave Thermography Utilizing Lossy Microwave Design Materials" Sensors 21, no. 14: 4830. https://doi.org/10.3390/s21144830

APA StyleBaer, C., Orend, K., Hattenhorst, B., & Musch, T. (2021). Field Representation Microwave Thermography Utilizing Lossy Microwave Design Materials. Sensors, 21(14), 4830. https://doi.org/10.3390/s21144830