Deposition of a SiO2 Shell of Variable Thickness and Chemical Composition to Carbonyl Iron: Synthesis and Microwave Measurements

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

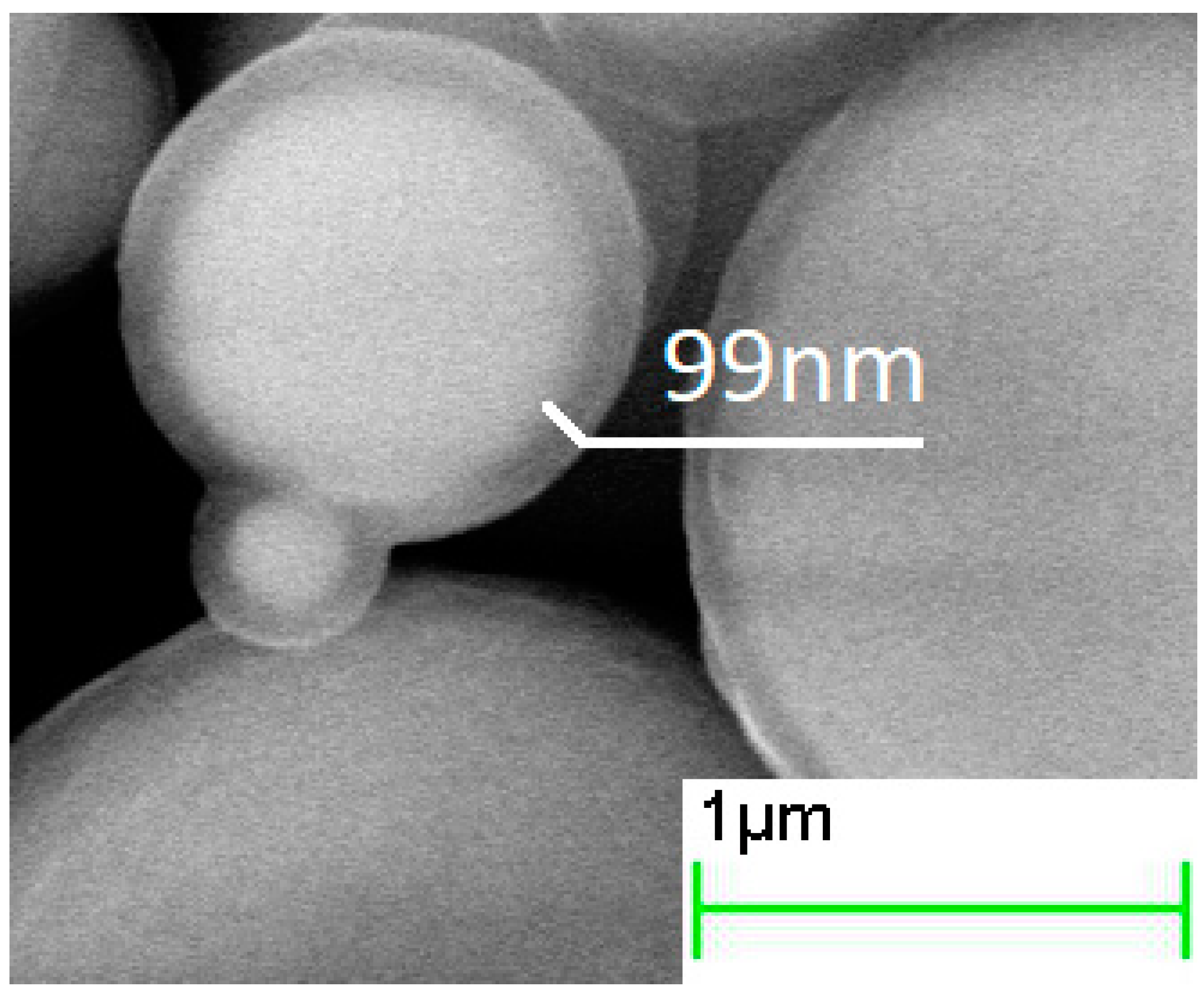

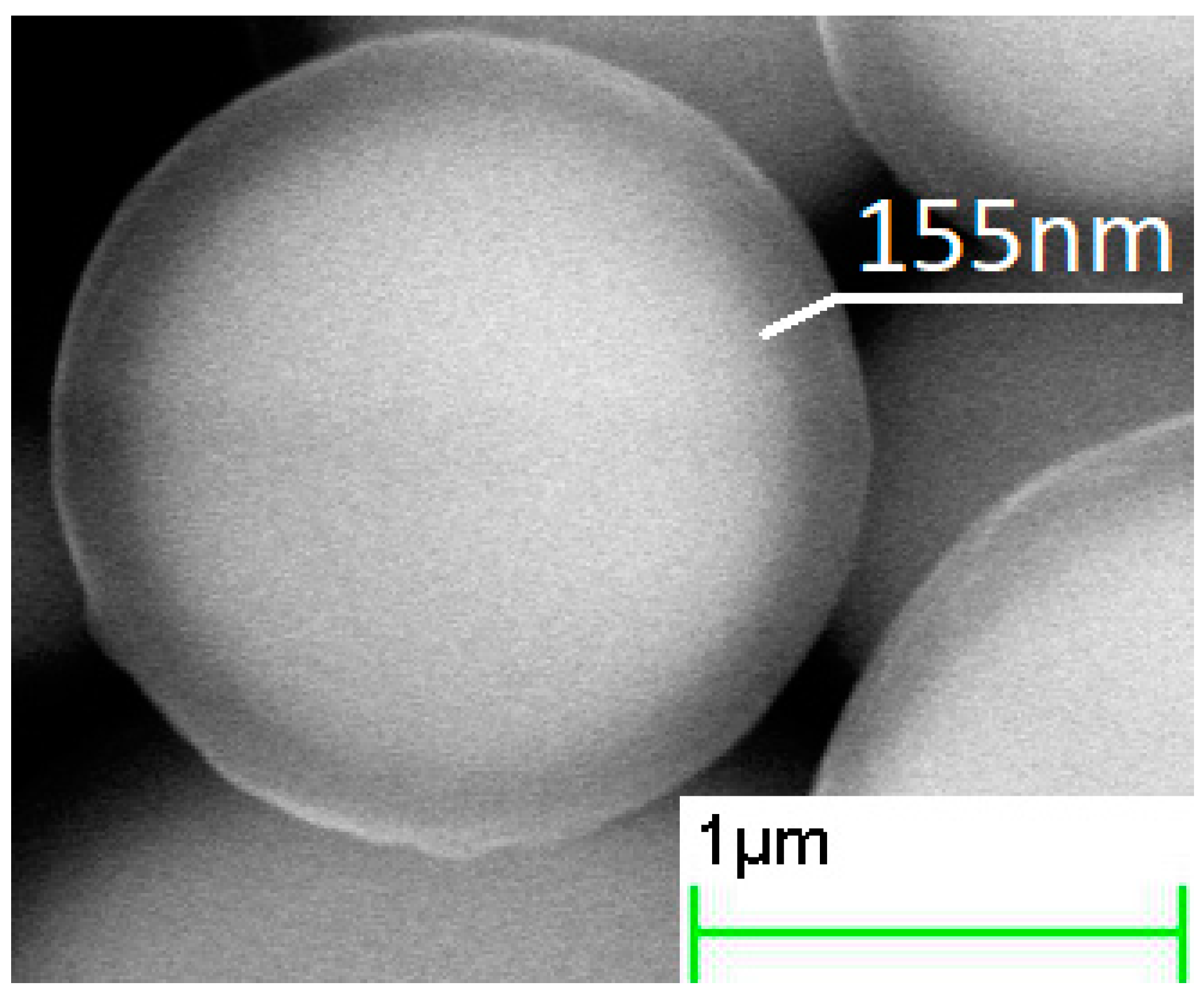

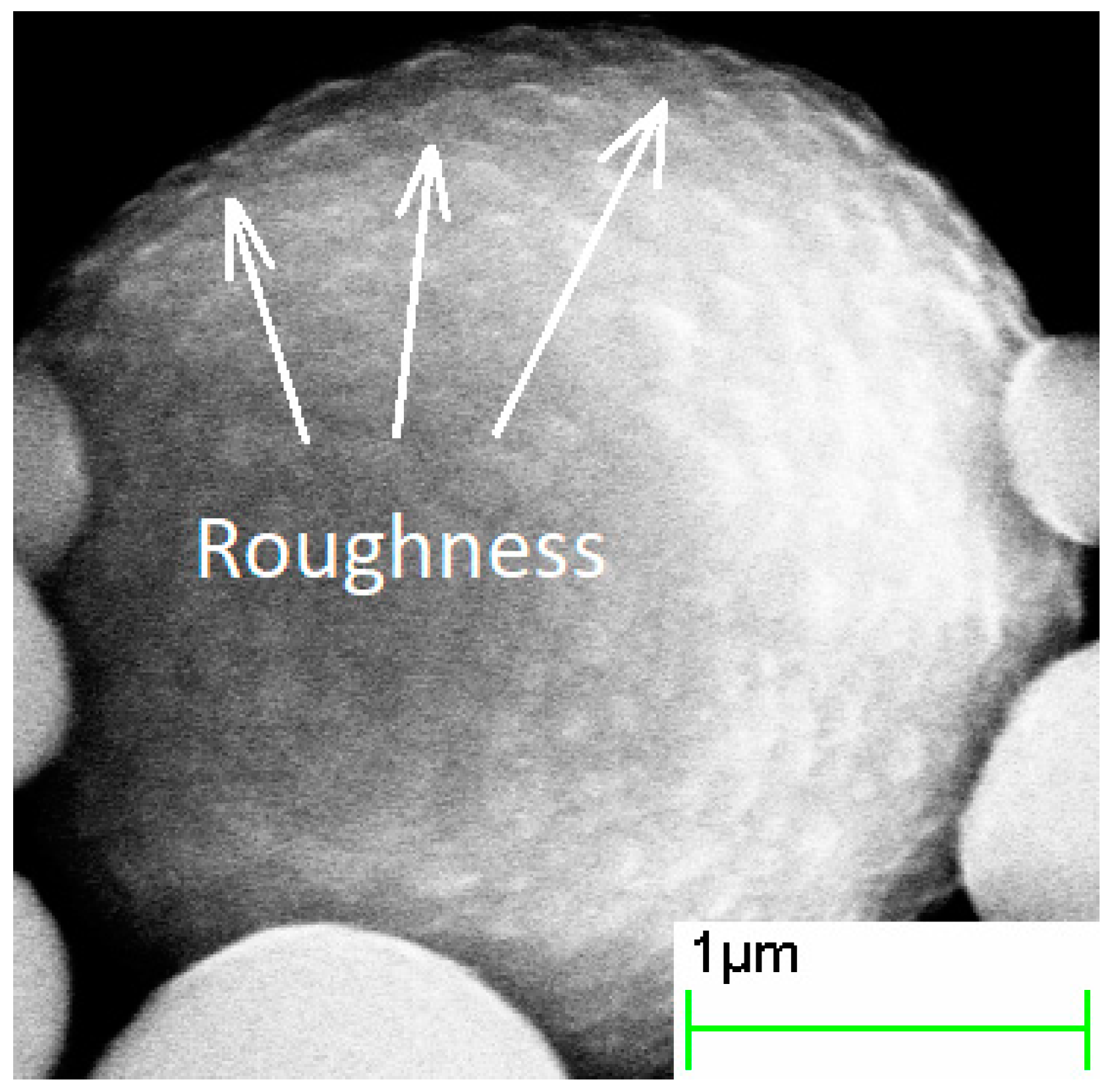

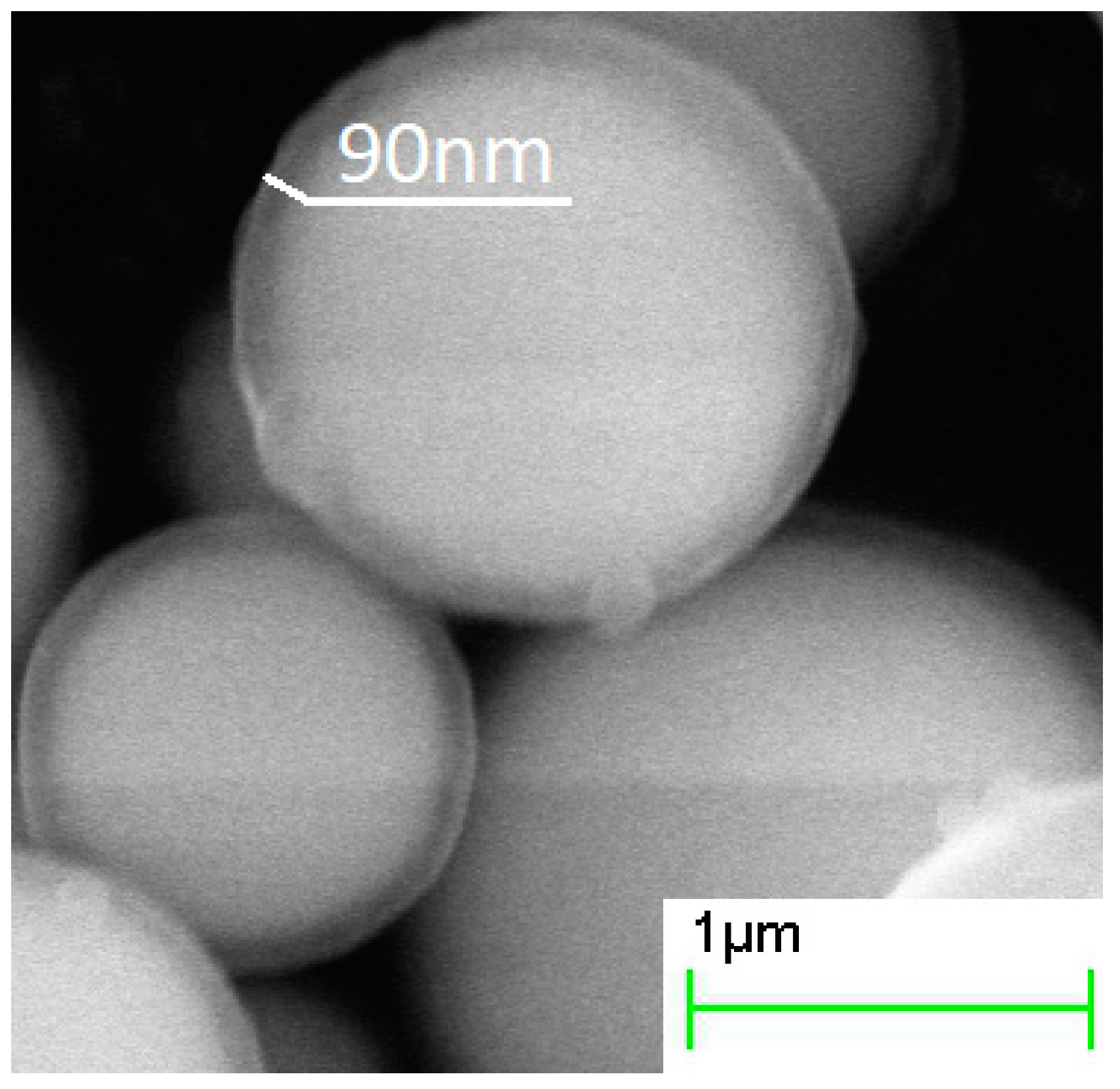

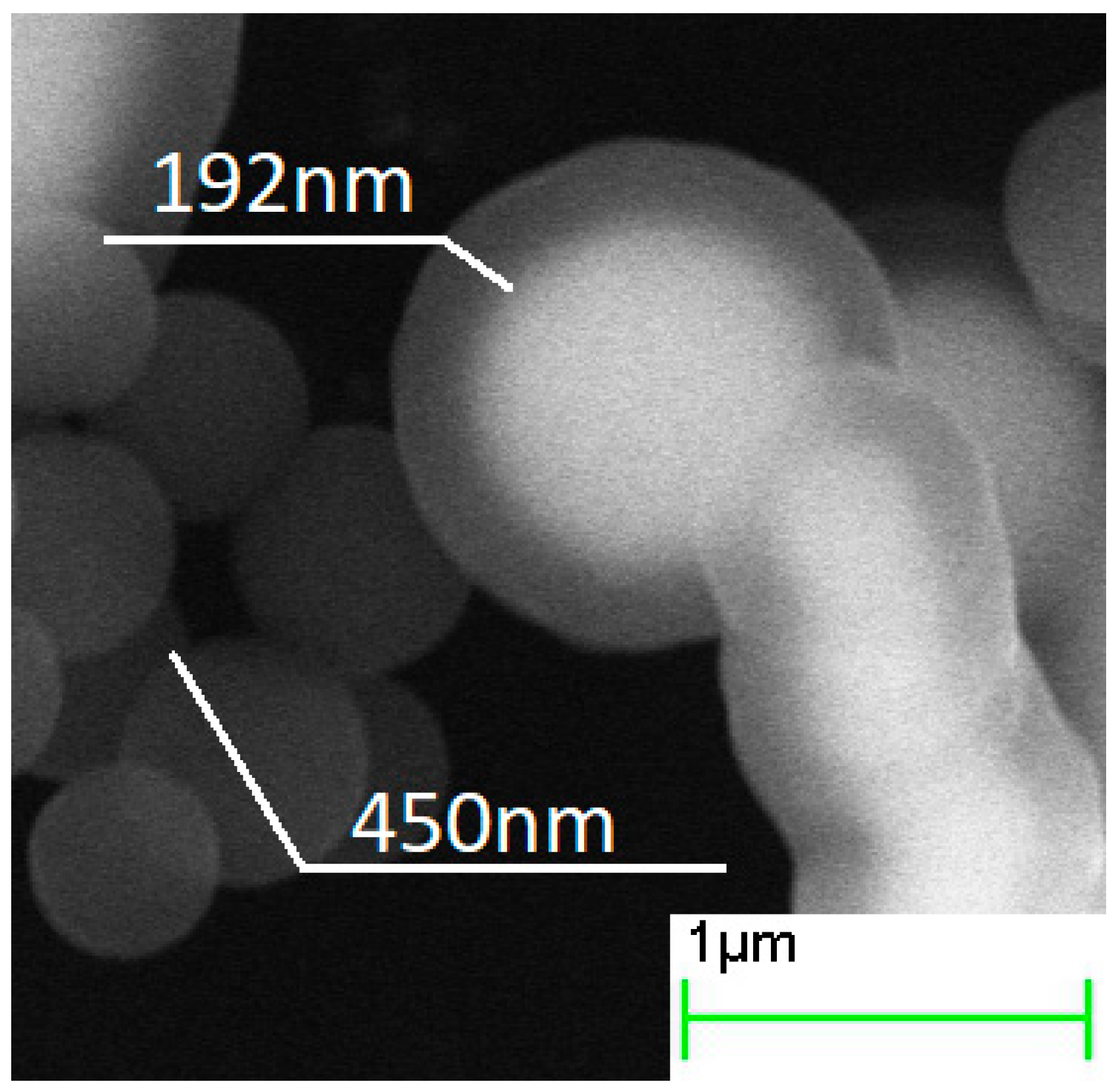

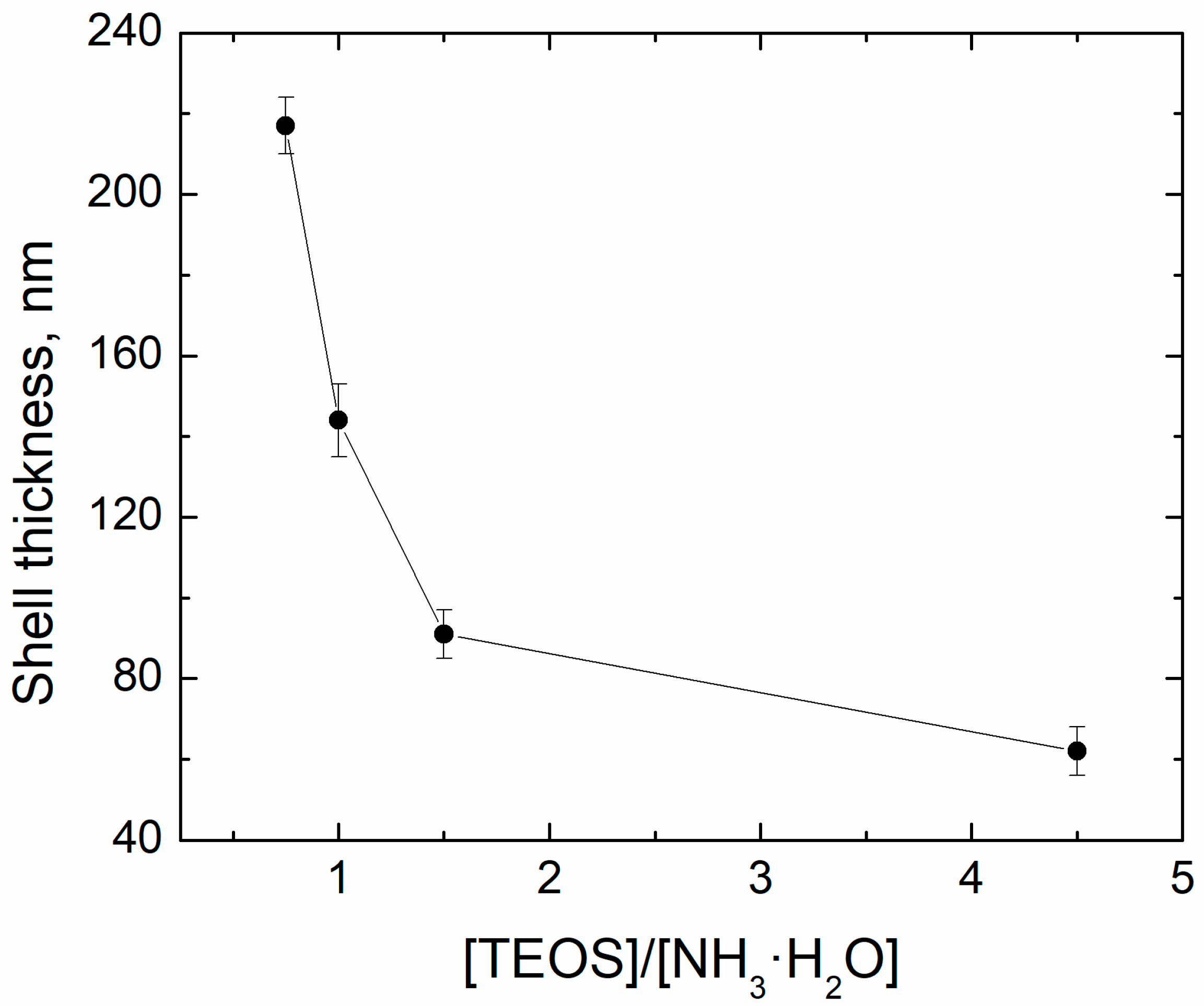

3.1. Structure and Morphology

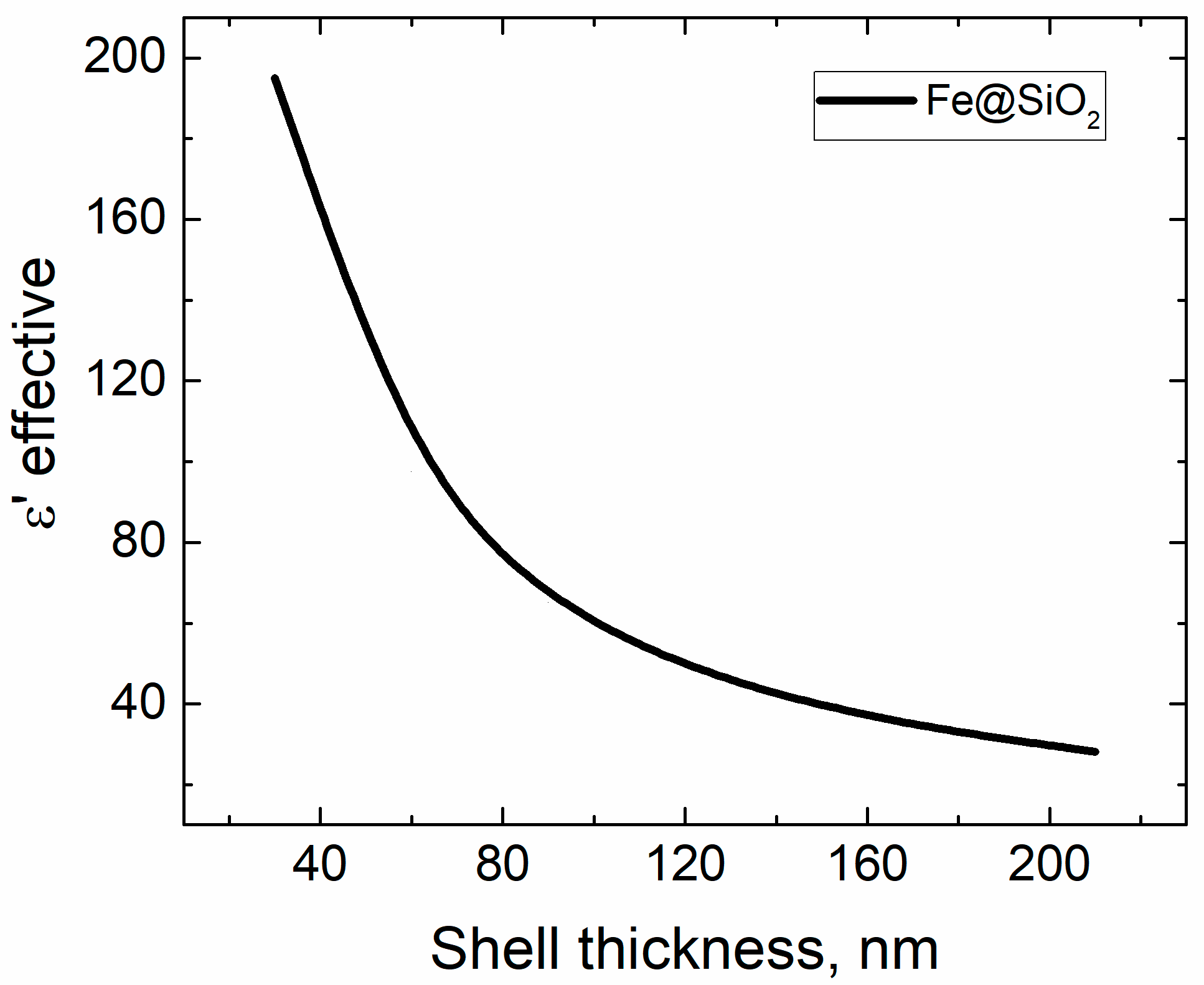

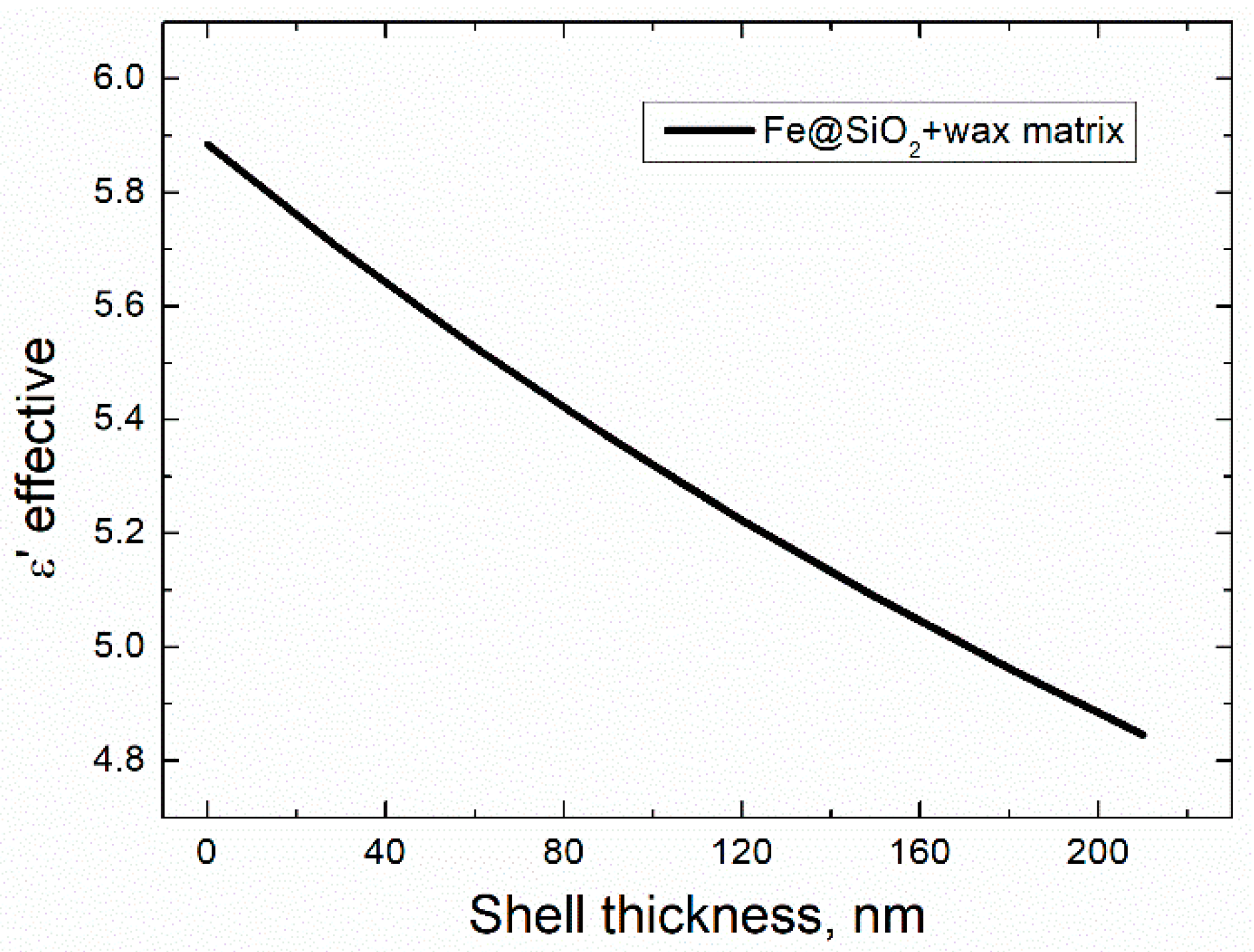

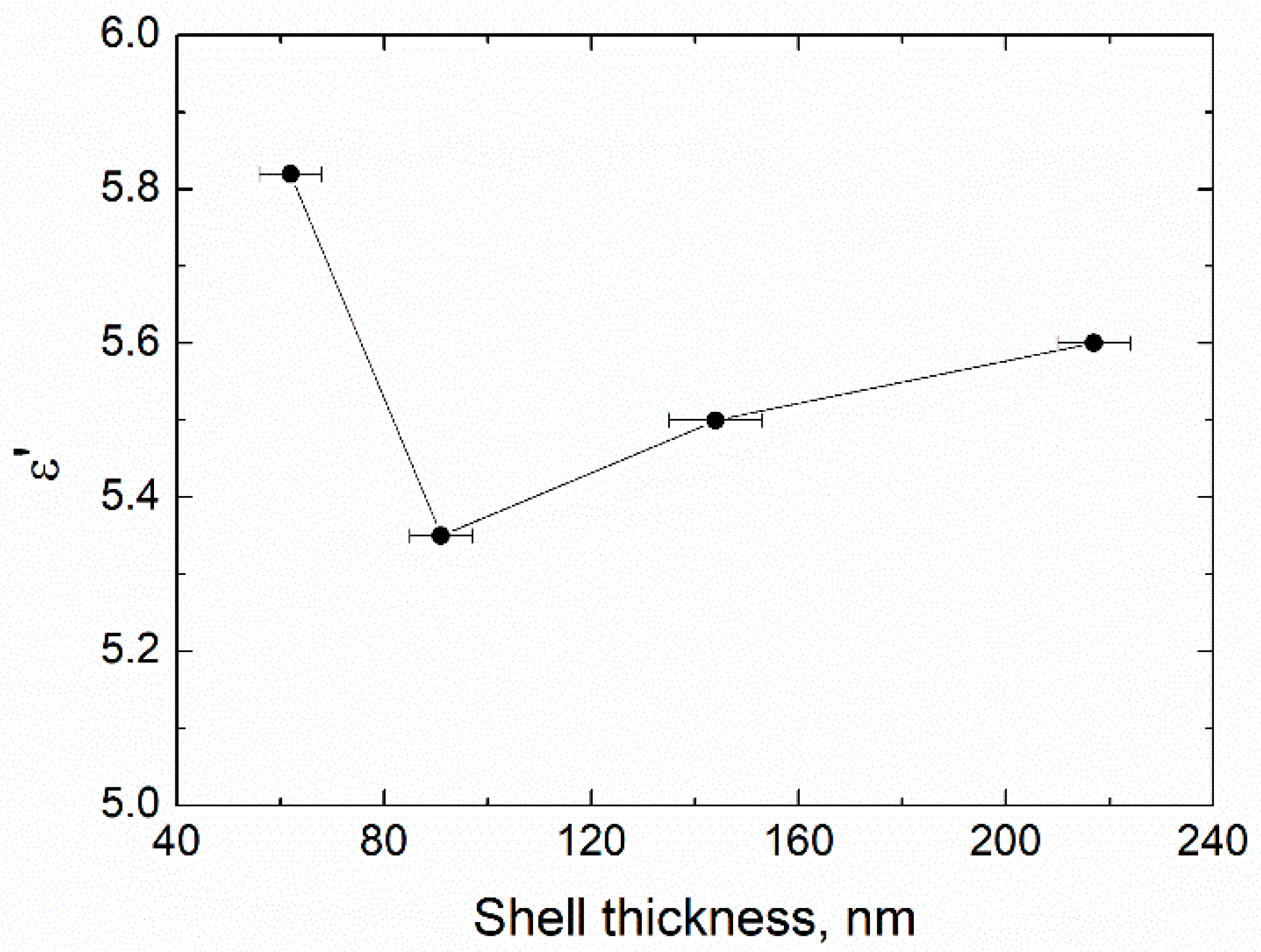

3.2. Dielectric Permittivity: Theoretical Approach

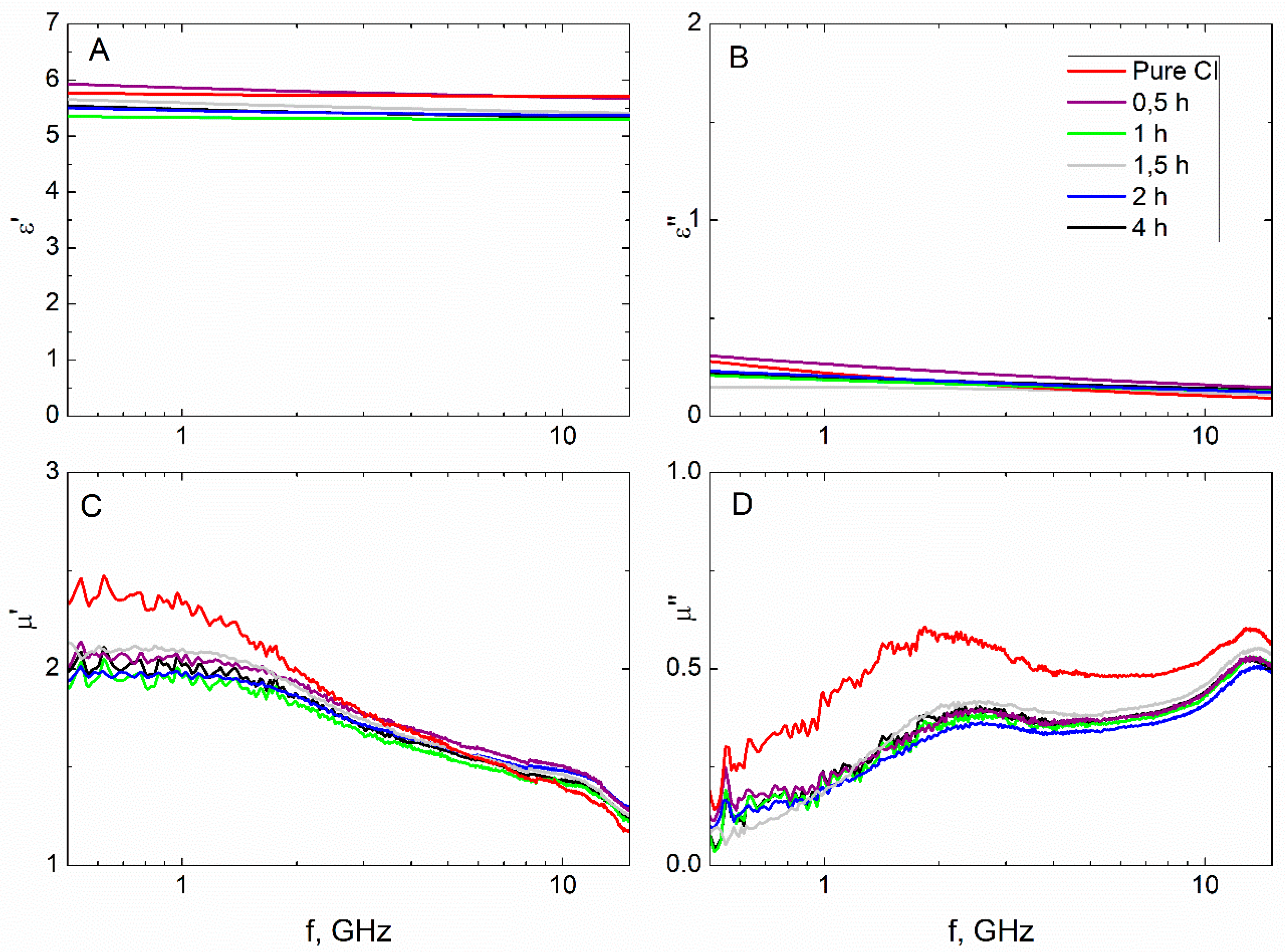

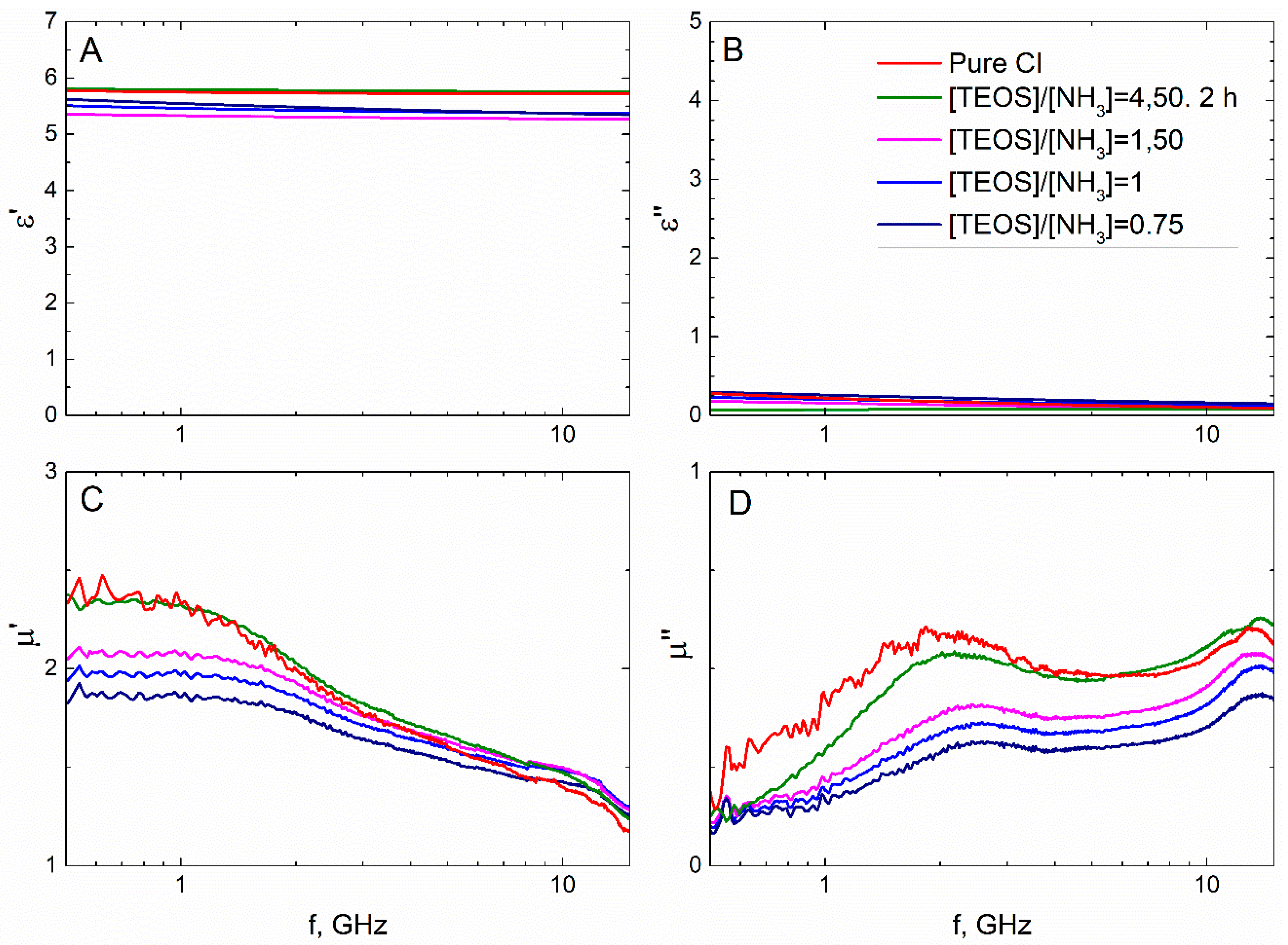

3.3. Frequency Dispersions of Complex Permittivity and Permeability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, L.; Chen, Q.; Gao, Z.; Ge, Y.; Yi, J. Fe@SiO2@(MnZn)Fe2O4 soft magnetic composites with enhanced permeability and low core loss for high-frequency applications. J. Alloy. Compd. 2019, 805, 609–616. [Google Scholar] [CrossRef]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Khadheer Pasha, S.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Wang, H.; Wang, M.; Zhang, X.; Lu, Z.; Fu, W.; Zhong, B.; Wang, C.; Zou, J.; Huang, X.; Wen, G. A new type of catalyst allows carbonyl iron powder to be coated with SiO2 for tuned microwave absorption. Surf. Interfaces 2020, 21, 100755. [Google Scholar] [CrossRef]

- Ge, C.; Wang, L.; Liu, G.; Wang, T. Enhanced electromagnetic properties of carbon nanotubes and SiO2-coated carbonyl iron microwave absorber. J. Alloy. Compd. 2018, 767, 173–180. [Google Scholar] [CrossRef]

- Maklakov, S.S.; Lagarkov, A.N.; Maklakov, S.A.; Adamovich, Y.A.; Petrov, D.A.; Rozanov, K.N.; Ryzhikov, I.A.; Zarubina, A.Y.; Pokholok, K.V.; Filimonov, D.S. Corrosion-resistive magnetic powder Fe@SiO2 for microwave applications. J. Alloy. Compd. 2017, 706, 267–273. [Google Scholar] [CrossRef]

- Wu, S.; Sun, A.; Lu, Z.; Cheng, C. Fabrication and properties of iron-based soft magnetic composites coated with parylene via chemical vapor deposition polymerization. Mater. Chem. Phys. 2015, 153, 359–364. [Google Scholar] [CrossRef]

- Ge, J.; Cui, Y.; Liu, L.; Li, R.; Meng, F.; Wang, F. Enhanced electromagnetic wave absorption of hybrid-architectures Co@ SiOxC. J. Alloy. Compd. 2020, 831, 154442. [Google Scholar] [CrossRef]

- Yuchang, Q.; Wancheng, Z.; Shu, J.; Fa, L.; Dongmei, Z. Microwave electromagnetic property of SiO2-coated carbonyl iron particles with higher oxidation resistance. Phys. B Condens. Matter 2011, 406, 777–780. [Google Scholar] [CrossRef]

- Li, J.; Feng, W.J.; Wang, J.S.; Zhao, X.; Zheng, W.Q.; Yang, H. Impact of silica-coating on the microwave absorption properties of carbonyl iron powder. J. Magn. Magn. Mater. 2015, 393, 82–87. [Google Scholar] [CrossRef]

- Wu, Z.; Fan, X.; Wang, J.; Li, G.; Gan, Z.; Zhang, Z. Core loss reduction in Fe–6.5wt.%Si/SiO2 core–shell composites by ball milling coating and spark plasma sintering. J. Alloy. Compd. 2014, 617, 21–28. [Google Scholar] [CrossRef]

- Slovenský, P.; Kollár, P.; Mei, N.; Jakubčin, M.; Zeleňáková, A.; Halama, M.; Odnevall Wallinder, I.; Hedberg, Y.S. Mechanical surface smoothing of micron-sized iron powder for improved silica coating performance as soft magnetic composites. Appl. Surf. Sci. 2020, 531, 147340. [Google Scholar] [CrossRef]

- Kim, S.-S.; Kim, H.-S.; Kim, S.G.; Kim, W.-S. Effect of electrolyte additives on sol-precipitated nano silica particles. Ceram. Int. 2004, 30, 171–175. [Google Scholar] [CrossRef]

- Han, Y.; Lu, Z.; Teng, Z.; Liang, J.; Guo, Z.; Wang, D.; Han, M.-Y.; Yang, W. Unraveling the Growth Mechanism of Silica Particles in the Stöber Method: In Situ Seeded Growth Model. Langmuir 2017, 33, 5879–5890. [Google Scholar] [CrossRef]

- Green, D.L.; Jayasundara, S.; Lam, Y.-F.; Harris, M.T. Chemical reaction kinetics leading to the first Stober silica nanoparticles—NMR and SAXS investigation. J. Non-Cryst. Solids 2003, 315, 166–179. [Google Scholar] [CrossRef]

- Chen, S.-L.; Dong, P.; Yang, G.-H.; Yang, J.-J. Kinetics of Formation of Monodisperse Colloidal Silica Particles through the Hydrolysis and Condensation of Tetraethylorthosilicate. Ind. Eng. Chem. Res. 1996, 35, 4487–4493. [Google Scholar] [CrossRef]

- Kosevich, A.; Petrusevich, E.; Maklakov, S.; Naboko, A.; Kolesnikov, E.; Petrov, D.; Zezyulina, P.; Pokholok, K.; Filimonov, D.; Han, M. Low Weight Hollow Microspheres of Iron with Thin Dielectric Coating: Synthesis and Microwave Permeability. Coatings 2020, 10, 995. [Google Scholar] [CrossRef]

- Nichols, L.B.; Thorp, J.M. Dielectric constant of silica gel activated at different temperatures. Trans. Faraday Soc. 1970, 66, 1741–1747. [Google Scholar] [CrossRef]

- Hotta, M.; Hayashi, M.; Nishikata, A.; Nagata, K. Complex Permittivity and Permeability of SiO2 and Fe3O4 Powders in Microwave Frequency Range between 0.2 and 13.5 GHz. ISIJ Int. 2009, 49, 1443–1448. [Google Scholar] [CrossRef]

- Malvindi, M.A.; Brunetti, V.; Vecchio, G.; Galeone, A.; Cingolani, R.; Pompa, P.P. SiO2 nanoparticles biocompatibility and their potential for gene delivery and silencing. Nanoscale 2012, 4, 486–495. [Google Scholar] [CrossRef]

- Cvek, M.; Mrlík, M.; Ilčíková, M.; Mosnáček, J.; Münster, L.; Pavlínek, V. Synthesis of Silicone Elastomers Containing Silyl-Based Polymer-Grafted Carbonyl Iron Particles: An Efficient Way To Improve Magnetorheological, Damping, and Sensing Performances. Macromolecules 2017, 50, 2189–2200. [Google Scholar] [CrossRef]

- Xu, J.; Pei, L.; Li, J.; Pang, H.; Li, Z.; Li, B.; Xuan, S.; Gong, X. Flexible, self-powered, magnetism/pressure dual-mode sensor based on magnetorheological plastomer. Compos. Sci. Technol. 2019, 183, 107820. [Google Scholar] [CrossRef]

- Karkkainen, K.; Sihvola, A.; Nikoskinen, K. Analysis of a three-dimensional dielectric mixture with finite difference method. IEEE Trans. Geosci. Remote Sens. 2001, 39, 1013–1018. [Google Scholar] [CrossRef]

- Polder, D.; van Santeen, J.H. The effective permeability of mixtures of solids. Physica 1946, 12, 257–271. [Google Scholar] [CrossRef]

- Tuncer, E. Dielectric mixtures-importance and theoretical approaches. IEEE Electr. Insul. Mag. 2013, 29, 49–58. [Google Scholar] [CrossRef]

- Engen, G.F.; Hoer, C.A. Thru-Reflect-Line: An Improved Technique for Calibrating the Dual Six-Port Automatic Network Analyzer. IEEE Trans. Microw. Theory Tech. 1979, 27, 987–993. [Google Scholar] [CrossRef]

- Nicolson, A.M.; Ross, G.F. Measurement of the Intrinsic Properties of Materials by Time-Domain Techniques. IEEE Trans. Instrum. Meas. 1970, 19, 377–382. [Google Scholar] [CrossRef]

- Weir, W.B. Automatic measurement of complex dielectric constant and permeability at microwave frequencies. Proc. IEEE 1974, 62, 33–36. [Google Scholar] [CrossRef]

- Havriliak, S.; Negami, S. A complex plane analysis of α-dispersions in some polymer systems. J. Polym. Sci. Part C Polym. Symp. 1966, 14, 99–117. [Google Scholar] [CrossRef]

- Petrov, D.A.; Rozanov, K.N.; Koledintseva, M.Y. Influence of Higher-order Modes in Coaxial Waveguide on Measurements of Material Parameters. In Proceedings of the 2018 IEEE Symposium on Electromagnetic Compatibility, Signal Integrity and Power Integrity (EMC, SI & PI), Long Beach, CA, USA, 30 July–3 August 2018; pp. 66–70. [Google Scholar]

- LeFrancois, S.; Pasquet, D.; Maze-Merceur, G. A new model for microwave characterization of composite materials in guided-wave medium. IEEE Trans. Microw. Theory Tech. 1996, 44, 1557–1562. [Google Scholar] [CrossRef]

- Greasley, S.L.; Page, S.J.; Sirovica, S.; Chen, S.; Martin, R.A.; Riveiro, A.; Hanna, J.V.; Porter, A.E.; Jones, J.R. Controlling particle size in the Stöber process and incorporation of calcium. J. Colloid Interface Sci. 2016, 469, 213–223. [Google Scholar] [CrossRef]

- Rahman, I.A.; Vejayakumaran, P.; Sipaut, C.S.; Ismail, J.; Abu Bakar, M.; Adnan, R.; Chee, C.K. Effect of anion electrolytes on the formation of silica nanoparticles via the sol–gel process. Ceram. Int. 2006, 32, 691–699. [Google Scholar] [CrossRef]

- Chettiar, U.K.; Engheta, N. Internal homogenization: Effective permittivity of a coated sphere. Opt. Express 2012, 20, 22976–22986. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez Vela, Y.; Ortiz, D.; Osa, R.; Saiz, J.; González, F.; Moreno, F. Electromagnetic Effective Medium Modelling of Composites with Metal-Semiconductor Core-Shell Type Inclusions. Catalysts 2019, 9, 626. [Google Scholar] [CrossRef]

- Robertson, J. High dielectric constant oxides. Eur. Phys. J. Appl. Phys. 2004, 28, 265–291. [Google Scholar] [CrossRef]

- Nazarov, R.; Zhang, T.; Khodzitsky, M. Effective Medium Theory for Multi-Component Materials Based on Iterative Method. Photonics 2020, 7, 113. [Google Scholar] [CrossRef]

- Dionne, G.F.; Fitzgerald, J.F.; Aucoin, R.C. Dielectric constants of paraffin-wax–TiO2 mixtures. J. Appl. Phys. 1976, 47, 1708–1709. [Google Scholar] [CrossRef]

- Mandal, A.K.; Sen, R. Microwave Absorption of Barium Borosilicate, Zinc Borate, Fe-Doped Alumino-Phosphate Glasses and Its Raw Materials. Technologies 2015, 3, 111. [Google Scholar] [CrossRef]

- Ghassemiparvin, B.; Ghalichechian, N. Permittivity and dielectric loss measurement of paraffin films for mmW and THz applications. In Proceedings of the 2016 International Workshop on Antenna Technology (iWAT), Cocoa Beach, FL, USA, 29 Februry–2 March 2016; pp. 48–50. [Google Scholar]

| Hydrolysis duration, h | 0.5 | 1 | 1.5 | 2 | 3 | 4 |

| Shell thickness, nm | 95 ± 11 | 148 ± 22 | 125 ± 23 | 144 ± 13 | 172 ± 12 | 189 ± 14 |

| [TEOS]/[NH3·H2O] ratio | 4.5 | 1.5 | 1 | 0.75 |

| Shell thickness, nm | 62 ± 9 | 90 ± 8 | 146 ± 12 | 218 ± 10 |

| Si:O atomic ratio | SiO3.0 | SiO3.3 | SiO3.8 | SiO8.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolmatov, A.V.; Maklakov, S.S.; Zezyulina, P.A.; Osipov, A.V.; Petrov, D.A.; Naboko, A.S.; Polozov, V.I.; Maklakov, S.A.; Starostenko, S.N.; Lagarkov, A.N. Deposition of a SiO2 Shell of Variable Thickness and Chemical Composition to Carbonyl Iron: Synthesis and Microwave Measurements. Sensors 2021, 21, 4624. https://doi.org/10.3390/s21144624

Dolmatov AV, Maklakov SS, Zezyulina PA, Osipov AV, Petrov DA, Naboko AS, Polozov VI, Maklakov SA, Starostenko SN, Lagarkov AN. Deposition of a SiO2 Shell of Variable Thickness and Chemical Composition to Carbonyl Iron: Synthesis and Microwave Measurements. Sensors. 2021; 21(14):4624. https://doi.org/10.3390/s21144624

Chicago/Turabian StyleDolmatov, Arthur V., Sergey S. Maklakov, Polina A. Zezyulina, Alexey V. Osipov, Dmitry A. Petrov, Andrey S. Naboko, Viktor I. Polozov, Sergey A. Maklakov, Sergey N. Starostenko, and Andrey N. Lagarkov. 2021. "Deposition of a SiO2 Shell of Variable Thickness and Chemical Composition to Carbonyl Iron: Synthesis and Microwave Measurements" Sensors 21, no. 14: 4624. https://doi.org/10.3390/s21144624

APA StyleDolmatov, A. V., Maklakov, S. S., Zezyulina, P. A., Osipov, A. V., Petrov, D. A., Naboko, A. S., Polozov, V. I., Maklakov, S. A., Starostenko, S. N., & Lagarkov, A. N. (2021). Deposition of a SiO2 Shell of Variable Thickness and Chemical Composition to Carbonyl Iron: Synthesis and Microwave Measurements. Sensors, 21(14), 4624. https://doi.org/10.3390/s21144624