A Simple Sensor System for Onsite Monitoring of O2 in Vacuum-Packed Meats during the Shelf Life

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. O2 Sensor Preparation and Calibration

2.3. Preparation and Testing of Vacuum-Packed Meat Samples

2.4. Microbiological Analysis

2.5. Meat pH Measurement

2.6. Measurement of the Meat Colour

2.7. Data Analysis

3. Results

3.1. Assembling a Low-Cost O2 Sensor System for Food Packaging Applications

3.2. Preparation and Characterization of Disposable O2 Sensor Dots

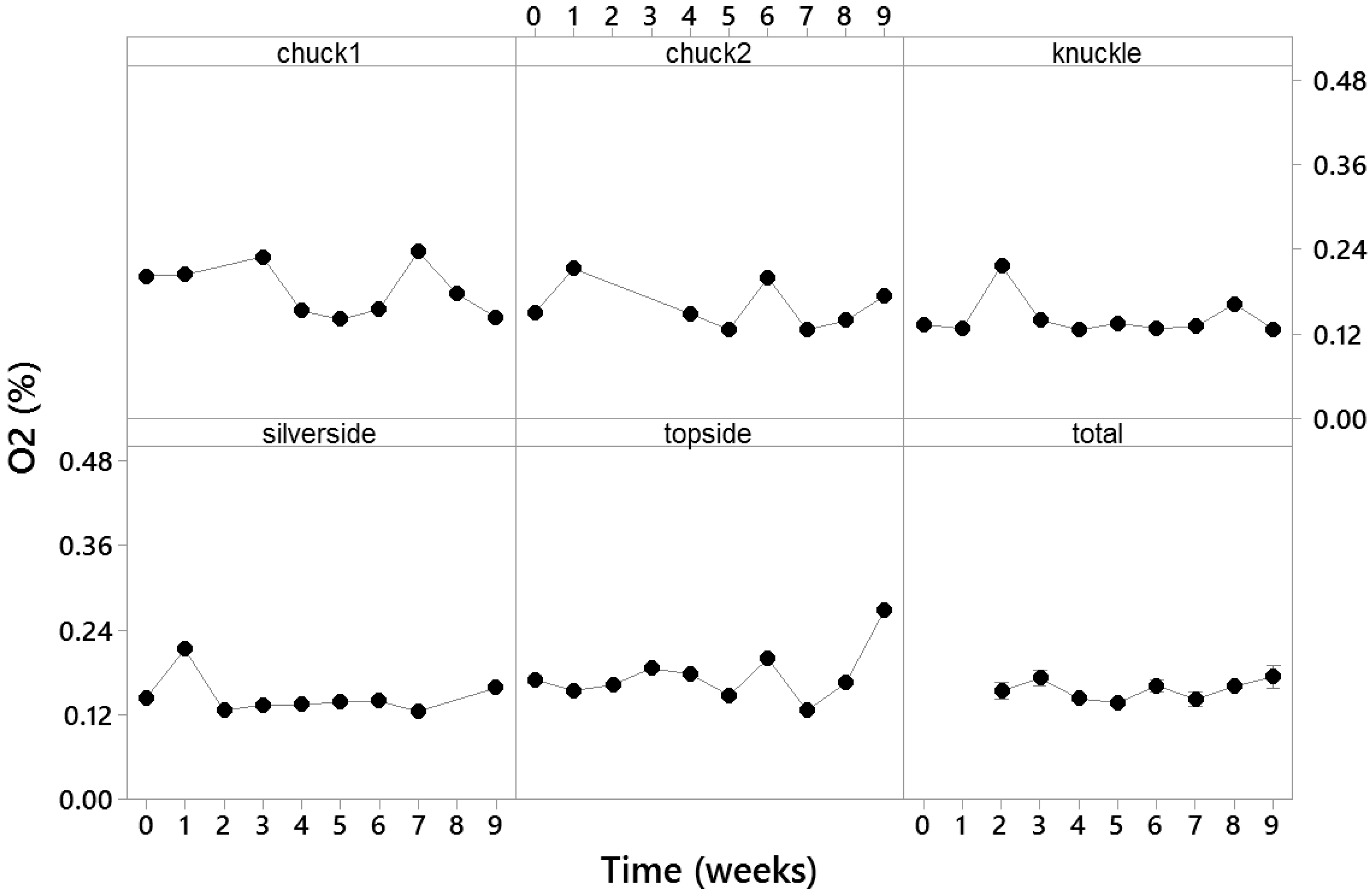

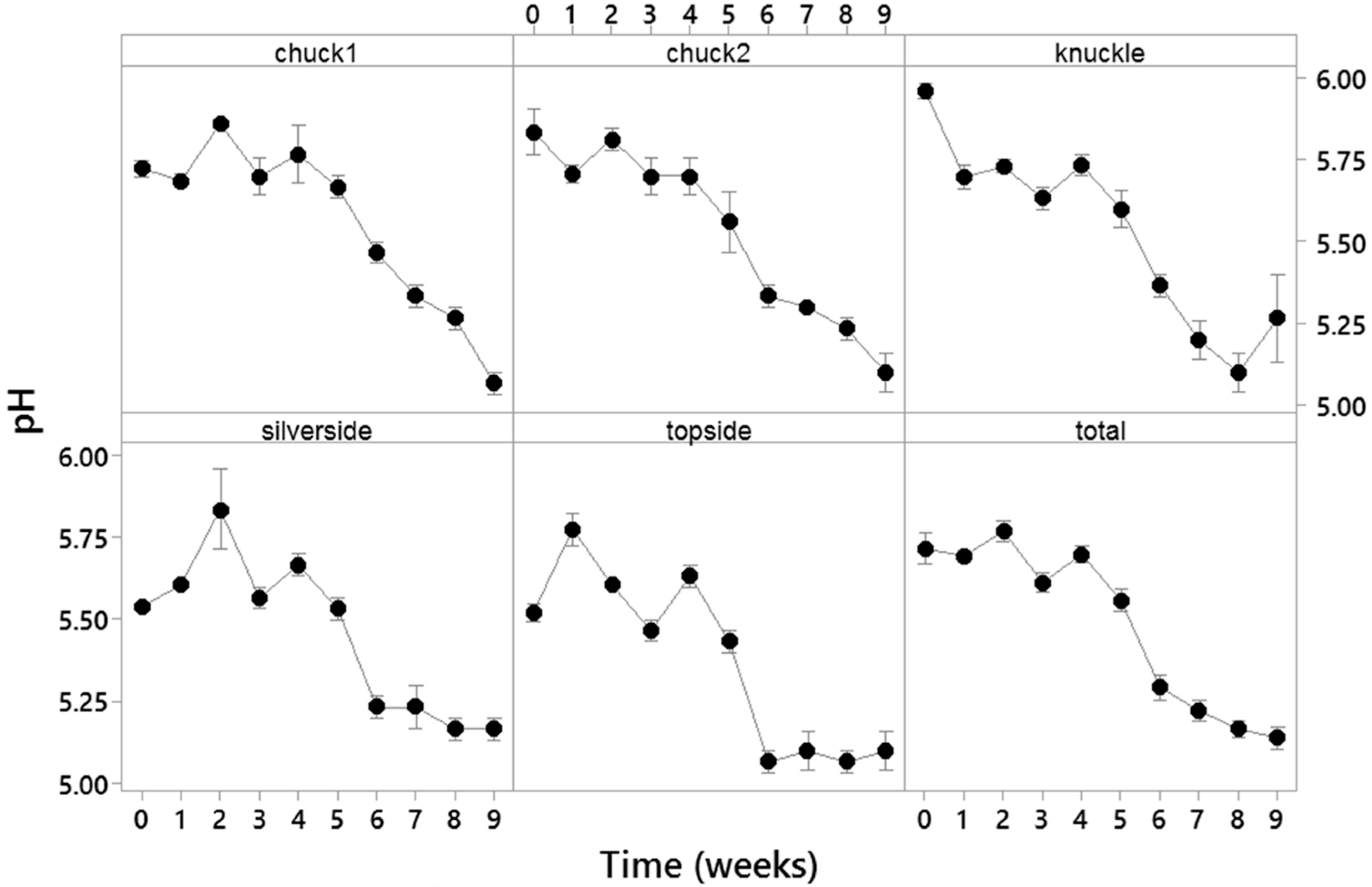

3.3. Measurement of the Residual O2 Content in VP Meat Samples during Chilling Storage

3.4. Microbiological Analysis during Refrigerated Storage

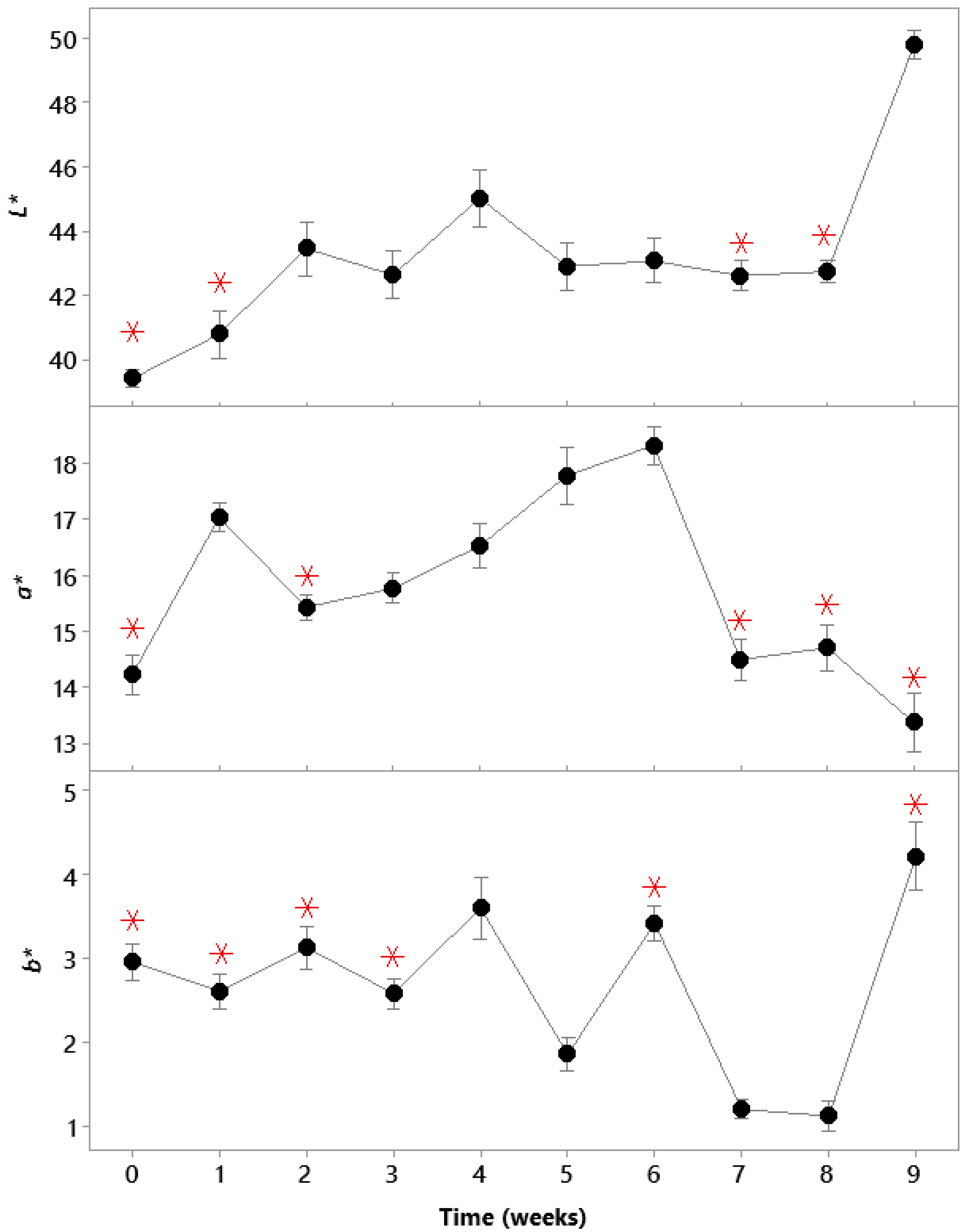

3.5. Colorimetric Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OECD-FAO. Agricultural Outlook 2015; OECD-FAO Agricultural Outlook; OECD: Paris, France, 2015; ISBN 9789264231900. [Google Scholar]

- Ahmed, I.; Lin, H.; Zou, L.; Li, Z.; Brody, A.L.; Qazi, I.M.; Lv, L.; Pavase, T.R.; Khan, M.U.; Khan, S.; et al. An overview of smart packaging technologies for monitoring safety and quality of meat and meat products. Packag. Technol. Sci. 2018, 31, 449–471. [Google Scholar] [CrossRef]

- Ahmed, I.; Lin, H.; Zou, L.; Brody, A.L.; Li, Z.; Qazi, I.M.; Pavase, T.R.; Lv, L. A comprehensive review on the application of active packaging technologies to muscle foods. Food Control. 2017, 82, 163–178. [Google Scholar] [CrossRef]

- Chen, J.; Brody, A.L. Use of active packaging structures to control the microbial quality of a ready-to-eat meat product. Food Control. 2013, 30, 306–310. [Google Scholar] [CrossRef]

- Corradini, M.G. Shelf Life of Food Products: From Open Labeling to Real-Time Measurements. Annu. Rev. Food Sci. Technol. 2018, 9, 251–269. [Google Scholar] [CrossRef]

- Kerry, J.; O’Grady, M.; Hogan, S. Past, current and potential utilisation of active and intelligent packaging systems for meat and muscle-based products: A review. Meat Sci. 2006, 74, 113–130. [Google Scholar] [CrossRef]

- Sardarodiyan, M.; Mahdian, E. Active packaging systems for a modern society. Int. J. Pharm. Tech. Res. 2016, 9, 357–363. [Google Scholar]

- Cummins, E.J.; Lyng, J. Emerging Technologies in Meat Processing; John Wiley & Sons, Ltd: Chichester, UK, 2016; ISBN 1118350685. [Google Scholar]

- Jeremiah, L. Packaging alternatives to deliver fresh meats using short- or long-term distribution. Food Res. Int. 2001, 34, 749–772. [Google Scholar] [CrossRef]

- Fregonesi, R.; Portes, R.; Aguiar, A.; Figueira, L.; Gonçalves, C.; Arthur, V.; Lima, C.; Fernandes, A.; Trindade, M. Irradiated vacuum-packed lamb meat stored under refrigeration: Microbiology, physicochemical stability and sensory acceptance. Meat Sci. 2014, 97, 151–155. [Google Scholar] [CrossRef]

- Polkinghorne, R.; Philpott, J.; Perovic, J.; Lau, J.; Davies, L.; Mudannayake, W.; Watson, R.; Tarr, G.; Thompson, J. The effect of packaging on consumer eating quality of beef. Meat Sci. 2018, 142, 59–64. [Google Scholar] [CrossRef]

- Sun, Q.; Sun, F.; Zheng, D.; Kong, B.; Liu, Q. Complex starter culture combined with vacuum packaging reduces biogenic amine formation and delays the quality deterioration of dry sausage during storage. Food Control. 2019, 100, 58–66. [Google Scholar] [CrossRef]

- Greene, B.E.; Hsin, I.-M.; Zipser, M.Y.W. Retardation of Oxidative Color Changes in Raw Ground Beef. J. Food Sci. 1971, 36, 940–942. [Google Scholar] [CrossRef]

- Font-I-Furnols, M.; Guerrero, L. Consumer preference, behavior and perception about meat and meat products: An overview. Meat Sci. 2014, 98, 361–371. [Google Scholar] [CrossRef]

- Issanchou, S. Consumer expectations and perceptions of meat and meat product quality. Meat Sci. 1996, 43, 5–19. [Google Scholar] [CrossRef]

- Cruz-Romero, M.C.; Kelly, C.A.; Papkovsky, D.B.; Kerry, J.P. Applications of phosphorescent O2 Sensors in food and bev-erage packaging systems. In RSC Detection Science; Royal Society of Chemistry: Cambridge, UK, 2018; Volume 2018, pp. 335–360. ISBN 9781788011754. [Google Scholar]

- Cruz-Romero, M.C.; Santovito, E.; Kerry, J.P.; Papkovsky, D. Oxygen Sensors for Food Packaging. Innov. Food Process. Technol. 2019, 2019, 507–522. [Google Scholar] [CrossRef]

- Kelly, C.; Toncelli, C.; Cruz-Romero, M.; Arzhakova, O.; Kerry, J.; Papkovsky, D. Phosphorescent O2 sensors integrated in polymeric film materials by local solvent crazing. Mater. Des. 2015, 77, 110–113. [Google Scholar] [CrossRef]

- Papkovsky, D.B.; Dmitriev, R.I. Biological detection by optical oxygen sensing. Chem. Soc. Rev. 2013, 42, 8700–8732. [Google Scholar] [CrossRef]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent food packaging: The next generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Elisseeva, S.; Kelly, C.; Cruz-Romero, M.; Zhdanov, A.V.; Kerry, J.P.; Papkovsky, D.B. The use of optical oxygen sensing and respirometry to quantify the effects of antimicrobials on common food spoilage bacteria and food samples. Sens. Actuators B Chem. 2020, 322, 128572. [Google Scholar] [CrossRef]

- Kelly, C.A.; Cruz-Romero, M.; Kerry, J.P.; Papkovsky, D.B. Stability and Safety Assessment of Phosphorescent Oxygen Sensors for Use in Food Packaging Applications. Chemosensors 2018, 6, 38. [Google Scholar] [CrossRef] [Green Version]

- Papkovsky, D.; Smiddy, M.; Papkovskaia, N.; Kerry, J. Nondestructive Measurement of Oxygen in Modified Atmosphere Packaged Hams Using a Phase-Fluorimetric Sensor System. J. Food Sci. 2002, 67, 3164–3169. [Google Scholar] [CrossRef]

- Kelly, C.; Santovito, E.; Cruz-Romero, M.; Kerry, J.; Papkovsky, D. Application of O2 sensor technology to monitor performance of industrial beef samples packaged on three different vacuum packaging machines. Sens. Actuators B Chem. 2020, 304, 127338. [Google Scholar] [CrossRef]

- O’Flynn, C.C.; Cruz-Romero, M.C.; Troy, D.; Mullen, A.M.; Kerry, J.P. The application of high-pressure treatment in the reduction of salt levels in reduced-phosphate breakfast sausages. Meat Sci. 2014, 96, 1266–1274. [Google Scholar] [CrossRef]

- Banerjee, S.; Kelly, C.; Kerry, J.P.; Papkovsky, D.B. High throughput non-destructive assessment of quality and safety of packaged food products using phosphorescent oxygen sensors. Trends Food Sci. Technol. 2016, 50, 85–102. [Google Scholar] [CrossRef] [Green Version]

- Rao, M.S.; Chander, R.; Sharma, A. Synergistic effect of chitooligosaccharides and lysozyme for meat preservation. LWT-Food Sci. Technol. 2008, 41, 1995–2001. [Google Scholar] [CrossRef]

- Lagerstedt, Å.; Ahnström, M.L.; Lundström, K. Vacuum skin pack of beef—A consumer friendly alternative. Meat Sci. 2011, 88, 391–396. [Google Scholar] [CrossRef] [PubMed]

- Seideman, S.C.; Durland, P.R. Vacuum Packaging of Fresh Beef: A Review. J. Food Qual. 1983, 6, 29–47. [Google Scholar] [CrossRef]

- Broda, D.M.; Delacy, K.M.; Bell, R.; Braggins, T.J.; Cook, R.L. Psychrotrophic Clostridium spp. associated with ‘blown pack’ spoilage of chilled vacuum-packed red meats and dog rolls in gas-impermeable plastic casings. Int. J. Food Microbiol. 1996, 29, 335–352. [Google Scholar] [CrossRef]

- Duran, A.; Kahve, H.I. The effect of chitosan coating and vacuum packaging on the microbiological and chemical properties of beef. Meat Sci. 2020, 162, 107961. [Google Scholar] [CrossRef]

- Conte-Junior, C.A.; Monteiro, M.L.G.; Patrícia, R.; Mársico, E.T.; Lopes, M.M.; Alvares, T.S.; Mano, S.B. The Effect of Different Packaging Systems on the Shelf Life of Refrigerated Ground Beef. Foods 2020, 9, 495. [Google Scholar] [CrossRef] [PubMed]

- Jouki, M.; Khazaei, N. Lipid oxidation and color changes of fresh camel meat stored under different atmosphere packaging systems. J. Food Process. Technol. 2012, 3, 189. [Google Scholar]

- Hui, Y.H.; Nip, W.K.; Rogers, R. Meat Science and Applications; Taylor & Francis: Abingdon, UK, 2001; ISBN 9780824741693. [Google Scholar]

represent outliers. (E) The O2 calibration curve for sensor dots; the red line indicates the polynomial fitting curve.

represent outliers. (E) The O2 calibration curve for sensor dots; the red line indicates the polynomial fitting curve.

represent outliers. (E) The O2 calibration curve for sensor dots; the red line indicates the polynomial fitting curve.

represent outliers. (E) The O2 calibration curve for sensor dots; the red line indicates the polynomial fitting curve.

).

).

).

).

) were not significantly different from the control level mean at time 0 (day 1, week 1) according to the ANOVA test (Dunnet comparisons, α = 0.05). The error bars represent the standard errors of the means.

) were not significantly different from the control level mean at time 0 (day 1, week 1) according to the ANOVA test (Dunnet comparisons, α = 0.05). The error bars represent the standard errors of the means.

) were not significantly different from the control level mean at time 0 (day 1, week 1) according to the ANOVA test (Dunnet comparisons, α = 0.05). The error bars represent the standard errors of the means.

) were not significantly different from the control level mean at time 0 (day 1, week 1) according to the ANOVA test (Dunnet comparisons, α = 0.05). The error bars represent the standard errors of the means.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santovito, E.; Elisseeva, S.; Cruz-Romero, M.C.; Duffy, G.; Kerry, J.P.; Papkovsky, D.B. A Simple Sensor System for Onsite Monitoring of O2 in Vacuum-Packed Meats during the Shelf Life. Sensors 2021, 21, 4256. https://doi.org/10.3390/s21134256

Santovito E, Elisseeva S, Cruz-Romero MC, Duffy G, Kerry JP, Papkovsky DB. A Simple Sensor System for Onsite Monitoring of O2 in Vacuum-Packed Meats during the Shelf Life. Sensors. 2021; 21(13):4256. https://doi.org/10.3390/s21134256

Chicago/Turabian StyleSantovito, Elisa, Sophia Elisseeva, Malco C. Cruz-Romero, Geraldine Duffy, Joseph P. Kerry, and Dmitri B. Papkovsky. 2021. "A Simple Sensor System for Onsite Monitoring of O2 in Vacuum-Packed Meats during the Shelf Life" Sensors 21, no. 13: 4256. https://doi.org/10.3390/s21134256

APA StyleSantovito, E., Elisseeva, S., Cruz-Romero, M. C., Duffy, G., Kerry, J. P., & Papkovsky, D. B. (2021). A Simple Sensor System for Onsite Monitoring of O2 in Vacuum-Packed Meats during the Shelf Life. Sensors, 21(13), 4256. https://doi.org/10.3390/s21134256