Field Test and Numerical Simulation on the Long-Term Thermal Response of PHC Energy Pile in Layered Foundation

Abstract

1. Introduction

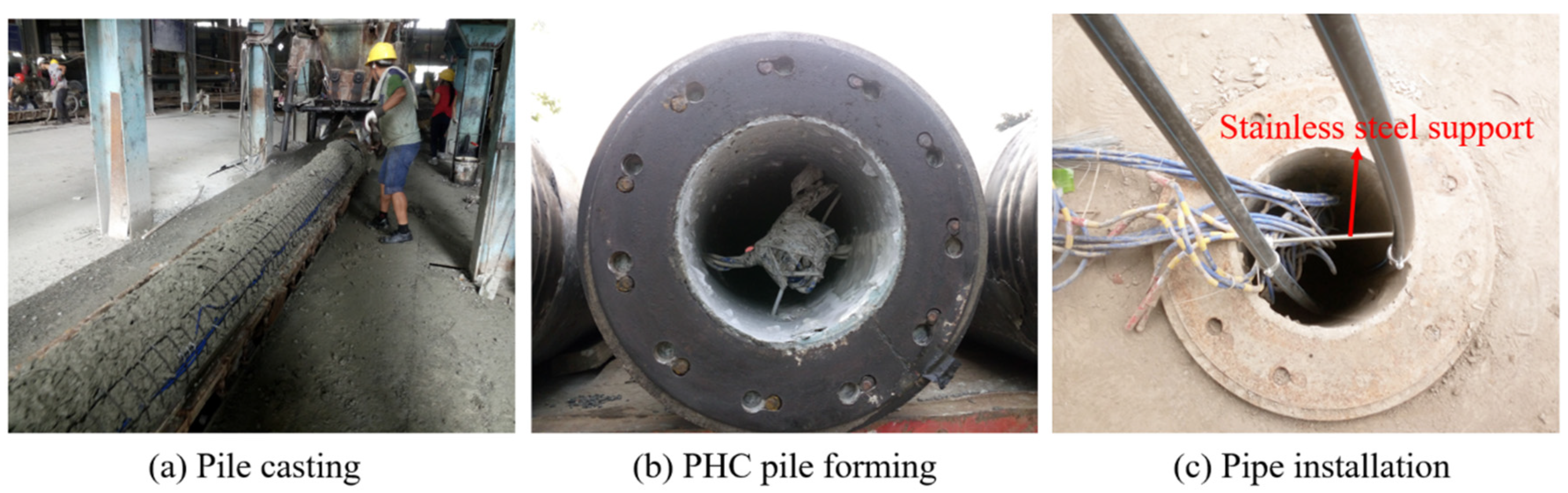

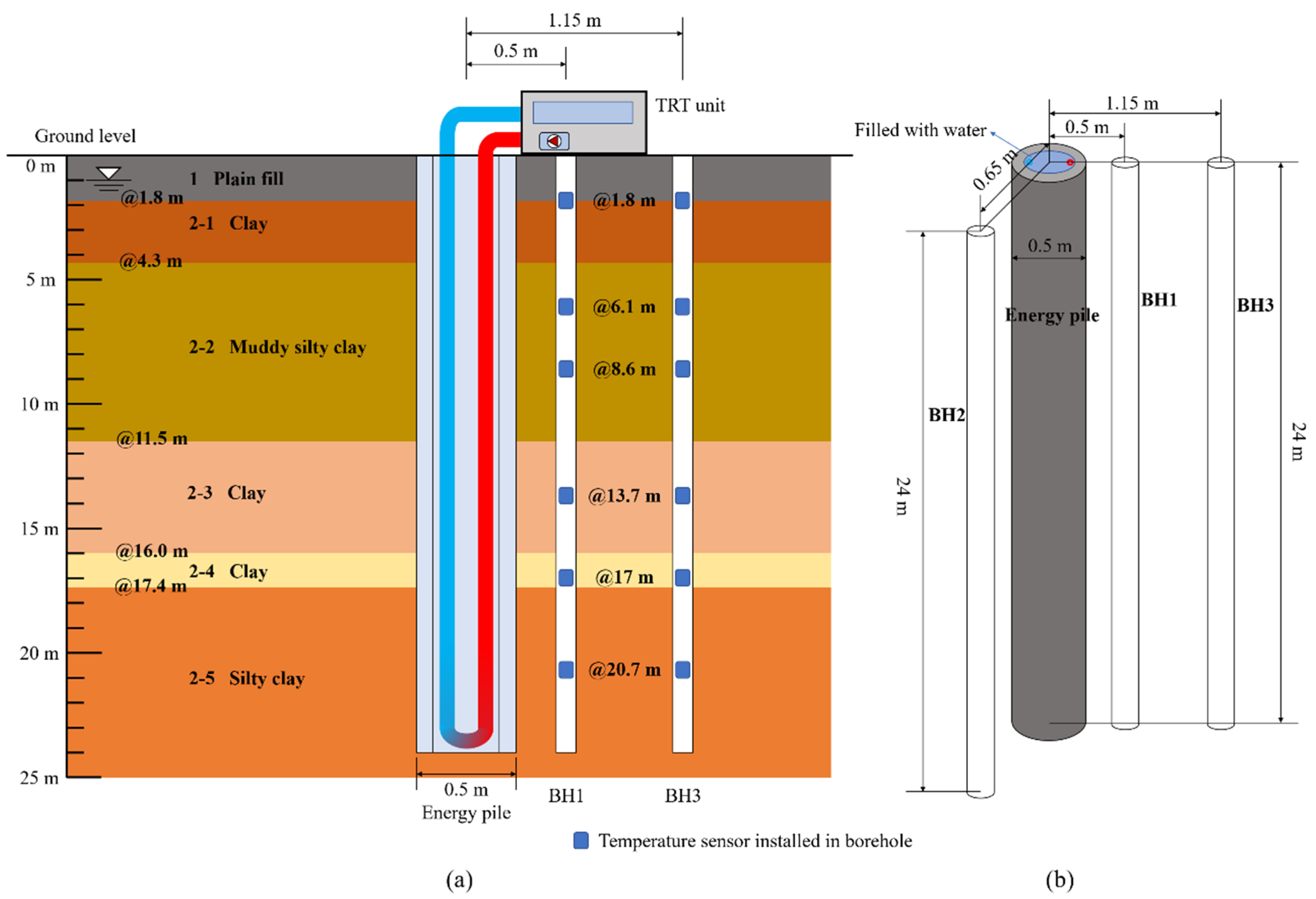

2. Description of Field Test

2.1. Location of Testing Site

2.2. Geological Conditions of Testing Site

2.3. Experimental Scheme

2.4. Uncertainty Analysis

3. Results and Analysis of Field Experiments

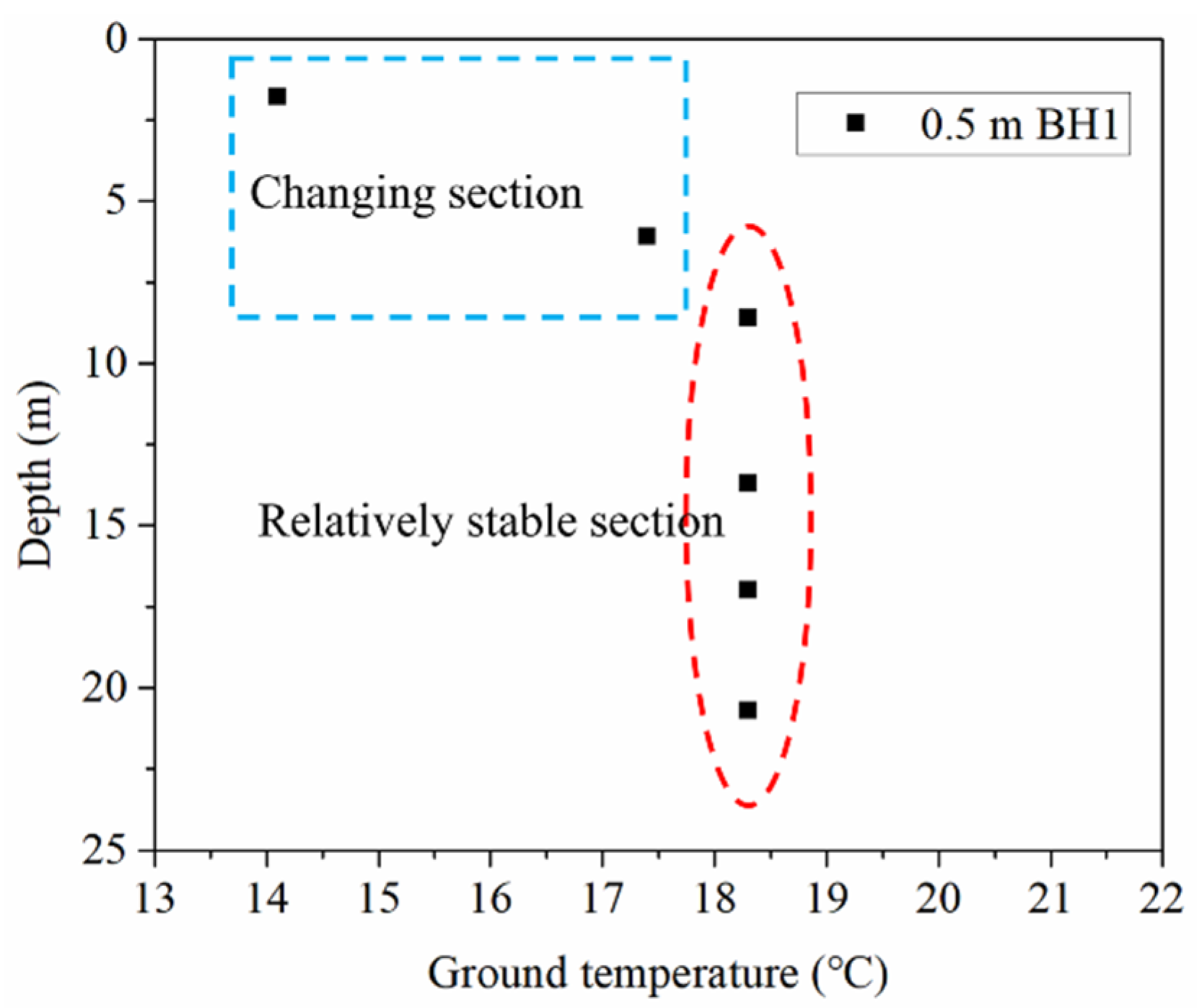

3.1. Initial Ground Temperature

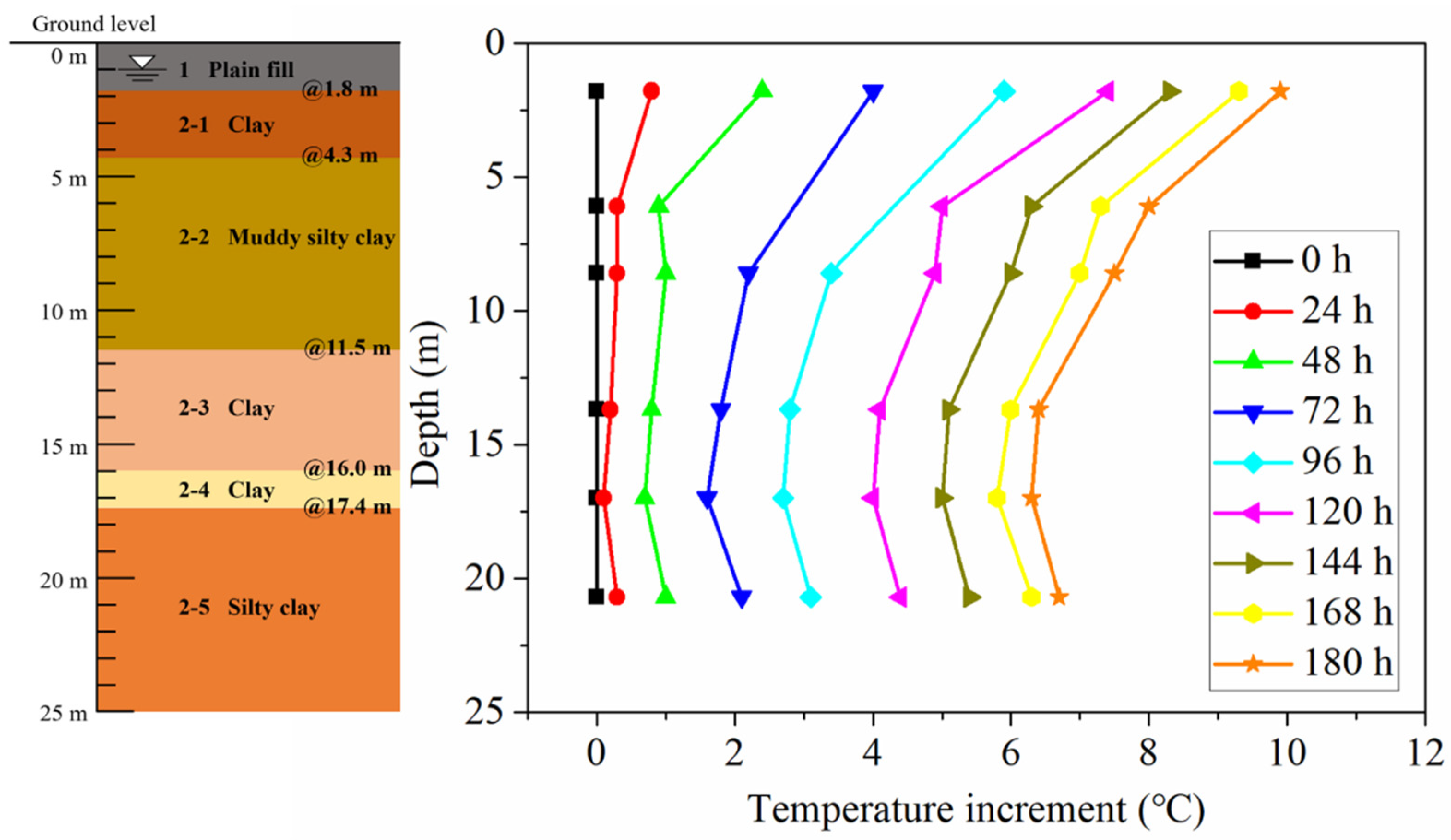

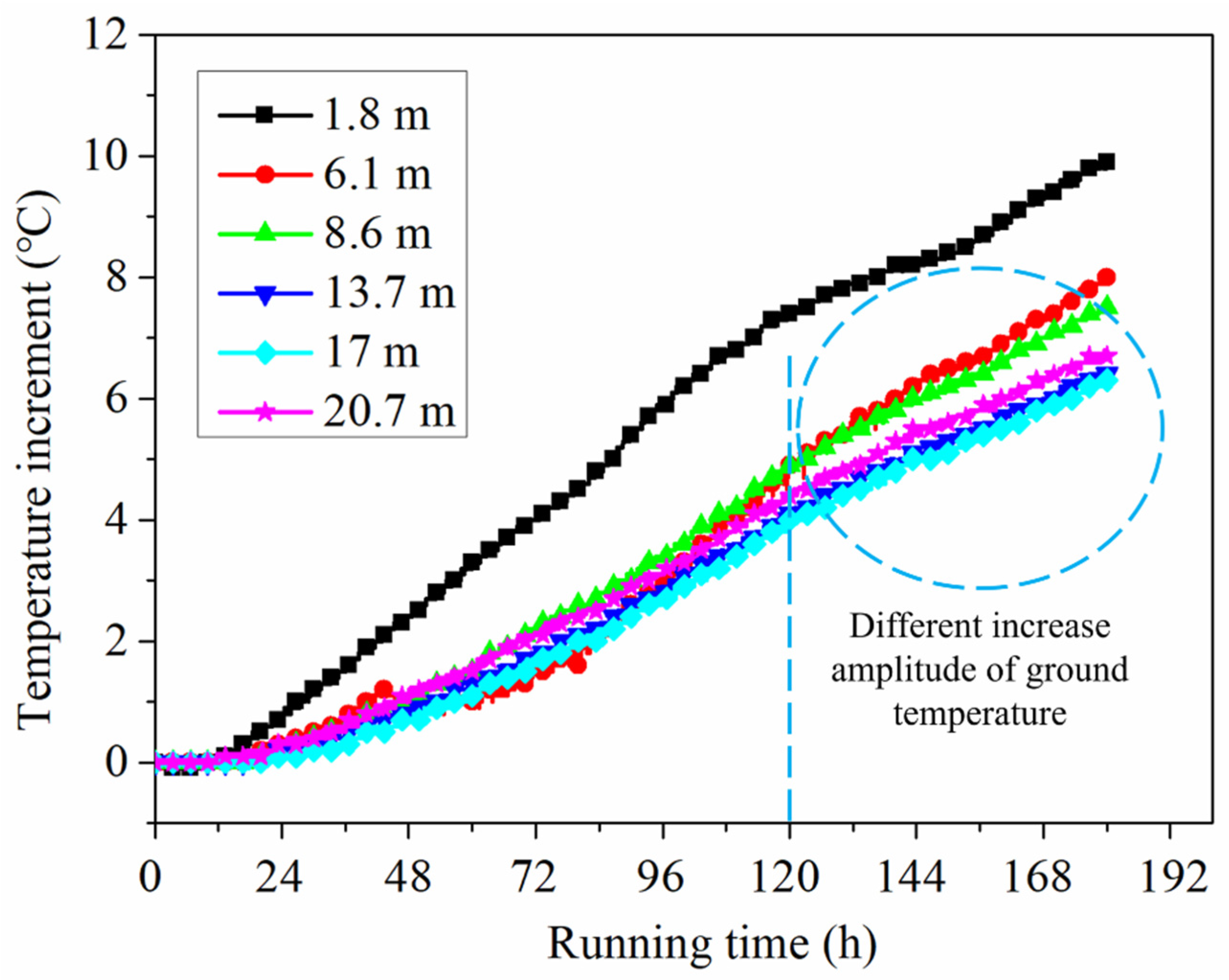

3.2. Effect of Depth on Ground Temperature Variation

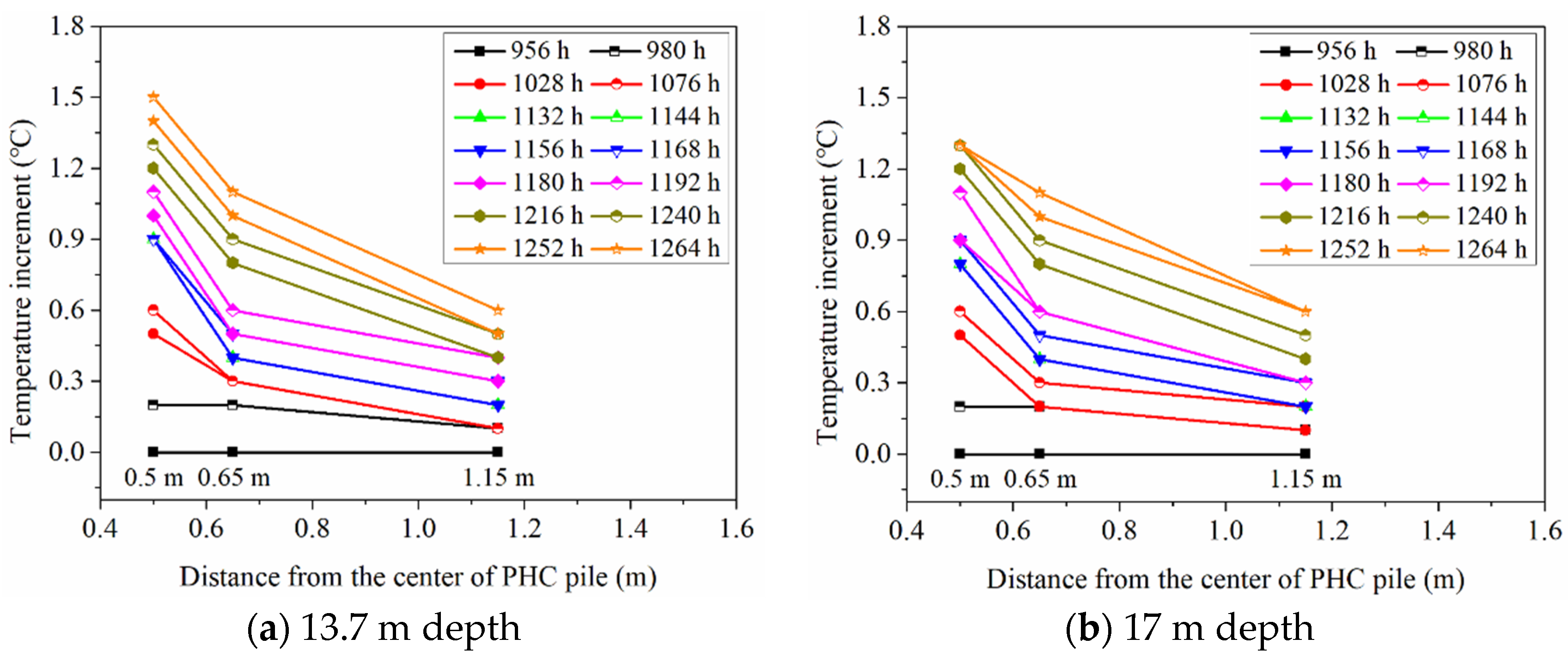

3.3. Ground Temperature Variation at Various Distances from Energy Pile

4. Numerical Simulation and Analysis

4.1. Theoretical Analysis of Heat Transfer

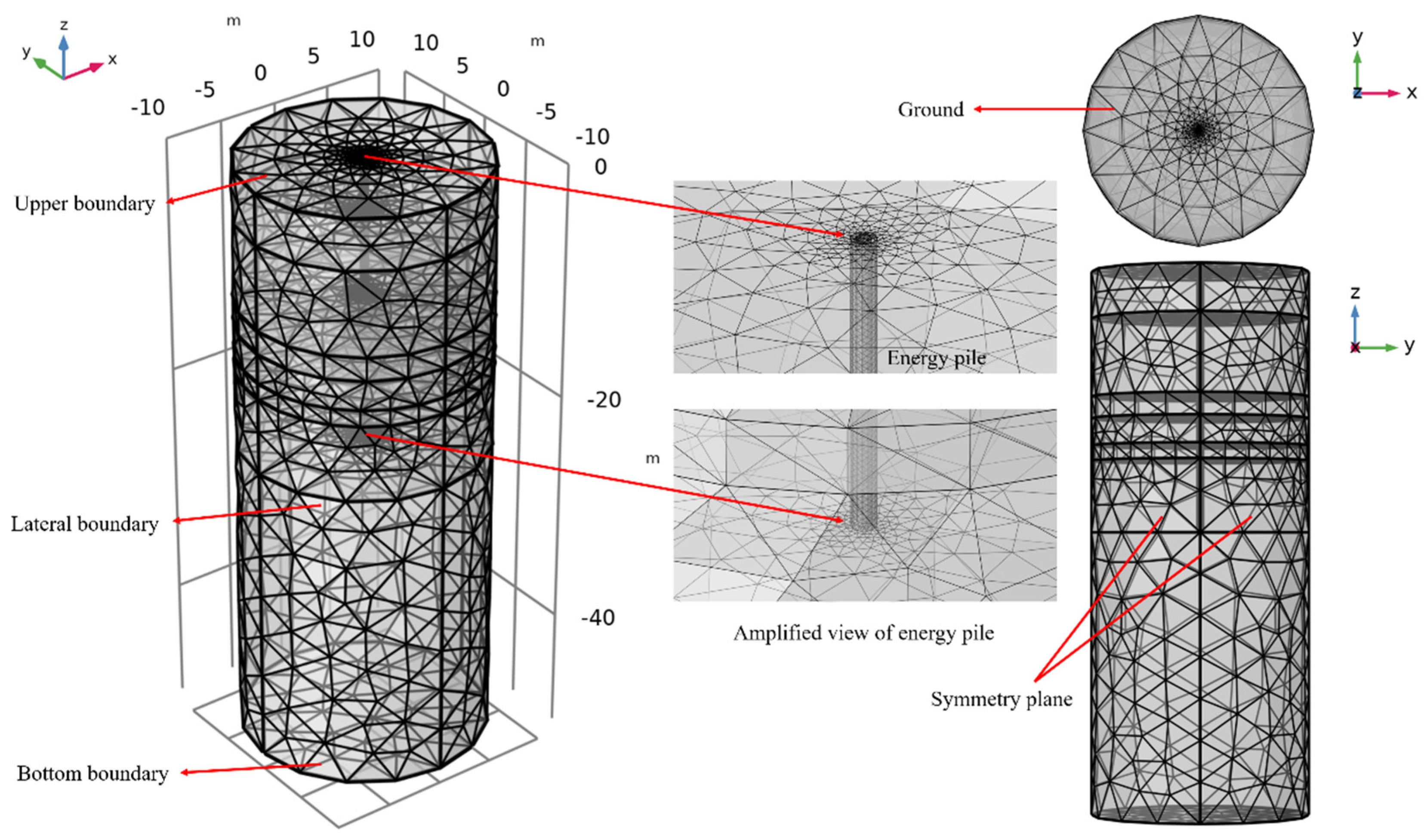

4.2. Finite Element Modeling and Initial and Boundary Conditions

4.3. Verification of Numerical Model

4.4. Analysis of Parameters for Long-Term Thermal Response of Energy Pile

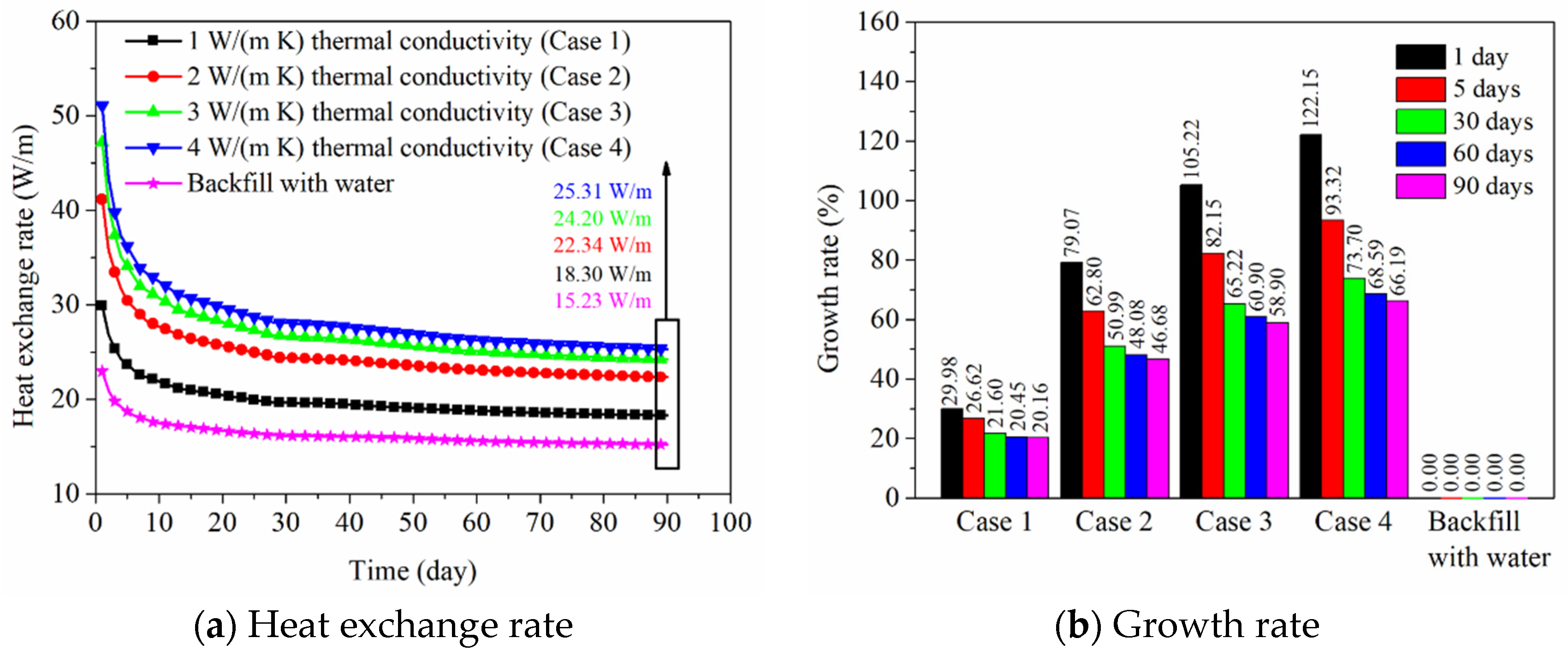

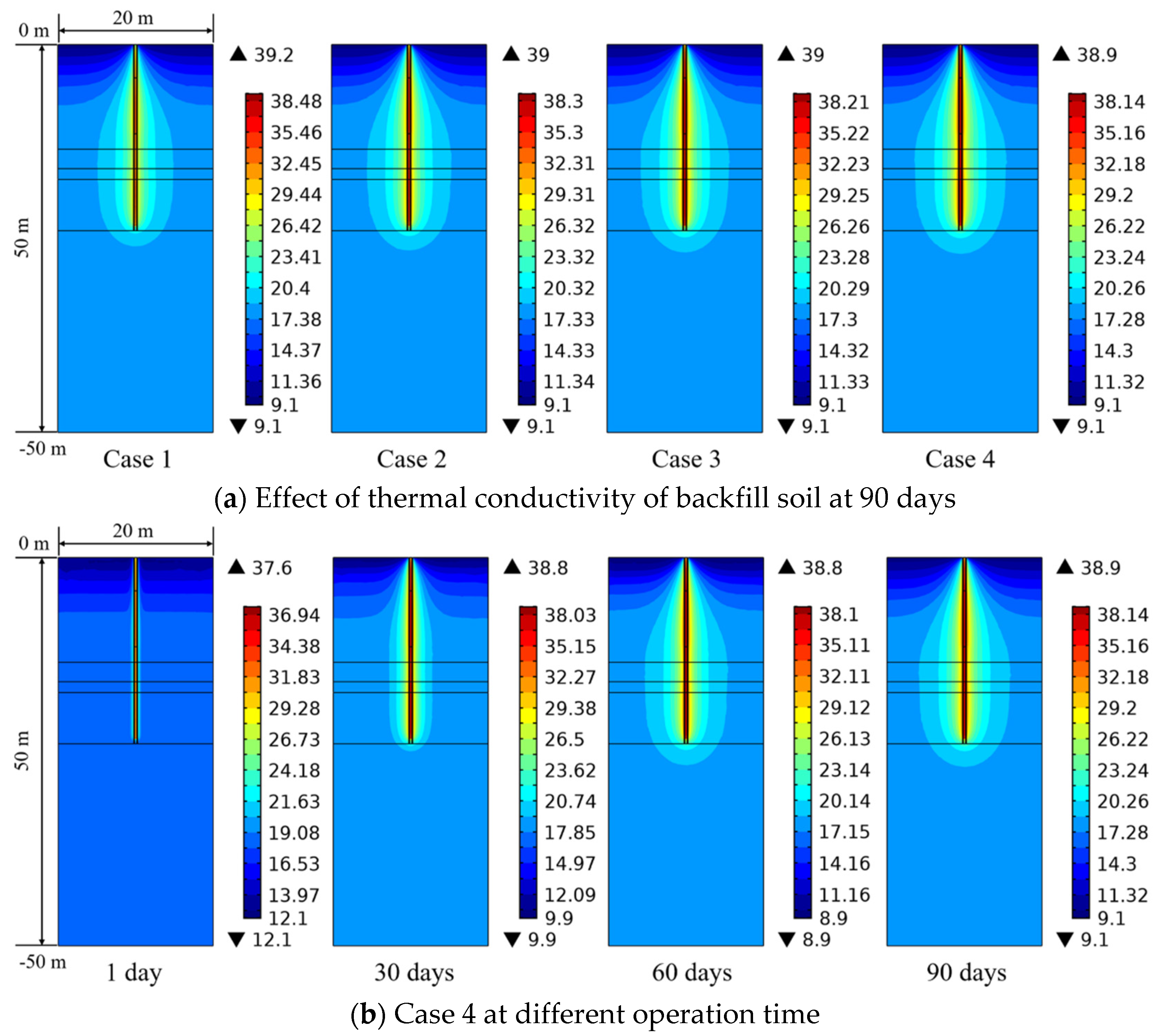

4.4.1. Effect of Thermal Conductivity of Backfill Soil in PHC Pile

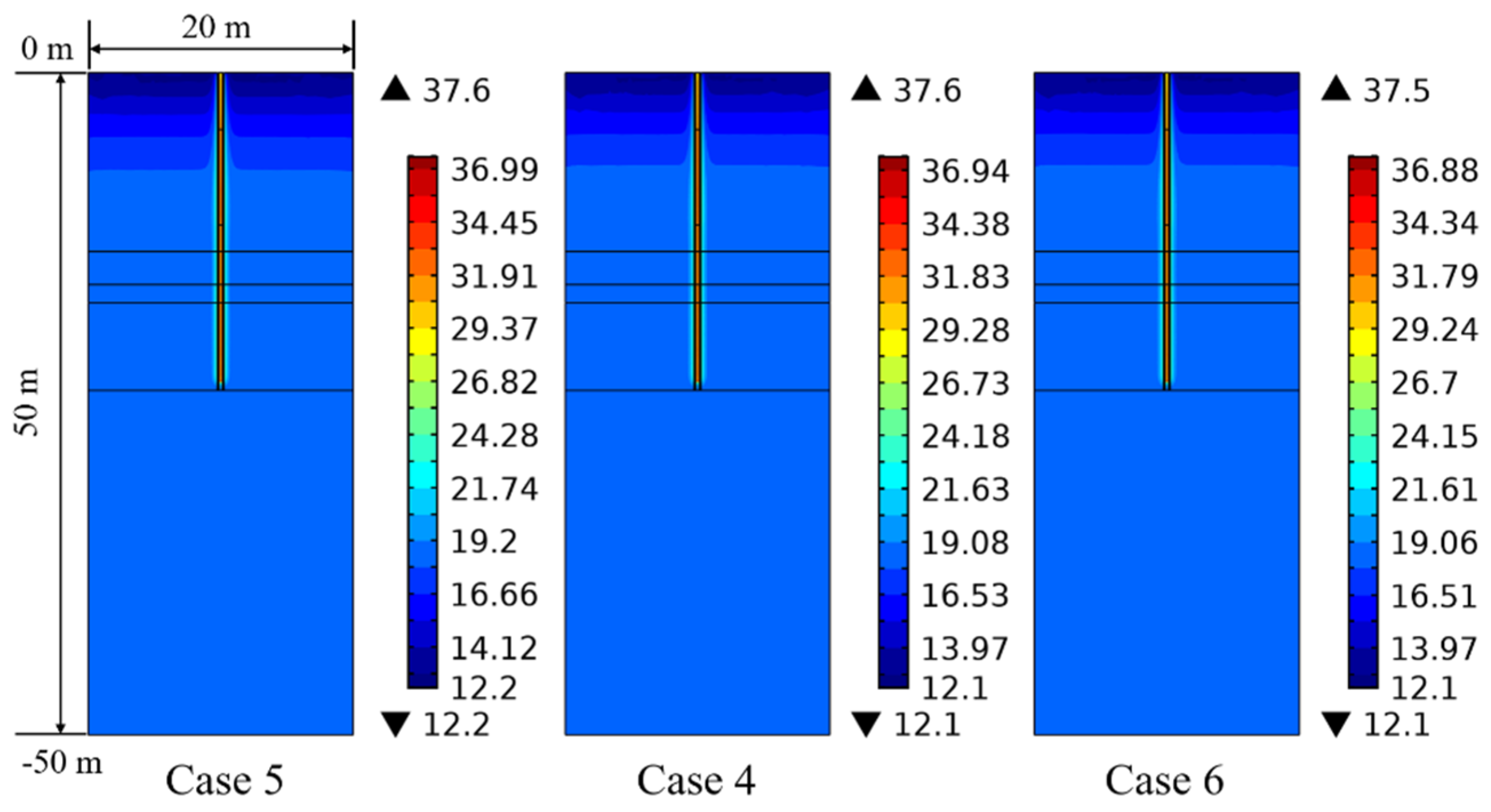

4.4.2. Effect of Specific Heat Capacity of Backfill Soil in PHC Pile

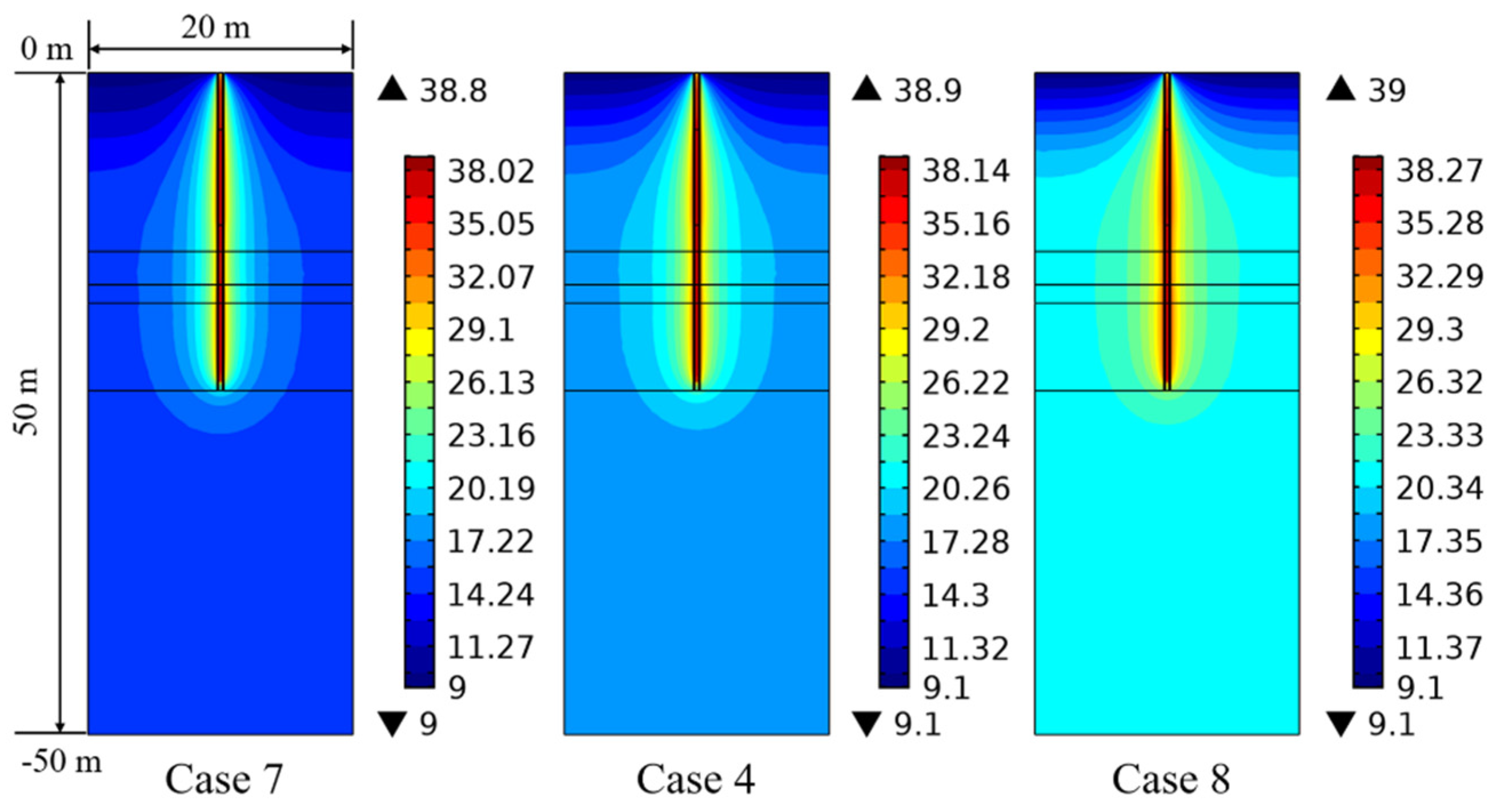

4.4.3. Effect of Initial Ground Temperature

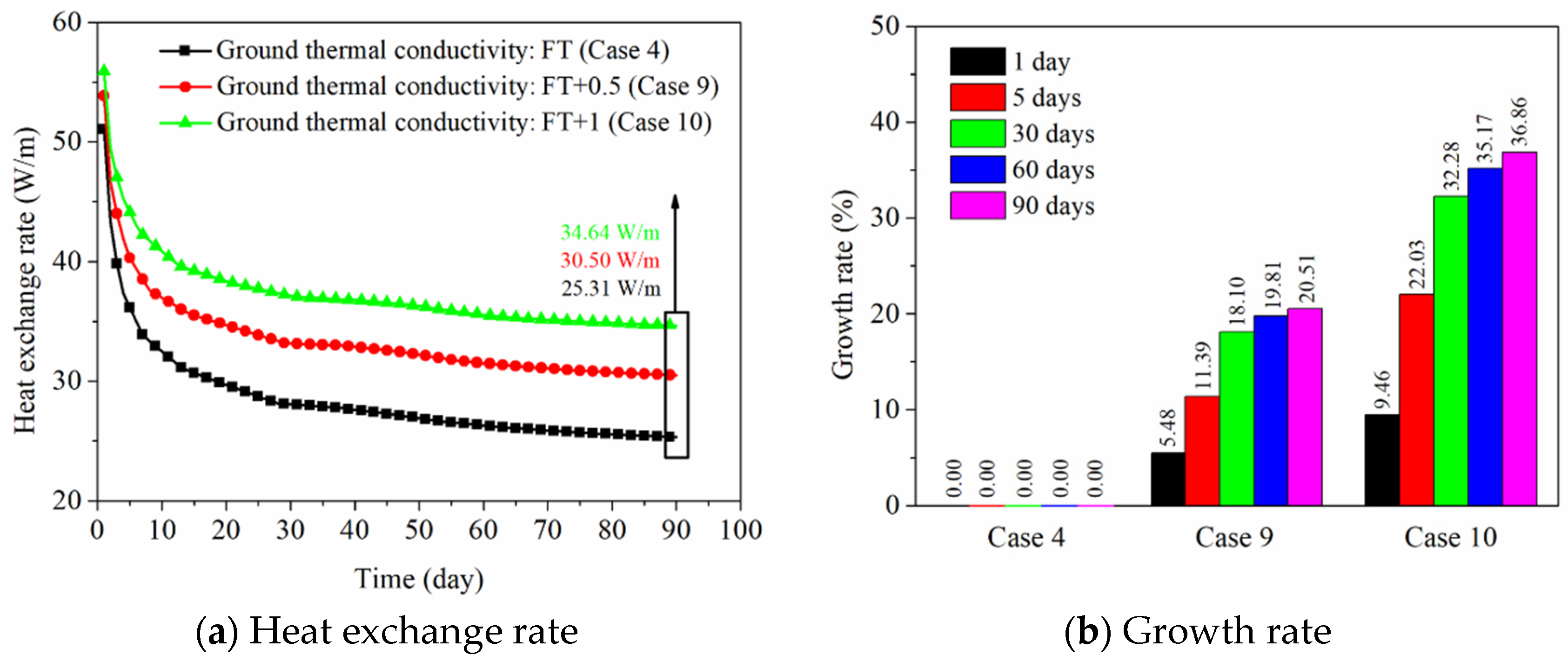

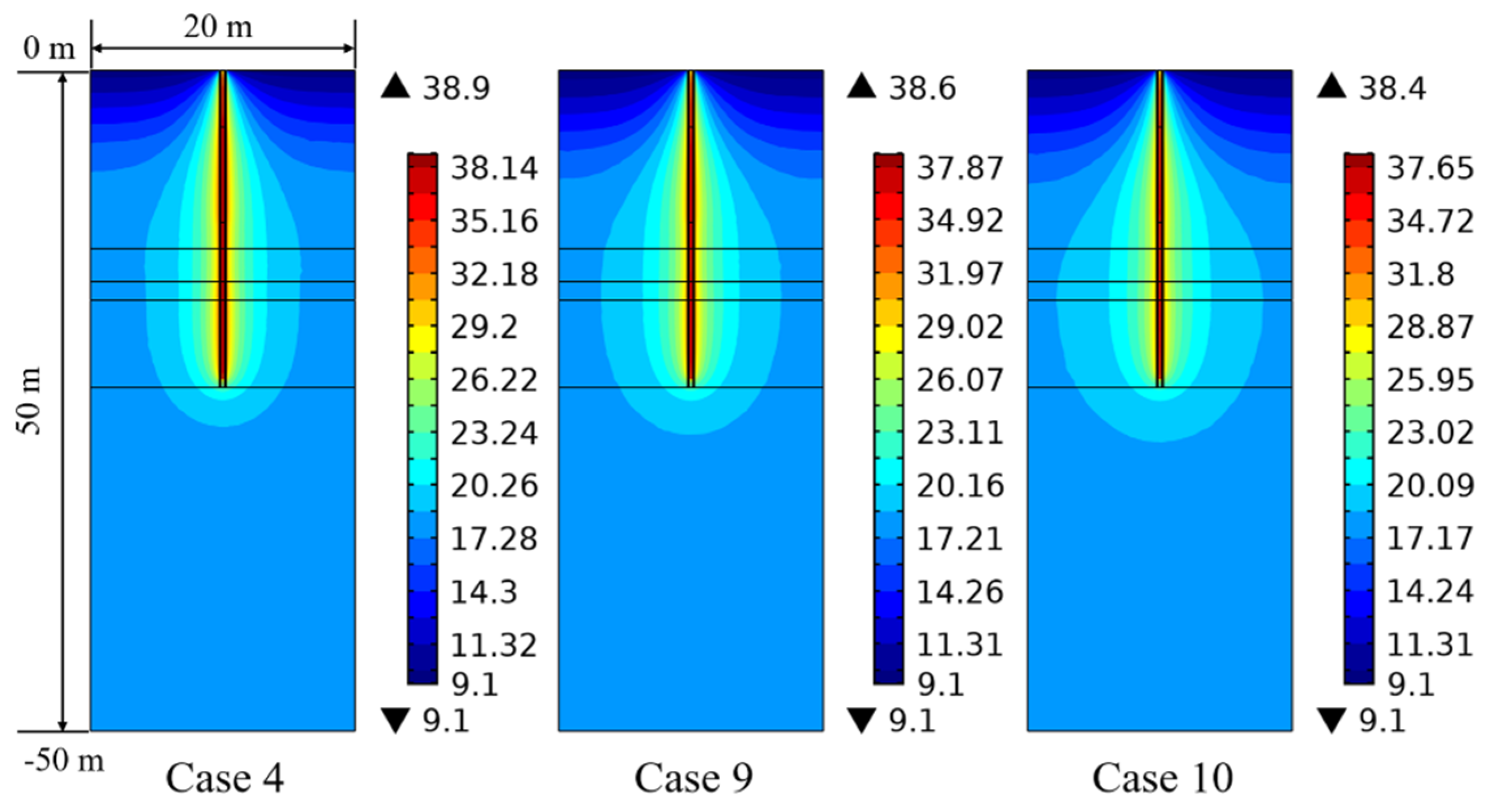

4.4.4. Effect of Thermal Conductivity of the Ground

5. Discussion

6. Conclusions

- The thermophysical properties of the ground have an effect on the ground temperature variation at the relatively long-term operation. The relatively higher thermal conductivity of the soil layers can generate a slower growth trend of the ground temperature near to the PHC energy pile. The influence of the soil to the energy pile temperature weakens as the radial distance from the pile increases.

- Based on the theoretical analysis of heat transfer, the 3D numerical simulations of PHC energy pile in the layered foundation were performed. The numerical data agreed very well with the measured in situ data.

- The parametric analysis shows that the thermal conductivity of the backfill soil in PHC pile, initial ground temperature, and thermal conductivity of the ground both have an influence on the long-term thermal performance and ground temperature variation, while the impact of the specific heat capacity of the backfill soil is negligible.

- The short- and long-term heat transfer performance of the PHC energy pile can be enhanced by increasing the thermal conductivity of the backfill soil in the PHC pile. The heat exchange rates reach 29.87, 41.15, 47.16, and 51.05 W/m at 1 day and 18.30, 22.34, 24.20, and 25.31 W/m at 90 days as the thermal conductivities of the backfill soil are 1, 2, 3, and 4 W/(m K), which have been improved by about 30%, 79%, 105%, and 122% at 1 day and 20%, 47%, 59%, and 66% at 90 days compared with the PHC pile backfill with water.

- The initial ground temperature variation also has an impact on the short- and long-term thermal response. The heat exchange rates of the energy pile, respectively, increase by about 13% and 11% at 1 day and 90 days as the initial ground temperature reduces 3 °C, and they decrease by 13% and 11% at 1 day and 90 days as the initial ground temperature rises 3 °C.

- The thermal conductivity of the ground produces a significant effect on the long-term heat exchange amount of energy pile, while it has a relatively small impact on the short-term performance. When the thermal conductivities of each soil layer rise by 0.5 and 1 W/(m K), the heat exchange rates have improved by about 5% and 9% at 1 day, and they have improved by 21% and 37% at 90 days.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brandl, H. Energy foundations and other thermo-active ground structures. Géotechnique 2006, 56, 81–122. [Google Scholar] [CrossRef]

- Adam, D.; Markiewicz, R. Energy from earth-coupled structures, foundations, tunnels and sewers. Géotechnique 2009, 59, 229–236. [Google Scholar] [CrossRef]

- Xia, C.; Sun, M.; Zhang, G.; Xiao, S.; Zou, Y. Experimental study of geothermal heat exchangers buried in diaphragm walls. Energy Build. 2012, 52, 50–55. [Google Scholar] [CrossRef]

- Rui, Y.; Yin, M. Thermo-hydro-mechanical coupling analysis of a thermo-active diaphragm wall. Can. Geotech. J. 2018, 55, 720–735. [Google Scholar] [CrossRef]

- Zhang, G.; Xia, C.; Yang, Y.; Sun, M.; Zou, Y. Experimental study on the thermal performance of tunnel lining ground heat exchangers. Energy Build. 2014, 77, 149–157. [Google Scholar] [CrossRef]

- Insana, A.; Barla, M. Experimental and numerical investigations on the energy performance of a thermo-active tunnel. Renew. Energy 2020, 152, 781–792. [Google Scholar] [CrossRef]

- De Moel, M.; Bach, P.M.; Bouazza, A.; Singh, R.M.; Sun, J.O. Technological advances and applications of geothermal energy pile foundations and their feasibility in Australia. Renew. Sustain. Energy Rev. 2010, 14, 2683–2696. [Google Scholar] [CrossRef]

- Ren, L.-W.; Xu, J.; Kong, G.-Q.; Liu, H.-L. Field tests on thermal response characteristics of micro-steel-pipe pile under multiple temperature cycles. Renew. Energy 2020, 147, 1098–1106. [Google Scholar] [CrossRef]

- Park, S.; Sung, C.; Jung, K.; Sohn, B.; Chauchois, A.; Choi, H. Constructability and heat exchange efficiency of large diameter cast-in-place energy piles with various configurations of heat exchange pipe. Appl. Therm. Eng. 2015, 90, 1061–1071. [Google Scholar] [CrossRef]

- Laloui, L.; Nuth, M.; Vulliet, L. Experimental and numerical investigations of the behaviour of a heat exchanger pile. Int. J. Numer. Anal. Methods Géoméch. 2006, 30, 763–781. [Google Scholar] [CrossRef]

- Bourne-Webb, P.J.; Amatya, B.; Soga, K.; Amis, T.; Davidson, C.; Payne, P. Energy pile test at Lambeth College, London: Geotechnical and thermodynamic aspects of pile response to heat cycles. Géotechnique 2009, 59, 237–248. [Google Scholar] [CrossRef]

- Hamada, Y.; Saitoh, H.; Nakamura, M.; Kubota, H.; Ochifuji, K. Field performance of an energy pile system for space heating. Energy Build. 2007, 39, 517–524. [Google Scholar] [CrossRef]

- Yang, W.; Lu, P.; Chen, Y. Laboratory investigations of the thermal performance of an energy pile with spiral coil ground heat exchanger. Energy Build. 2016, 128, 491–502. [Google Scholar] [CrossRef]

- Jalaluddin; Miyara, A.; Tsubaki, K.; Inoue, S.; Yoshida, K. Experimental study of several types of ground heat exchanger using a steel pile foundation. Renew. Energy 2011, 36, 764–771. [Google Scholar] [CrossRef]

- Amatya, B.; Soga, K.; Bourne-Webb, P.; Amis, T.; Laloui, L. Thermo-mechanical behaviour of energy piles. Géotechnique 2012, 62, 503–519. [Google Scholar] [CrossRef]

- Akrouch, G.A.; Sánchez, M.; Briaud, J.-L. An experimental, analytical and numerical study on the thermal efficiency of energy piles in unsaturated soils. Comput. Geotech. 2016, 71, 207–220. [Google Scholar] [CrossRef]

- Xiao, S.; Suleiman, M.T.; Naito, C.; Al-Khawaja, M. Modified–Thermal Borehole Shear Test Device and Testing Procedure to Investigate the Soil-Structure Interaction of Energy Piles. Geotech. Test. J. 2017, 40, 20160257. [Google Scholar] [CrossRef]

- Guo, Y.M.; Zhang, G.Z.; Liu, S.Y. Investigation on the thermal response of full-scale PHC energy pile and ground temperature in multi-layer strata. Appl. Therm. Eng. 2018, 143, 836–848. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, X.; Liu, J.; Li, K.S.; Yang, J. Thermal performance and ground temperature of vertical pile-foundation heat exchangers: A case study. Appl. Therm. Eng. 2008, 28, 2295–2304. [Google Scholar] [CrossRef]

- Luo, J.; Zhao, H.F.; Gui, S.Q.; Xiang, W.; Rohn, J.; Blum, P. Thermo-economic analysis of four different types of ground heat exchangers in energy piles. Appl. Therm. Eng. 2016, 108, 11–19. [Google Scholar] [CrossRef]

- Faizal, M.; Bouazza, A.; Singh, R.M. An experimental investigation of the influence of intermittent and continuous operating modes on the thermal behaviour of a full scale geothermal energy pile. Géoméch. Energy Environ. 2016, 8, 8–29. [Google Scholar] [CrossRef]

- You, S.; Cheng, X.H.; Guo, H.X.; Yao, Z.Q. In-situ experimental study of heat exchange capacity of CFG pile geothermal exchangers. Energy Build. 2014, 79, 23–31. [Google Scholar] [CrossRef]

- Sani, A.K.; Singh, R.M. Response of unsaturated soils to heating of geothermal energy pile. Renew. Energy 2020, 147, 2618–2632. [Google Scholar] [CrossRef]

- Batini, N.; Loria, A.F.R.; Conti, P.; Testi, D.; Grassi, W.; Laloui, L. Energy and geotechnical behaviour of energy piles for different design solutions. Appl. Therm. Eng. 2015, 86, 199–213. [Google Scholar] [CrossRef]

- Zarrella, A.; De Carli, M.; Galgaro, A. Thermal performance of two types of energy foundation pile: Helical pipe and triple U-tube. Appl. Therm. Eng. 2013, 61, 301–310. [Google Scholar] [CrossRef]

- Gashti, E.H.N.; Uotinen, V.-M.; Kujala, K. Numerical modelling of thermal regimes in steel energy pile foundations: A case study. Energy Build. 2014, 69, 165–174. [Google Scholar] [CrossRef]

- Cecinato, F.; Loveridge, F. Influences on the thermal efficiency of energy piles. Energy 2015, 82, 1021–1033. [Google Scholar] [CrossRef]

- Kramer, C.A.; Ghasemi-Fare, O.; Basu, P. Laboratory Thermal Performance Tests on a Model Heat Exchanger Pile in Sand. Geotech. Geol. Eng. 2015, 33, 253–271. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, G.; Lu, J.; Yang, X.; Zhuang, C. A novel truncated cone helix energy pile: Numerical and laboratory investigations of thermal performance. Int. J. Heat Mass Transf. 2018, 126, 681–699. [Google Scholar] [CrossRef]

- Cui, H.Z.; Zou, J.P.; Bao, X.H.; Qi, X.D.; Qi, H. Heat exchange behavior of the phase change energy pile under cooling condition. J. Tsinghua Univ. Sci. Tech. 2020, 60, 715–725. [Google Scholar]

- Park, S.; Lee, D.; Lee, S.; Chauchois, A.; Choi, H. Experimental and numerical analysis on thermal performance of large-diameter cast-in-place energy pile constructed in soft ground. Energy 2017, 118, 297–311. [Google Scholar] [CrossRef]

- Adinolfi, M.; Loria, A.F.R.; Laloui, L.; Aversa, S. Experimental and numerical investigation of the thermo-mechanical behaviour of an energy sheet pile wall. Geomech. Energy Environ. 2021, 25, 100208. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.-R.; Yoon, S.; Choi, J.-C. Evaluation of thermal response and performance of PHC energy pile: Field experiments and numerical simulation. Appl. Energy 2013, 103, 12–24. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Singh, R.M.; Bouazza, A.; Wang, B. Near-field ground thermal response to heating of a geothermal energy pile: Observations from a field test. Soils Found. 2015, 55, 1412–1426. [Google Scholar] [CrossRef]

- Péron, H.; Knellwolf, C.; Laloui, L. A method for the geotechnical design of heat exchanger piles. In Geo-Frontiers: Advances in Geotechnical Engineering; Geotechnical Special Publication 211; Han, J., Alzamora, D.E., Eds.; ASCE: Reston, VA, USA, 2011; pp. 470–479. [Google Scholar]

- Ma, Q.; Wang, P. Underground solar energy storage via energy piles. Appl. Energy 2020, 261, 114361. [Google Scholar] [CrossRef]

- COMSOL Multiphysics, User’s Guide; COMSOL: Stockholm, Sweden, 2020.

- Park, S.; Lee, S.; Oh, K.; Kim, D.; Choi, H. Engineering chart for thermal performance of cast-in-place energy pile considering thermal resistance. Appl. Therm. Eng. 2018, 130, 899–921. [Google Scholar] [CrossRef]

- Qi, D.; Pu, L.; Sun, F.; Li, Y. Numerical investigation on thermal performance of ground heat exchangers using phase change materials as grout for ground source heat pump system. Appl. Therm. Eng. 2016, 106, 1023–1032. [Google Scholar] [CrossRef]

| Layer Name | Scope of Depth (m) | Plastic Limit (%) | Liquid Limit (%) | Plasticity Index (%) | Void Ratio | Water Content (%) | Unit Weight (kN/m3) |

|---|---|---|---|---|---|---|---|

| 2-1 | 1.8–4.3 | 25.8 | 47.9 | 22.1 | 0.926 | 31.8 | 18.5 |

| 2-2 | 4.3–11.5 | 26.8 | 44.3 | 17.5 | 1.251 | 43.2 | 17.1 |

| 2-3 | 11.5–16 | 21.0 | 39.2 | 18.2 | 0.731 | 24.5 | 19.3 |

| 2-4 | 16–17.4 | 20.1 | 33.2 | 13.1 | 0.741 | 24.7 | 19.1 |

| 2-5 | 17.4–24 | 20.1 | 36.2 | 16.1 | 0.697 | 23.5 | 19.5 |

| Layer Name | Scope of Depth (m) | Thermal Conductivity (W m−1 K−1) | Specific Heat Capacity (J kg−1 K−1) | Thermal Diffusivity (mm2/s) | Density (g/cm3) |

|---|---|---|---|---|---|

| 2-1 | 1.8–4.3 | 1.37 | 885 | 0.84 | 1.89 |

| 2-2 | 4.3–11.5 | 1.15 | 877 | 0.77 | 1.74 |

| 2-3 | 11.5–13.5 | 1.54 | 918 | 0.87 | 1.97 |

| 2-3 | 13.5–16 | 1.71 | 934 | 0.95 | 1.97 |

| 2-4 | 16–17.4 | 1.35 | 843 | 0.84 | 1.95 |

| 2-5 | 17.4–24 | 1.30 | 775 | 0.86 | 1.99 |

| Material Name | Thermal Conductivity (W m−1 K−1) | Specific Heat Capacity (J kg−1 K−1) | Density (kg/m3) |

|---|---|---|---|

| PHC | 1.78 | 800 | 2490 |

| HDPE pipe a | 0.42 | 2300 | 957 |

| Circulating fluid (water) | kw [38] | Cpw [38] | ρw [38] |

| Case | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Thermal conductivity of backfill soil in PHC pile (W m−1 K−1) | 1 | 2 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Specific heat capacity of backfill soil in PHC pile (J kg−1 K−1) | 1200 | 1200 | 1200 | 1200 | 800 | 1600 | 1200 | 1200 | 1200 | 1200 |

| Initial ground temperature (°C) | FT | FT | FT | FT | FT | FT | FT-3 | FT + 3 | FT | FT |

| Thermal conductivity of the ground (W m−1 K−1) | FT | FT | FT | FT | FT | FT | FT | FT | FT + 0.5 | FT + 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Cao, Z.; Liu, Y.; Chen, J. Field Test and Numerical Simulation on the Long-Term Thermal Response of PHC Energy Pile in Layered Foundation. Sensors 2021, 21, 3873. https://doi.org/10.3390/s21113873

Zhang G, Cao Z, Liu Y, Chen J. Field Test and Numerical Simulation on the Long-Term Thermal Response of PHC Energy Pile in Layered Foundation. Sensors. 2021; 21(11):3873. https://doi.org/10.3390/s21113873

Chicago/Turabian StyleZhang, Guozhu, Ziming Cao, Yiping Liu, and Jiawei Chen. 2021. "Field Test and Numerical Simulation on the Long-Term Thermal Response of PHC Energy Pile in Layered Foundation" Sensors 21, no. 11: 3873. https://doi.org/10.3390/s21113873

APA StyleZhang, G., Cao, Z., Liu, Y., & Chen, J. (2021). Field Test and Numerical Simulation on the Long-Term Thermal Response of PHC Energy Pile in Layered Foundation. Sensors, 21(11), 3873. https://doi.org/10.3390/s21113873