Ankle Angle Prediction Using a Footwear Pressure Sensor and a Machine Learning Technique

Abstract

1. Introduction

2. Materials and Methods

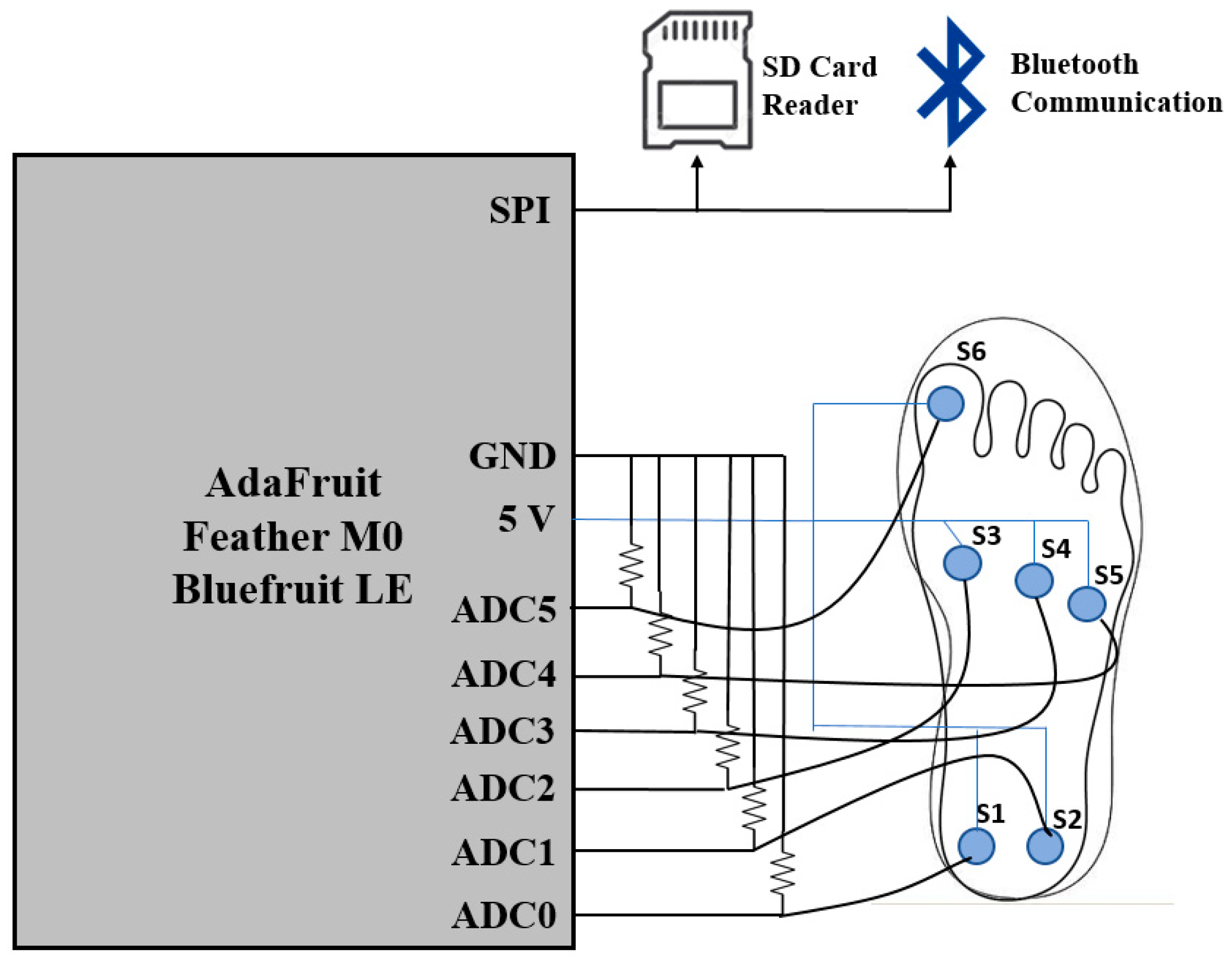

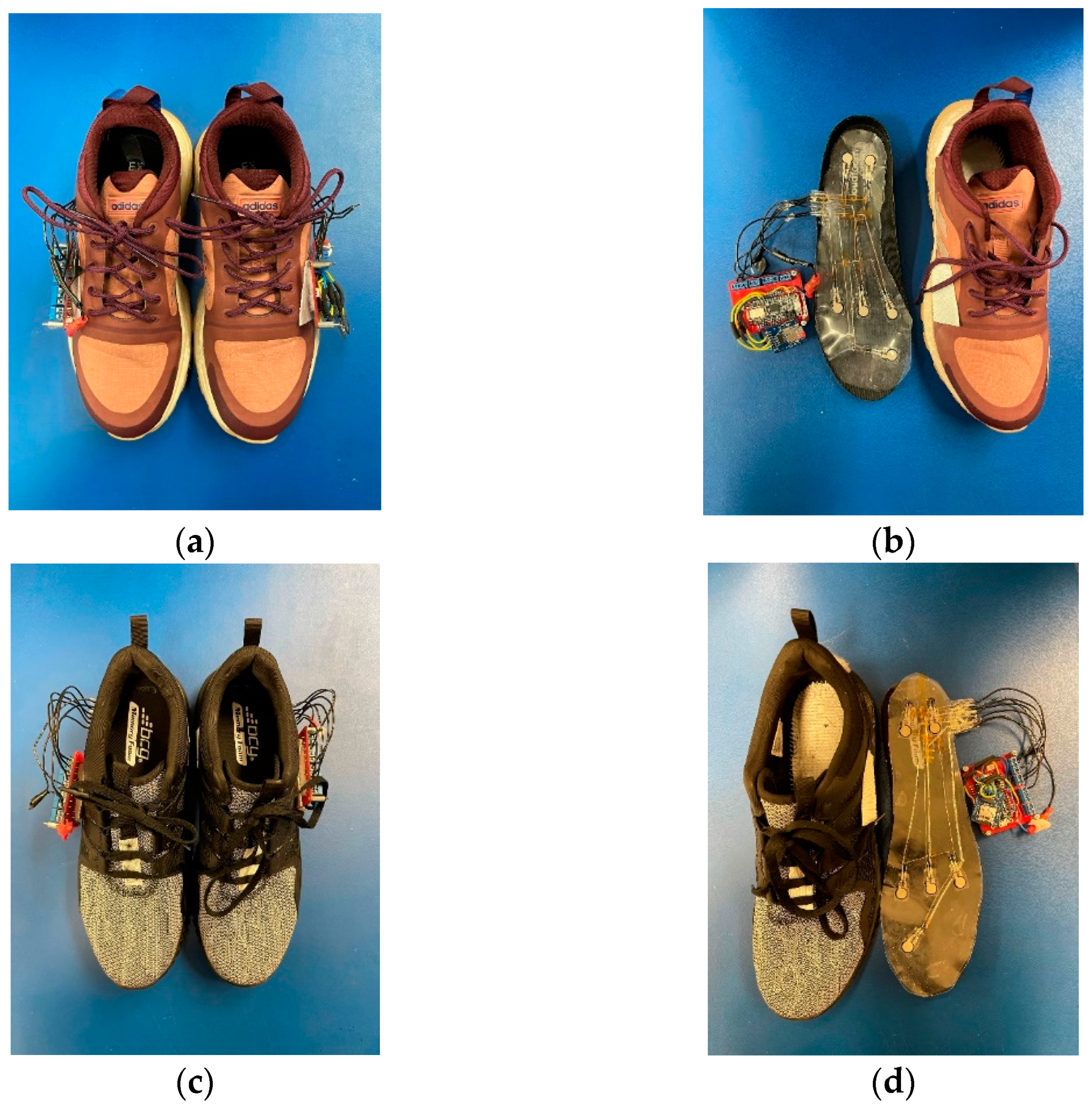

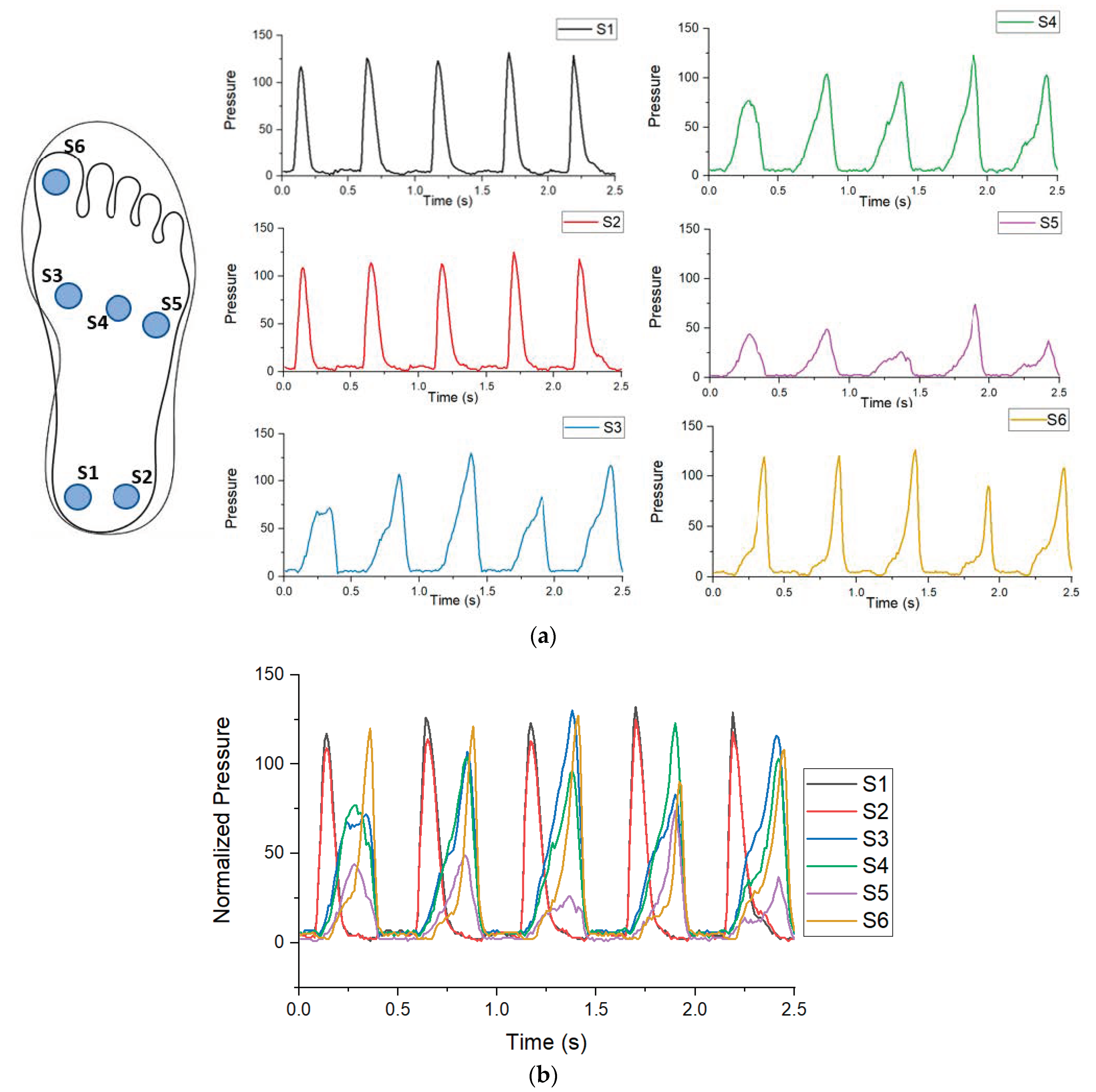

2.1. Insole Pressure Sensor System

2.2. Motion Capture for Reference Data

2.3. Data Collection

2.3.1. Sensor Synchronization

2.3.2. Data Collection

2.4. Experimental Procedure

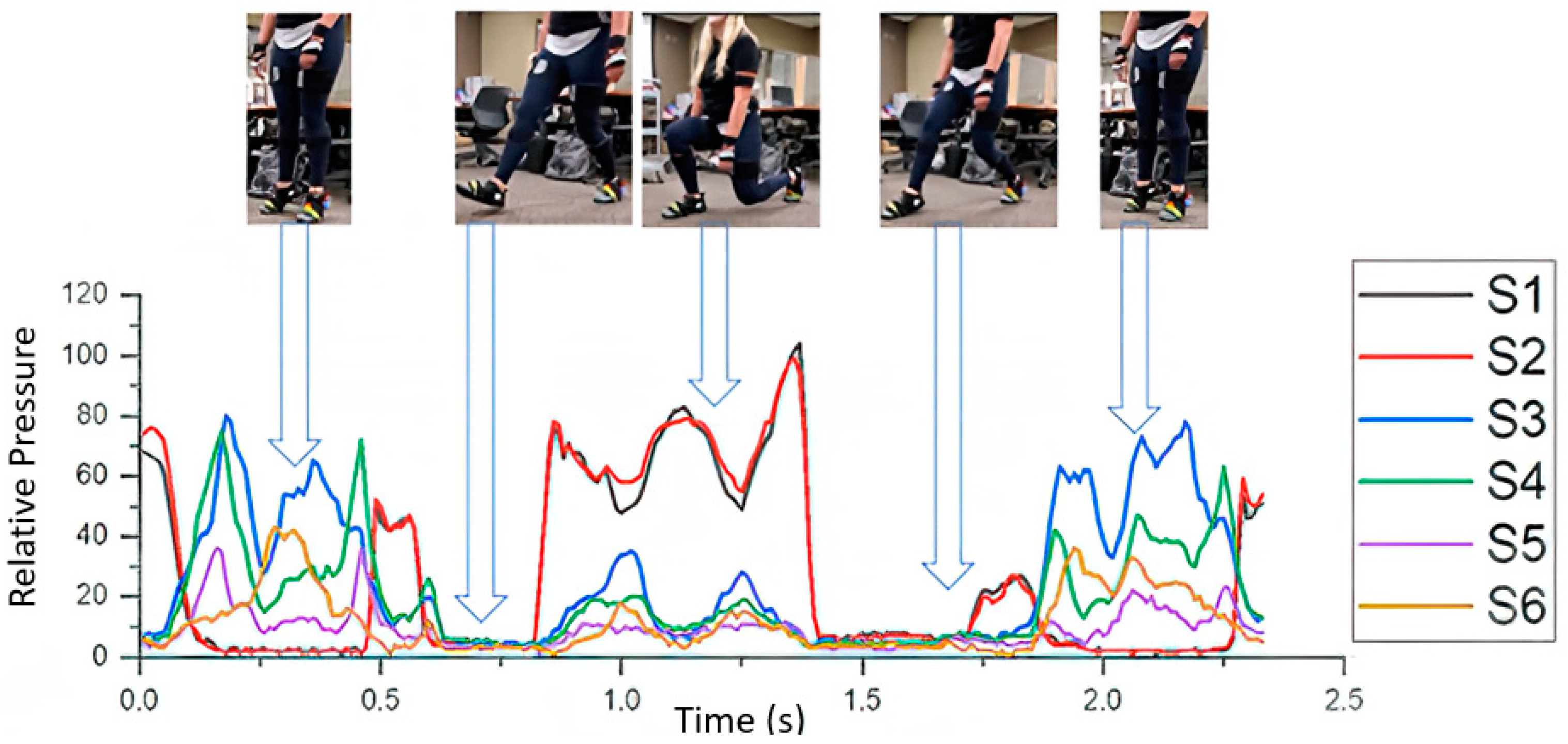

2.5. Movement Description

2.5.1. Movement Rationale

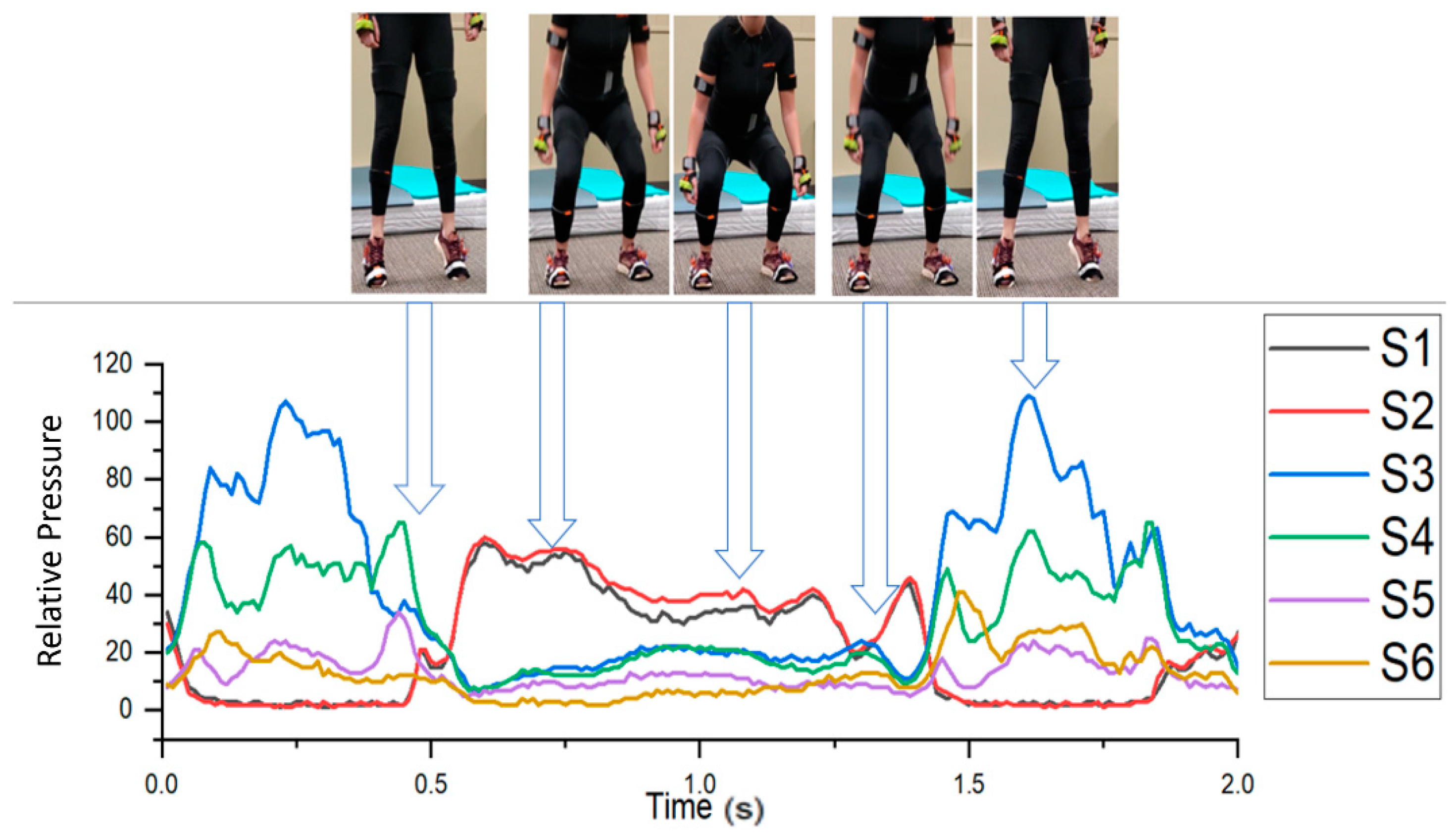

2.5.2. Squat

2.5.3. Stoop

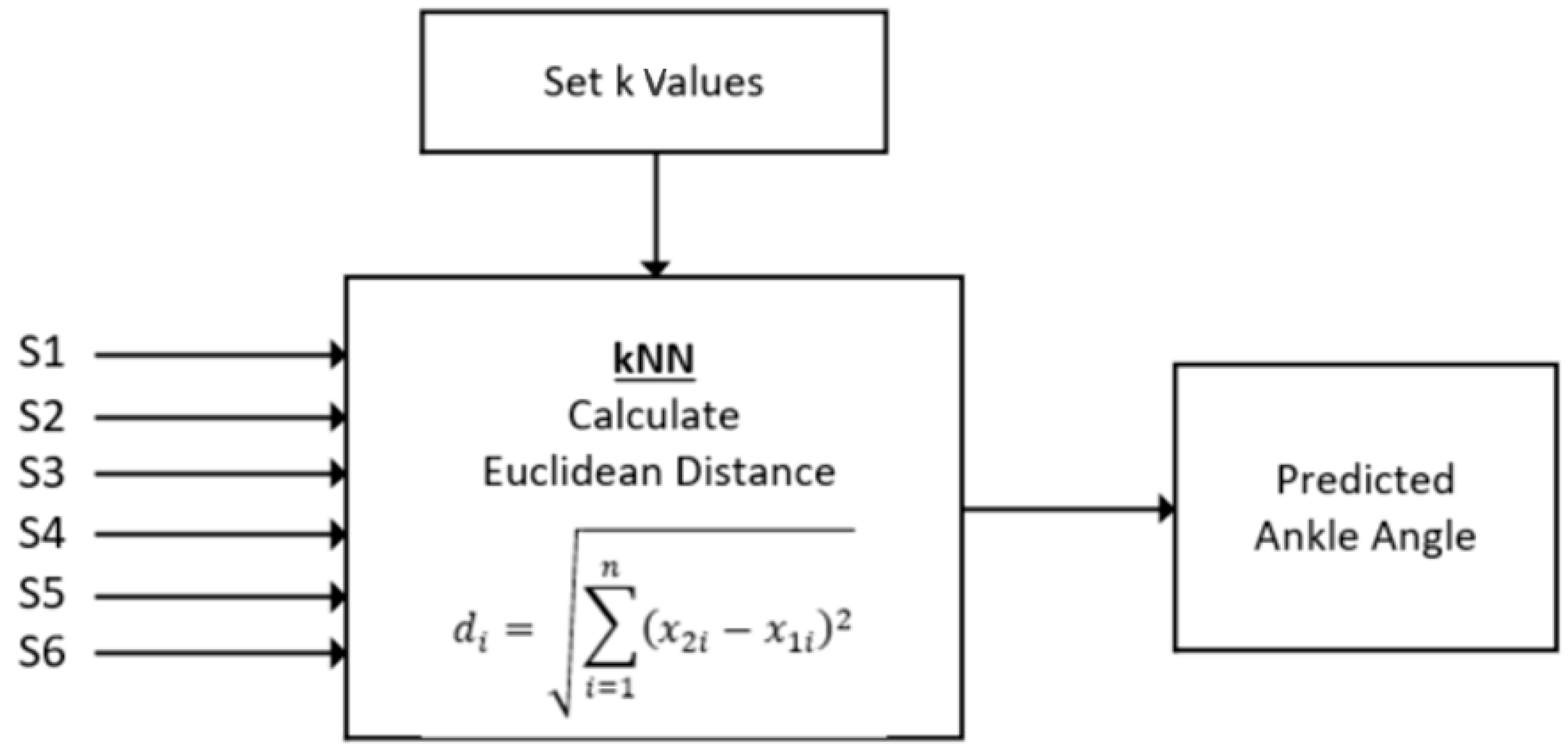

2.6. Machine Learning to Predict Ankle Angles

3. Results

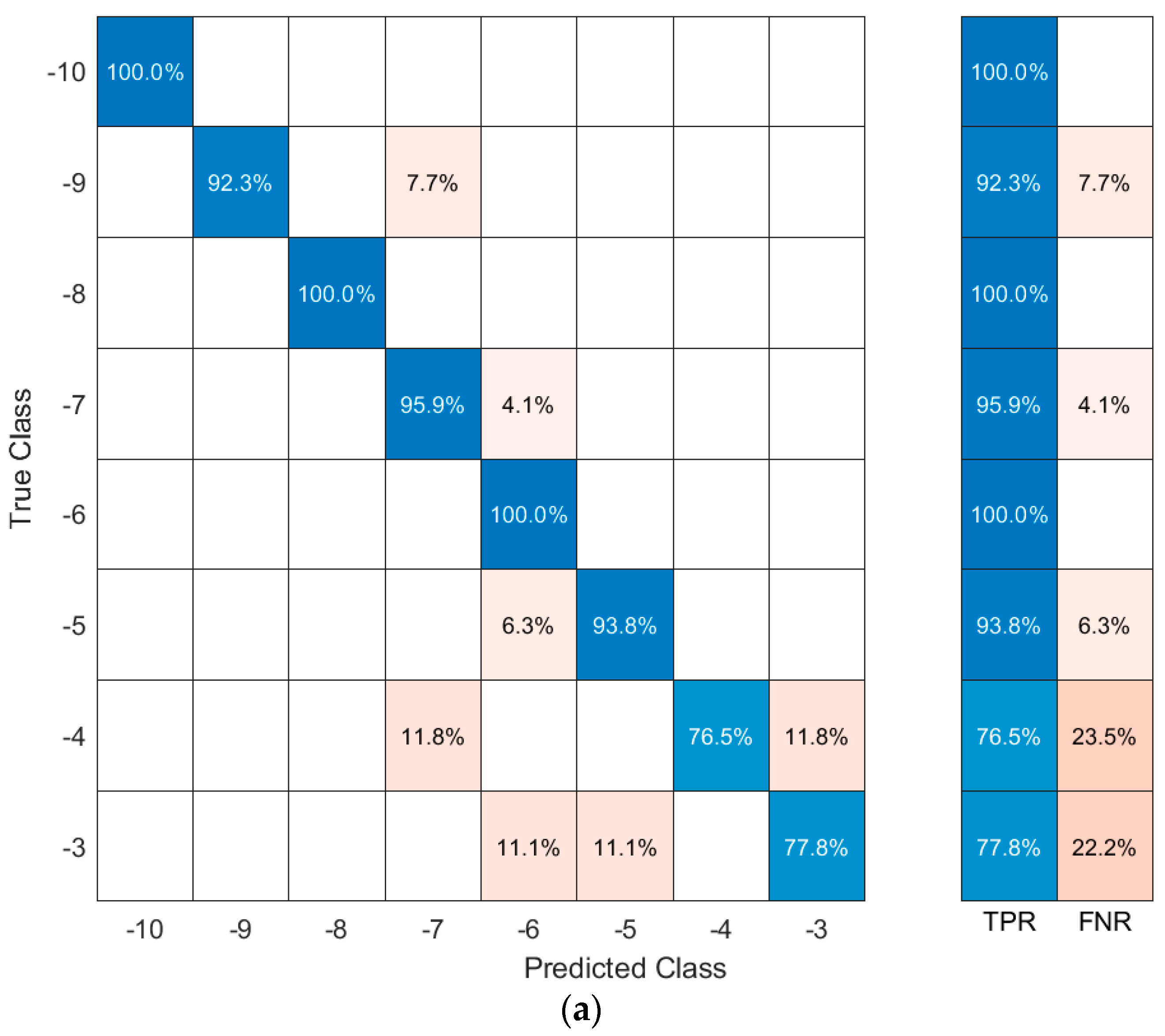

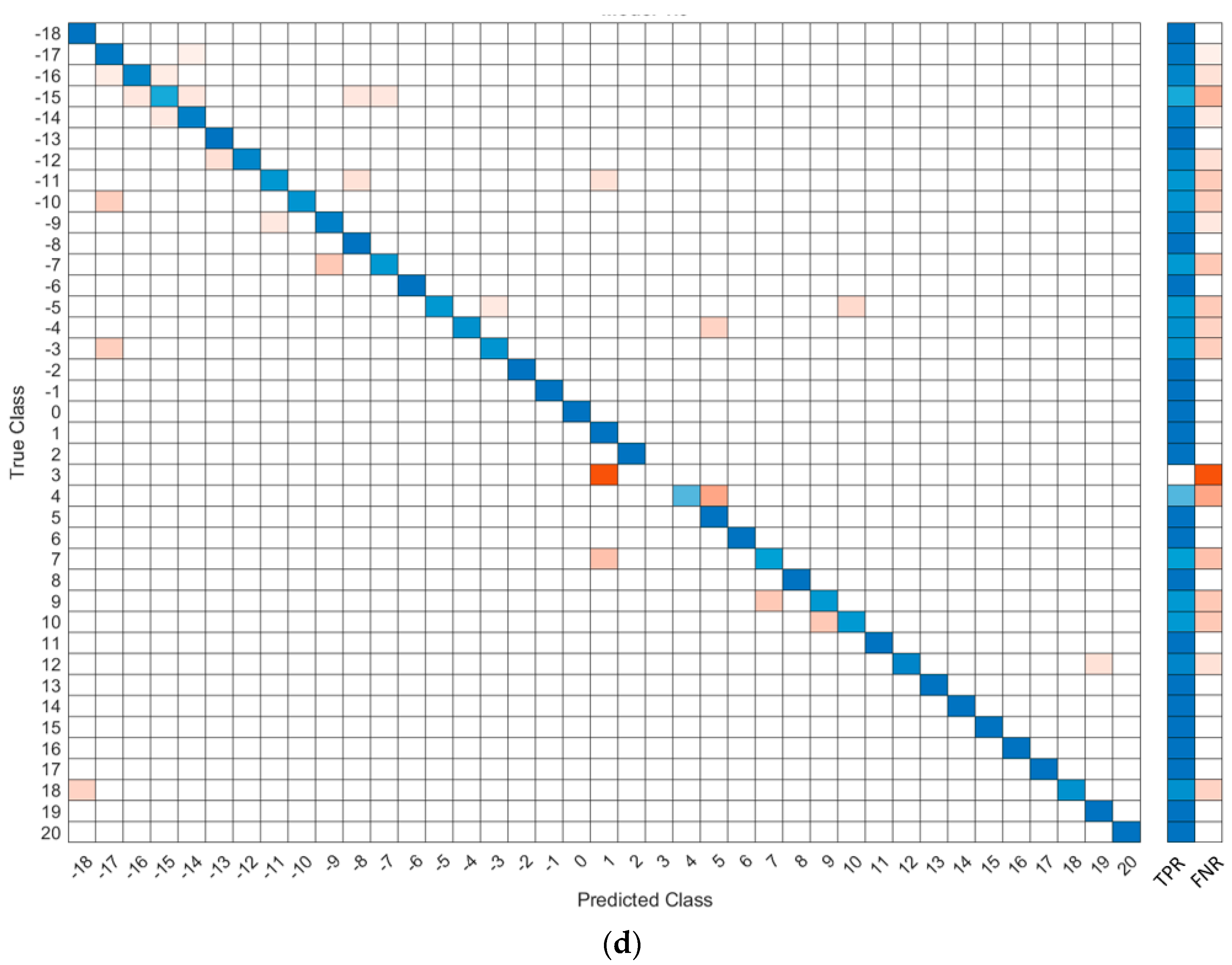

3.1. Machine Learning Result

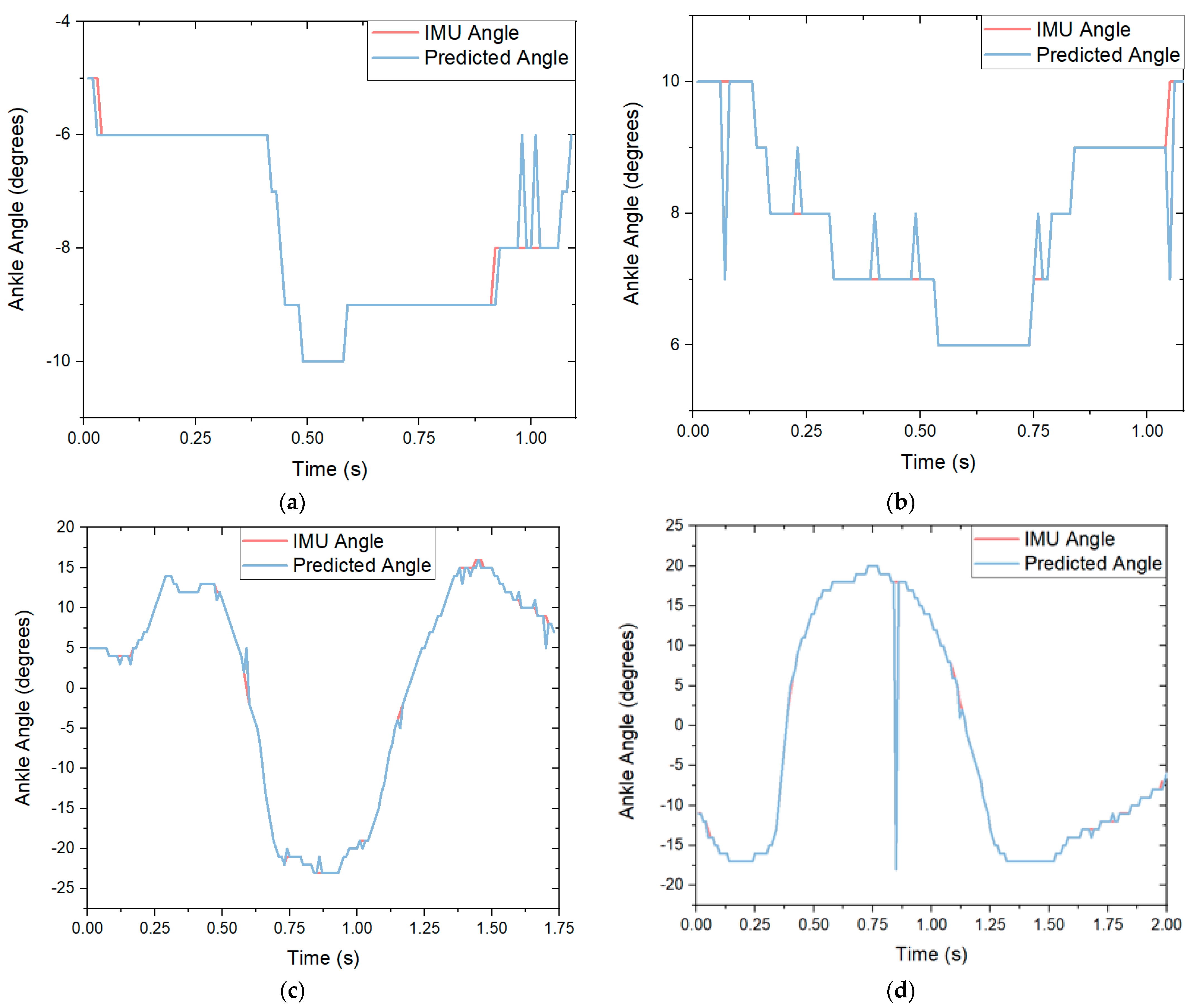

3.2. Predicting the Angle of a Movement

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Statistics, B.o.L. Injuries, Illnesses, and Fatalities. Available online: https://www.bls.gov/web/osh/cd_eh1.htm (accessed on 18 May 2021).

- Caughman, A.; Gross, C.E. A Detailed Analysis of Workplace Foot and Ankle Injuries. Foot Ankle Orthop. 2020, 5, 2473011420S2473000156. [Google Scholar] [CrossRef]

- Winter, D.A. Biomechanics and Motor Control of Human Movement; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2009; Volume 370. [Google Scholar]

- Menz, H.B.; Dufour, A.B.; Riskowski, J.L.; Hillstrom, H.J.; Hannan, M.T. Foot posture, foot function and low back pain: The Framingham Foot Study. Rheumatology 2013, 52, 2275–2282. [Google Scholar] [CrossRef] [PubMed]

- Castro-Méndez, A.; Munuera, P.V.; Albornoz-Cabello, M. The short-term effect of custom-made foot orthoses in subjects with excessive foot pronation and lower back pain: A randomized, double-blinded, clinical trial. Prosthet. Orthot. Int. 2013, 37, 384–390. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Singh, H.; Godiyal, A.K. Wearable knee joint angle measurement system based on force sensitive resistors. In Proceedings of the 2018 IEEE Long Island Systems, Applications and Technology Conference (LISAT), Farmingdale, NY, USA, 4 May 2018; pp. 1–3. [Google Scholar]

- Fathima, S.M.H.S.S.; Banu, R.S.D.W. Human gait recognition based on motion analysis including ankle to foot angle measurement. In Proceedings of the 2012 International Conference on Computing, Electronics and Electrical Technologies (ICCEET), Nagercoil, India, 21–22 March 2012; pp. 1133–1136. [Google Scholar]

- Pilkar, R.B.; Moosbrugger, J.C.; Bhatkar, V.V.; Schilling, R.J.; Storey, C.M.; Robinson, C.J. A Biomechanical Model of Human Ankle Angle Changes Arising From Short Peri-Threshold Anterior Translations of Platform on Which a Subject Stands. In Proceedings of the 2007 29th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Lyon, France, 22–26 August 2007; pp. 4308–4311. [Google Scholar]

- Yonezawa, T.; Onodera, T.; Ding, M.; Mizoguchi, H.; Takemura, H.; Ogitsu, T. Development of three-dimensional motion measuring device for the human ankle joint by using parallel link mechanism. In Proceedings of the 2014 36th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Chicago, IL, USA, 26–30 August 2014; pp. 4358–4361. [Google Scholar]

- Saito, H.; Watanabe, T.; Arifin, A. Ankle and knee joint angle measurements during gait with wearable sensor system for rehabilitation. In World Congress on Medical Physics and Biomedical Engineering, Munich, Germany, 7–12 September 2009; Springer: Berlin/Heidelberg, Germany, 2009; pp. 506–509. [Google Scholar]

- Miyatake, T.; Lee, S.; Galiana, I.; Rossi, D.M.; Siviy, C.; Panizzolo, F.A.; Walsh, C.J. Biomechanical analysis and inertial sensing of ankle joint while stepping on an unanticipated bump. In Wearable Robotics: Challenges and Trends; Springer: Cham, Germany, 2017; pp. 343–347. [Google Scholar]

- Sun, T.; Li, H.; Liu, Q.; Duan, L.; Li, M.; Wang, C.; Liu, Q.; Li, W.; Shang, W.; Wu, Z.; et al. Inertial Sensor-Based Motion Analysis of Lower Limbs for Rehabilitation Treatments. J. Healthc. Eng. 2017. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Liu, Q.; Li, W.; Lu, Z.; Chen, H.; Chen, P.; Lu, Z.; Wei, C.; Hou, A.; Wang, C.; et al. Hip, knee and ankle motion angle detection based on inertial sensor. In Proceedings of the 2016 IEEE International Conference on Information and Automation (ICIA), Ningbo, China, 1–3 August 2016; pp. 1612–1617. [Google Scholar]

- Rosenberg, Z.S.; Beltran, J.; Bencardino, J.T. MR Imaging of the Ankle and Foot. RadioGraphics 2000, 20, S153–S179. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Kim, K.; Sharma, N. Prediction of Ankle Dorsiflexion Moment by Combined Ultrasound Sonography and Electromyography. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Vasarhelyi, A.; Lubitz, J.; Gierer, P.; Gradl, G.; Rösler, K.; Hopfenmüller, W.; Klaue, K.; Mittlmeier, T.W. Detection of fibular torsional deformities after surgery for ankle fractures with a novel CT method. Foot Ankle Int. 2006, 27, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- Dey, S.; Eslamy, M.; Yoshida, T.; Ernst, M.; Schmalz, T.; Schilling, A. A support vector regression approach for continuous prediction of ankle angle and moment during walking: An implication for developing a control strategy for active ankle prostheses. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 727–733. [Google Scholar]

- Pei, Y.A.-O.; Yang, W.; Wei, S.; Cai, R.; Li, J.; Guo, S.; Li, Q.A.-O.; Wang, J.; Li, X. Automated measurement of hip-knee-ankle angle on the unilateral lower limb X-rays using deep learning. Phys. Eng. Sci. Med. 2021, 44, 53–62. [Google Scholar] [CrossRef] [PubMed]

- Wei, T.-S.; Liu, P.-T.; Chang, L.-W.; Liu, S.-Y. Gait asymmetry, ankle spasticity, and depression as independent predictors of falls in ambulatory stroke patients. PLoS ONE 2017, 12, e0177136. [Google Scholar] [CrossRef] [PubMed]

- Matijevich, E.S.; Scott, L.R.; Volgyesi, P.; Derry, K.H.; Zelik, K.E. Combining wearable sensor signals, machine learning and biomechanics to estimate tibial bone force and damage during running. Hum. Mov. Sci. 2020, 74, 102690. [Google Scholar] [CrossRef] [PubMed]

- Gholami, M.; Ejupi, A.; Rezaei, A.; Ferrone, A.; Menon, C. Estimation of Knee Joint Angle Using a Fabric-Based Strain Sensor and Machine Learning: A Preliminary Investigation. In Proceedings of the 2018 7th IEEE International Conference on Biomedical Robotics and Biomechatronics (Biorob), Enschede, The Netherlands, 26–29 August 2018; pp. 589–594. [Google Scholar]

- Svensson, W.; Holmberg, U. Ground angle estimator from an ankle foot orthosis based on strain sensing and Fourier series. In Proceedings of the 2008 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 5–8 August 2008; pp. 203–206. [Google Scholar]

- Song, K.; Chu, J.; Park, S.E.; Hwang, D.; Youn, I. Ankle-Angle Estimation from Blind Source Separated Afferent Activity in the Sciatic Nerve for Closed-Loop Functional Neuromuscular Stimulation System. IEEE Trans. Biomed. Eng. 2017, 64, 834–843. [Google Scholar] [CrossRef] [PubMed]

- Huihui, C.; Farong, G.; Chao, C.; Taixing, T. Estimation of Ankle Angle Based on Multi-Feature Fusion with Random Forest. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 5549–5553. [Google Scholar]

- Tekscan. FlexiForce A301 Sensor. Available online: https://www.tekscan.com/products-solutions/force-sensors/a301 (accessed on 3 March 2021).

- Adafruit. Adafruit Feather M0 Bluefruit LE. Available online: https://www.adafruit.com/product/2995 (accessed on 22 April 2021).

- Mickle, K.; Munro, B.; Lord, S.; Menz, H.; Steele, J. Foot shape of older people: Implications for shoe design. Footwear Sci. 2010, 2, 131–139. [Google Scholar] [CrossRef]

- Nguyen, N.D.; Bui, D.T.; Truong, P.H.; Jeong, G. Classification of Five Ambulatory Activities Regarding Stair and Incline Walking Using Smart Shoes. IEEE Sens. J. 2018, 18, 5422–5428. [Google Scholar] [CrossRef]

- Fix, E.; Hodges, J.L. Discriminatory Analysis. Nonparametric Discrimination: Consistency Properties. Int. Stat. Rev. Rev. Int. Stat. 1989, 57, 238–247. [Google Scholar] [CrossRef]

- Zeblok. Wifi Smart Shoes. Available online: https://docs.zeblok.com/scientific/WIFI-smart-shoes.php# (accessed on 18 May 2021).

| Subject | Sex | Age | Height | Weight | Shoe Size |

|---|---|---|---|---|---|

| 1 | Female | 21 | 5′3″ | 120 | 8.5 |

| 2 | Female | 21 | 5′4″ | 185 | 8.5 |

| 3 | Female | 21 | 5′7” | 130 | 10.5 |

| 4 | Female | 21 | 5′7” | 135 | 8.5 |

| 6 | Male | 21 | 5′11” | 180 | 10.5 |

| 7 | Female | 21 | 5′9″ | 170 | 10.5 |

| 8 | Female | 21 | 5′8″ | 125 | 8.5 |

| 9 | Female | 21 | 5′4″ | 165 | 8.5 |

| 10 | Male | 21 | 6′1″ | 170 | 10.5 |

| 11 | Female | 20 | 5′7″ | 140 | 8.5 |

| 12 | Male | 24 | 5′10″ | 185 | 10.5 |

| 13 | Male | 21 | 5′11″ | 170 | 10.5 |

| 14 | Female | 20 | 5′7″ | 170 | 8.5 |

| 15 | Female | 29 | 5′3″ | 145 | 8.5 |

| 16 | Male | 23 | 5′10″ | 175 | 10.5 |

| 17 | Male | 21 | 6′1″ | 150 | 10.5 |

| 18 | Female | 21 | 5′4″ | 150 | 8.5 |

| 19 | Female | 23 | 5′5″ | 155 | 8.5 |

| 20 | Male | 19 | 6′1″ | 135 | 10.5 |

| 21 | Male | 21 | 5′8″ | 160 | 10.5 |

| 23 | Female | 22 | 5′8″ | 150 | 8.5 |

| 24 | Male | 22 | 5′11″ | 145 | 10.5 |

| 25 | Female | 22 | 5′4″ | 165 | 8.5 |

| 26 | Female | 21 | 5′10″ | 135 | 8.5 |

| Movement | Foot | Angle Range | Accuracy |

|---|---|---|---|

| Squat | Left | −10 to −3 | 93.6% |

| Squat | Right | 6 to 13 | 93.8% |

| Right Stoop | Left | −27 to 17 | 89.5% |

| Left Stoop | Right | −20 to 20 | 87.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choffin, Z.; Jeong, N.; Callihan, M.; Olmstead, S.; Sazonov, E.; Thakral, S.; Getchell, C.; Lombardi, V. Ankle Angle Prediction Using a Footwear Pressure Sensor and a Machine Learning Technique. Sensors 2021, 21, 3790. https://doi.org/10.3390/s21113790

Choffin Z, Jeong N, Callihan M, Olmstead S, Sazonov E, Thakral S, Getchell C, Lombardi V. Ankle Angle Prediction Using a Footwear Pressure Sensor and a Machine Learning Technique. Sensors. 2021; 21(11):3790. https://doi.org/10.3390/s21113790

Chicago/Turabian StyleChoffin, Zachary, Nathan Jeong, Michael Callihan, Savannah Olmstead, Edward Sazonov, Sarah Thakral, Camilee Getchell, and Vito Lombardi. 2021. "Ankle Angle Prediction Using a Footwear Pressure Sensor and a Machine Learning Technique" Sensors 21, no. 11: 3790. https://doi.org/10.3390/s21113790

APA StyleChoffin, Z., Jeong, N., Callihan, M., Olmstead, S., Sazonov, E., Thakral, S., Getchell, C., & Lombardi, V. (2021). Ankle Angle Prediction Using a Footwear Pressure Sensor and a Machine Learning Technique. Sensors, 21(11), 3790. https://doi.org/10.3390/s21113790