Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting

Abstract

1. Introduction

2. Literature Review

2.1. Multisource Data Fusion Framework Based on DT

2.2. Security Risk Coupling Analysis

2.3. Research Gap

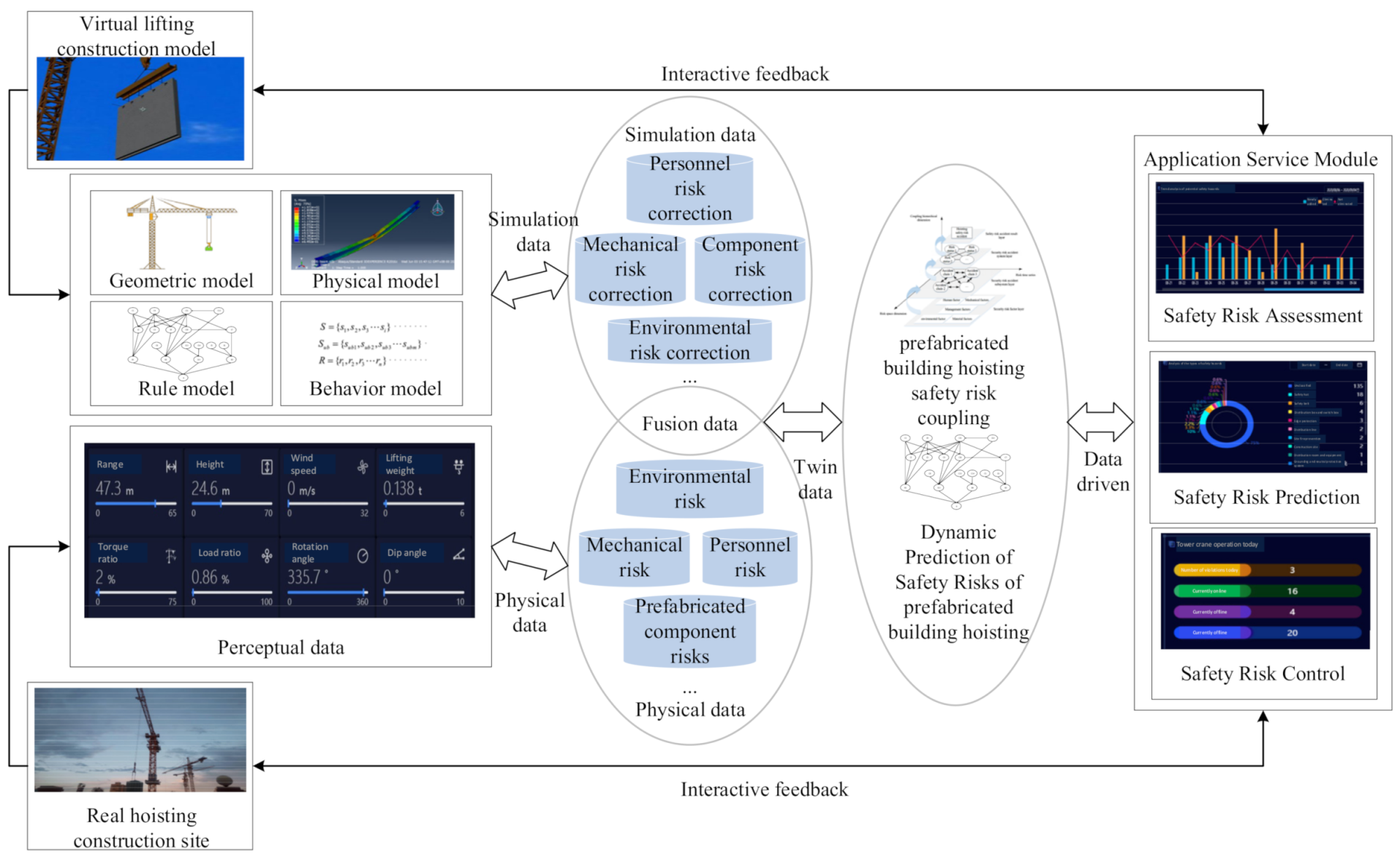

3. Framework for DT-Based Safety Risk Management of Prefabricated Building Hoisting

3.1. Framework Overview

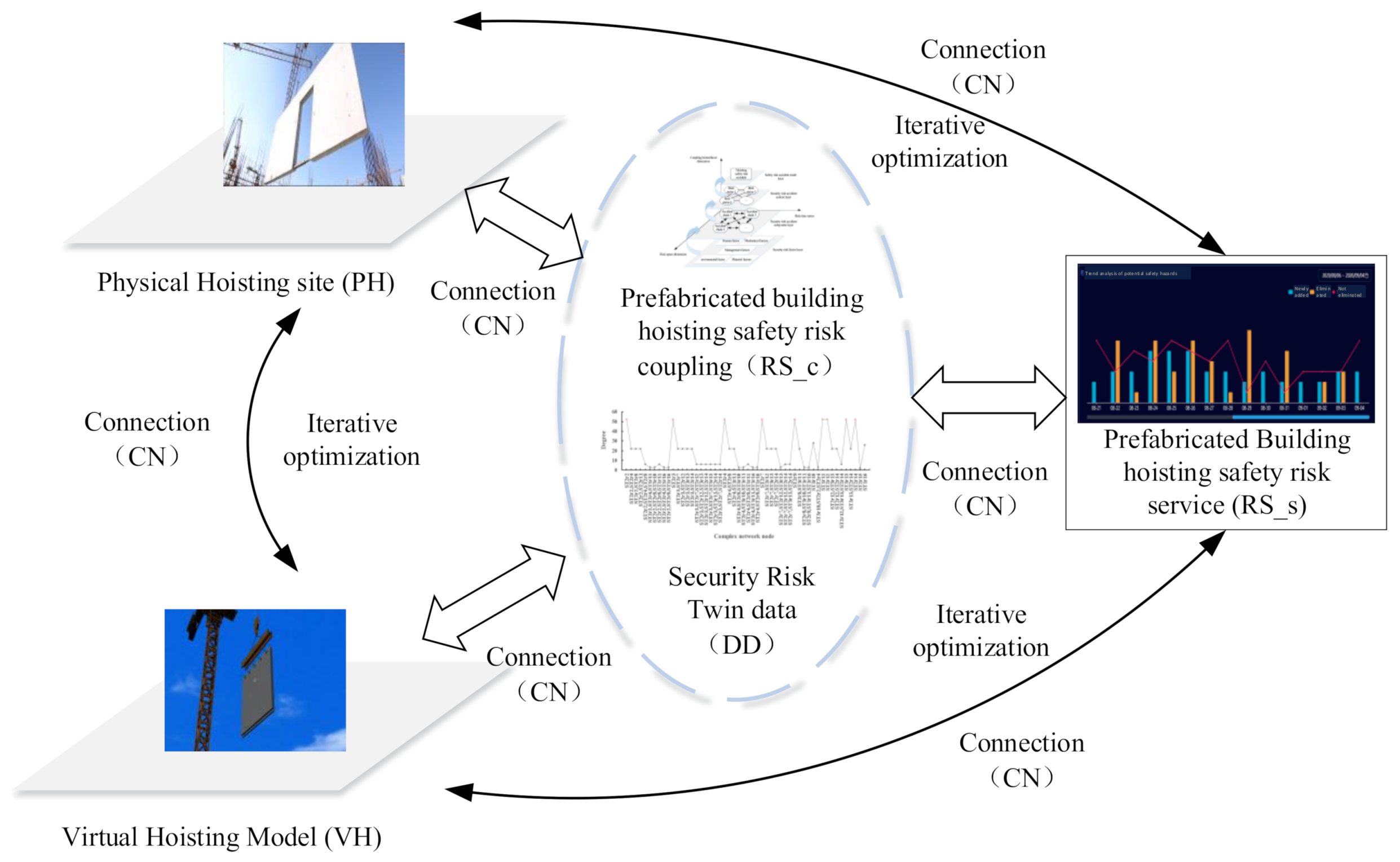

3.2. DT-Based Safety Risk Coupling Model

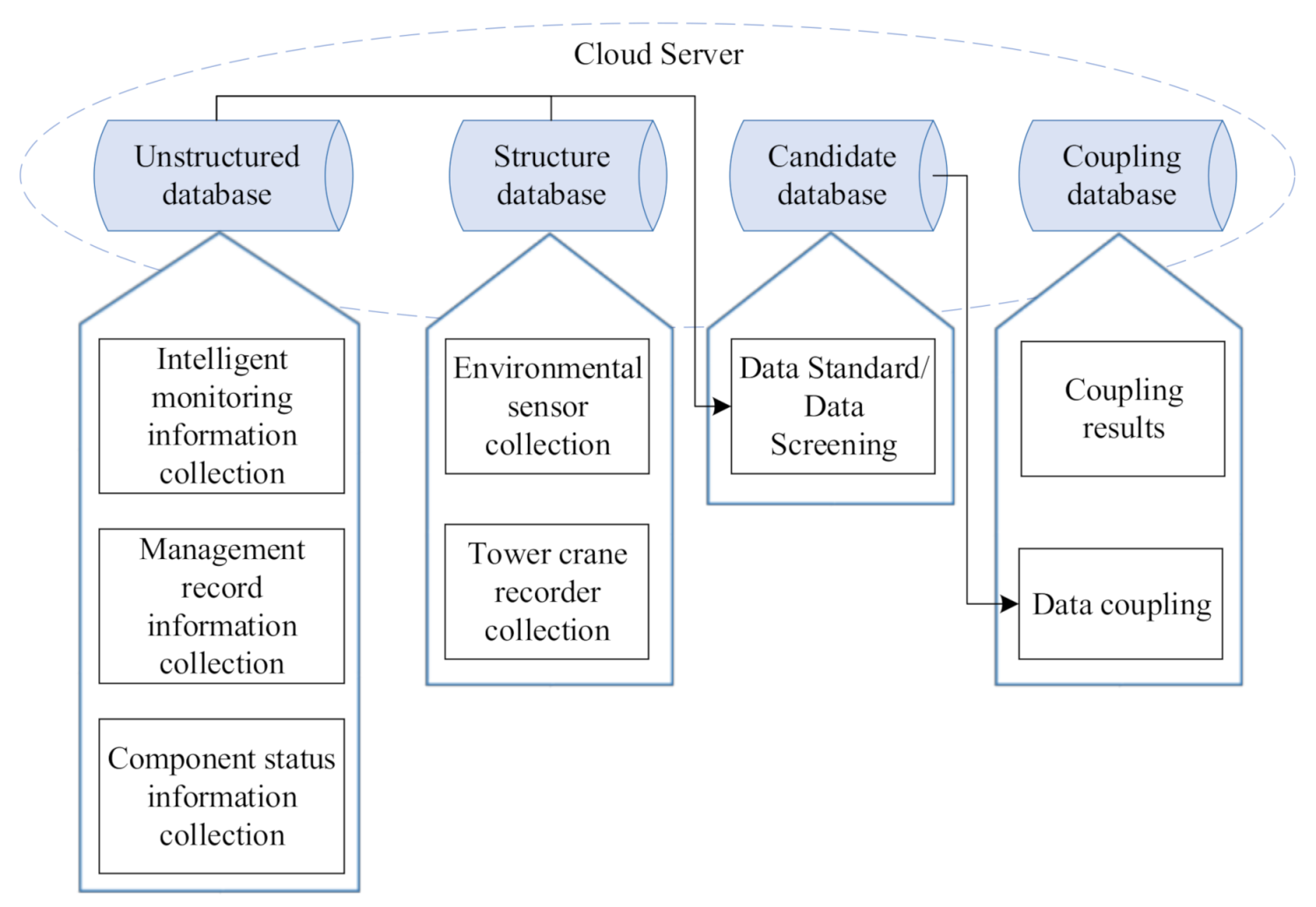

3.3. Perception and Interaction of Data

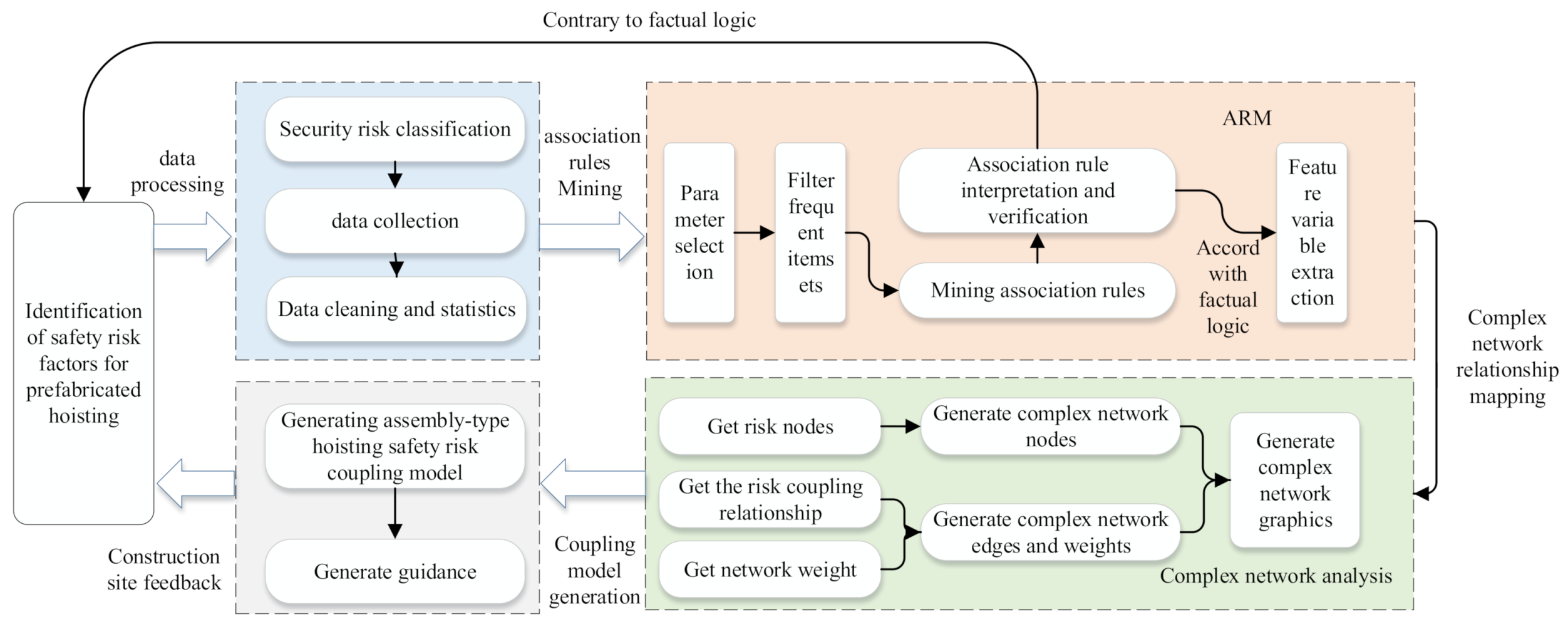

4. Safety Risk Coupling Analysis Method of Prefabricated Building Hoisting

4.1. Safety Risk Coupling Mechanism

- (1)

- (2)

- (3)

4.2. Security Risk Coupling Analysis

4.2.1. Data Processing

- (1)

- Risk factor status classification

- (2)

- Risk classification

4.2.2. Association Rules Mining

4.2.3. Complex Network Analysis

5. Case Study

5.1. Project Background

5.2. Framework Implementation

5.2.1. Data Preparation

5.2.2. Construction of Coupling Model

- (1)

- Data mining

- (2)

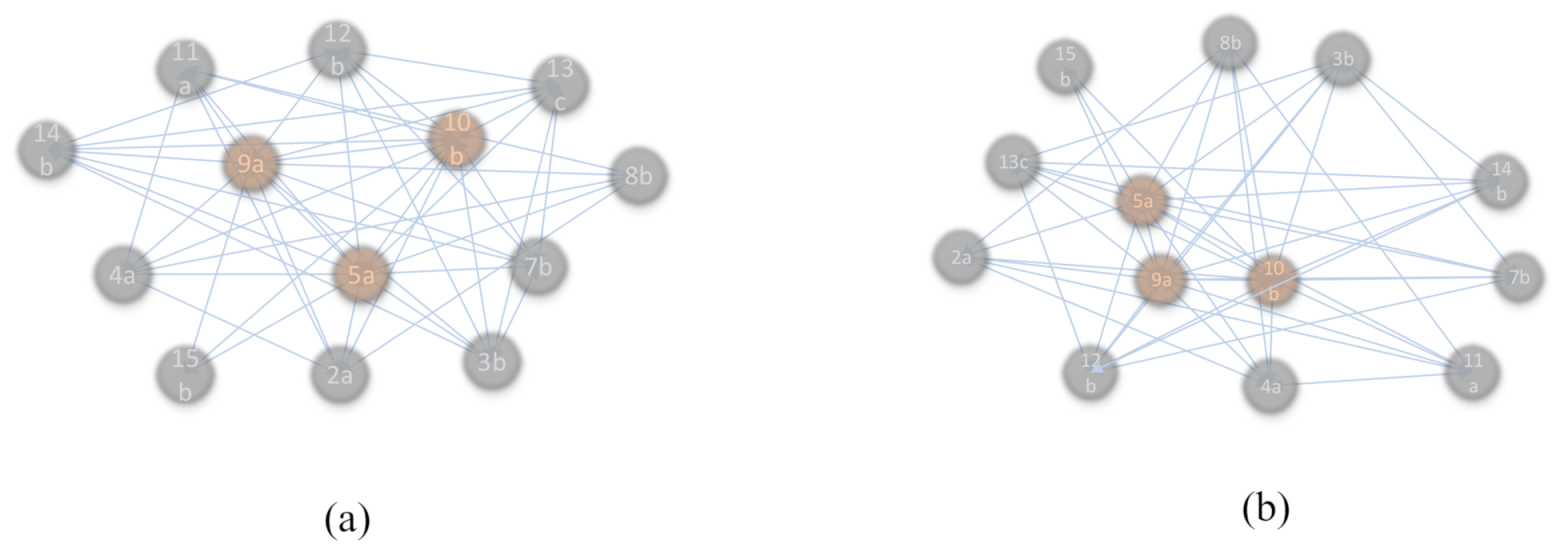

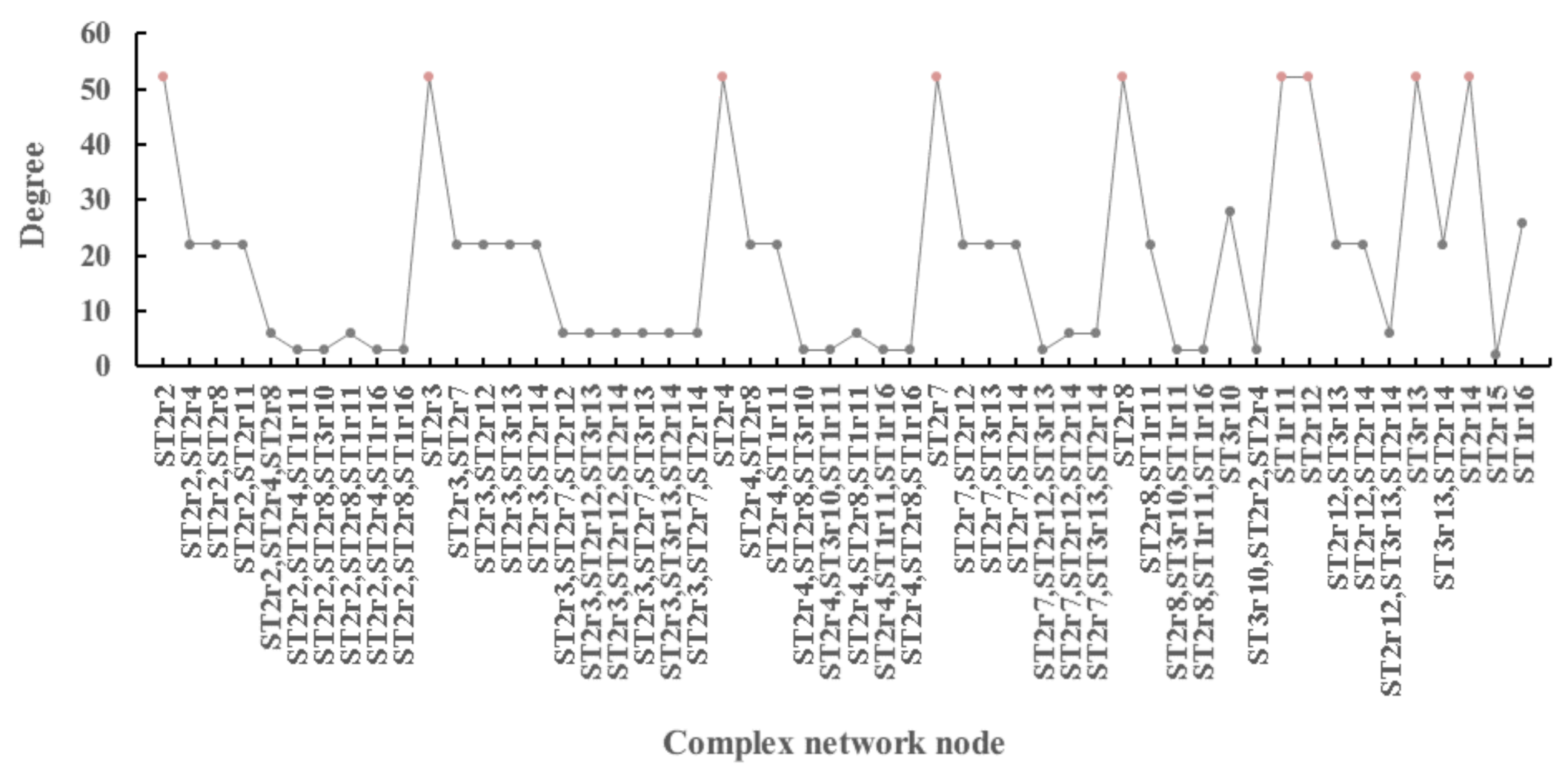

- Complex network establishment

5.2.3. On-Site Construction Guidance

6. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, J.R.; Zhang, J.P.; Zhang, X.Y.; Hu, Z.Z. Automating closed-loop structural safety management for bridge construction through multisource data integration. Adv. Eng. Softw. 2019, 128, 152–168. [Google Scholar] [CrossRef]

- Maryam, M.F.; Seyyed, A.T.; Charles, J.K.; Hamed, H. Safety concerns related to modular/prefabricated building construction. Safety concerns related to modular/prefabricated building construction. Int. J. Inj. Control Saf. Promot. 2017, 24, 10–23. [Google Scholar]

- Baniassadi, F.A.; Mostafavi, A. A simulation-based framework for concurrent safety and productivity improvement in construction projects. Constr. Arch. Manag. 2018, 25, 1501–1515. [Google Scholar] [CrossRef]

- Rajguru, A.; Mahatme, P. Effective techniques in cost optimization of construction project: A review. Int. Res. Eng. Technol. 2015, 4, 464–469. [Google Scholar]

- Ding, L.Y.; Zhou, C. Development of web-based system for safety risk early warning in urban metro construction. Autom. Constr. 2013, 34, 45–55. [Google Scholar] [CrossRef]

- Gunduz, M.; Laitinen, H. Construction safety risk assessment with introduced control levels. J. Civ. Eng. Manag. 2018, 24, 11–18. [Google Scholar] [CrossRef]

- Zou, Y.; Kiviniemi, A.; Jones, S.W. A review of risk management through BIM and BIM-related technologies. Saf. Sci. 2017, 97, 88–98. [Google Scholar] [CrossRef]

- Hu, S.; Corry, E.; Horrigan, M. Building Performance Evaluation using OpenMath and Linked Data. Energy Build. 2018, 174, 484–494. [Google Scholar] [CrossRef]

- Dave, B.; Buda, A.; Nurminen, A.; Frmling, K. A framework for integrating BIM and IoT through open standards. Autom. Constr. 2018, 95, 35–45. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Alruqi, W.M.; Hallowell, M.R. Critical success factors for construction safety: Review and meta-analysis of safety leading indicators. Constr. Eng. Manag. 2019, 145, 1–11. [Google Scholar] [CrossRef]

- Gabriel, R.; Aviad, S.; Barak, F. AHP-based analysis of the risk potential of safety incidents: Case study of cranes in the construction industry. Saf. Sci. 2014, 91, 298–309. [Google Scholar]

- Dai, H.; Cao, Z. A Wavelet Support Vector Machine-Based Neural Network Metamodel for Structural Reliability Assessment. Comput.-Aided Civ. Inf. 2017, 32, 334–357. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, C.; Zhou, C.; Luo, H. Using bayesian network for safety risk analysis of diaphragm wall deflection based on field data. Reliab. Eng. Syst. Saf. 2018, 180, 152–167. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Kahlen, F.J., Flumerfelt, S., Alves, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Xu, H.; Huang, Z.; et al. Digital twin five-dimensional model and its ten major applications. Comput. Integr. Manuf. Syst. 2019, 25, 1–18. [Google Scholar]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A. Digital twin drieven progonostics and health management for complex equipment. CIRP Ann. Manuf. Technol. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Xie, X.; Schooling, J.M. Developing a dynamic digital twin at building and city levels: A case study of the West Cambridge campus. J. Manag. Eng. 2019, 36, 1–19. [Google Scholar]

- Liu, Z.; Zhang, A.; Wang, W.; Wang, J. Digital twin-driven dynamic evacuation method for winter Olympic stadium fire safety. J. Tongji Univ. Nat. Sci. Ed. 2020, 48, 962–971. [Google Scholar]

- Liu, Z.; Bai, W.; Du, X.; Zhang, A.; Xing, X.; Jiang, A.; Jin, J. Digital Twin-based Safety Evaluation of Prestressed Steel Structure. Adv. Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Dongmin, L.; Sang, H.L.; Neda, M.; Krishnan, M.S.; Victor, C.L. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 1–9. [Google Scholar]

- Pan, Y.; Zhang, L. A BIM-data mining integrated digital twin framework for advanced project management. Autom. Constr. 2021, 124, 1–15. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Q.; Hu, Z.; Lin, J.; Yu, F. A multi-server information-sharing environment for cross-party collaboration on a private cloud. Autom. Constr. 2017, 81, 180–195. [Google Scholar] [CrossRef]

- Chen, K.; Lu, W.; Peng, Y.; Rowlinson, S.; Huang, G.Q. Bridging BIM and building: From a literature review to an integrated conceptual framework. Int. J. Proj. Manag. 2015, 33, 1405–1416. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An internet of things-enabled bim platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, F.; Ding, L.; Hu, Z. Development and Implementation of an Industry Foundation Classes—Based Graphic Information Model for Virtual Construction. Comput. Aided Civ. Infrastruct. Eng. 2013, 29, 60–74. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction. Autom. Constr. 2021, 126, 1–12. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, C.; Su, H.; Arafin, M.T.; Qu, G. Voltage Over-scaling-based Lightweight Authentication for IoT Security. IEEE Trans. Comput. 2021. [Google Scholar] [CrossRef]

- Li, A.; Spano, D.; Krivochiza, J.; Domouchtsidis, S.; Tsinos, C.G.; Masouros, C.; Ottersten, B. A Tutorial on Interference Exploitation via Symbol-Level Precoding: Overview, State-of-the-Art and Future Directions. IEEE Commun. Surv. Tutor. 2020, 22, 796–839. [Google Scholar] [CrossRef]

- Li, B.; Liang, R.; Zhou, W.; Yin, H.; Cai, K. Lbs meets blockchain:an efficient method with security preserving trust in SAGIN. IEEE Internet Things J. 2021. [Google Scholar] [CrossRef]

- Niu, Z.; Zhang, B.; Wang, J.; Liu, K.; Chen, Z.; Yang, K.; Liu, Y. The research on 220 GHz multicarrier high-speed communication system. China Commun. 2020, 17, 131–139. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Xu, Z.; Wu, X.; Shi, W. Experimental Investigation and Error Analysis of High Precision FBG Displacement Sensor for Structural Health Monitoring. Int. J. Struct. Stab. Dyn. 2020, 20, 1–17. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, Y.; Zhang, T. Research on the formation mechanism of coupled disaster risk. J. Nat. Disasters 2013, 22, 44–50. [Google Scholar]

- Zhang, J.; Xu, K.; Wang, B.; Wang, Y.; Wang, R. Study on the evolution mechanism of gas explosion accident risk coupling. Chin. Saf. Sci. J. 2016, 26, 81–85. [Google Scholar]

- Zhang, J.; Xu, K.; You, G.; Wang, B.; Zhao, L. Causation Analysis of Risk Coupling of Gas Explosion Accident in Chinese Underground Coal Mines. Risk Anal. 2019, 39, 1634–1646. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Xiang, P.; Jia, F.; Liu, Z. Risk Assessment of High-Speed Rail Projects: A Risk Coupling Model Based on System Dynamics. Int. J. Environ. Res. Public Health 2020, 17, 5307. [Google Scholar] [CrossRef] [PubMed]

- Abhishek, V.; Sudha, D.K.; Maiti, J.; Krishna, O.B. Identifying patterns of safety related incidents in a steel plant using association rule mining of incident investigation reports. Saf. Sci. 2014, 70, 89–98. [Google Scholar]

- Xu, R.; Luo, F. Risk prediction and early warning for air traffic controllers’ unsafe acts using association rule mining and random forest. Saf. Sci. 2021, 135, 105–125. [Google Scholar] [CrossRef]

- Lin, C.W.; Hong, T.P.; Lan, G.C.; Wong, J.W.; Lin, W.Y. Efficient updating of discovered high-utility itemsets for transaction deletion in dynamic databases. Adv. Eng. Inform. 2015, 29, 16–27. [Google Scholar] [CrossRef]

- Aqra, I.; Abdul Ghani, N.; Maple, C.; Machado, J.; Sohrabi Safa, N. Incremental algorithm for association rule mining under dynamic threshold. Appl. Sci. 2019, 9, 5398. [Google Scholar] [CrossRef]

- Wen, Q.; Zhang, J.P.; Hu, Z.Z.; Xiang, X.S.; Shi, T. A data-driven approach to improve the operation and maintenance management of large public buildings. IEEE Access 2019, 7, 176127–176140. [Google Scholar] [CrossRef]

- Zhou, C.; Kong, T.; Jiang, S.; Chen, S.; Zhou, Y.; Ding, L. Quantifying the evolution of settlement risk for surrounding environments in underground construction via complex network analysis. Tunn. Undergr. Space Technol. 2020, 103, 1–17. [Google Scholar] [CrossRef]

- Pastén, D.; Torres, F.; Toledo, B.; Muñoz, V.; Rogan, J.; Valdivia, J. Non-universal critical exponents in earthquake complex networks. Physica A 2018, 491, 445–452. [Google Scholar] [CrossRef]

- Zhou, C.; Ding, L. Safety barrier warning system for underground construction sites using Internet-of-Things technologies. Autom. Constr. 2017, 83, 372–389. [Google Scholar] [CrossRef]

- Zhou, C.; Luo, H.; Fang, W.; Wei, R.; Ding, L. Cyber-physical-system-based safety monitoring for blind hoisting with the internet of things: A case study. Autom. Constr. 2019, 97, 138–150. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, K.; Wang, Y.; Wang, B. Risk Coupling Analysis of Gas Explosion Accident. J. Northeast. Univ. Nat. Sci. Ed. 2017, 38, 414–417. [Google Scholar]

- Zhou, H.; Yang, Q.; Yang, Z.; Chen, C.; Ji, M. Analysis and control of tower crane safety risk factors based on complex network and N-K model. J. Saf. Environ. 2020, 20, 816–823. [Google Scholar]

- Thai, H.-T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Shen, L.; Tang, Y.; Mou, Y. Safety evaluation of prefabricated residential component hoisting based on Cloud-BN. Chin. Saf. Sci. J. 2019, 29, 147–153. [Google Scholar]

- Zhou, Y.; Li, C.; Ding, L.; Sekula, P.; Love, P.; Zhou, C. Combining Association Rules Mining with Complex Networks to Monitor Coupled Risks. Reliab. Eng. Syst. Saf. 2019, 186, 194–208. [Google Scholar] [CrossRef]

| Number | Level | Coding | Specific Risk Indicators | Coding |

|---|---|---|---|---|

| 1 | Security incident layer | Lifting safety accident | ||

| 2 | Hoisting safety risk accident system layer | General risk ; high risk ; extremely high risk | ||

| 3 | Lifting safety risk accident subsystem layer | Human factor accident chain; management factor accident chain; environmental factor accident chain; mechanical factor accident chain; material factor accident chain | ||

| 4 | Security risk factor layer | Technical level of operators ; operational violations by operators ; safety protection wearing status ; percentage of people participating in safety clarification ; sling inclination ; quality level of prefabricated components ; actual service life of hoisting machinery ; wear rate of hoisting equipment ; speed ; acceleration ; prefabrication rate ; cross-interference situation of tower crane operation ; actual load ratio ; construction safety management level of hoisting site ; security measures cost investment ratio ; wind speed of hoisting construction site ; layout of prefabricated components storage yard |

| Risk Indicators | ||

|---|---|---|

| Operational violations by operators () | Compliance | Illegal operation |

| Safety protection wearing status () | Complete | Missing accessories |

| Cross-interference situation of tower crane operation () | Uncrossed | Cross |

| Risk Indicators | |||

|---|---|---|---|

| Technical level of operators () | Good | General | Poor |

| Quality level of prefabricated components ( ) | Good | Qualified | Unqualified |

| Construction safety management level of hoisting site () | Good | General | Poor |

| Layout of prefabricated components storage yard () | Good | General | Poor |

| Risk Indicators | |||

|---|---|---|---|

| Percentage of people participating in safety clarification (/%) | [90, 100) | [60, 90) | [0, 60) |

| Sling inclination (/°) | [30, 40) | [40, 50) | [50, 60) |

| Actual service life of hoisting machinery (/a) | [0, 5) | [5, 10) | [10, 20) |

| Wear rate of hoisting equipment ( /%) | [0, 10) | [10, 40) | [40, 50) |

| Speed (/m·s−1) | [0, 40) | [40, 60) | [60, 80) |

| Acceleration (/m·s−2) | [0, 0.015) | [0.015, 0.025) | [0.025, 0.045) |

| Prefabrication rate (/%) | [0, 30) | [30, 50) | [50, 100) |

| Actual load ratio ( /%) | [0, 80) | [80, 100) | [100, 150) |

| Security measures cost investment ratio ( /%) | [3, 5) | [1.5, 3) | [0, 1.5) |

| Wind speed of hoisting construction site (/m·s−1) | [0, 7.9) | [7.9, 10.8) | [10.8, 16) |

| Risk Accident Level | |||

|---|---|---|---|

| Normalized value | [0, 0.243) | [0.243, 13.275) | [13.275, 17) |

| Risk Indicators | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Record the Moment | ||||||||||||||

| Moment 1 | 1 | 1 | 1 | 1 | 1 | |||||||||

| Moment 2 | 1 | 1 | 1 | 1 | 1 | |||||||||

| Moment 3 | 1 | 1 | 1 | 1 | 1 | |||||||||

| Number | Left | Right | ||

|---|---|---|---|---|

| 1 | {Higher acceleration, illegal operation, poorer ratio of personnel participating in safety confession} | → | {} | 1.7994 |

| 2 | {Higher acceleration, average prefabrication rate, poor hoisting equipment wears} | → | {} | 1.7893 |

| 3 | {Higher acceleration, illegal operation, poor hoisting equipment wears} | → | {} | 1.756 |

| 4 | {High wind speed, illegal operation, poorer ratio of personnel participating in safety confession} | → | {} | 1.7508 |

| 5 | {High wind speed, poorer ratio of personnel participating in safety confession, poor hoisting equipment wears} | → | {} | 1.7428 |

| 6 | {High wind speed, higher acceleration} | → | {} | 1.7393 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Meng, X.; Xing, Z.; Jiang, A. Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors 2021, 21, 3583. https://doi.org/10.3390/s21113583

Liu Z, Meng X, Xing Z, Jiang A. Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors. 2021; 21(11):3583. https://doi.org/10.3390/s21113583

Chicago/Turabian StyleLiu, Zhansheng, Xintong Meng, Zezhong Xing, and Antong Jiang. 2021. "Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting" Sensors 21, no. 11: 3583. https://doi.org/10.3390/s21113583

APA StyleLiu, Z., Meng, X., Xing, Z., & Jiang, A. (2021). Digital Twin-Based Safety Risk Coupling of Prefabricated Building Hoisting. Sensors, 21(11), 3583. https://doi.org/10.3390/s21113583