Instrumental Odour Monitoring System Classification Performance Optimization by Analysis of Different Pattern-Recognition and Feature Extraction Techniques

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. IOMS Technology and Data Acquisition

2.3. Odour Classification Monitoring Model (OCMM) Elaboration

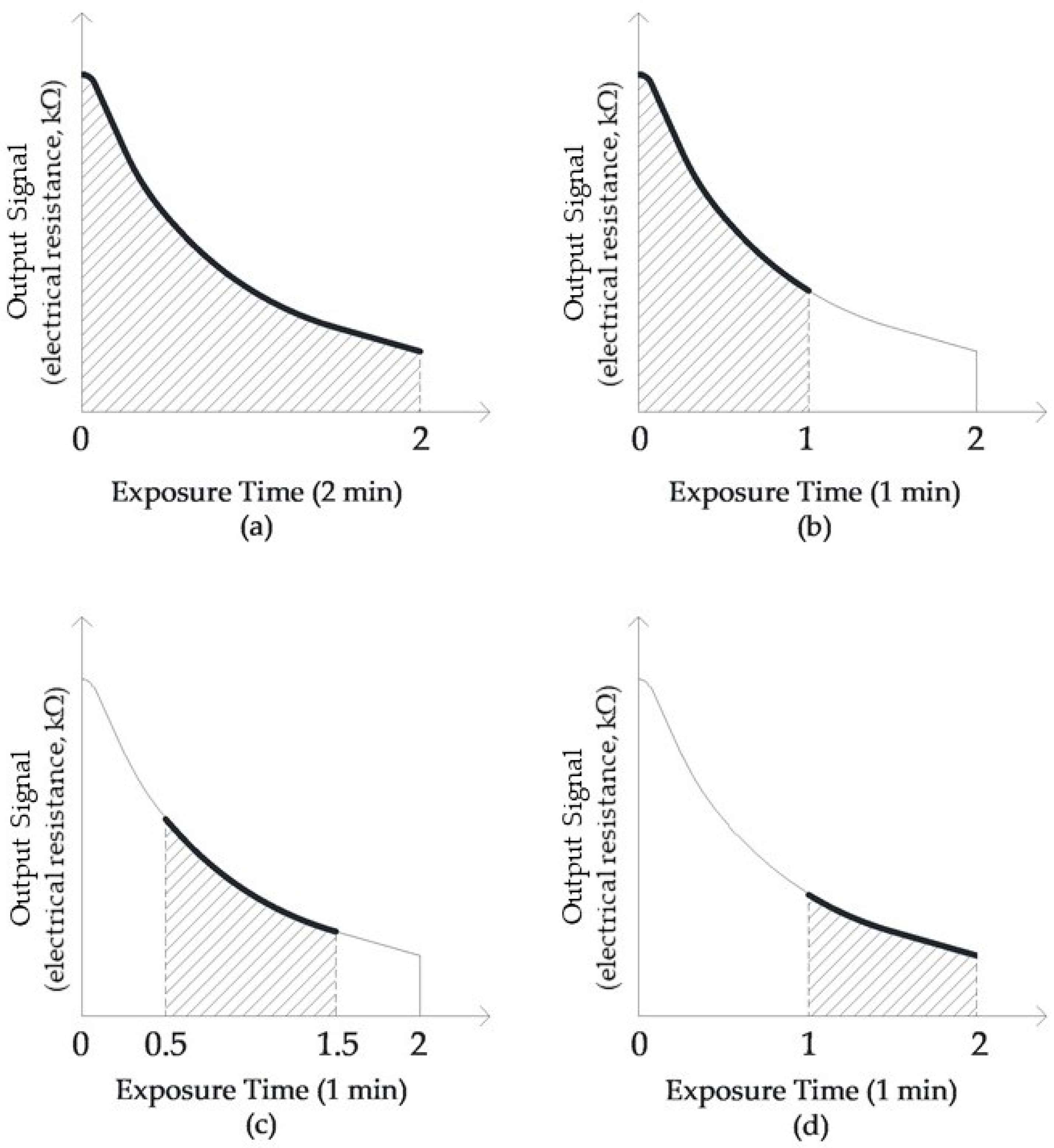

2.3.1. Data Acquisition

2.3.2. Data Reduction

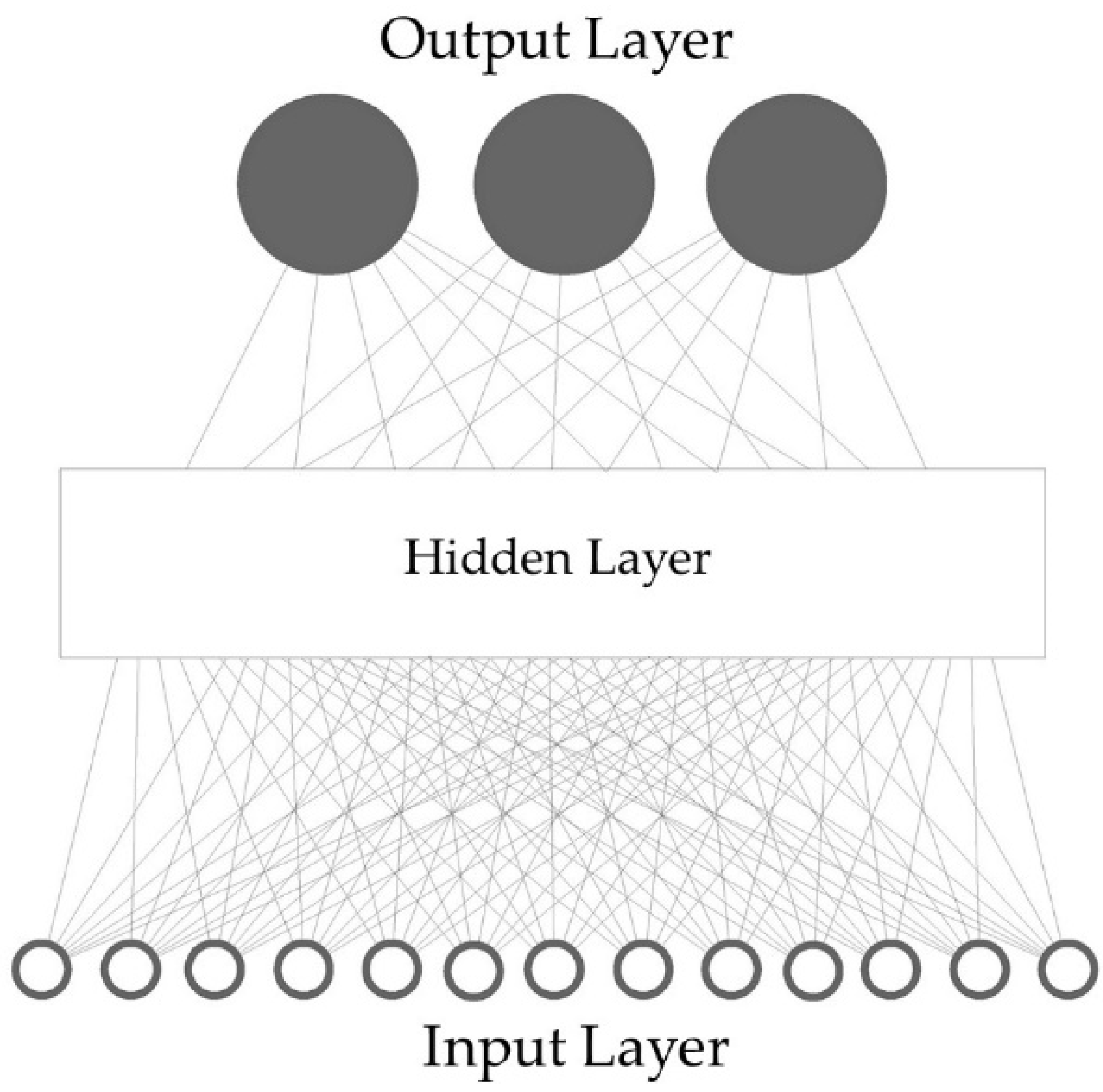

2.3.3. Pattern-Recognition Algorithms

2.3.4. Training and Validation datasets

2.4. Statistical Analysis

2.5. Comparison Studies

3. Results

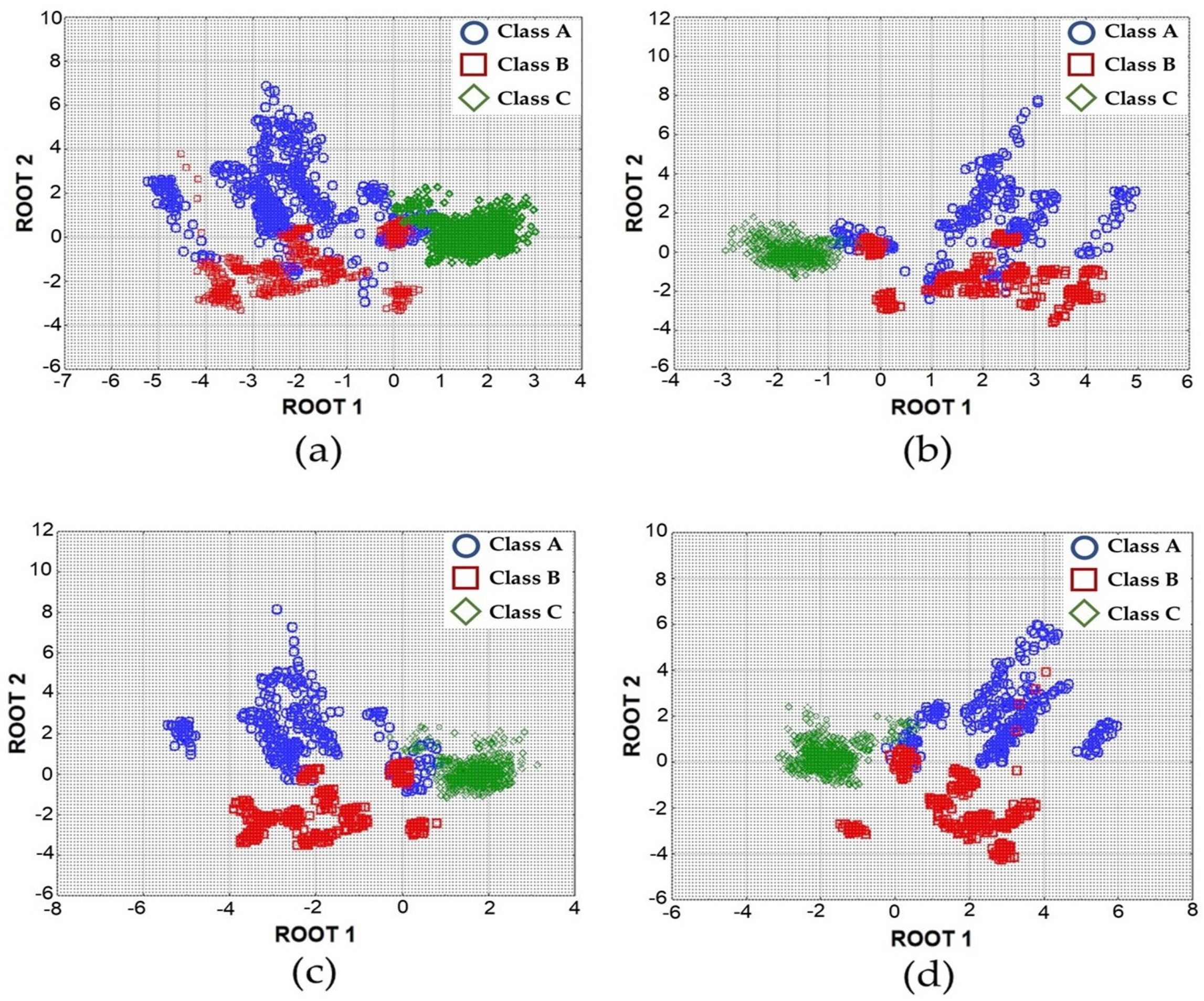

3.1. OCMMs Using Different Extracted Signals and LDA Application

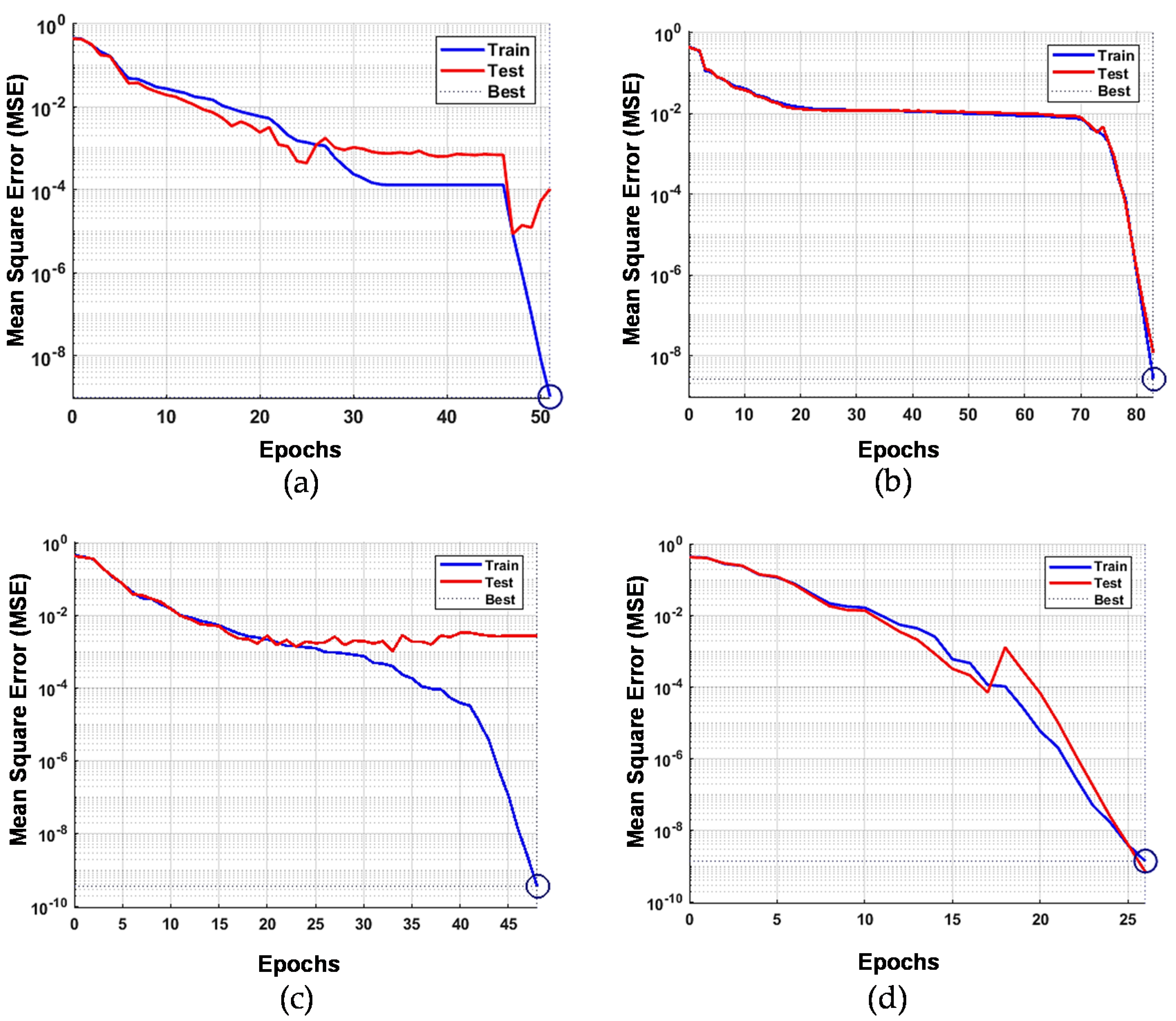

3.2. OCMMs Using Different Extracted Signals and ANN Application

3.3. Comparison Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giuliani, S.; Zarra, T.; Nicolas, J.; Naddeo, V.; Belgiorno, V.; Romain, A.C. An alternative approach of the E-Nose Training Phase in odour Impact Assessment. Chem. Eng. Trans. 2012, 30, 139–144. [Google Scholar]

- Capelli, L.; Sironi, S.; Centola, P.; Del Rosso, R.; Il Grande, M. Electronic noses for the continuous monitoring of odours from a wastewater treatment plant at specific receptors: Focus on training methods. Sens. Actuators B Chem. 2008, 131, 53–62. [Google Scholar] [CrossRef]

- Brattoli, M.; De Gennaro, G.; De Pinto, V.; Demarinis Loiotile, A.; Lovascio, S.; Penza, M. Odour Detection Methods: Olfactory and Chemical Sensors. Sensors 2011, 11, 5290–5322. [Google Scholar] [CrossRef] [PubMed]

- Arroyo, P.; Melendez, F.; Suares, J.I.; Herrero, J.L.; Rodriguez, S.; Lozano, J. Electronic Nose with digitl gas sensors connected via Bluetooth to a Smartphone for Air Quality Measurements. Sensors 2020, 20, 786. [Google Scholar] [CrossRef] [PubMed]

- Brancher, M.; David Griffiths, K.; Franco, D.; Melo Lisboa, H. A review of odour impact criteria in selected countries around the world. Chemosphere 2017, 168, 1531–1570. [Google Scholar] [CrossRef] [PubMed]

- Zarra, T.; Galang, M.G.; Ballesteros, F.; Naddeo, V.; Belgiorno, V. Environmental odour management by artificial neural network—A review. Environ. Int. 2019, 133, 105189. [Google Scholar] [CrossRef] [PubMed]

- Garbacz, M.; Malec, A.; Duda-Saternus, S.; Suchorab, Z.; Guz, L.; Lagod, G. Methods for Early Detection of Microbial Infestation of Buildings Based on Gas Sensors Technologies. Chemosensors 2020, 8, 7. [Google Scholar] [CrossRef]

- Szulczynski, B.; Arminski, K.; Namiesnik, J.; Gebicki, J. Determination of Odour Interactions in Gaseous Mixtures Using Electronic Nose Methods with Artificial Neural Networks. Sensors 2018, 18, 519. [Google Scholar] [CrossRef]

- Slimani, S.; Bultel, E.; Cubizolle, T.; Herrier, C.; Rouselle, T.; Livache, T. Opto-Electronic Nose Coupled to a Silicon Micro Pre-Concentrator Device for Selective Sensing of Flavored Waters. Chemosensors 2020, 8, 60. [Google Scholar] [CrossRef]

- Gebicki, J.; Szulczyński, B. Discrimination of selected fungi species based on their odour profile using prototypes of electronic nose instruments. Measurement 2018, 116, 307–313. [Google Scholar] [CrossRef]

- Cui, S.; Ling, P.; Zhu, H.; Keener, H.M. Plant Pest Detection Using an Artificial Nose System: A Review. Sensors 2018, 18, 378. [Google Scholar] [CrossRef] [PubMed]

- Marek, G.; Dobrzanski, B., Jr.; Oniszczuk, T.; Combrzynski, M.; Cwikla, D.; Rusinek, R. Detection and Differentiation of Volatile Compound Profiles in Roasted Coffee Arabica Beans from Different Countries Using an Electronic Nose and GC-MS. Sensors 2020, 20, 2124. [Google Scholar] [CrossRef] [PubMed]

- Zarra, T.; Naddeo, V.; Belgiorno, V.; Reiser, M.; Kranert, M. Instrumental characterization of odour: A combination of olfactory and analytical methods. Water Sci. Technol. 2009, 59, 1603–1609. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.; Li, G.; Qin, Y.; Freeman, W.J. A pattern recognition method for electronic noses based on an olfactory neural network. Sens. Actuators B Chem. 2007, 125, 489–497. [Google Scholar] [CrossRef]

- Orzi, V.; Riva, C.; Scaglia, B.; D’Imporzano, G.; Tambone, F.; Adani, F. Anaerobic digestion coupled with digestate injection reduced odour emissions from soil during manure distribution. Sci. Total Environ. 2018, 621, 168–176. [Google Scholar] [CrossRef]

- Ragothaman, A.; Anderson, W.A. Air Quality Impacts of Petroleum Refining and Petrochemical Industries. Environments 2017, 4, 66. [Google Scholar] [CrossRef]

- Kim, J.H.; Mirzaei, A.; Kim, H.W.; Kim, H.J.; Vuong, P.Q.; Kim, S.S. A Novel X-Ray Radiation Sensor Based on Networked SnO2 Nanowires. Appl. Sci. 2019, 9, 4878. [Google Scholar] [CrossRef]

- Szczurek, A.; Maciejewska, M. Relationship between odour intensity assessed by human assessor and TGS sensor array response. Sens. Actuators B Chem. 2005, 106, 13–19. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Yan, B.; Zhang, L.; Gu, Y. Bionic Electronic Nose Based on MOS Sensors Array and Machine Learning Algorithms Used for Wine Properties Detection. Sensors 2019, 19, 45. [Google Scholar] [CrossRef]

- Yan, J.; Guo, X.; Duan, S.; Jia, P.; Wang, L.; Peng, C.; Zhang, S. Electronic Nose Feature Extraction Methods: A Review. Sensors 2015, 15, 27804–27831. [Google Scholar] [CrossRef]

- Distante, C.; Leo, M.; Siciliano, P.; Persaud, K.C. On the study of feature extraction methods for an electronic nose. Sens. Actuators B Chem. 2002, 87, 274–288. [Google Scholar] [CrossRef]

- Carmel, L.; Levy, S.L.; Lancet, D.; Harel, D. A feature extraction method for chemical sensors in electronic noses. Sens. Actuators B 2003, 93, 67–76. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, C.; Zeng, D.; Zhang, Q.; Li, H.; Bi, Z. A feature extraction method and a sampling system for fast recognition of flammable liquids with a portable E-nose. Sens. Actuators B Chem. 2007, 124, 437–443. [Google Scholar] [CrossRef]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Siwek, K.; Grzywacz, T. Odor Detection using an E-Nose with a Reduced Sensor Array. Sensors 2020, 20, 3542. [Google Scholar] [CrossRef] [PubMed]

- Gardner, J.W.; Boilot, P.; Hines, E.L. Enhancing electronic nose performance by sensor selection using a new integer-based genetic algorithm approach. Sens. Actuators B Chem. 2005, 106, 114–121. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Cheng, S. Discrimination among tea plants either with different invasive severities or different invasive times using MOS electronic nose combined with a new feature extraction method. Comput. Electron. Agric. 2017, 143, 293–301. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, W.; Pan, Y. Enhancing Electronic Nose Performance by Feature Selection using an Improved Grey Wolf Optimization Based Algorithm. Sensors 2020, 20, 4065. [Google Scholar] [CrossRef]

- Haddad, R.; Carmel, L.; Harel, D. A feature extraction algorithm for multi-peak signals in electronic nose. Sens. Actuators B Chem. 2007, 120, 467–472. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, C.; Hu, M.; Li, H.; Bai, Z.; Zend, D. An entire feature extraction method of metal oxide gas sensors. Sens. Actuators B Chem. 2008, 132, 81–89. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, W.; Ye, L.; Ueland, M.; Forbes, S.L.; Su, S.W. A novel multi-odour identification by electronic nose using non-parametric modelling-based feature extraction and time-series classification. Sens. Actuators B Chem. 2019, 298, 1226690. [Google Scholar] [CrossRef]

- Yan, J.; Tian, F.; He, Q.; Shen, Y.; Xu, S.; Feng, J.; Chaibou, K. Feature Extraction from Sensor Data for Detection of Wound Pathogen Based on Electronic Nose. Sens. Mater. 2012, 24, 57–73. [Google Scholar]

- Yang, W.; Wu, H. Regularized complete linear discriminant analysis. Neurocomputing 2014, 127, 185–191. [Google Scholar] [CrossRef]

- Rhif, M.; Abbes, A.B.; Farah, I.R.; Martinez, B.; Sang, Y. Wavelet Transform Application for/in Non-Stationary Time-Series Analysis: A Review. Appl. Sci. 2019, 9, 1345. [Google Scholar] [CrossRef]

- Zarra, T.; Giuliani, S.; Naddeo, V.; Belgiorno, V. Control of odour emission in wastewater treatment plants by direct and undirected measurement of odour emission capacity. Water Sci. Technol. 2012, 66, 1627–1633. [Google Scholar] [CrossRef]

- Vanarse, A.; Espinosa-Ramos, J.I.; Osseiran, A.; Rassau, A.; Kasabov, N. Application of a Brain-Inspired Spiking Neural Network Architecture to Odor Data Classification. Sensors 2020, 20, 2756. [Google Scholar] [CrossRef]

- Wei, H.; Gu, Y. A Machine Learning Method for the Detection of Brown Core in the Chinese Pear Variety Huangguan Using a MOS-Based E-Nose. Sensors 2020, 20, 4499. [Google Scholar] [CrossRef]

- Dong, Y.; Joe Qin, S. Regression on dynamic PLS structures for supervised learning of dynamic data. J. Process Control 2018, 68, 64–72. [Google Scholar] [CrossRef]

- Avila, R.; Horn, B.; Moriarty, E.; Hodson, R.; Moltchanova, E. Evaluating statistical model performance in water quality prediction. J. Environ. Manag. 2018, 206, 910–919. [Google Scholar] [CrossRef]

- Kuter, S.; Akyurek, Z.; Weber, G. Retrieval of fractional snow-covered area from MODIS data by multivariate adaptive regression splines. Remote Sens. Environ. 2018, 205, 236–252. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Zarra, T.; Naddeo, V.; Belgiorno, V. A novel tool for estimating the odour emissions of composting plants in air pollution management. Glob. Nest J. 2009, 11, 477–486. [Google Scholar]

- Giuliani, S.; Zarra, T.; Naddeo, V.; Belgiorno, V. Measurement of odour capacity in wastewater treatment plants by multisensor array system. Environ. Eng. Manag. J. 2013, 12, 173–176. [Google Scholar]

- Zarra, T.; Reiser, M.; Naddeo, V.; Belgiorno, V.; Kranert, M. Odour emissions characterization from wastewater treatment plants by different measurement methods. Chem. Eng. Trans. 2014, 40, 37–42. [Google Scholar]

- Viccione, G.; Zarra, T.; Giuliano, S.; Naddeo, V.; Belgiorno, V. Performance Study of E-Nose Measurement Chamber for Environmental Odour Monitoring. Chem. Eng. Trans. 2012, 30. [Google Scholar] [CrossRef]

- Jiang, W.; Gao, D. Five typical stenches detection using an Electronic Nose. Sensors 2020, 20, 2514. [Google Scholar] [CrossRef]

- Le, K.T.; Chaux, C.; Richard, F.J.P.; Guedj, E. An adapted linear discriminant analysis with variable selection for the classification in high-dimension, and an application to medical data. Comput. Stat. Data Anal. 2020, 152, 107031. [Google Scholar] [CrossRef]

- Galang, M.K.G.; Zarra, T.; Naddeo, V.; Belgiorno, V.; Ballesteros, F. Artificial neural network in the measurement of environmental odours by e-nose. Chem. Eng. Trans. 2018, 68, 247–252. [Google Scholar]

- Sarigiannis, D.A.; Karakitsios, S.P.; Gotti, A.; Papaloukas, C.L.; Kassomenos, P.A.; Pilidis, G.A. Bayesian Algorithm Implementation in a Real Time Exposure Assessment Model on Benzene with Calculation of Associated Cancer Risks. Sensors 2009, 9, 731–755. [Google Scholar] [CrossRef]

- Mjalli, F.S.; Al-Ashed, S.; Alfadala, H.E. Use of artificial neural network black-box modeling for the prediction of wastewater treatment plants performance. J. Environ. Manag. 2007, 83, 329–338. [Google Scholar] [CrossRef]

- Dharwal, R.; Kaur, L. Applications of Artificial Neural Networks: A Review. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Gardner, J.W.; Hines, E.L.; Wilkinson, M. Application of artificial neurl networks to an electronic olfactory system. Meas. Sci. Technol. 1990, 1, 446. [Google Scholar] [CrossRef]

- Jiang, Q.; Shen, Y.; Li, H.; Xu, F. New Fault Recognition Method for Rotary Machinery Based on Information Entropy and a Probabilistic Neural Network. Sensors 2018, 18, 337. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A Simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

| Technique | Sample Method | Characteristic/s | Equation/s | Reference/s |

|---|---|---|---|---|

| Extraction from original response curves of sensors |

|

| Difference: xij = RS − RO Relative: xij = RS/RO Fractional: xij = (RS − RO)/RO Logarithm: xij = ln (RS/RO) Normalized: xij = xij/(RS − RO) | [19,26,27] |

| Extraction from curve fitting parameters |

|

| Polynomial: y = A0 + A1x + A2x + A3x3 + …+ Anxn i = 1,2,3 … Fractional: y = x/Ax + B | [28,32] |

| Transform domains |

|

| dt Wavelet (mother): ya, b =y(; a > 0, -∞ < b < ∞ | [20,33] |

| Technique | Characteristic/s | Equation | Reference/s |

|---|---|---|---|

| Artificial Neural Network (ANN) |

| ) | [35,36] |

| Partial Least Square (PLS) |

| y = β0 + β1 x1 + β2 x2 … βn xn + C | [37] |

| Linear Discriminant Analysis (LDA) |

| y = k1+ax1+bx2…αxn | [32,38] |

| Multivariate adaptive regression splines (MARSPline) |

| y = f (X) = β0 +(X) | [39] |

| Response Surface Regression (RSR) |

| y = β0 + β1 w + β2 w2 + β3 x + β4 x2+ β5 z + β6 z2 + β7 w x + β8 w z + β9 z z | [40] |

| Sensor ID | Number | Target Gas |

|---|---|---|

| TGS880 | 2 | Alcohols, water vapors |

| TGS822 | 2 | Alcohols, organic solvent vapors |

| TGS842 | 2 | Methane |

| TGS2611 | 2 | Methane |

| TGS2620 | 2 | Solvent vapors |

| TGS2602 | 1 | Air contaminants |

| TGS825 | 1 | Hydrogen sulfide |

| TGS826 | 1 | Ammonia |

| Description | Number of Data | Output | |||

|---|---|---|---|---|---|

| Complete Response Curve | Rise | Intermediate | Peak | Group | |

| Class A | 600 | 300 | 300 | 300 | G1 |

| Class B | 780 | 390 | 390 | 390 | G2 |

| Class C | 1680 | 840 | 840 | 840 | G3 |

| Group | Number of Data | Assigned Output | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Complete Response Curve | Rise, Intermediate and Peak | ||||||||

| A | B | C | A | B | C | A | B | C | |

| Class A | 600 | 0 | 0 | 300 | 0 | 0 | 1 | 0 | 0 |

| Class B | 0 | 780 | 0 | 0 | 390 | 0 | 0 | 1 | 0 |

| Class C | 0 | 0 | 1680 | 0 | 0 | 840 | 0 | 0 | 1 |

| Group | Number of Data | Designated Output | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Complete Response Curve | Rise, Intermediate and Peak | ||||||||

| G1 | G2 | G3 | G1 | G2 | G3 | G1 | G2 | G3 | |

| Class A | 120 | 0 | 0 | 60 | 0 | 0 | 1 | 0 | 0 |

| Class B | 0 | 120 | 0 | 0 | 60 | 0 | 0 | 1 | 0 |

| Class C | 0 | 0 | 120 | 0 | 0 | 60 | 0 | 0 | 1 |

| Extracted Piecemeal Signal Features | Pattern Recognition Methods | |

|---|---|---|

| LDA | ANN | |

| Complete response curve | OCMM1.1 | OCMM2.1 |

| Rise | OCMM1.2 | OCMM2.2 |

| Intermediate | OCMM1.3 | OCMM2.3 |

| Peak | OCMM1.4 | OCMM2.4 |

| Group | Classification Accuracy Rate (%) | |||

|---|---|---|---|---|

| Complete Response Curve | Rise | Intermediate | Peak | |

| Class A | 74.83 | 65.16 | 80.97 | 86.77 |

| Class B | 79.10 | 76.92 | 79.65 | 78.41 |

| Class C | 99.94 | 100.00 | 99.88 | 99.77 |

| OVERALL | 89.71 | 87.29 | 91.02 | 91.78 |

| Wilks’ Lambda | 0.1091 | 0.1253 | 0.0824 | 0.0714 |

| Group | Classification Accuracy Rate (%) | |||

|---|---|---|---|---|

| Complete Response Curve | Rise | Intermediate | Peak | |

| Class A | 00.00 | 48.33 | 50.00 | 50.00 |

| Class B | 98.33 | 100.00 | 100.00 | 100.00 |

| Class C | 00.00 | 00.00 | 00.00 | 00.00 |

| OVERALL | 32.78 | 49.44 | 50.00 | 50.00 |

| Experiment Stage | Complete Response Curve | Rise | Intermediate | Peak |

|---|---|---|---|---|

| Train (R2) | 0.9999 | 0.9999 | 0.9999 | 0.9999 |

| Testing (R2) | 0.9954 | 0.9999 | 0.9876 | 0.9999 |

| Overall (R2) | 0.9999 | 0.9999 | 0.9981 | 0.9999 |

| Classification Rates (%) | 99% | 100% | 99% | 100% |

| Group | Classification Accuracy Rate (%) | |||

|---|---|---|---|---|

| Complete Response Curve | Rise | Intermediate | Peak | |

| Class A | 76.67 | 50.00 | 100.00 | 100.00 |

| Class B | 100.00 | 50.00 | 100.00 | 100.00 |

| Class C | 00.00 | 00.00 | 00.00 | 00.00 |

| OVERALL | 58.89 | 33.33 | 66.67 | 66.67 |

| Extracted Piecemeal Signal Features | φ% by LDA | φ% by ANN | ||

|---|---|---|---|---|

| Training | Validation | Training | Validation | |

| Complete response curve | 89.71% | 32.78% | 99.00% | 58.89% |

| Rise | 87.29% | 49.44% | 100.00% | 33.33% |

| Intermediate | 91.02% | 50.00% | 99.00% | 66.67% |

| Peak | 91.78% | 50.00% | 100.00% | 66.67% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zarra, T.; Galang, M.G.K.; Ballesteros, F.C., Jr.; Belgiorno, V.; Naddeo, V. Instrumental Odour Monitoring System Classification Performance Optimization by Analysis of Different Pattern-Recognition and Feature Extraction Techniques. Sensors 2021, 21, 114. https://doi.org/10.3390/s21010114

Zarra T, Galang MGK, Ballesteros FC Jr., Belgiorno V, Naddeo V. Instrumental Odour Monitoring System Classification Performance Optimization by Analysis of Different Pattern-Recognition and Feature Extraction Techniques. Sensors. 2021; 21(1):114. https://doi.org/10.3390/s21010114

Chicago/Turabian StyleZarra, Tiziano, Mark Gino K. Galang, Florencio C. Ballesteros, Jr., Vincenzo Belgiorno, and Vincenzo Naddeo. 2021. "Instrumental Odour Monitoring System Classification Performance Optimization by Analysis of Different Pattern-Recognition and Feature Extraction Techniques" Sensors 21, no. 1: 114. https://doi.org/10.3390/s21010114

APA StyleZarra, T., Galang, M. G. K., Ballesteros, F. C., Jr., Belgiorno, V., & Naddeo, V. (2021). Instrumental Odour Monitoring System Classification Performance Optimization by Analysis of Different Pattern-Recognition and Feature Extraction Techniques. Sensors, 21(1), 114. https://doi.org/10.3390/s21010114