Radiation Effects on Long Period Fiber Gratings: A Review

Abstract

1. Introduction

2. Irradiation of Long Period Gratings

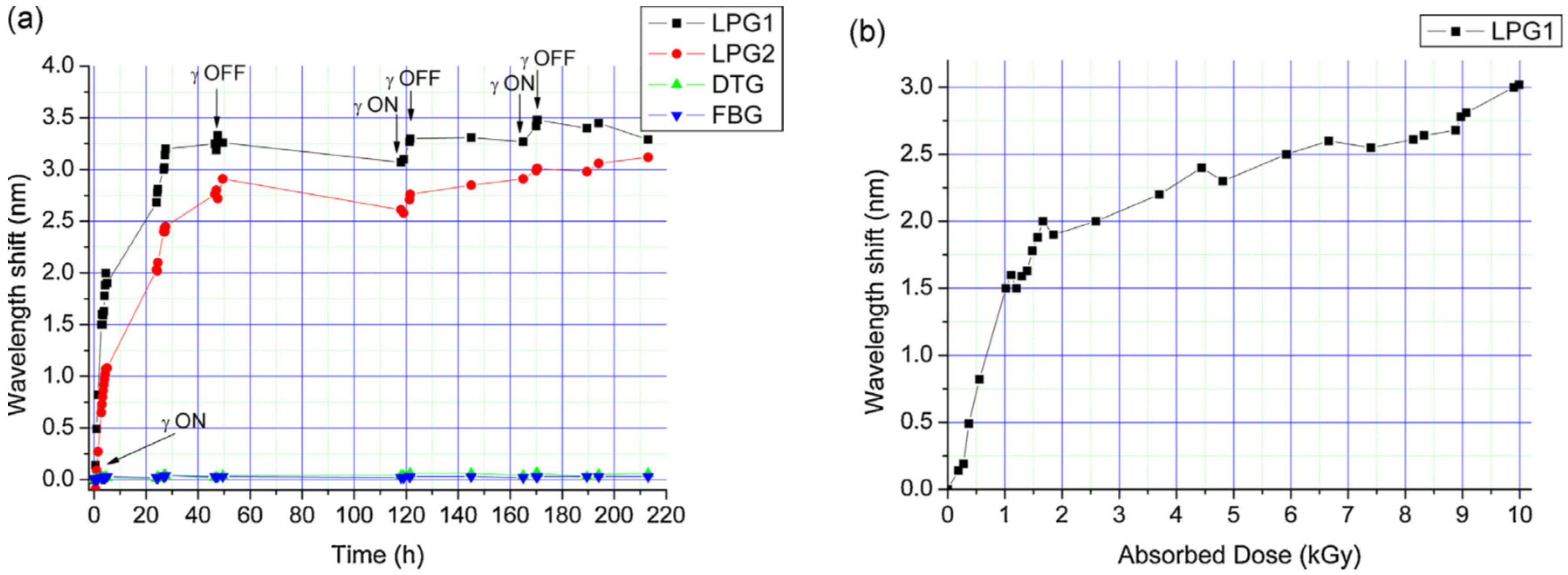

2.1. First Evidence of LPGs Investigated under Gamma Radiation

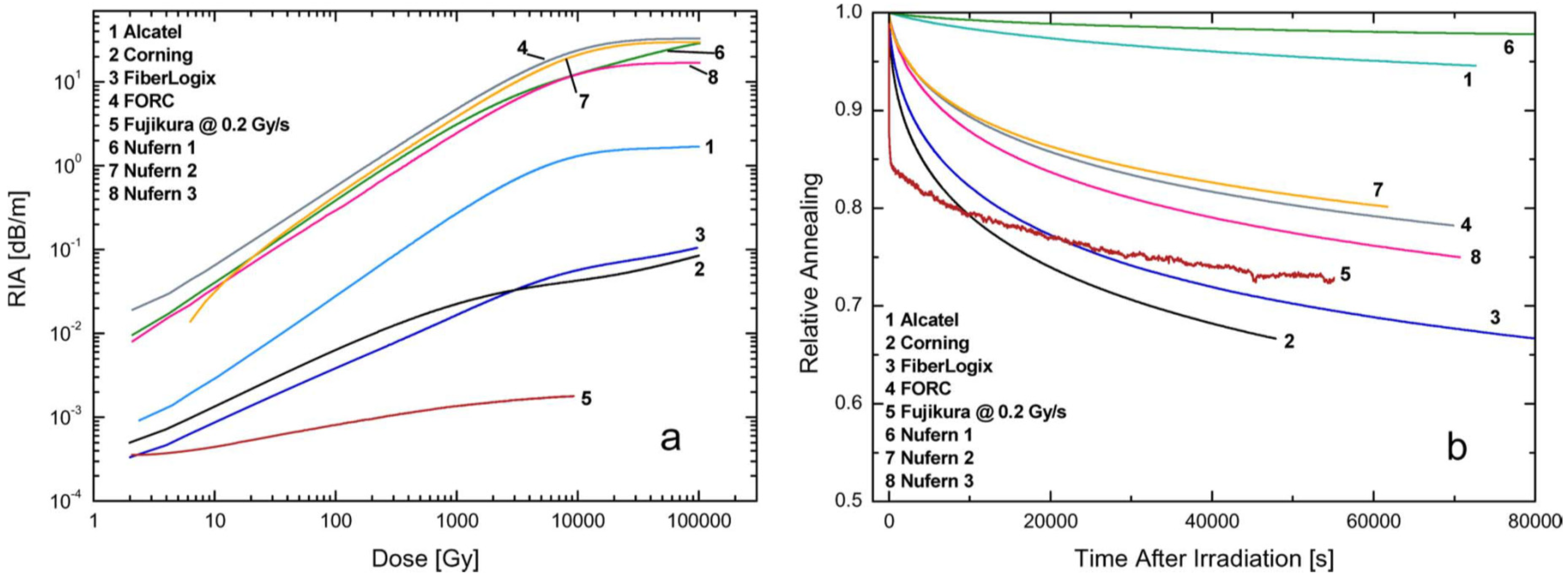

2.2. Systematic Study about Gamma Radiation on Chiral LPGs in Different Fibers

2.3. Gamma Radiation Sensitivity and Refractive Index Measurement Using TAP-LPG

2.4. Gamma Irradiation of CO2-Written LPGs

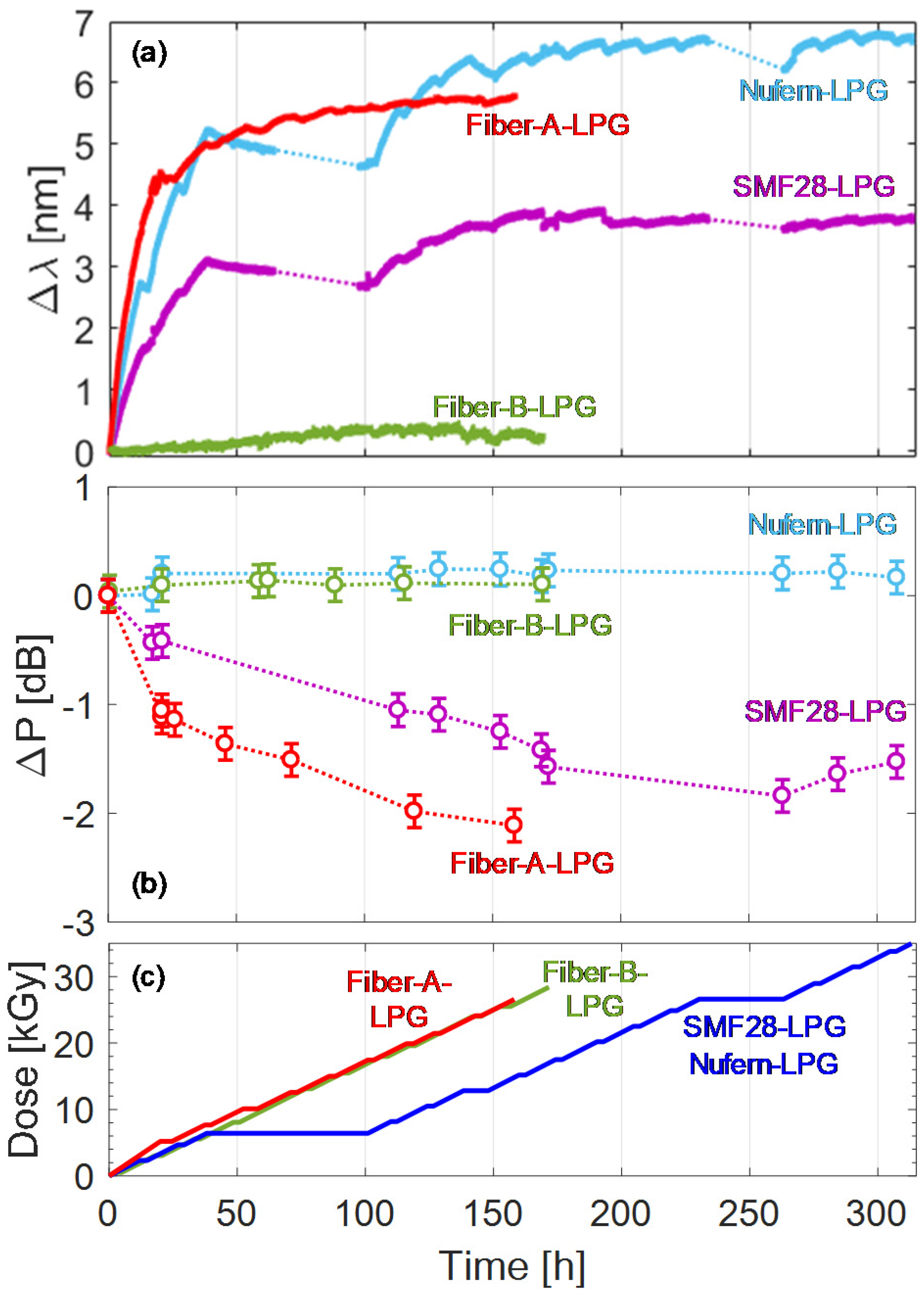

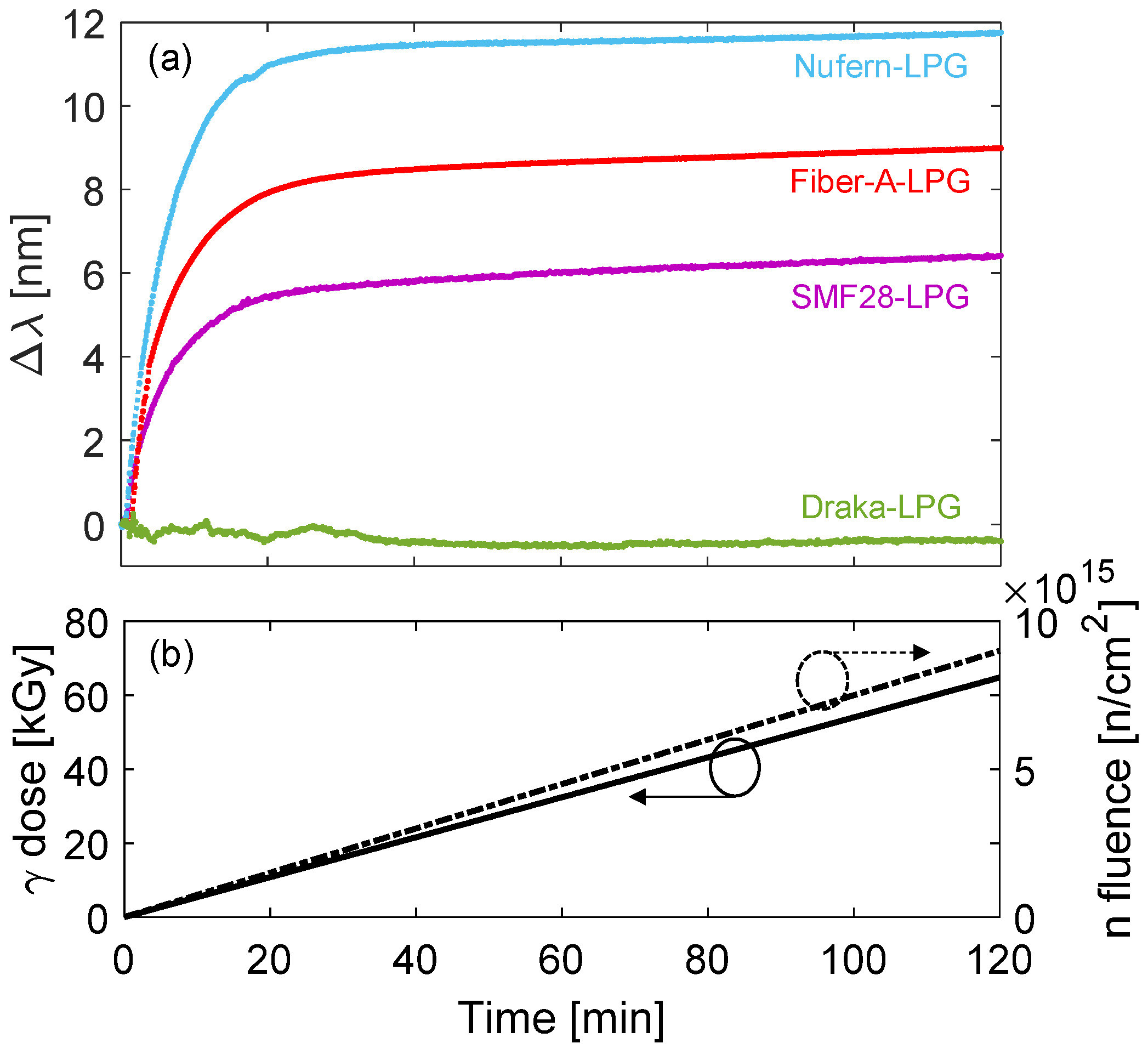

2.5. Systematic Study about Gamma and Neutron-Gamma Radiation on Arc-Induced LPGs in Different Fibers

2.6. Proton Irradiation of LPGs

2.7. Radiation Tolerant Humidity Sensors Based on LPG Coated with TiO2

3. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, B. Review of the present status of optical fiber sensors. Opt. Fiber Technol. 2003, 9, 57–79. [Google Scholar] [CrossRef]

- Lu, P.; Lalam, N.; Badar, M.; Liu, B.; Chorpening, B.T.; Buric, M.P.; Ohodnicki, P.R. Distributed optical fiber sensing: Review and perspective. Appl. Phys. Rev. 2019, 6, 041302. [Google Scholar] [CrossRef]

- Sporea, D.; Sporea, A.; O’Keeffe, S.; McCarthy, D.; Lewis, E. Optical Fibers and Optical Fiber Sensors Used in Radiation Monitoring. In Selected Topics on Optical Fiber Technology; Yasin, M., Harun, S.W., Arof, H., Eds.; IntechOpen: Rijeka, Croatia, 2012. [Google Scholar]

- O’Keeffe, S.; McCarthy, D.; Woulfe, P.; Grattan, M.W.D.; Hounsell, A.R.; Sporea, D.; Mihai, L.; Vata, I.; Leen, G.; Lewis, E. A review of recent advances in optical fibre sensors for in vivo dosimetry during radiotherapy. Br. J. Radiol. 2015, 88, 20140702. [Google Scholar] [CrossRef] [PubMed]

- Sporea, D.; Sporea, A. Radiation Effects in Optical Materials and Photonic Devices. In Radiation Effects in Materials; InTech: Rijeka, Croatia, 2016. [Google Scholar]

- Liu, D.T.; Johnston, A.R. Theory of radiation-induced absorption in optical fibers. Opt. Lett. 1994, 19, 548–550. [Google Scholar] [CrossRef]

- Griscom, D.L.; Gingerich, M.E.; Friebele, E.J. Model for the dose, dose-rate and temperature dependence of radiation-induced loss in optical fibers. IEEE Trans. Nucl. Sci. 1994, 41, 523–527. [Google Scholar] [CrossRef]

- Berghmans, F.; Brichard, B.; Fernandez, A.F.; Gusarov, A.; Uffelen, M.V.; Girard, S. An Introduction to Radiation Effects on Optical Components and Fiber Optic Sensors. In Optical Waveguide Sensing and Imaging; Springer: Berlin/Heidelberg, Germany, 2008; pp. 127–165. [Google Scholar]

- Girard, S.; Alessi, A.; Richard, N.; Martin-Samos, L.; De Michele, V.; Giacomazzi, L.; Agnello, S.; Di Francesca, D.; Morana, A.; Winkler, B.; et al. Overview of radiation induced point defects in silica-based optical fibers. Rev. Phys. 2019, 4, 100032. [Google Scholar] [CrossRef]

- Henschel, H.; Körfer, M.; Kuhnhenn, J.; Weinand, U.; Wulf, F. Fibre optic radiation sensor systems for particle accelerators. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2004, 526, 537–550. [Google Scholar] [CrossRef]

- Di Francesca, D.; Brugger, M.; Vecchi, G.L.; Girard, S.; Morana, A.; Reghioua, I.; Alessi, A.; Hoehr, C.; Robin, T.; Kadi, Y. Qualification and Calibration of Single-Mode Phosphosilicate Optical Fiber for Dosimetry at CERN. J. Light. Technol. 2019, 37, 4643–4649. [Google Scholar] [CrossRef]

- Brichard, B.; Fernandez Fernandez, A.; Ooms, H.; Berghmans, F.; Decréton, M.; Tomashuk, A.; Klyamkin, S.; Zabezhailov, M.; Nikolin, I.; Bogatyrjov, V.; et al. Radiation-hardening techniques of dedicated optical fibres used in plasma diagnostic systems in ITER. J. Nucl. Mater. 2004, 329–333, 1456–1460. [Google Scholar] [CrossRef]

- Girard, S.; Morana, A.; Ladaci, A.; Robin, T.; Mescia, L.; Bonnefois, J.-J.; Boutillier, M.; Mekki, J.; Paveau, A.; Cadier, B.; et al. Recent advances in radiation-hardened fiber-based technologies for space applications. J. Opt. 2018, 20, 093001. [Google Scholar] [CrossRef]

- Barth, J.L.; Dyer, C.S.; Stassinopoulos, E.G. Space, atmospheric, and terrestrial radiation environments. IEEE Trans. Nucl. Sci. 2003, 50, 466–482. [Google Scholar] [CrossRef]

- Friebele, E.J.; Askins, C.G.; Miller, G.A.; Peele, J.R.; Wasserman, L.R. Optical fiber sensors for spacecraft: Applications and challenges. In Photonics for Space Environments IX; Taylor, E.W., Ed.; SPIE: Bellingham, WA, USA, 2004; Volume 5554, pp. 120–131. [Google Scholar]

- Girard, S.; Kuhnhenn, J.; Gusarov, A.; Brichard, B.; Van Uffelen, M.; Ouerdane, Y.; Boukenter, A.; Marcandella, C. Radiation Effects on Silica-Based Optical Fibers: Recent Advances and Future Challenges. IEEE Trans. Nucl. Sci. 2013, 60, 2015–2036. [Google Scholar] [CrossRef]

- Brichard, B.; Borgermans, P.; Fernandez, A.F.; Lammens, K.; Decreton, A. Radiation effect in silica optical fiber exposed to intense mixed neutron-gamma radiation field. IEEE Trans. Nucl. Sci. 2001, 48, 2069–2073. [Google Scholar] [CrossRef]

- Van Uffelen, M.; Girard, S.; Goutaland, F.; Gusarov, A.; Brichard, B.; Berghmans, F. Gamma radiation effects in Er-doped silica fibers. IEEE Trans. Nucl. Sci. 2004, 51, 2763–2769. [Google Scholar] [CrossRef]

- Girard, S.; Brichard, B.; Baggio, J.; Berghmans, F.; Decre, M. Comparative Study of Pulsed X-Ray and gamma-Ray Radiation-Induced Effects in Pure-Silica-Core Optical Fibers. IEEE Trans. Nucl. Sci. 2006, 53, 1756–1763. [Google Scholar] [CrossRef]

- Regnier, E.; Flammer, I.; Girard, S.; Gooijer, F.; Achten, F.; Kuyt, G. Low-Dose Radiation-Induced Attenuation at InfraRed Wavelengths for P-Doped, Ge-Doped and Pure Silica-Core Optical Fibres. IEEE Trans. Nucl. Sci. 2007, 54, 1115–1119. [Google Scholar] [CrossRef]

- Girard, S.; Tortech, B.; Regnier, E.; Van Uffelen, M.; Gusarov, A.; Ouerdane, Y.; Baggio, J.; Paillet, P.; Ferlet-Cavrois, V.; Boukenter, A.; et al. Proton- and Gamma-Induced Effects on Erbium-Doped Optical Fibers. IEEE Trans. Nucl. Sci. 2007, 54, 2426–2434. [Google Scholar] [CrossRef]

- Girard, S.; Ouerdane, Y.; Tortech, B.; Marcandella, C.; Robin, T.; Cadier, B.; Baggio, J.; Paillet, P.; Ferlet-Cavrois, V.; Boukenter, A.; et al. Radiation Effects on Ytterbium- and Ytterbium/Erbium-Doped Double-Clad Optical Fibers. IEEE Trans. Nucl. Sci. 2009, 56, 3293–3299. [Google Scholar] [CrossRef]

- Girard, S.; Marcandella, C. Transient and Steady State Radiation Responses of Solarization-Resistant Optical Fibers. IEEE Trans. Nucl. Sci. 2010, 57, 2049–2055. [Google Scholar] [CrossRef]

- Di Francesca, D.; Girard, S.; Agnello, S.; Alessi, A.; Marcandella, C.; Paillet, P.; Richard, N.; Boukenter, A.; Ouerdane, Y.; Gelardi, F.M. Radiation Response of Ce-Codoped Germanosilicate and Phosphosilicate Optical Fibers. IEEE Trans. Nucl. Sci. 2016, 63, 2058–2064. [Google Scholar] [CrossRef]

- Quero, G.; Vaiano, P.; Fienga, F.; Giaquinto, M.; Di Meo, V.; Gorine, G.; Casolaro, P.; Campajola, L.; Breglio, G.; Crescitelli, A.; et al. A novel Lab-on-Fiber Radiation Dosimeter for Ultra-high Dose Monitoring. Sci. Rep. 2018, 8, 17841. [Google Scholar] [CrossRef] [PubMed]

- Girard, S.; Ouerdane, Y.; Bouazaoui, M.; Marcandella, C.; Boukenter, A.; Bigot, L.; Kudlinski, A. Transient radiation-induced effects on solid core microstructured optical fibers. Opt. Express 2011, 19, 21760. [Google Scholar] [CrossRef] [PubMed]

- Henschel, H.; Kuhnhenn, J.; Weinand, U. High Radiation Hardness of a Hollow Core Photonic Bandgap Fiber. In Proceedings of the 2005 8th European Conference on Radiation and Its Effects on Components and Systems, Cap d’Agde, France, 19–23 September 2005; IEEE: Piscataway, NJ, USA, 2005; pp. LN4-1–LN4-4. [Google Scholar]

- Girard, S.; Baggio, J.; Leray, J.-L. Radiation-induced effects in a new class of optical waveguides: The air-guiding photonic crystal fibers. IEEE Trans. Nucl. Sci. 2005, 52, 2683–2688. [Google Scholar] [CrossRef]

- Olanterä, L.; Sigaud, C.; Troska, J.; Vasey, F.; Petrovich, M.N.; Poletti, F.; Wheeler, N.V.; Wooler, J.P.; Richardson, D.J. Gamma irradiation of minimal latency Hollow-Core Photonic Bandgap Fibres. J. Instrum. 2013, 8, C12010. [Google Scholar] [CrossRef]

- O’Keeffe, S.; Fernandez Fernandez, A.; Fitzpatrick, C.; Brichard, B.; Lewis, E. Real-time gamma dosimetry using PMMA optical fibres for applications in the sterilization industry. Meas. Sci. Technol. 2007, 18, 3171–3176. [Google Scholar] [CrossRef]

- Stajanca, P.; Krebber, K. Radiation-Induced Attenuation of Perfluorinated Polymer Optical Fibers for Radiation Monitoring. Sensors 2017, 17, 1959. [Google Scholar] [CrossRef]

- Melin, G.; Guitton, P.; Montron, R.; Gotter, T.; Robin, T.; Overton, B.; Morana, A.; Rizzolo, S.; Girard, S. Radiation Resistant Single-Mode Fiber with Different Coatings for Sensing in High Dose Environments. IEEE Trans. Nucl. Sci. 2019, 66, 1657–1662. [Google Scholar] [CrossRef]

- Brichard, B.; Fernandez, A.F.; Ooms, H.; Berghmans, F. Fibre-optic gamma-flux monitoring in a fission reactor by means of Cerenkov radiation. Meas. Sci. Technol. 2007, 18, 3257–3262. [Google Scholar] [CrossRef]

- Di Francesca, D.; Girard, S.; Agnello, S.; Marcandella, C.; Paillet, P.; Boukenter, A.; Gelardi, F.M.; Ouerdane, Y. Near infrared radio-luminescence of O2 loaded radiation hardened silica optical fibers: A candidate dosimeter for harsh environments. Appl. Phys. Lett. 2014, 105, 183508. [Google Scholar] [CrossRef]

- Girard, S.; Capoen, B.; El Hamzaoui, H.; Bouazaoui, M.; Bouwmans, G.; Morana, A.; Di Francesca, D.; Boukenter, A.; Duhamel, O.; Paillet, P.; et al. Potential of Copper- and Cerium-Doped Optical Fiber Materials for Proton Beam Monitoring. IEEE Trans. Nucl. Sci. 2017, 64, 567–573. [Google Scholar] [CrossRef]

- Ramli, A.T.; Bradley, D.A.; Hashim, S.; Wagiran, H. The thermoluminescence response of doped SiO2 optical fibres subjected to alpha-particle irradiation. Appl. Radiat. Isot. 2009, 67, 428–432. [Google Scholar] [CrossRef] [PubMed]

- Benabdesselam, M.; Mady, F.; Girard, S.; Mebrouk, Y.; Duchez, J.B.; Gaillardin, M.; Paillet, P. Performance of Ge-Doped Optical Fiber as a Thermoluminescent Dosimeter. IEEE Trans. Nucl. Sci. 2013, 60, 4251–4256. [Google Scholar] [CrossRef]

- Fernandez, A.; Brichard, B.; Berghmans, F.; Decreton, M. Dose-rate dependencies in gamma-irradiated fiber bragg grating filters. IEEE Trans. Nucl. Sci. 2002, 49, 2874–2878. [Google Scholar] [CrossRef]

- Krebber, K.; Henschel, H.; Weinand, U. Fibre Bragg gratings as high dose radiation sensors? Meas. Sci. Technol. 2006, 17, 1095–1102. [Google Scholar] [CrossRef]

- Gusarov, A.; Chojetzki, C.; Mckenzie, I.; Thienpont, H.; Berghmans, F. Effect of the Fiber Coating on the Radiation Sensitivity of Type I FBGs. IEEE Photonics Technol. Lett. 2008, 20, 1802–1804. [Google Scholar] [CrossRef]

- Gusarov, A. Long-Term Exposure of Fiber Bragg Gratings in the BR1 Low-Flux Nuclear Reactor. IEEE Trans. Nucl. Sci. 2010, 57, 2044–2048. [Google Scholar] [CrossRef]

- Perry, M.; Niewczas, P.; Johnston, M. Effects of neutron-gamma radiation on fiber bragg grating sensors: A review. IEEE Sens. J. 2012, 12, 3248–3257. [Google Scholar] [CrossRef]

- Gusarov, A.; Hoeffgen, S.K. Radiation Effects on Fiber Gratings. IEEE Trans. Nucl. Sci. 2013, 60, 2037–2053. [Google Scholar] [CrossRef]

- Blanchet, T.; Morana, A.; Allanche, T.; Sabatier, C.; Reghioua, I.; Marin, E.; Boukenter, A.; Ouerdane, Y.; Paillet, P.; Gaillardin, M.; et al. X-ray, Proton and Electron Radiation Effects on Type I Fiber Bragg Gratings. IEEE Trans. Nucl. Sci. 2018, 65, 1632–1638. [Google Scholar] [CrossRef]

- Ju, S.; Kim, Y.; Linganna, K.; Kim, Y.H.; Han, W. Effect of Temperature and Gamma-Ray Irradiation on Optical Characteristics of Fiber Bragg Grating Inscribed Radiation-Resistant Optical Fiber. Photonic Sens. 2019, 10, 16–33. [Google Scholar] [CrossRef]

- Baccini, D.J.; Hinckley, S.; Canning, J.; Cook, K.; Allwood, G.; Wild, G.; Davies, J.; Banos, C. Gamma Irradiation Response in Photonic Crystal and Standard Optical Fiber Bragg Grating Sensors for Radiation Dosimetry. In Proceedings of the Proc. SPIE 11200, AOS Australian Conference on Optical Fibre Technology (ACOFT) and Australian Conference on Optics, Lasers, and Spectroscopy (ACOLS) 2019, Melbourne, Australia, 8–12 December 2019; Mitchell, A., Rubinsztein-Dunlop, H., Eds.; SPIE: Bellingham, WA, USA, 2019; p. 112000O. [Google Scholar]

- Girard, S.; Marin, E.; Lablonde, L.; Robin, T.; Lancry, M.; Boukenter, A.; Ouerdane, Y. Radiation-response of Fiber Bragg Gratings at Low Temperatures. IEEE Trans. Nucl. Sci. 2020. [Google Scholar] [CrossRef]

- Hromadka, J.; Korposh, S.; Partridge, M.C.; James, S.W.; Davis, F.; Crump, D.; Tatam, R.P. Multi-parameter measurements using optical fibre long period gratings for indoor air quality monitoring. Sens. Actuators B Chem. 2017, 244, 217–225. [Google Scholar] [CrossRef]

- Chiavaioli, F.; Baldini, F.; Tombelli, S.; Trono, C.; Giannetti, A. Biosensing with optical fiber gratings. Nanophotonics 2017, 6, 663–679. [Google Scholar] [CrossRef]

- Janczuk-Richter, M.; Dominik, M.; Roźniecka, E.; Koba, M.; Mikulic, P.; Bock, W.J.; Łoś, M.; Śmietana, M.; Niedziółka-Jönsson, J. Long-period fiber grating sensor for detection of viruses. Sens. Actuators B Chem. 2017, 250, 32–38. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, L.; Huang, J.; Tao, C.; Li, X.; Chen, W. Sensitivity enhancing of transition mode long-period fiber grating as methane sensor using high refractive index polycarbonate/cryptophane a overlay deposition. Sens. Actuators B Chem. 2015, 207, 477–480. [Google Scholar] [CrossRef]

- Esposito, F.; Srivastava, A.; Iadicicco, A.; Campopiano, S. Multi-parameter sensor based on single Long Period Grating in Panda fiber for the simultaneous measurement of SRI, temperature and strain. Opt. Laser Technol. 2019, 113, 198–203. [Google Scholar] [CrossRef]

- Sporea, D. Optical Fiber Sensors in Ionizing Radiation Environments. In Handbook of Optical Fibers; Springer: Singapore, 2018; pp. 1–42. ISBN 9789811014772. [Google Scholar]

- Wang, Y. Review of long period fiber gratings written by CO2 laser. J. Appl. Phys. 2010, 108, 081101. [Google Scholar] [CrossRef]

- Rego, G. Arc-Induced Long Period Fiber Gratings. J. Sens. 2016, 2016, 1–14. [Google Scholar] [CrossRef]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar] [CrossRef]

- Xuewen, S.; Lin, Z.; Bennion, I. Sensitivity characteristics of long-period fiber gratings. J. Light. Technol. 2002, 20, 255–266. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Mou, C.; Zou, F.; Wang, T. CO2 laser-written long-period fiber grating with a high diffractive order cladding mode near the turning point. Appl. Opt. 2018, 57, 4756. [Google Scholar] [CrossRef] [PubMed]

- Heck, M.; Krämer, R.G.; Ullsperger, T.; Goebel, T.A.; Richter, D.; Tünnermann, A.; Nolte, S. Efficient long period fiber gratings inscribed with femtosecond pulses and an amplitude mask. Opt. Lett. 2019, 44, 3980. [Google Scholar] [CrossRef] [PubMed]

- Savin, S.; Digonnet, M.J.; Kino, G.S.; Shaw, H.J. Tunable mechanically induced long-period fiber gratings. Opt. Lett. 2000, 25, 710–712. [Google Scholar] [CrossRef] [PubMed]

- Colaco, C.; Caldas, P.; Del Villar, I.; Chibante, R.; Rego, G. Arc-Induced Long Period Fiber Gratings in the Dispersion Turning Points. J. Light. Technol. 2016, 34, 4584–4590. [Google Scholar] [CrossRef]

- Esposito, F.; Ranjan, R.; Campopiano, S.; Iadicicco, A. Arc-Induced Long Period Gratings from Standard to Polarization-Maintaining and Photonic Crystal Fibers. Sensors 2018, 18, 918. [Google Scholar] [CrossRef]

- Vasiliev, S.A.; Dianov, E.M.; Golant, K.M.; Medvedkov, O.I.; Tomashuk, A.L.; Karpov, V.I.; Grekov, M.V.; Kurkov, A.S.; Leconte, B.; Niay, P. Performance of Bragg and long-period gratings written in N- and Ge-doped silica fibers under gamma-radiation. IEEE Trans. Nucl. Sci. 1998, 45, 1580–1583. [Google Scholar] [CrossRef]

- Li, L.; Xia, L.; Xie, Z.; Liu, D. All-fiber Mach-Zehnder interferometers for sensing applications. Opt. Express 2012, 20, 11109. [Google Scholar] [CrossRef]

- Henschel, H.; Hoeffgen, S.K.; Kuhnhenn, J.; Weinand, U. High Radiation Sensitivity of Chiral Long Period Gratings. IEEE Trans. Nucl. Sci. 2010, 57, 2915–2922. [Google Scholar] [CrossRef]

- Kher, S.; Chaubey, S.; Kashyap, R.; Oak, S.M. Turnaround-Point Long-Period Fiber Gratings (TAP-LPGs) as High-Radiation-Dose Sensors. IEEE Photonics Technol. Lett. 2012, 24, 742–744. [Google Scholar] [CrossRef]

- Kher, S.; Chaubey, S.; Oak, S.M. LONG-PERIOD FIBER GRATING–BASED NUCLEAR RADIATION SENSORS FOR HIGH-LEVEL DOSE APPLICATIONS. Instrum. Sci. Technol. 2013, 41, 135–142. [Google Scholar] [CrossRef]

- Kher, S.; Chaubey, S.; Oak, S.M.; Gusarov, A. Measurement of γ-Radiation Induced Refractive Index Changes in B/Ge Doped Fiber Using LPGs. IEEE Photonics Technol. Lett. 2013, 25, 2070–2073. [Google Scholar] [CrossRef]

- Kher, S.; Chaubey, S.; Kishore, J.; Raju, S.; Oak, S.M. Fiber Optic Temperature-Insensitive, Strain Sensors for nuclear applications. Int. J. Appl. Eng. Technol. 2011, 1, 61–67. [Google Scholar]

- Kher, S.; Kumar Saxena, M. Distributed, Advanced Fiber Optic Sensors. In Applications of Optical Fibers for Sensing; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar]

- Srivastava, A.; Esposito, F.; Campopiano, S.; Iadicicco, A. Fabrication and characterization of long period gratings in pure-silica fibers. In Proceedings of the SPIE 11028, Optical Sensors 2019, Prague, Czech Republic, 1–4 April 2019; Lieberman, R.A., Baldini, F., Homola, J., Eds.; SPIE: Bellingham, WA, USA, 2019; p. 110282E. [Google Scholar]

- Sporea, D.; Stancalie, A.; Negut, D.; Pilorget, G.; Delepine-Lesoille, S.; Lablonde, L. Online tests of an optical fiber long-period grating subjected to gamma irradiation. IEEE Photonics J. 2014, 6, 1–9. [Google Scholar] [CrossRef]

- Sporea, D.; Stăncalie, A.; Neguţ, D.; Pilorget, G.; Delepine-Lesoille, S.; Lablonde, L. Comparative study of long period and fiber Bragg gratings under gamma irradiation. Sens. Actuators A Phys. 2015, 233, 295–301. [Google Scholar] [CrossRef]

- Sporea, D.; Stӑncalie, A.; Neguţ, D.; Delepine-Lesoille, S.; Lablonde, L. Long Period Grating Response to Gamma Radiation. In Proceedings of the SPIE Photonics Europe 2016, Brussels, Belgium, 3–7 April 2016; Kalli, K., Mendez, A., Eds.; SPIE: Bellingham, WA, USA, 2016; Volume 9886. [Google Scholar]

- Rego, G.; Fernandez Fernandez, A.; Gusarov, A.; Brichard, B.; Berghmans, F.; Santos, J.L.; Salgado, H.M. Effect of ionizing radiation on the properties of arc-induced long-period fiber gratings. Appl. Opt. 2005, 44, 6258–6263. [Google Scholar] [CrossRef]

- Esposito, F.; Ranjan, R.; Stăncălie, A.; Sporea, D.; Neguţ, D.; Becherescu, N.; Campopiano, S.; Iadicicco, A. Real-time analysis of arc-induced Long Period Gratings under gamma irradiation. Sci. Rep. 2017, 7, 43389. [Google Scholar] [CrossRef]

- Stăncălie, A.; Sporea, D.; Neguţ, D.; Esposito, F.; Ranjan, R.; Campopiano, S.; Iadicicco, A. Long Period Gratings in unconventional fibers for possible use as radiation dosimeter in high-dose applications. Sens. Actuators A Phys. 2018, 271, 223–229. [Google Scholar] [CrossRef]

- Esposito, F.; Stăncălie, A.; Ranjan, R.; Neguţ, D.; Campopiano, S.; Sporea, D.; Iadicicco, A. Gamma Radiation Effects on Long Period Gratings and Transmitted Power in Different Optical Fibers: Towards Dosimetry Applications. In Proceedings of the 26th International Conference on Optical Fiber Sensors, Lausanne, Switzerland, 24–28 September 2018; OSA: Washington, DC, USA, 2018; p. TuE85. [Google Scholar]

- Esposito, F.; Stancalie, A.; Negut, C.-D.; Campopiano, S.; Sporea, D.; Iadicicco, A. Comparative Investigation of Gamma Radiation Effects on Long Period Gratings and Optical Power in Different Optical Fibers. J. Light. Technol. 2019, 37, 4560–4566. [Google Scholar] [CrossRef]

- Alam, M.; Abramczyk, J.; Farroni, J.; Manyam, U.; Guertin, D. Passive and Active Optical Fibers for Space and Terrestrial Applications. In Proceedings of the SPIE Optics + Photonics, San Diego, CA, USA, 13–17 August 2006; Taylor, E.W., Ed.; SPIE: Bellingham, WA, USA, 2006; Volume 6308, p. 630808. [Google Scholar]

- Esposito, F.; Campopiano, S.; Iadicicco, A. Arc-Induced Long Period Gratings in Erbium-Doped Fiber. IEEE Photonics J. 2019, 11, 1–8. [Google Scholar] [CrossRef]

- Del Villar, I.; Matías, I.; Arregui, F.; Lalanne, P. Optimization of sensitivity in Long Period Fiber Gratings with overlay deposition. Opt. Express 2005, 13, 56–69. [Google Scholar] [CrossRef]

- Esposito, F.; Sansone, L.; Taddei, C.; Campopiano, S.; Giordano, M.; Iadicicco, A. Ultrasensitive biosensor based on long period grating coated with polycarbonate-graphene oxide multilayer. Sens. Actuator B Chem. 2018, 274, 517–526. [Google Scholar] [CrossRef]

- Stancălie, A.; Esposito, F.; Ranjan, R.; Bleotu, P.; Campopiano, S.; Iadicicco, A.; Sporea, D. Arc-induced Long Period Gratings in standard and speciality optical fibers under mixed neutron-gamma irradiation. Sci. Rep. 2017, 7, 15845. [Google Scholar] [CrossRef] [PubMed]

- Esposito, F.; Stăncălie, A.; Neguţ, D.; Iadicicco, A.; Sporea, D.; Campopiano, S. Response of Long Period Gratings to Gamma and Neutron-Gamma Radiations. In Proceedings of the SPIE 11199, Seventh European Workshop on Optical Fibre Sensors, Limassol, Cyprus, 1–4 October 2019; Kalli, K., Brambilla, G., O’Keeffe, S.O., Eds.; SPIE: Bellingham, WA, USA, 2019; p. 111990B. [Google Scholar]

- Berruti, G.M.; Pimentel Das Neves, T.F.; Consales, M.; Vaiano, P.; Quero, G.; Petagna, P.; Cusano, A. Radiation Sensitivity of Long Period Gratings written in B-Ge doped fiber under proton irradiation at CERN. In Proceedings of the 26th International Conference on Optical Fiber Sensors, Lausanne, Switzerland, 24–28 September 2018; OSA: Washington, DC, USA, 2018; p. WF57. [Google Scholar]

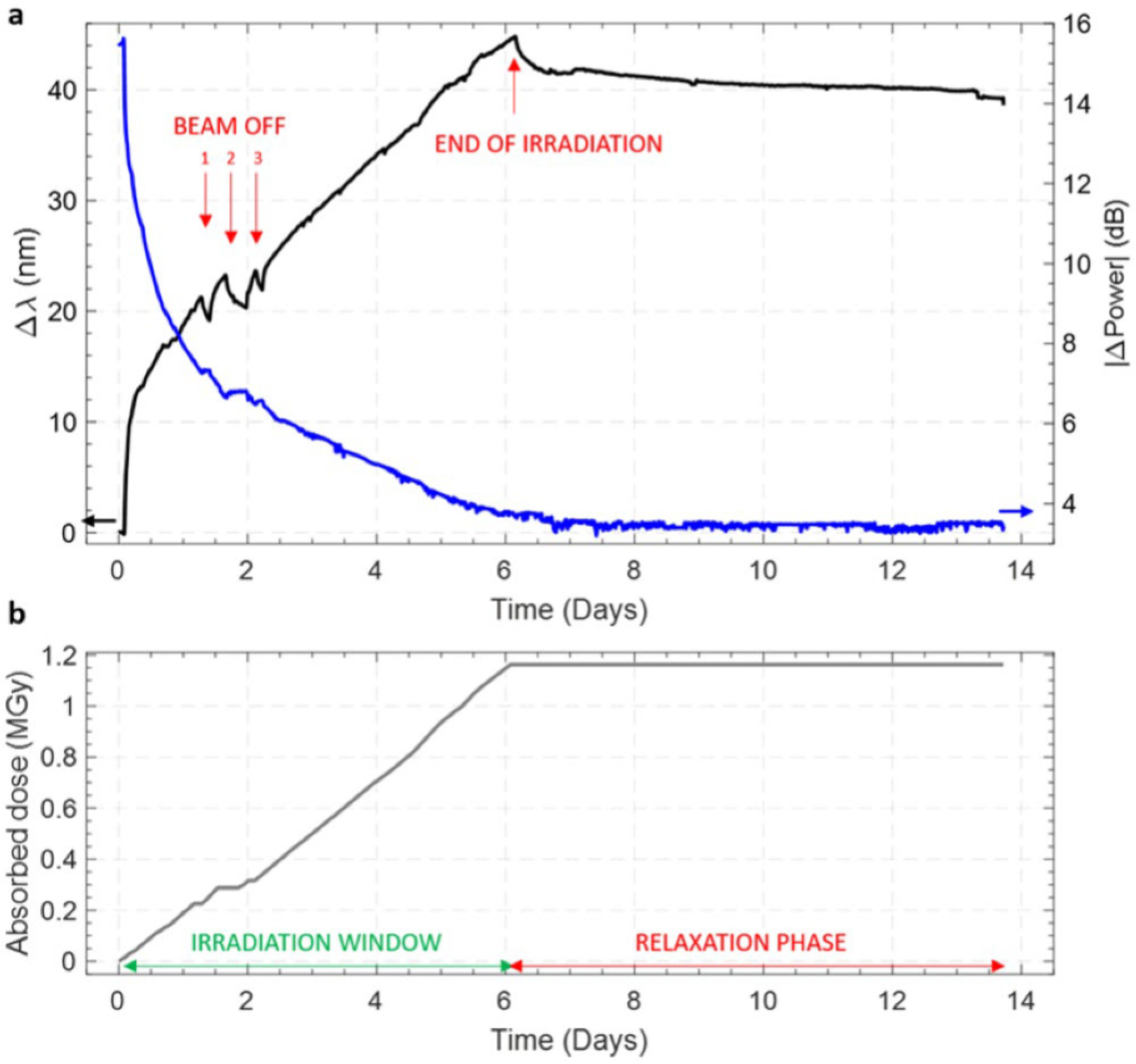

- Berruti, G.M.; Vaiano, P.; Quero, G.; Pimentel Das Neves, T.F.; Boniello, A.; Consales, M.; Petagna, P.; Cusano, A. Analysis of uncoated LPGs written in B-Ge doped fiber under proton irradiation for sensing applications at CERN. Sci. Rep. 2020, 10, 1344. [Google Scholar] [CrossRef] [PubMed]

- Consales, M.; Berruti, G.; Borriello, A.; Giordano, M.; Buontempo, S.; Breglio, G.; Makovec, A.; Petagna, P.; Cusano, A. Nanoscale TiO2-coated LPGs as radiation-tolerant humidity sensors for high-energy physics applications. Opt. Lett. 2014, 39, 4128. [Google Scholar] [CrossRef] [PubMed]

- Berruti, G.; Consales, M.; Borriello, A.; Giordano, M.; Buontempo, S.; Makovec, A.; Breglio, G.; Petagna, P.; Cusano, A. A Comparative Study of Radiation-Tolerant Fiber Optic Sensors for Relative Humidity Monitoring in High-Radiation Environments at CERN. IEEE Photonics J. 2014, 6, 1–15. [Google Scholar] [CrossRef]

- Cusano, A.; Iadicicco, A.; Pilla, P.; Contessa, L.; Campopiano, S.; Cutolo, A.; Giordano, M. Mode transition in high refractive index coated long period gratings. Opt. Express 2006, 14, 19–34. [Google Scholar] [CrossRef] [PubMed]

- Esposito, F.; Zotti, A.; Ranjan, R.; Zuppolini, S.; Borriello, A.; Campopiano, S.; Zarrelli, M.; Iadicicco, A. Single-Ended Long Period Fiber Grating Coated with Polystyrene Thin Film for Butane Gas Sensing. J. Light. Technol. 2018, 36, 825–832. [Google Scholar] [CrossRef]

- Esposito, F.; Srivastava, A.; Sansone, L.; Giordano, M.; Campopiano, S.; Iadicicco, A. Sensitivity Enhancement in Long Period Gratings by Mode Transition in Uncoated Double Cladding Fibers. IEEE Sens. J. 2020, 20, 234–241. [Google Scholar] [CrossRef]

| No. | Fiber | Dcore (µm) | Core Dopants | Cladding Dopants |

|---|---|---|---|---|

| 1 | Alcatel 6901 | 8.8 | GeO2 | P2O5, GeO2, F |

| 2 | Corning SMF28-e | 8.2 | GeO2 | None |

| 3 | FiberLogix FL-HNA-01 | - | GeO2, F | P2O5, F |

| 4 | FORC No. 141-2 | 4.9 | Al2O3, P2O5, GeO2, F | P2O5, F |

| 5 | Fujikura RR-C | 8.7 | F | F |

| 6 | Nufern 1 (confidential) | 7.5 | P2O5 | P2O5, others |

| 7 | Nufern 2 (confidential) | 5.25 | Rare earths, others | None |

| 8 | Nufern 3 (confidential) | 4.5 | Rare earths, others | P2O5, others |

| No. | Fiber | Dcore (µm) | Core Dopants | Cladding Dopants |

|---|---|---|---|---|

| 1 | Corning SMF28 | 8.2 | GeO2 | None |

| 2 | Nufern R1310-HTA | 9.0 | - | - |

| 3 | Fiber-A (confidential) | - | - | None |

| 4 | Fiber-B (confidential) | - | None | F |

| 5 | Prysmian DrakaSRH | 9.0 | None | F |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esposito, F.; Srivastava, A.; Campopiano, S.; Iadicicco, A. Radiation Effects on Long Period Fiber Gratings: A Review. Sensors 2020, 20, 2729. https://doi.org/10.3390/s20092729

Esposito F, Srivastava A, Campopiano S, Iadicicco A. Radiation Effects on Long Period Fiber Gratings: A Review. Sensors. 2020; 20(9):2729. https://doi.org/10.3390/s20092729

Chicago/Turabian StyleEsposito, Flavio, Anubhav Srivastava, Stefania Campopiano, and Agostino Iadicicco. 2020. "Radiation Effects on Long Period Fiber Gratings: A Review" Sensors 20, no. 9: 2729. https://doi.org/10.3390/s20092729

APA StyleEsposito, F., Srivastava, A., Campopiano, S., & Iadicicco, A. (2020). Radiation Effects on Long Period Fiber Gratings: A Review. Sensors, 20(9), 2729. https://doi.org/10.3390/s20092729