1. Introduction

There has been a global increase in the scale of research on developing and operating ocean platforms for ocean surveys and underwater structure management, owing to geopolitical reasons such as importance of maritime transportation routes and safety of navigation, as well as energy-related reasons such as securing underwater resources [

1]. In particular, in coastal areas where construction and human activities occur frequently, humans may find it difficult to dive beyond 30 m or work continuously for more than an hour. Hence, several countries around the world have been researching and developing unmanned ships and underwater robots to replace such manual tasks [

2,

3].

Typical water surface survey platforms include ship, unmanned surface vehicles (USVs) [

4], and towfishes [

5], whereas underwater survey platforms include remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), and underwater gliders, as reported by Steven et al. [

6]. A survey performed on the surface of water makes it possible to acquire the exact position of a platform by employing a global positioning system (GPS) [

7]. Alternatively, underwater survey platforms have a common advantage in that they yield results with high resolution and reliability; hence, they can approach the exploration targets. However, in the case of underwater platforms, errors in the position and azimuth are likely to increase gradually even if inertial navigation is performed using expensive sensors; this is because GPS data cannot be accessed when using these platforms [

8]. Furthermore, in the case of an AUV or a glider, there are constraints on real-time data communication and limitations in the operating time due to the limited energy of the battery [

6]. In contrast, an ROV has the advantage of acquiring GPS data or supplying power, as it is operated on a manned ship; however, an ROV is expensive to operate and has limitations in terms of its movement in a broad area of the sea and when acquiring a wide range of underwater data.

Recently, platforms capable of combining underwater and water surface platforms have been evaluated to address these problems and to expand the survey area of underwater platforms. For example, studies on cooperating USV and AUV were performed. Sarda et al. proposed a platform that employs thin tether cables in a form that combines a commercial USV and AUV, to launch and recover (L&R) an AUV [

9]. However, real-time communication or power transmission between the USV and AUV is limited. Zwolak et al. studied a platform comprising an USV and AUV, similar to the previously mentioned configuration; this platform could L&R and can also acquire data from a wide underwater area [

10]. In these types of platform, USV and AUV are combined to explore a wide range of the water and the position of the USV and the relative position of the AUV can be determined using GPS and hydroacoustic device. However, these platforms were associated with limitations in terms of real-time power supply and large underwater data transmission.

Only a few years ago, to compensate for the weak points of individual AUV, ROV, and the USV–AUV cooperative platform, studies on the USV and ROV cooperating system were performed. Lachaud, Emilie, et al. proposed a concept of combining USV–ROV and a communication analysis between the USV and ROV was performed [

11]. Furthermore, a study on a small-sized USV and ROV observation system wasstudied, where the system was constructed using small-sized ROV and catamaran USV. It showed that the combined USV and ROV observation system has the potential to vastly increase the speed and range of inspection of the ROV. However, it does not have a coordination system between the USV and ROV, such that it cannot get accurate underwater images or sonar data [

12]. Additionally, a study was performed for a surface–underwater combined platform using underwater cables. However, it focused mainly on the robot’s mathematical modeling and the underwater cable drag analysis without an actual platform or field test results [

13]. There are also a few commercial platforms combining underwater and water surface platforms capable of acquiring real-time data via an underwater cable, but only the platform structure and operating system were introduced. The performance of the cooperating USV and UUV has not yet been presented [

14,

15].

In this paper, a new integrated USV and UUV platform connected by the underwater cable capable of acquiring real-time underwater data and long-time operation is studied. The main focus of the study is coordination of the UUV position with respect to the GPS attached at USV. For coordination of the integrated platform, a study on accurate measurement system of the relative position between the USV and the UUV by using the GPS and the ultrashort baseline (USBL) device was performed. Using the accurate measurement system, a tracking control of the UUV to the USV was implemented in field test, which is a new trial in the surface–underwater platform. For implementation of the cooperative motion of the platform, the structure and control system were constructed and designed. Furthermore, an integrated control algorithm of the surface–underwater platform was developed, and the performance of the developed integrated platform was verified through field tests.

The underwater cables provide stable and continuous power to the underwater platform such that it can perform tasks for extended periods and, consequently, acquire a large amount of underwater data in real time. In the integrated platform, USBL is a type of hydroacoustic position reference (HPR) system that is suitable for small platforms because the distance of the baseline is short, and the size of the measurement system is smaller than that of other HPR systems [

16]. HPR systems can be used to compensate for errors that accumulate when conventional inertial navigation is employed; several previous studies have employed USBL to correct the position of an underwater platform. For example, Caiti et al. investigated the position of an AUV using a mixed LBL/USBL positioning method [

17], and Ji et al. developed an algorithm to compensate for the position error using a USBL on a track-based robot for underwater construction [

18].

The integrated platform developed in this study was aimed at achieving long hours of operation in the seacoast; acquiring a large amount of data and controlling the platform in real time; and accurately measuring the relative position between a USV and UUV using GPS and USBL, even after long hours of operation.

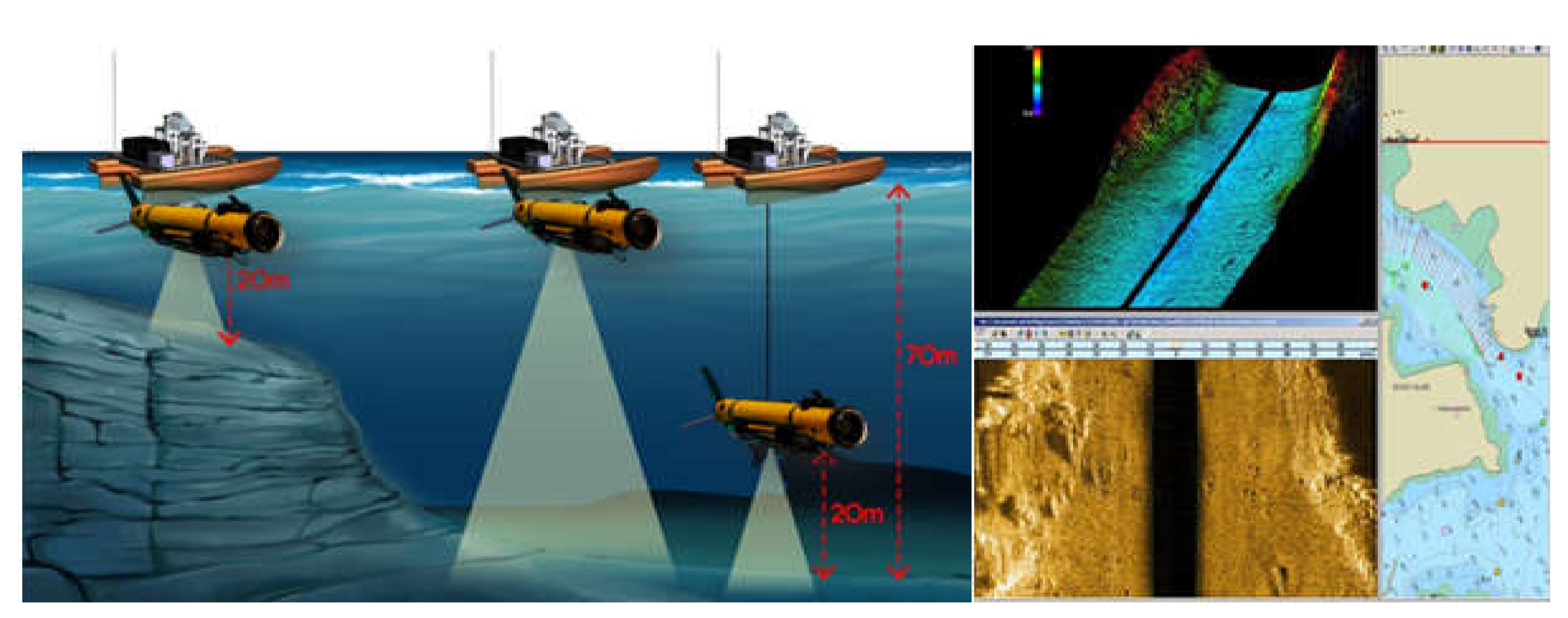

Figure 1 presents the operating concept of the platform and expected results. By the winch and underwater cable, UUV can approach to inspection targets and receive sonar and video data in real time.

4. Combined Control System of Integrated Platform

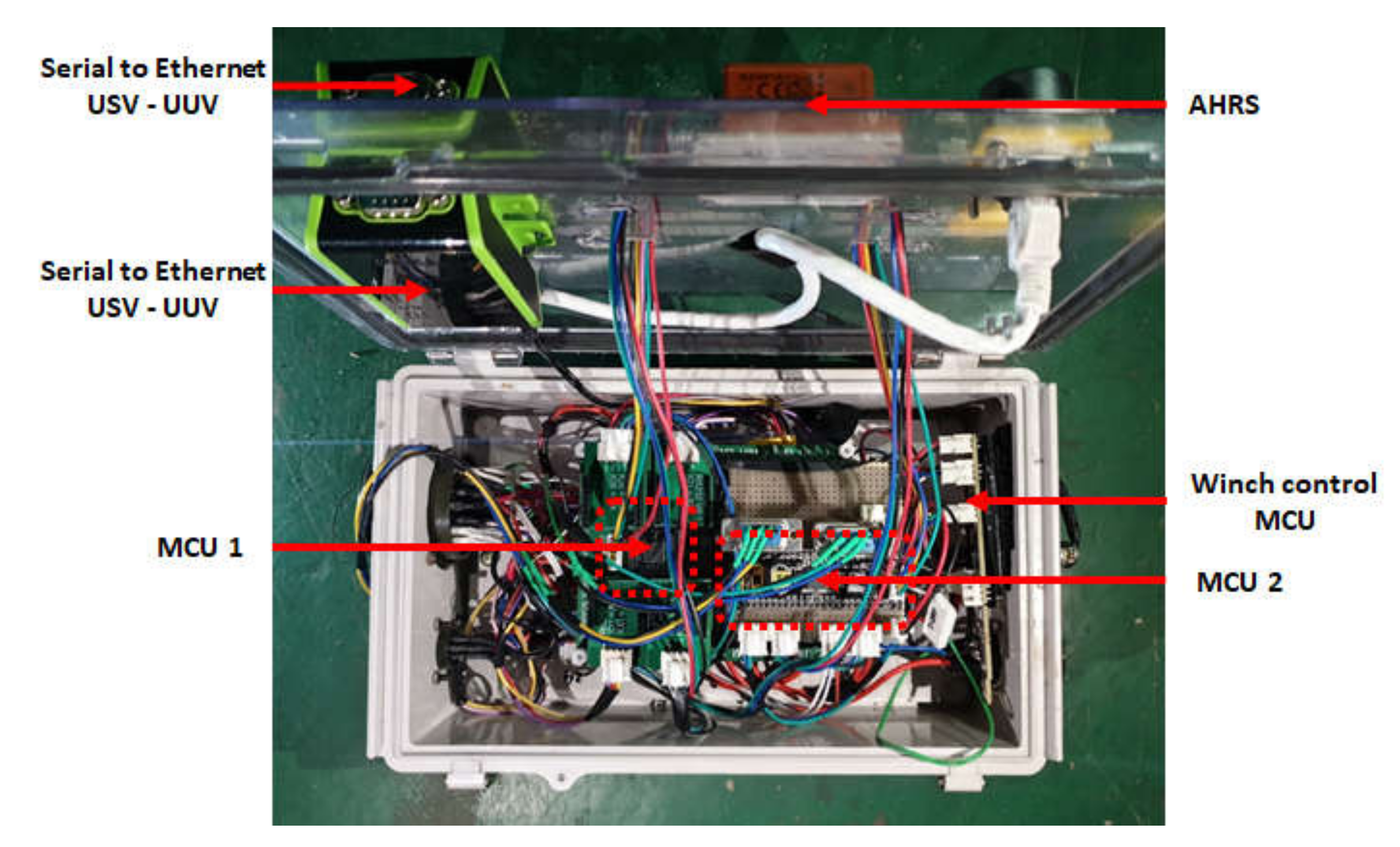

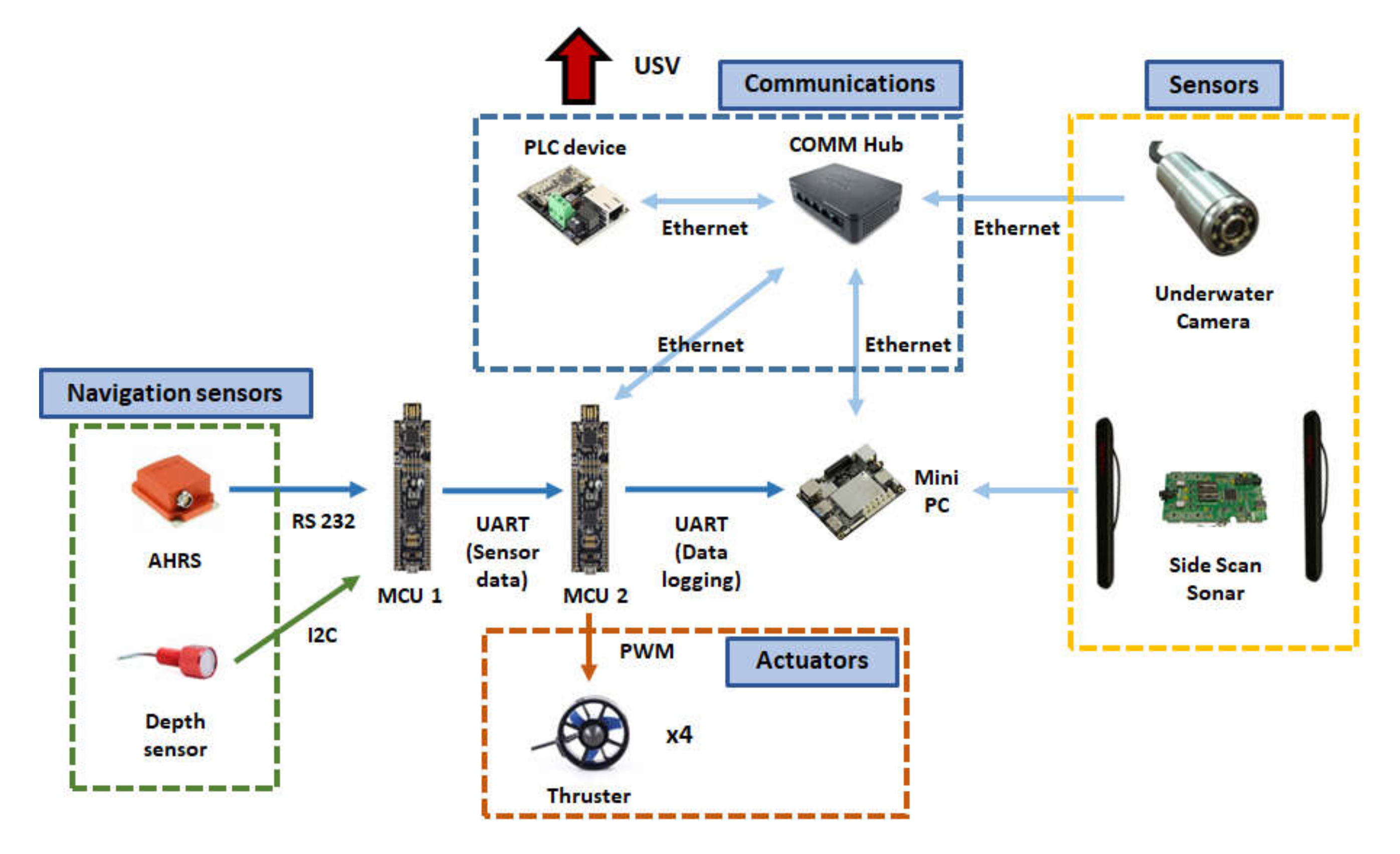

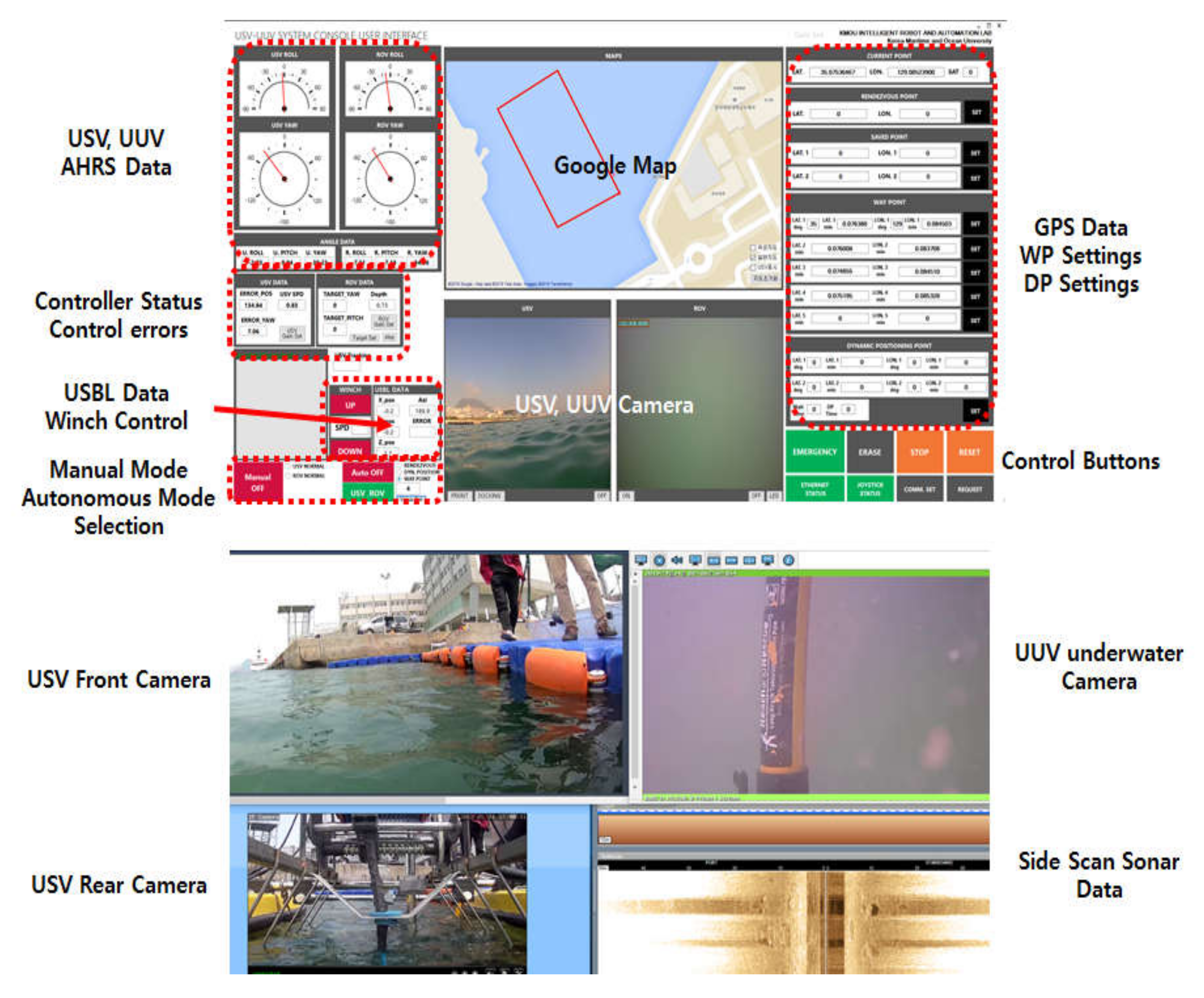

Figure 16 shows the overall configuration diagram of the integrated platform control system. The integrated platform needs to process a large amount of data such as sonar data and image data between the operation console, USV, and UUV, and transmission control protocol/internet protocol (TCP/IP) communication was adopted to accomplish this. The control commands of the platform are sent and received in packets; in the case of USV-only control, the control command packet sent from the operation console is input to the MCU via the communication hub of the USV to control the USV. However, if the packet input to the USV is USV–UUV co-operative commands, USV will generate packets which include USV’s sensor data. Subsequently, it sends the control command to the UUV via the communication hub.

The integrated platform has to process a large amount of data such as sonar data and image data between the operation console, USV, and UUV, and TCP/IP communication is adopted to accomplish this. The control commands of the platform are sent and received in packets, and in the case of single command of USV, the control command packet sent from the operation console is input to the MCU of USV via the communication hub of USV to execute the control of USV. However, if the packet input to the USV is a cooperation command of USV and UUV, the USV generates packets for the USV and the UUV including the control command and the USV’s sensor data. Then, it sends the control command to the UUV via the communication hub.

In this study, the integrated platform’s control method is based on proportional integral differential (PID) controllers with modifications. There are advanced path tracking algorithms currently presented [

20,

21], but the goal of this combined controller is based on verifying the controllability based on experimental results. By adopting PID-based controller, it was possible to adjust the variables easily while performing field tests. Advanced path tracking control algorithm is considered for future research.

In this study, a leader–follower strategy was used for tracking UUV along the USV motion. When considering tracking of the UUV along the USV, sway motion can be neglected. In this manner, the control mission is to achieve the position error and the yaw angle error .

For this, PID-based anti-windup control was applied.

Figure 17 represents the coordination control between USV and UUV. In case of manual control operation, the USV moves first and the UUV follows to compensate the compared position error and the heading angle error, which is derived by the USV and the UUV dynamics.

4.1. USV’s Waypoint Tracking Control Algorithm

The USV’s path control is a control process in which the USV follows a path connecting the target waypoint coordinates. Path control consists of recursion of heading control and tracking control. Heading control is a method of controlling the hull direction in a position to match the desired heading angle obtained using the line of sight (LOS) method [

22] and the direction of the USV’s bow. Tracking control is a process that enables tracking of the path connecting the target position and the current position after setting the heading.

This study considered straight driving and turning simultaneously when tracking control is performed to track the path between the waypoints. The control error for straight driving is input as distance, and the error for turning is input as heading angle. The two controllers for the PID-based distance and direction can be expressed as:

In Equation (3),

represents the output of the PID controller. As mentioned, while performing tracking control, both the heading angle and distance are considered as control error in order to enhance tracking performance. The output of the two main thrusters at the stern is controlled using the weight scheduling method, which assigns different weights to the powers of the two controllers. The weights were assigned to effectively allocate the power of the two controllers within the limited range of thruster control inputs. Different weights can be assigned at the starting stage of a movement that requires a larger input energy for acceleration or when smooth turning is performed. The weight scheduling method is described as:

In the above equation,

and

is the output of two different controllers, as shown in Equation (4) and

is the value that determines the sign of the relative angle between the desired heading angle and the platform.

represent the weight, the values which are between 0 to 1.

Figure 18 shows a block diagram of the tracking control based on an anti-windup PID controller and Equation (4).

This control method includes an anti-windup scheme in the PID controller. Various schemes have been implemented for anti-windup, including the back-calculation method, anti-windup method, and restricted integral method [

23,

24]. This study used the anti-windup method employing the clamping method, which is easy to implement.

4.2. UUV’s Waypoint Tracking Control Algorithm

Heading angle tracking and the relative distance control method were employed in the integrated platform for UUV’s USV tracking control. Heading angle tracking is a method used for matching the heading angle of the UUV’s hull with the heading angle of the USV’s hull. It consists of a controller for matching the heading angle of the UUV based on the heading angle data of the USV and a controller for maintaining the posture of the UUV to achieve stable sensor data. The heading angle is controlled using two thrusters at the stern, and the attitude angle is controlled using two thrusters at the center of the hull.

The relative distance control method uses the relative distance data

obtained from USBL relative position coordinate data and the relative heading

obtained from USBL azimuth data. The visual description of

and

is shown in

Figure 19. Path control is performed, similar to the tracking control method of the USV, to rotate the hull direction of the UUV toward the origin point of the USBL (the coordinate of the USBL transceiver installed in the USV) and reduce the relative position toward the origin point of the USV. Here, the relative angle and relative position are continuously updated as the moving USV’s position and direction change continuously.

6. Conclusions

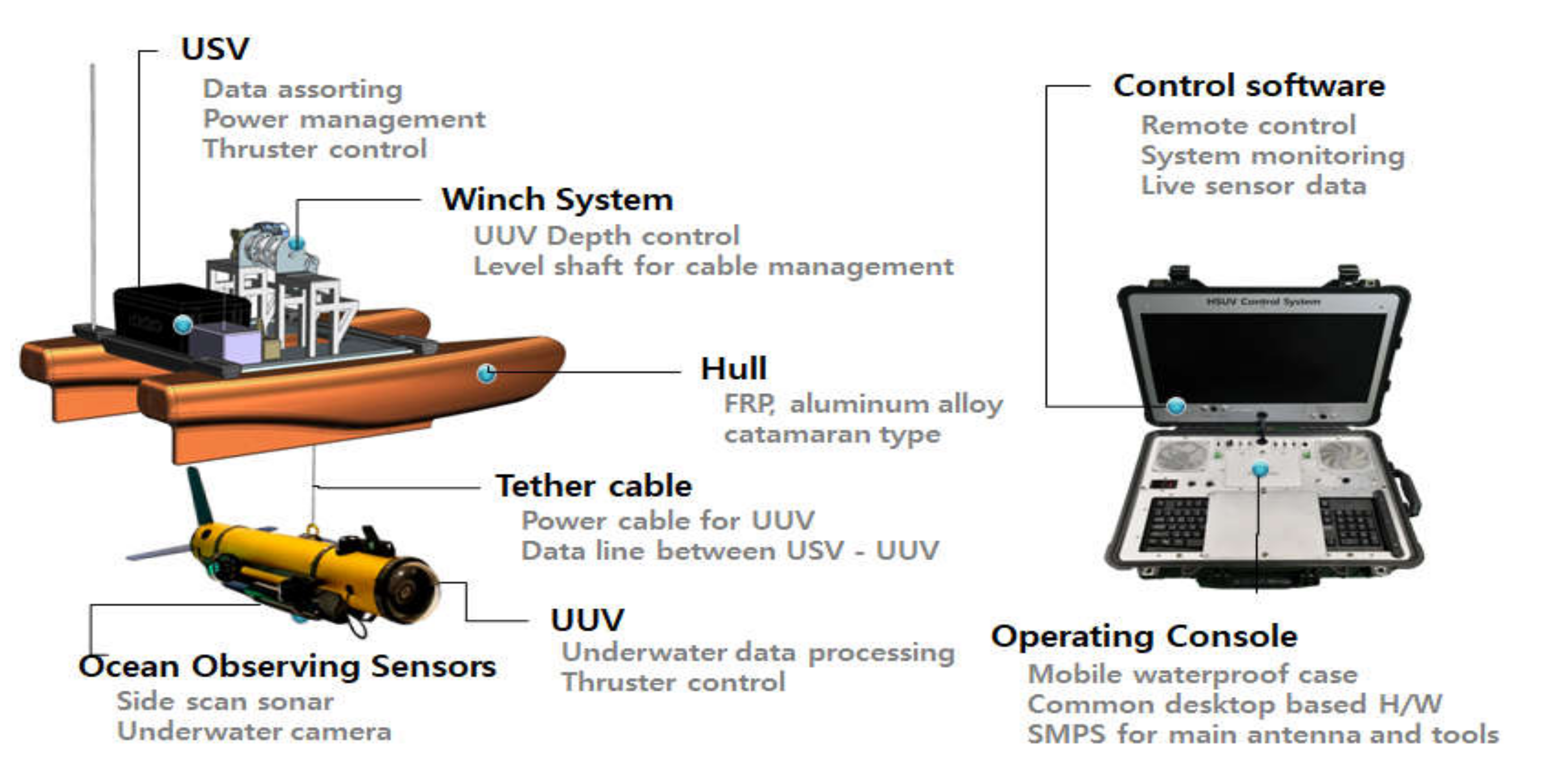

In this paper, in order to overcome typical disadvantages of previously commercialized ocean platforms, a new integrated maritime platform composed of a highly operable unmanned ship and an underwater vehicle capable of acquiring underwater data connected by a tether cable is studied. Subsequently, an algorithm was developed for waypoint tracking and tests were conducted to verify the performance of the integrated platform. Different from other previously studied cooperation system of USV and AUV, the benefit of the proposed system is real-time motion coordination control between the USV and UUV while transmitting a large amount of data using the tether cable.

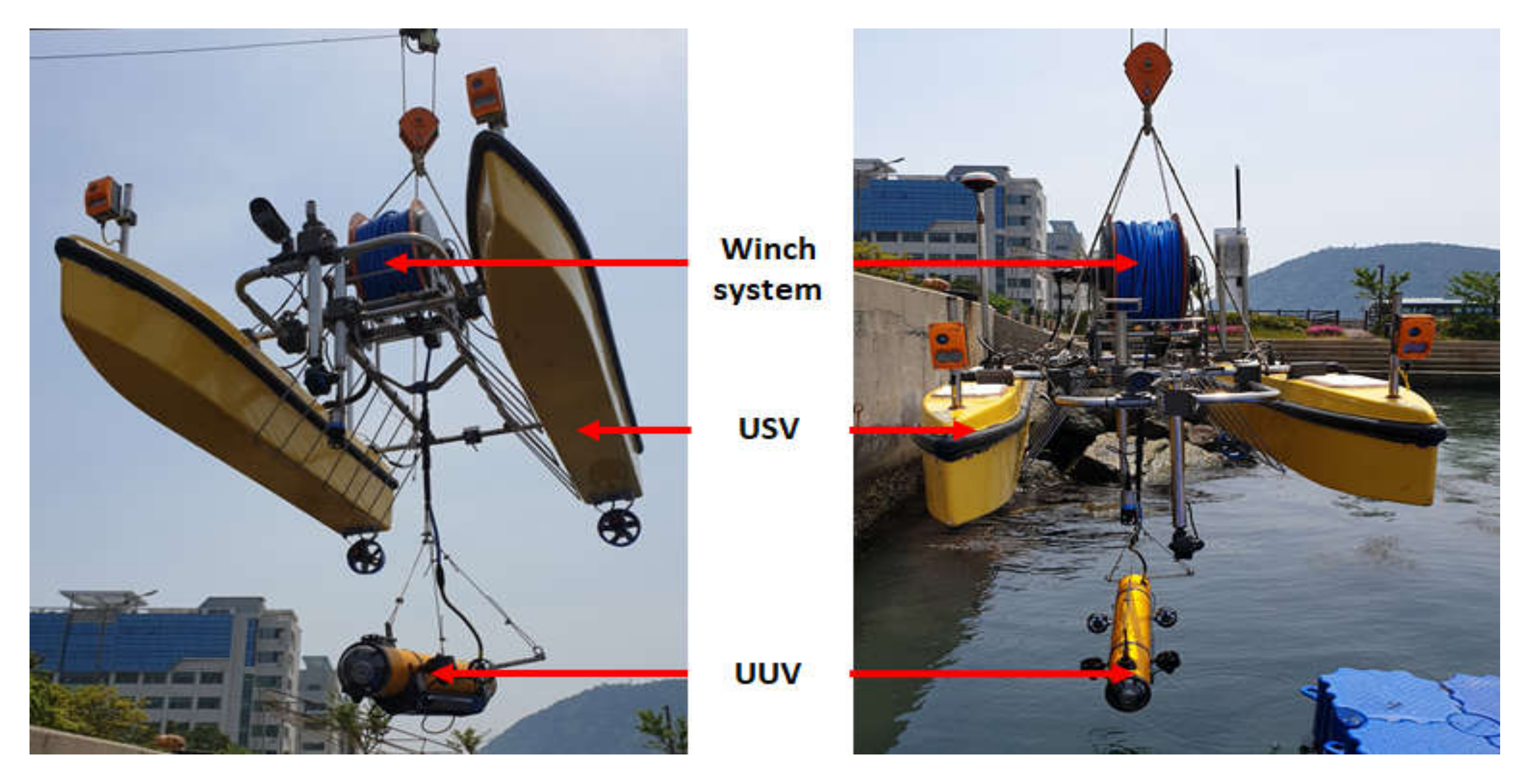

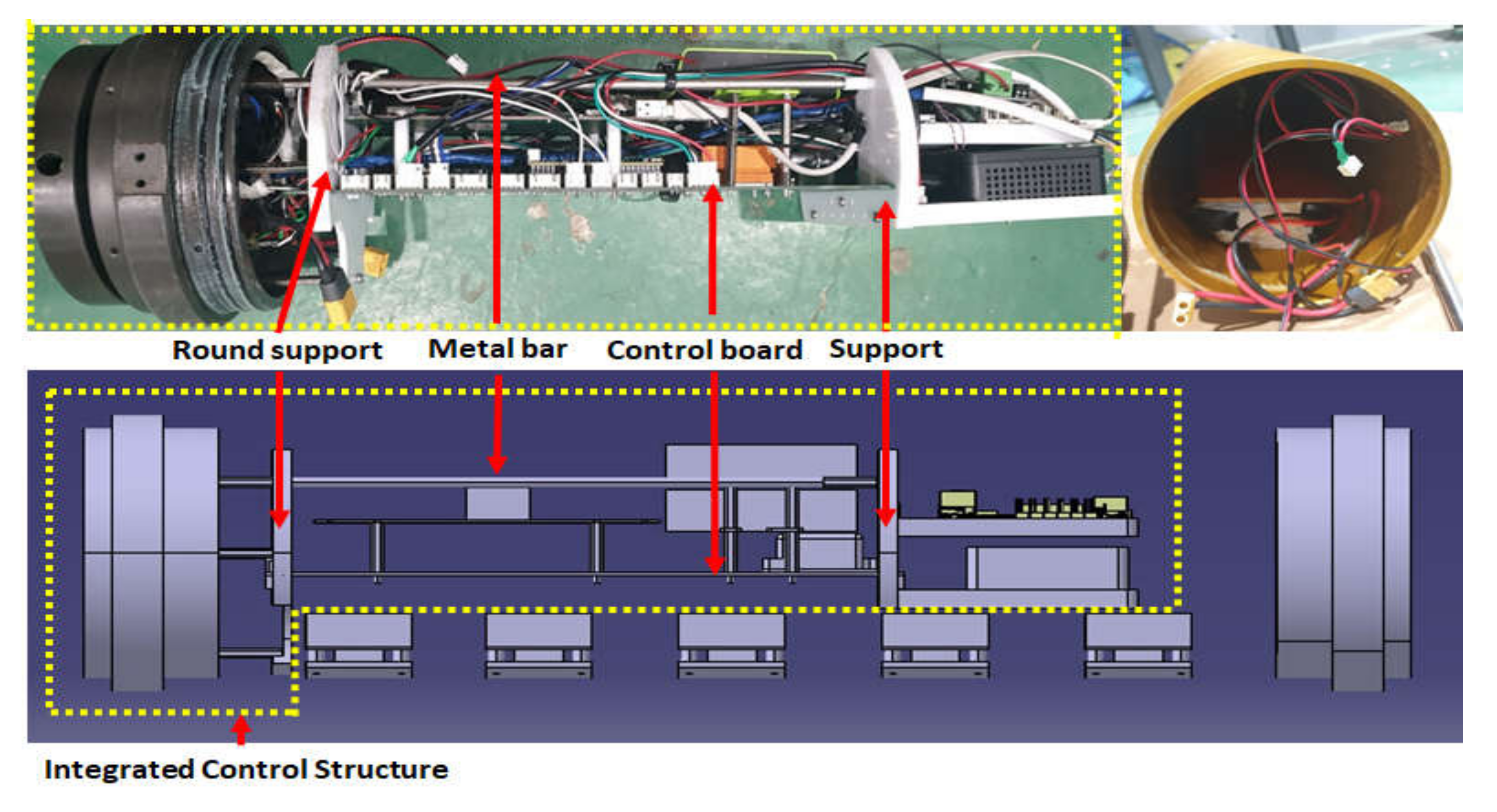

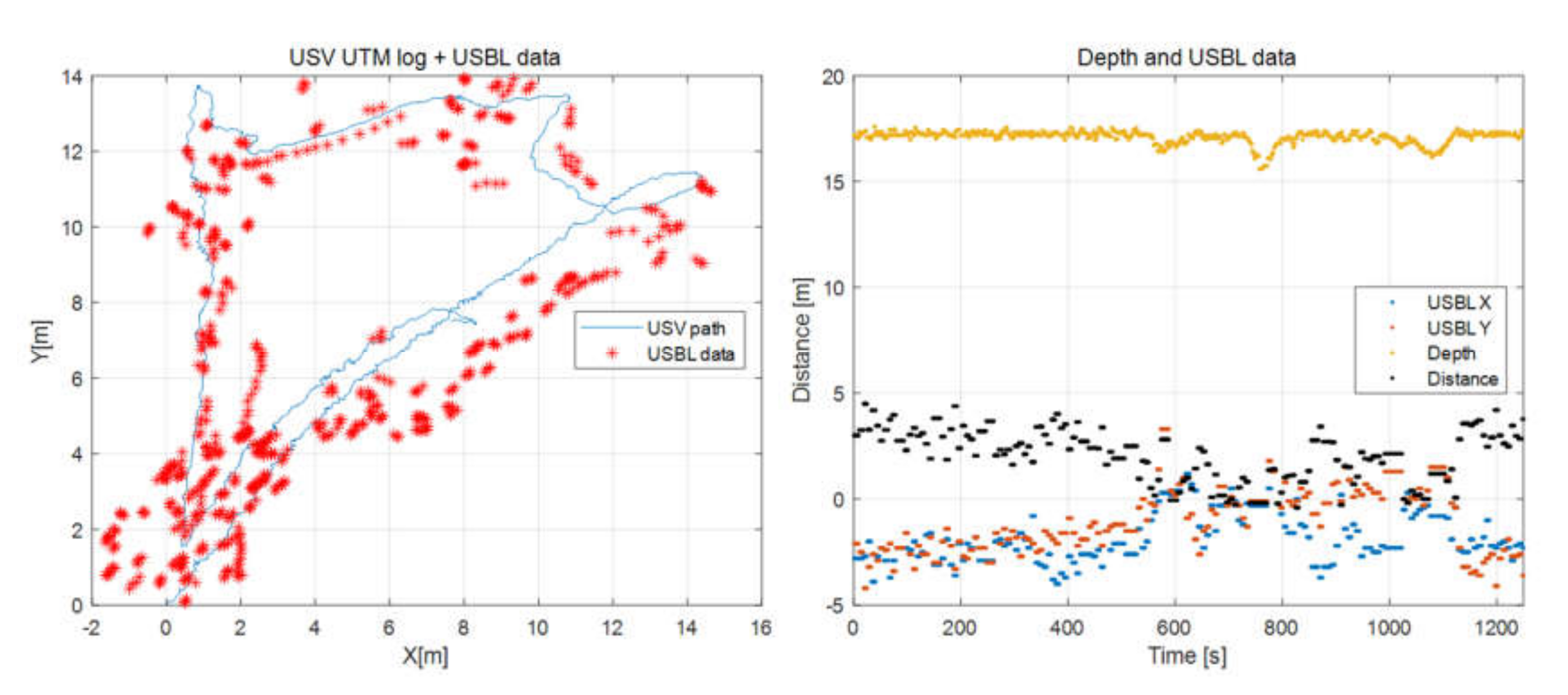

In the integrated platform, a catamaran-type USV was designed to overcome the limitations of an ocean environment, whereas the UUV was designed as torpedo-shaped to minimize hydrodynamic resistance. The underwater cable driven by a winch system was installed to supply power from the USV to the UUV and to transmit acquired data from an underwater sonar sensor or camera. Moreover, for fast and accurate coordination of the UUV with respect to the USV, USBL sensor was installed to measure the relative position data of the UUV.

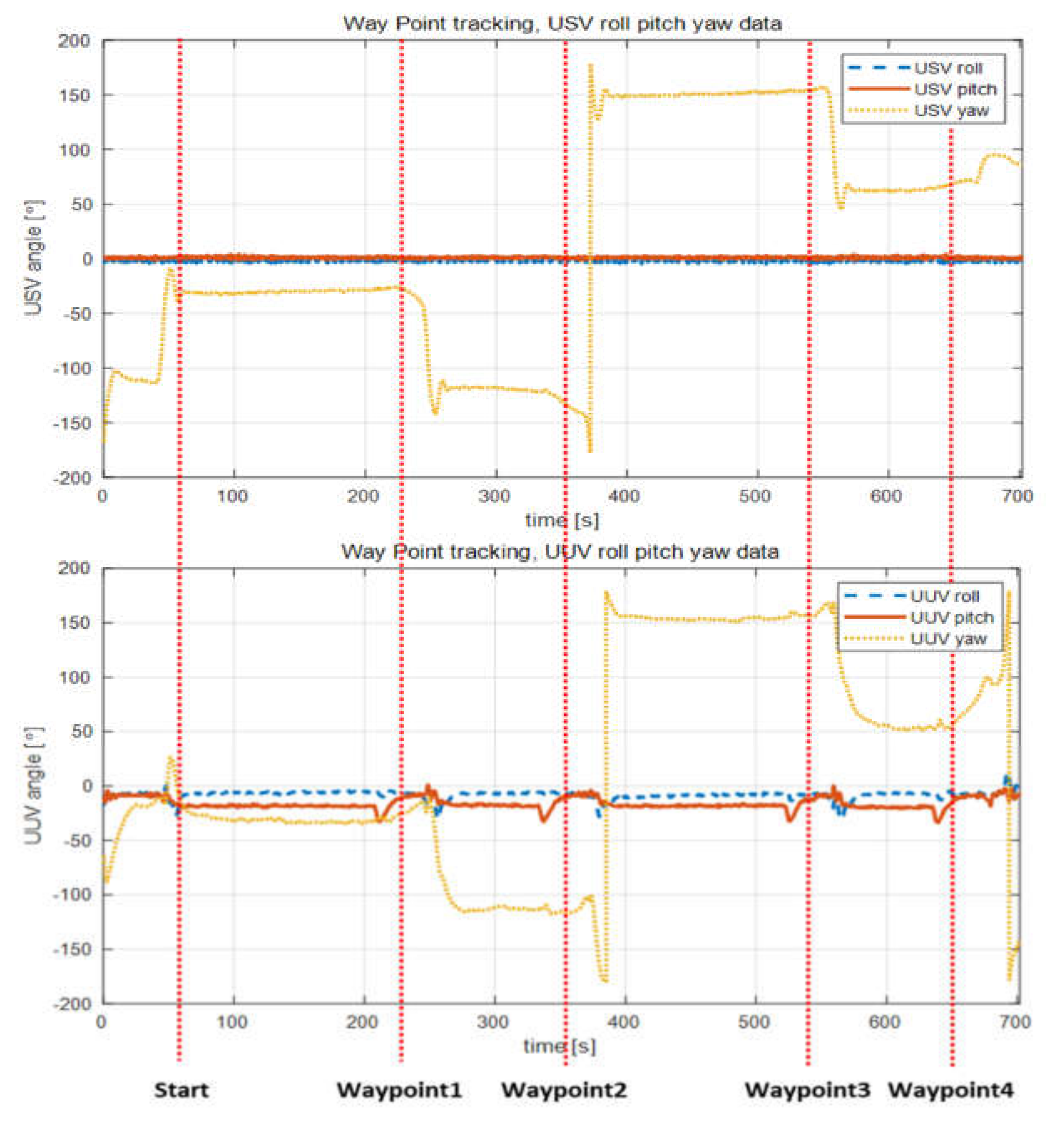

A control algorithm was developed for the integrated platform. The USV has different controllers for distance error and heading angle error with respect to the desired position during waypoint tracking control. Different controller’s output is applied to thrust force by weight scheduling method, which assigns different weights to the powers of the respective controllers according to conditions such as the magnitude of the distance and heading errors with respect to the target position. While USV performing the waypoint tracking control, heading angle tracking, and relative distance control method were employed in the UUV in order to achieve USV–UUV coordination waypoint tracking.

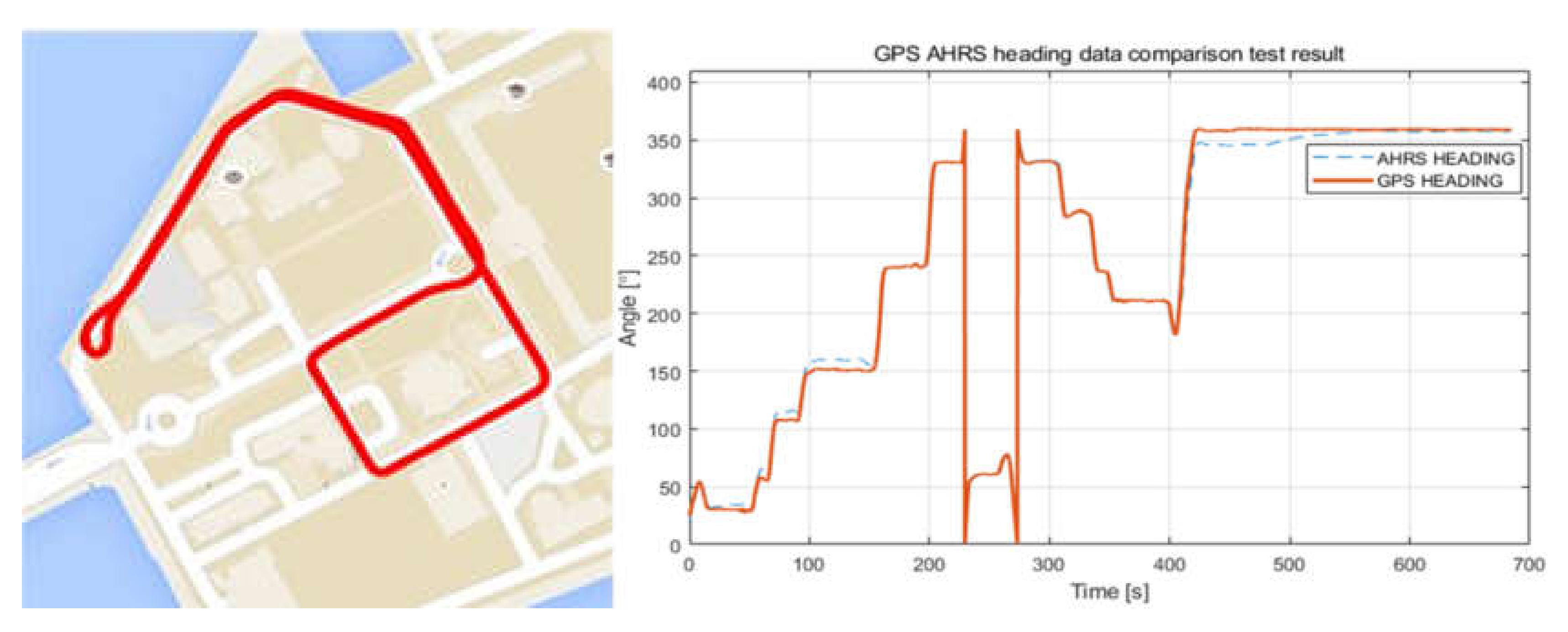

Individual tests were conducted to verify the performance in terms of controlling the USBL and AHRS, which provided the position and heading data of the UUV in the sensors mounted on an actual platform. The results demonstrated the reliability of the sensor measurement. In addition, a number of field tests were performed to verify performance of the control hardware system and designed tracking control algorithm. Firstly, the USV waypoint tracking control test was performed, where results of the test showed that the tracking errors along the path through four designated waypoints were confined to less than 4 m. Secondly, the tracking attitude control test was performed, where the attitude of UUV follows that of the USV quite well with a little time delay. Finally, the relative distance tracking test of the UUV to USV was performed, and the results of relative distance control between the USV and UUV showed that the relative distance was maintained within 5 m under the estimated tidal current of 0.7–0.93 knots, which is acceptable for maritime data application.